Patents

Literature

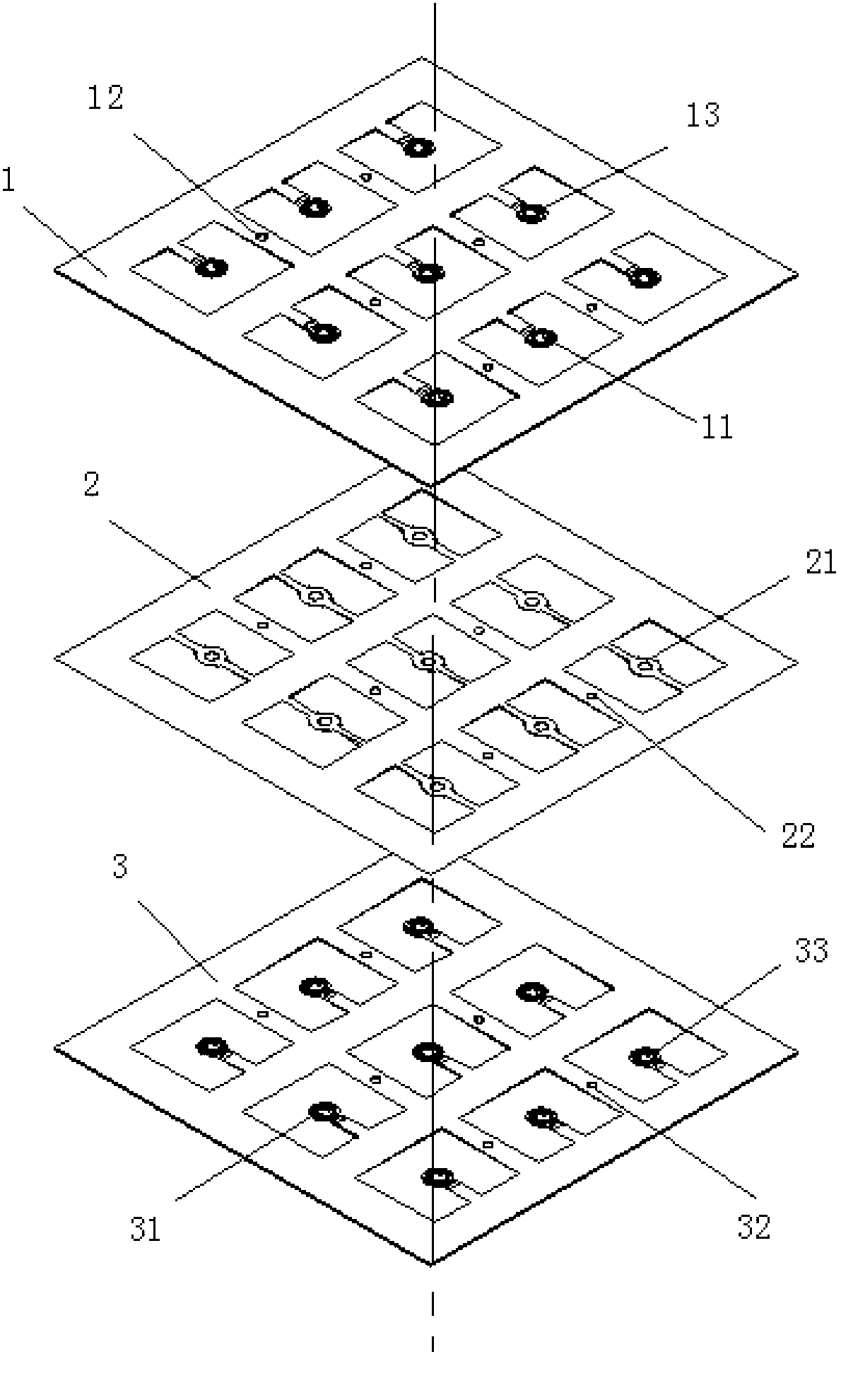

375results about How to "Easy to locate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

