System and process for transporting wind turbines

A technology for wind turbines and towers, applied in the field of wind turbines, can solve the problems of vulnerable parts, large structures of wind turbines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

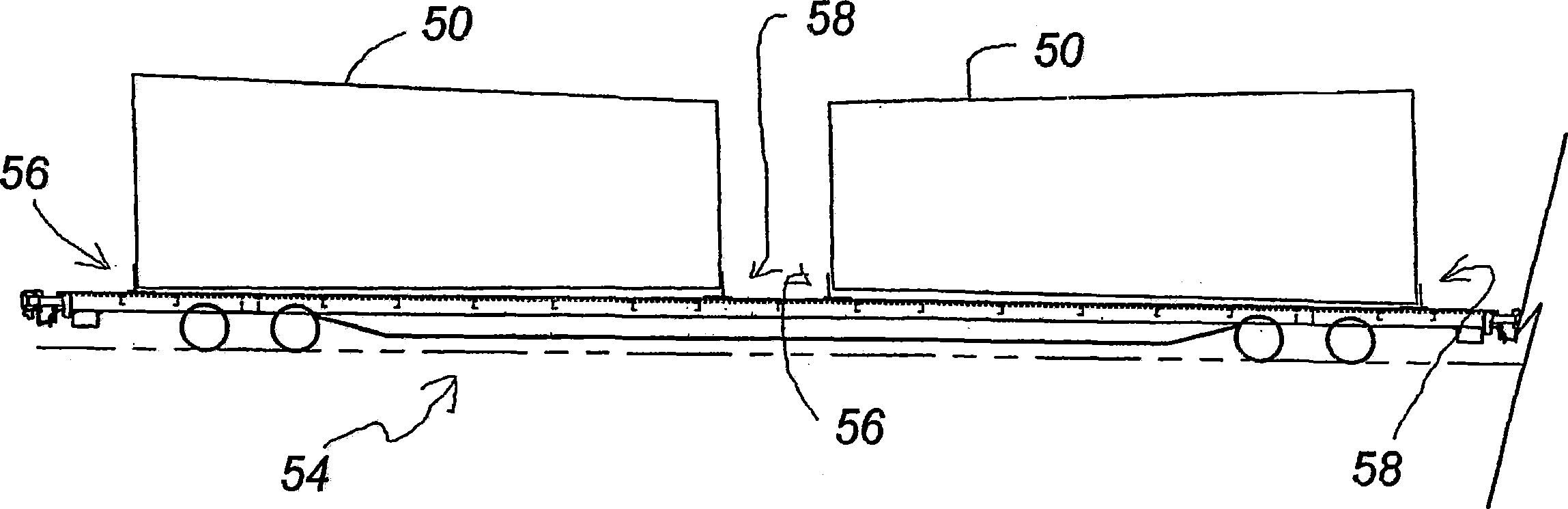

[0037] turn to Figure 3 to Figure 16 , showing a rail transport system for the tower section. refer to image 3 and Figure 4 , the bottom tower section 50 and the top tower section 52 are located on a rail car 54 . It is worth noting that the tower sections are substantially cylindrical and that the length of the bottom tower section 50 is roughly half the length of the top tower section 52 . Since the middle tower section is of similar length to the top member 52 and is shipped in the same manner as the top member 52, the middle tower section is not shown. Tower sections 52 and 50 are coupled to railcar 54 via mounting systems 56 and 58, which will be described further below.

[0038] refer to Figure 5 , it will be appreciated that there are two types of loading systems, a first type 56 and a second type 58 . The first type of loading system 56 includes two short floor pockets 59 and four end stops 62 each welded to the floor of the rail car 54 near one end of the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com