A cutting device for door and window production

A cutting, door and window technology, applied in the direction of positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems that the end of the profile cannot be supported, the profile is easy to shake, and the labor intensity of the workers is high, so as to improve flexibility and increase the overall Strength, effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

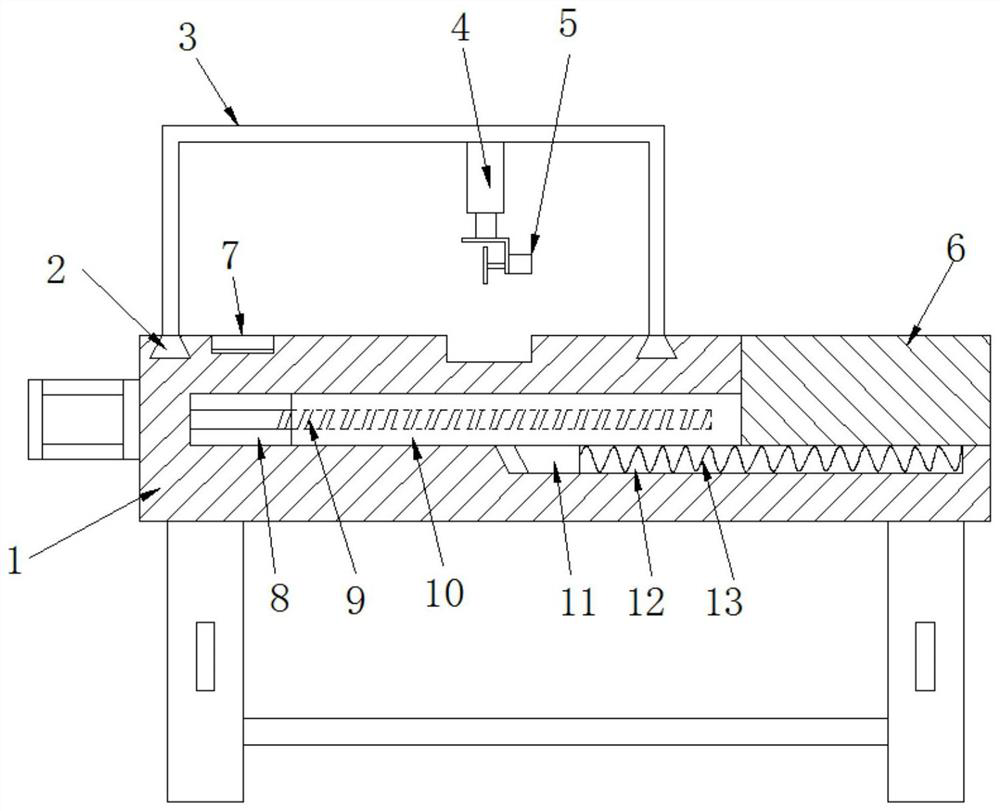

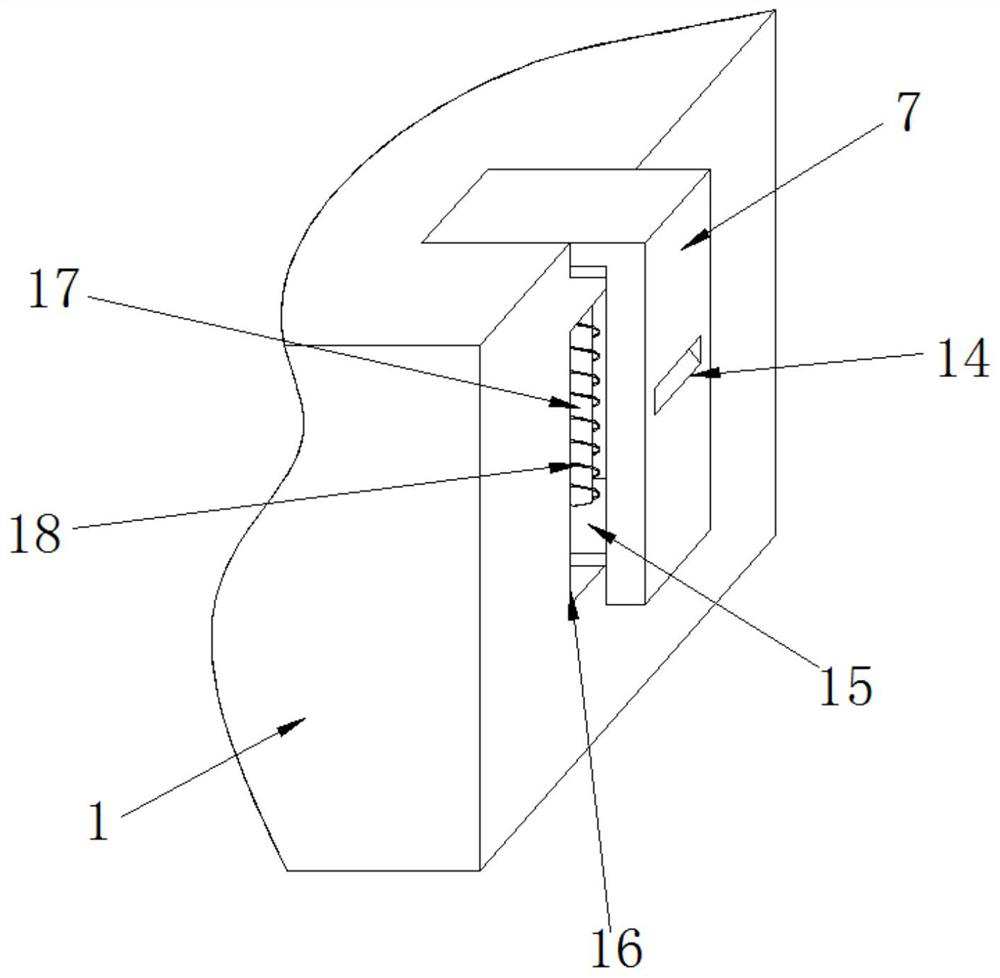

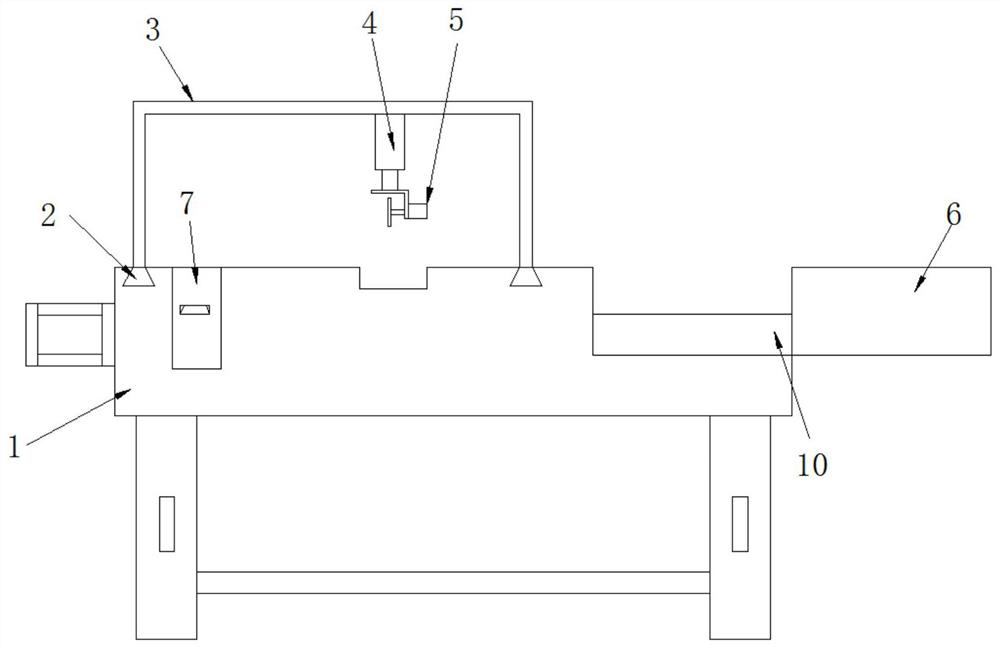

[0026] refer to Figure 1-3 , a cutting device for door and window production, comprising a base 1, a cutting mechanism 5 is arranged above the top of the base 1, a cutting groove is opened on the outer wall of the top of the base 1 below the cutting mechanism 5, and the outer walls of the two sides of the base 1 are opened. There is an installation groove 16, and a clamping mechanism is arranged in the installation groove 16. The right side of the abutment 1 is provided with a fitting support platform 6, and the bottom end of the outer wall on the left side of the support platform 6 is fixed with an extension plate 10, and the extension plate 10 is movably plugged in. In the storage groove 8 opened in the base 1, the end of the extension plate 10 away from the support table 6 is connected with a transverse drive mechanism, and the bottom of the extension plate 10 is fixed with a guide block 11, and the guide block 11 is movably inserted on the right side of the base 1. In the...

Embodiment 2

[0031] refer to Figure 4 , a cutting device for door and window production. The difference between this embodiment and Embodiment 1 is that the outer wall of one side of the abutment 1 is close to the position of the support platform 6. There is also an embedding groove 20, and the embedding groove 20 is fixed with an extension plate 10 The brush 21 attached to the outer wall of the top, and the support platform 6 has a material guide port 19 with the same level as the brush 21, and the inner wall at the bottom of the material guide port 19 is provided with a material guide slope.

[0032] The working principle of this embodiment: the brush 21 can form opposite movement with the support table 6 for storage work, so that the brush 21 can clean and push the impurities on the upper surface of the extension plate 10, and the impurities move along the upper surface of the extension plate 10 to The material guide port 19 discharges impurities along the material guide slope to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com