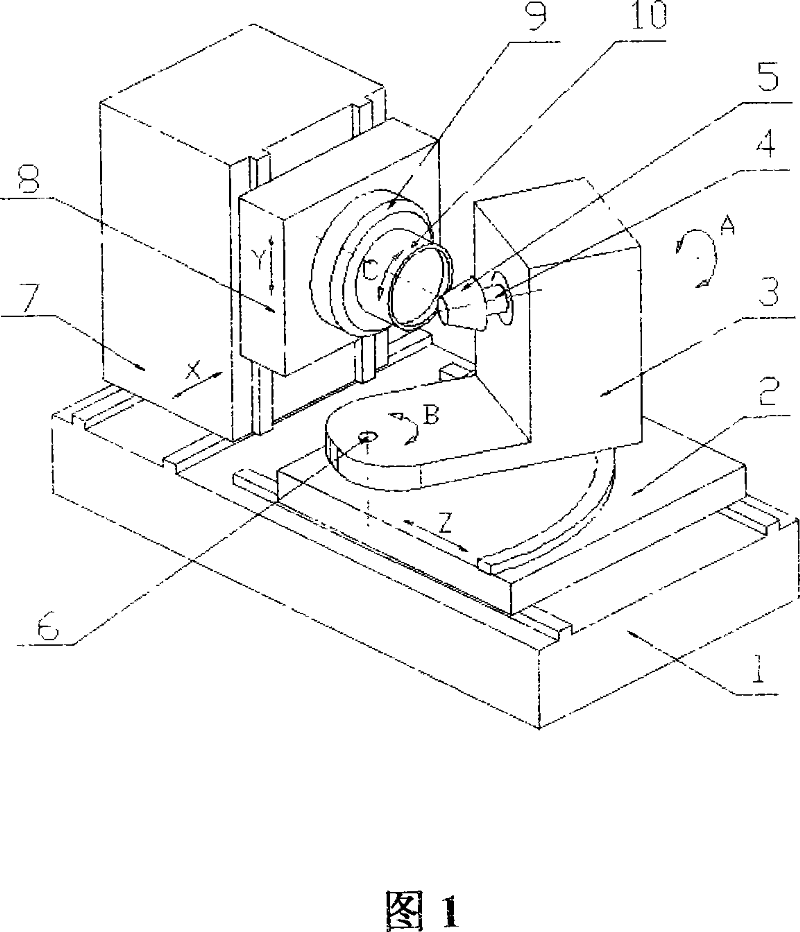

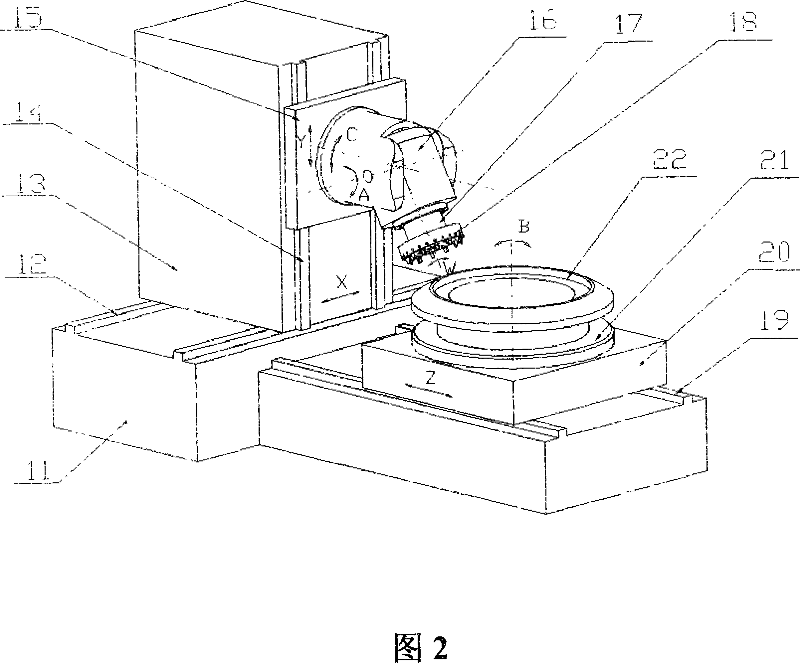

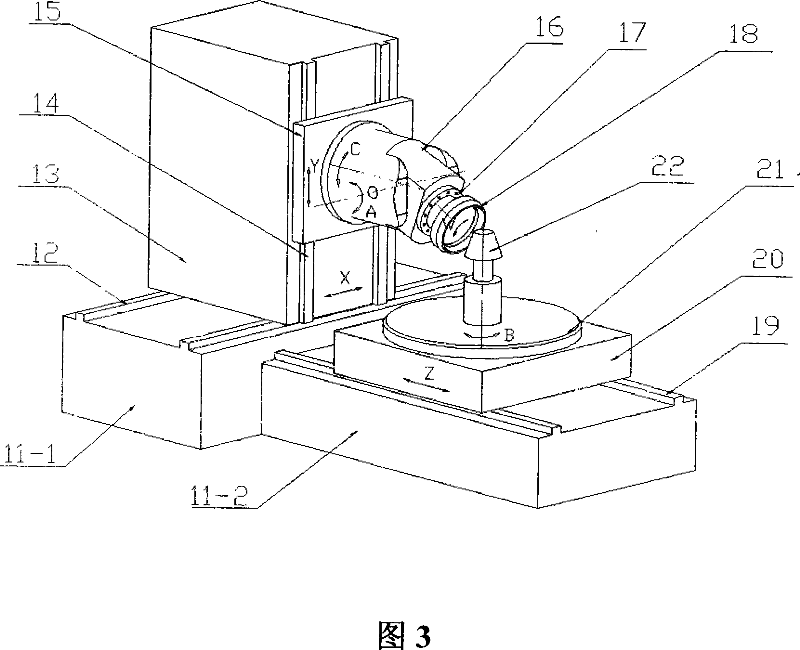

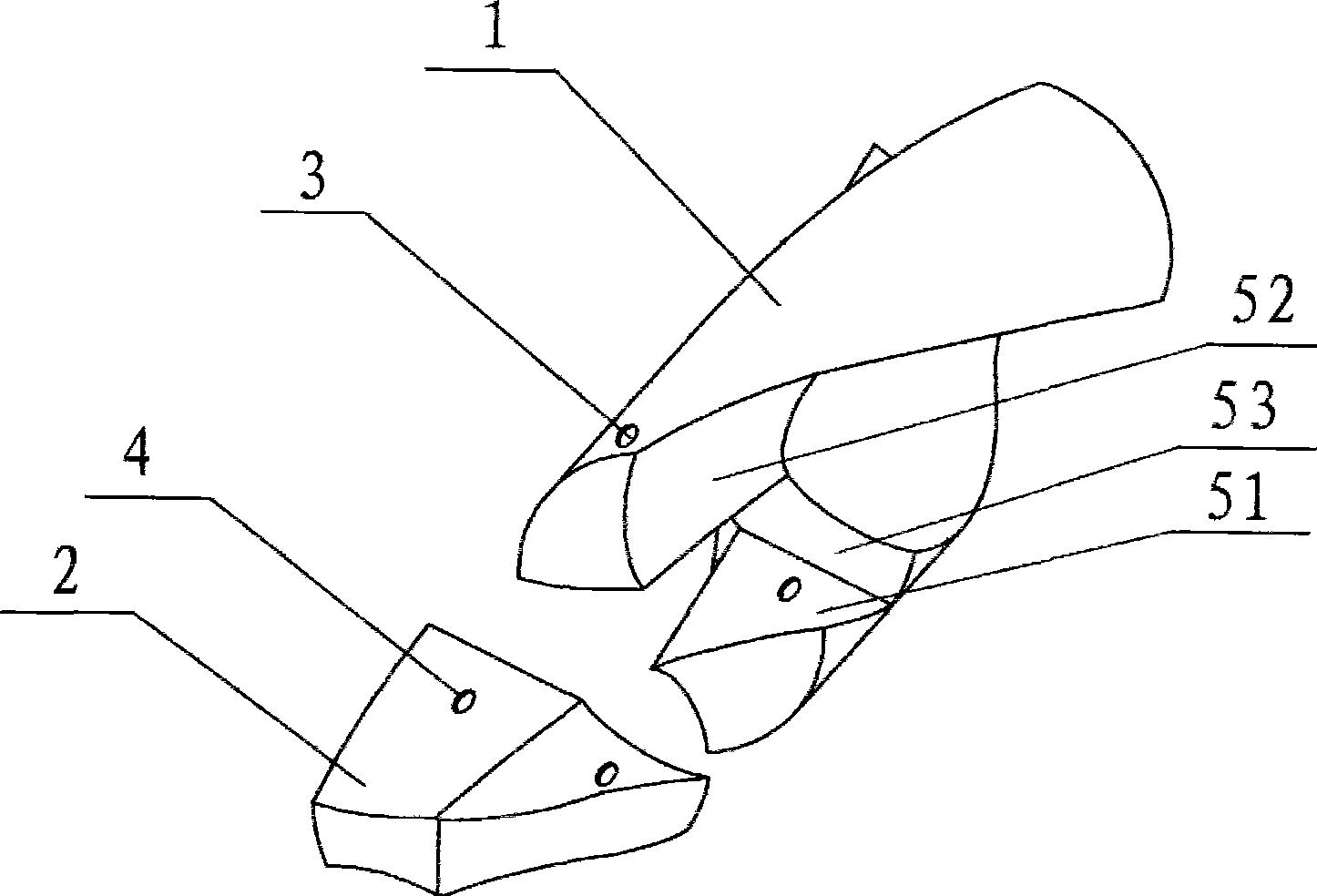

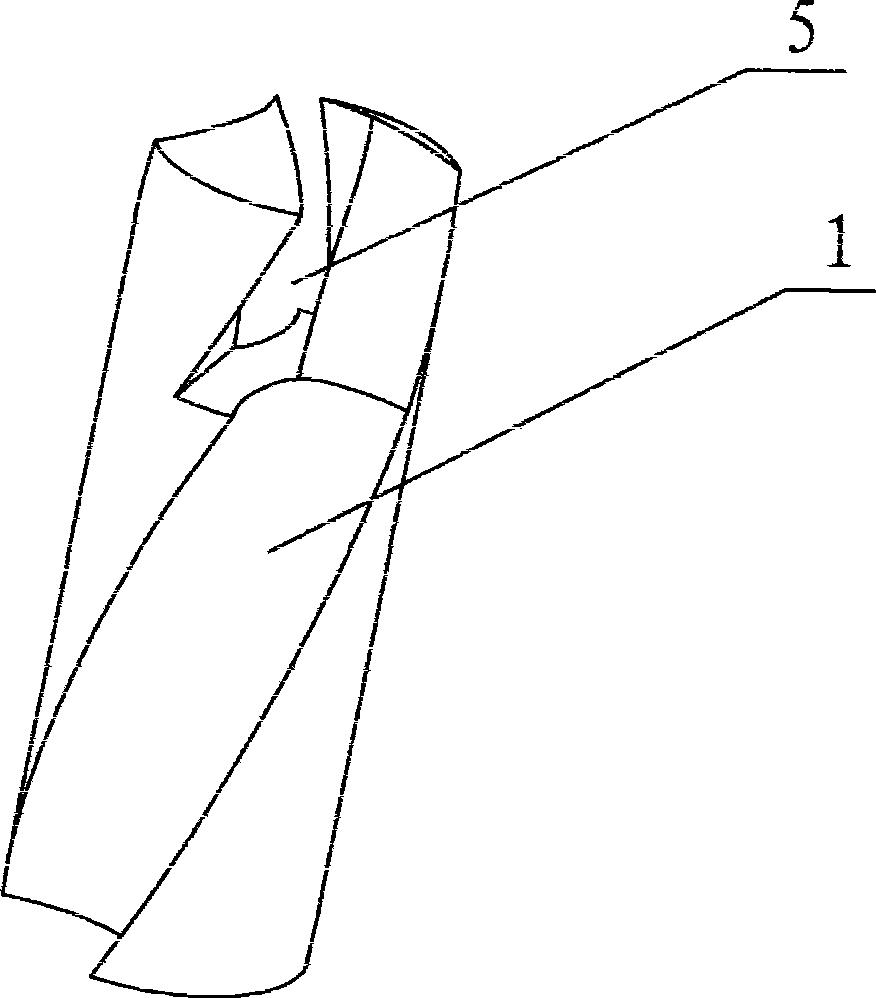

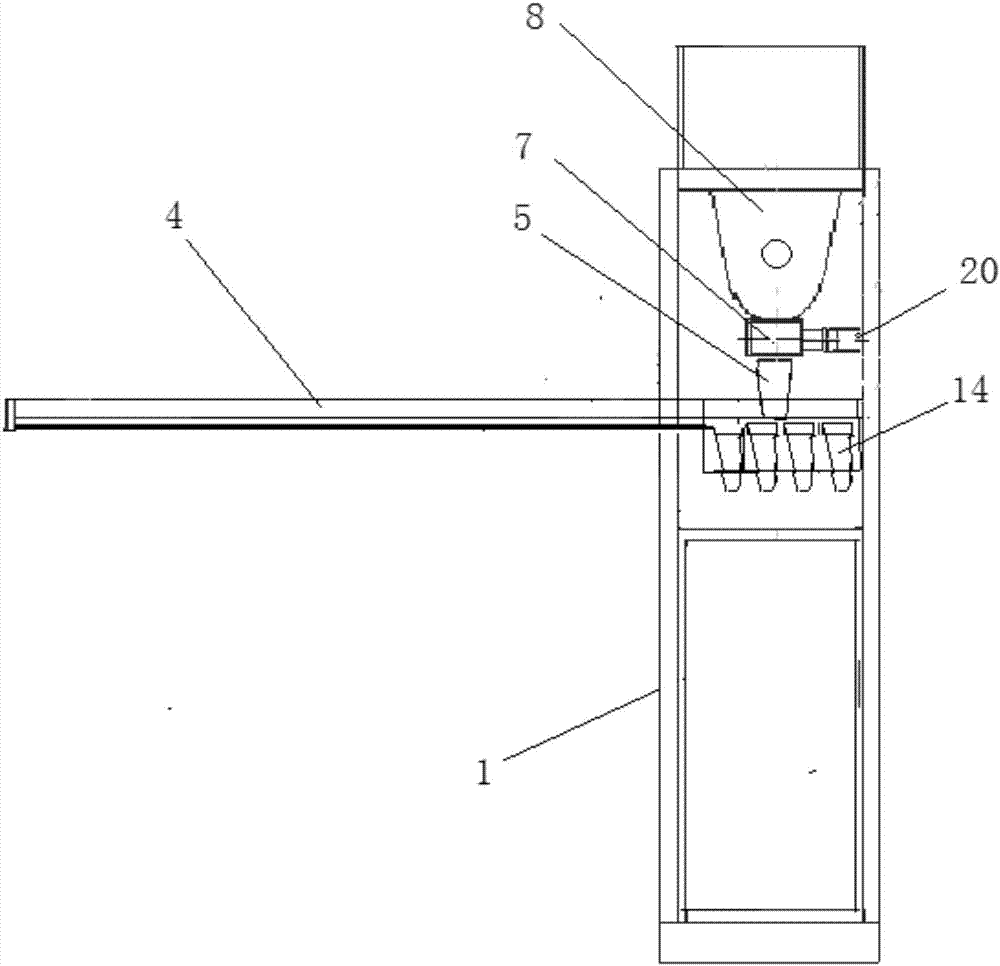

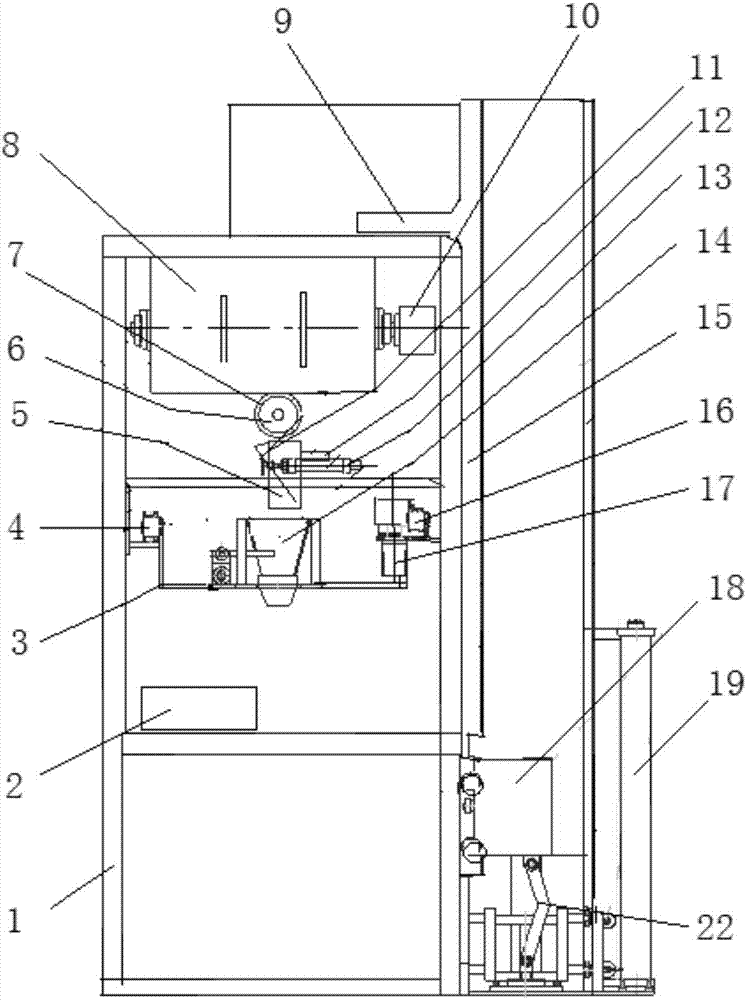

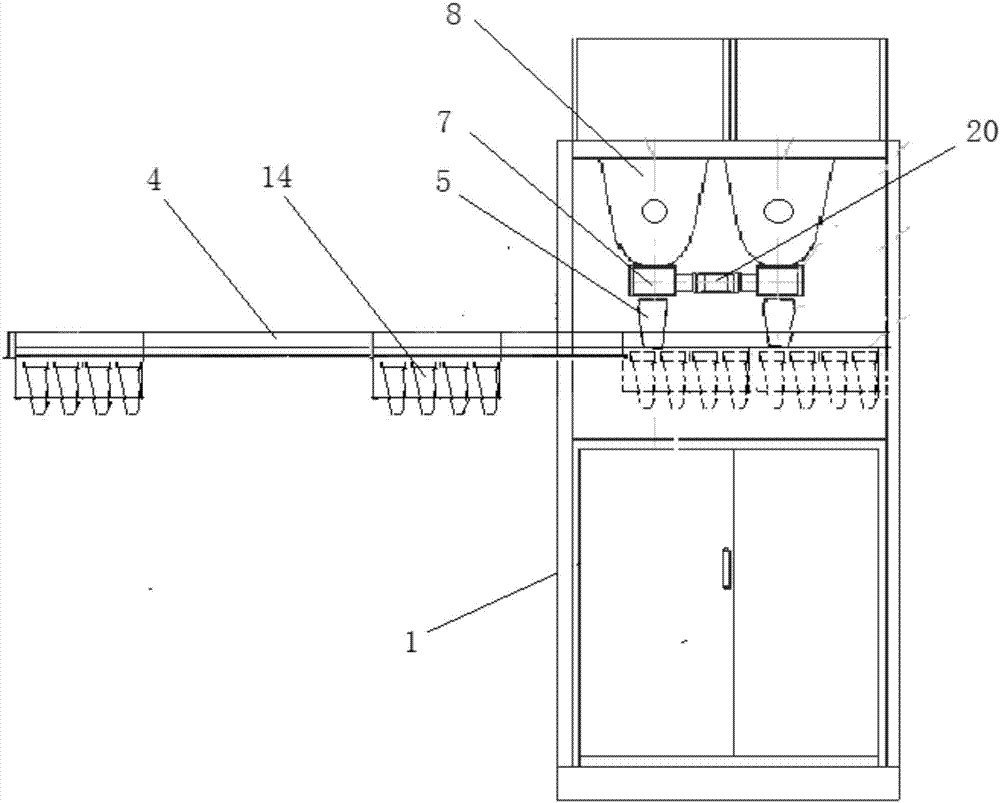

Numerical control machine for processing huge conical gear with curved teeth

InactiveCN101041194AEasy to locateHigh machine rigidityLarge fixed membersGear-cutting machinesProcessing accuracyEngineering

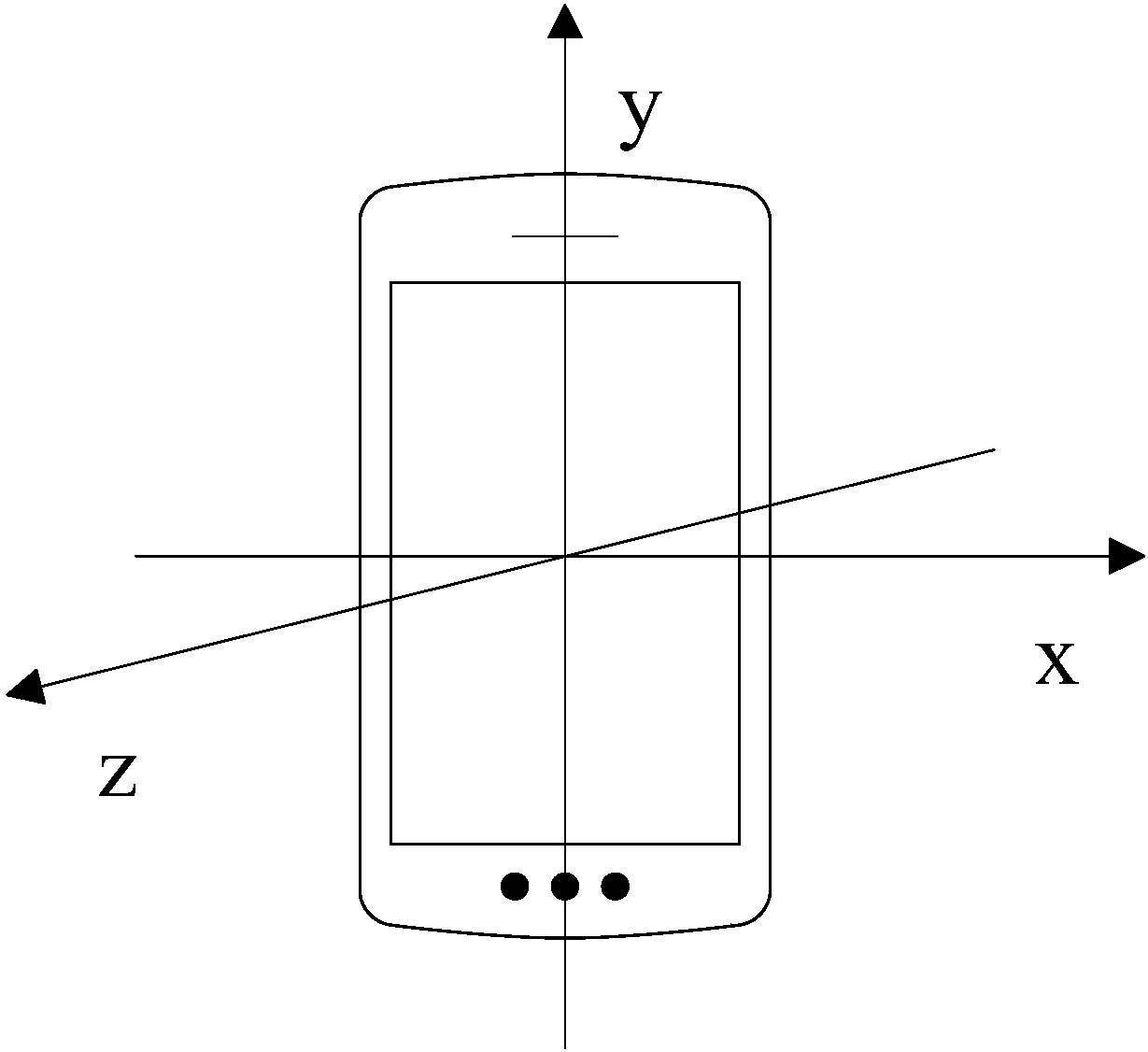

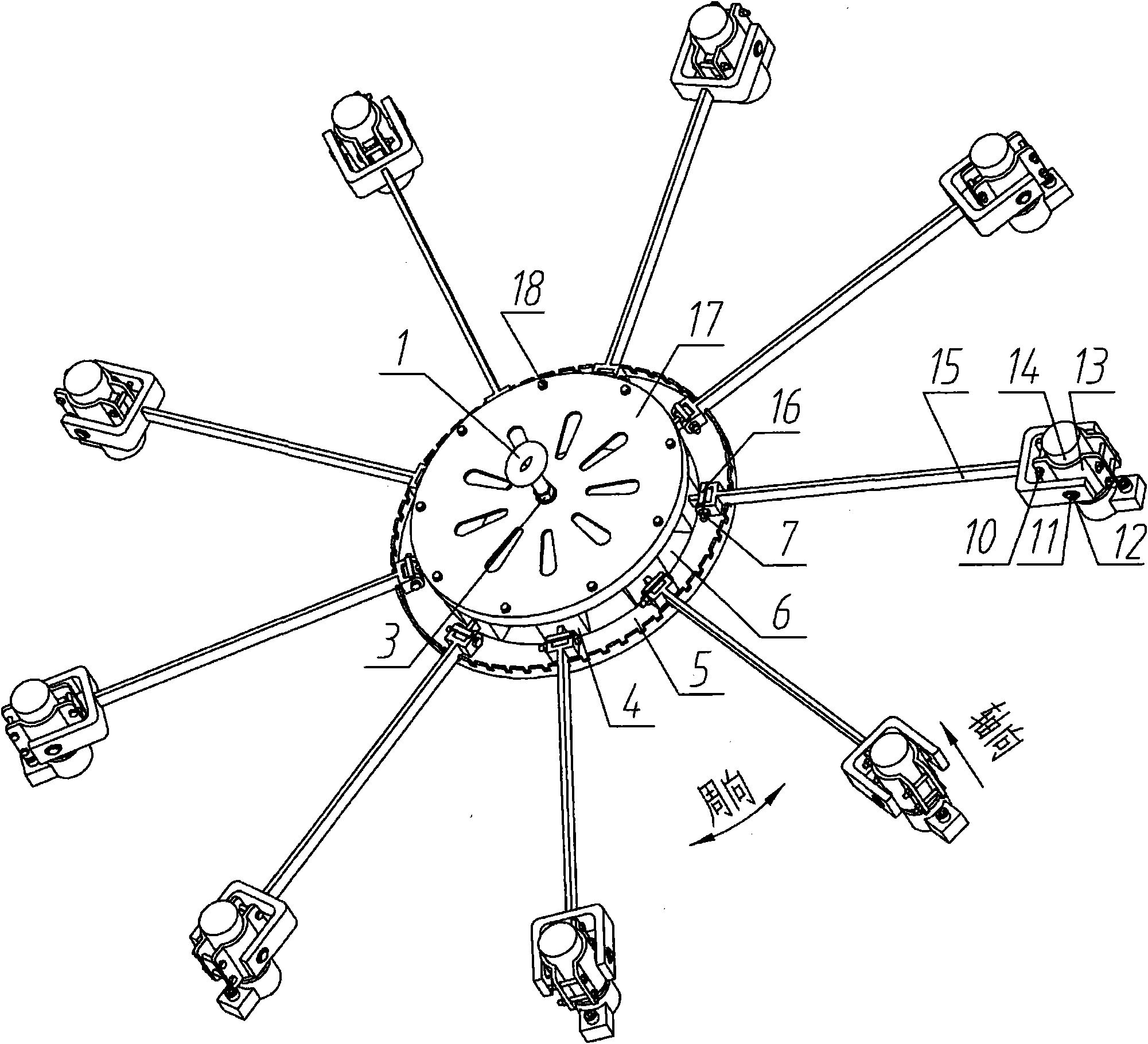

The invention relates to a NC machine tool for machining large-scale curve bevel gear, characterized in that the machine body is set in T-shape in horizontal direction and the workpeice shaft is changed into vertical placement; tool seat, which can adjust space attitude, is used to adjust the angle among the machine spindle, cutting tool and workpeice to realize the machining for large-scale curve bevel gear. The invention solves problems that when prior machine tool is used to machine large-scale curve bevel gear difficulties of installing, clamping, locating and aligning exists; rigidity and stability of machine tool is lack; the machining accuracy can not be improved; the machine tool is provided with big space dimension, heavy weight and difficult manufacture. The machine tool in invention is characterized in that it have X, Y, Z, A, B, C, W moving axes; it can realize seven-axis six linkage control or seven-axis seven linkage control under the control of computer; the workpeice on the machine tool is set smoothly; installing and aligning are convenient; the machine tool with big machine rigidity and good stability can improve gear processing accuracy; it is provided with compact machine structure and small occupied area to conquer defects of prior machine tool.

