Patents

Literature

422results about "Railway device loading/unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

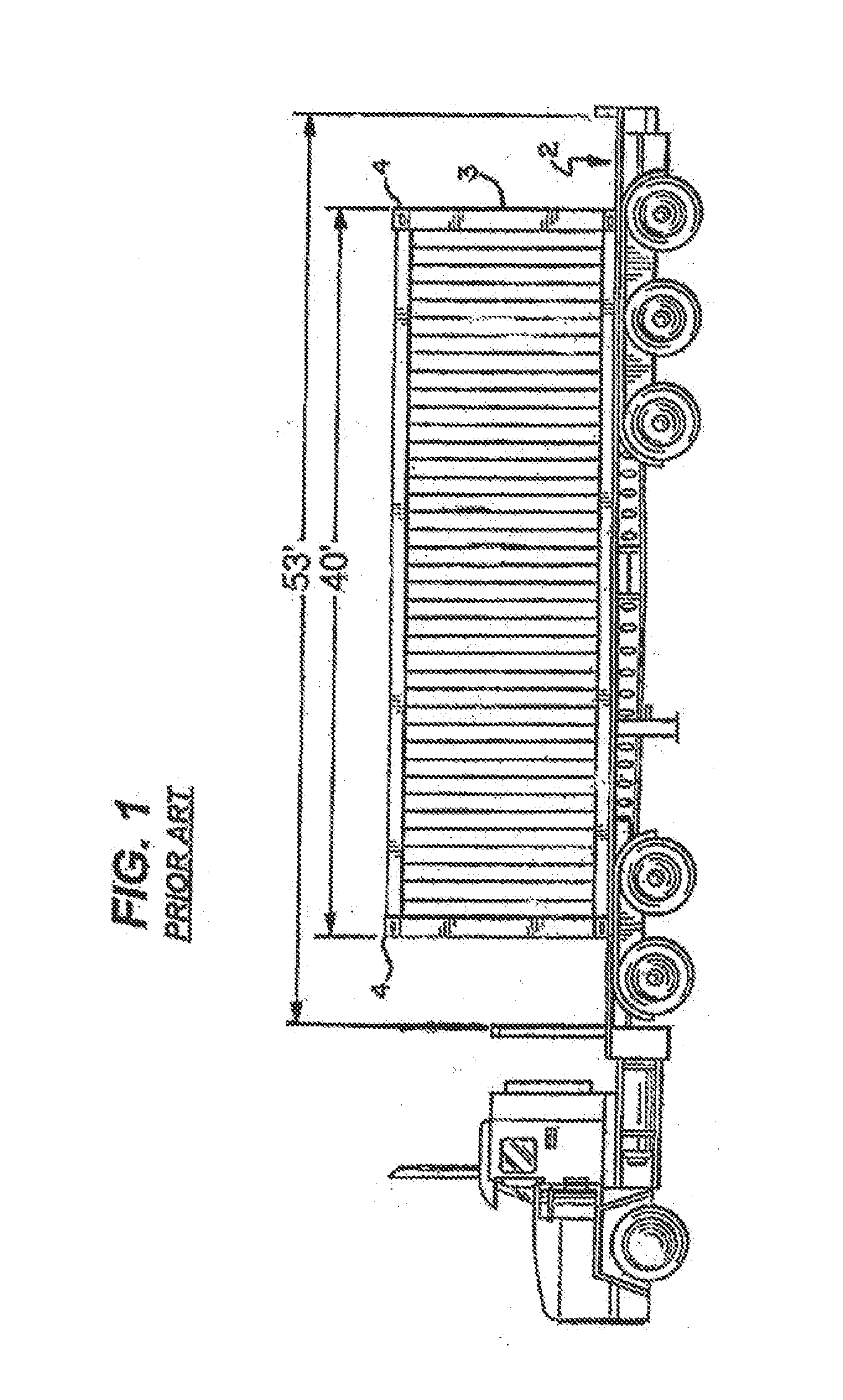

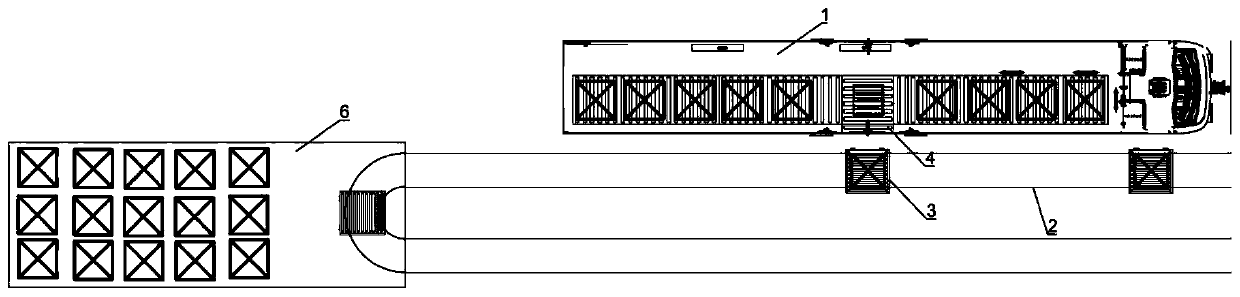

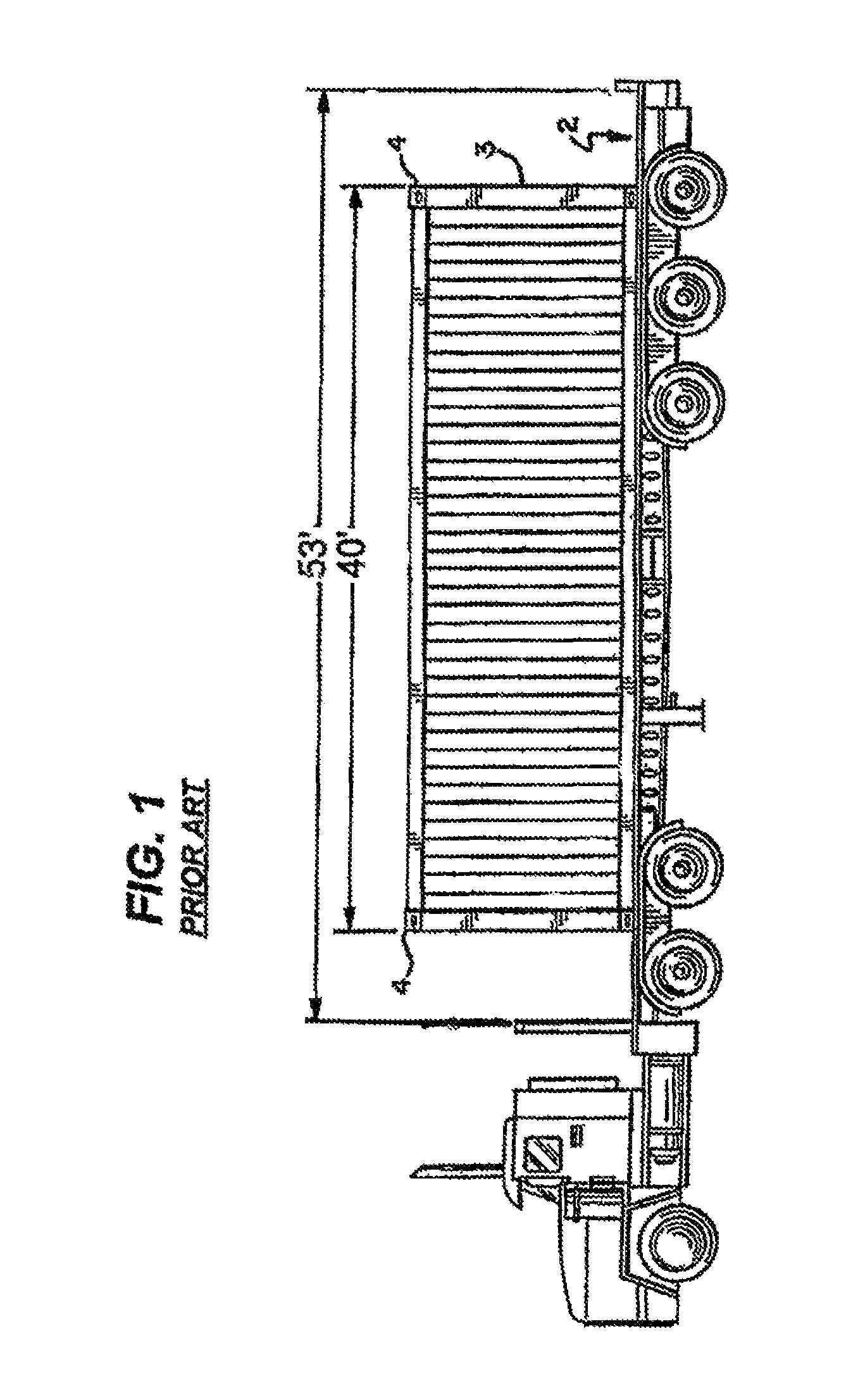

Method for railroad transport and apparatus for loading and unloading trains

InactiveCN1635965AEasy to operateQuick implementationStorage devicesLoading/unloadingTransfer systemRemote control

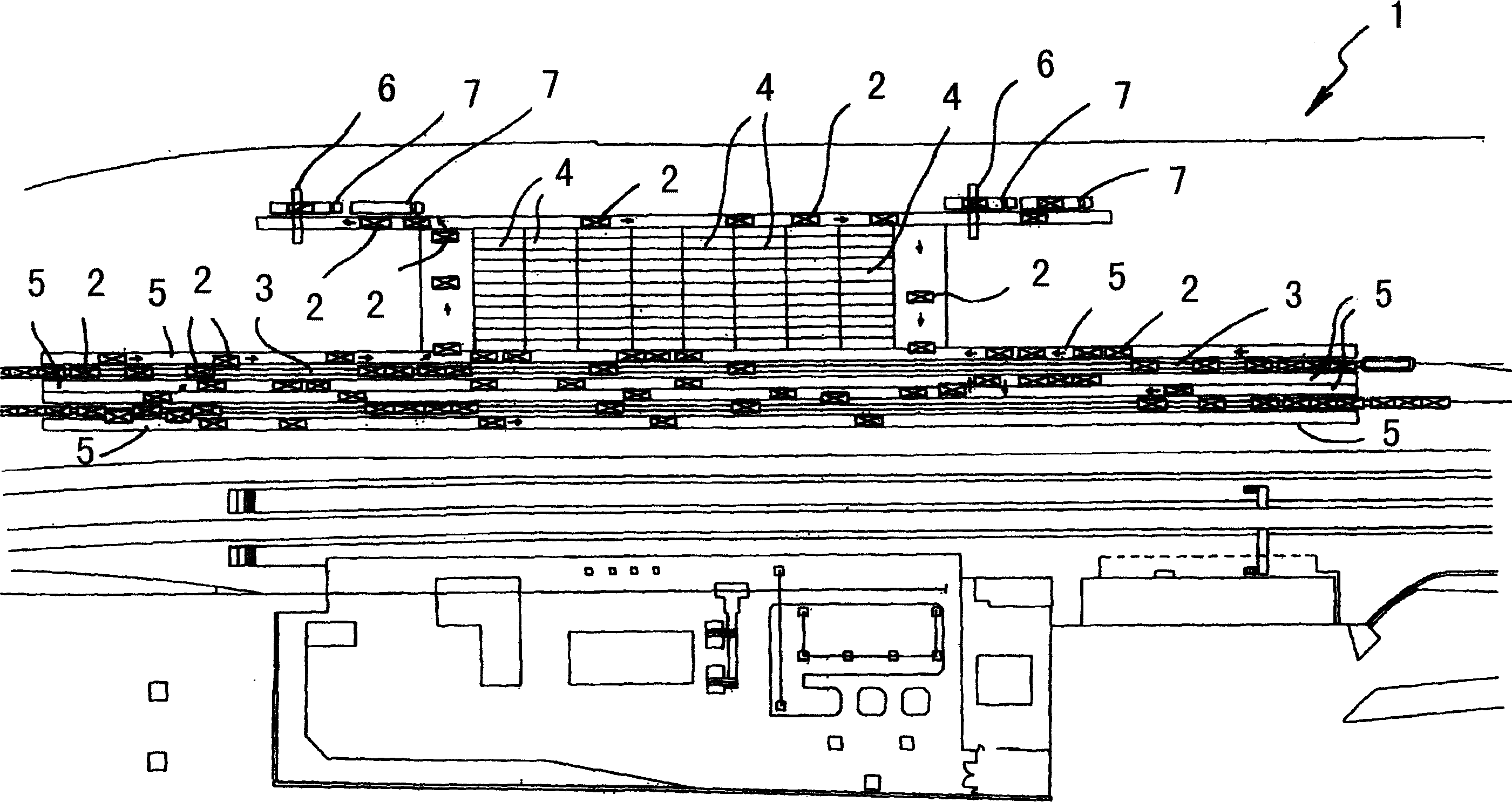

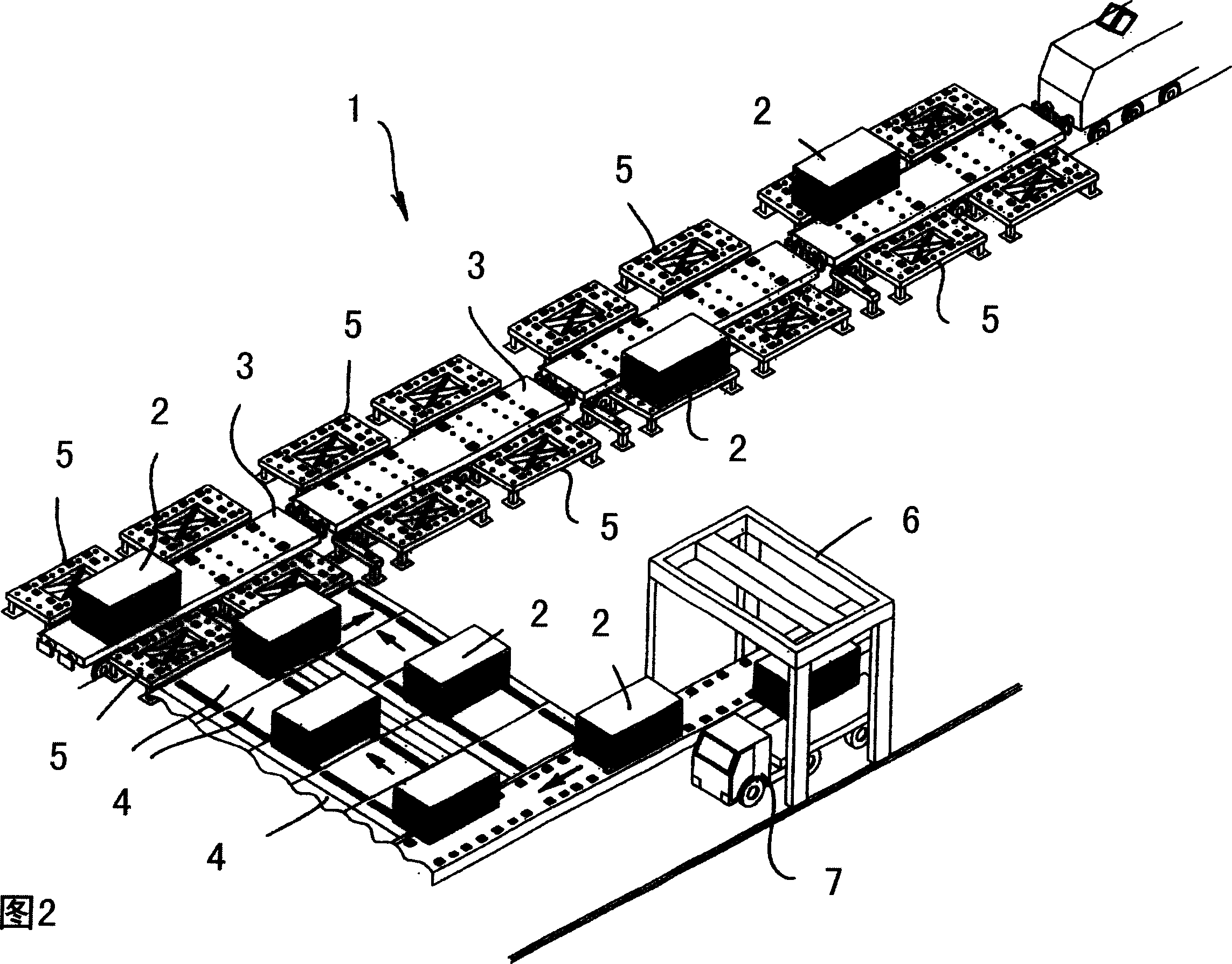

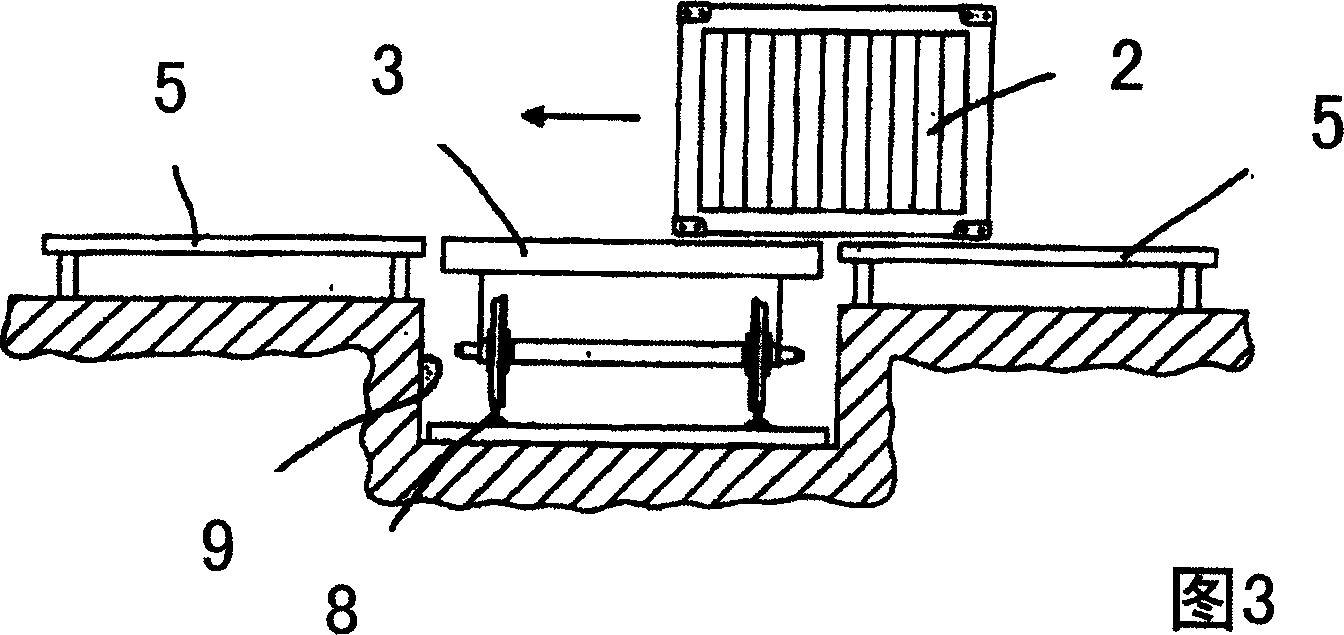

The method according to the invention comprises the following steps: first transport by truck to the nearest station equipped with a special pivot station (1); placing the cargo unit (2) on the ground or on a transfer system (4) , the transfer system in turn provides an automatic loading platform that loads the cargo unit (2) onto a railcar (3) with a system for horizontal translation through an auxiliary servo remote control system.

Owner:圭多・波尔塔

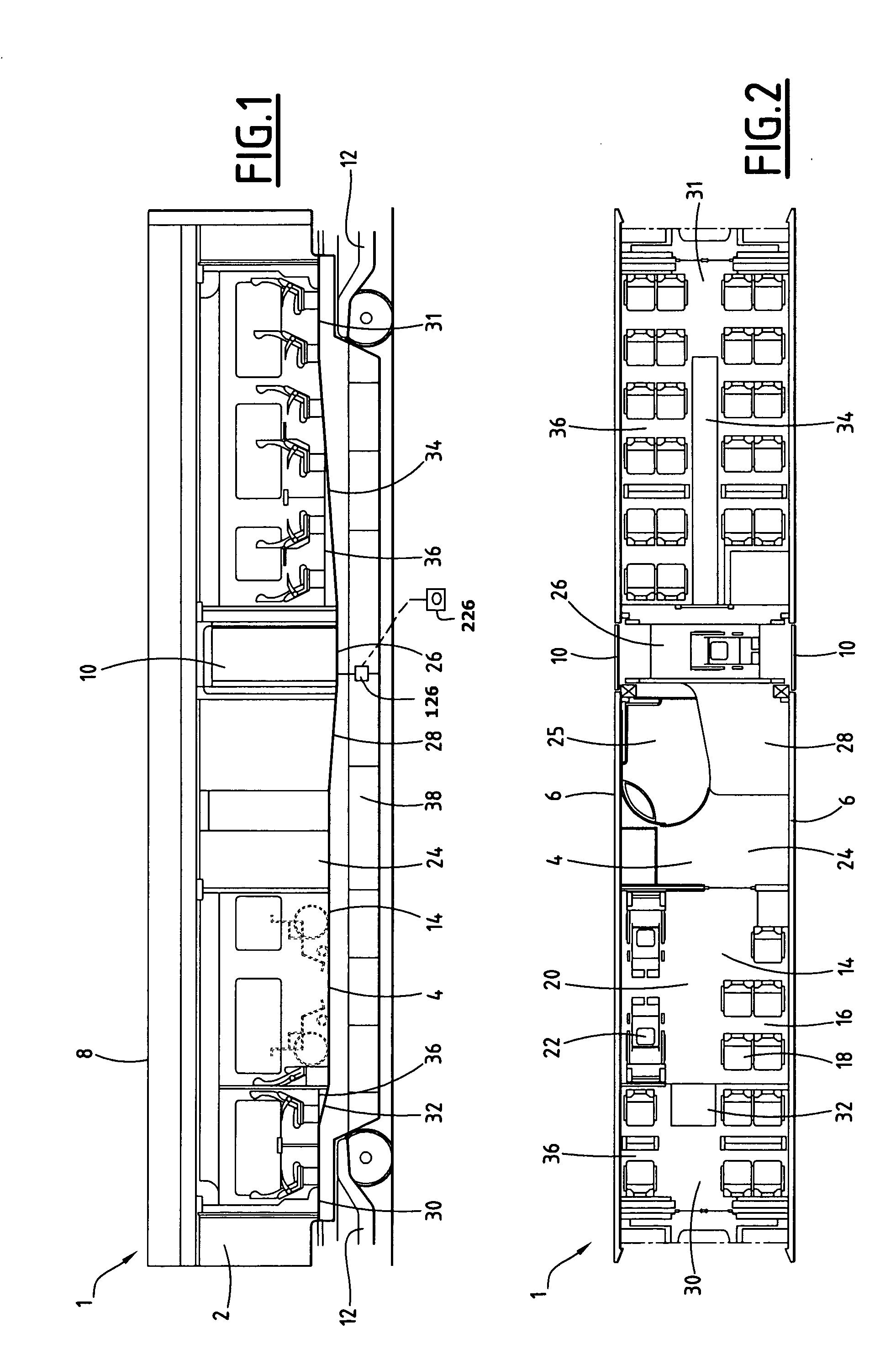

Railway vehicle carriage facilitating access for passengers with reduced mobility

ActiveUS20090255437A1Easy accessLow mobilityVehicle arrangementsAxle-box lubricationEngineeringReduced mobility

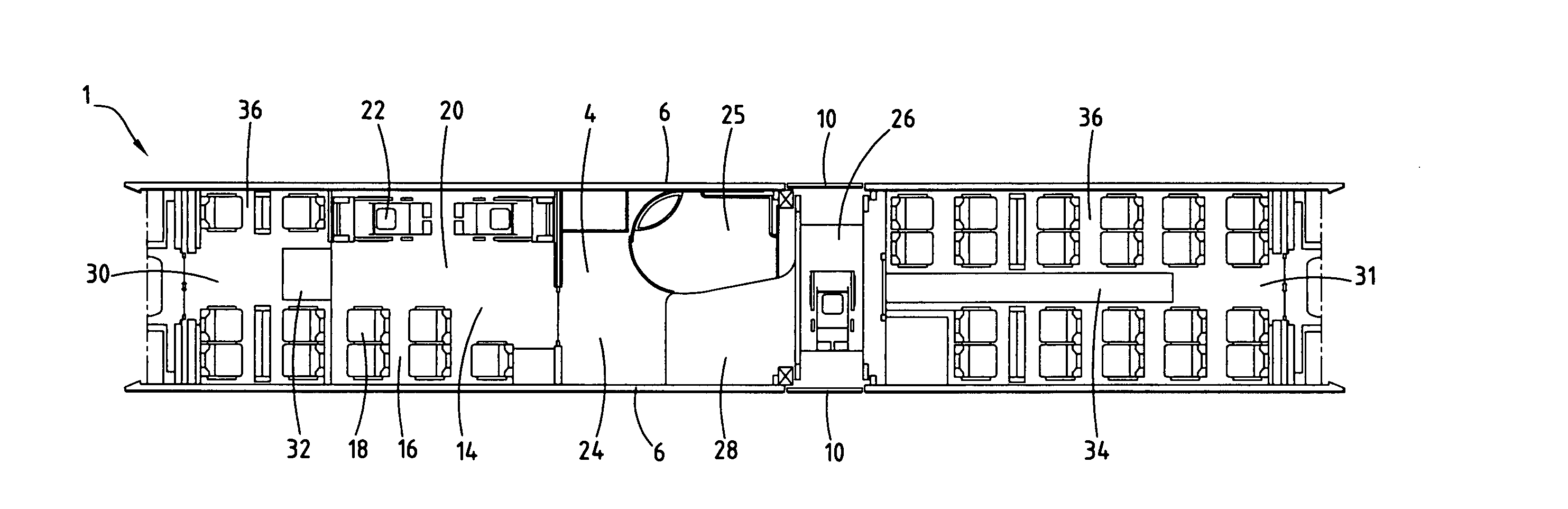

A carriage including a floor comprising at least one low platform and two high floor levels, the low platform having a floor height lower than that of the high floor levels and being arranged opposite a door, the low platform being movable in translation is provided. The low platform is connected to said high floor levels by ramps.

