Tool structure for measuring plunger bottom clearance groove depths

A technology for measuring column and head clearance, applied in the direction of mechanical depth measurement, etc., can solve problems such as affecting the processing progress and production efficiency, increasing the cost of human resources, and inaccurate measurement, achieving flexible and convenient adjustment, simple structure, and guaranteed accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

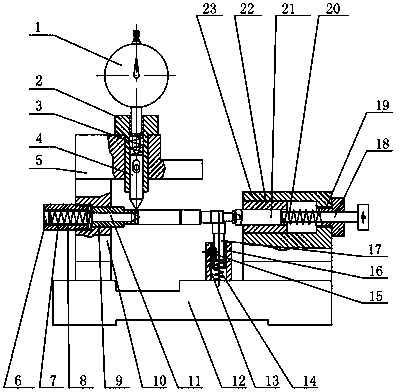

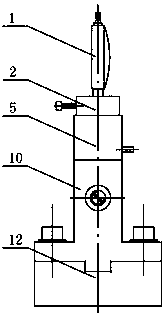

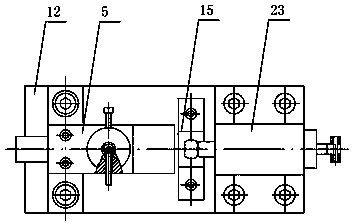

[0021] Such as figure 1 , figure 2 and image 3 As shown, a tooling structure for measuring the depth of the top gap groove of a plunger includes a base 12, including a first assembly unit and a measuring unit arranged perpendicularly to each other, and on the base 12, relative to the first assembly unit, they are arranged at intervals second assembly unit;

[0022] The specific structure of the first assembly unit is as follows:

[0023] Including the male top seat 10, the screw sleeve 8 is screwed to the male top seat 10, one end of the male top bushing 9 extends into the male top seat 10 and abuts against the screw sleeve 8, and the second spring 7 is installed in the screw sleeve 8 , the male tip 11 runs through the male tip bushing 9 and is connected to one end of the second spring 7, the other end of the second spring 7 abuts ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com