Owner:林杨

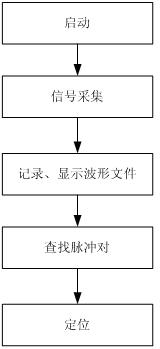

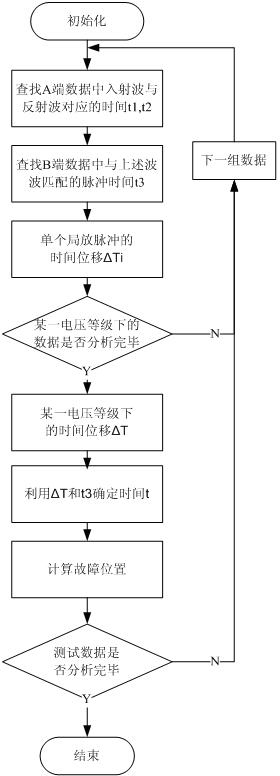

Recognition and location method of oscillatory wave partial discharge in asynchronous double-ended power cable

ActiveCN102288883ANo timing errorEliminate interferenceTesting dielectric strengthData acquisitionEngineering

The invention discloses an oscillation wave partial discharge identifying and positioning method for an asynchronous double-end power cable. The method disclosed by the invention comprises the following specific steps: respectively installing oscillation wave partial discharge signal acquisition devices at the two ends of the cable; obtaining the voltage and partial discharge capacity signals at the two ends of the detected cable through data acquisition; recording and converting the corresponding data to obtain a waveform file which is needed for failure positioning; calling a partial discharge positioning algorithm to carry out the failure positioning; and computing the accurate position of a failure point generating partial discharge signals. The positioning analysis result obtained by the invention is more accurate; the error rate is small; the wave velocity does not need to be known, thereby reducing the errors caused by computing the wave velocity; the excessive manual intervention is needed; the problems of large data quantity, inaccuracy in positioning and the like because different pulses under the voltage of each experiment are matched are avoided; and the rapid and accurate failure positioning course of the method is beneficial to the timely repair of faulty lines and the reduction of loss caused by power failure.

