Shaft type vertical multi-spindle numerical control lathe with narrow-spacing multi-shaft station storing and extending function

A technology for CNC lathes and vertical lathes, applied in the field of CNC lathes, can solve the problems of debris accumulation, gaps, and difficulty in clamping operations, and achieve the effect of good working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

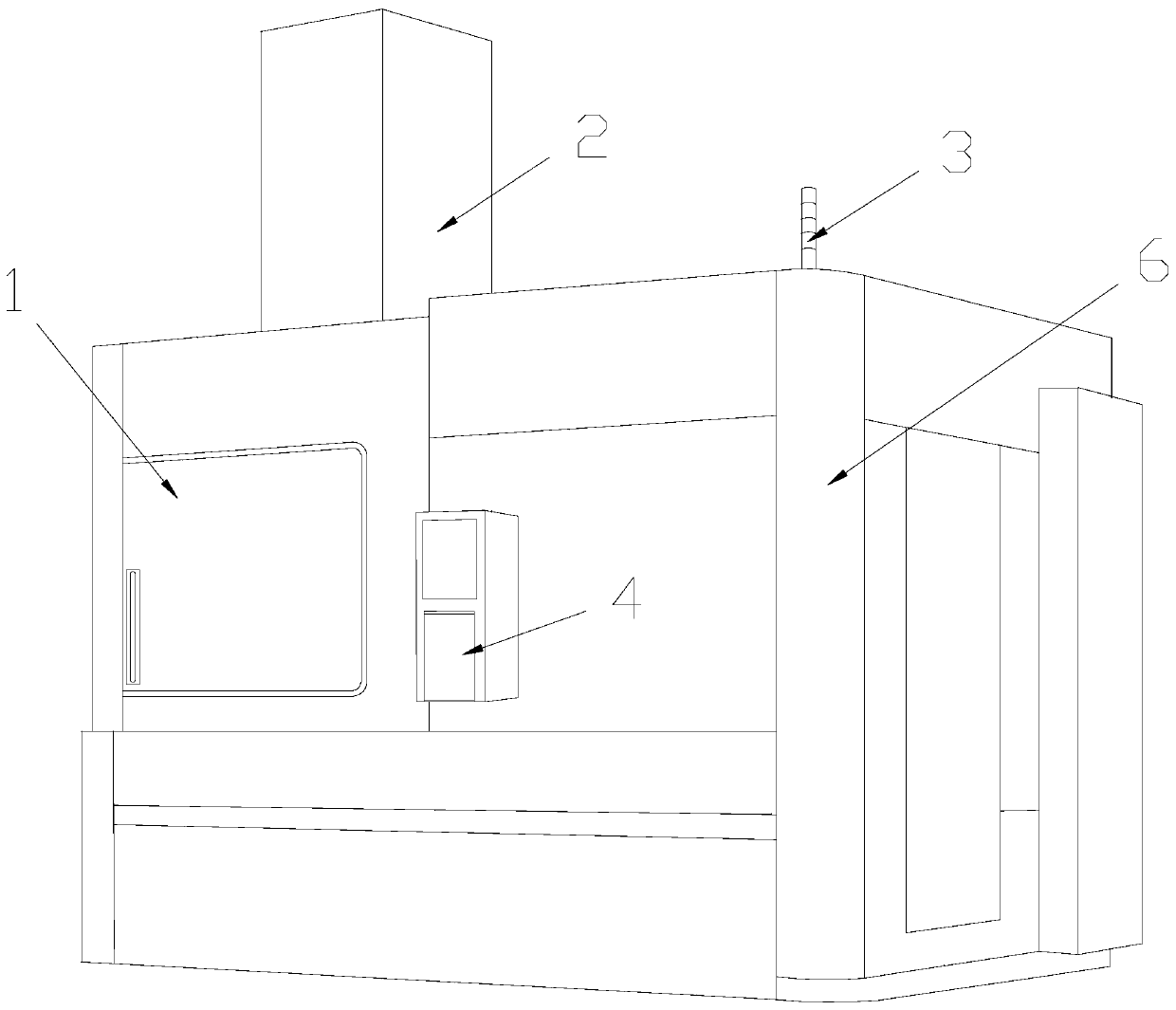

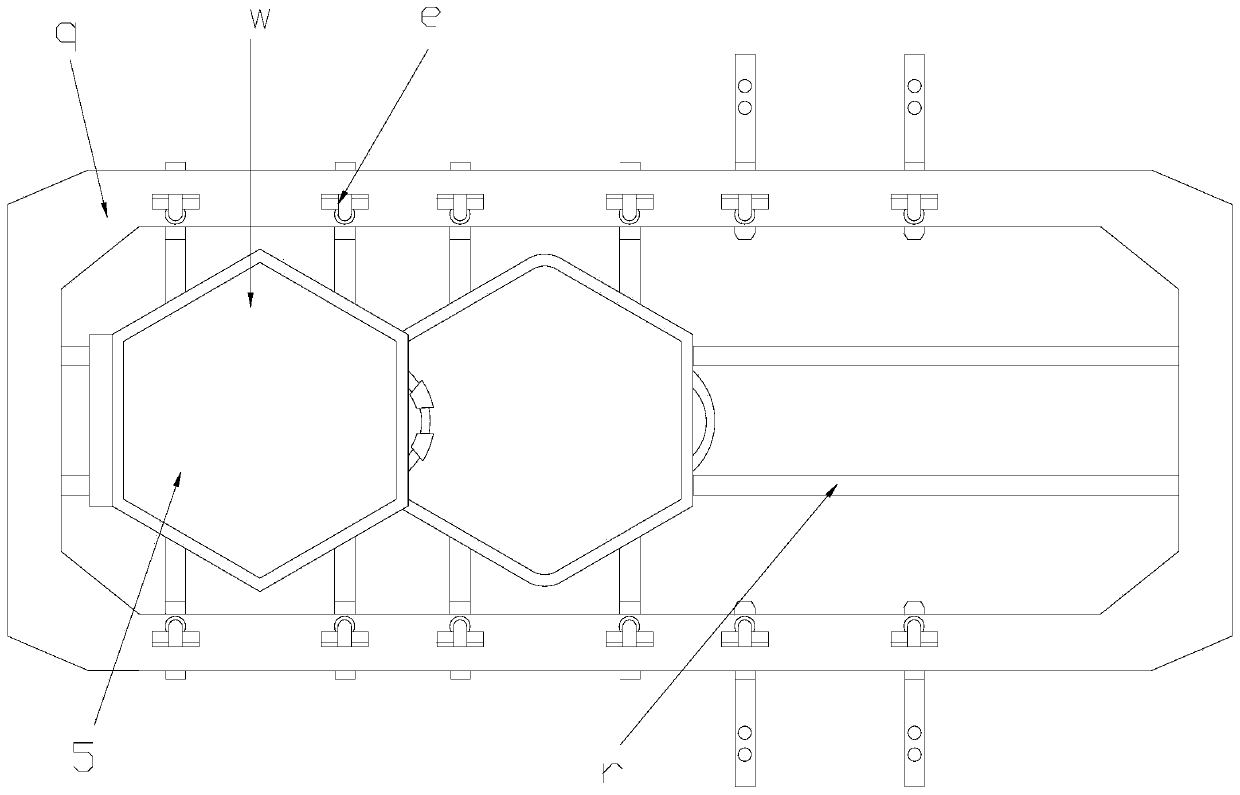

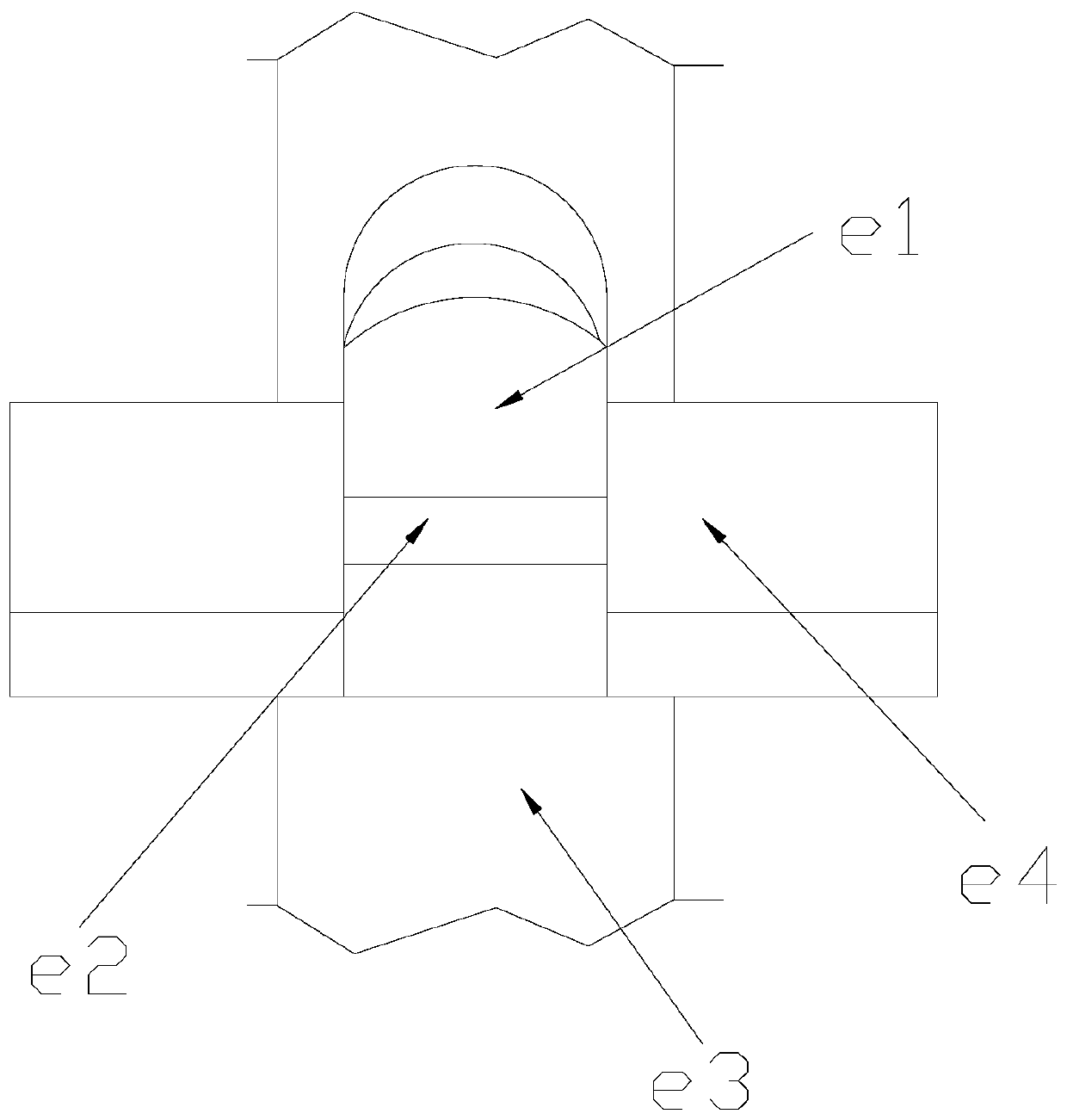

[0027] as attached figure 1 to attach Figure 7 Shown:

[0028] The present invention provides a shaft-type vertical multi-spindle numerical control lathe with narrow-spacing multi-axis stations, and its structure includes a protective door 1, a vertical lathe power column 2, a lathe failure alarm light 3, a flipping hidden control table 4, Narrow spacing multi-axis station extension device 5, CNC lathe 6, the protective door 1 is installed on the left side of the CNC lathe 6 by embedding, the vertical lathe power column 2 is arranged on the top of the CNC lathe 6, the The narrow-spacing multi-axis station extension device 5 is fixedly connected to the inside of the CNC lathe 6 by means of electric welding, the bottom end of the lathe fault alarm light 3 is electrically connected to the CNC lathe 6, and the flip hidden control console 4 is located at the protective door 1 On the right side, the narrow-pitch multi-axis station extension device 5 includes a station frame q, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com