Owner:ALSTOM TRANSPORT TECH SAS

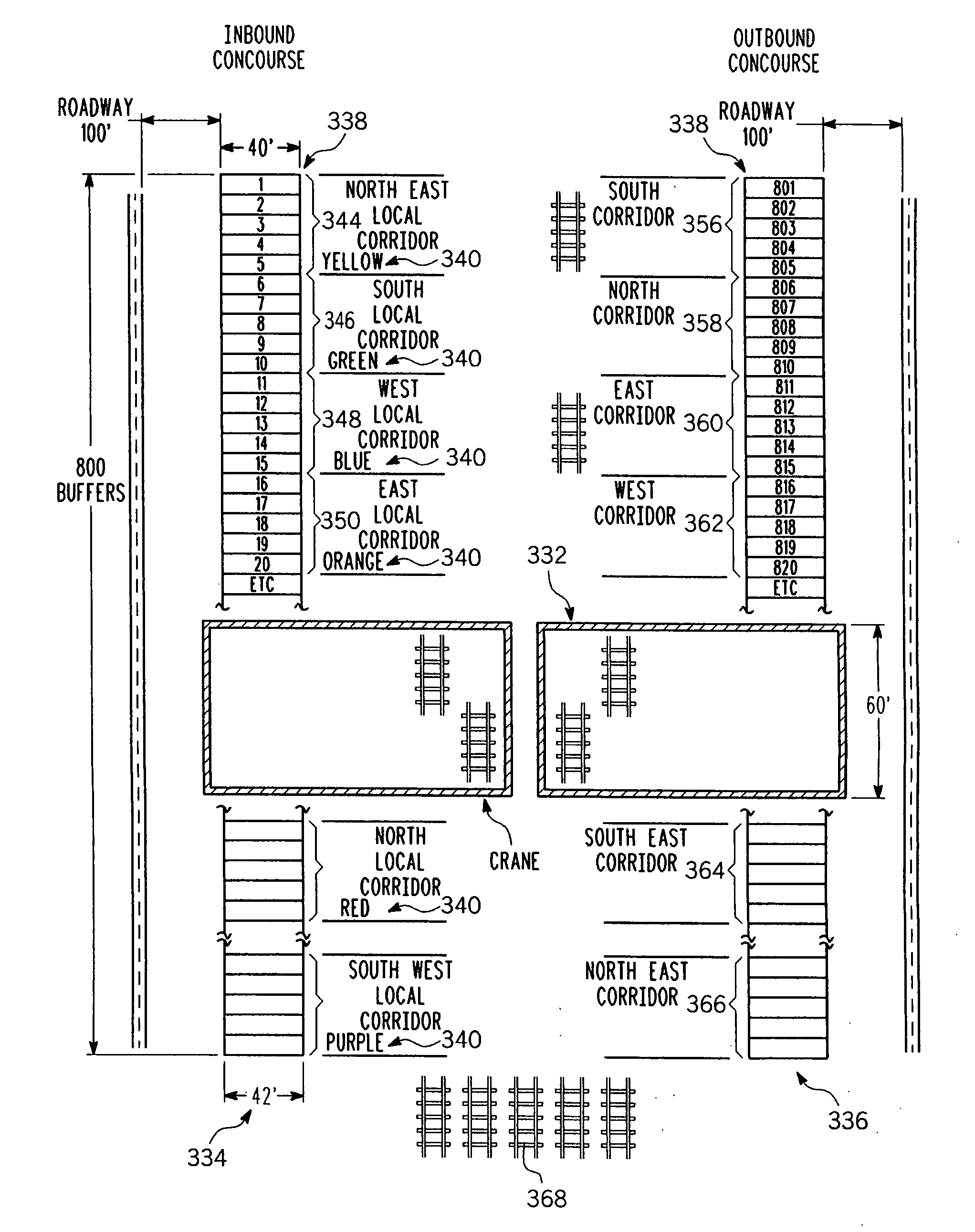

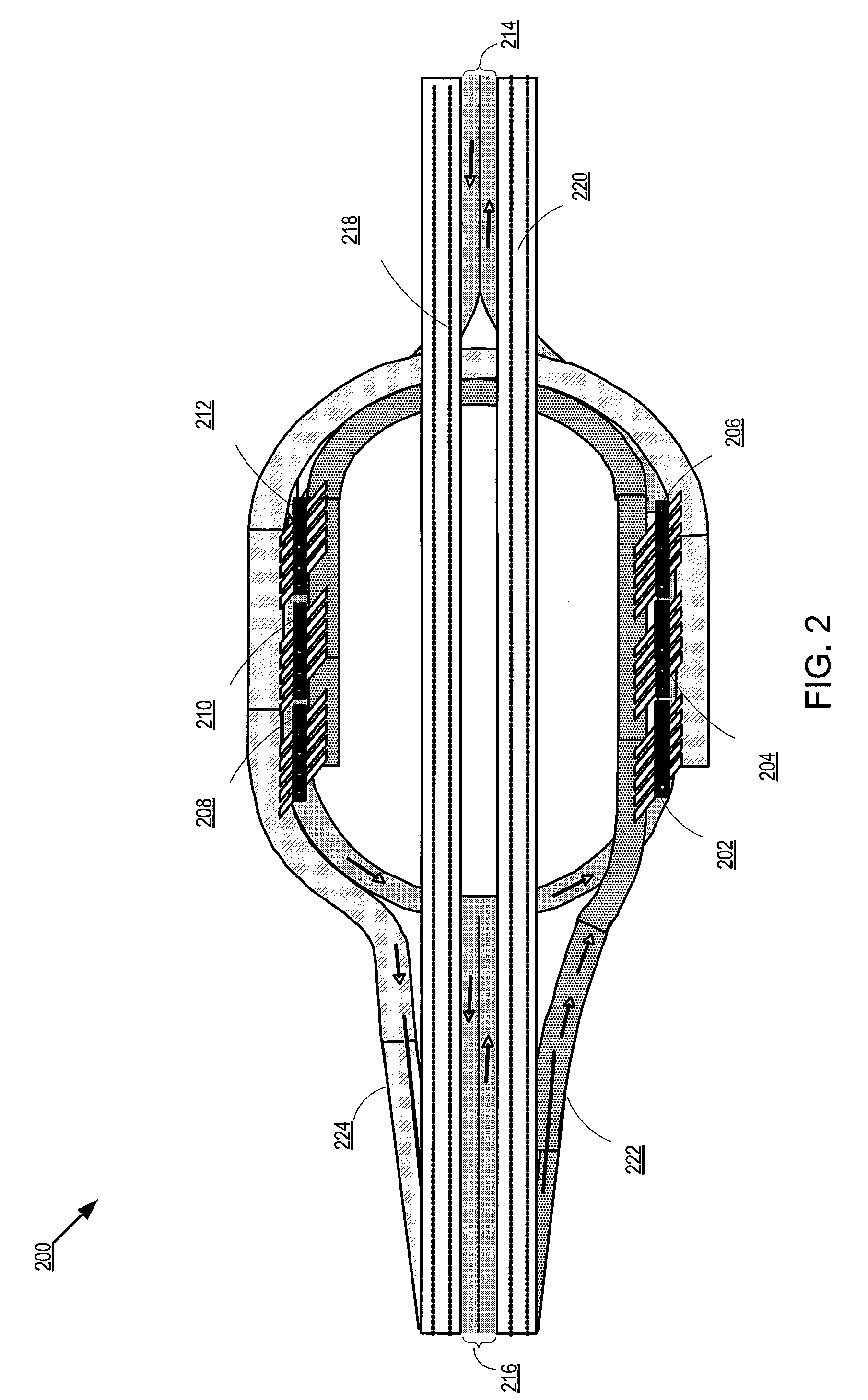

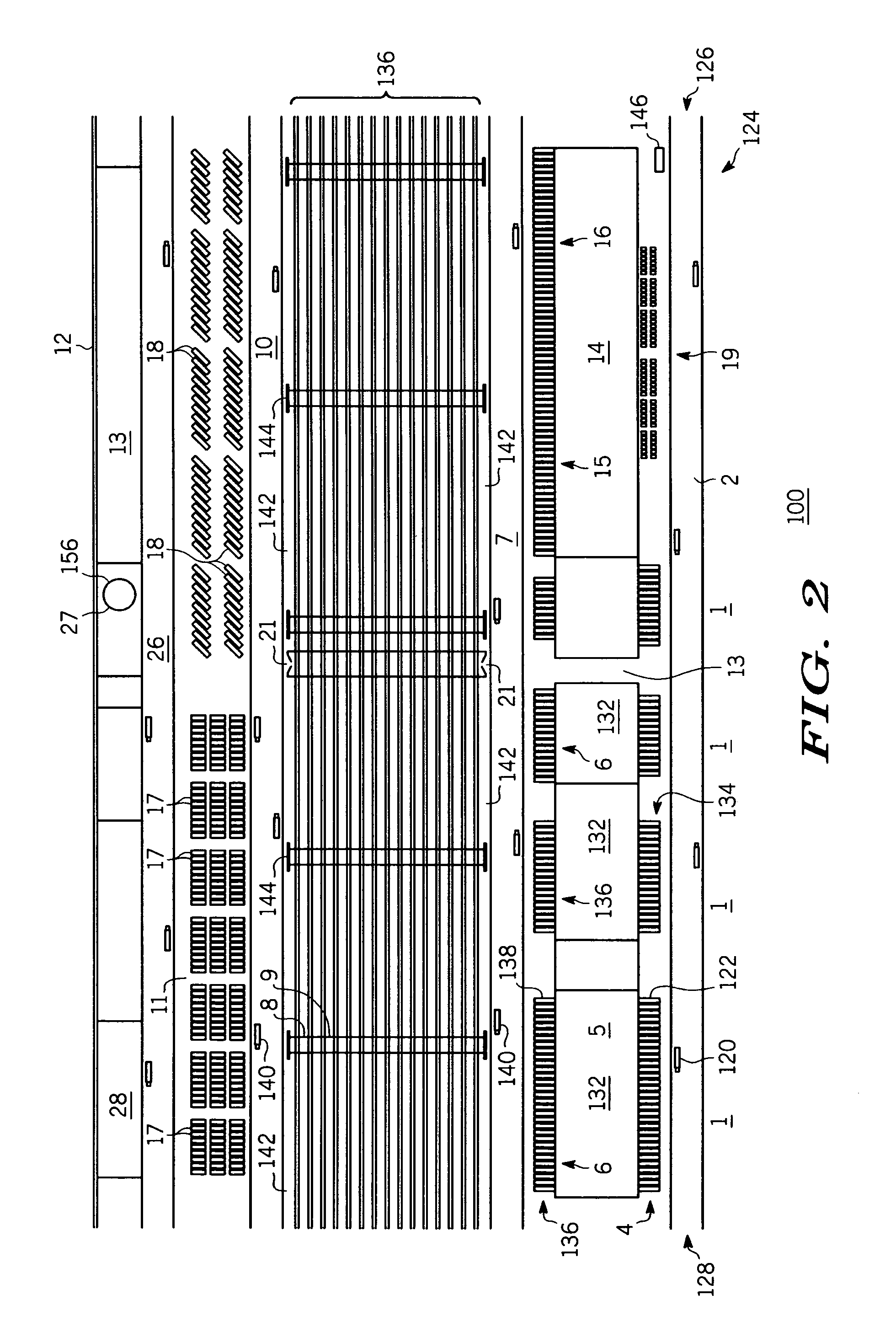

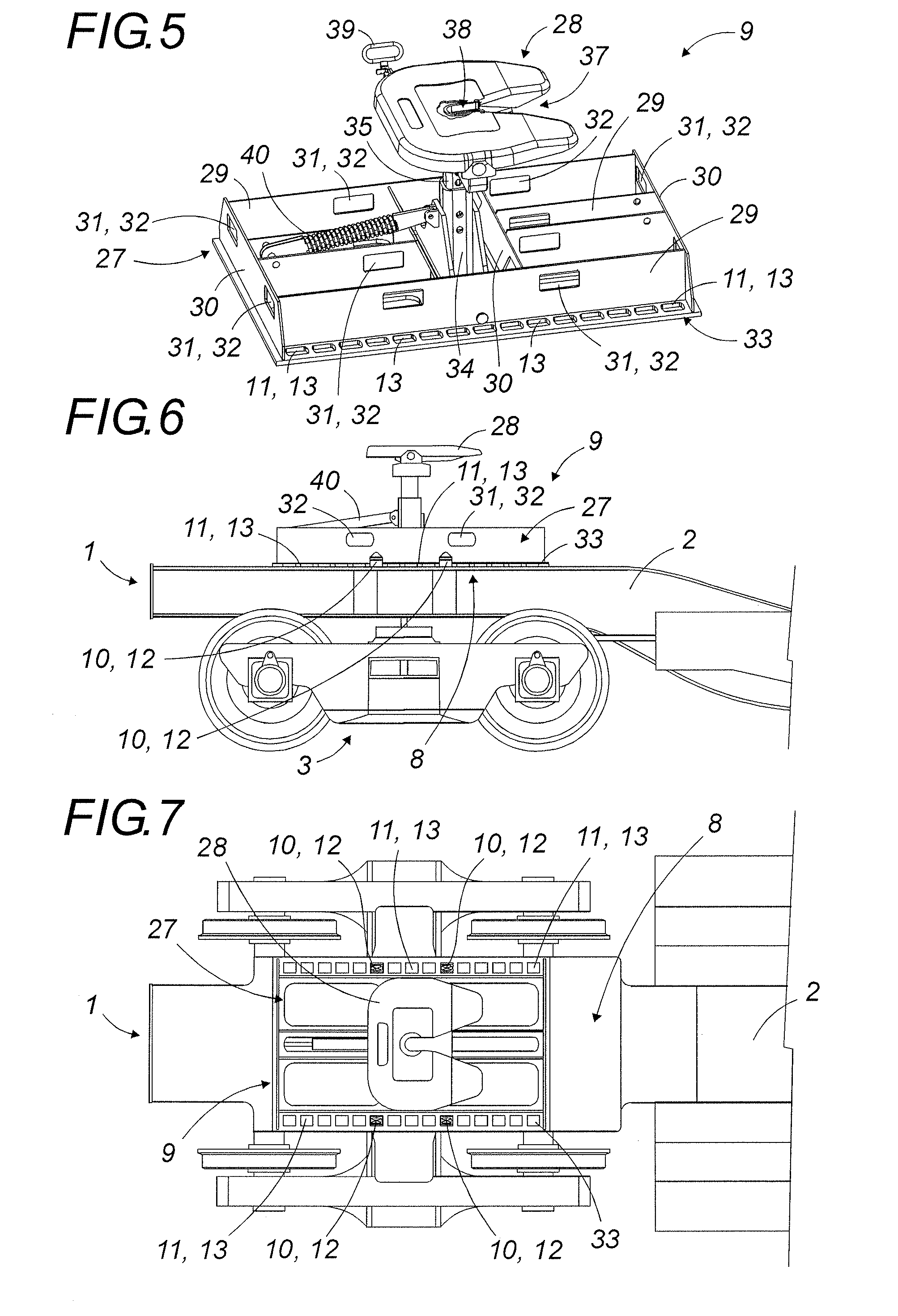

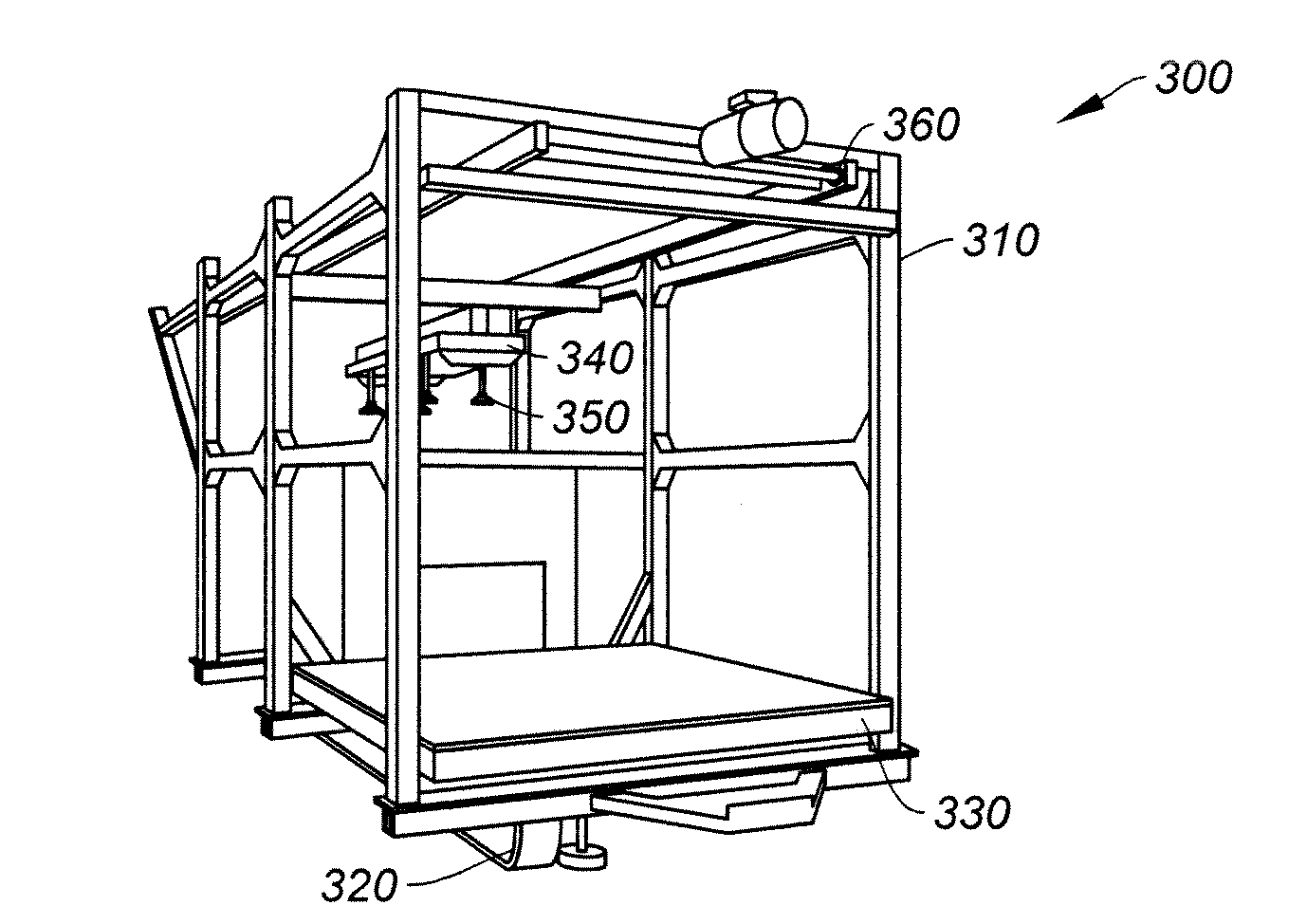

Inline terminal, hub and distribution system

ActiveUS20080219827A1Improve productivityTruck, buffer and crane utilization and efficiencyStacking articlesLoading/unloadingDistribution systemComputer terminal

An inline terminal system (300), which includes the steps of: (i) transporting (302) a first container with a cargo via an inbound railroad car to a terminal having a plurality of train rails; (ii) picking and placing (304) the first container from the railroad car to a track side location having at least one buffer in proximity to the plurality of train rails, including: (a) rotating the first container at an angle of at least ten or more degrees with respect to the train rails; and (b) positioning the at least one buffer substantially adjacent to the train rails, at the track side location, at an angle of at least ten or more degrees with respect to the train rails; and (iii) moving (306) the first container via a tractor truck to a desired location for unloading. This system provides a simple, robust and efficient method to load, and in the reverse unload, a container on a chassis or rail car, respectively.

Owner:MI JACK PRODS

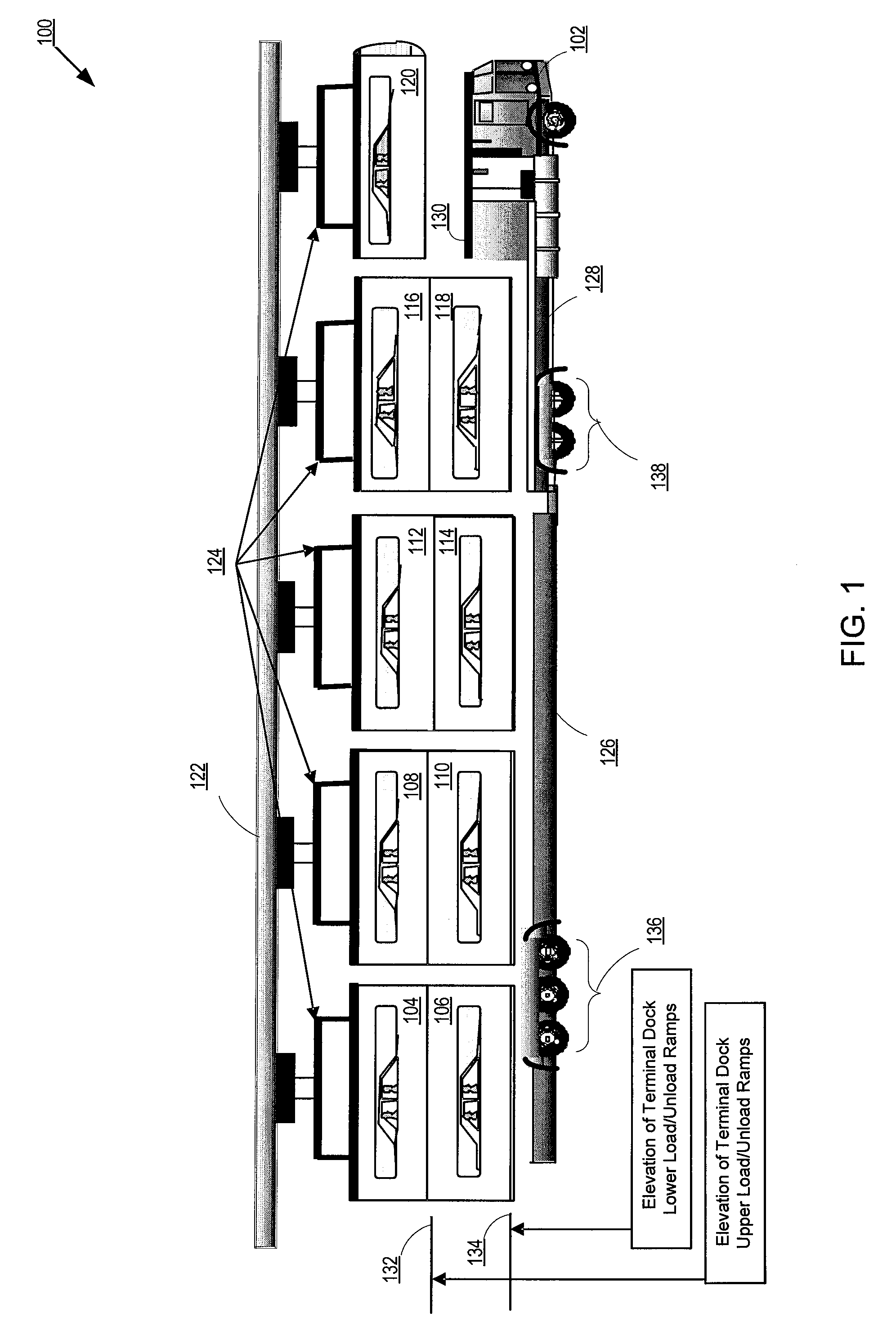

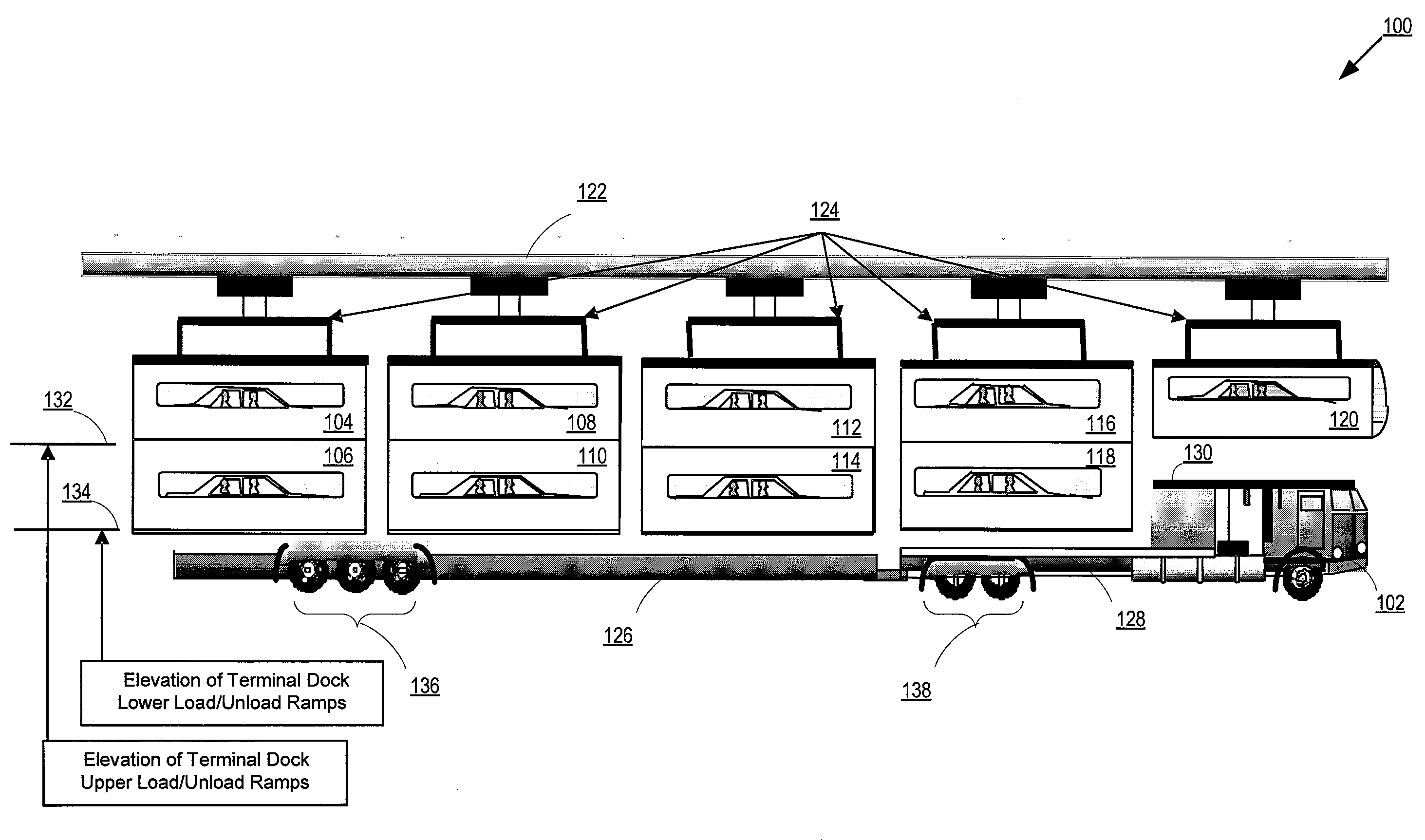

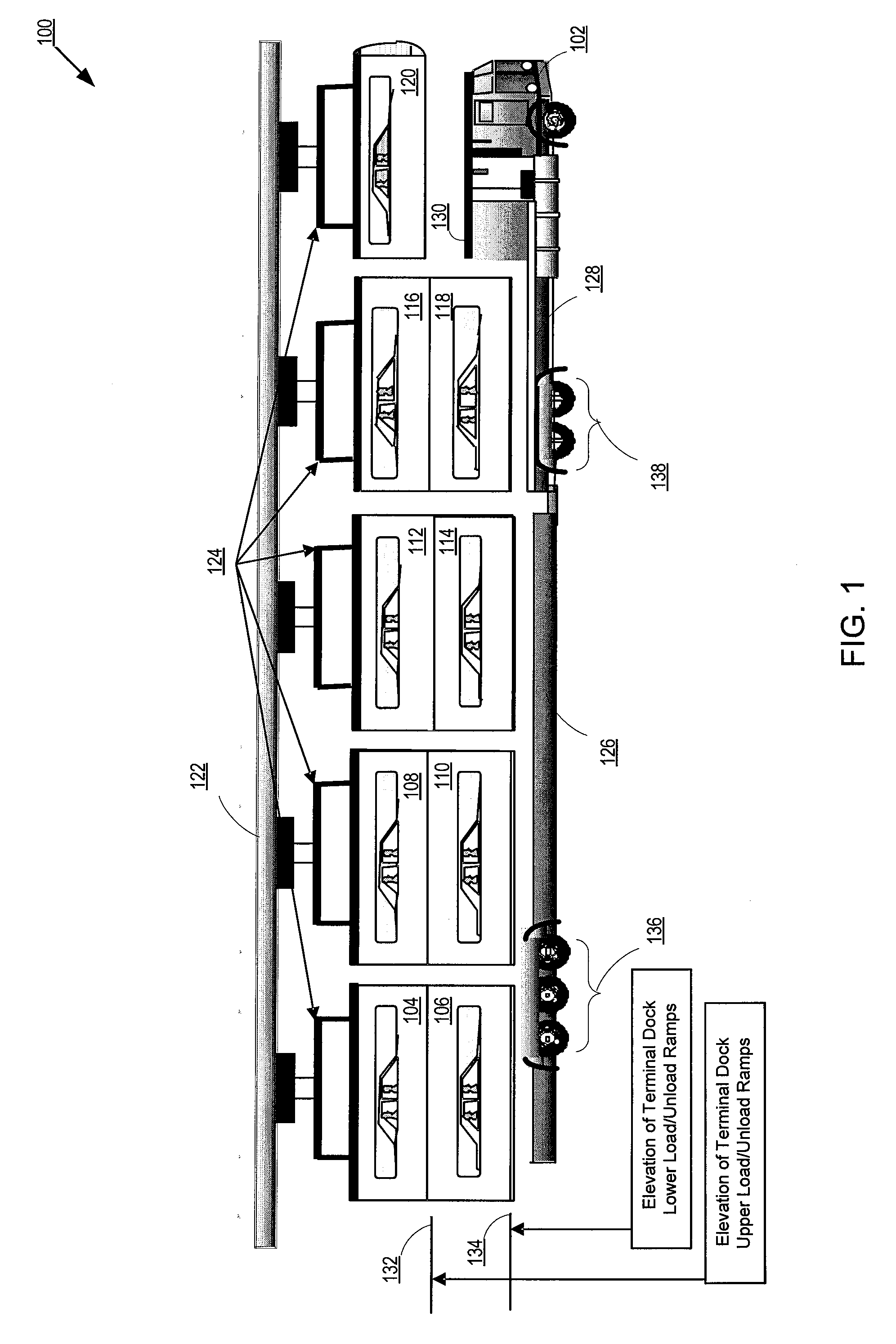

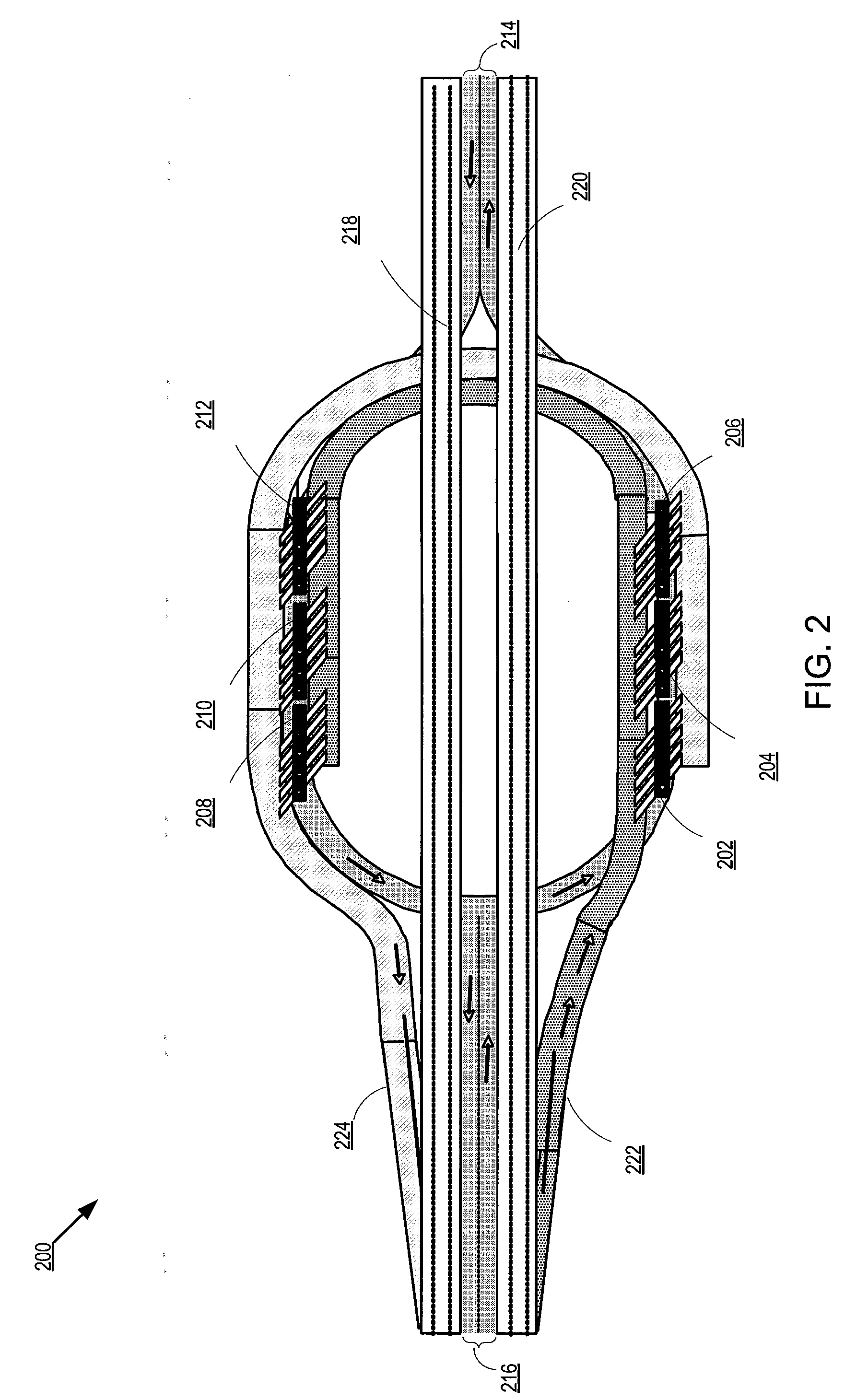

Multiple driver occupied passenger vehicles transporter system

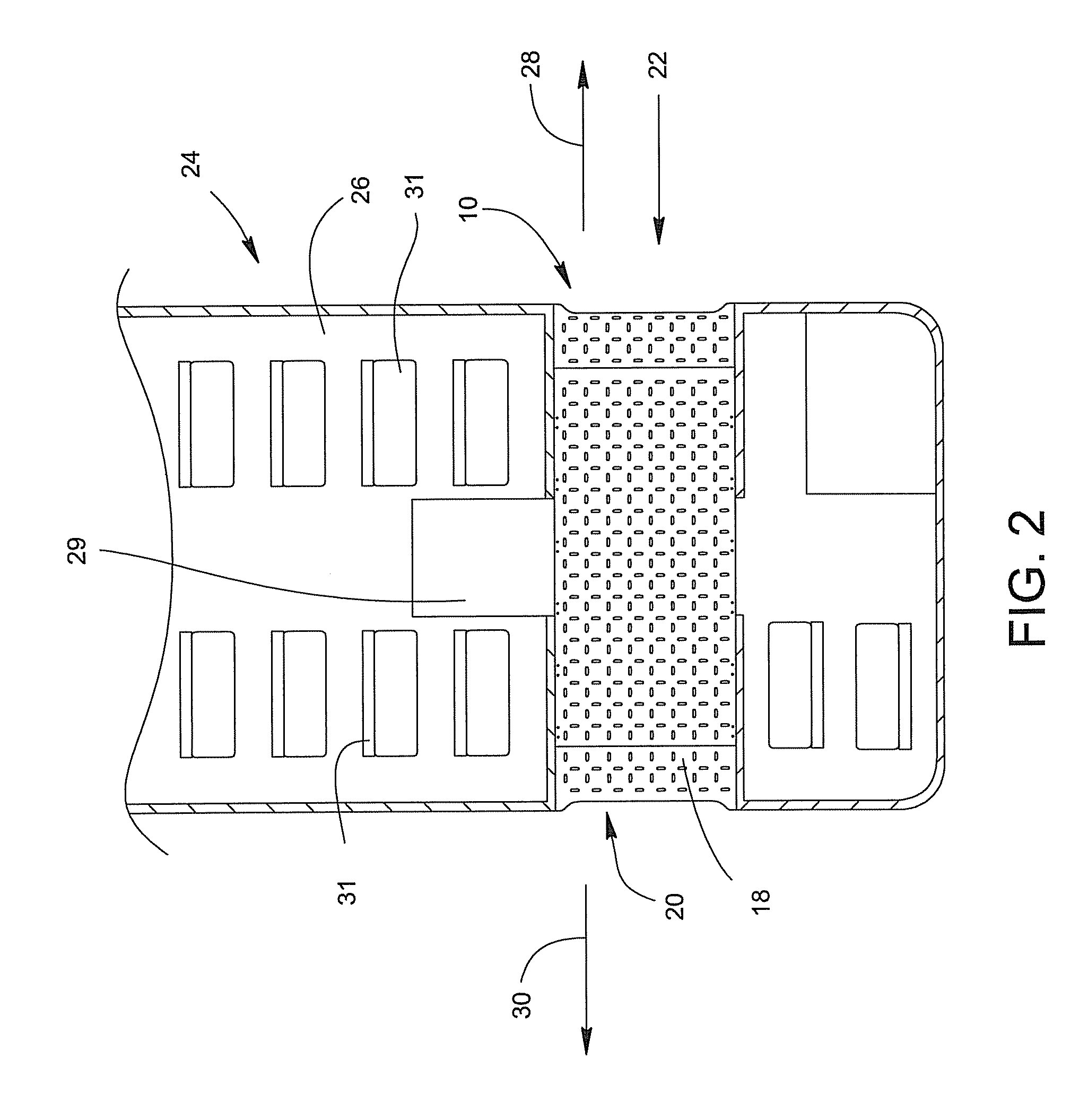

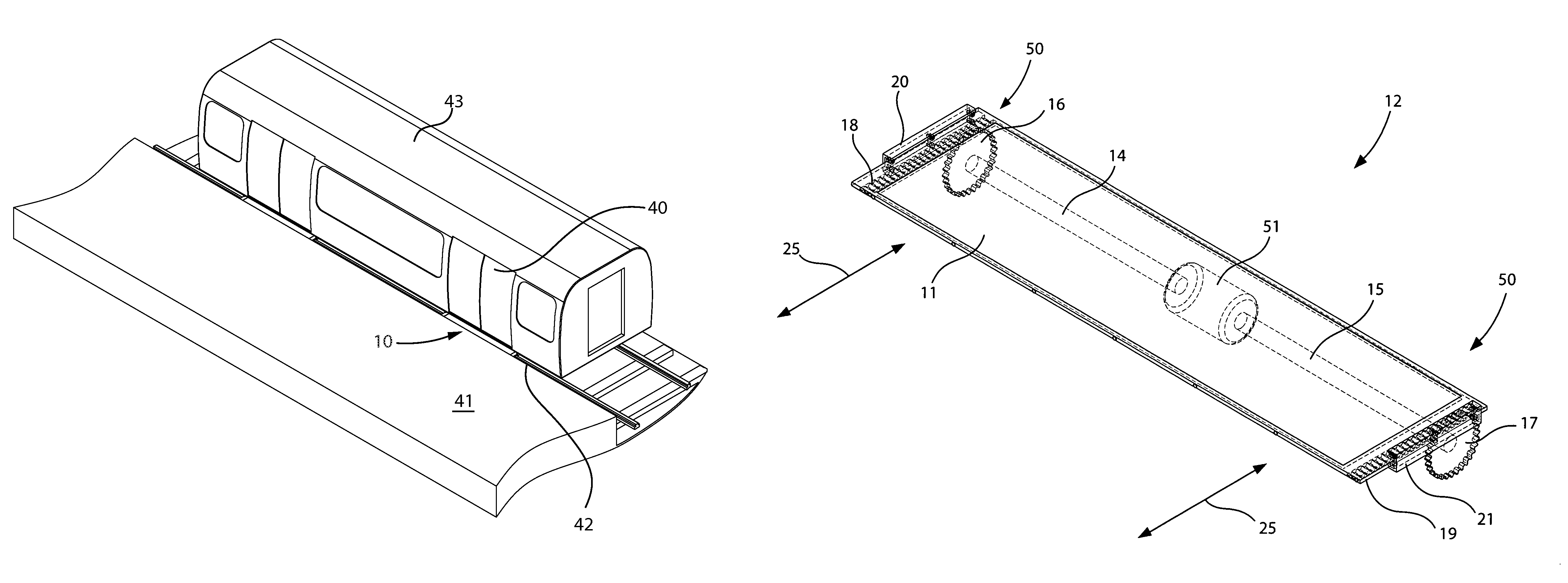

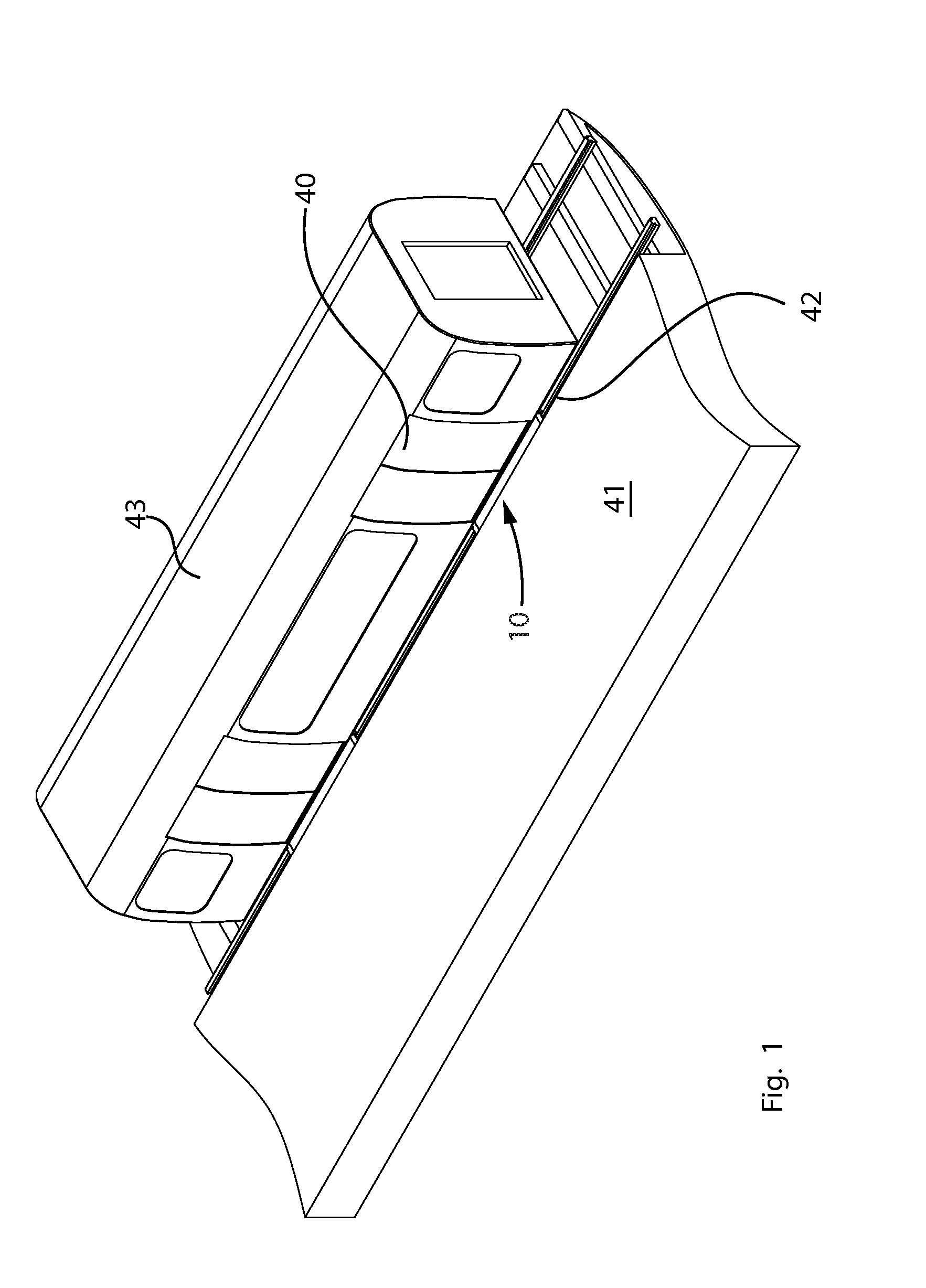

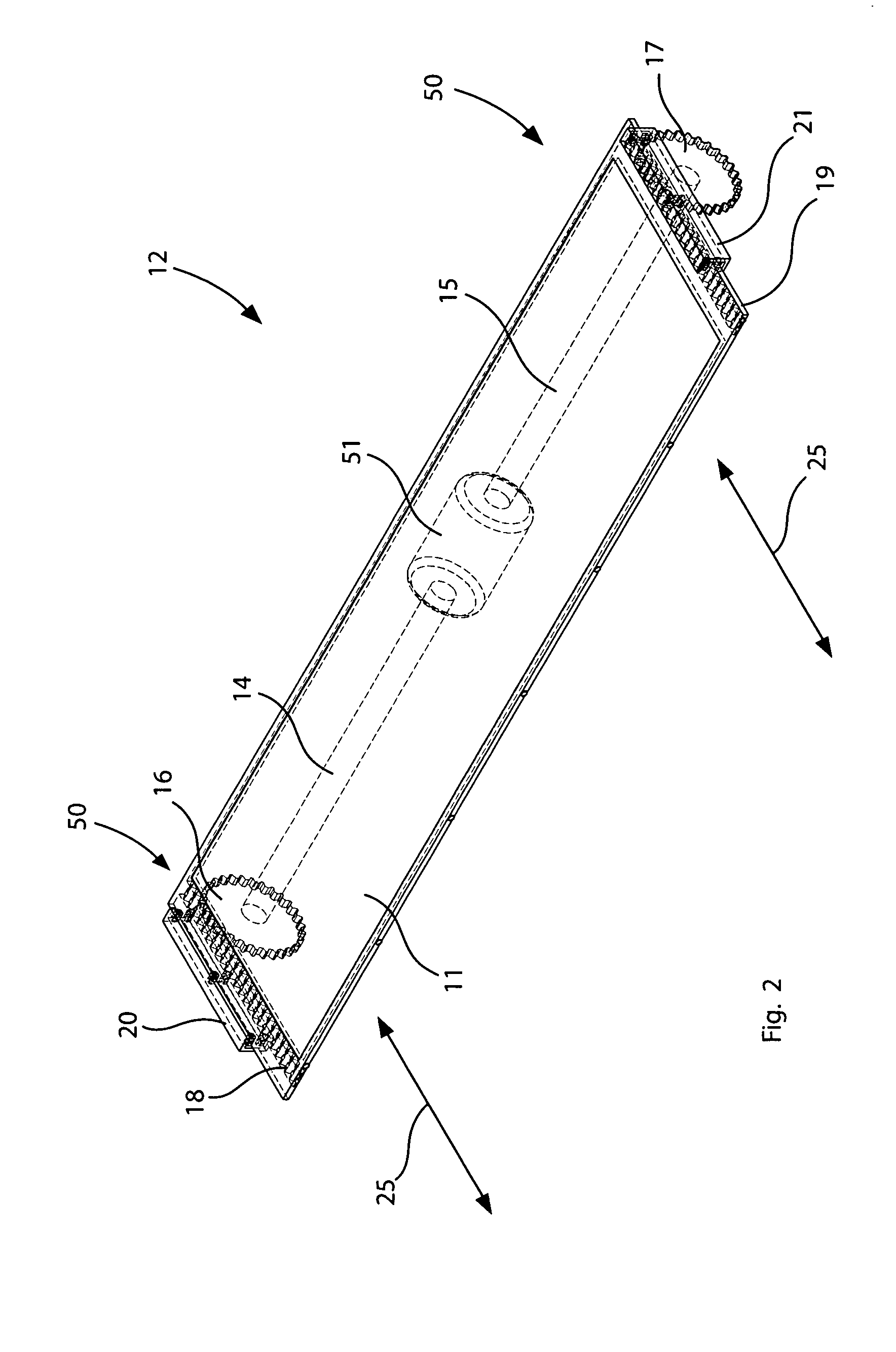

InactiveUS8195382B2Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficEngineeringTruck

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

Multiple driver occupied passenger vehicles transporter system

InactiveUS20100104392A1Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficTraffic capacityDriver/operator