Owner:广州安电测控技术有限公司

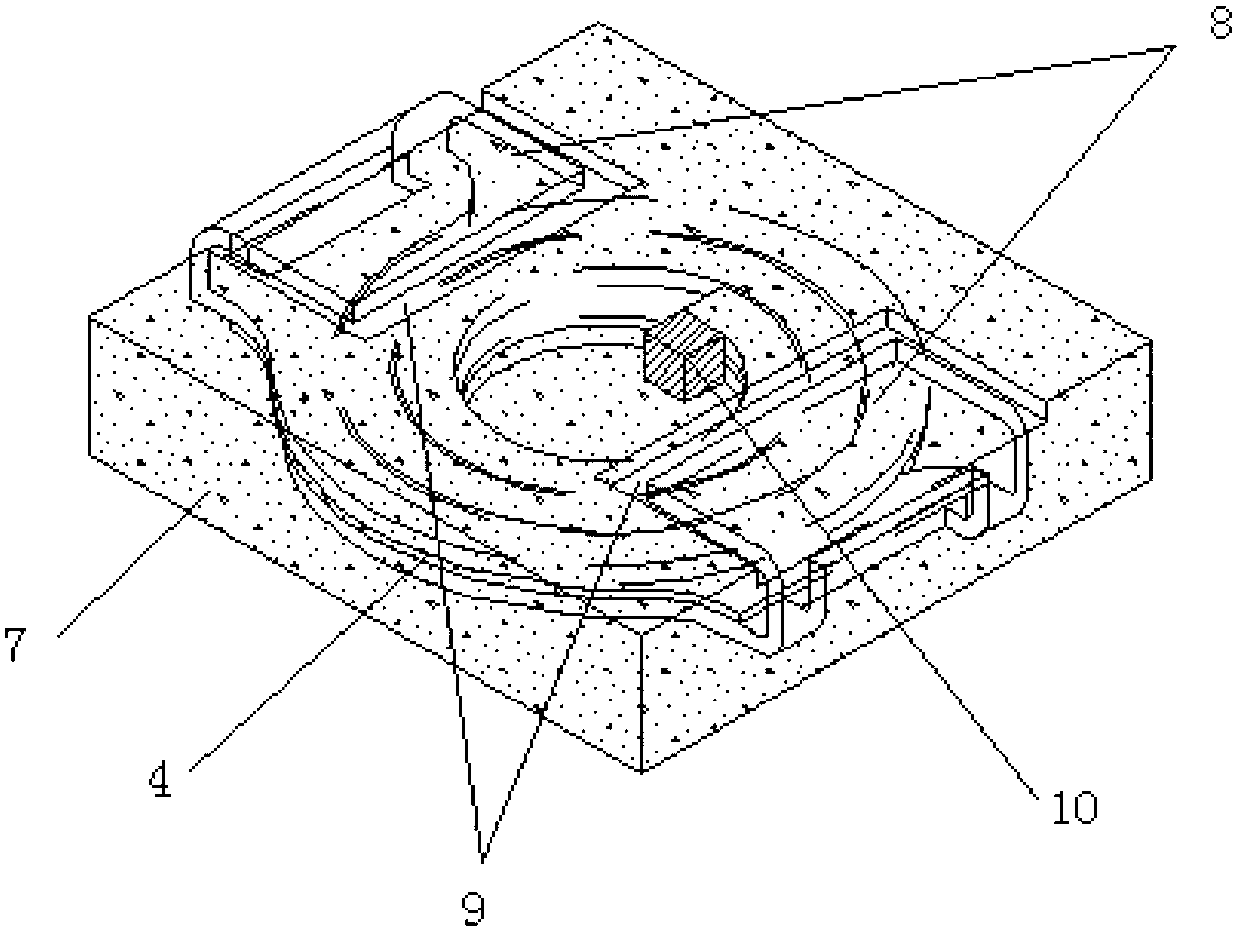

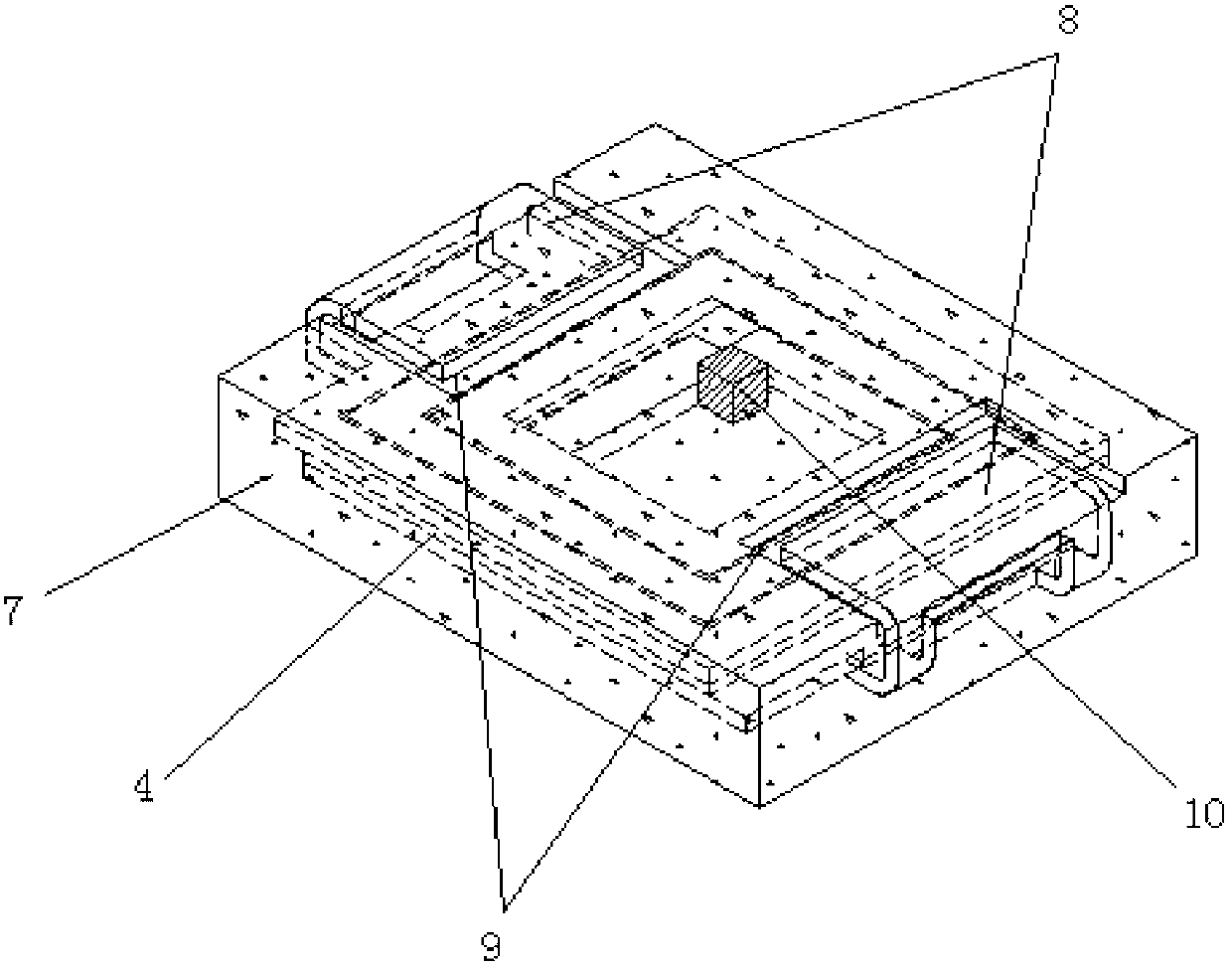

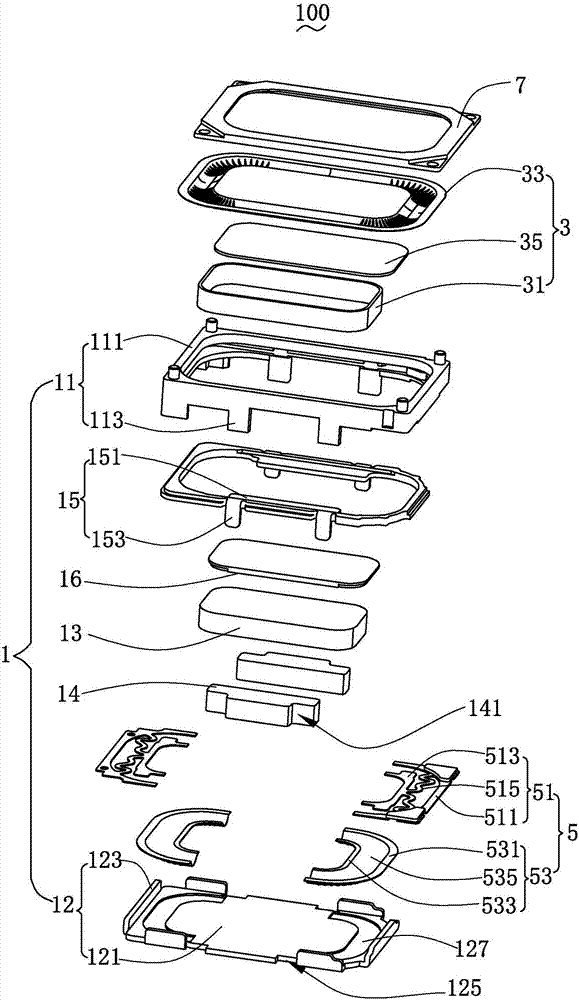

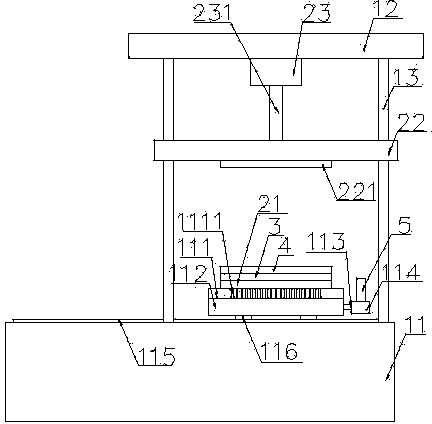

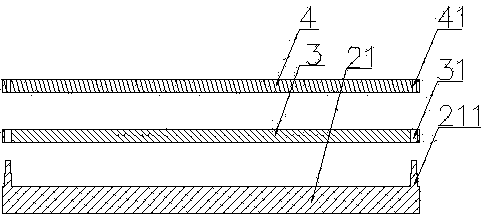

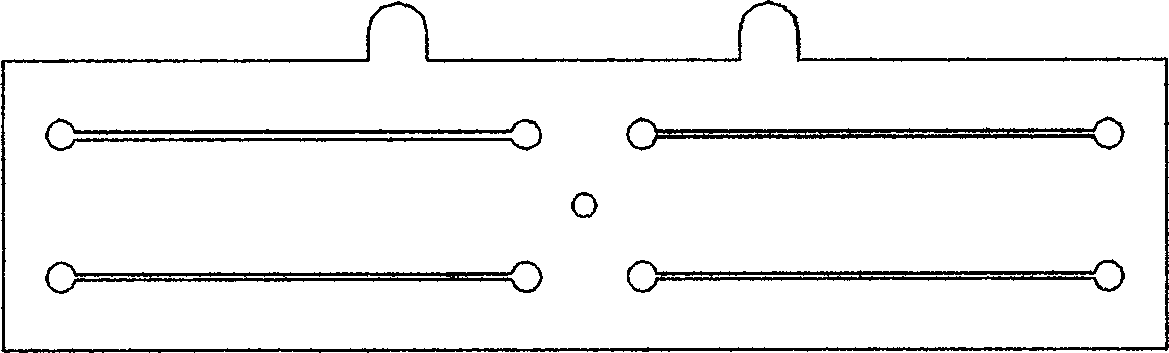

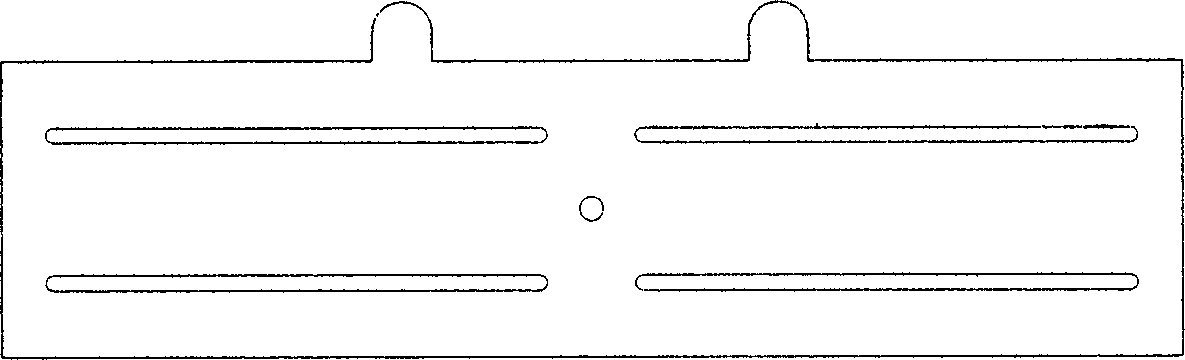

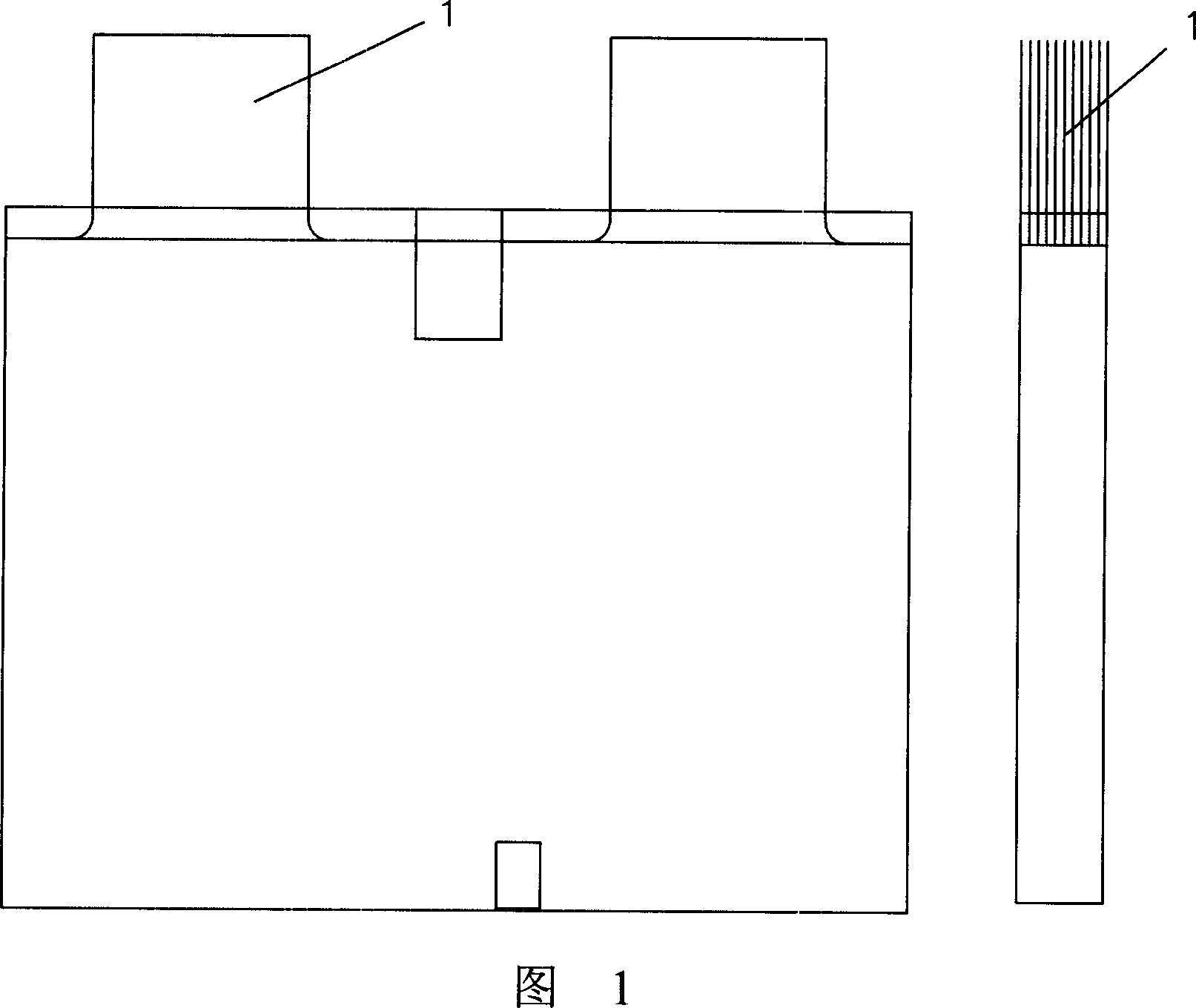

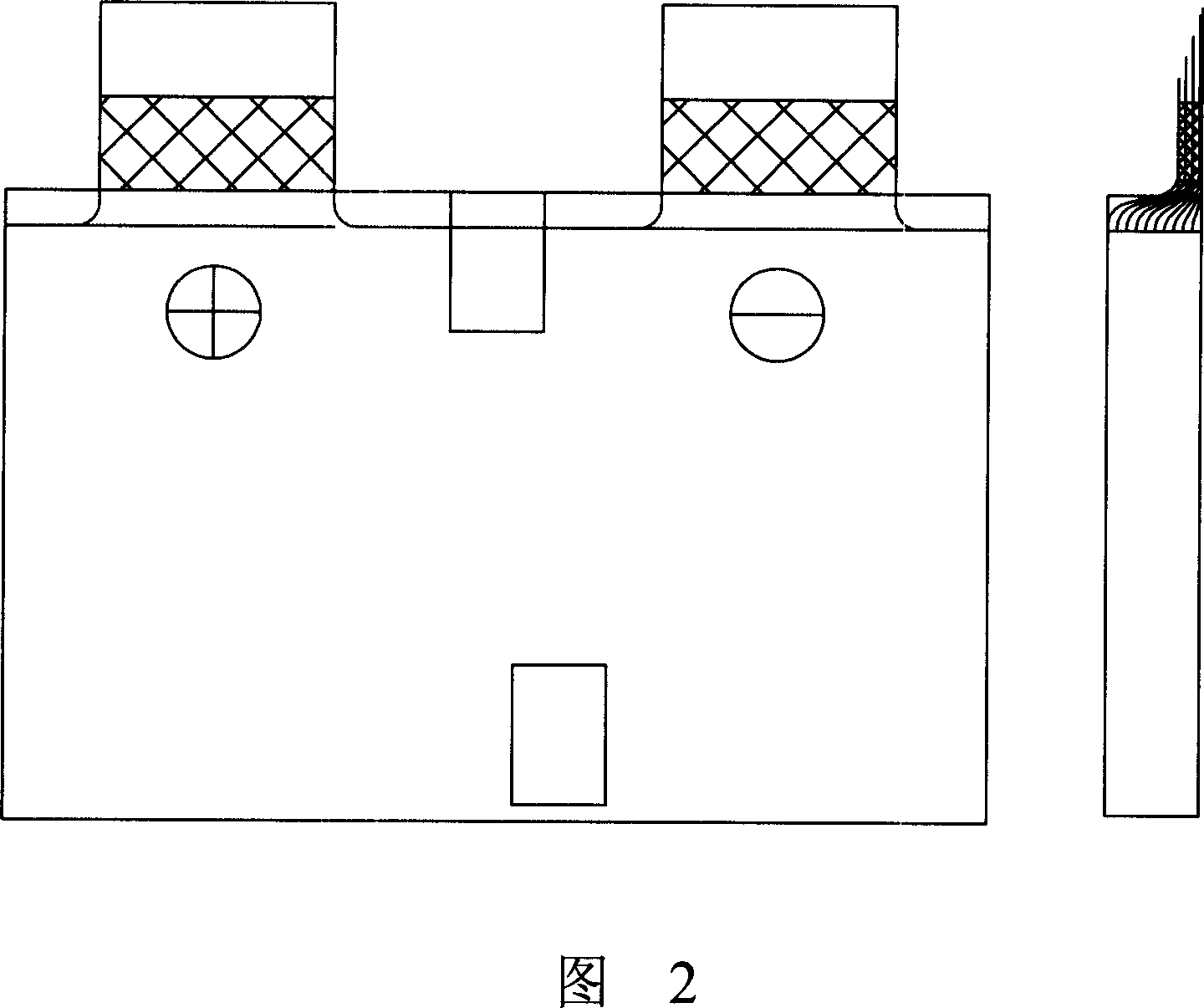

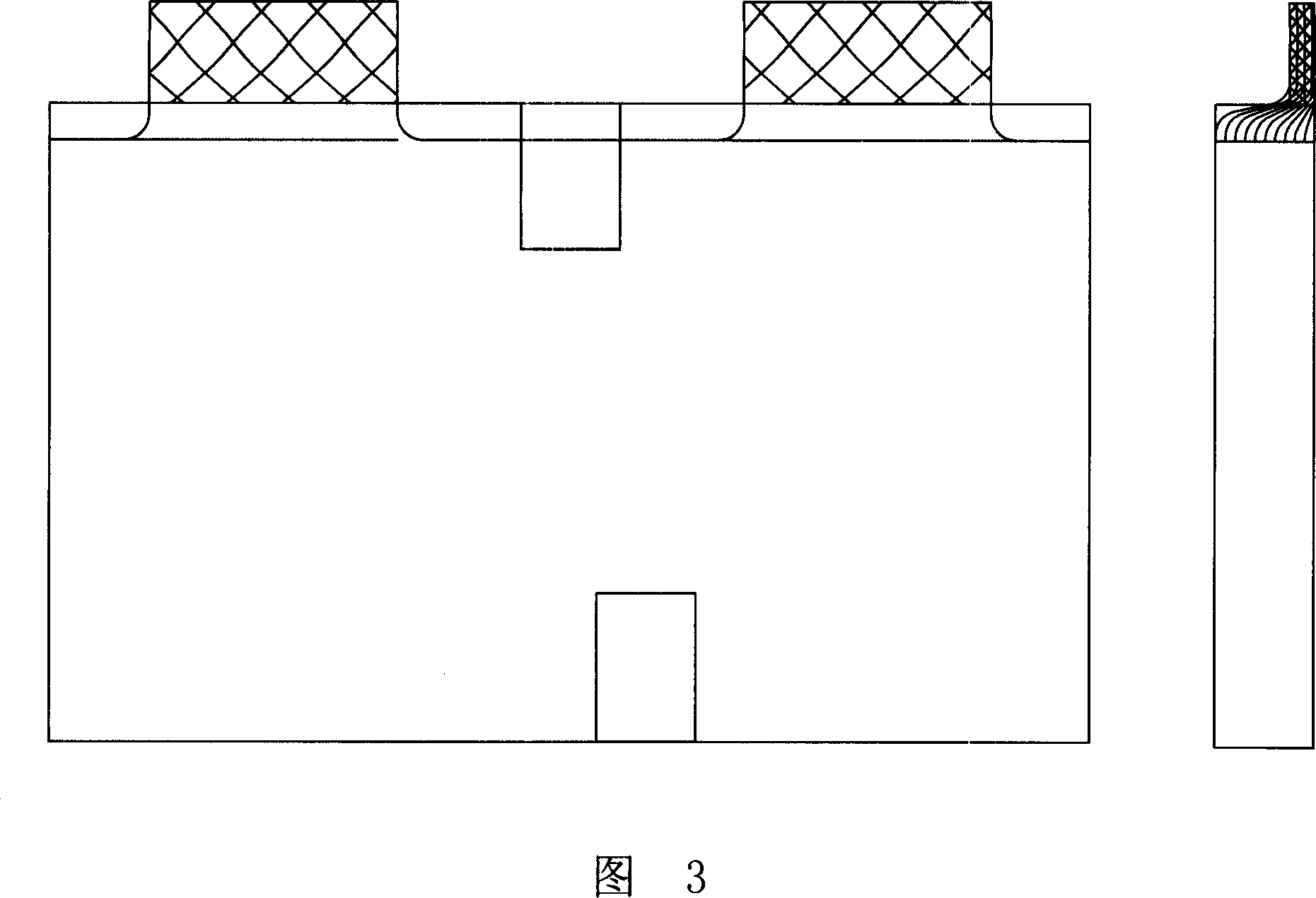

Inductance coil and laser-cutting manufacturing method of inductance coil

InactiveCN103280298AReduce negative impactOvercome immobilityTransformers/inductances coils/windings/connectionsWelding apparatusLaser cuttingLaser light

The invention provides an inductance coil and a laser-cutting manufacturing method of the inductance coil. The inductance coil comprises an upper copper foil coil, a lower copper foil coil, a heat-resistant organic thin film and magnetic material layers, wherein the outer surface of the upper copper foil coil and the outer surface of the lower copper foil coil are provided with insulating coatings for insulating treatment, the heat-resistant organic thin film is arranged between the upper copper foil coil and the lower copper foil coil, and the magnetic material layers wrap the periphery of the upper copper foil coil and the periphery of the lower copper foil coil. Coil patterns of the upper copper foil coil and the lower copper foil coil are formed through cutting by a laser light source. The insulating coatings are heat-resistant coatings. The magnetic material layers are formed through compression molding, and a magnetic material is iron metal alloy soft magnetic powder. The laser-cutting manufacturing method comprises laser cutting on the upper copper foil coil, the lower copper foil coil and the heat-resistant organic thin film. The inductance coil is formed by copper foil in a laser-cutting mode, parameters including line width, thickness, distance between lines, coil center pillars and the like can be adjusted to form the coil patterns on normal positions, and target characteristic specifications can be designed quite easily. The inductance coil and the laser-cutting manufacturing method of the inductance coil overcome the shortcomings that an existing inductance coil is difficult to fix and loses efficacy in an open circuit and a short circuit, and end electrodes are difficult to design, and better accord with the development tendency that a power inductor is small, thin and low in cost.

