Tamping device

A technology of clamping and inner pick arms, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of increased line maintenance costs, low reliability of tamping devices, easy damage of internal and external oil cylinders, etc., and achieves simple structure and impact resistance Enhanced capability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

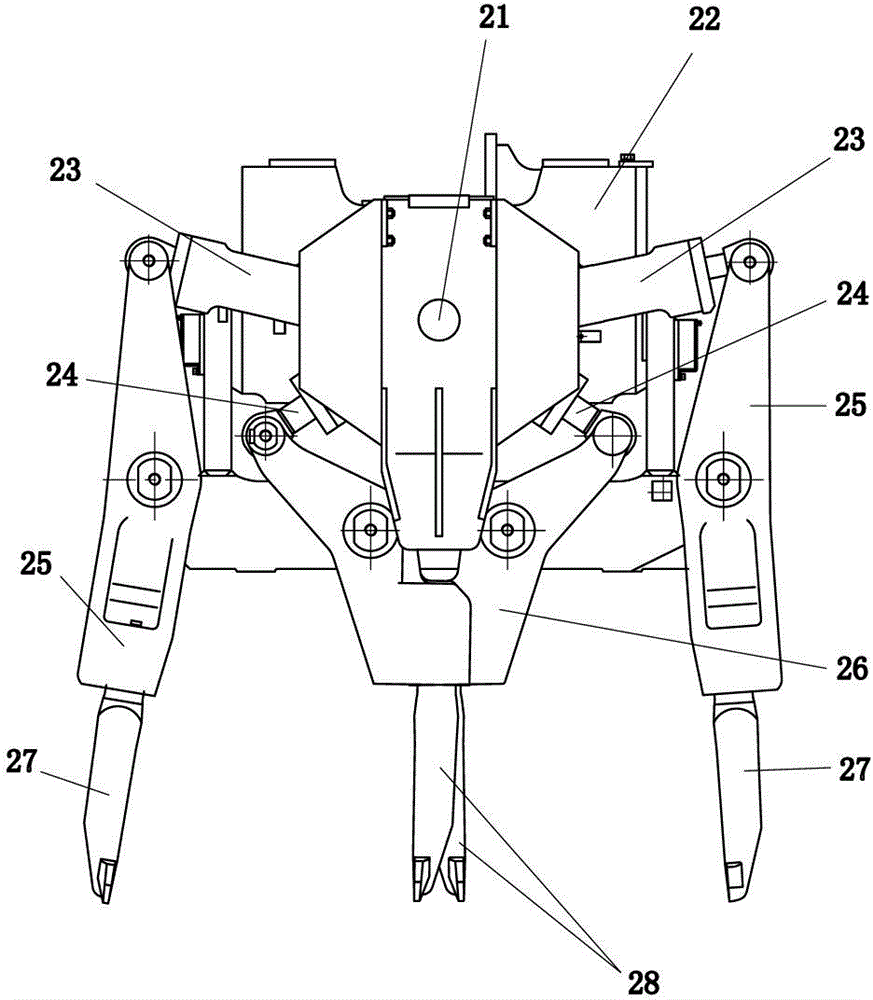

[0025] Such as figure 1 As shown, the uniaxial excitation type tamping device of the prior art includes a vibrating shaft 21, a casing 22, an outer oil cylinder 23, an inner oil cylinder 24, an outer pick arm 25, an inner pick arm 26, an outer tamping pick 27 and an inner tamping Pick 28 etc. The vibration shaft 21 is installed on the casing 22, and the vibration shaft 21 is connected with the inner and outer pick arms 26, 25 through the inner and outer oil cylinders 24, 23 respectively.