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

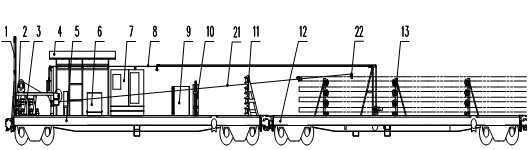

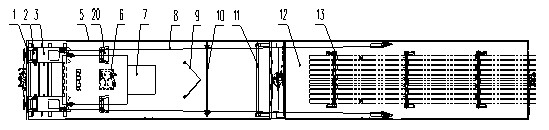

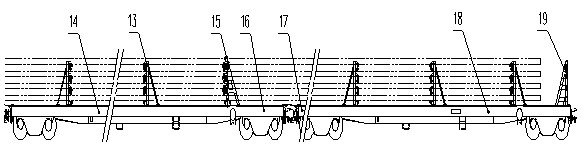

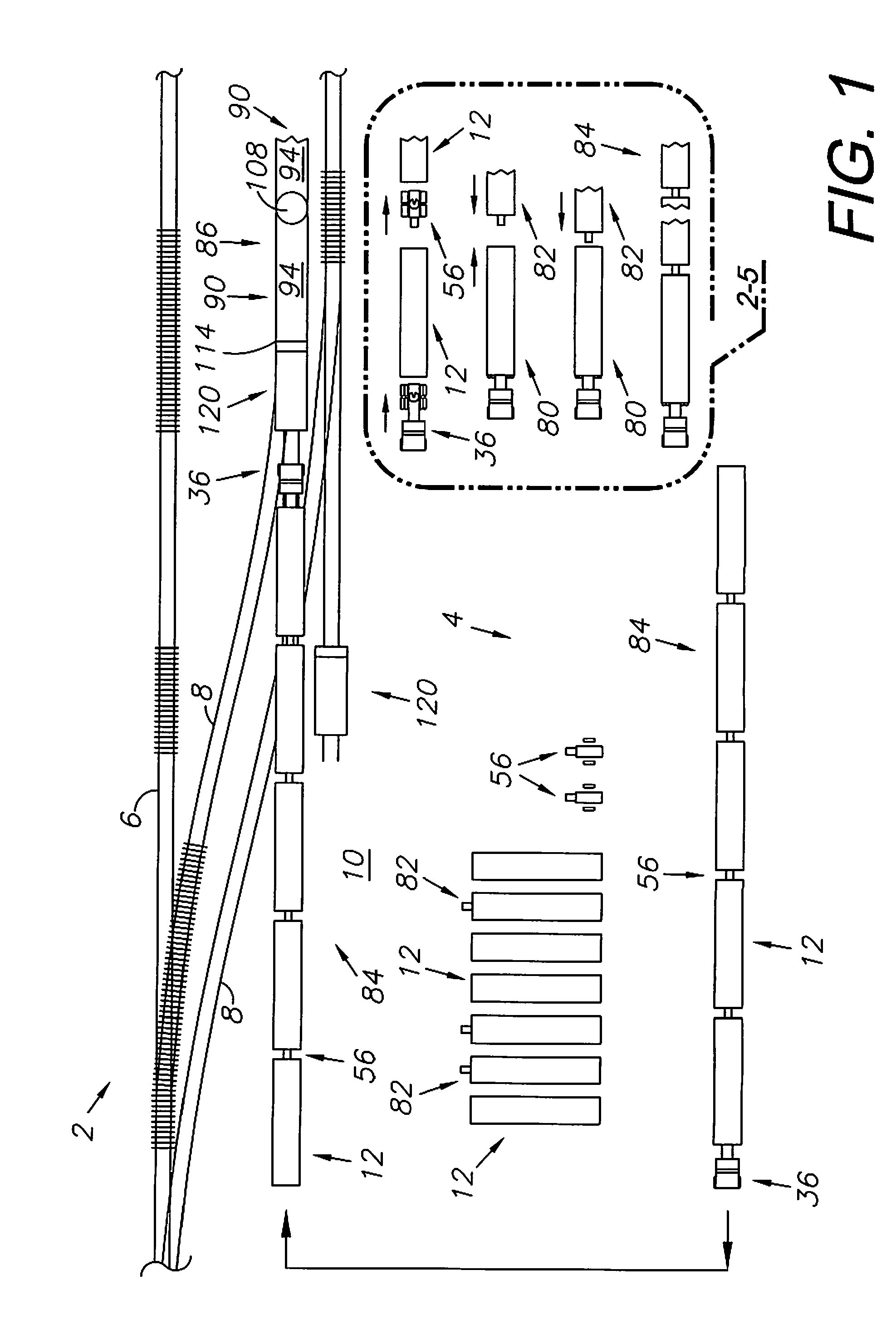

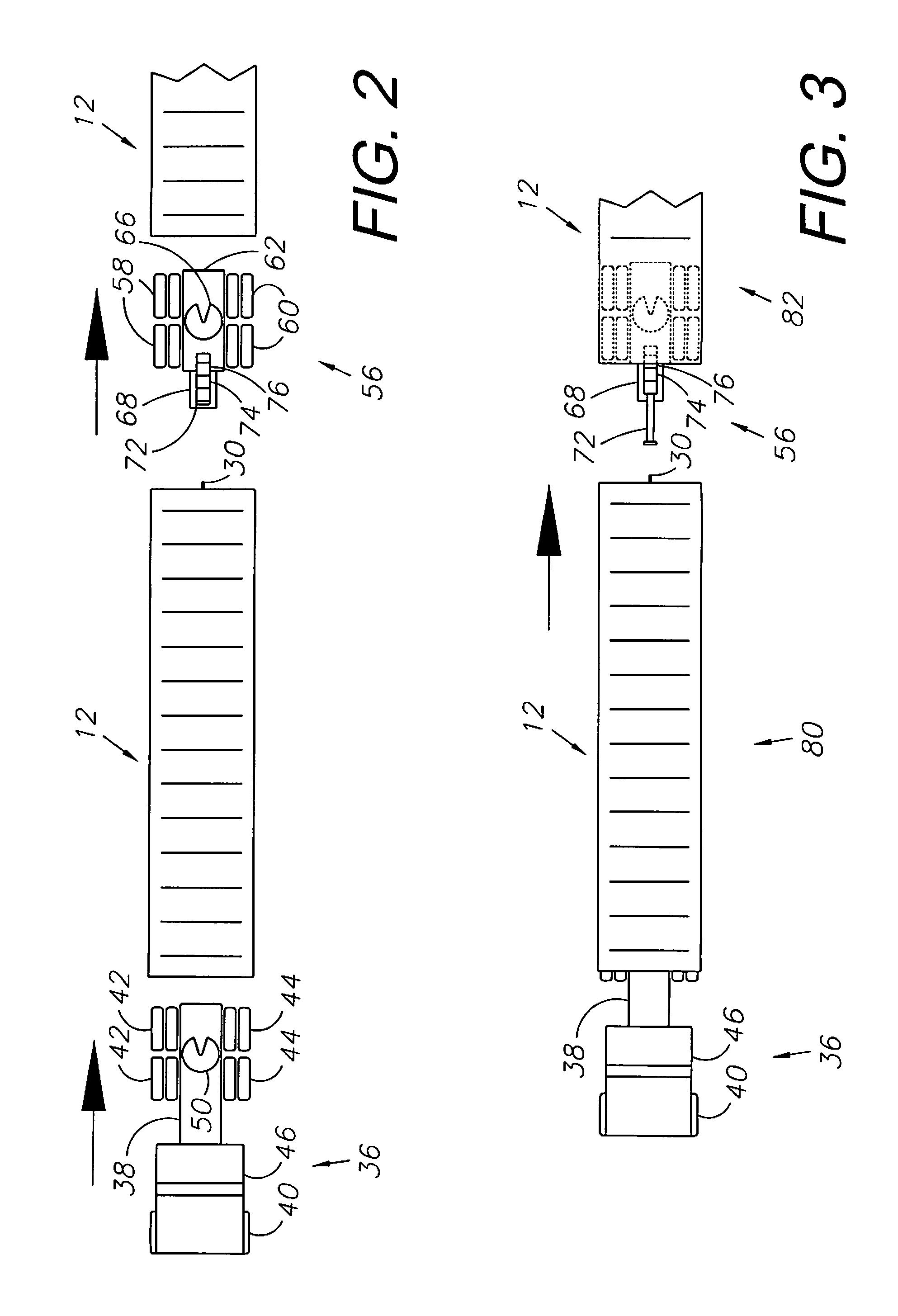

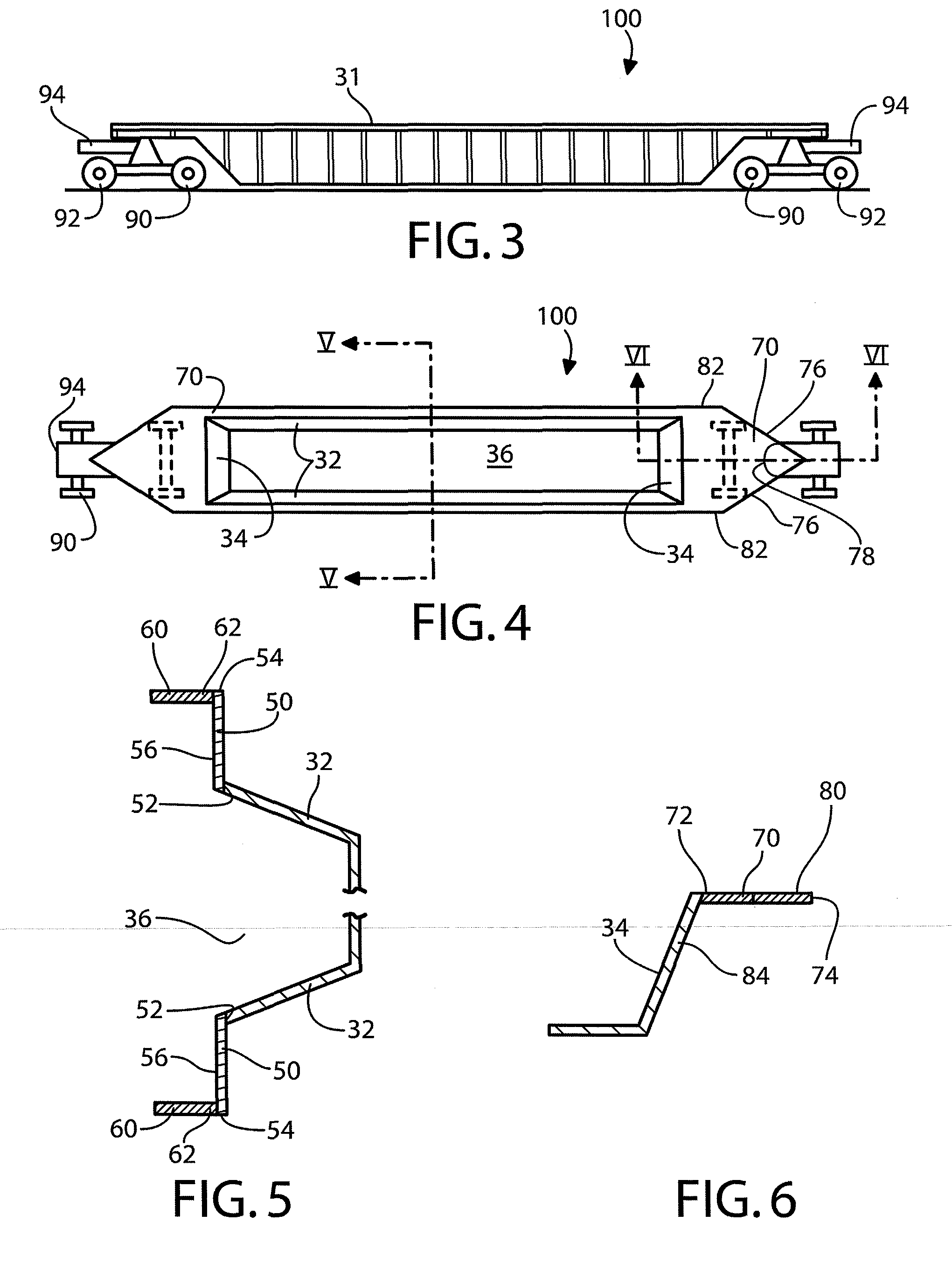

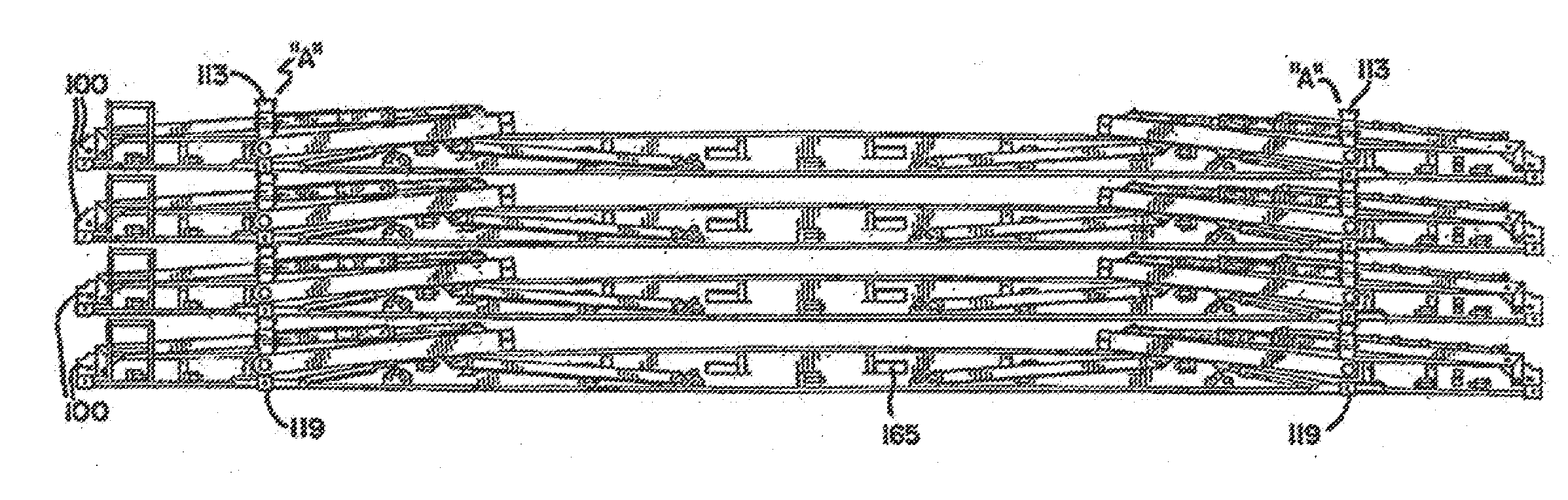

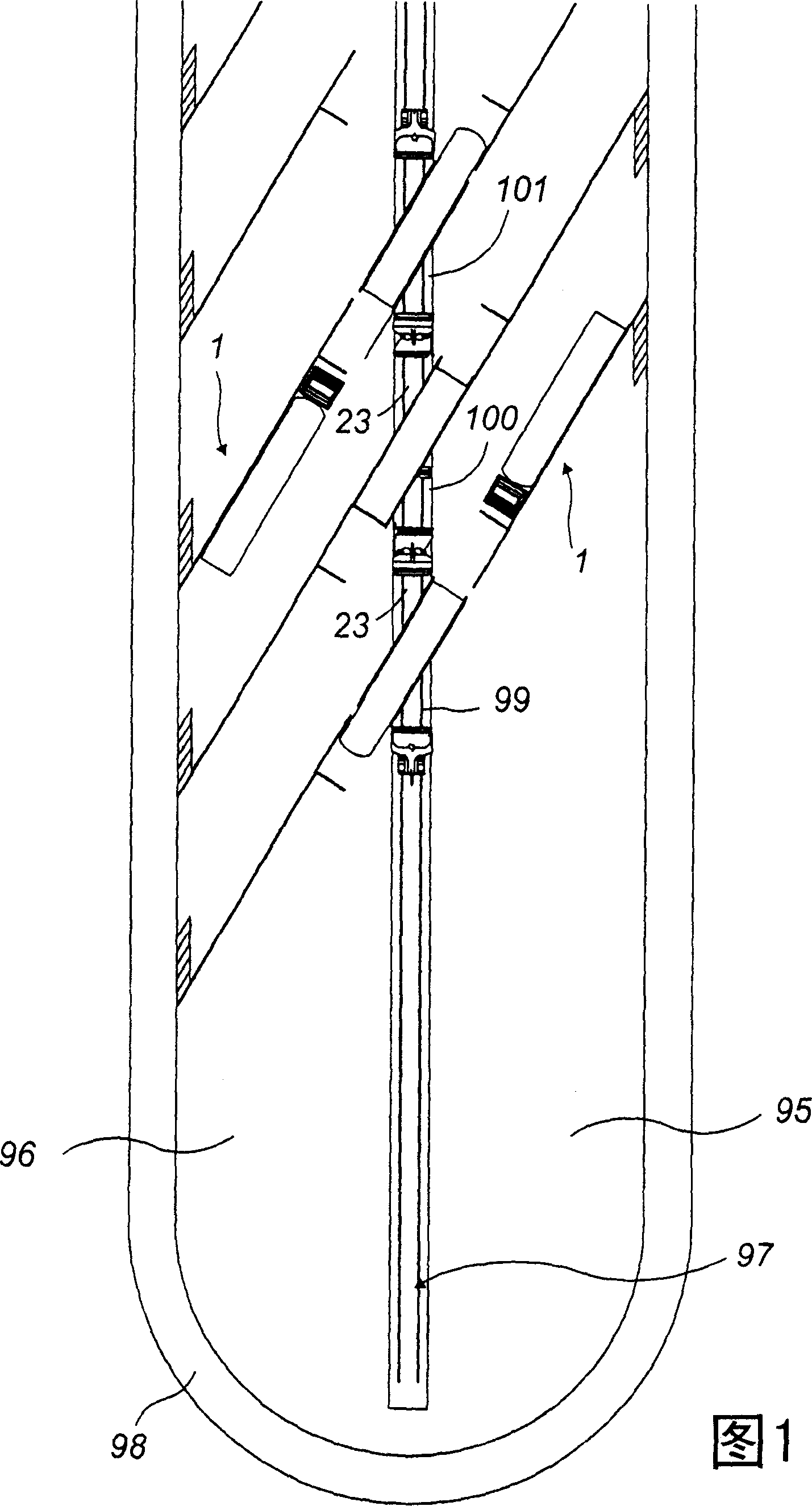

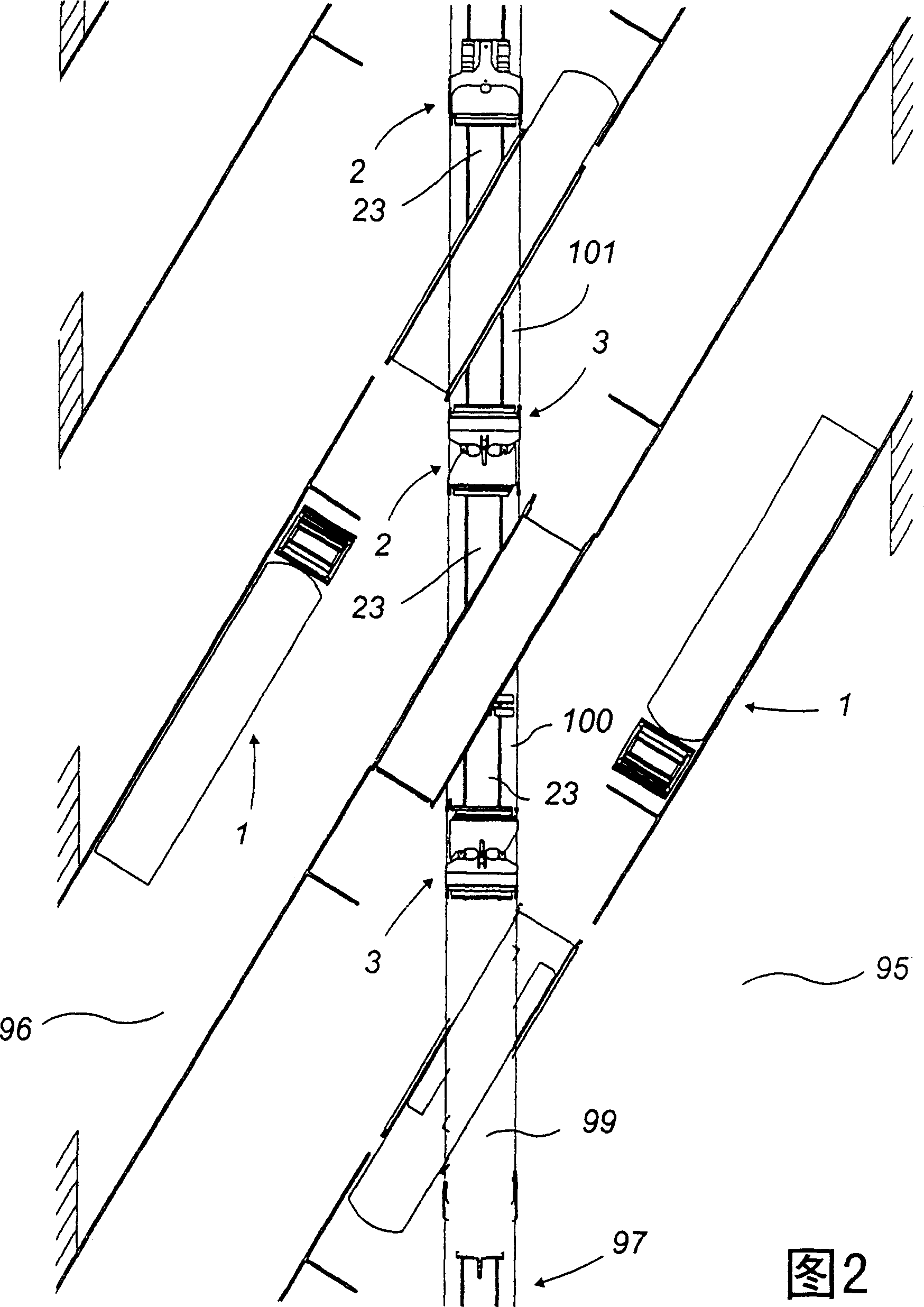

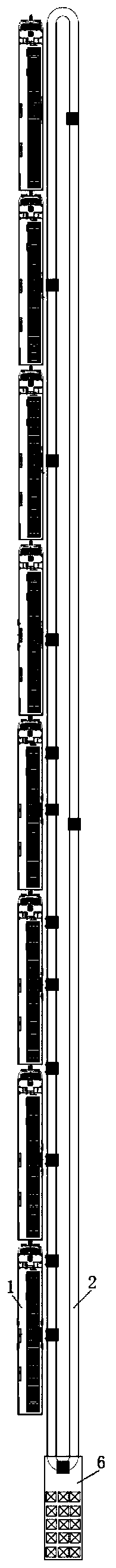

Long steel rail transport vehicle set capable of rapidly unloading steel rails

ActiveCN102009657AAchieve longitudinal movementEasy to adjustWagons/vansRailway device loading/unloadingTransportation costAutomotive engineering

The invention relates to a long steel rail transport vehicle set capable of rapidly unloading steel rails, which is characterized by comprising an unloading operation vehicle, wherein the unloading operation vehicle is provided with a steel rail unloading device; the steel rail unloading device comprises a winding device for pulling and unloading the steel rails and a pusher for pushing the steelrails; tracks are controlled by a guiding device, a tracking device and a lifting rail door at the time of unloading the steel rails; and the winding device, the pusher, the guiding device, the tracking device, the lifting rail door are fixed on the unloading operation vehicle body in sequence along with the running direction. The long steel rail transport vehicle set is formed by grouping six types of vehicles which are successively hung in serials, namely an unloading operation vehicle, a rail transporting heading vehicle, front rail transporting vehicles, a locking vehicle I, a locking vehicle II, rear rail transporting vehicles, and a rail transporting tail vehicle, wherein the number of the front rail transporting vehicles and the rear rail transporting vehicles depends on length of the transported steel rails. The long steel rail transport vehicle set has the advantages of large carrying capacity, simple structure, safety and reliability, high working efficiency of transporting and unloading the steel rails, and lower transportation cost.

Owner:株洲新通铁路装备有限公司 +1

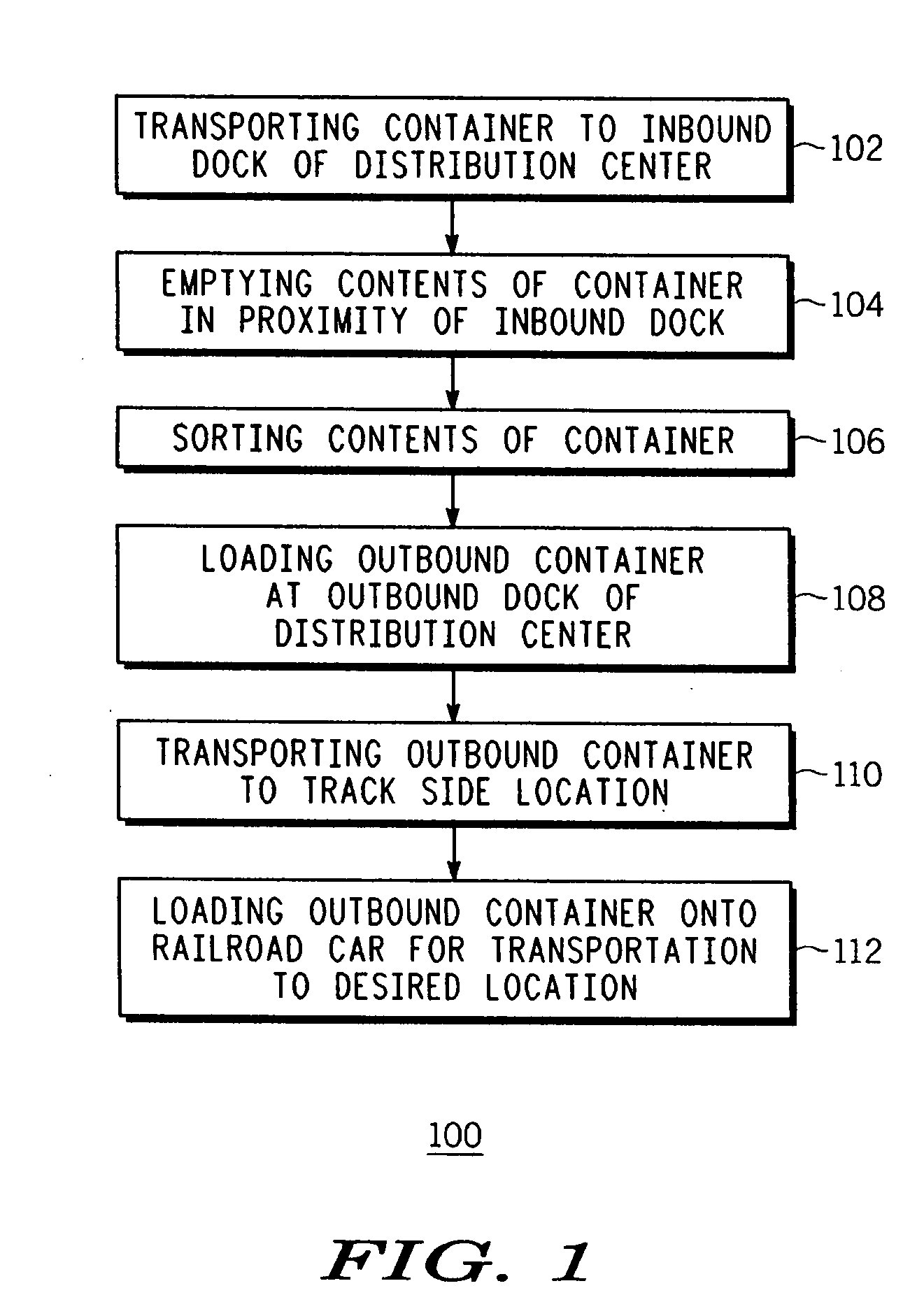

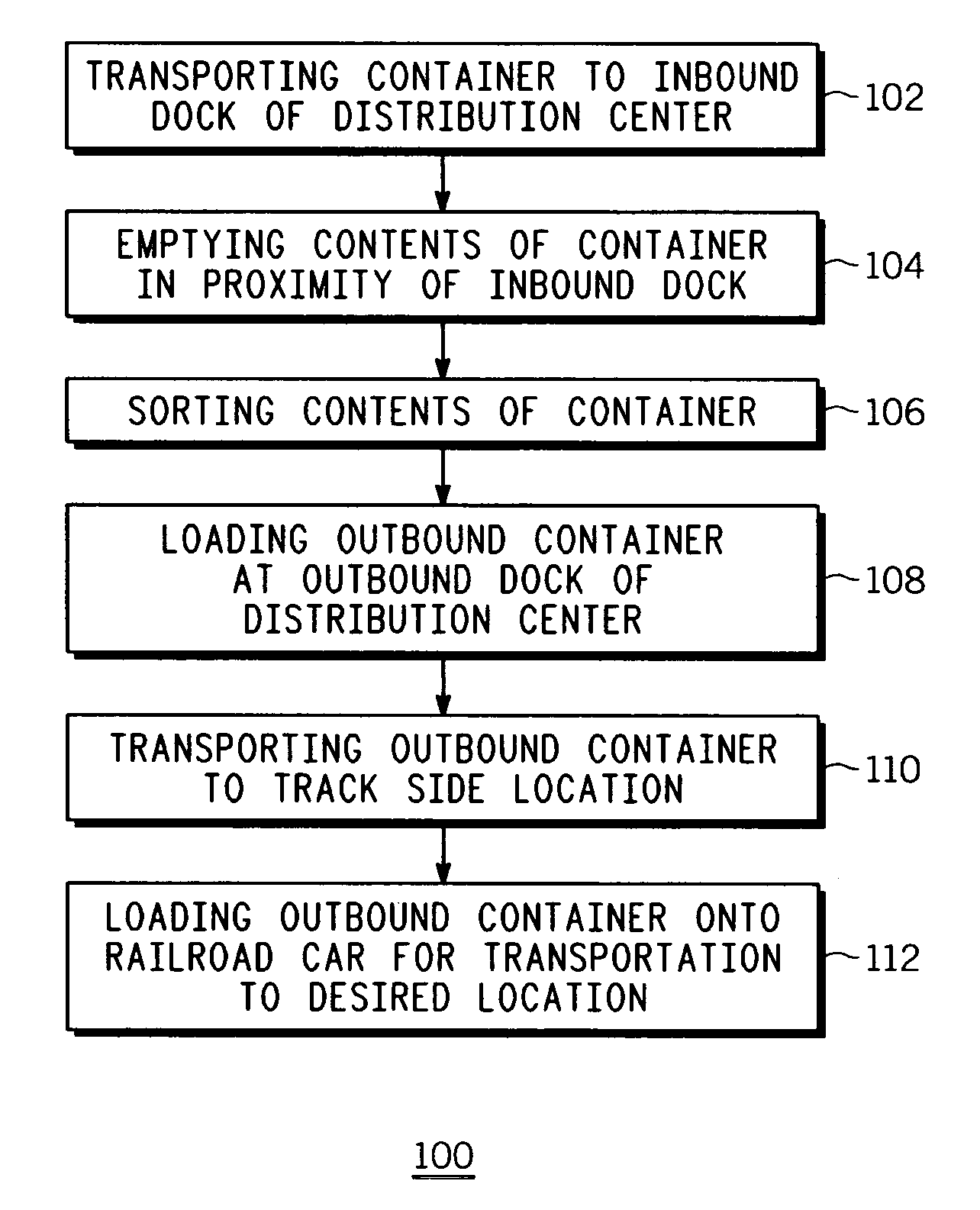

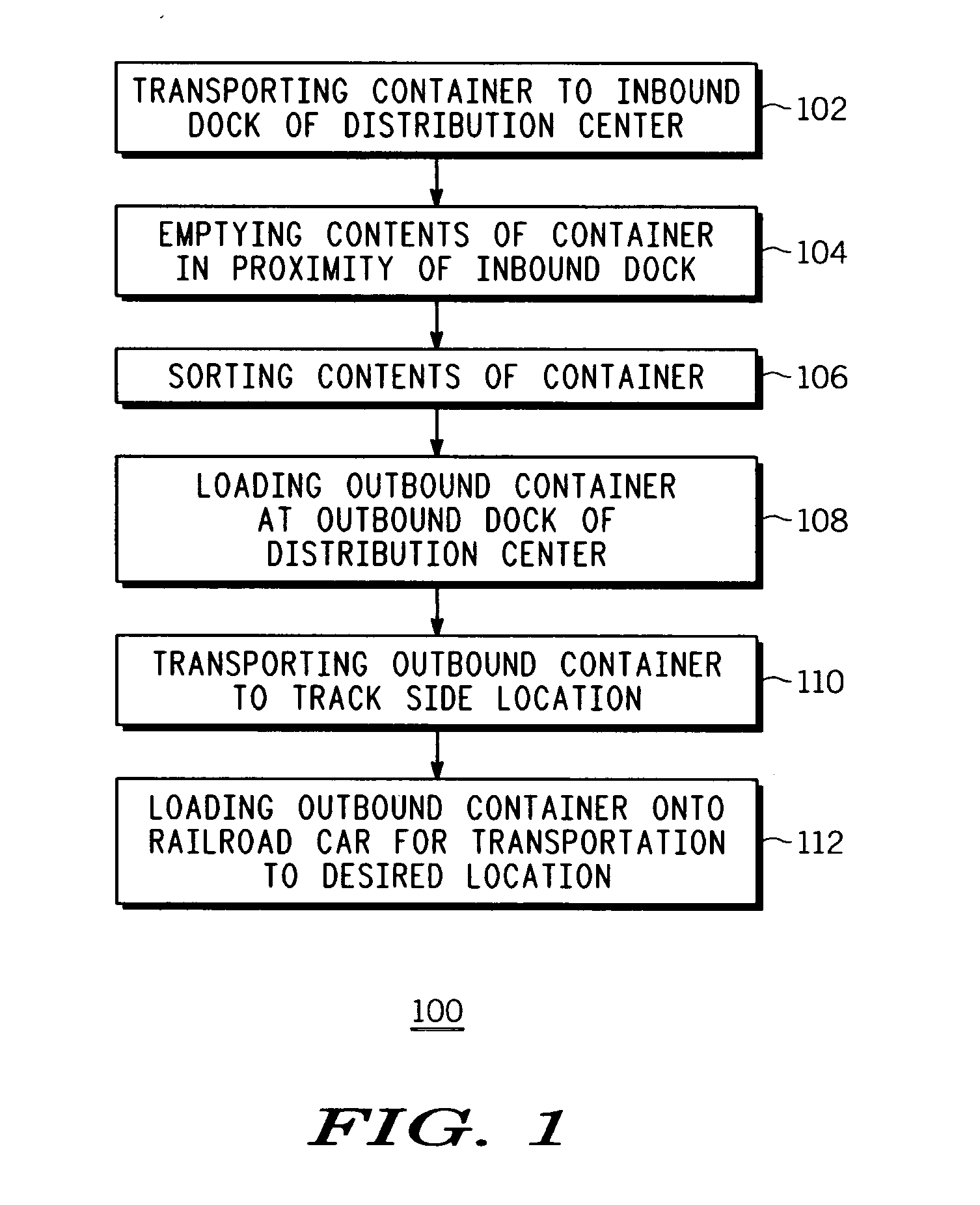

Inline terminal, hub and distribution system

InactiveUS20080141895A1Refuge islandsRailway system combinationsDistribution systemComputer terminal

The present invention provides an inline terminal, hub and distribution system. It comprises the steps of: transporting (102) a container to an inbound dock of a distribution center; emptying (104) the contents of the container in proximity to the inbound dock; sorting (106) the contents of the container; loading (108) an outbound container at an outbound dock of the distribution center; transporting (110) the outbound container to a track side location; loading (112) the outbound container onto a railroad car for transportation to a desired location.