Owner:SHENZHEN SUNLORD ELECTRONICS

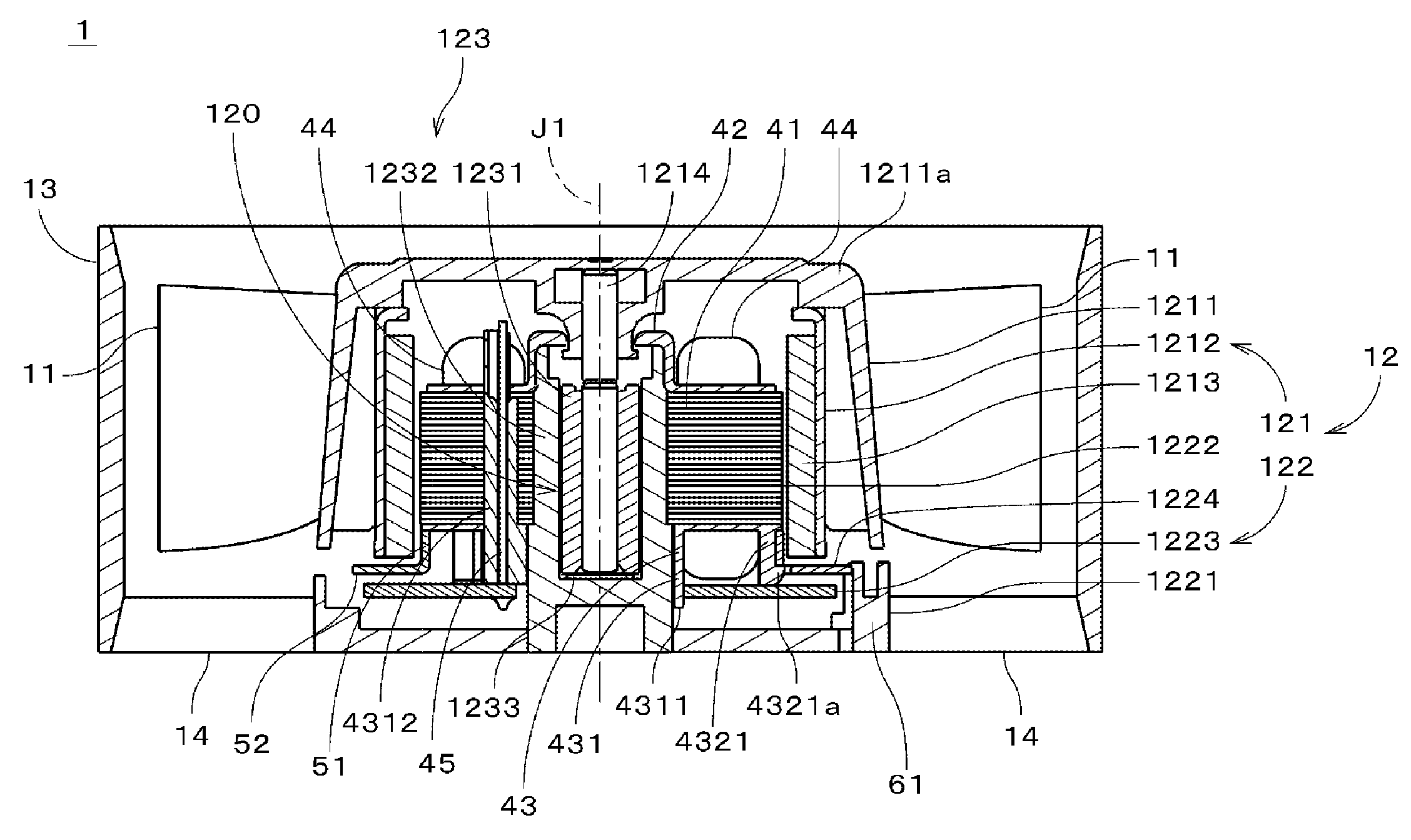

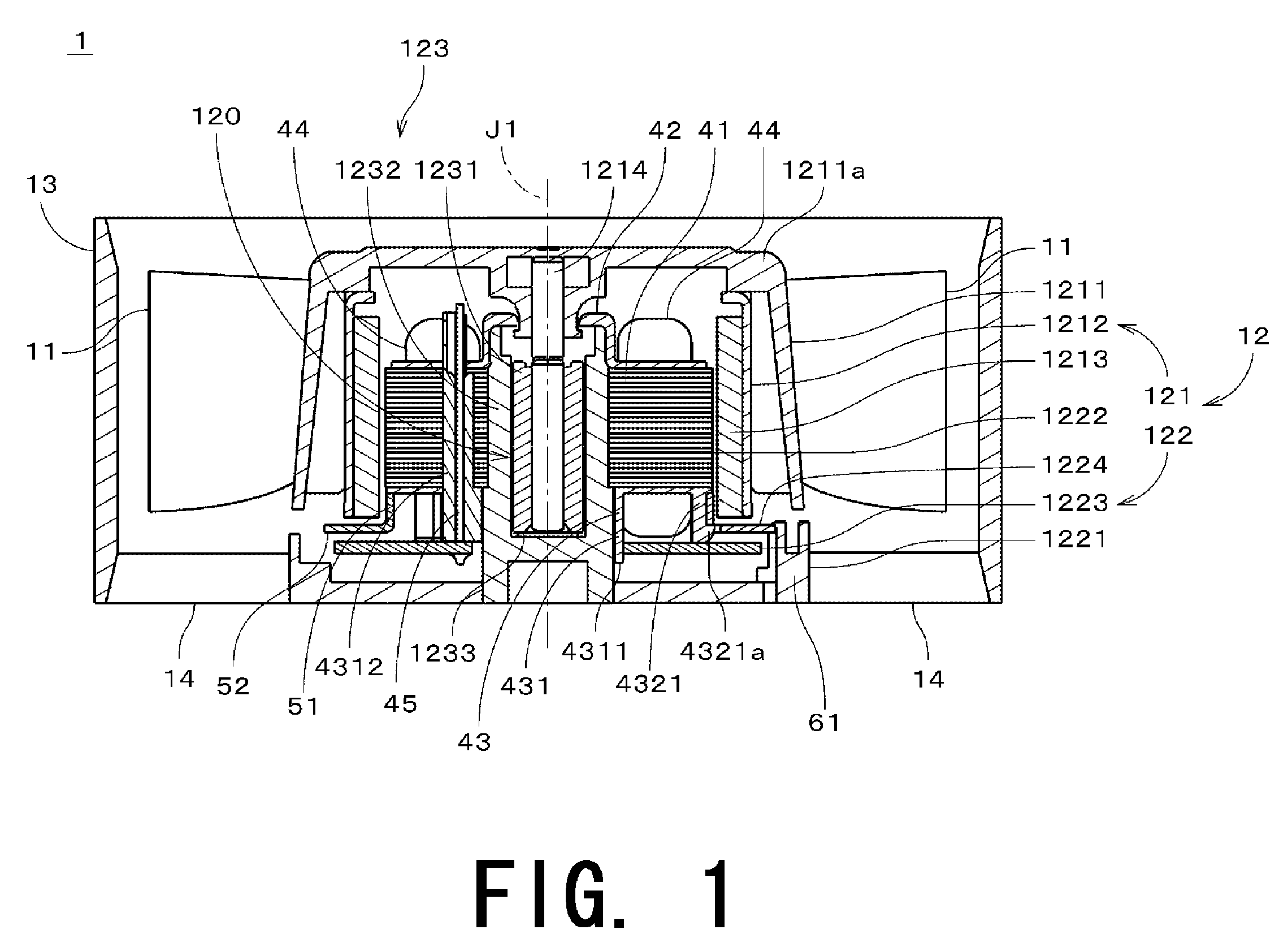

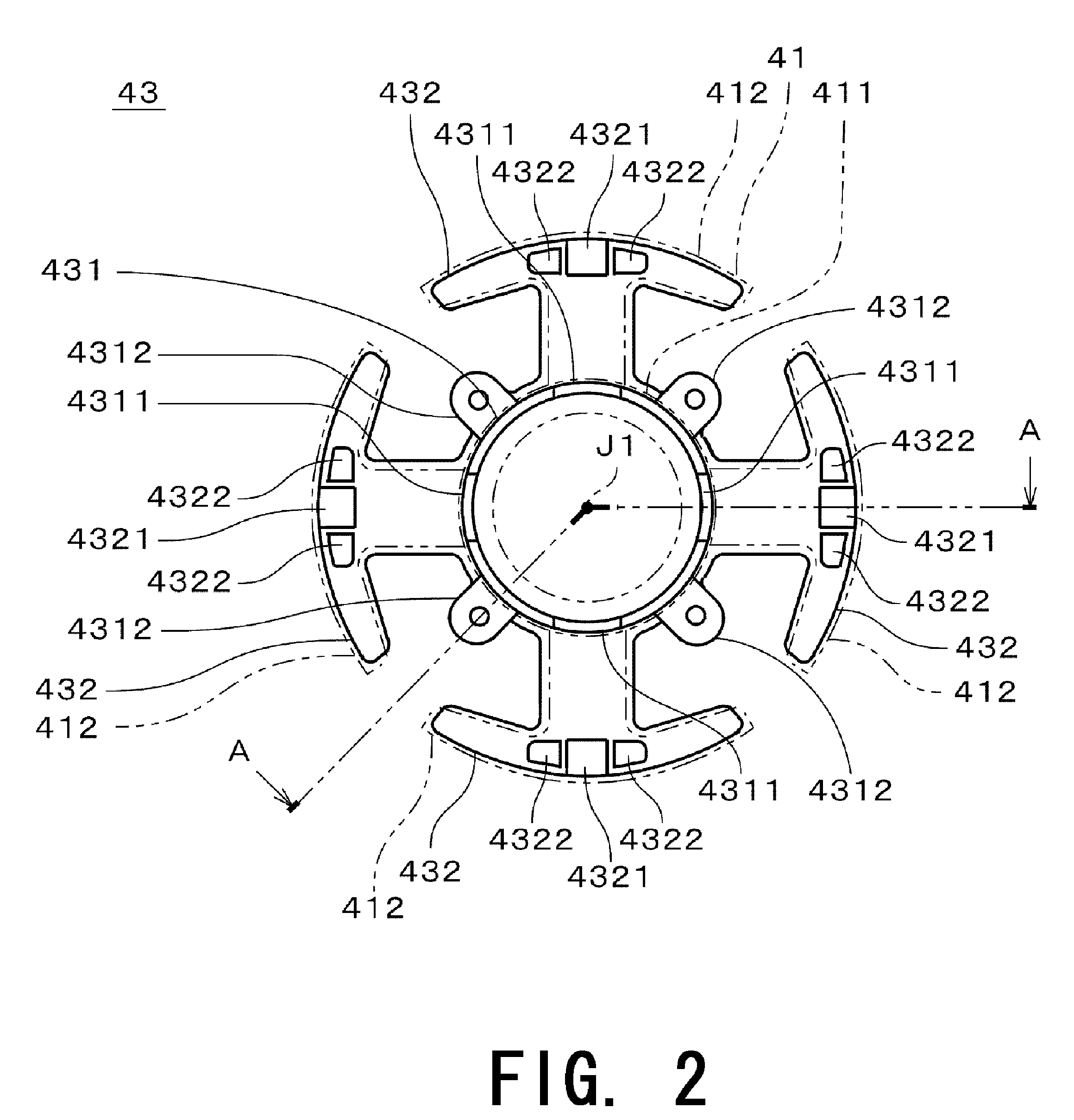

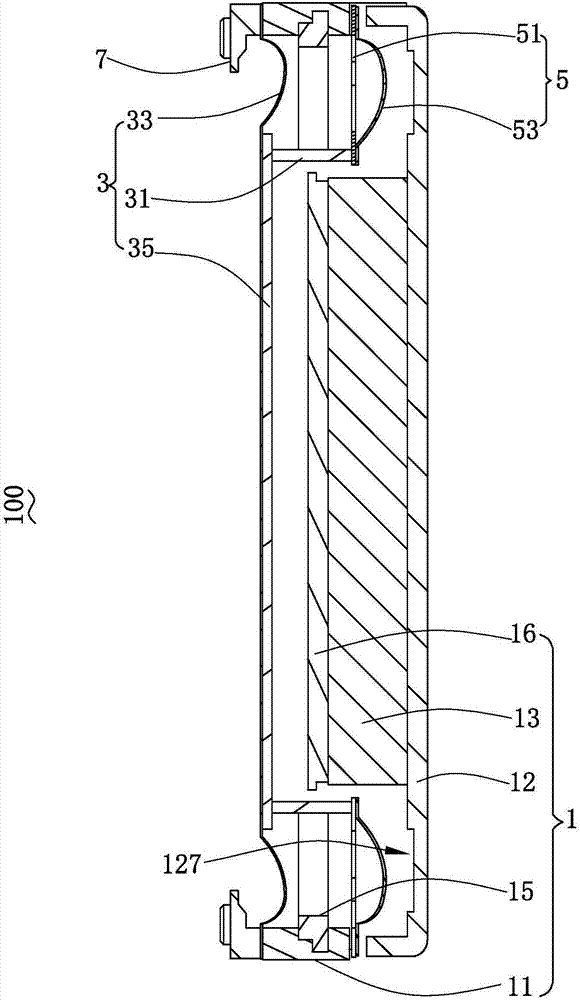

Motor and fan apparatus having the motor

ActiveUS20090285699A1Easy to locatePrecise positioningMagnetic circuit rotating partsPiston pumpsStatorMagnet

An electric motor includes a stator portion, a rotor portion, and a bearing mechanism, wherein the rotor portion includes a rotor holder having a substantially cylindrical shape with a closed end, and a field magnet fixed to an inner circumference of the rotor holder; the stator portion includes a stator, a base portion to which the stator is fixed, and a magnetic member; and the magnetic member includes a cylindrical portion having a substantially cylindrical shape into which a lower end portion of an insulator of the stator is inserted, the lower end portion being a portion of an outer portion of the insulator and opposing the base portion, and a flat portion having a substantially annular shape which spreads outwardly in a radial direction from a lower edge of the cylindrical portion and opposes a lower edge of the field magnet.

Owner:NIDEC CORP

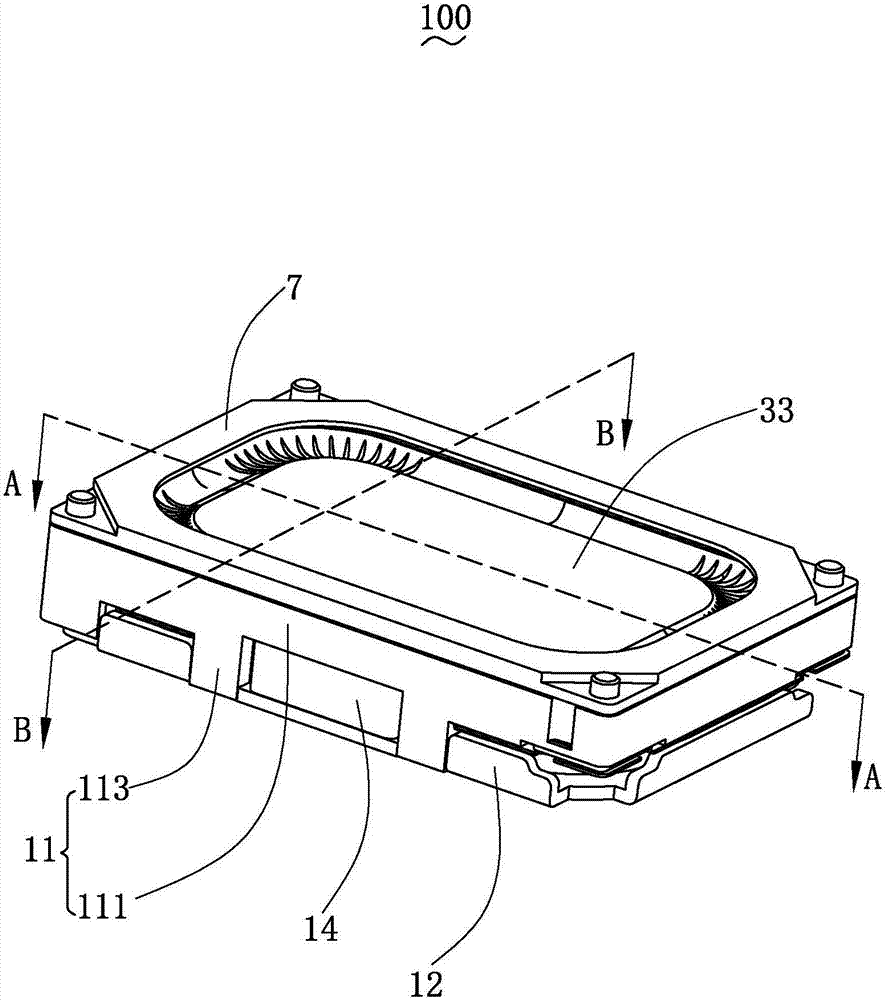

Loudspeaker

ActiveCN107277706AEffective protectionHigh strengthLoudspeakersNon-planar diaphragms/conesEngineeringLoudspeaker

The invention discloses a loudspeaker. The loudspeaker comprises a fixing system and a vibration system, the fixing system comprises a basin frame, a lower clamp board which forms an accommodating space with the basin frame, main magnetic steel which is arranged in the accommodating space and is arranged on the lower clamp board, auxiliary magnetic steel which forms magnetic gaps with the main magnetic steel, and an upper clamp board which is arranged on the auxiliary magnetic steel and fixed with the basin frame. The upper clamp board fixes the auxiliary magnetic steel in the accommodating space. The upper clamp board comprises a body corresponding to the auxiliary magnetic steel in shape, and multiple bending parts extending from the body toward the lower clamp board. The outer sides of the auxiliary magnetic steel recess to form avoidance parts corresponding to the bending parts, and the bending parts pass through the avoidance parts. In the speaker provided by the present invention, the auxiliary magnetic steel is sandwiched between the body and the lower clamp board, and is positioned by the bending parts, so that the magnetic circuit structure can be effectively protected when the product falls.