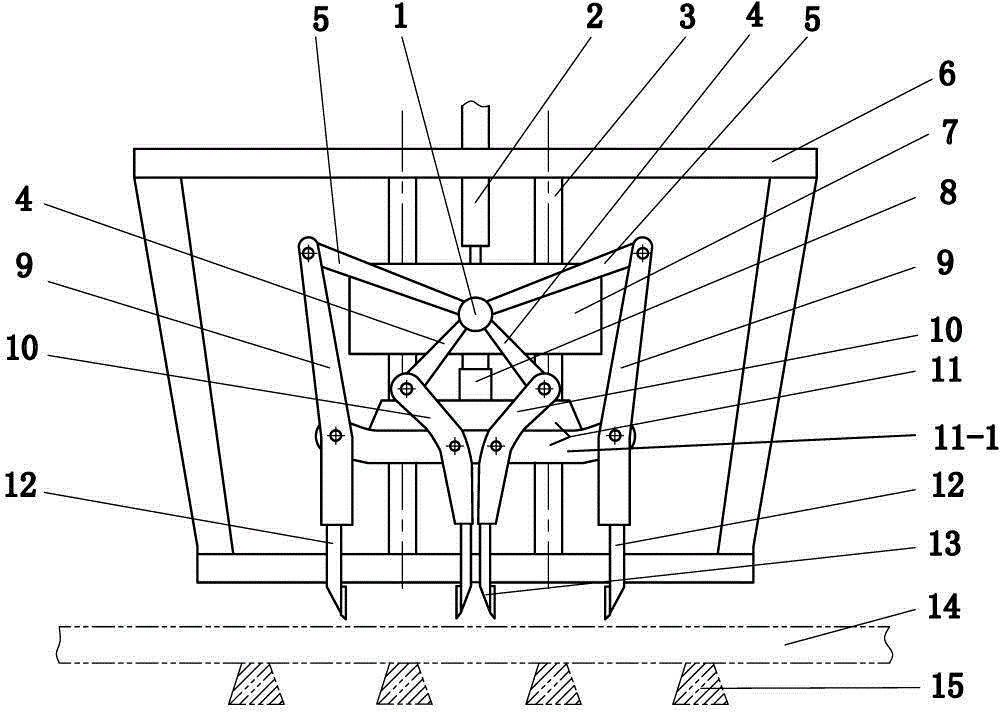

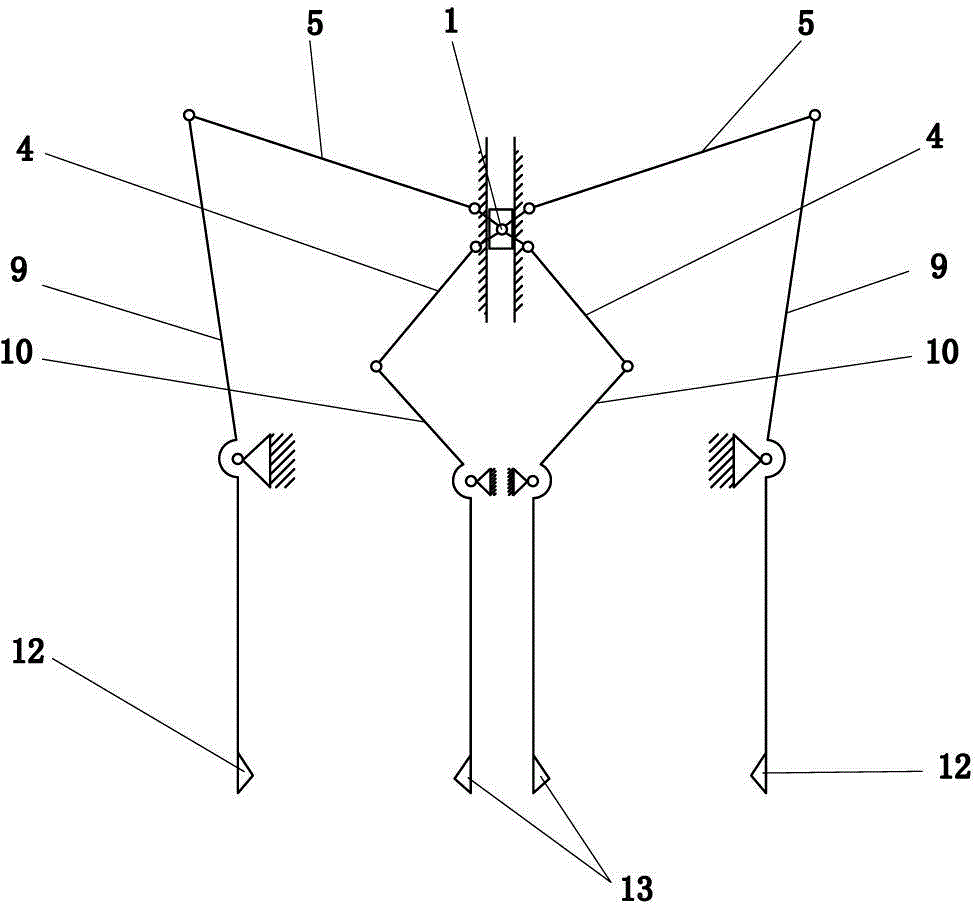

[0026] Such as figure 2 , 3 , 4, 5, and 6, a tamping device of the present invention includes a mobile body 7, an eccentric vibration shaft 1, an inner pick arm 10, and an outer pick arm 9, and the eccentric vibration shaft 1 is rotationally supported on the mobile body 7 On, it also includes the inner pick arm connecting rod 4, the outer pick arm co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com