Owner:LANIGAN JOHN J +1

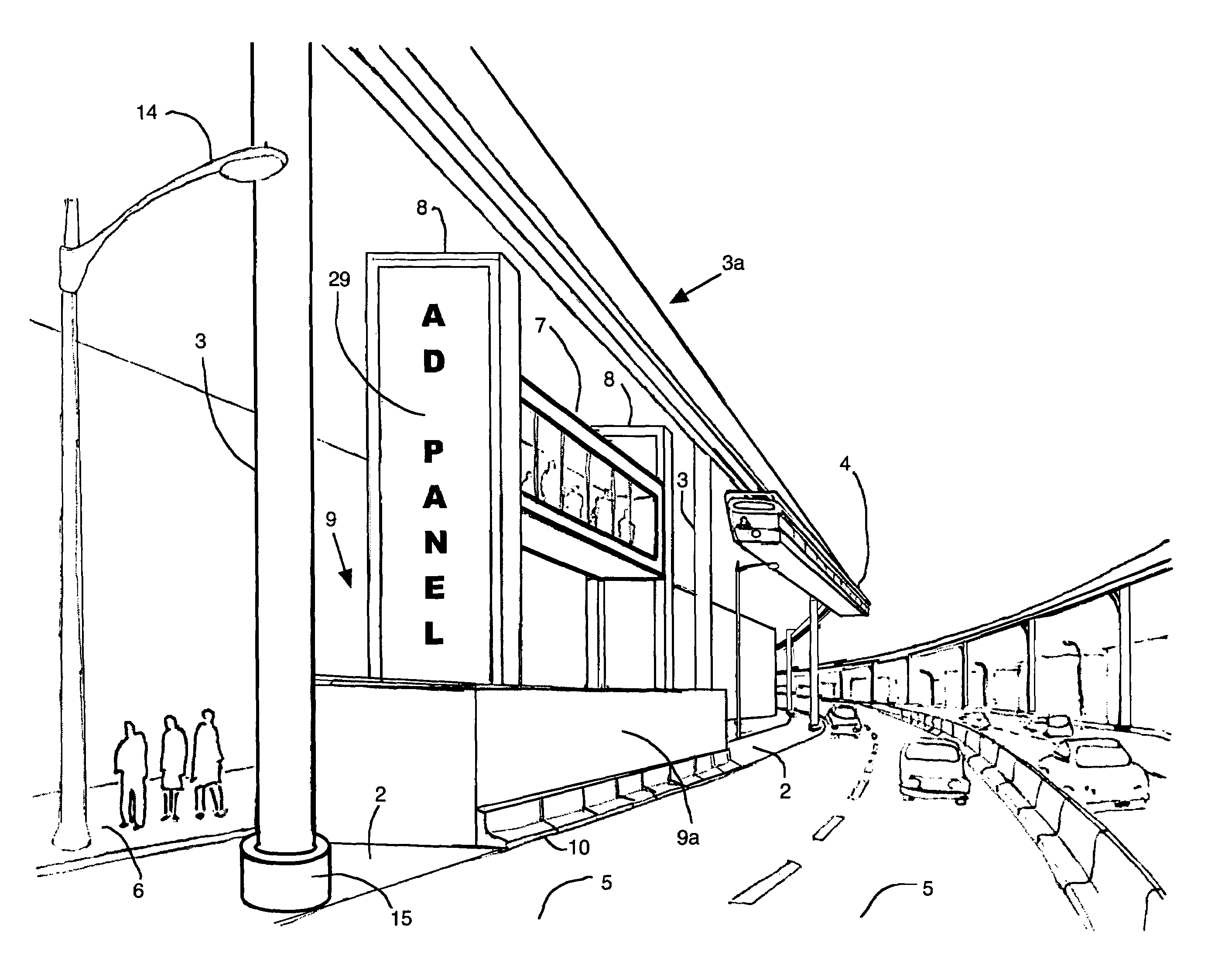

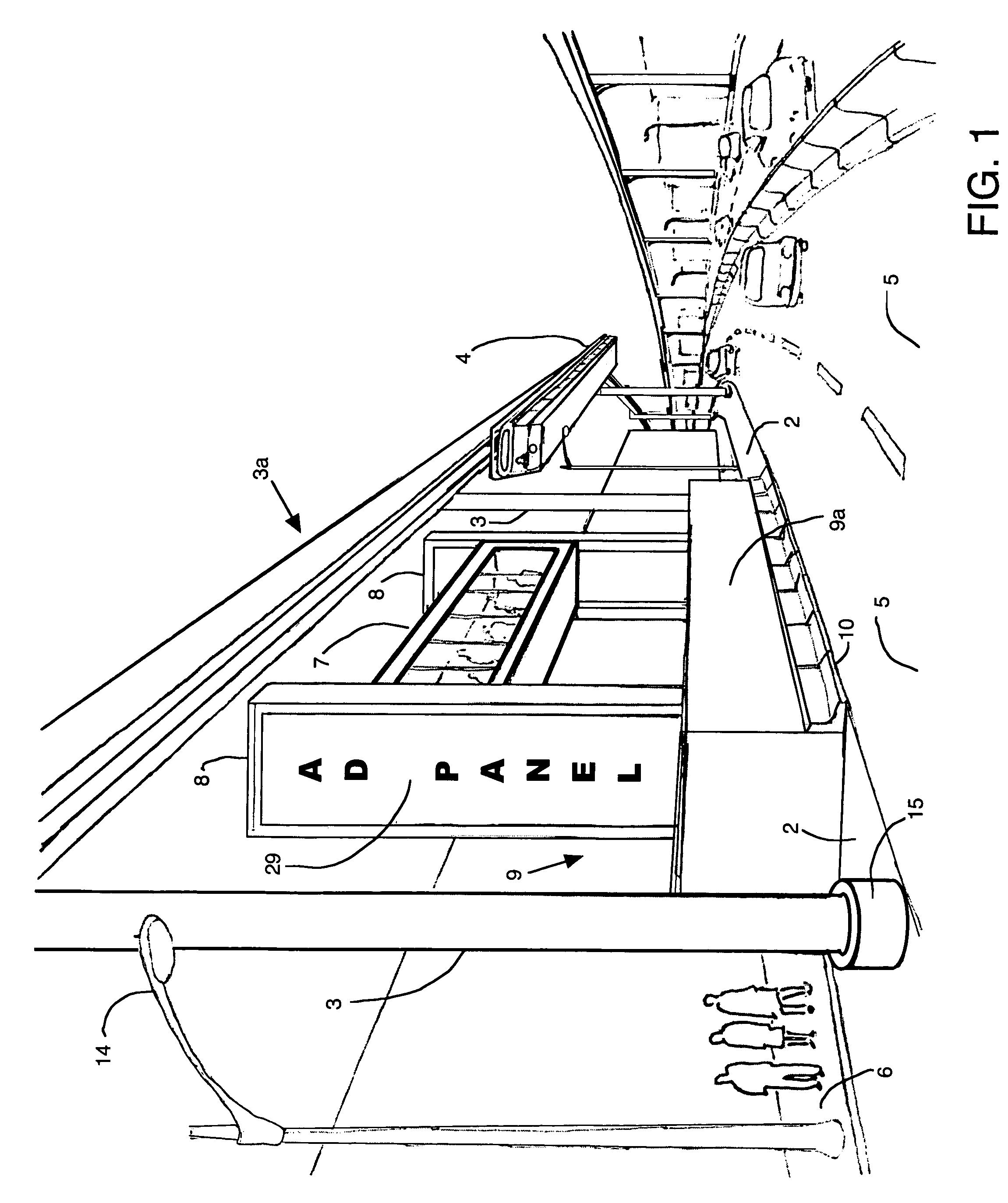

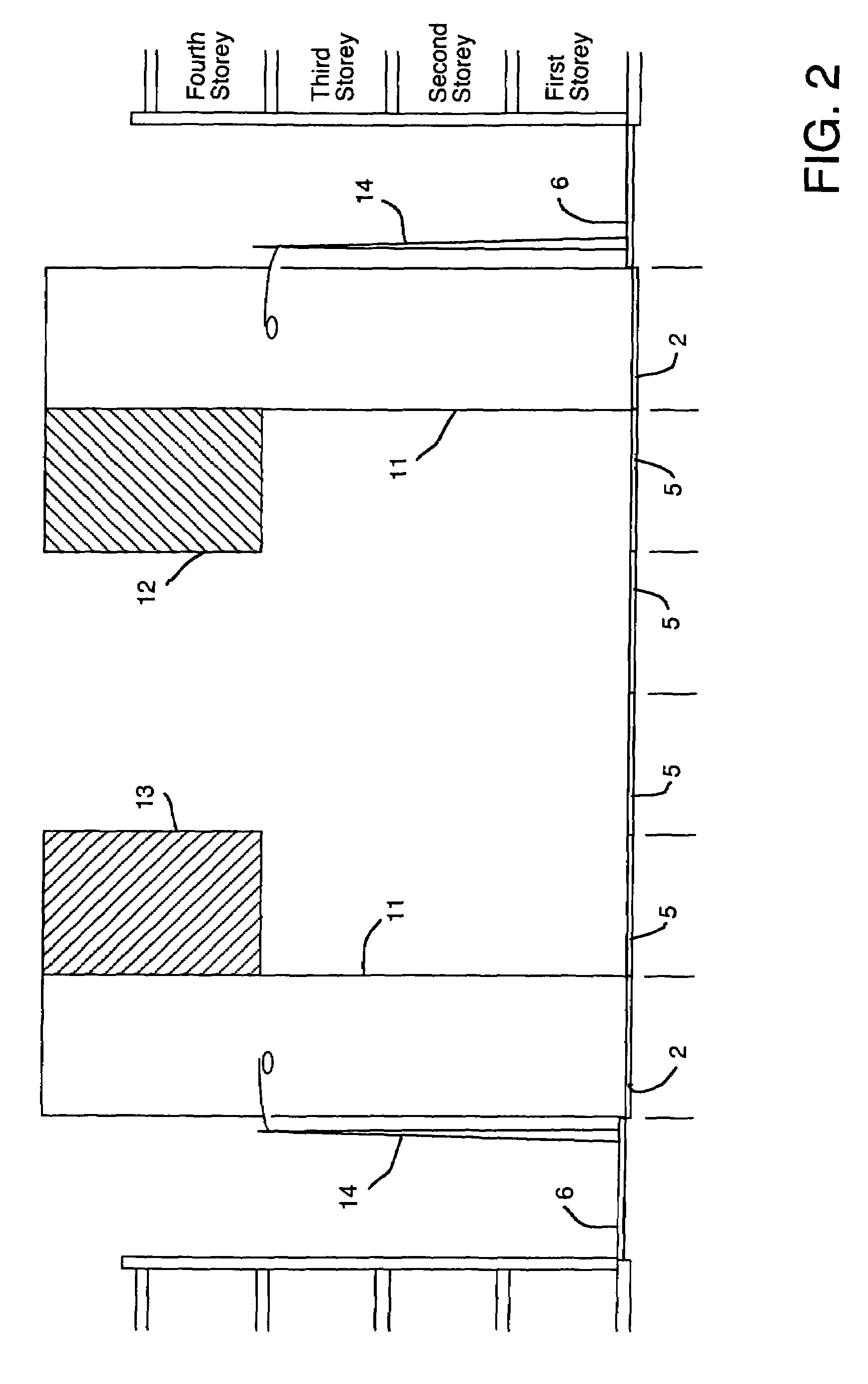

Elevated bus rapid transit system

InactiveUS7246559B2Efficient configurationEliminating time-consume switchingRope railwaysElevated railway with suspended vehicleEngineeringRapid transit

Owner:STROMBERG DALE MARIE

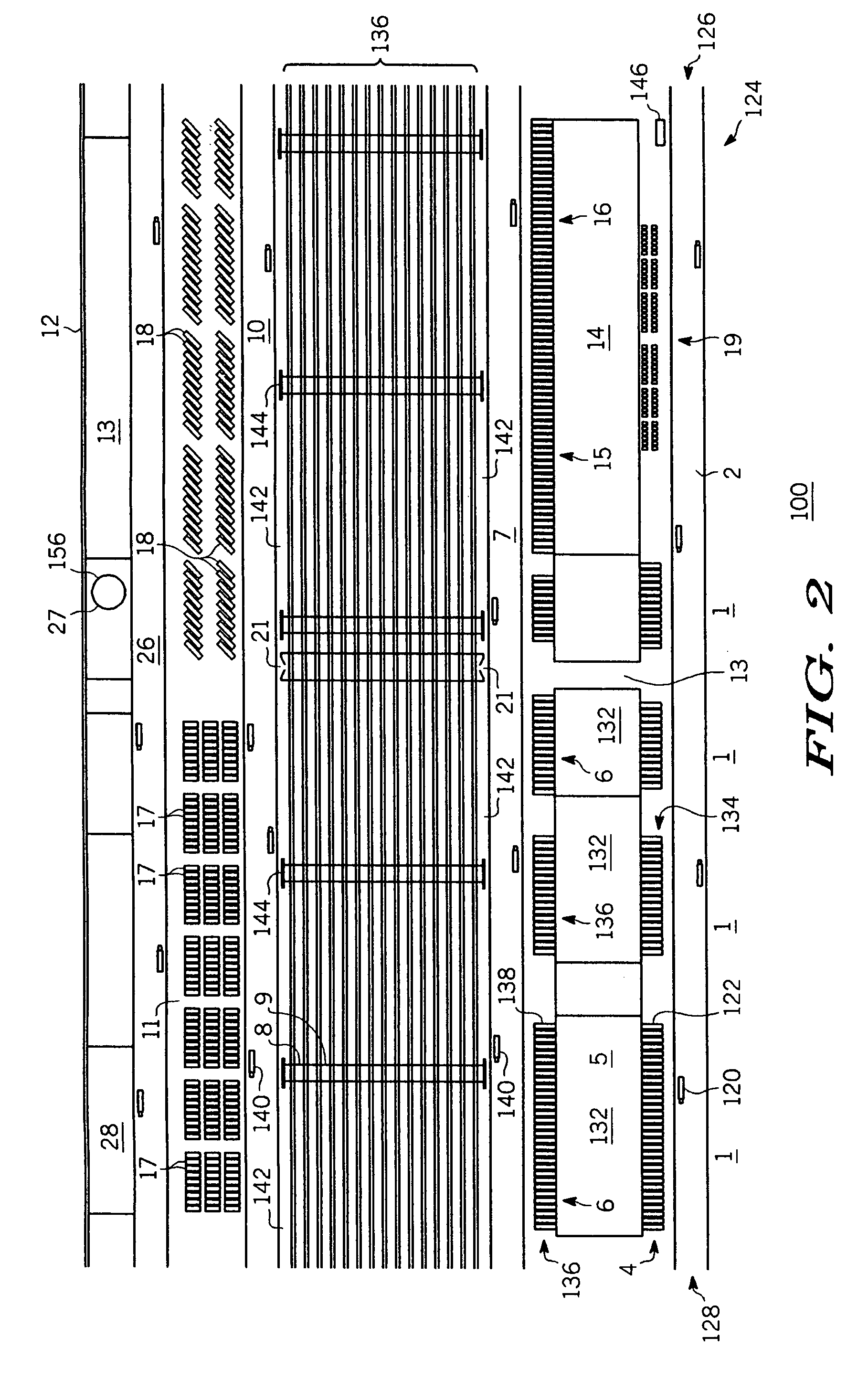

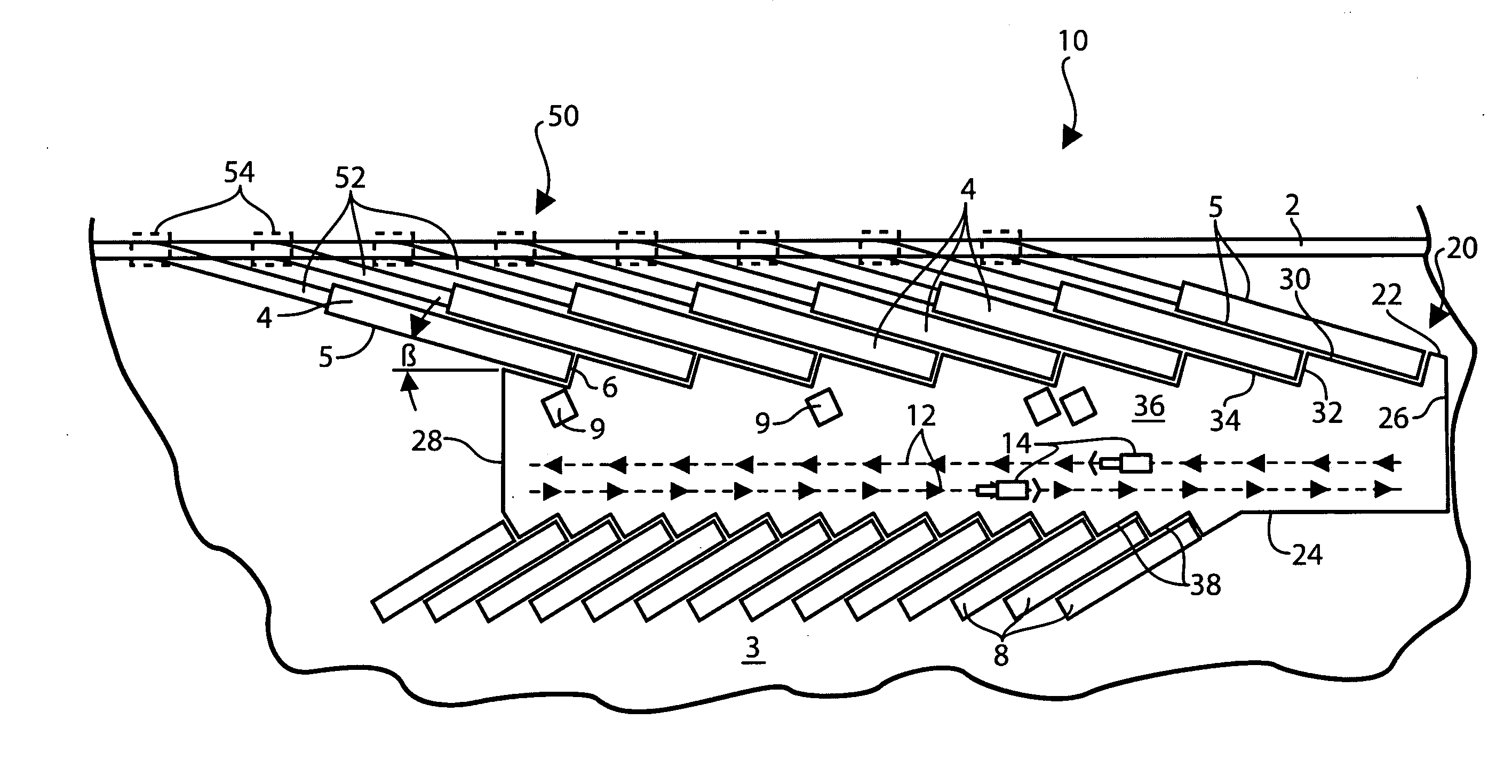

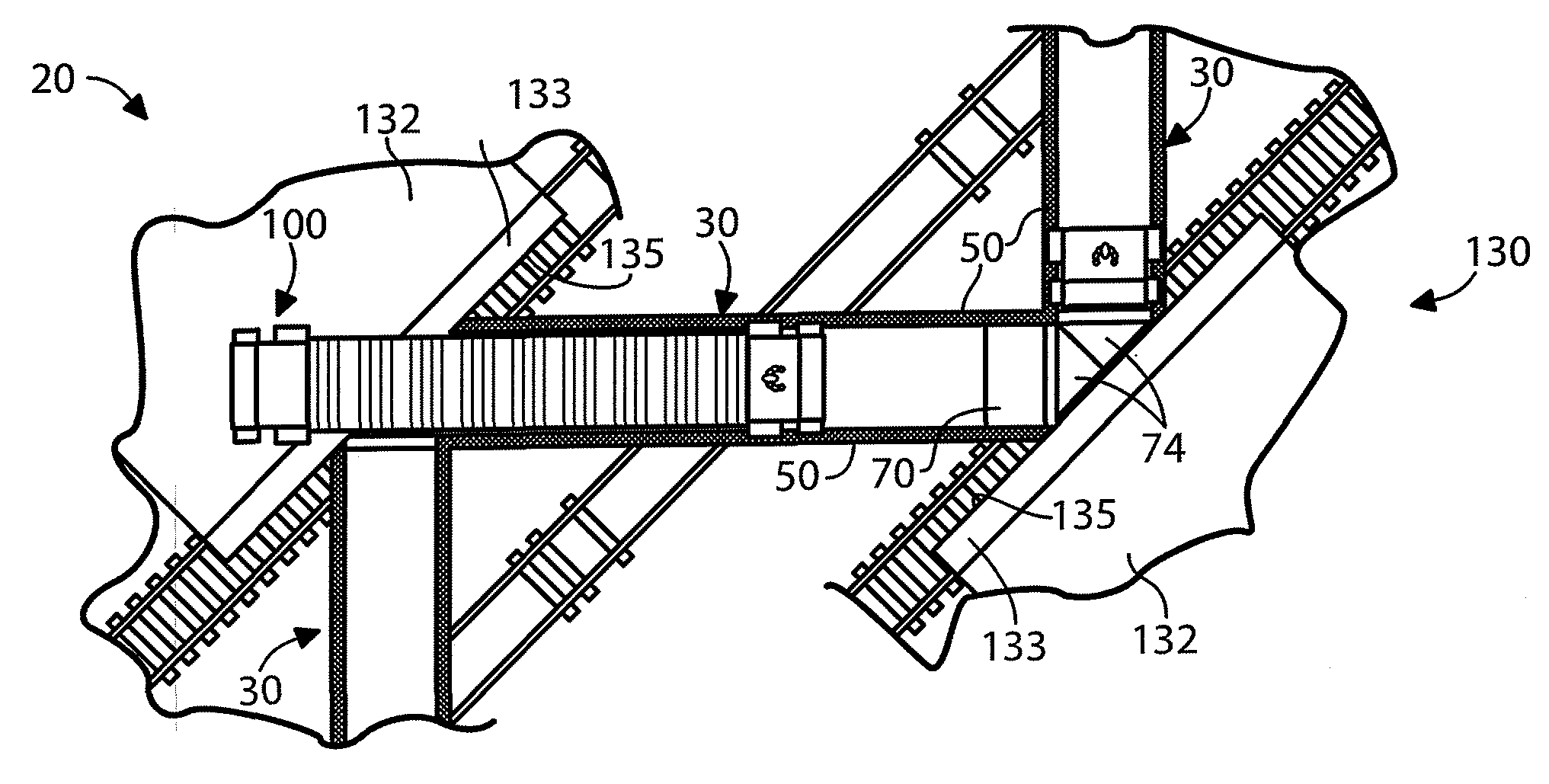

System, network and method for transporting cargo

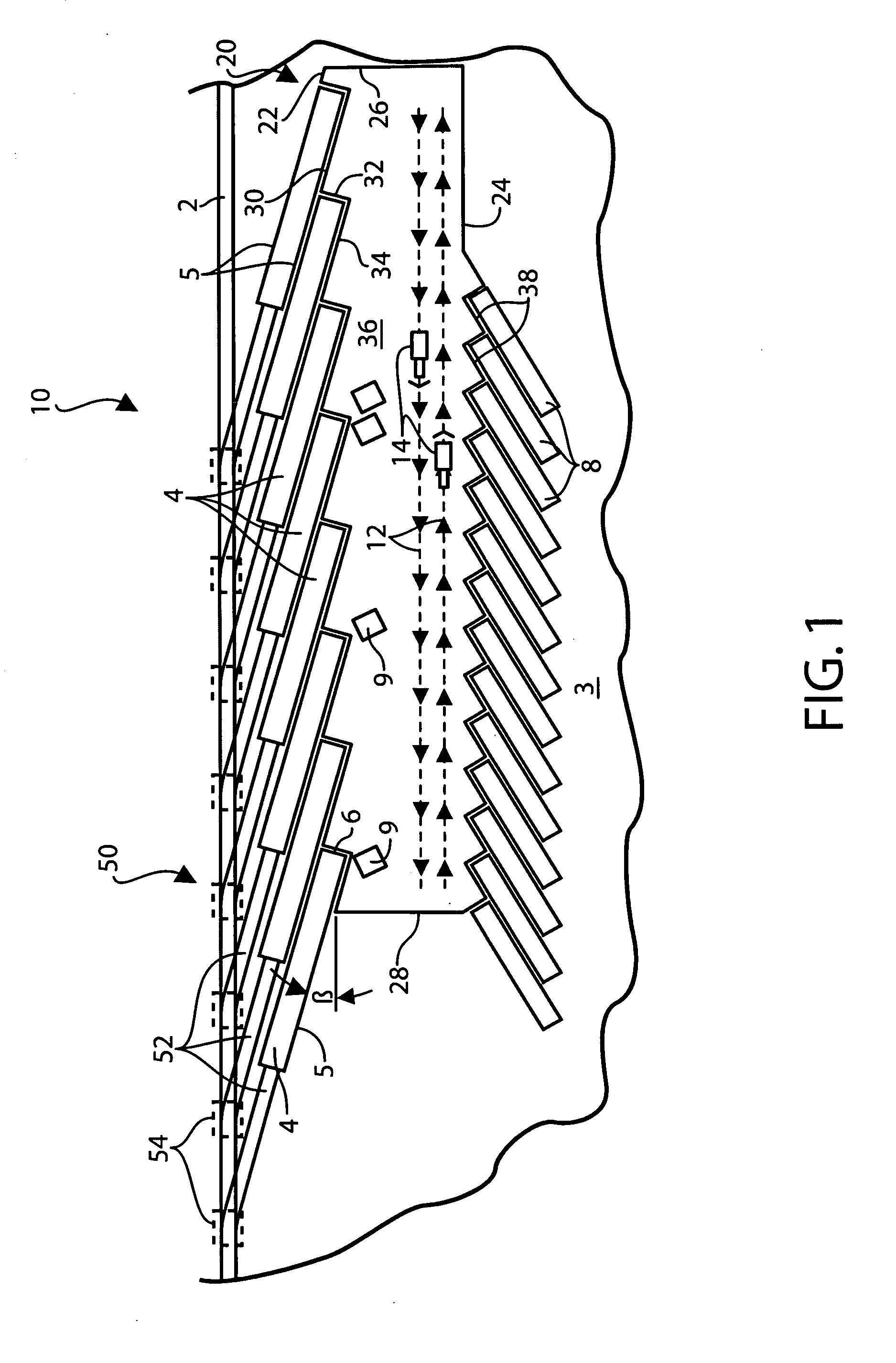

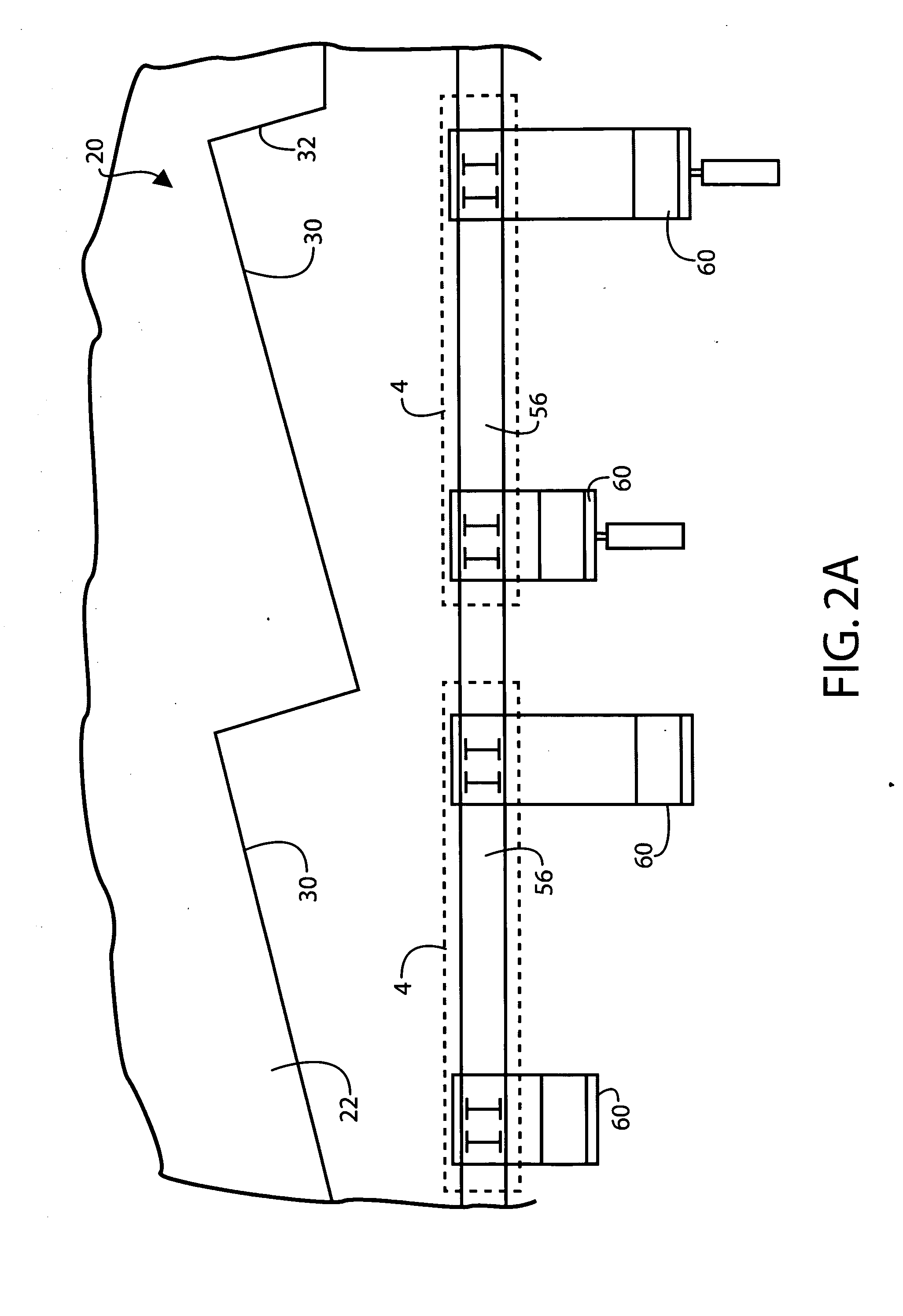

InactiveUS20090293756A1Improve efficiencyReduce operating costsRefuge islandsRail switchesAcute angleEngineering

A system for transporting cargo includes a cargo terminal having a pair of longitudinal sides, at least one of the pair of longitudinal sides disposed adjacent to and spaced a predetermined distance from a railway track and at least one railcar positioned at a predetermined acute angle relative to the at least one of the pair of longitudinal sides of the cargo terminal and having one end thereof disposed in close proximity thereto so as to enable loading or unloading such cargo through such one end of such at least one railcar. A network of at least two cargo terminals and a method of intermodal cargo transporting are also provided.

Owner:KACI INTERMODAL SYST

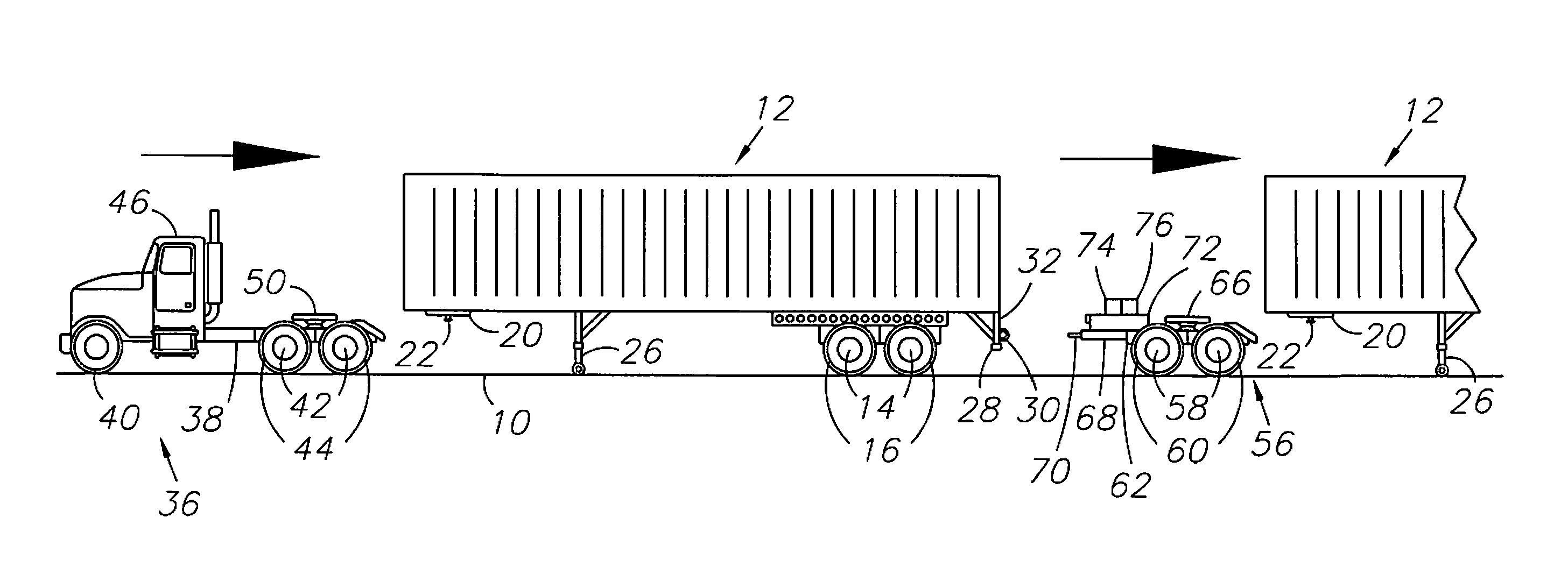

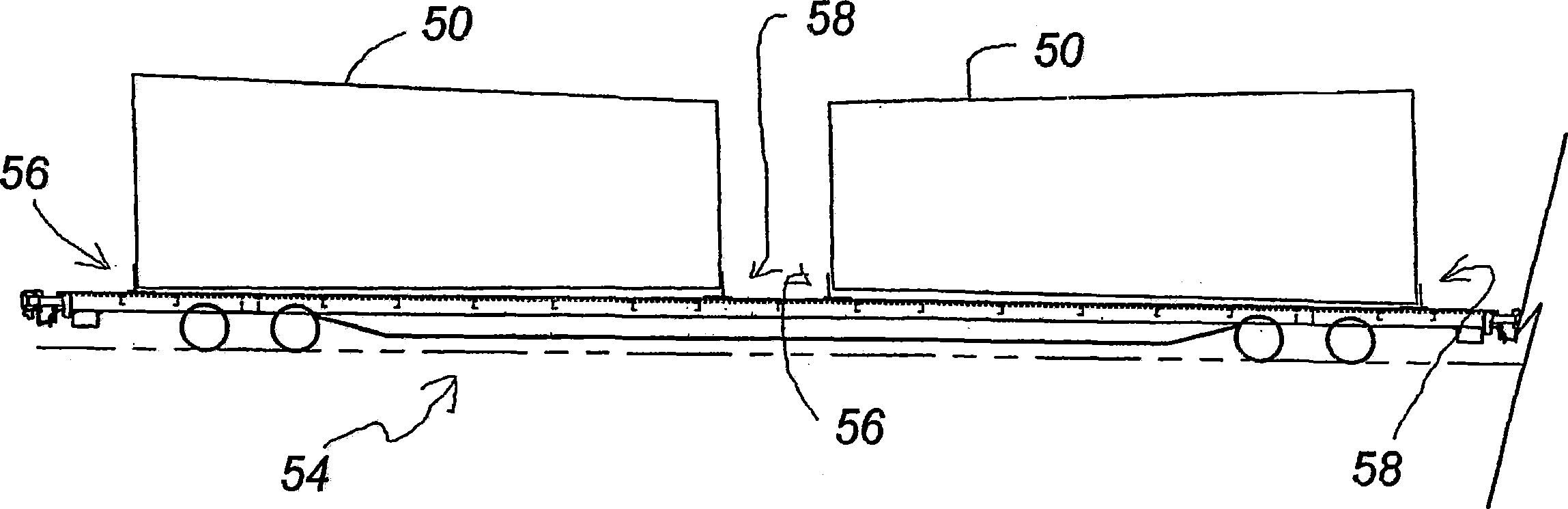

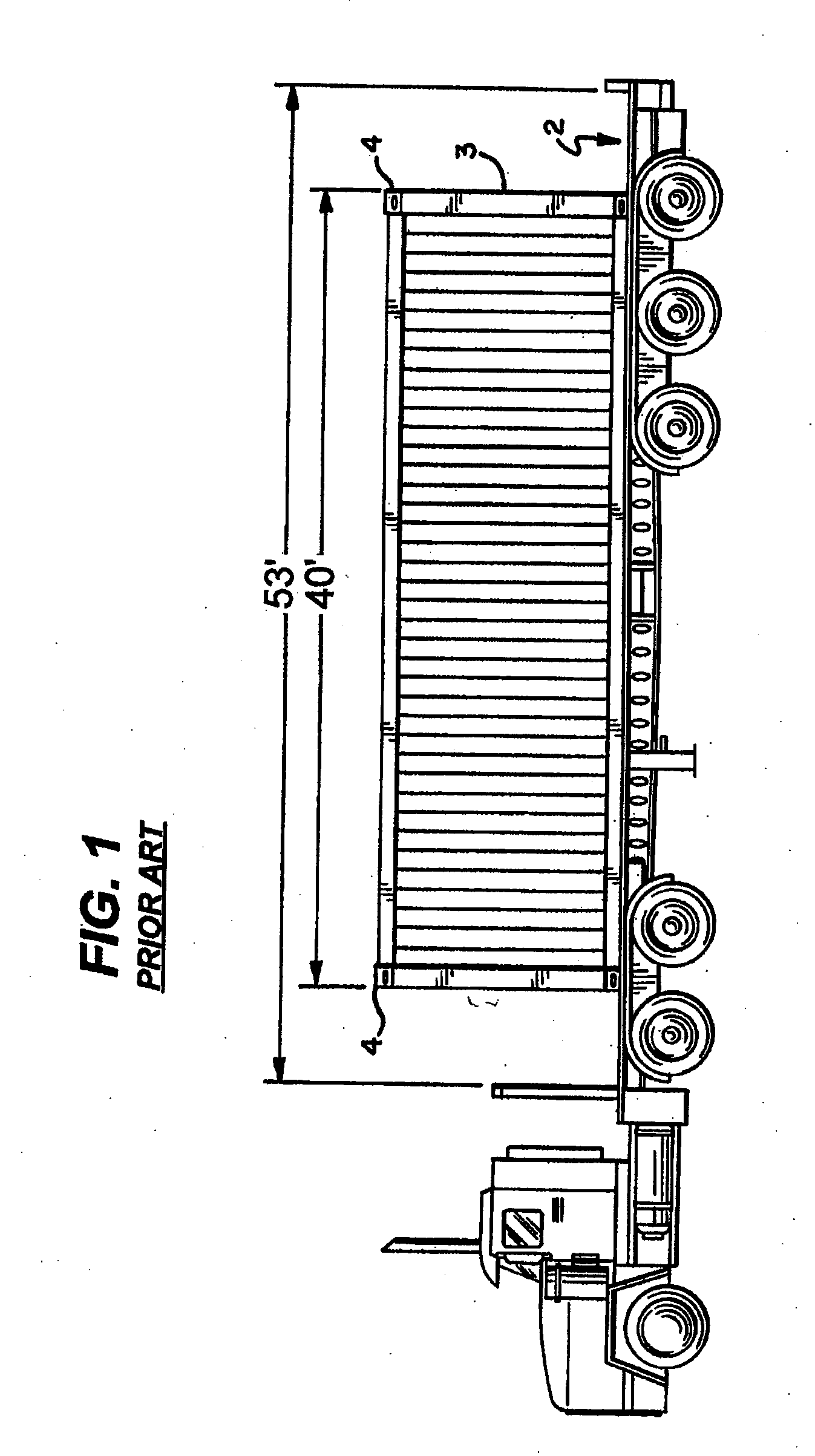

Intermodal transportation system with movable loading ramps and local hybrid delivery

An intermodal transportation system having interconnected railcars adapted for transporting interconnected freight trailers where the freight trailers remain connected while being transported on the railcars. Individual trailers are assembled into trailer assemblies at an assembly area. Trailers containing freight are assembled into trailer assembles using specialized dollies. A preferred embodiment includes using a self-powered dolly having tires and mounting a fifth-wheel pickup plate and a ring coupler for engaging the kingpin of a trailer. Multiple dolly-trailer assemblies are connected together to form a trailer assembly. A self-powered movable ramp is positioned at an end of the railcar assembly and a tractor pulls the trailer assembly onto a railcar assembly by driving up a self-powered movable ramp and across the top of the railcars.