Owner:AAC TECH PTE LTD

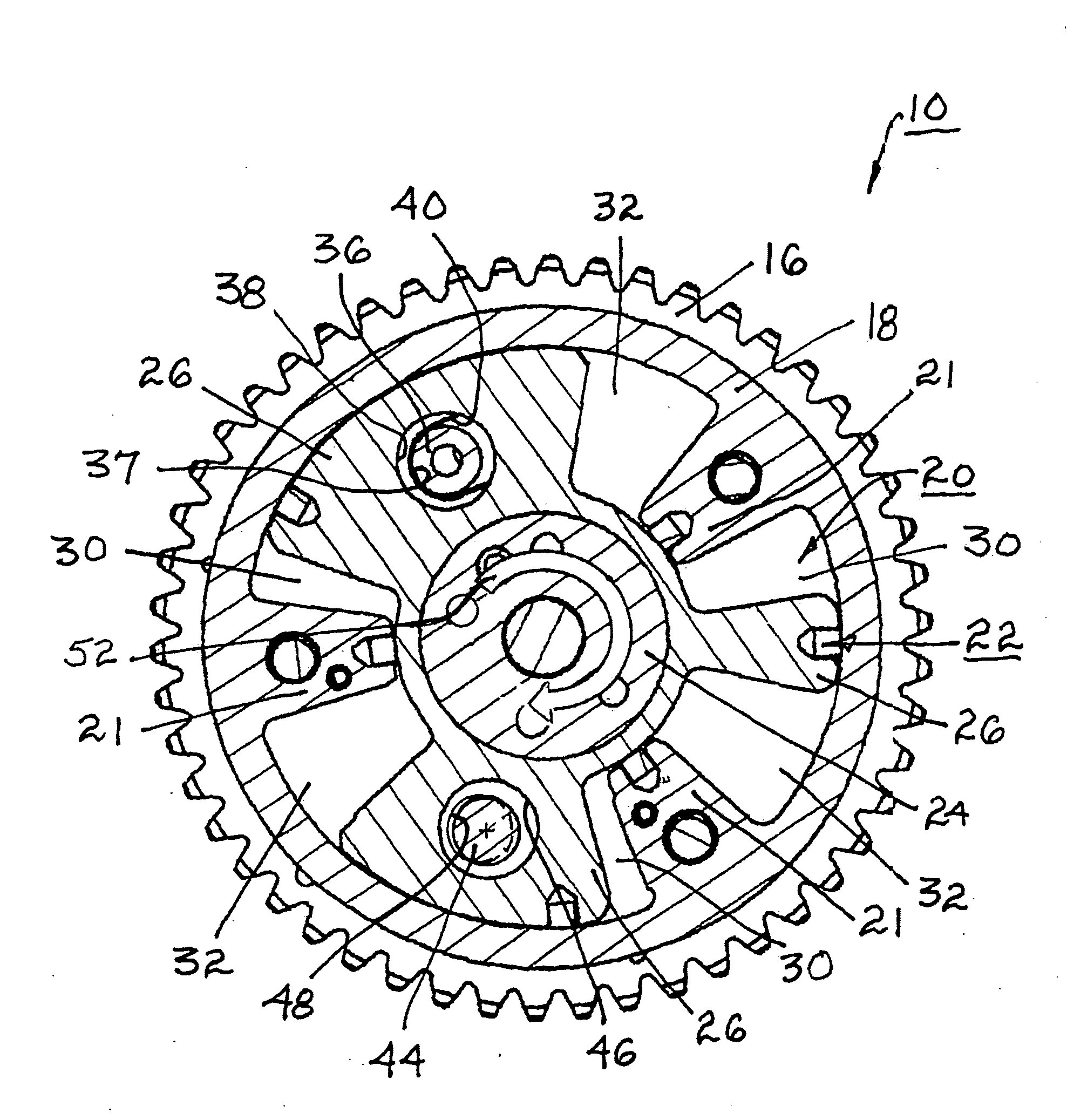

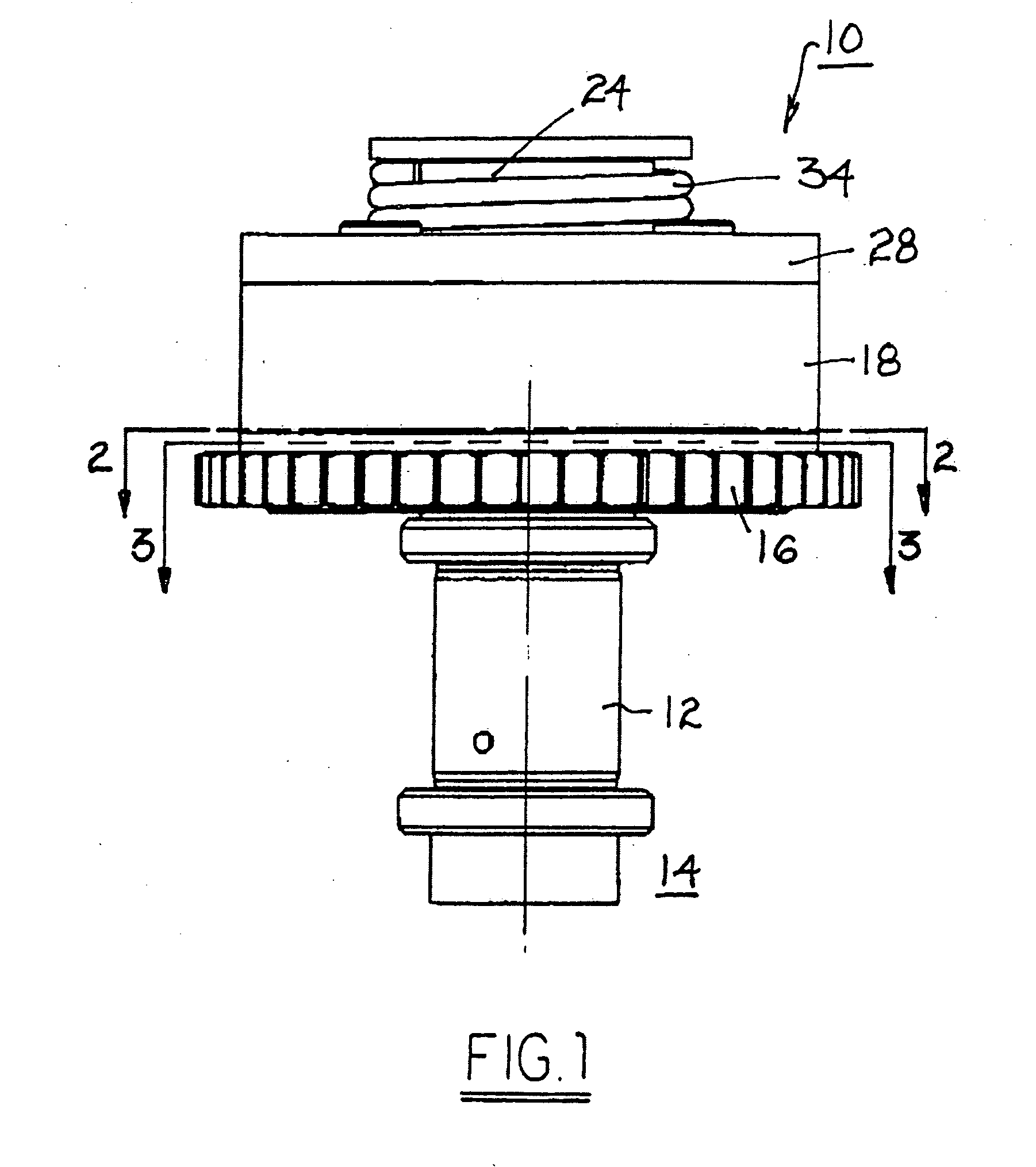

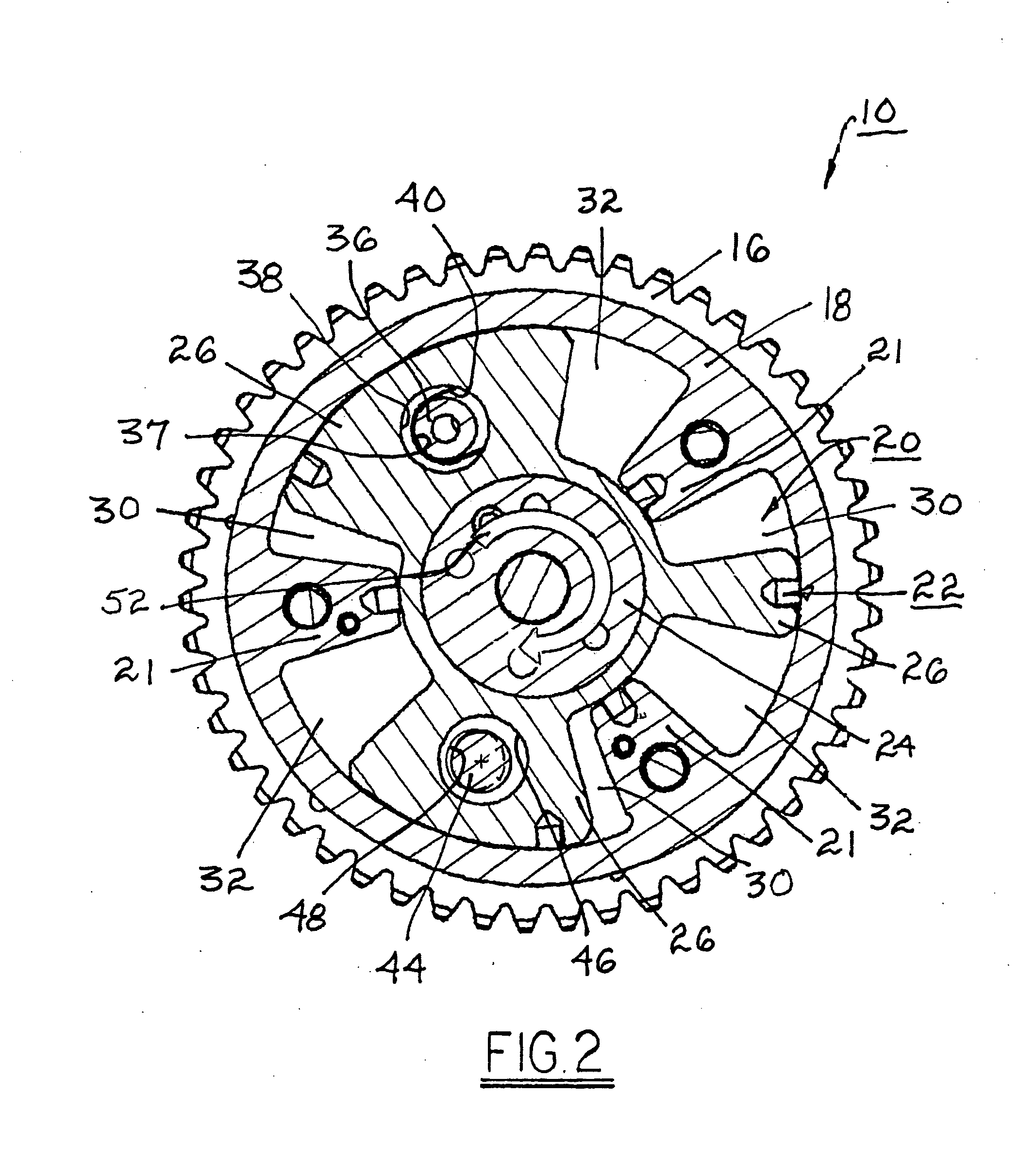

Vane-type cam phaser having staged locking pins to assist intermediate position locking

ActiveUS20090266322A1Reduce manufacturing costEasy to locateYielding couplingValve drivesMajor and minorStator

A vane-type camshaft phaser including a bias spring to urge the rotor toward an intermediate locking position from any rotational position retarded of the locking position. The rotor comprises non-coaxially acting primary and secondary locking pins for mating with primary and secondary locking pin seats in the phaser stator. The primary seat is elongated and is readily located by the primary locking pin to provide a first limit to the rotor phase angle authority in the retard direction. Camshaft torque reversals cause the rotor phase angle to dither. With each torque reversal the secondary locking pin passes over its seat, allowing multiple opportunities for re-engagement. The clearance of the secondary locking pin to its seat defines the rotary lash in the phaser.

Owner:DELPHI TECH IP LTD

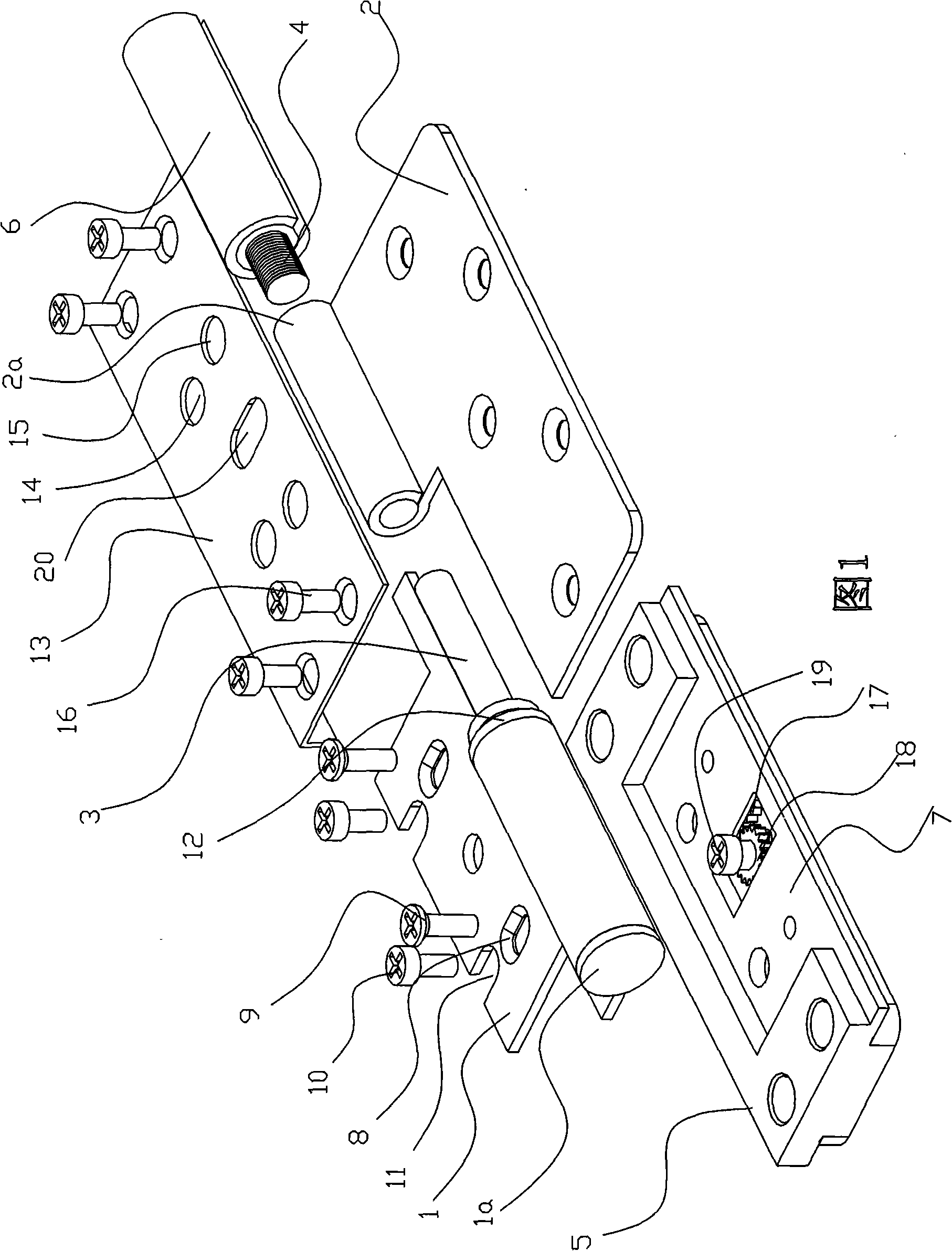

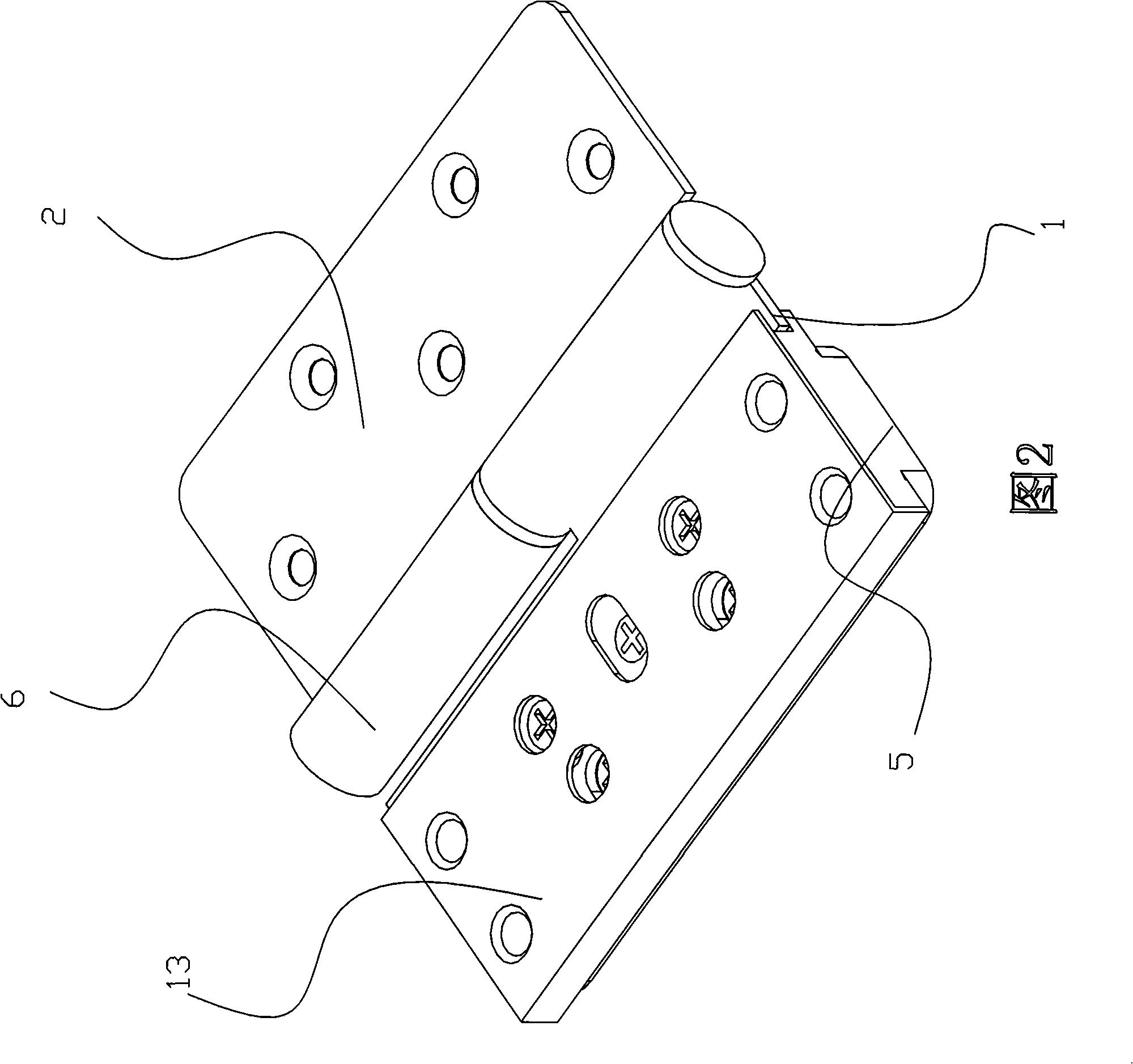

Multidimensional regulation hinge

InactiveCN101255779ALarge amount of adjustmentEasy to locatePin hingesAgricultural engineeringScrew head

A multidimensional adjusting hinge comprises a frame leaf fixed on the doorframe, a door leaf fixed on the door, a rotating axle connecting the frame leaf and the door leaf together, an adjusting screw which is screw-connected on the axle sleeve of the frame leaf or the axle sleeve of the door leaf, and a fixing block which is provided below the frame leaf or the door leaf. The frame leaf or the door leaf is fixed on the door through the fixing block. The invention is characterized in that the axle sleeve of the frame leaf or the axle sleeve of the door leaf which is provided with an adjusting screw is sleeved with a protecting cover. The fixing block is provided with a groove matched with the frame leaf or door leaf. The frame leaf or door leaf is provided with a screw adjusting groove. The fixing screw traverses the screw adjusting groove and fixes the frame leaf or door leaf on the fixing block. The fixing block is provided with a front-and-back adjusting screw traversing the fixing block. The frame leaf or the door leaf corresponding with the front-and-back adjusting screw head is provided with a groove hole. Compared with the existing technique, the invention has the advantages of large adjusting amount of the front and back distance between the frame leaf and the door leaf, clearance which is between the axle sleeve of the frame leaf and the axle sleeve of the door leaf and is not adjusted by the upper and lower distance of the frame leaf and the door leaf, and easy accurate locating when the transverse distance between the left-and-right adjusting block and the door leaf is adjusted.

Owner:刘国德

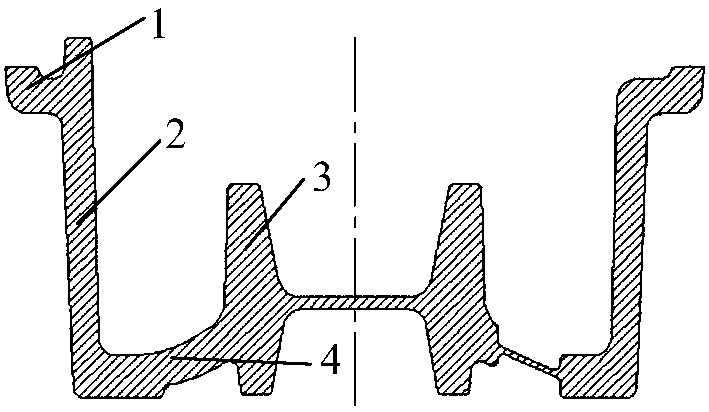

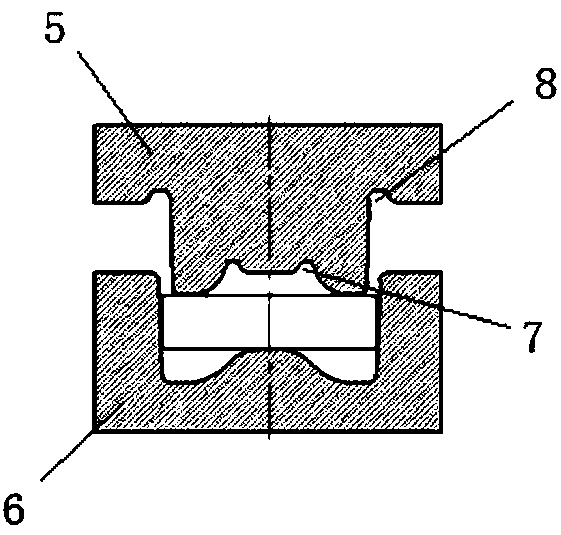

Forging method of thin-wall deep cavity airplane hub die forge piece

ActiveCN108580778APrevents scratches and foldsEasy to locateForging/hammering/pressing machinesWheelsAirplaneThin walled

The invention discloses a forging method of a thin-wall deep cavity airplane hub die forge piece. The forging method comprises a pre-forging method and a final forging method. According to the pre-forging method, a pre-forging die adopted in the method comprises a pre-forging upper male die and a pre-forging lower female die, the depth of the pre-forging lower female die is the same with the depthof a lower female die of a thin-wall deep cavity airplane hub final forging die, the bottom end of the pre-forging lower female die is of a boss structure drawing down from bottom to top, a round groove is formed in the lower surface of the pre-forging upper male die, an annular groove is formed in the edge of the bottom face of the round groove, an annular concave pit is arranged on the outer side of a pre-forging upper male die cavity, bottom surfaces of the annular concave pit and the annular groove are arc, the inclination angle of the outer wall of the pre-forging upper male die is the same with the inclination angle of the outer wall of the upper male die of the thin-wall deep cavity airplane hub final forging die, and the inclination angle of the inner wall of the pre-forging lowerfemale die is the same with the inclination angle of the inner wall of the lower female die of the thin-wall deep cavity airplane hub final forging die.

