Long steel rail transport vehicle set capable of rapidly unloading steel rails

A technology of long steel rails and steel rails, which is applied in the directions of transporting passenger cars, transporting and packaging, and trucks, can solve the problems of high transportation costs, centralized installation and unloading devices, and high manufacturing costs, and achieves compact and simple device structure, high operation efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

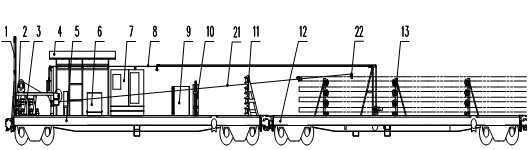

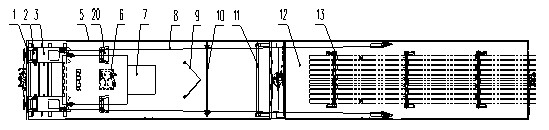

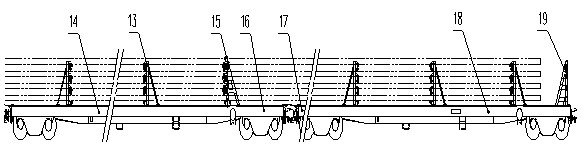

[0060] A long rail transport car group for quickly unloading rails, which is a rail transport car group for transporting 350-meter-long rails, such as Figure 1 to Figure 12 As shown, it is composed of nineteen vehicles, including the unloading operation vehicle 5 connected in sequence, the first rail transport vehicle 12, seven rail transport vehicles 14, the locking vehicle I, the locking vehicle II 17, and seven Rail car 14, rail tail car 18, wherein the unloading operation vehicle 5 is located at the first place of the whole train, the first rail car 12 is located at the second place of the whole train, and the rail car 14 includes the front rail at the 3rd-9th place of the whole train rail car and the rear rail car at the 12th-18th position, the rail locking car I is at the 10th position of the whole train, the rail locking car II17 is at the 11th position of the whole train, and the rail transporting tail car 18 is at the 19th position of the whole train. The car body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com