Owner:TWENTY FIRST CENTURY TRANSPORT SYST INC

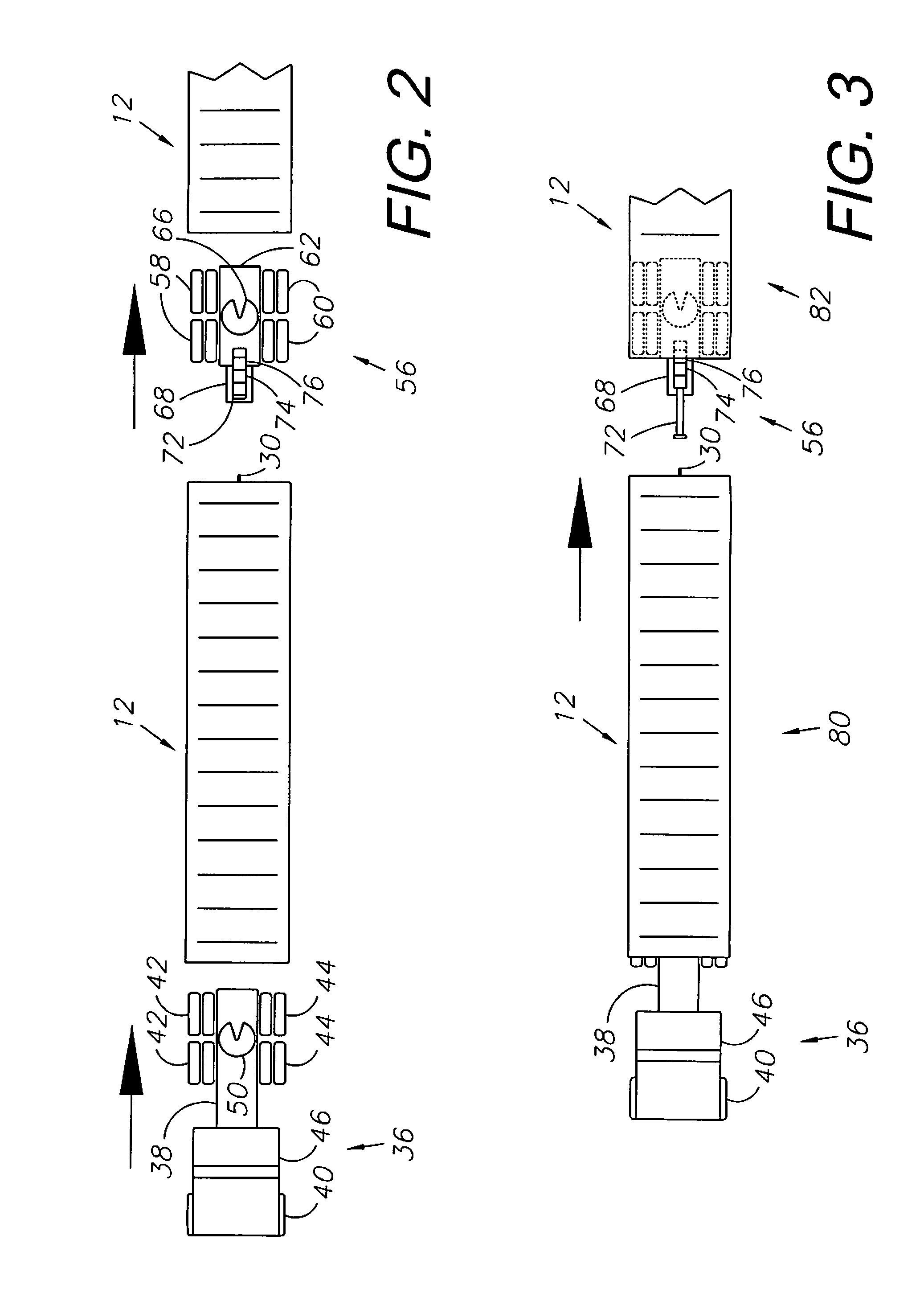

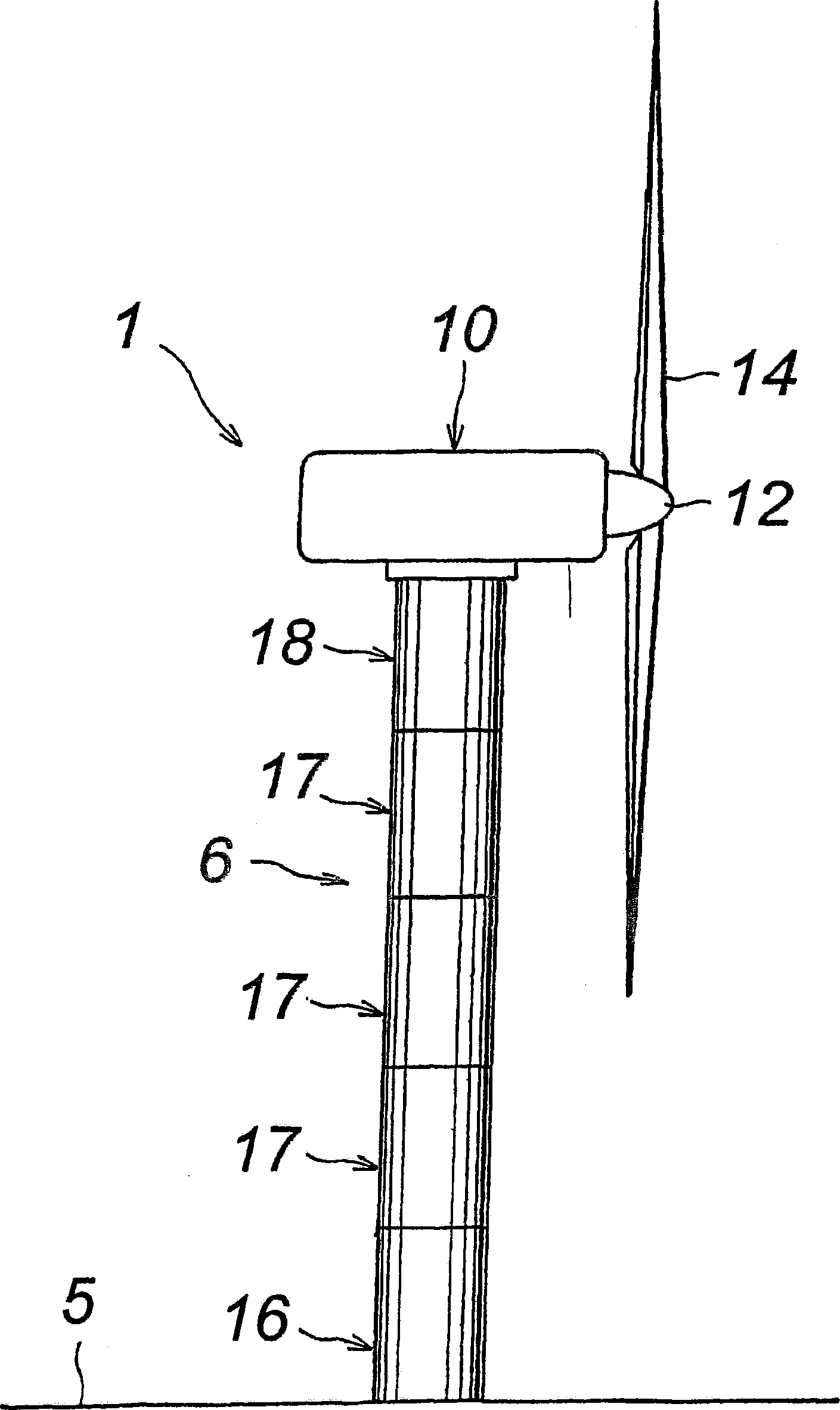

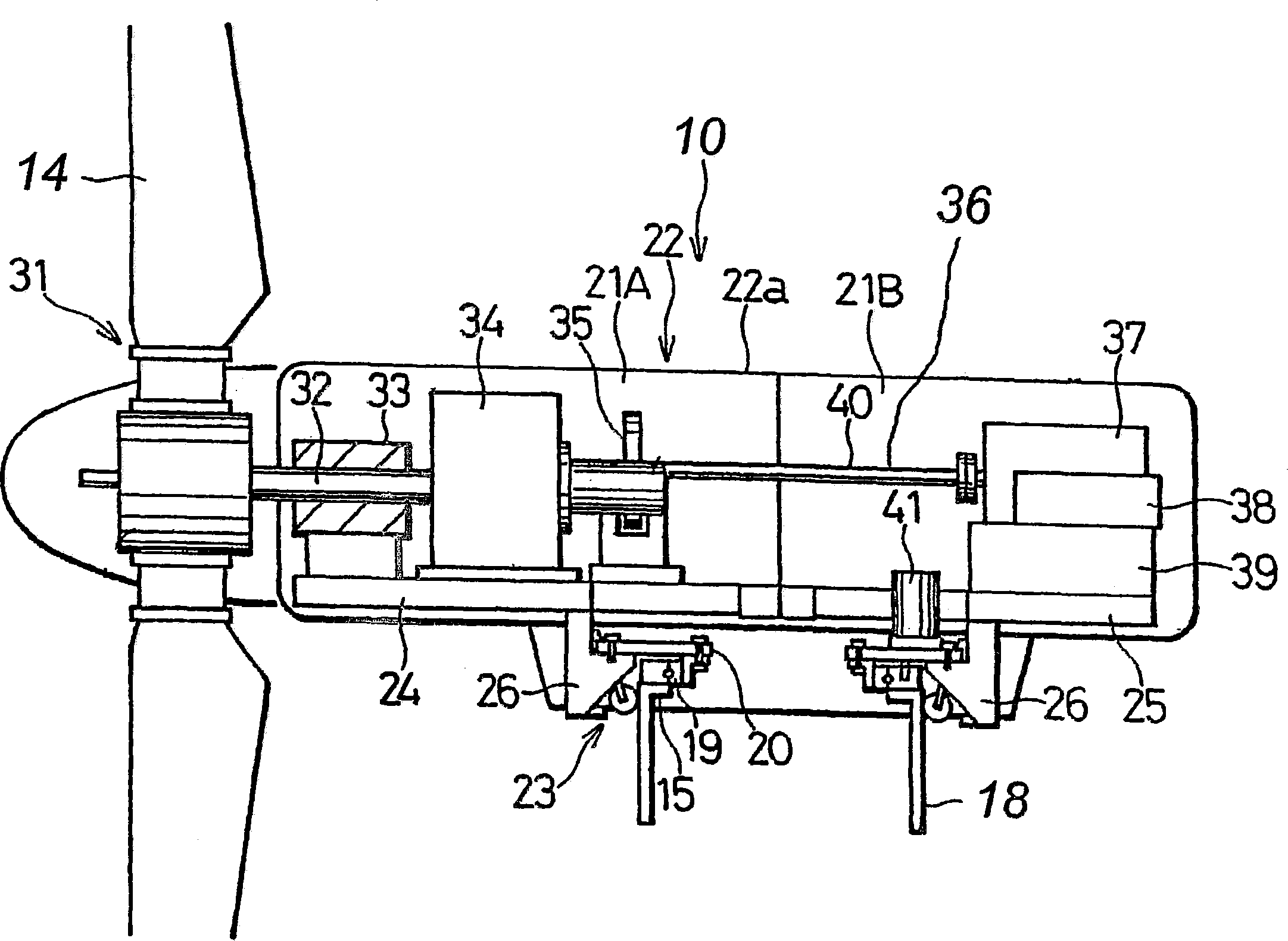

System and process for transporting wind turbines

A system is used to transport wind turbines on railroad cars. The wind turbines are partially disassembled into four types of components - nacelles, blades, rotor hubs and tower sections. The blades are stored in cargo containers suitable for use in multi-mode transportation of freight by ship, rail and truck. The nacelles and rotor hubs are not stored in containers but are affixed to transport structures. Brackets are affixed to the tower sections. Then the components are mounted on railroad cars.

Owner:VESTAS AMERICAN WIND TECH

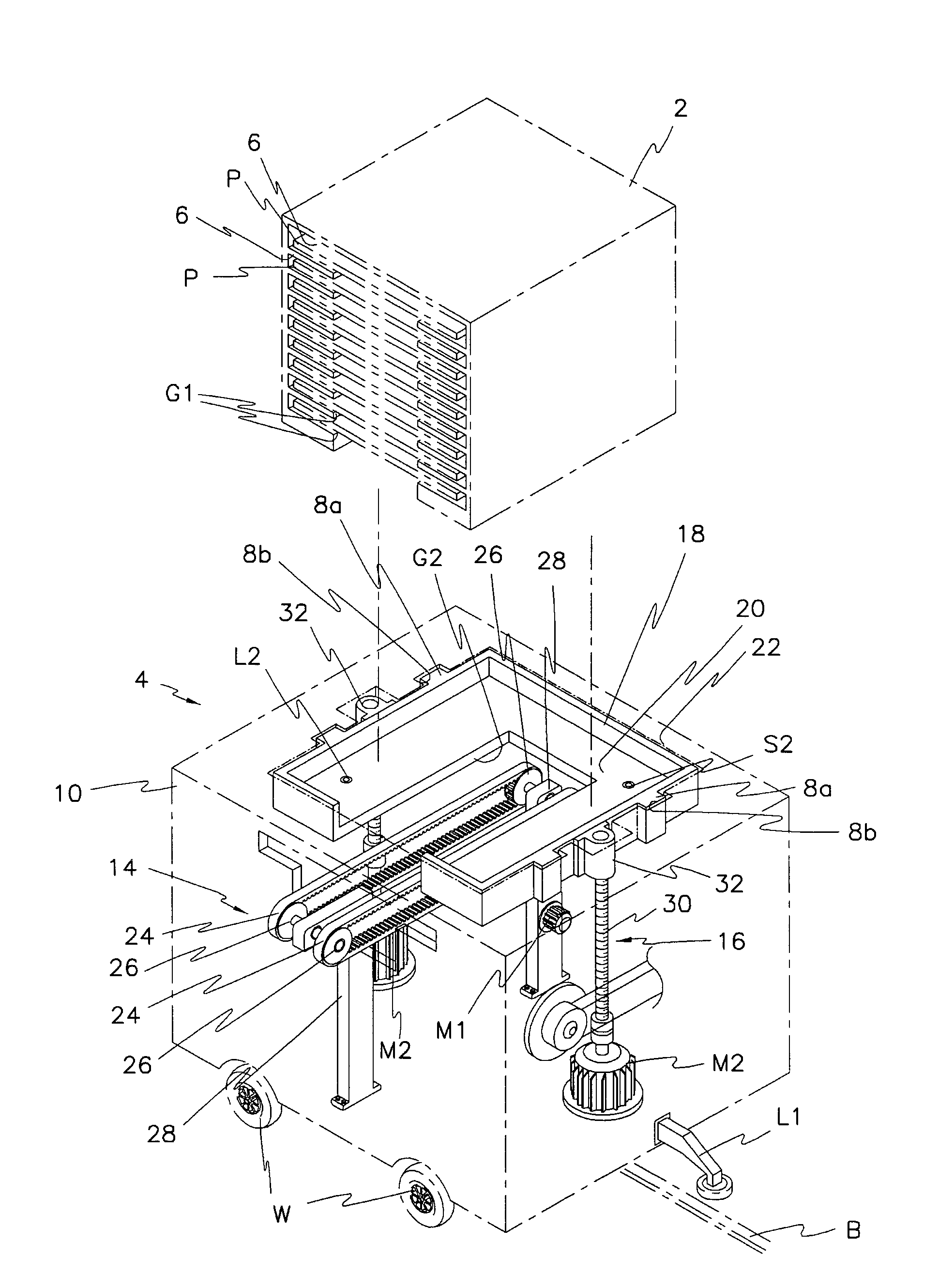

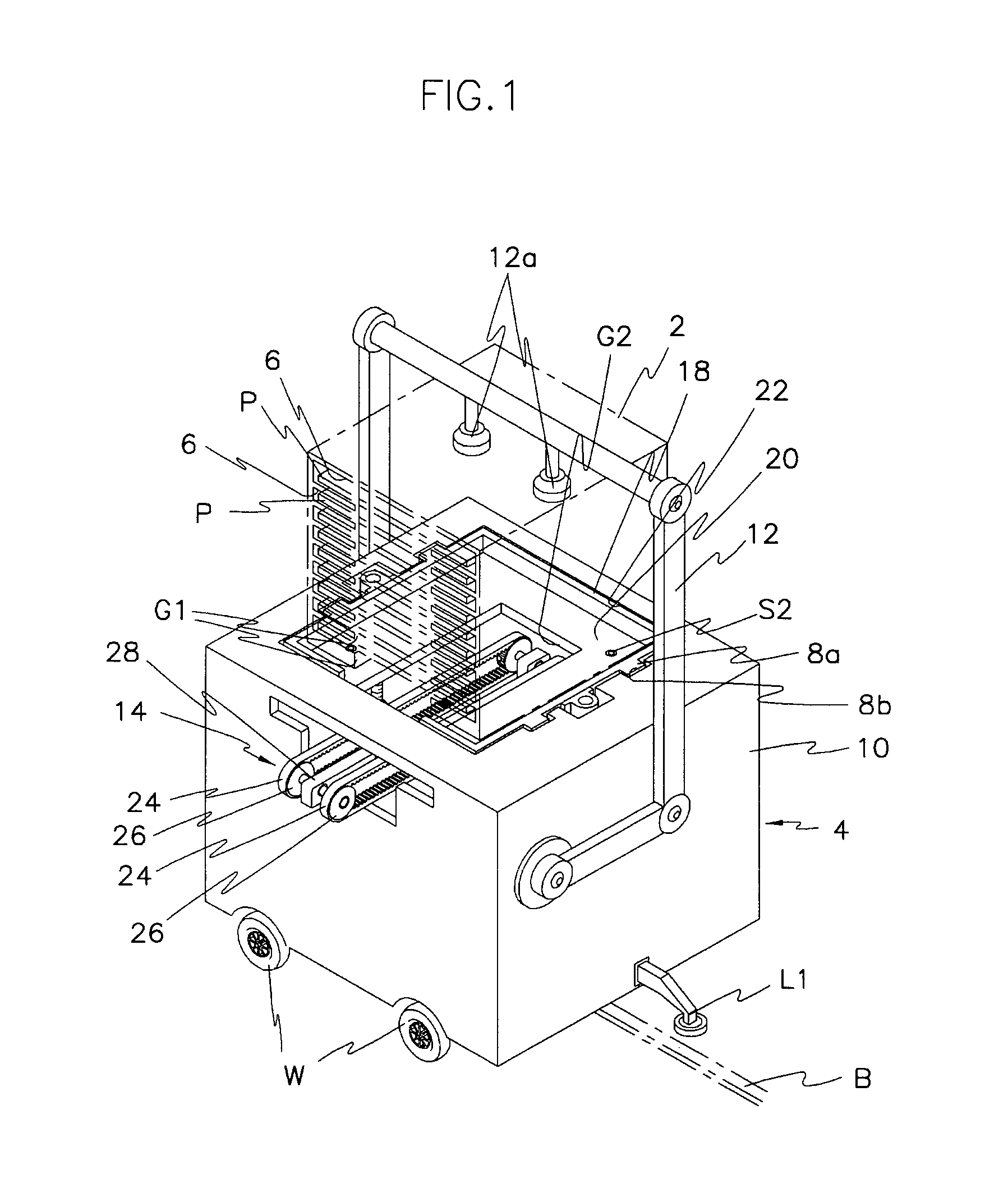

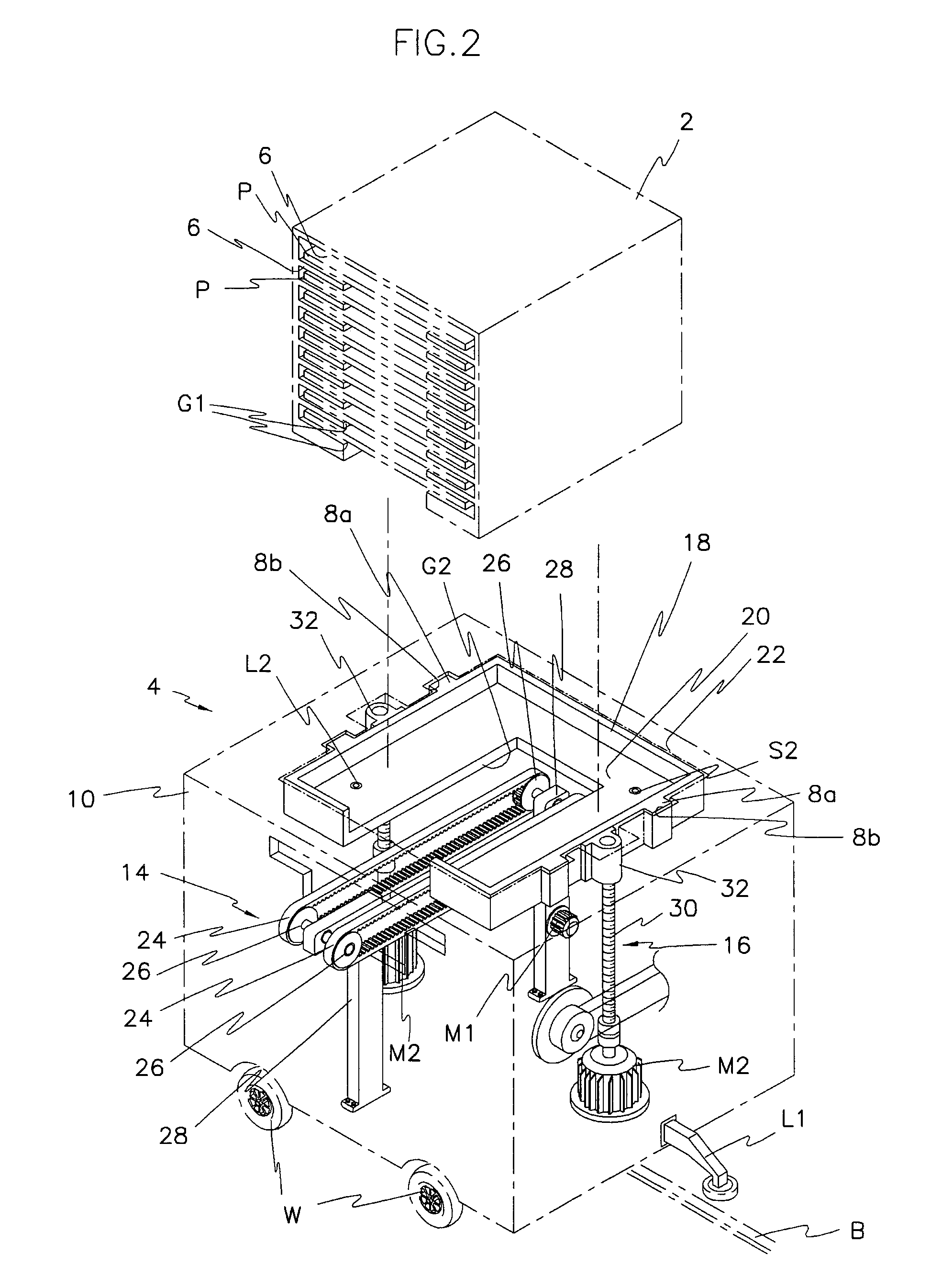

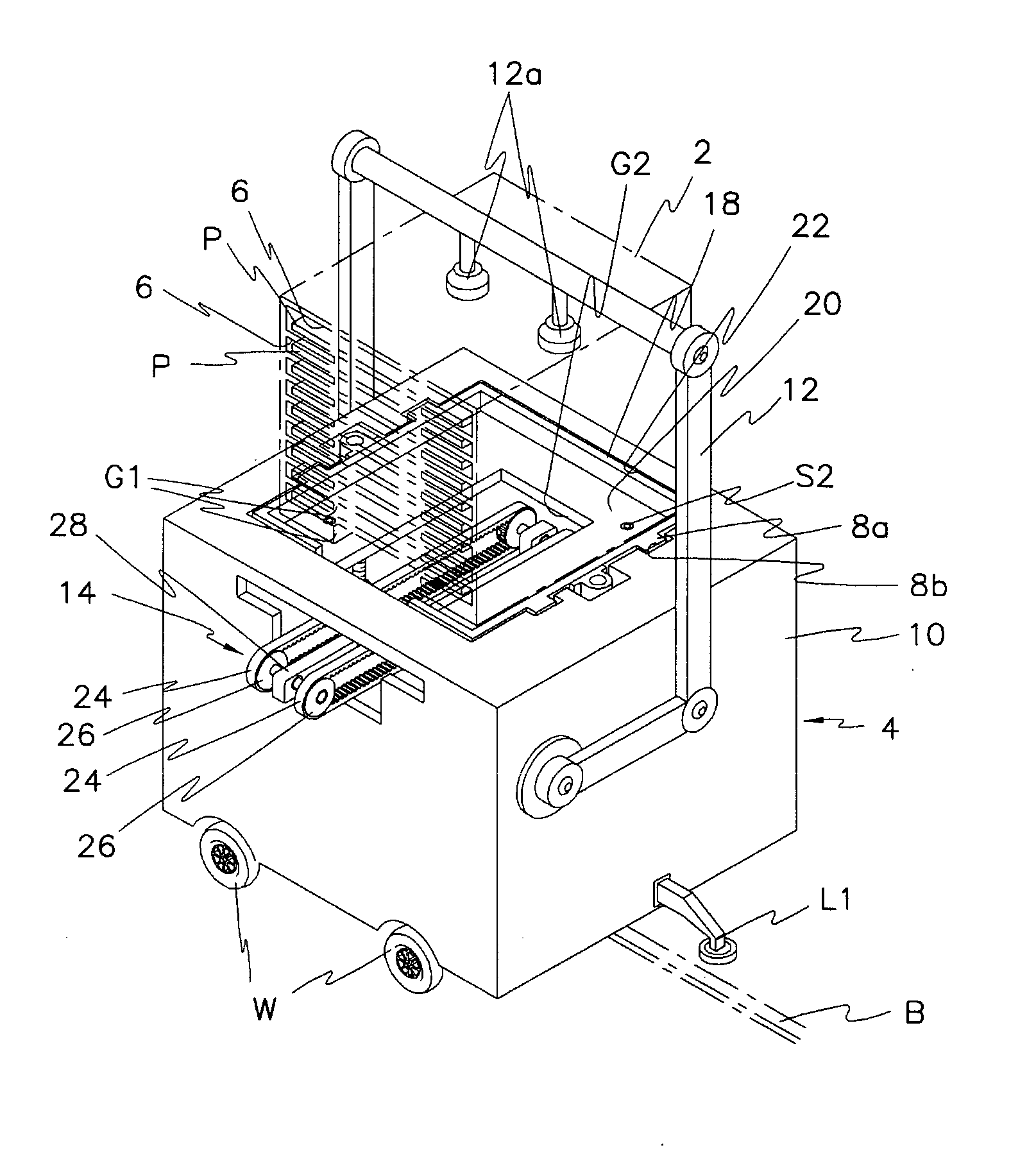

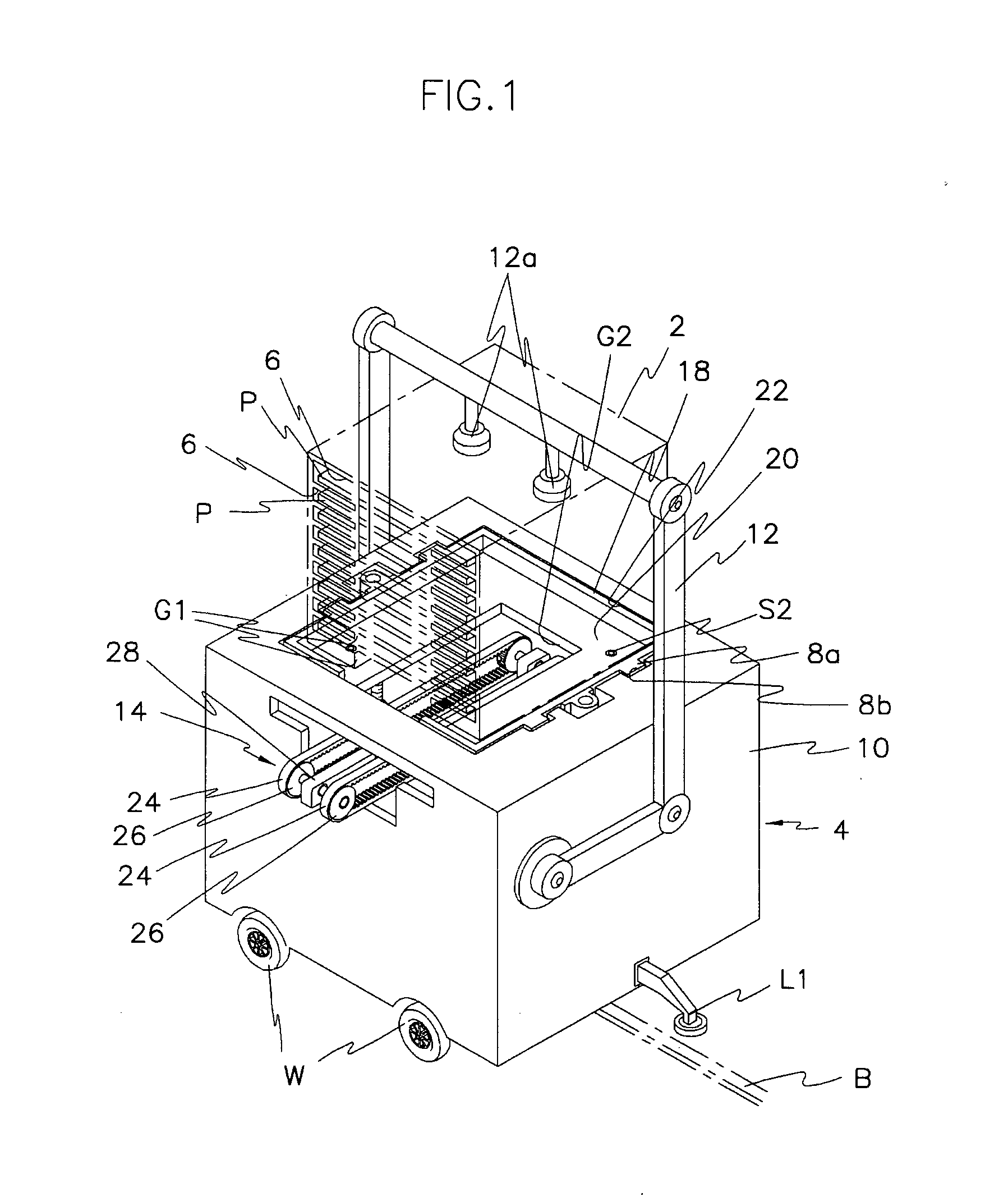

System and method for conveying flat panel display

InactiveUS7311488B2Reduce in quantitySave spaceRailway heating/coolingPropulsion using engine-driven generatorsDisplay deviceEngineering

Owner:DMS CO LTD

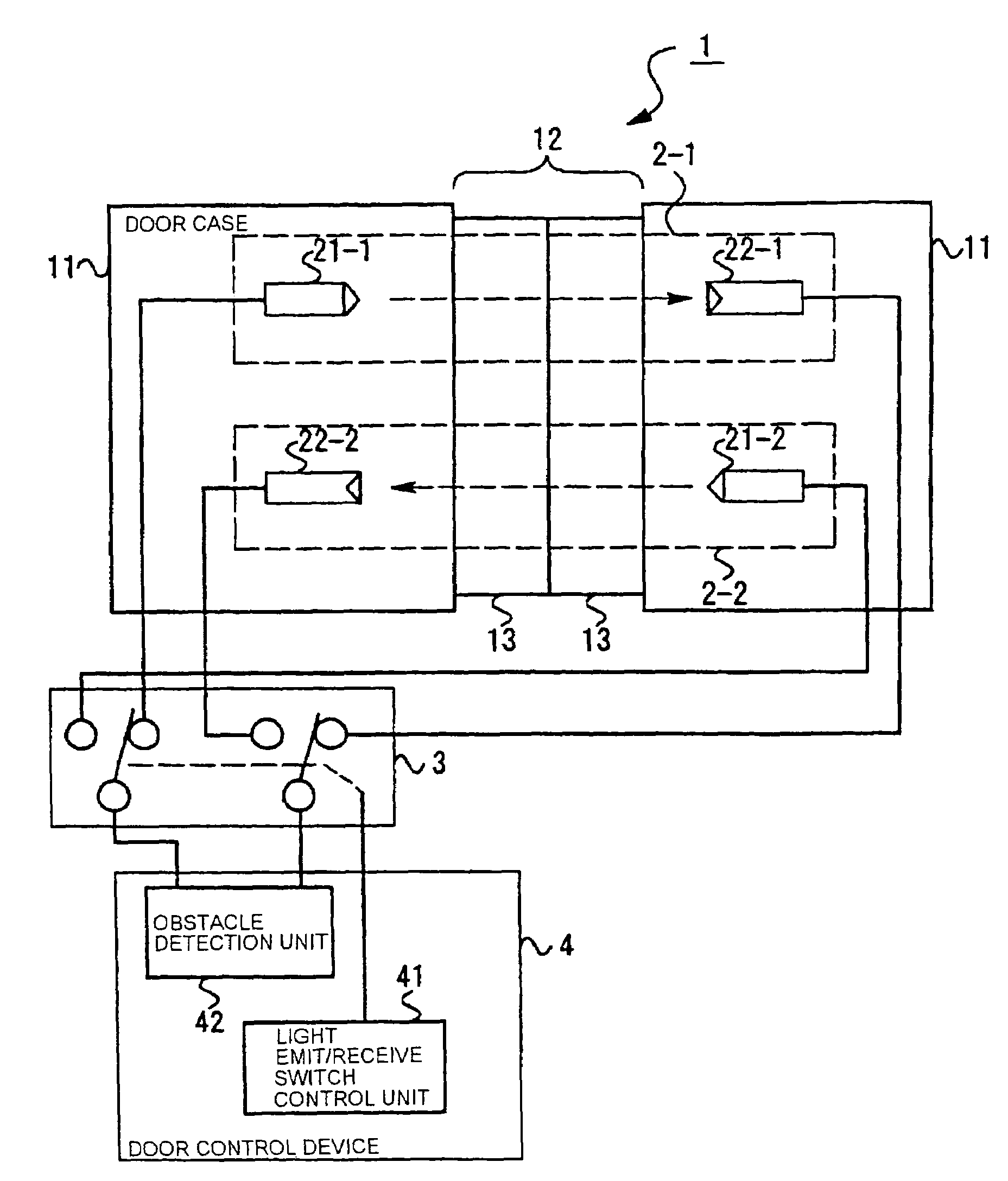

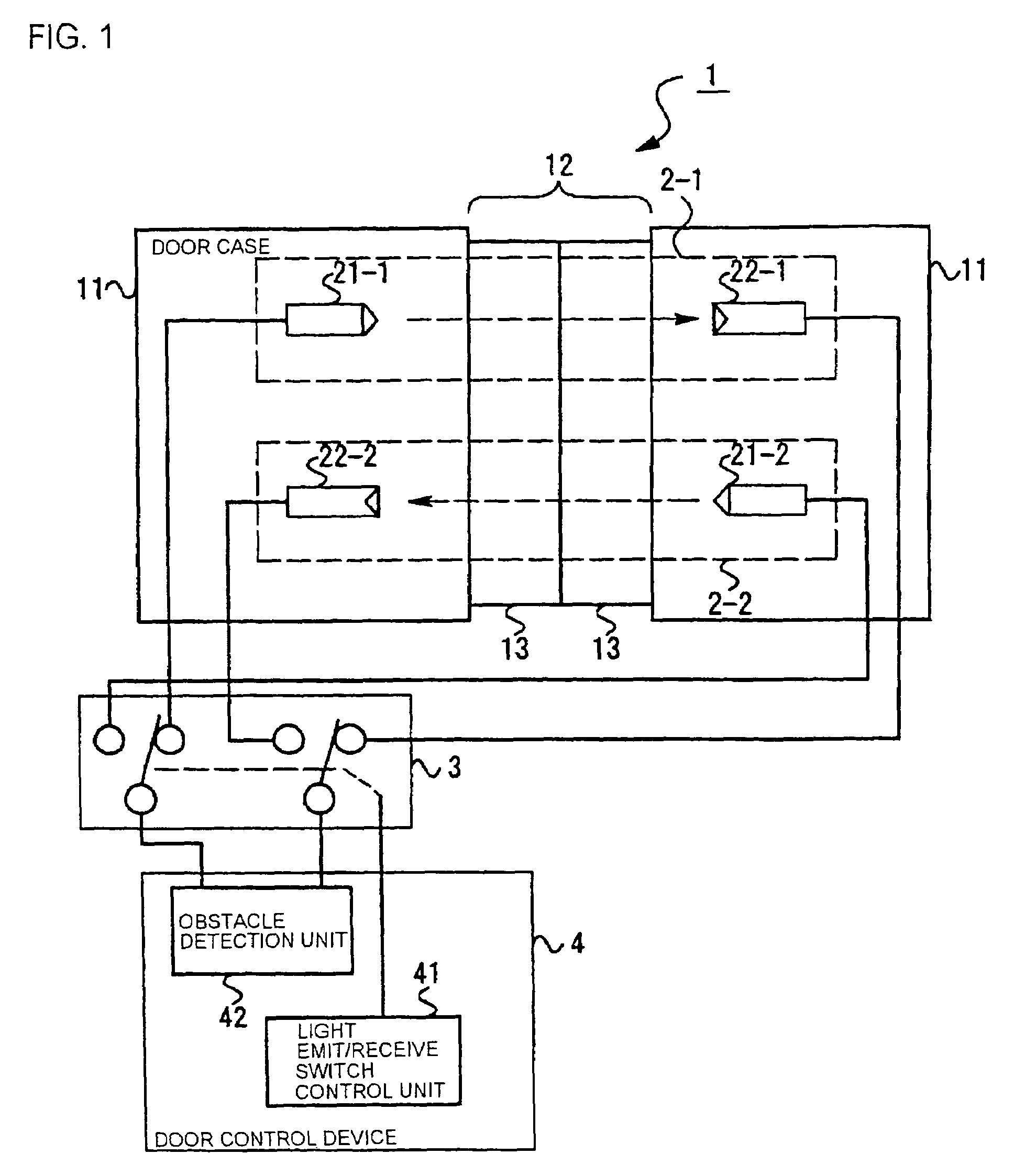

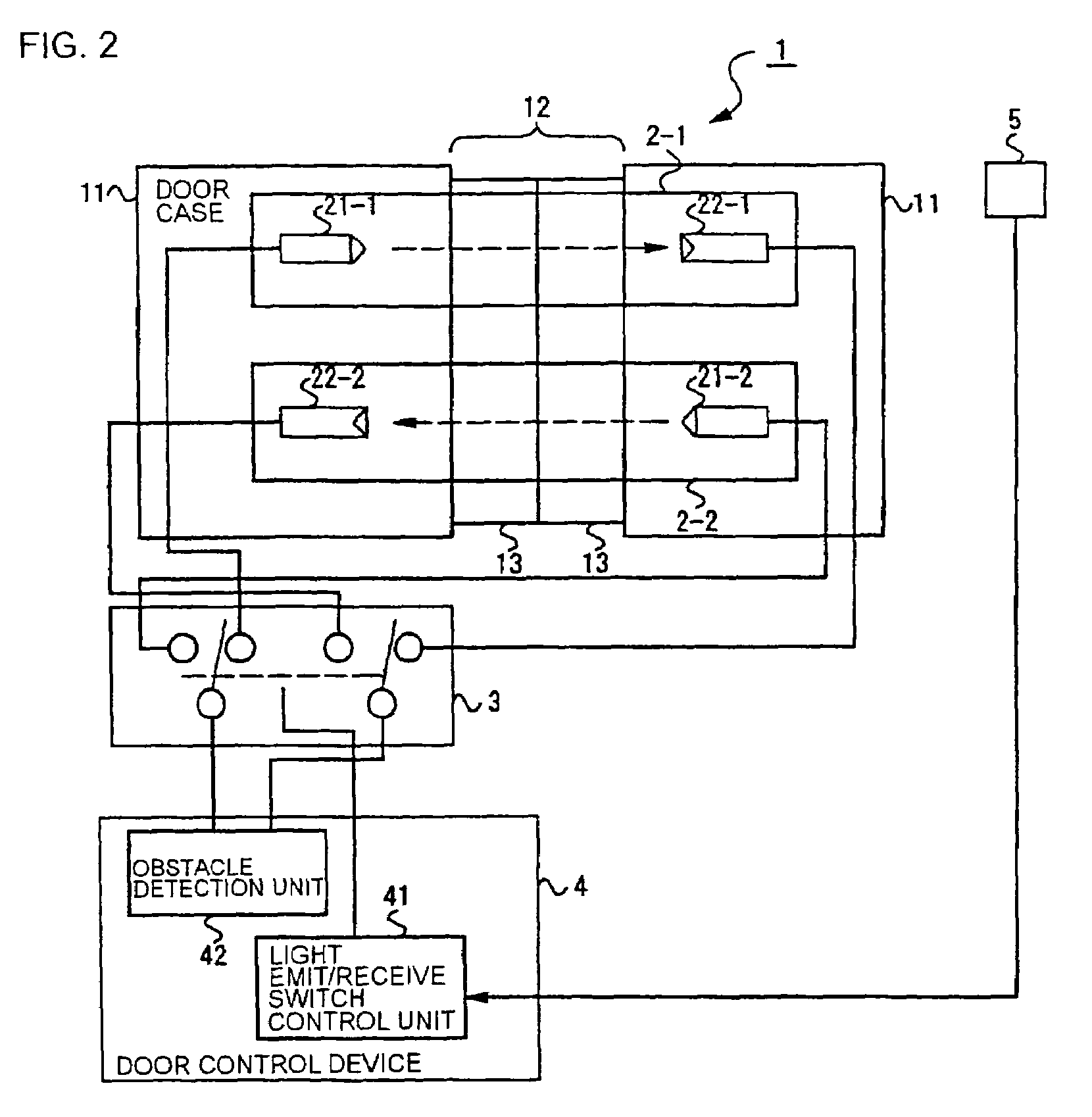

Platform gate door device

ActiveUS7328662B2Highly reliable photoelectricSure easyRefuge islandsElectrically conductive connectionsEngineeringOpto electronic

The invention provides a platform gate door device equipped with highly reliable photoelectric obstacle detectors that do not malfunction by disturbance light that moves, such as sunlight. The platform gate door device comprises a platform gate door 13 installed on a platform at a position where passengers get on and off a vehicle; a door control device 4 for opening and closing the platform gate door; at least two photoelectric obstacle detectors 2 disposed between the platform gate door 13 and the vehicle for detecting a presence of an obstacle, wherein each obstacle detector 2 has a light emitter 21 and a light receiver 22 disposed on either side of an opening 12 of the platform gate door, and wherein the obstacle detectors 2 are arranged so that the direction of emission from the light emitters are mutually inversed; and a switching means 3 for activating one of the plurality of obstacle detectors.