Owner:SHANDONG UNIV +1

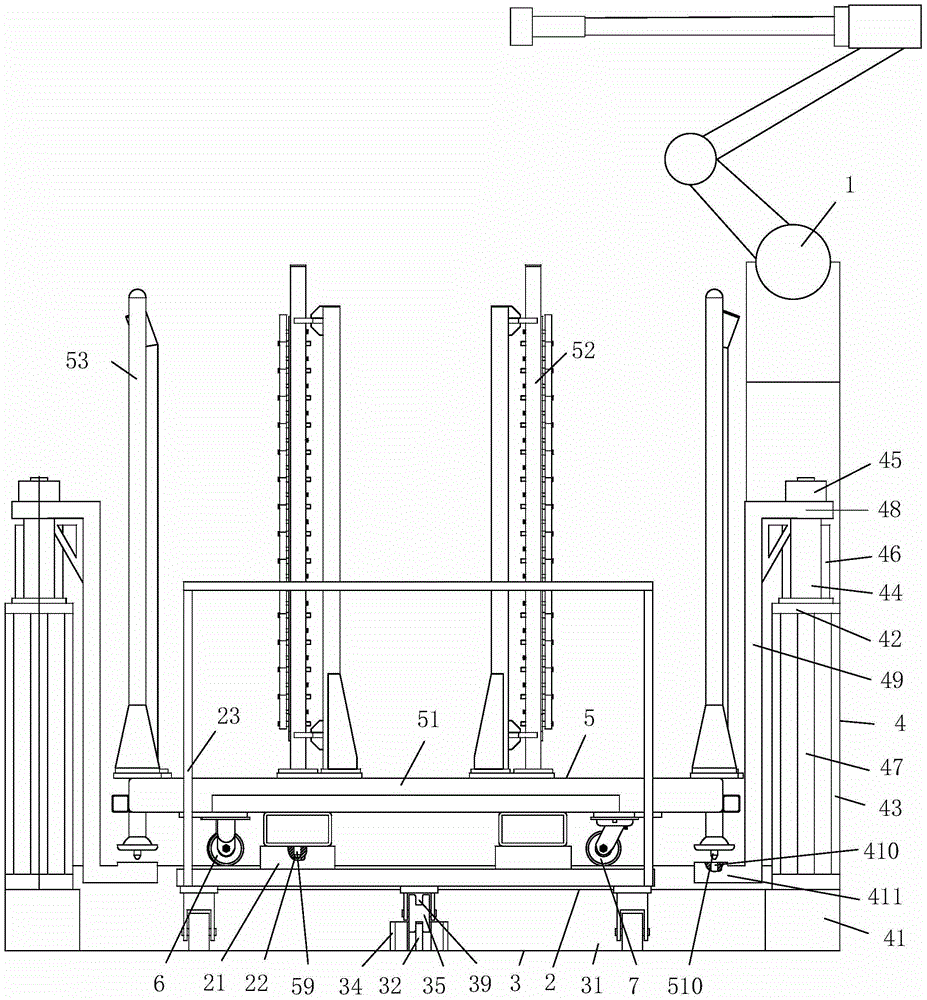

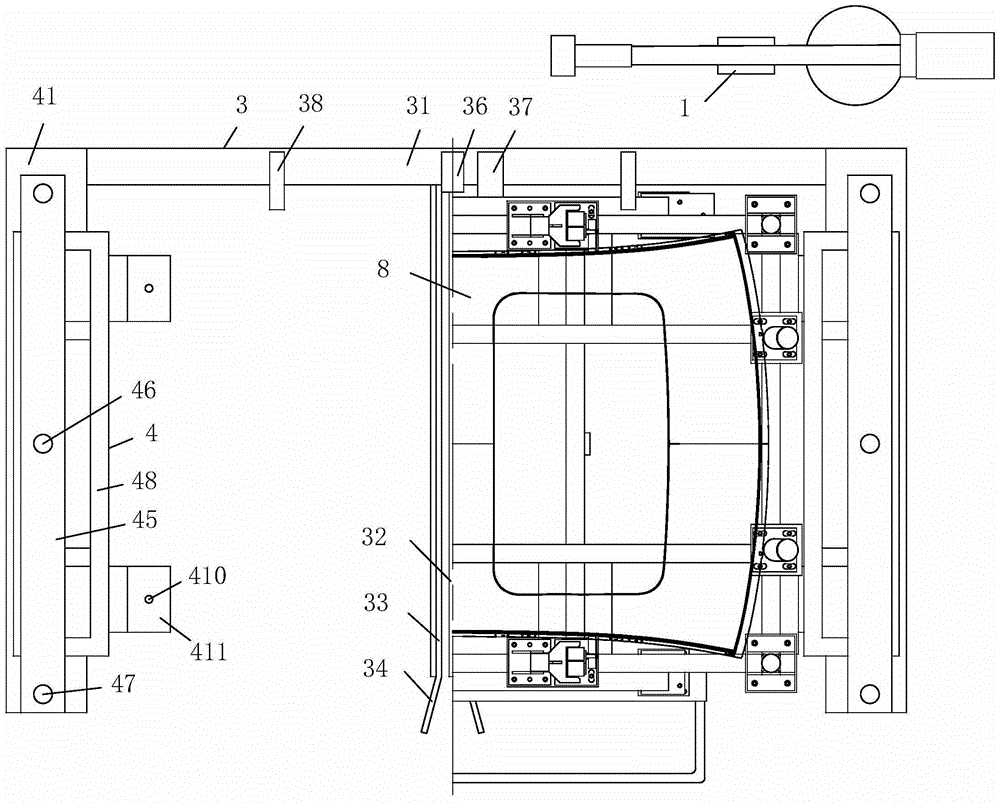

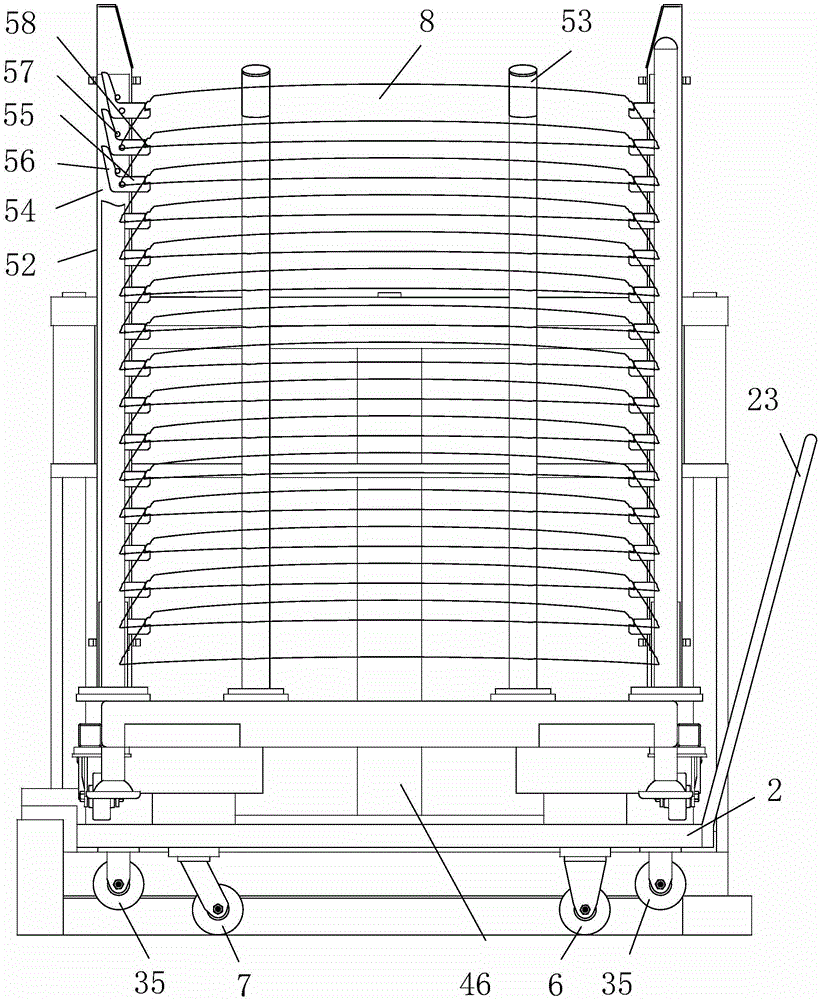

Car body top cover loading device

InactiveCN103909364AEasy to locatePositioning adjustment assistance time is shortWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringRobot

The invention relates to the automotive body manufacturing field, and aims at providing a car body top cover loading device. The car body top cover loading device comprises a transfer trolley, a transfer trolley entering locating component, two material shelf lifting mechanisms respectively arranged on two sides of the transfer trolley entering locating component, a material shelf and a loading industry robot. When the car body top cover loading device is used, the material shelf filled with car body top covers is hoisted onto the transfer trolley and positioned, the transfer trolley moves to the transfer trolley entering locating component and is positioned, the loading industry robot grabs the car body top covers one by one, and the car body top covers are welded by a welding robot after the loading industry robot places the car body top covers on car bodies. When around one half of the car body top covers are left on the material shelf, the two material shelf lifting mechanisms drive the material shelf to rise, the loading industry robot continues to grab the car body top covers one by one from the material shelf, and the car body top covers which are left are welded by the welding robot after the loading industry robot places the car body top covers which are left on car bodies. The car body top cover loading device conveniently positions the car body top covers before welding, and is short in positioning adjustment auxiliary time.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

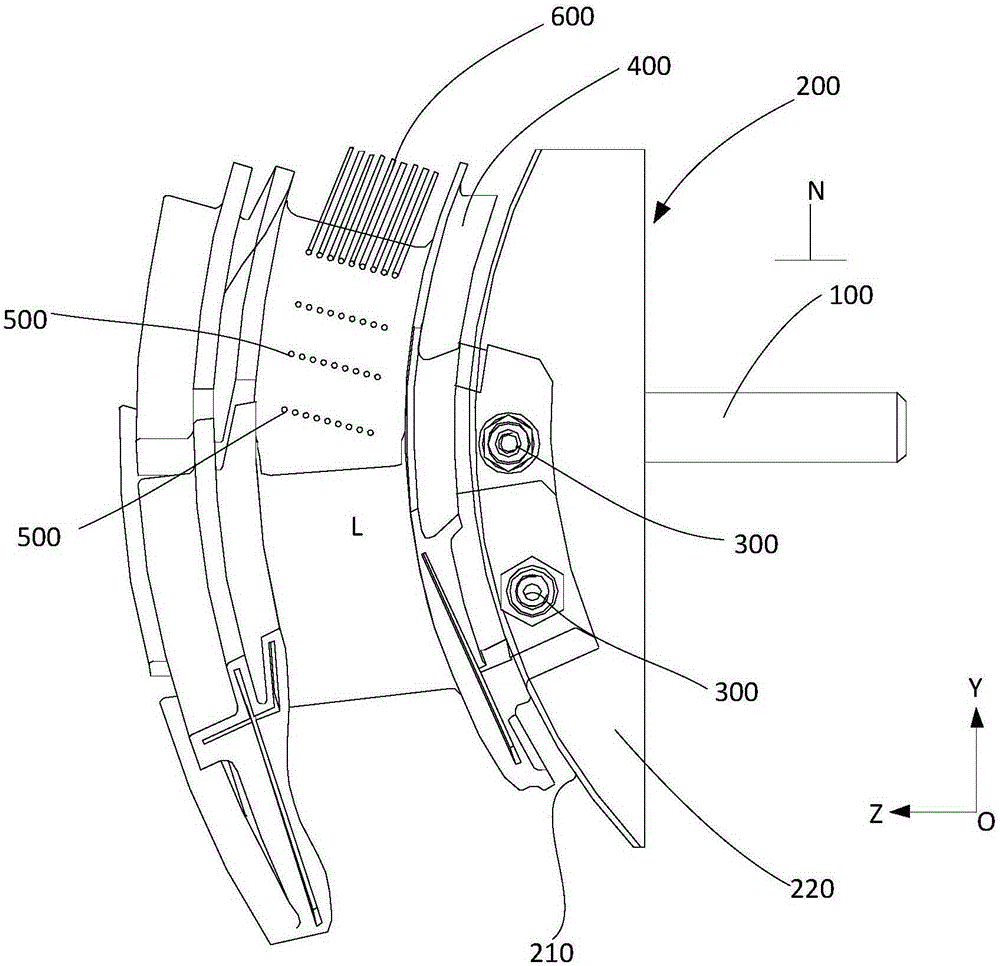

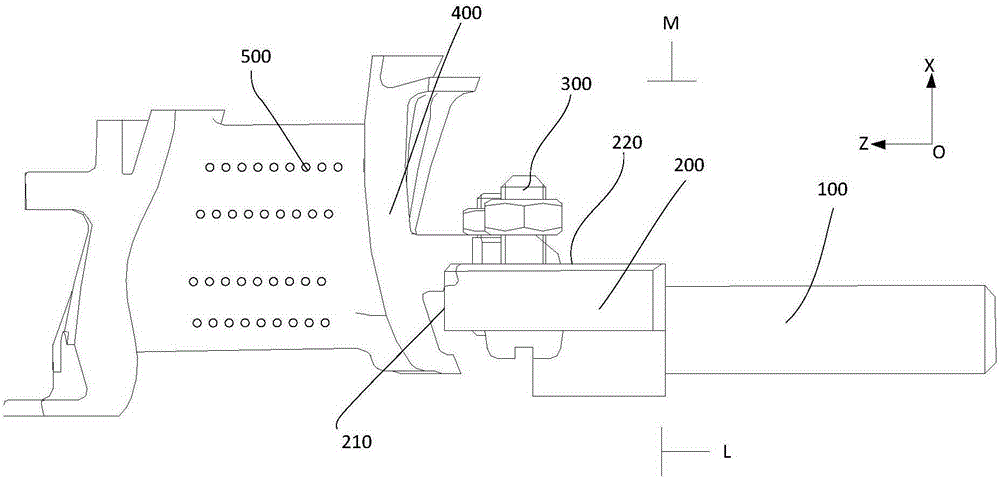

Auxiliary fixture for gas turbine primary guide vanes and film hole measuring method

ActiveCN105180844AEasy to locateEasy to determine the coordinate systemWork holdersUsing optical meansGas turbinesAerospace engineering

The invention discloses an auxiliary fixture for gas turbine primary guide vanes and a film hole measuring method. The auxiliary fixture is used for auxiliary positioning when a gas turbine primary guide vane is measured. The auxiliary fixture comprises a support disk used for assembling a gas turbine primary guide vane and a clamp holder used for clamping the gas turbine primary guide vane. The support disk comprises a flat top face and an end face fitting the outer edge plate of the gas turbine primary guide vane, and one end of the clamp holder is connected to the opposite face of the end face. On one hand, the auxiliary fixture is used as an assembling tool to guide the gas turbine primary guide vane into a composite optical coordinate machine. On the other hand, the clamp holder indicates the center of the stacking shaft of the gas turbine primary guide vane to enable the composite optical coordinate machine to easily find the center of the stacking shaft of the gas turbine primary guide vane and establish a coordinate system and assist the composite optical coordinate machine in positioning. The auxiliary fixture makes a gas turbine primary guide vane positioned easily, facilitates determination of a coordinate system, and makes measurement more convenient.