Owner:HIATACHI POWER SOLUTIONS CO LTD

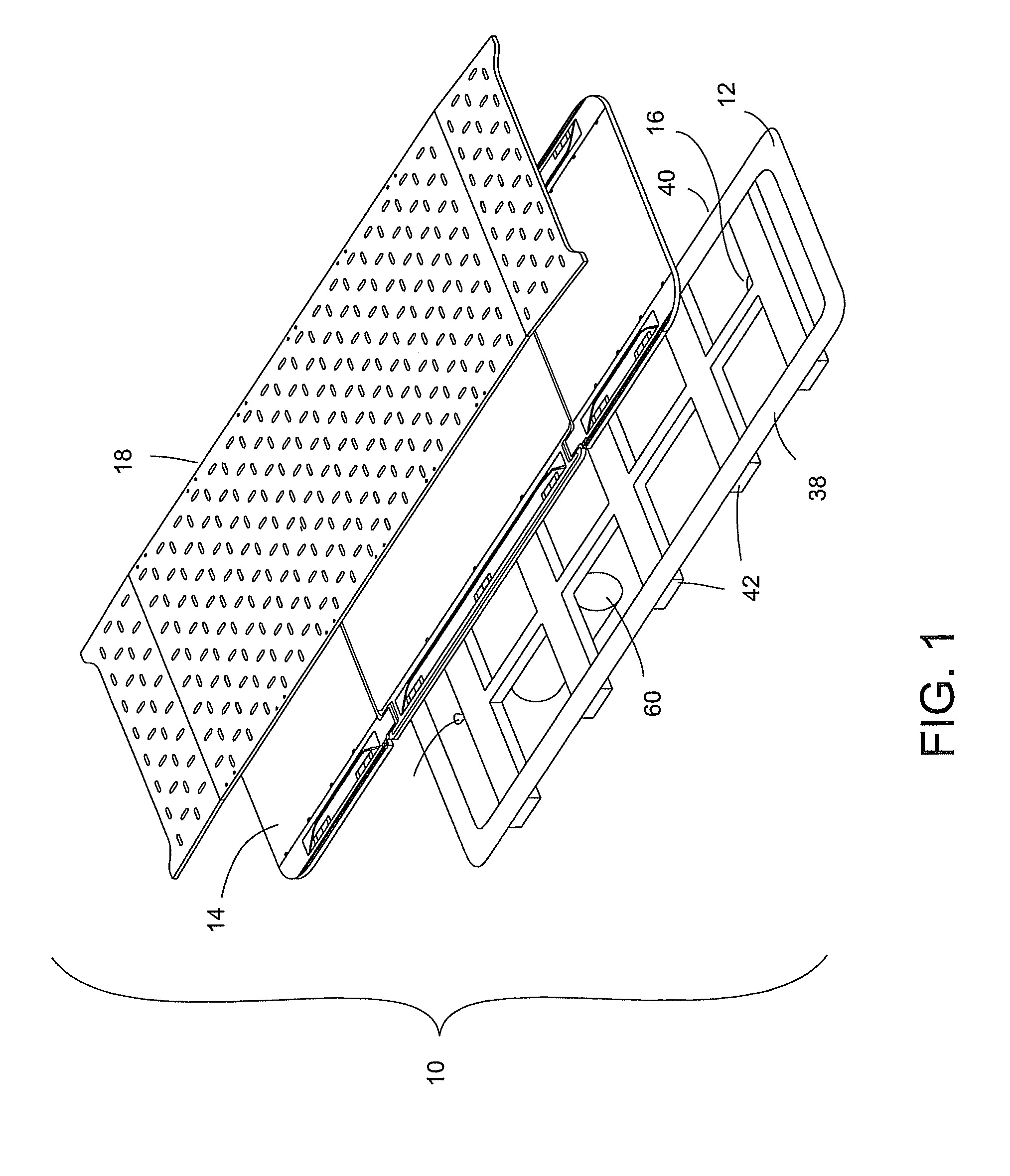

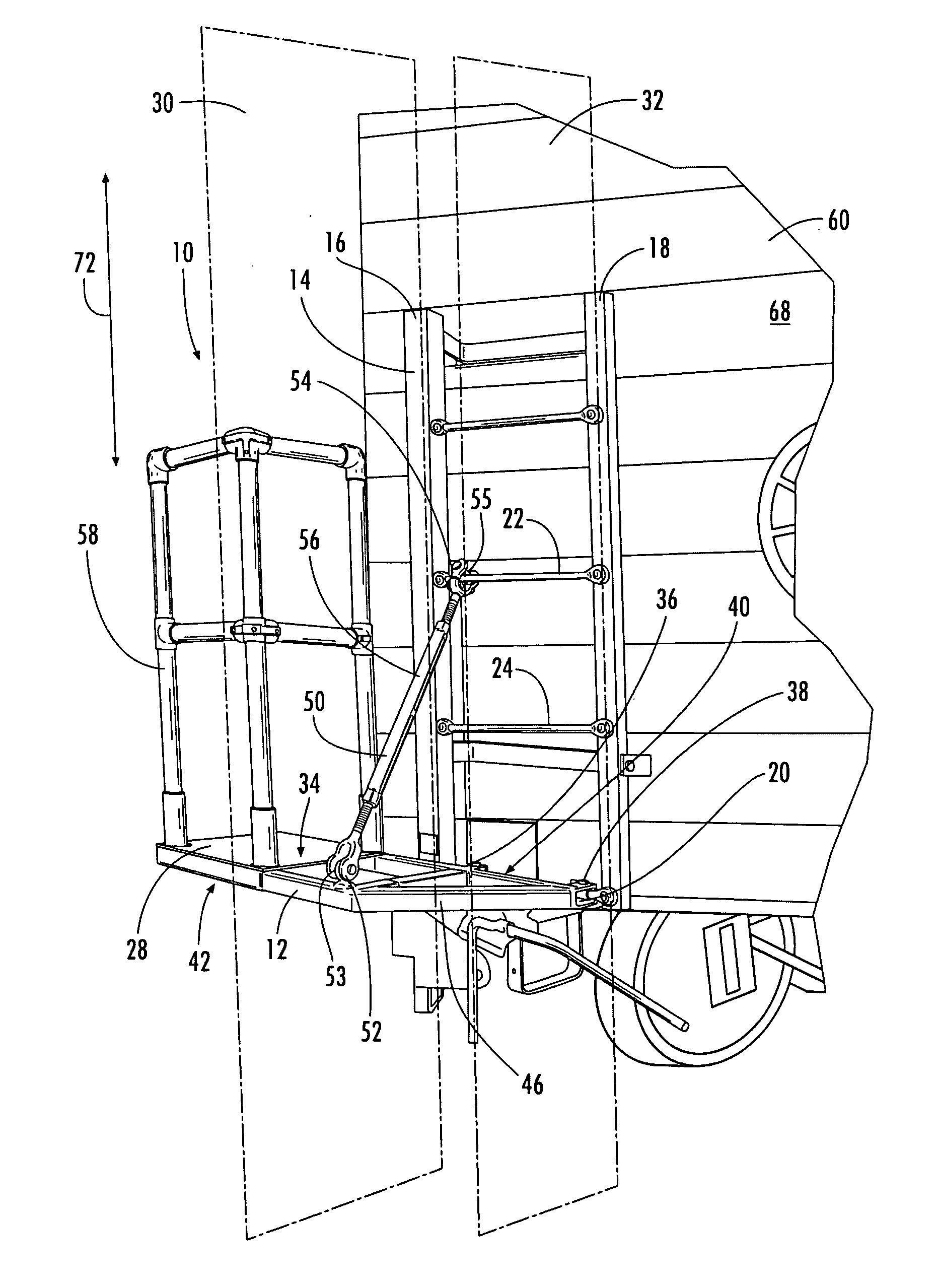

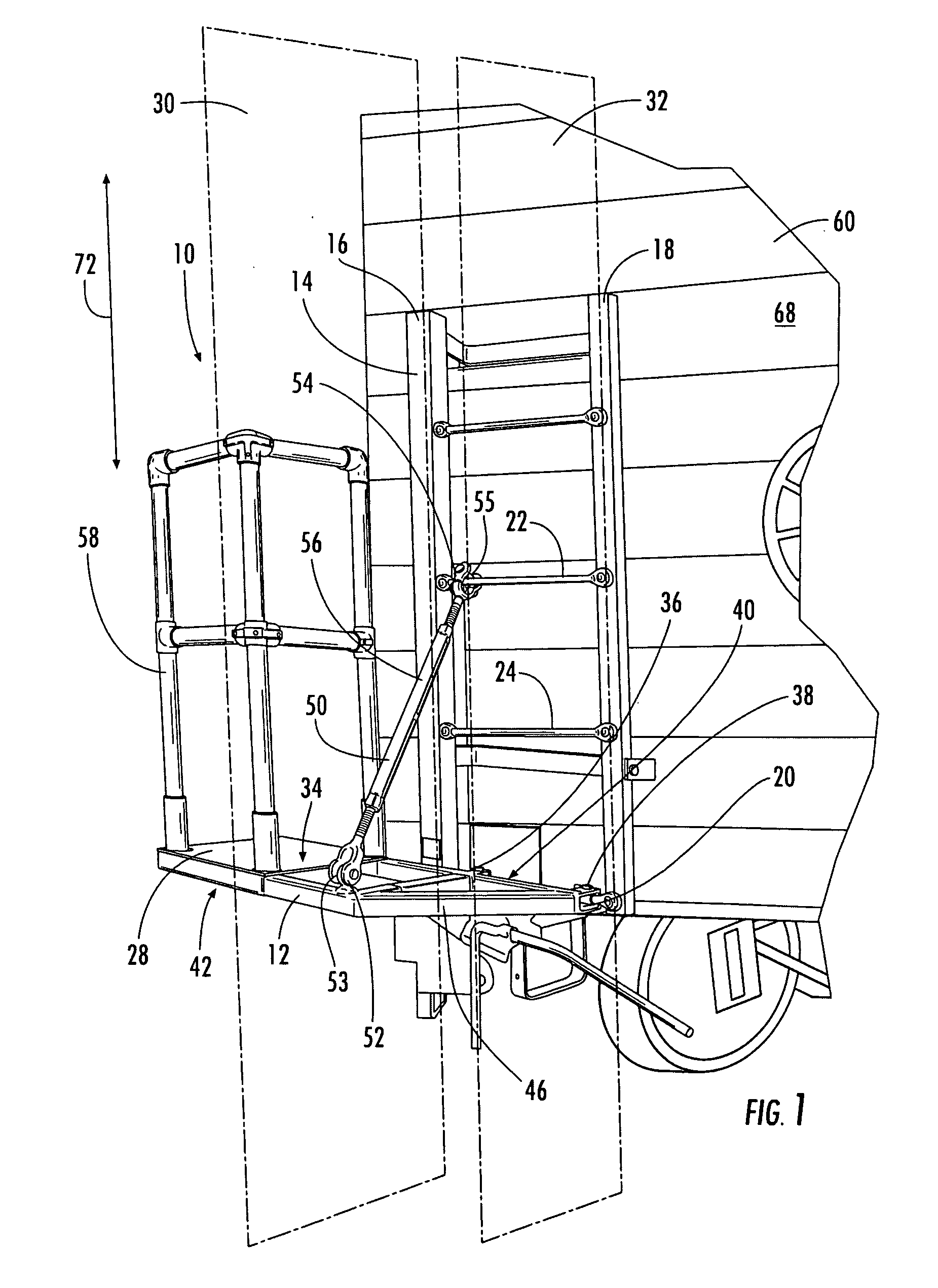

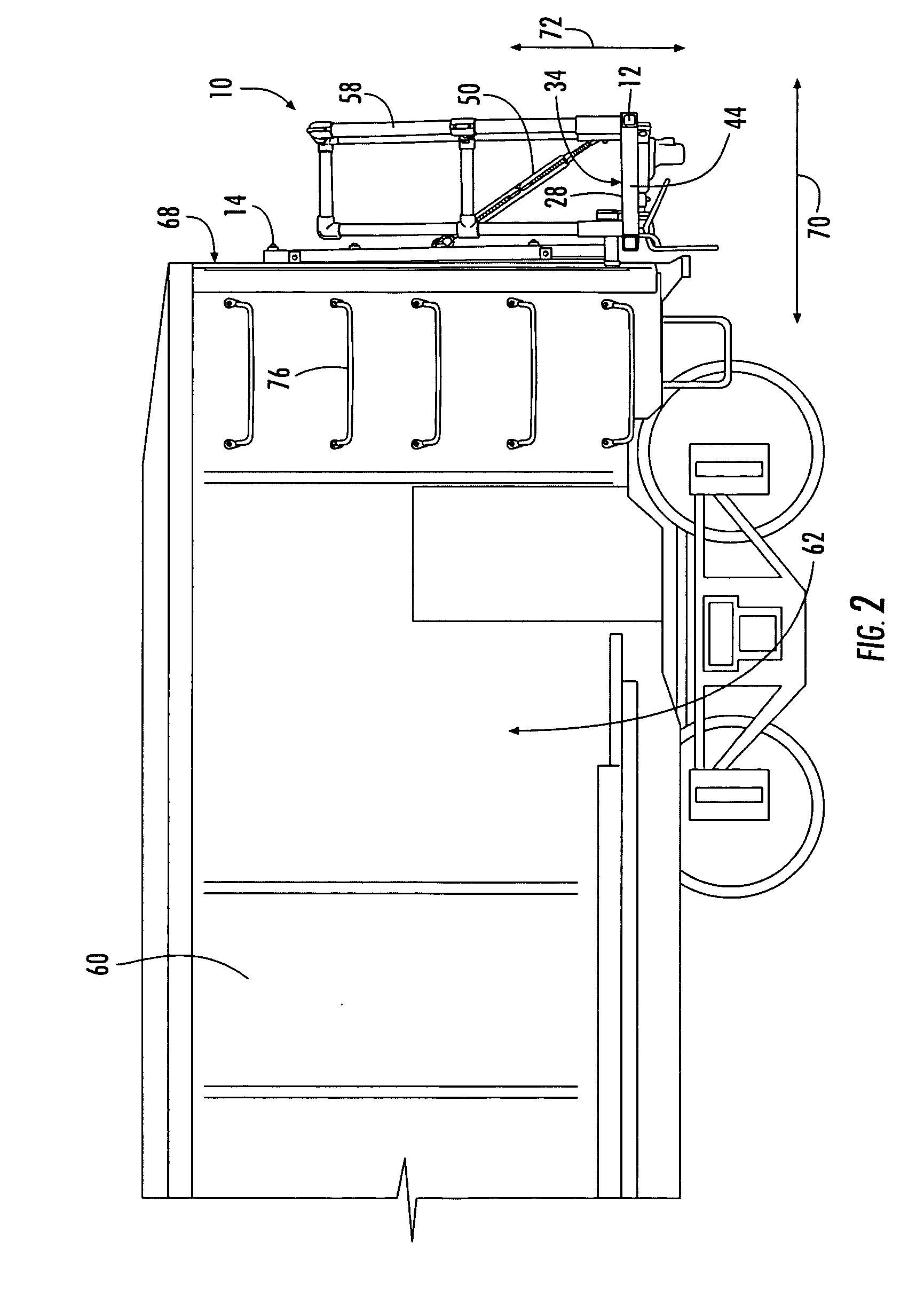

Retractable ramp

InactiveUS7802337B2Quickly and inexpensively retrofittedSmooth transitionRefuse receptaclesLoading/unloading vehicle arrangmentLocking mechanismEngineering

A ramp assembly includes an elongated frame sized and shaped to extend between a first door and a second door aligned opposite each other on opposed sides of a vehicle; a first sectional ramp section having a first end and a second end; and a second sectional ramp having a first end and a second end. The first sectional ramp is slidably moveable along the frame from a stored position to a deployed position on either of the opposed sides of the vehicle. The second sectional ramp is positioned adjacent the first sectional ramp and is slidably moveable along the frame from a stored position to a deployed position on either of the opposed sides of the vehicle. The ramp assembly also includes a first locking mechanism coupled to the first end of each of the first sectional ramp and the second sectional ramp; and a second locking mechanism coupled to the second end of each of the first sectional ramp and the second sectional ramp. The first locking mechanism is placed in a locked position and the second locking mechanism is placed in an unlocked position to allow the first and second sectional ramps to be coupled together and moved from the stored position to the deployed position through the first door. The second locking mechanism is placed in a locked position and the first locking mechanism is placed in an unlocked position to allow the first and second sectional ramps to be coupled together and moved from the stored position to the deployed position through the second door.

Owner:LINC DESIGN +2

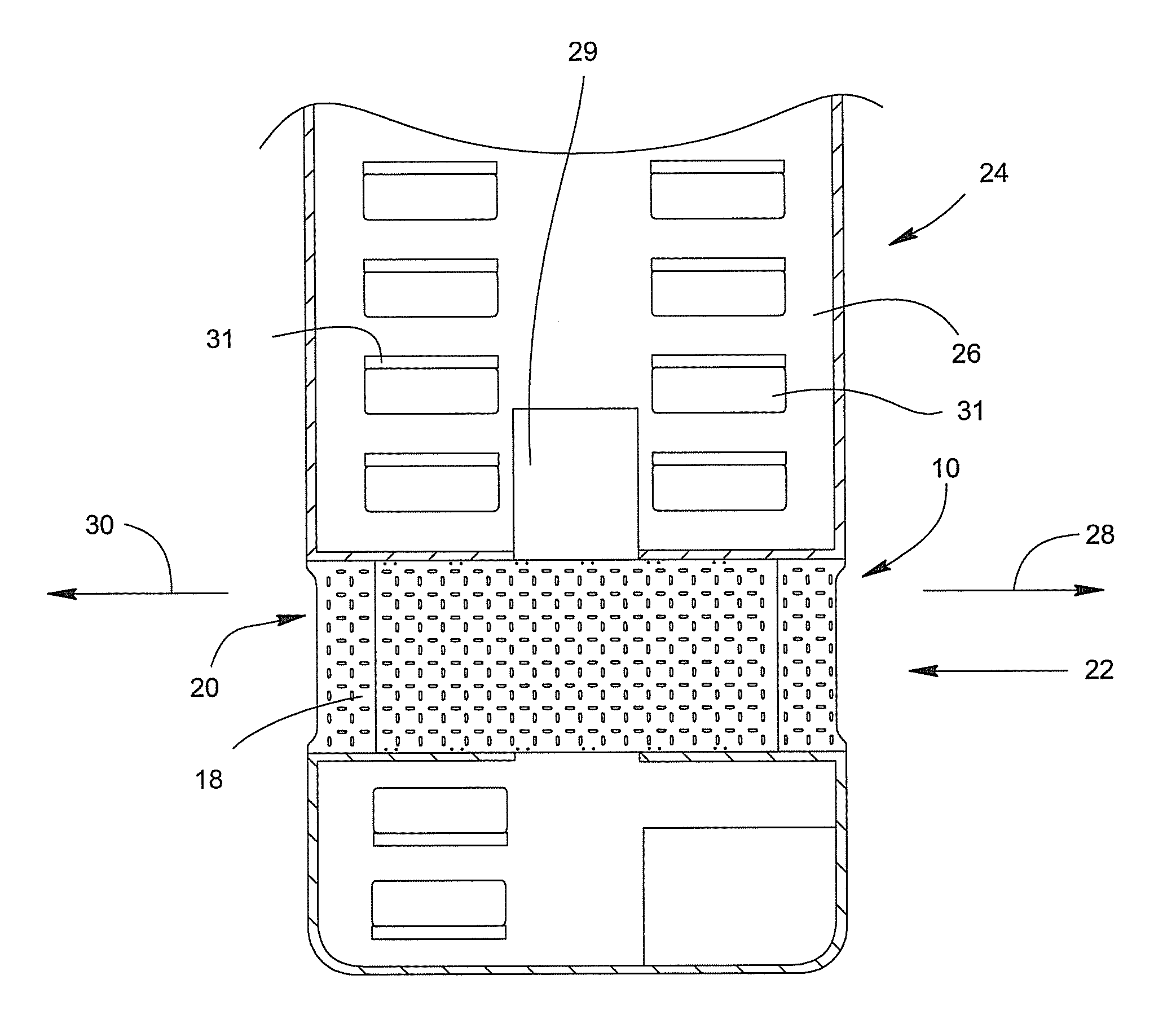

Retractable platform device for use with subway trains and associated method

ActiveUS8020496B1Convenient and reliable safetyRailway stationRailway device loading/unloadingMarine engineeringHeavy duty

The device would be a metal or heavy-duty plastic retractable loading platform, designed to bridge the gap between the train car and the station platform. When not in use, the retractable platform would be retracted into a position of concealment beneath the door(s) of the train car. At the station, the device would move outward, either abutting or overlapping the station platform, just prior to the train door(s) opening.

Owner:MAYSONET IGNACIO

System and method for conveying flat panel display

InactiveUS20050089388A1Reduce in quantitySave spaceRailway heating/coolingSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A panel conveying system includes a panel cassette for receiving a plurality of panels, and a conveying vehicle for conveying the panel cassette. The conveying vehicle includes a loading / unloading unit installed on the main body to load and / or unload the panel cassette on and / or from a panel processing unit, a panel conveying unit installed on the main body to feed and / or collect the panels to and / or from a panel processing area, and a lifting unit supporting the panel cassette in the main body.

Owner:DMS CO LTD

Intermodal transportation system with movable loading ramps and local hybrid delivery

Owner:TWENTY FIRST CENTURY TRANSPORT SYST INC

Rail-car unloading apparatus and method

Owner:ASHROSS

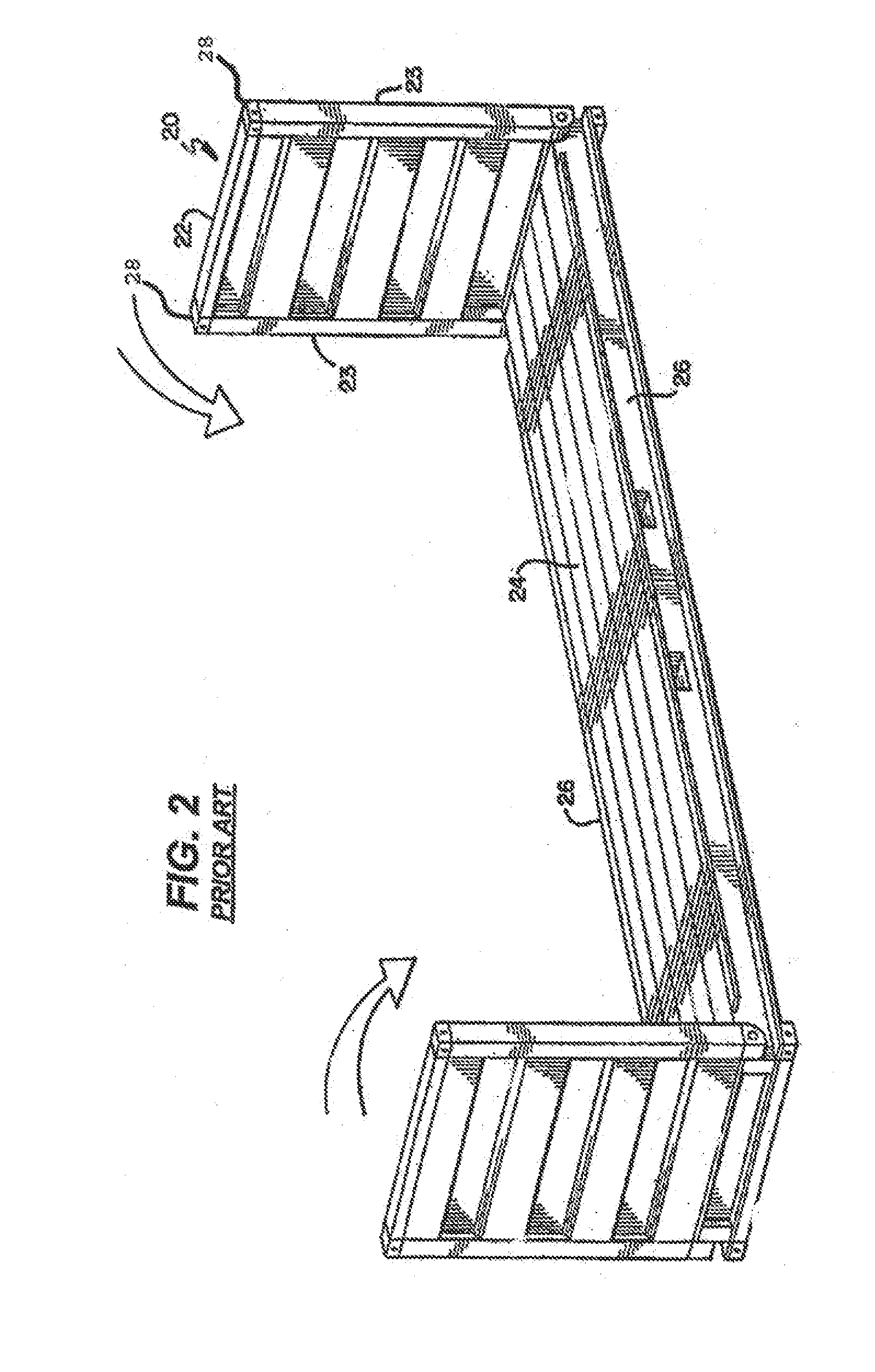

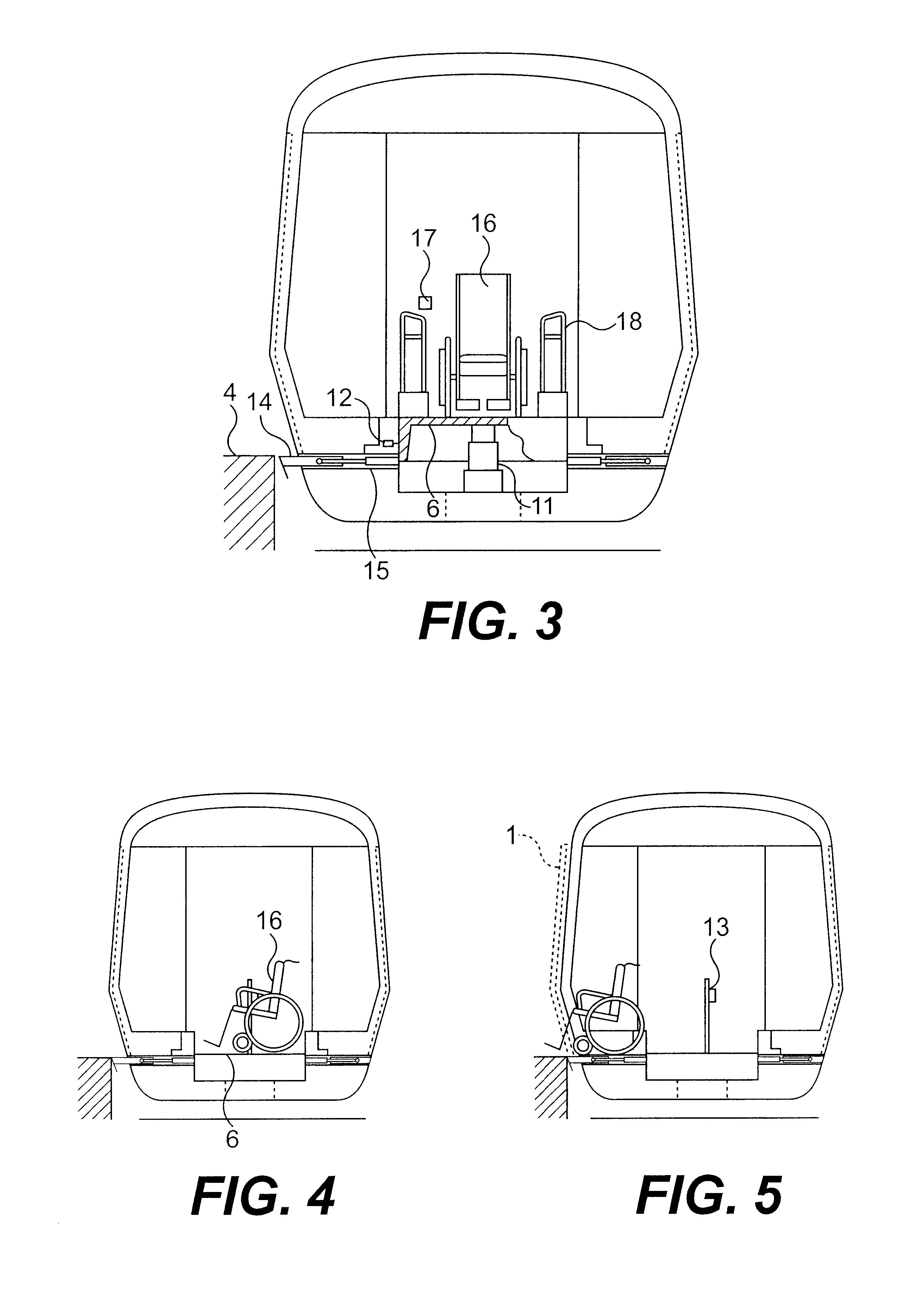

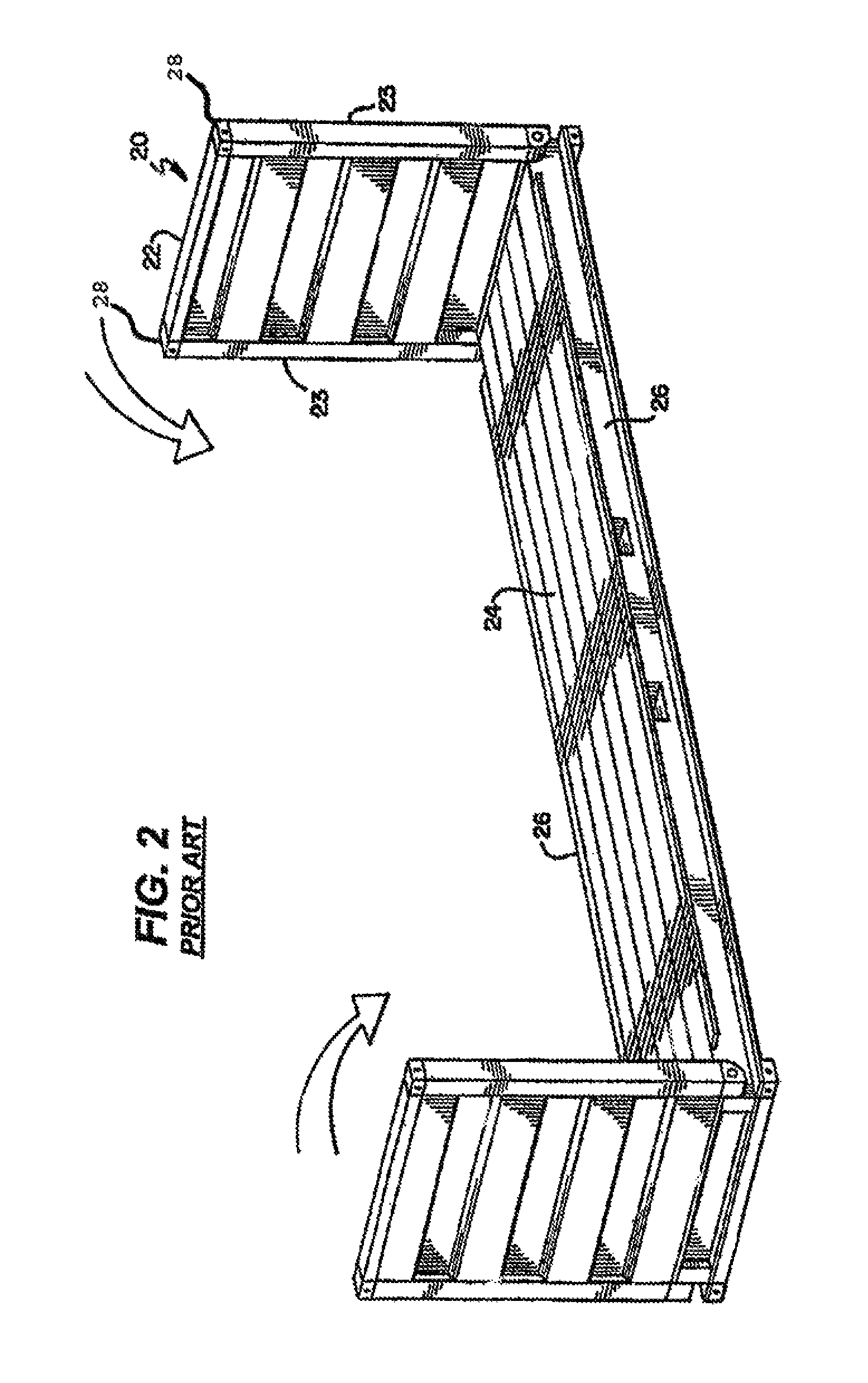

Collapsible intermodal transport platform

ActiveUS20120076605A1Improve load effectMinimize deflectionVehicle with removable loadingLarge containersCarrying capacityMarine engineering

A collapsible intermodal transport platform and methods for its operation are disclosed. The invention comprises structural ribbings that rotate about an axle disposed beneath the loading surface of the platform. The ribbings are positioned along the platform so as to provide lifting and stacking fitments at the standard overhead crane lifting points when in a lift configuration. The ribbings may be rotated inboard down to the loading surface, thereby presenting stacking blocks at the crane lifting points for stacking several platforms together. Alternatively, the ribbings may be rotated outboard to accommodate full size loading of cargo. The ribbings are rotated under electric or hydraulic power, according to the various embodiments disclosed. Other features and aspects disclosed lend to the invention's low weight and high carrying capacity, as well as its unique load securing features.

Owner:PILLAR CAPITAL CORP

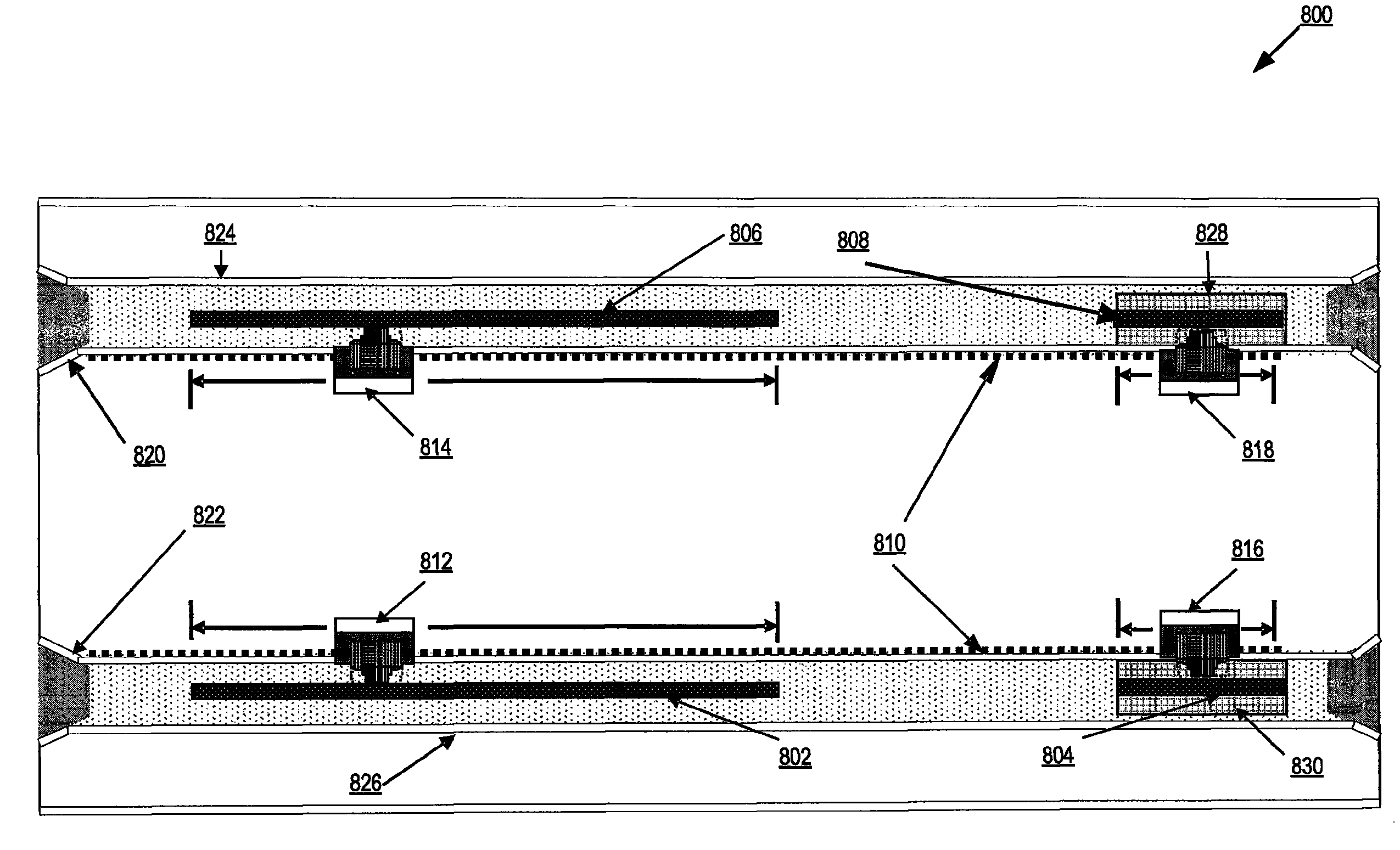

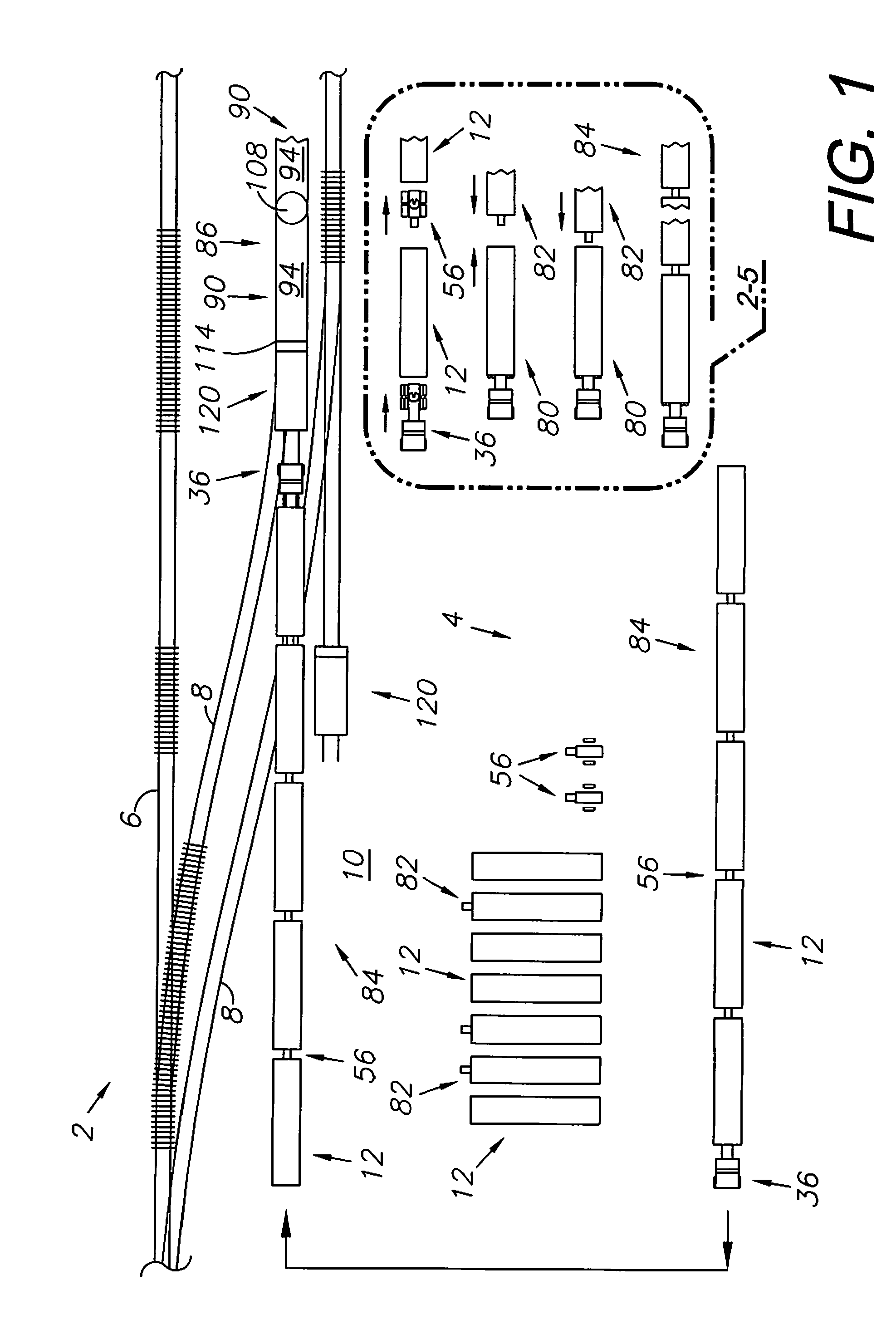

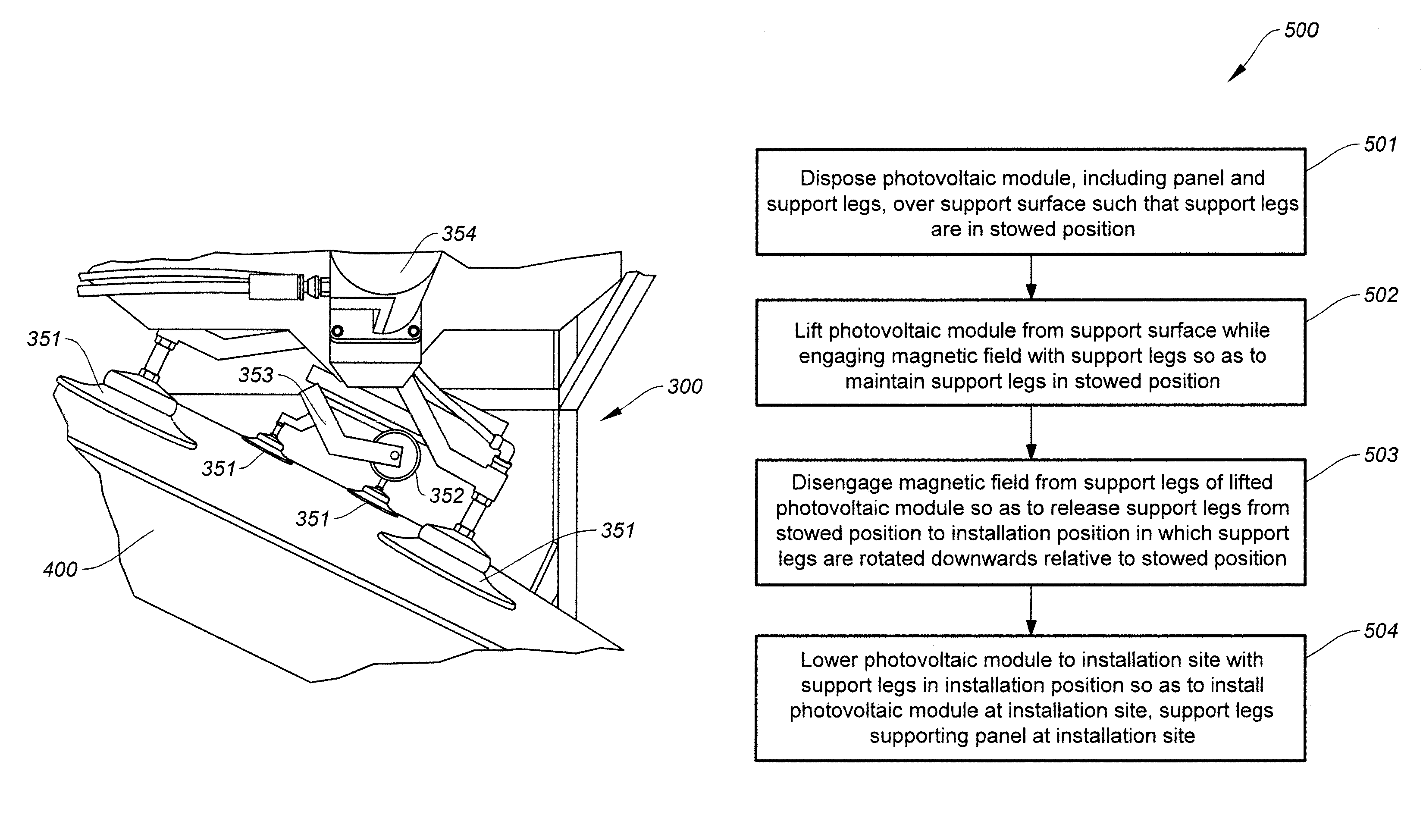

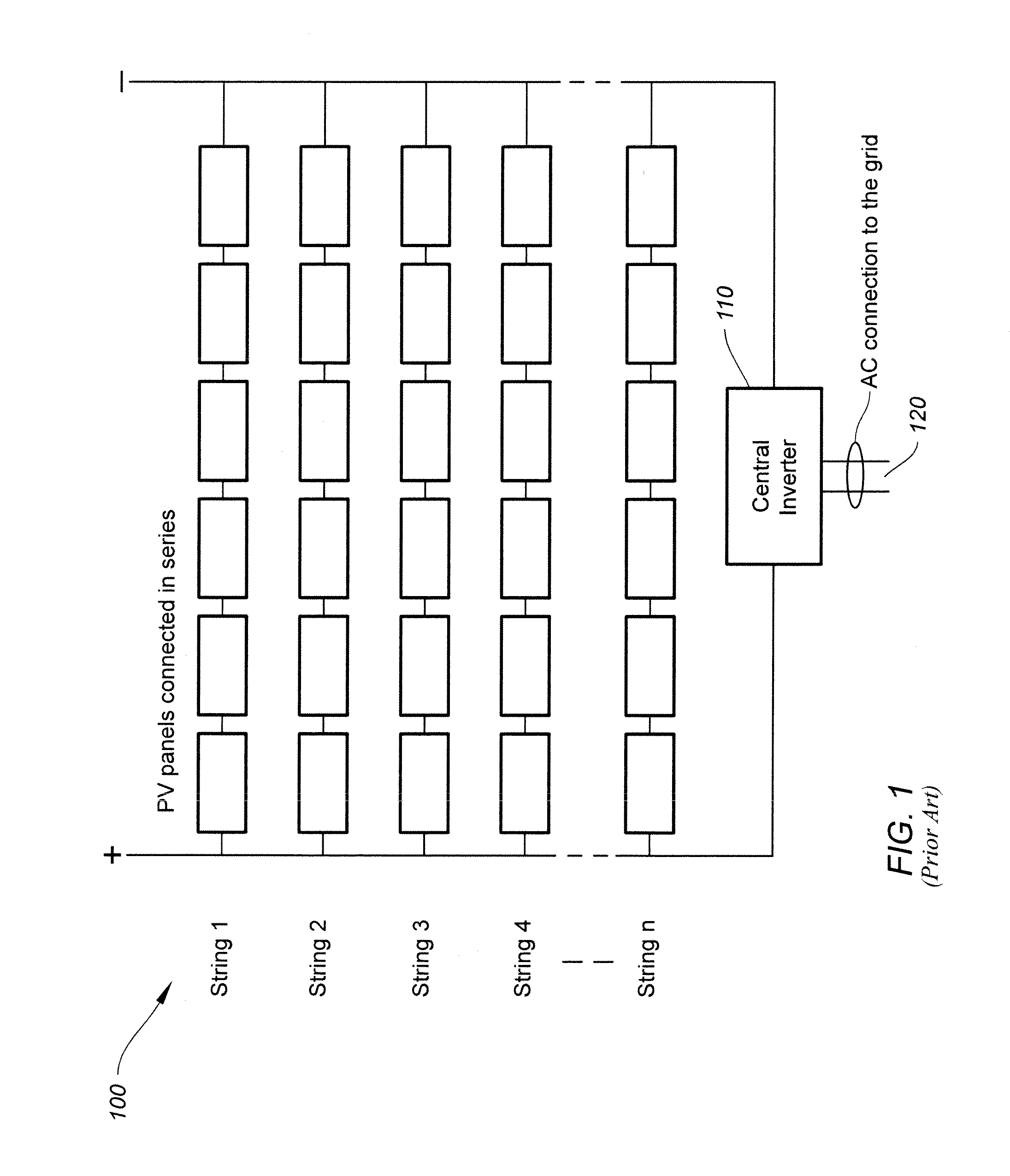

Vehicles and methods for magnetically managing legs of rail-based photovoltaic modules during installation

An exemplary method for installing at an installation site a photovoltaic module including a panel and support legs includes disposing the photovoltaic module over a support surface such that the support legs are in a stowed position; lifting the photovoltaic module from a support surface while engaging a magnetic field with the support legs so as to maintain the support legs in the stowed position; disengaging the magnetic field from the support legs of the lifted photovoltaic module so as to release the support legs from the stowed position to an installation position in which the support legs are rotated downwards relative to the stowed position; and lowering the photovoltaic module to the installation site with the support legs in the installation position so as to install the photovoltaic module at the installation site, the support legs supporting the panel at the installation site.

Owner:ALION

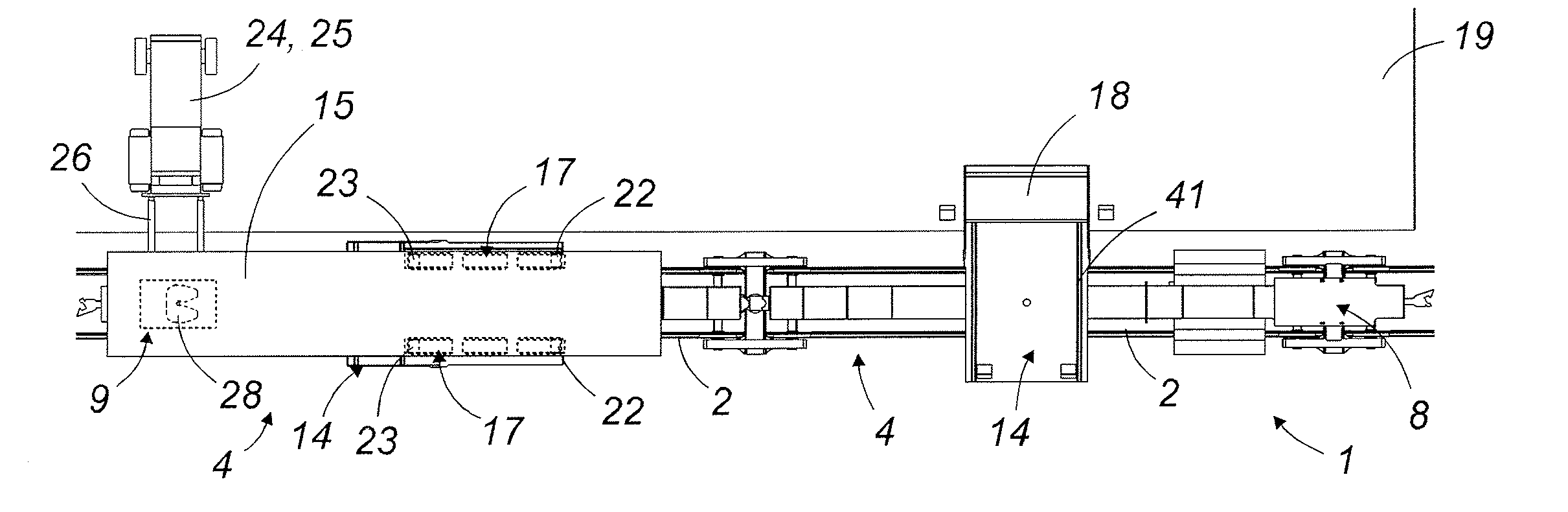

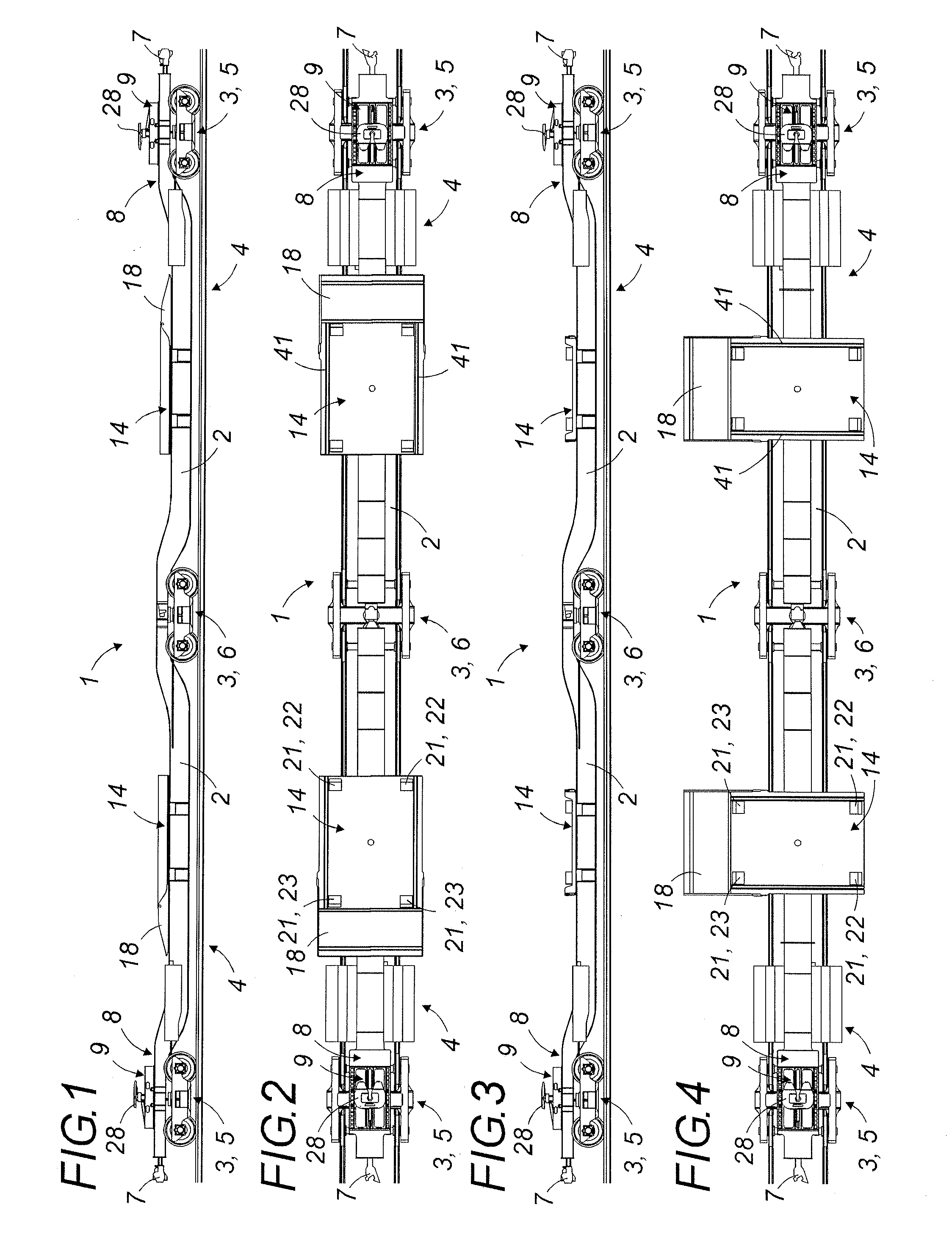

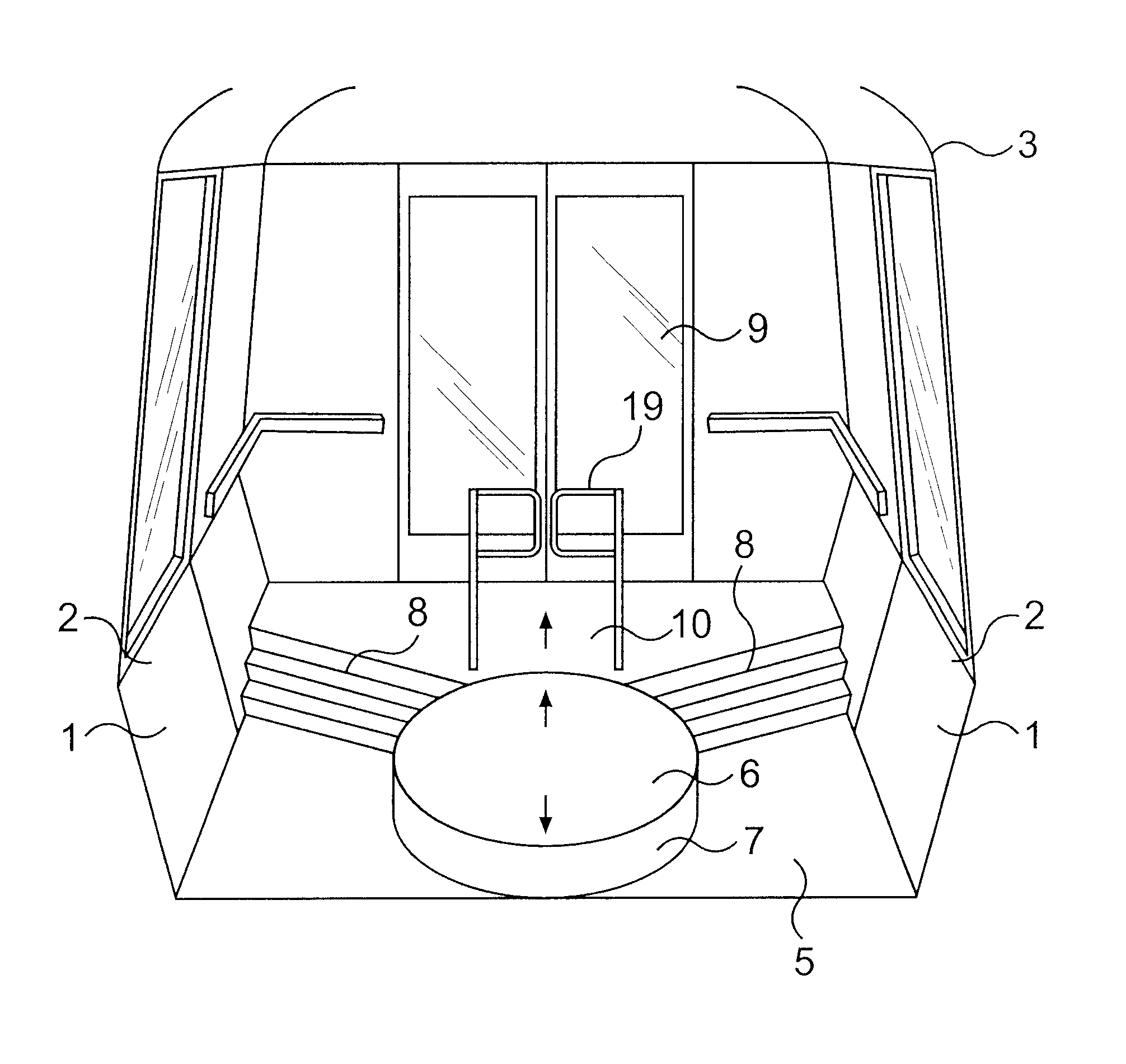

Universal system for the loading/unloading and rail transport of road semitrailers

ActiveUS20130272828A1Simpler and less-costlyEasy constructionRefuse transferringRailway transportMachineSemi-trailer

A system for loading, unloading and rail transportation of road-hauled semi-trailers, having multiple wagons (1) constituting a railway train, with each of them incorporating at least one pivotable turntable (14) for accommodating a semi-trailer via its wheel assembly. The system also comprises a detachable hitch mounting (9) that can be gripped by a handling machine which carries the detachable mounting and assembles it, after adjustment on the semi-trailer's pivoting turntable. The hitch mounting is assembled on an accommodating platform (8) that is secured immobile to the wagon chassis (2) and independently of the pivoting turntable, in order to support the front of the semi-trailer during rail transportation. This invention is of interest to rail carriers and railway transport equipment manufacturers.

Owner:LOHR IND

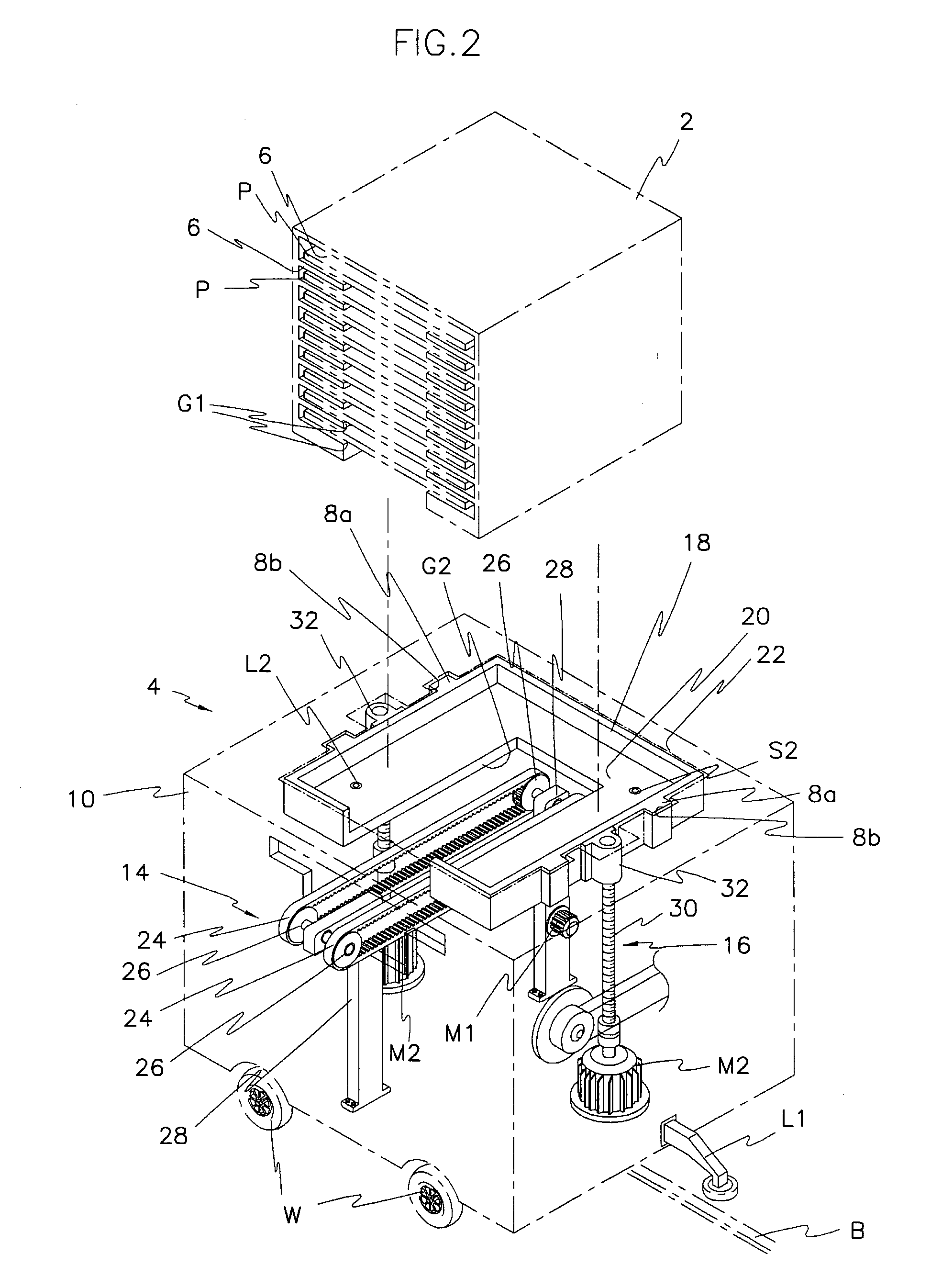

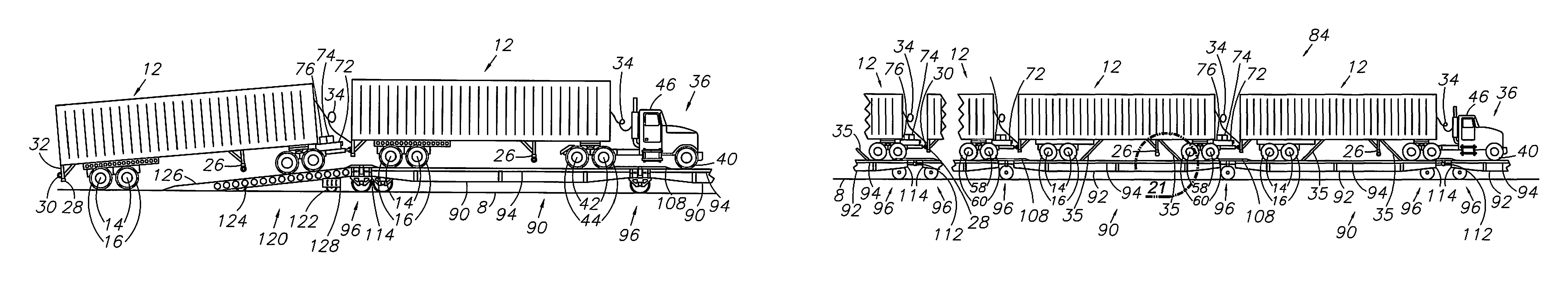

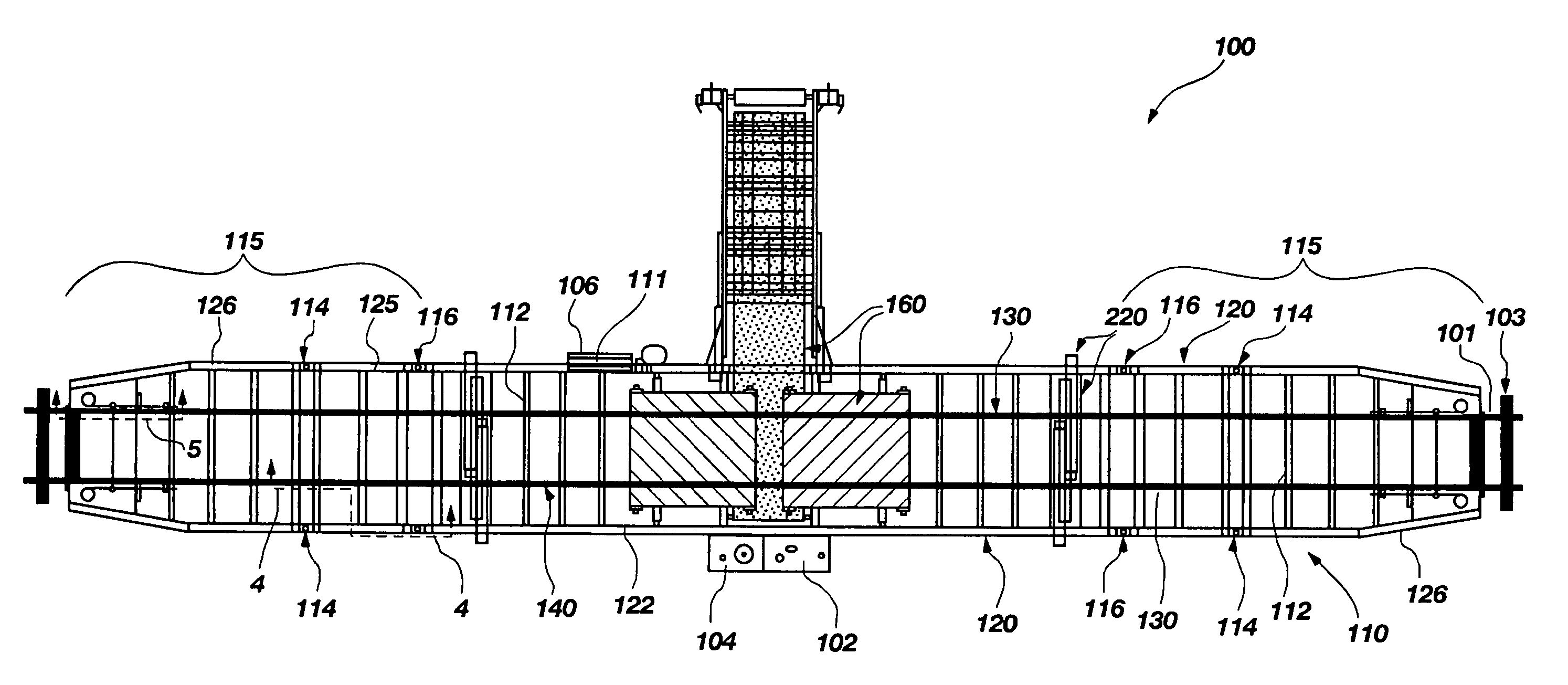

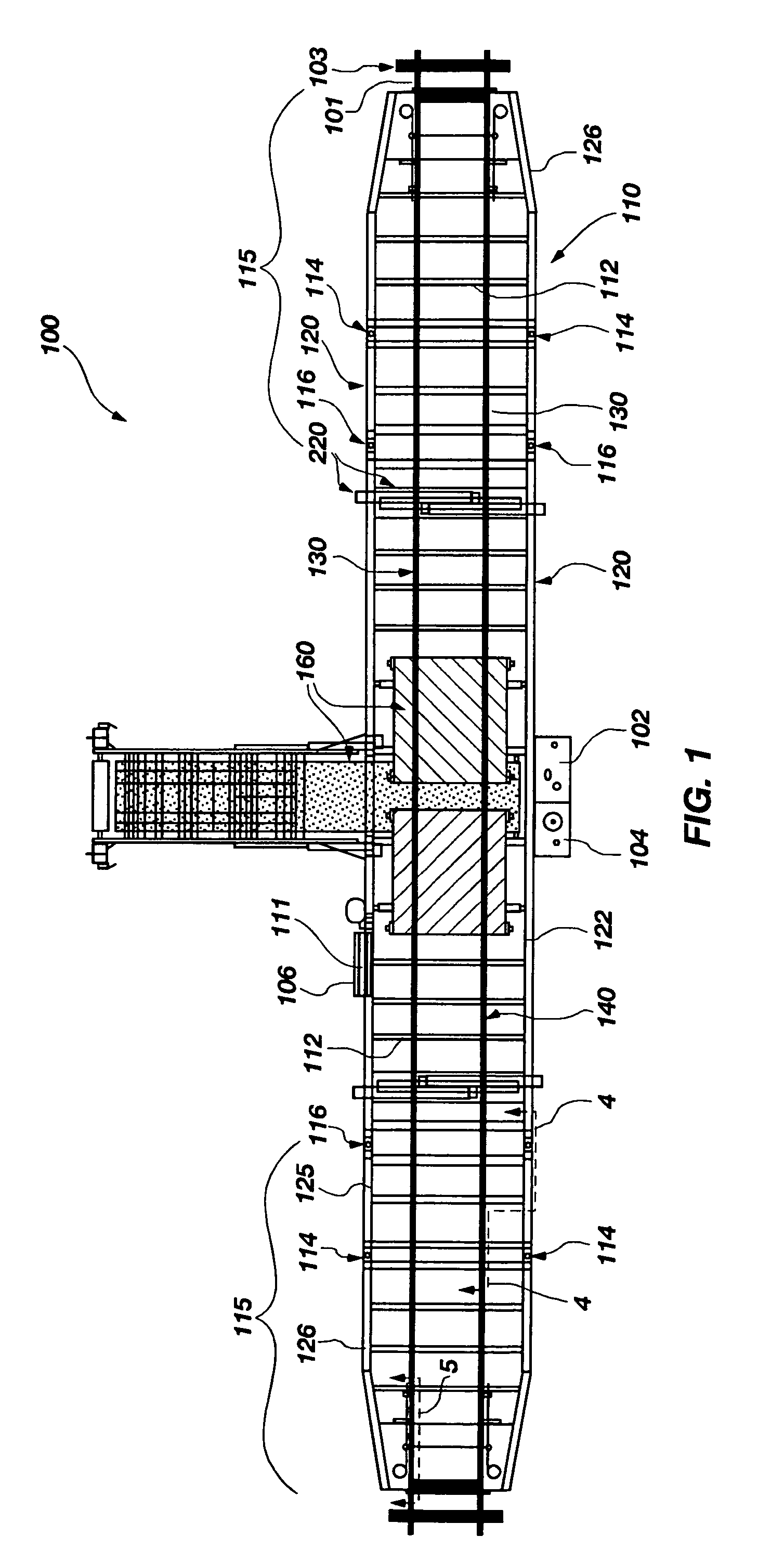

Vehicle, system and method for handling cargo containers

A system for handling cargo containers includes at least one intermodal railroad car having a pair of longitudinal ramps and a pair of tapered ends, at least one vehicle connectable to a cargo container and having ground engaging wheels mounted in a spaced apart relationship for travel on the pair of longitudinal ramps and further having linear actuators for moving the cargo container in a vertical direction, and at least one cargo handling terminal enabling movement of the at least one vehicle onto and from each of the pair of longitudinal ramps and the pair of ends for loading the cargo container onto and unloading the cargo container from the at least one intermodal railroad car. A vehicle adapted for travel on both ground surface and rail track and a method for transporting cargo using such vehicle are also provided.

Owner:KACI INTERMODAL SYST

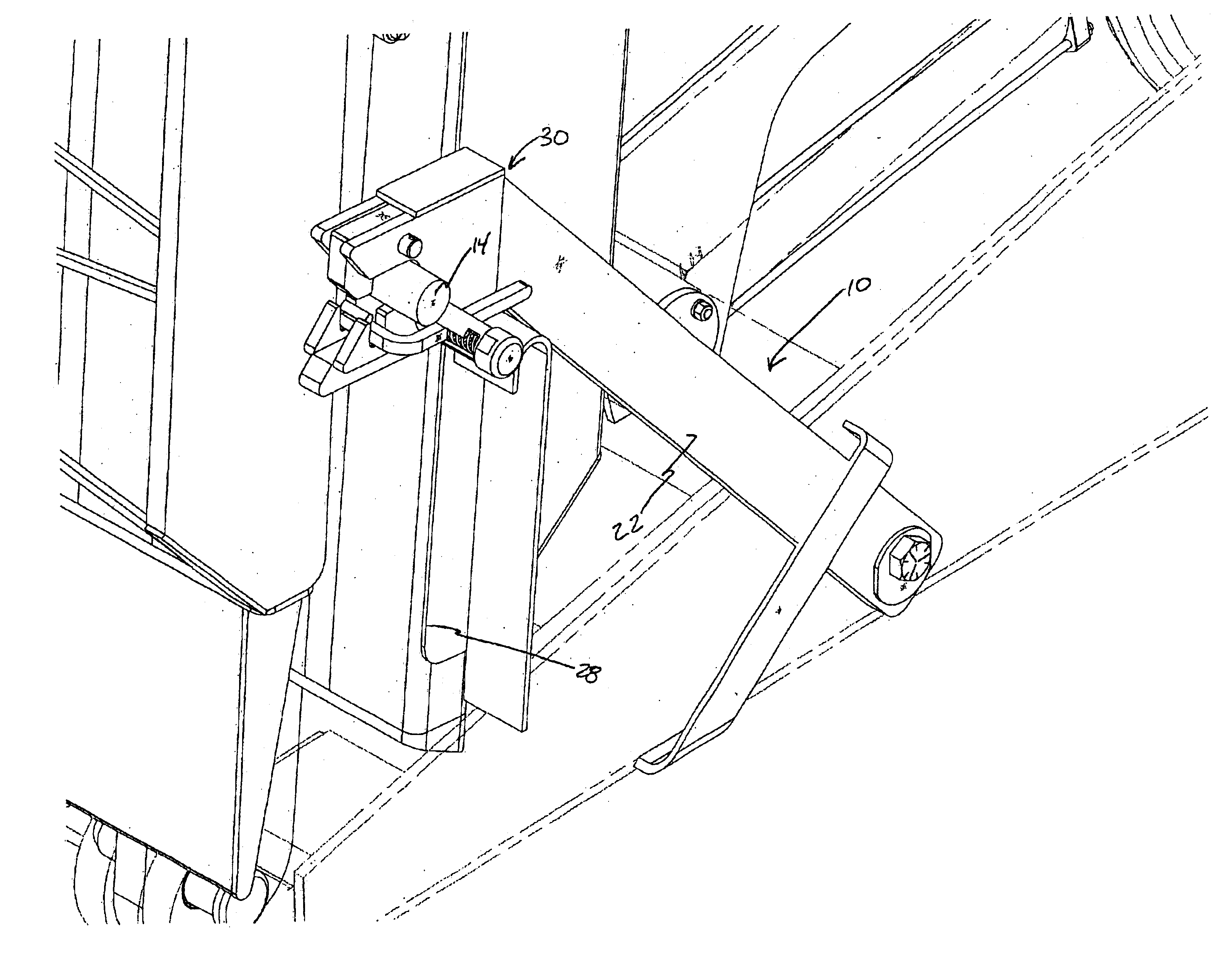

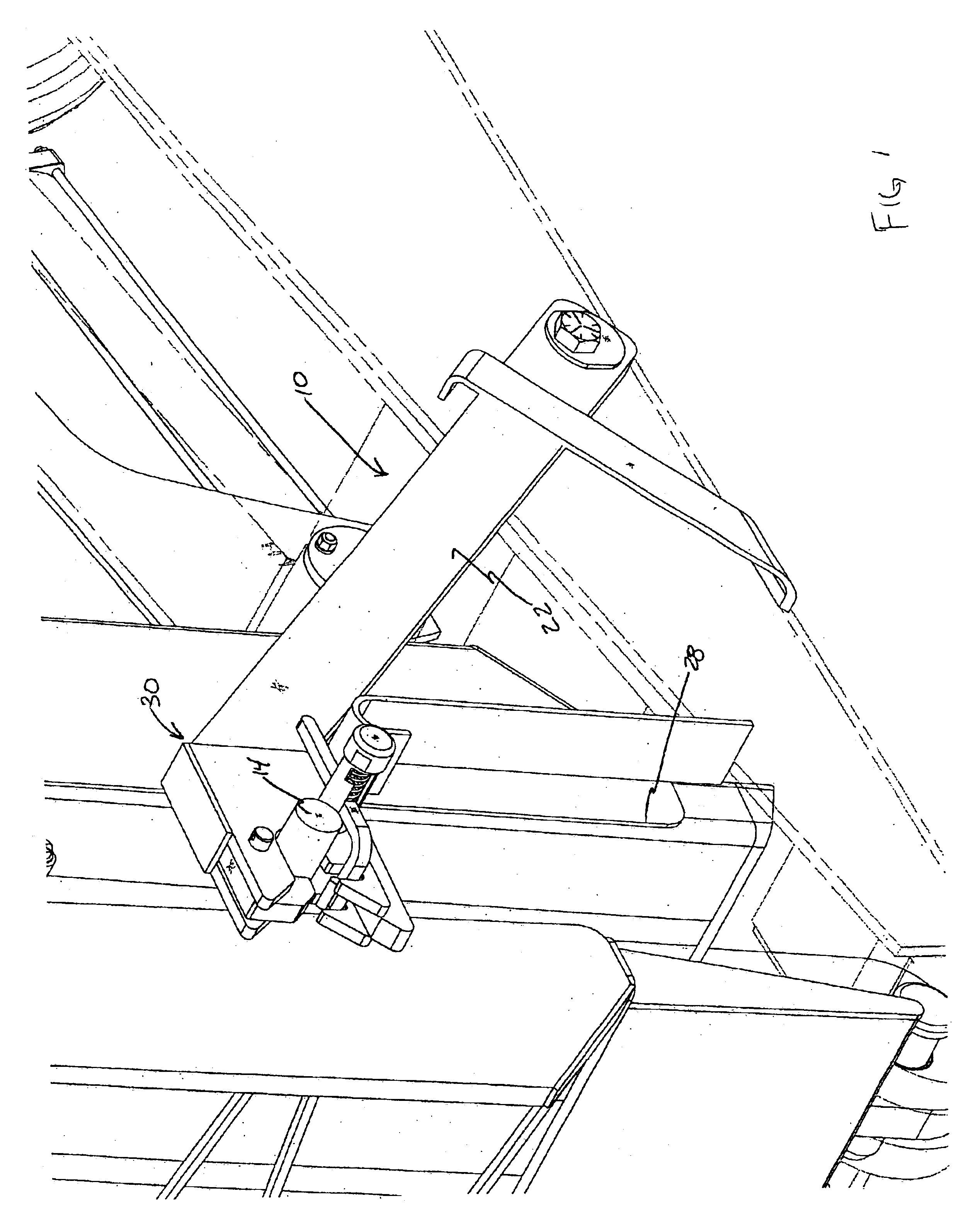

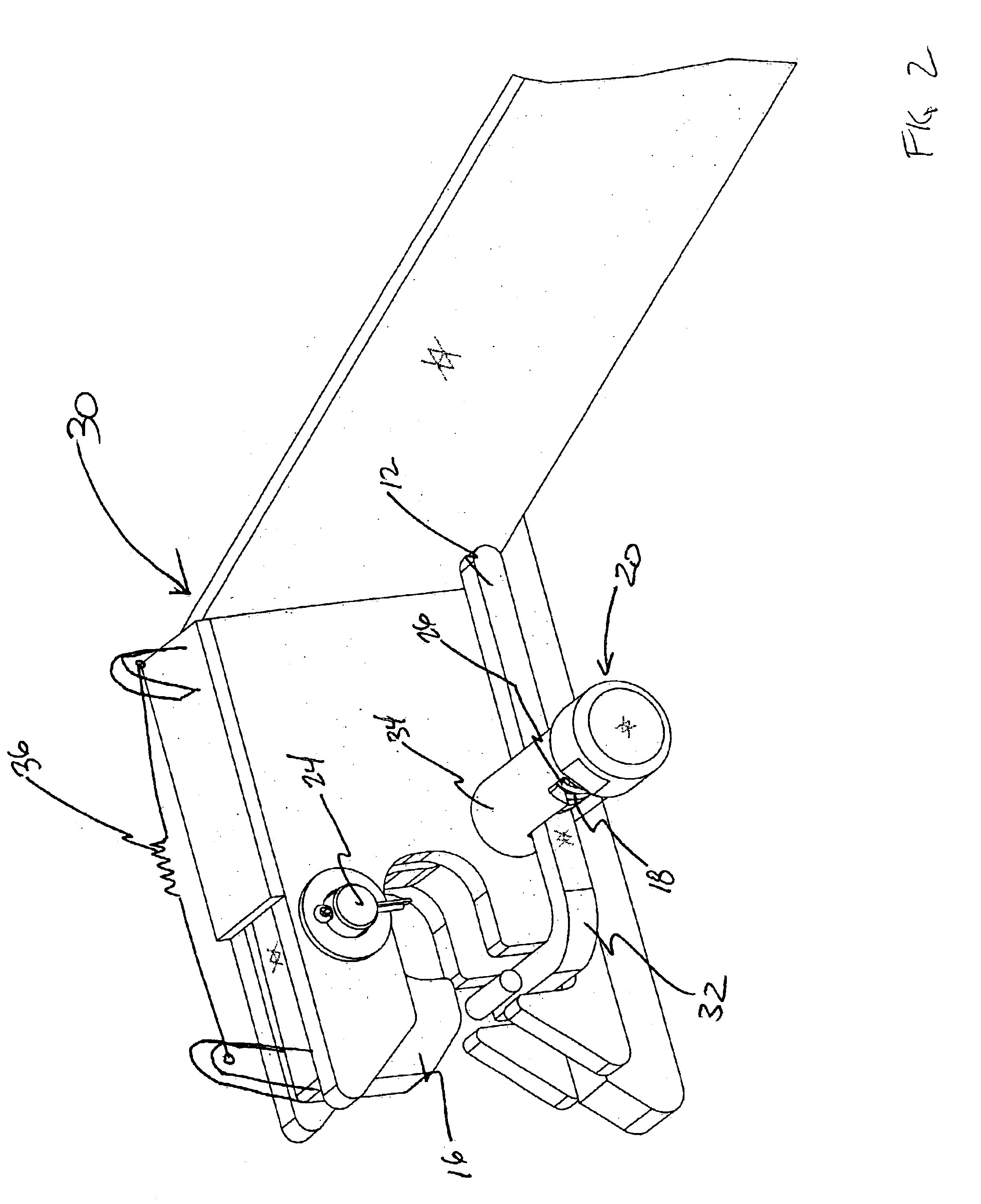

Ramp latching mechanism

A latching mechanism for use with a raisable and lowerable folding ramp having a bridge section and a toe section, such ramp being carried on one end of a railway car. The latching mechanism comprises an arm-like member pivotally connected at one end thereof to a predetermined structure of such railway car and a latch means attached to and extending outwardly from one of the bridge section and toe section of such folding ramp. A latching head portion is disposed at a radially opposed end of such arm-like member, and the latching head portion including a means for securing the latch means. A rotatable latching member is disposed in the latching head portion to engage and lock such latch means when such folding ramp reaches a fully raised position.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Ladder attachment platform

ActiveUS20110265685A1Railway device loading/unloadingRailway auxillary equipmentMechanical engineering

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS

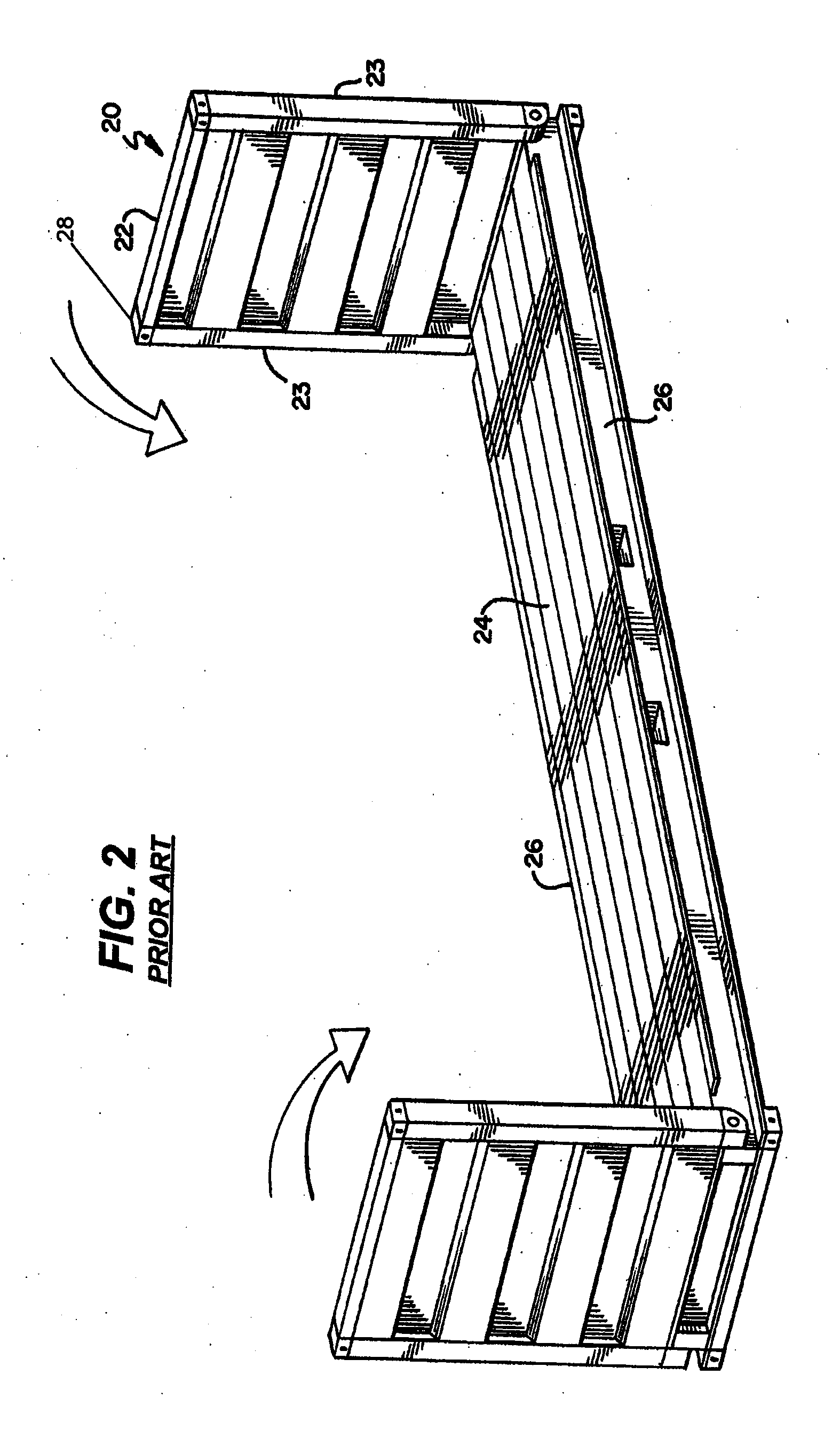

Stacking System For Intermodal Platforms

ActiveUS20120074012A1Improve load effectMinimize deflectionVehicle with removable loadingLarge containersEngineeringMechanical engineering

A stacking and lifting system for intermodal transport platforms is disclosed. Transport platforms can be converted between a storage or empty transport position and a haul or load position through rotation of support posts that provide structural support and locate fitments that align with adjoining fitments on standard intermodal containers. The support posts have fitments at their distal ends for use during lifting or stacking operations when the transport platform is loaded and in use. The support posts also have stacking blocks that provide flip-up fitments for use when the posts are in a lowered configuration for stacking transport platforms with other transport platforms or with standard intermodal containers. The stacking blocks may be lifted directly or may be locked in to adjoining fitment housings, such that the transport platform will cling to the adjoining platform or intermodal container above it that is being lifted.

Owner:PILLAR CAPITAL CORP

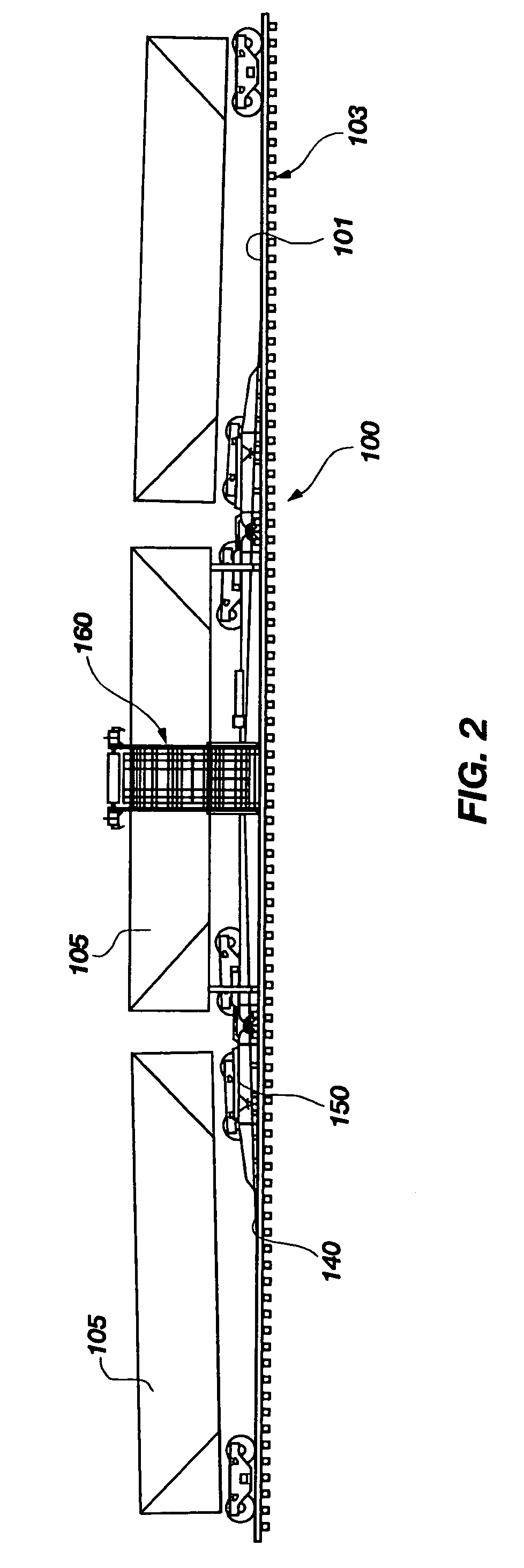

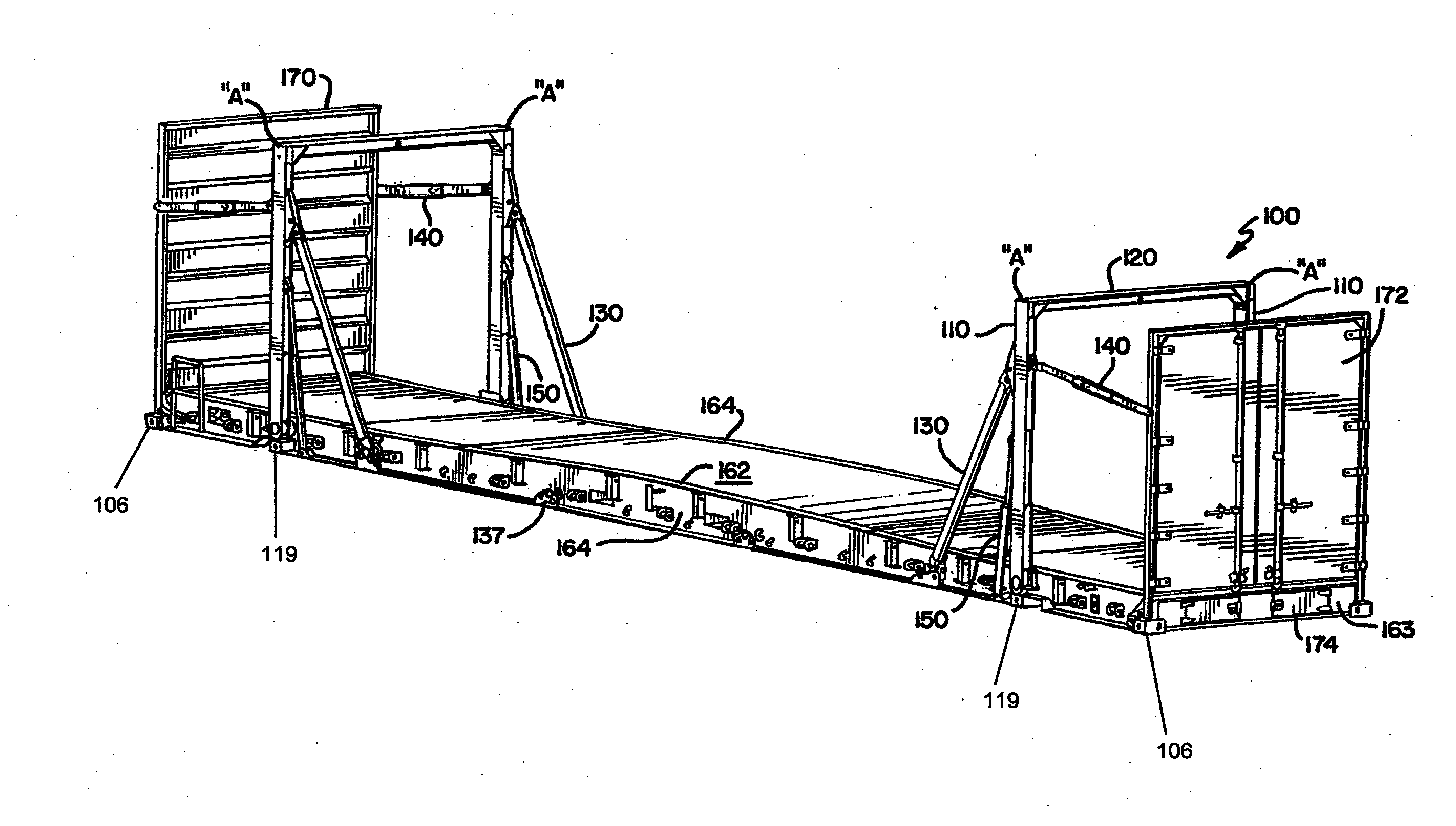

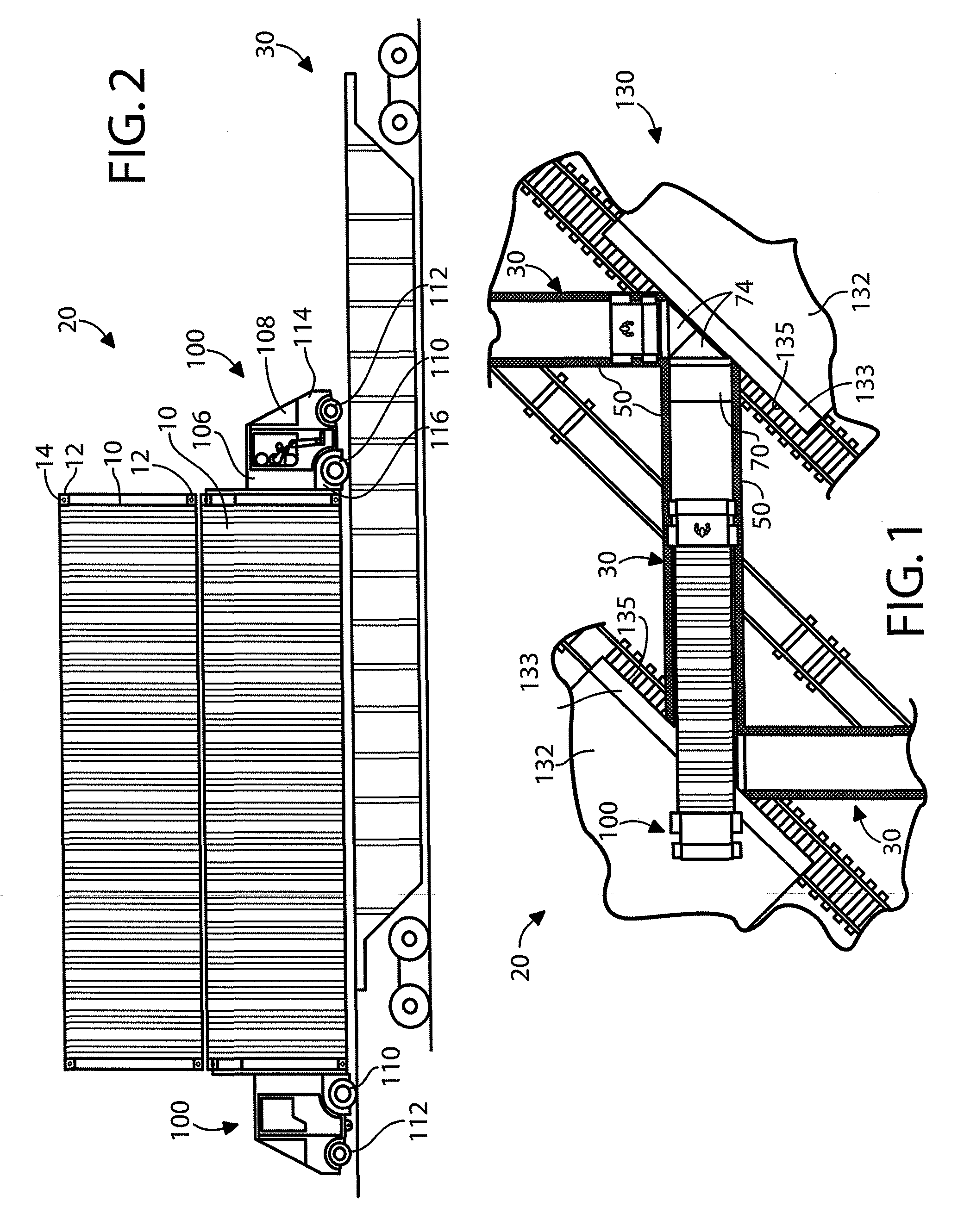

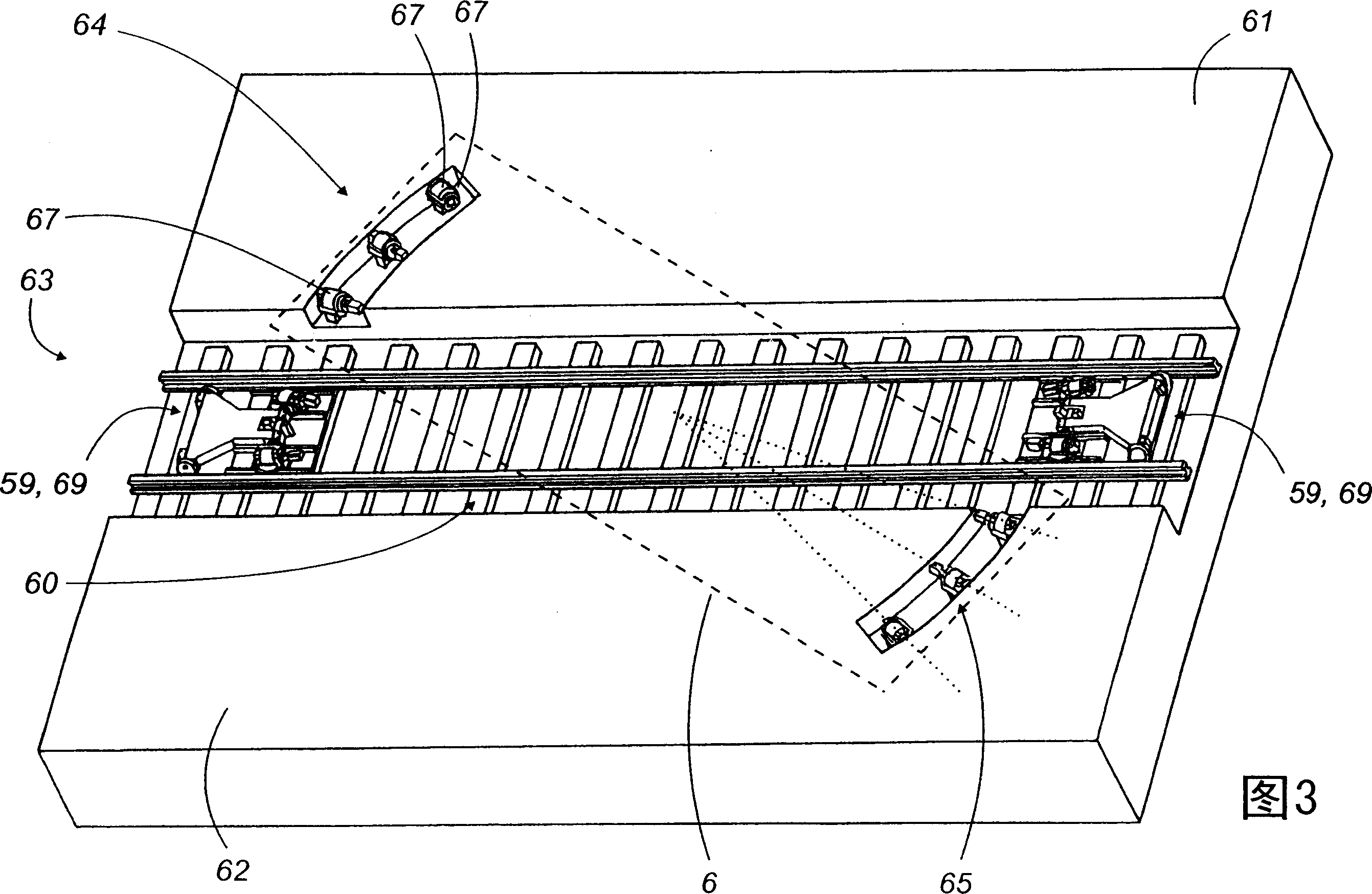

System for transporting and skew loading/unloading of cars in combined railway/road transport railway station and method for using same

The railway / road combined transportation system includes at least one railway (60), a platform (61) or (62), a carriage (1) and a loading / unloading station (63). It is characterized in that: each carriage (1) includes two terminals. lower platforms (2) and (3) and a railway structure (6) for carrying road loads, which is rotatably mounted on the carriage (1) and connected by detachable and lockable rigid assembly parts Connected to the end platforms (2) and (3); each station (63) is equipped with at least one lifting and pivoting device for the railway carrying structure (6) on the ground to allow the railway carrying structure (6) to be separated and directed The platform (61) or (62) equipped with the receiving and carrying means (64) or (65) rotates; and the system includes means for maintaining the end platform (2) or (3) in its position and condition. The present invention relates to specific structures related to combined rail / road transport.

Owner:LOHR IND

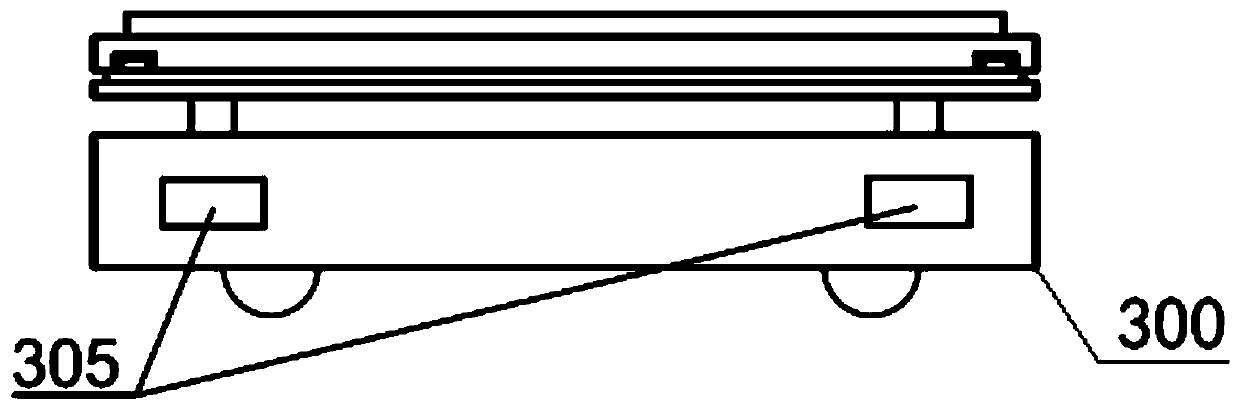

High-speed rail logistics track type automatic induction platform automatic loading and unloading system

PendingCN110116889AAvoid damageGuarantee automatic operationControl devices for conveyorsLoading/unloadingLogistics managementInductor

The invention discloses a high-speed rail logistics track type automatic induction platform automatic loading and unloading system. The system comprises a transfer rail, an in-car conveying device, acar door signal emitter and a rail loading and unloading car; the rail loading and unloading car comprises a loading and unloading car body, wheels, a lifting cylinder, an electric sliding rail, a roller bed conveying device and an inductor, the inductor is arranged on the side, close to a high-speed rail, of the loading and unloading car body, and used for receiving a position signal sent out ofthe car door signal emitter, the signal is transmitted to a controller, the controller controls the position of the loading and unloading car body on the transfer ail on the basis of the position signal through the wheels, through the stretching out and drawing back of the electric sliding rail, the horizontal interval between the roller bed conveying device and the car door can be controlled, through the lifting cylinder, the height of the roller bed conveying device is controlled, cargos can be transferred between the in-car conveying device and the roller bed conveying device, manual carrying is avoided, automatic running of the cargos in the loading and unloading process can be ensured, manpower cost is reduced, and work efficiency is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

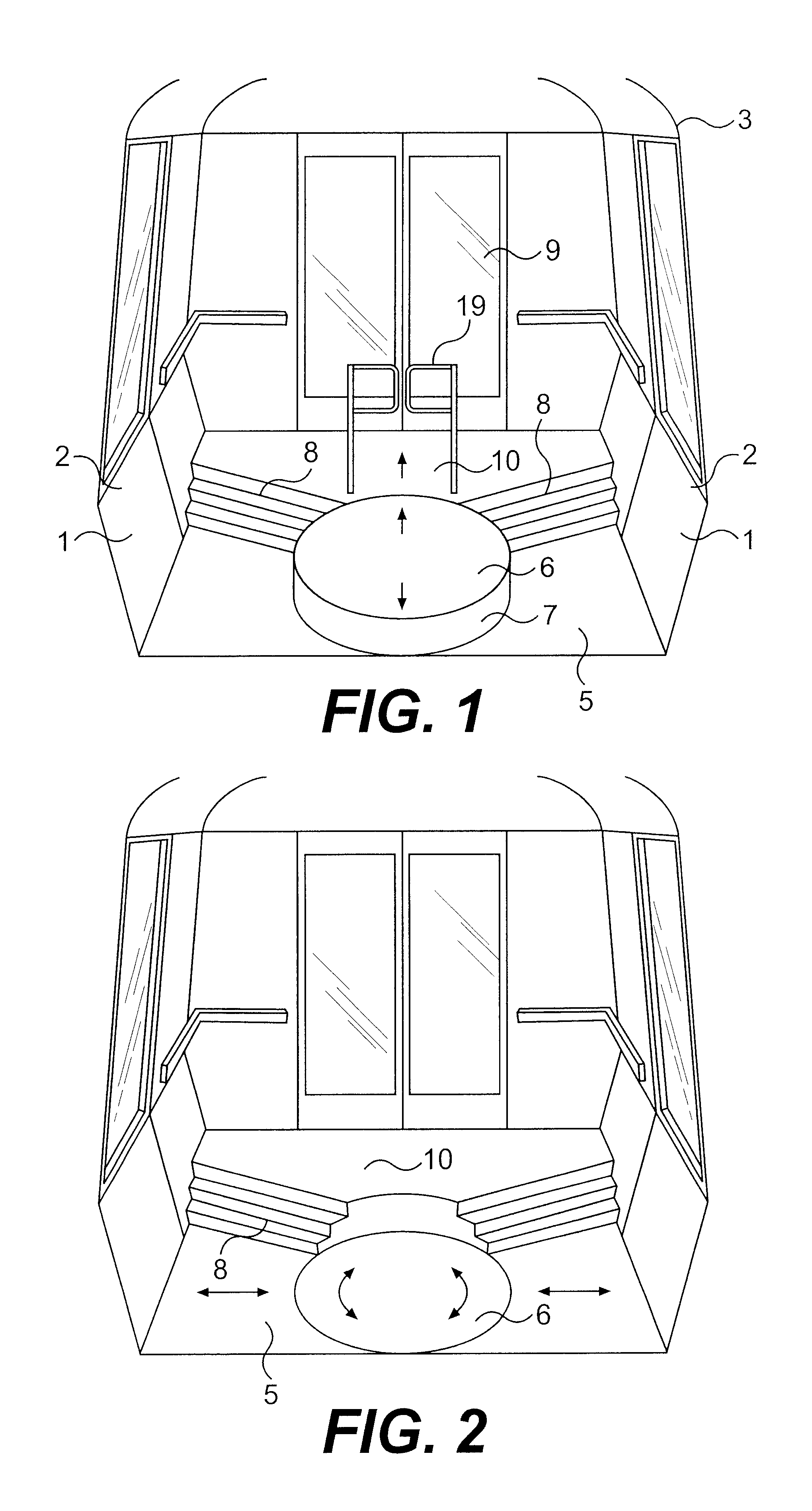

Lifting device for railway vehicles

InactiveUS6599080B1Semiconductor/solid-state device manufacturingRefuse receptaclesMarine engineeringSupport surface

In a device for transfering especially a person sitting in a wheel-chair between a platform and a passenger department of a vehicle having a floor on a higher level than the platform a first floor surface (5) is arranged inside the vehicle closest to an entrance (2) into the vehicle from a platform side and arranged on substantially the same level as the platform. Power means are adapted to move a support surface (6) arranged inside the vehicle and reachable through the first floor surface (5) between platform level and the level of the floor of the passenger department so as to join a first floor surface and a second floor surface (10) leading to the passenger department or belonging thereto, respectively. A staircase (8) is arranged between the two levels beside the support surface (6) and directly reachable through the first floor surface (5) as well as the second floor surface (10) independently of the position of the support surface (6).

Owner:BOMBARDIER TRANSPORTATION GMBH

Collapsible intermodal transport platform

ActiveUS8262328B2Improve load effectMinimize deflectionVehicle with removable loadingLarge containersMarine engineeringOverhead crane

A collapsible intermodal transport platform and methods for its operation are disclosed. The invention comprises structural ribbings that rotate about an axle disposed beneath the loading surface of the platform. The ribbings are positioned along the platform so as to provide lifting and stacking fitments at the standard overhead crane lifting points when in a lift configuration. The ribbings may be rotated inboard down to the loading surface, thereby presenting stacking blocks at the crane lifting points for stacking several platforms together. Alternatively, the ribbings may be rotated outboard to accommodate full size loading of cargo. The ribbings are rotated under electric or hydraulic power, according to the various embodiments disclosed. Other features and aspects disclosed lend to the invention's low weight and high carrying capacity, as well as its unique load securing features.

Owner:PILLAR CAPITAL CORP

Vehicles and methods for magnetically managing legs of rail-based photovoltaic modules during installation

InactiveUS20150069001A1Achieve benefitsPhotovoltaic supportsSolar heating energyEngineeringSupport surface

An exemplary method for installing at an installation site a photovoltaic module including a panel and support legs includes disposing the photovoltaic module over a support surface such that the support legs are in a stowed position; lifting the photovoltaic module from a support surface while engaging a magnetic field with the support legs so as to maintain the support legs in the stowed position; disengaging the magnetic field from the support legs of the lifted photovoltaic module so as to release the support legs from the stowed position to an installation position in which the support legs are rotated downwards relative to the stowed position; and lowering the photovoltaic module to the installation site with the support legs in the installation position so as to install the photovoltaic module at the installation site, the support legs supporting the panel at the installation site.

Owner:ALION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com