Owner:CHINA HANGFA SOUTH IND CO LTD

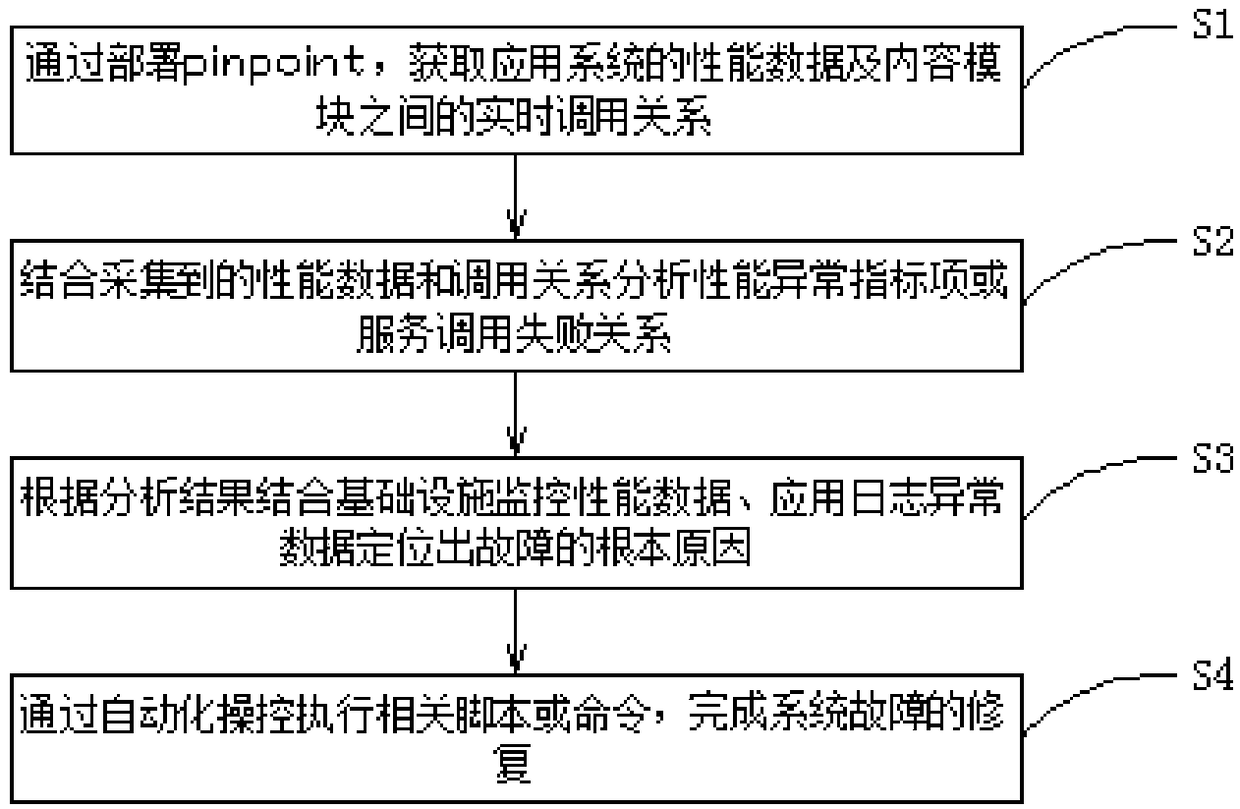

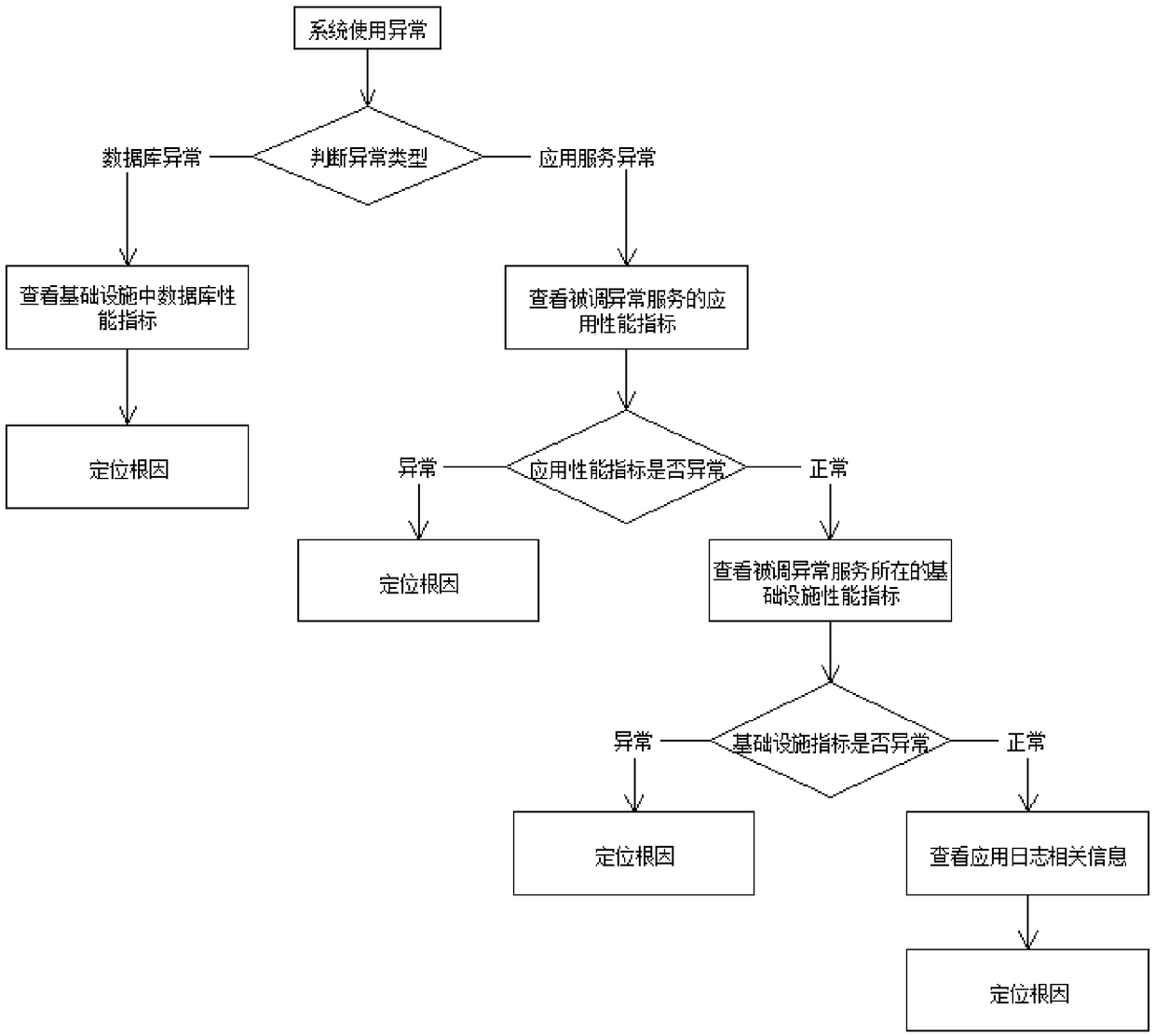

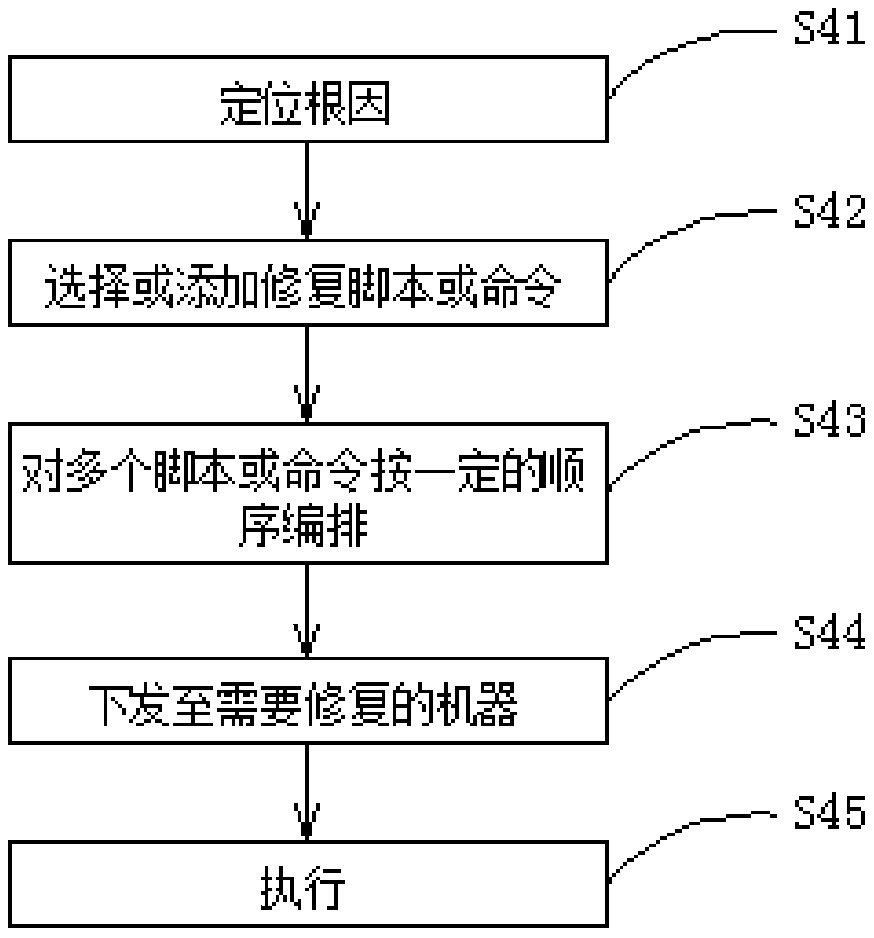

IT system fault diagnosis and repair method, device and apparatus and storage medium

PendingCN109343987AImprove user experience and user perceptionEasy to locateHardware monitoringNon-redundant fault processingInformation technologyUsers perceptions

The invention discloses an IT system fault diagnosis and repair method, device and apparatus and a storage medium, belonging to the technical field of information technology and a user interface. Themethod comprises the following steps of obtaining the performance data of an application system and the real-time calling relationship between the content modules by deploying pinpoint; combining thecollected performance data and invocation relationship, analyzing the performance exception index item or service invocation failure relationship; according to the analysis results, combining with theperformance data of infrastructure monitoring, locating the root cause of the fault by using abnormal data of log; completing the repair of the system failure by automating the execution of relevantscripts or commands. The technical proposal of the example of the invention solves the problem that the existing application monitoring method can only monitor the relevant performance parameters of the application, can not locate the fault, and can not realize self-repair to the fault, effectively improves the user experience and the user perception, lightens the user workload, and greatly improves the operation and maintenance efficiency.

Owner:USTC SINOVATE SOFTWARE

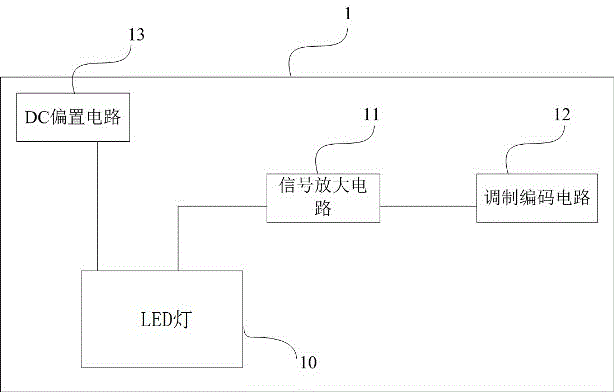

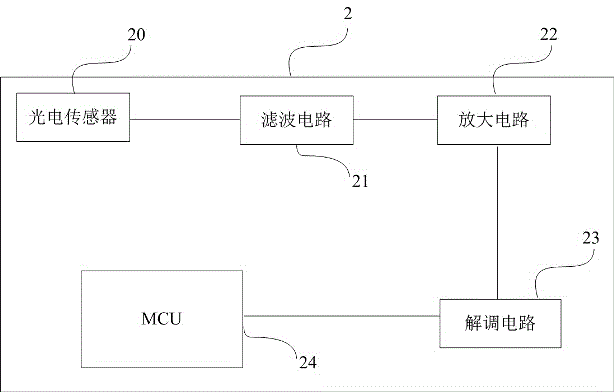

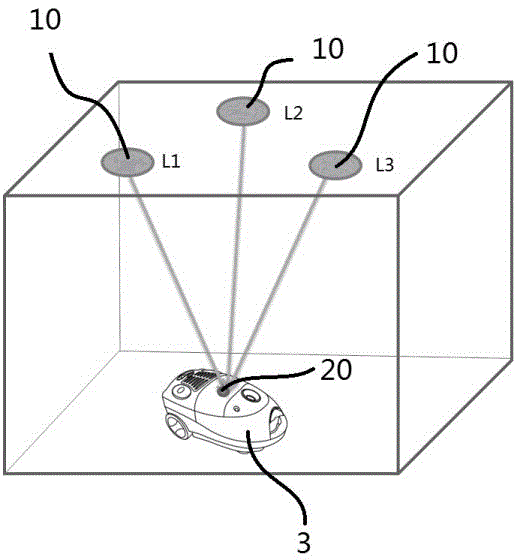

Light locating system and method used for cleaning robot

InactiveCN103983945AEasy to locateHigh positioning accuracyPosition fixationMicrocontrollerEffect light

The invention discloses a light locating system used for a cleaning robot. The light locating system comprises a light emitting device, a signal receiver arranged on the cleaning robot and a microcontroller. The light emitting device comprises a plurality of luminous sources, each luminous source loads a recognition code of itself into a light signal to be transmitted, and the recognition codes are position information of the luminous sources in the light emitting device. The signal receiver is used for receiving the light signals from the luminous sources. The microcontroller is used for conducting calculating processing on the strength and the time of the light signals, received by the signal receiver, of at least three of the luminous sources to obtain the spatial position of the signal receiver. According to the light locating system, the luminous sources realize an indoor locating function while being used for lighting, therefore, the indoor spatial position of the cleaning robot is determined and automatic cleaning work for preset specific lines is completed. A locating method is simple, convenient to implement and high in locating precision, and greatly reduces the housework burden of people.

Owner:SUZHOU LUXCOM PHOTOELECTRIC TECH

Assembling positioning jig

InactiveCN103419456AEasy to locatePrevent assembly deformationLaminationLamination apparatusEngineeringDisplay device

The invention discloses an assembling positioning jig which is used for installing a protection screen of a display on a display front frame and comprises a machine frame and a pressing device. The assembling positioning jig is high in positioning accuracy and accurate in installation and achieves mechanical automation.

Owner:昆山濡鑫光电科技有限公司

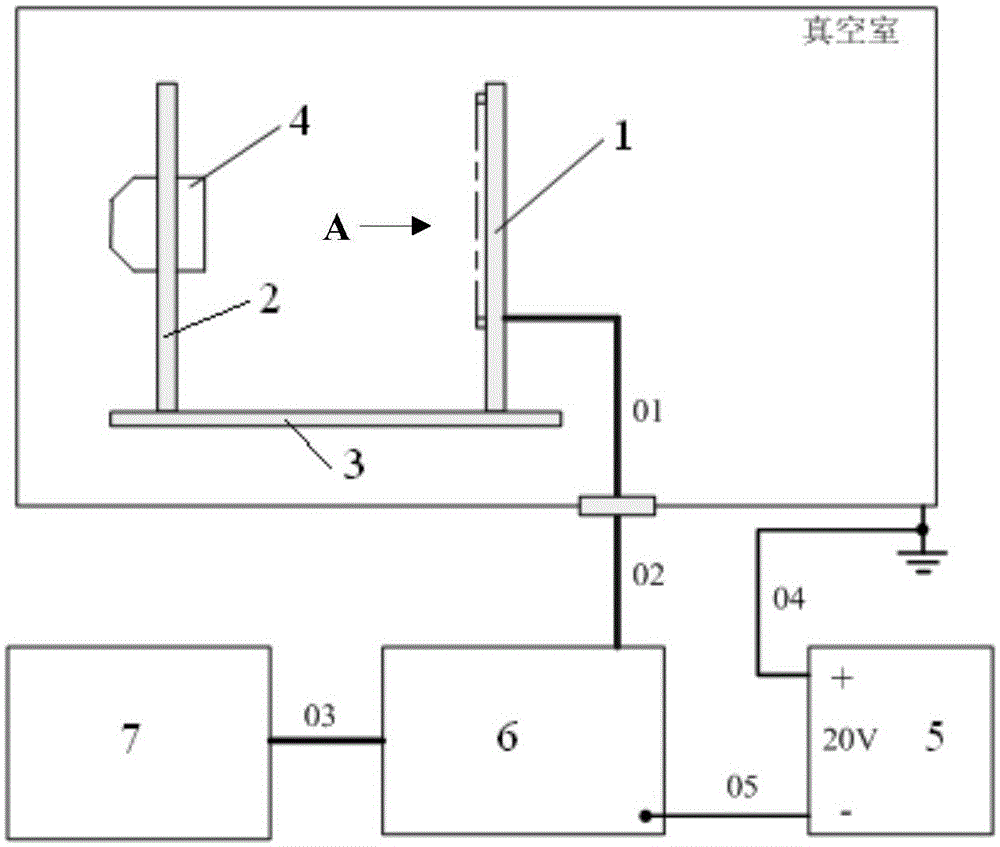

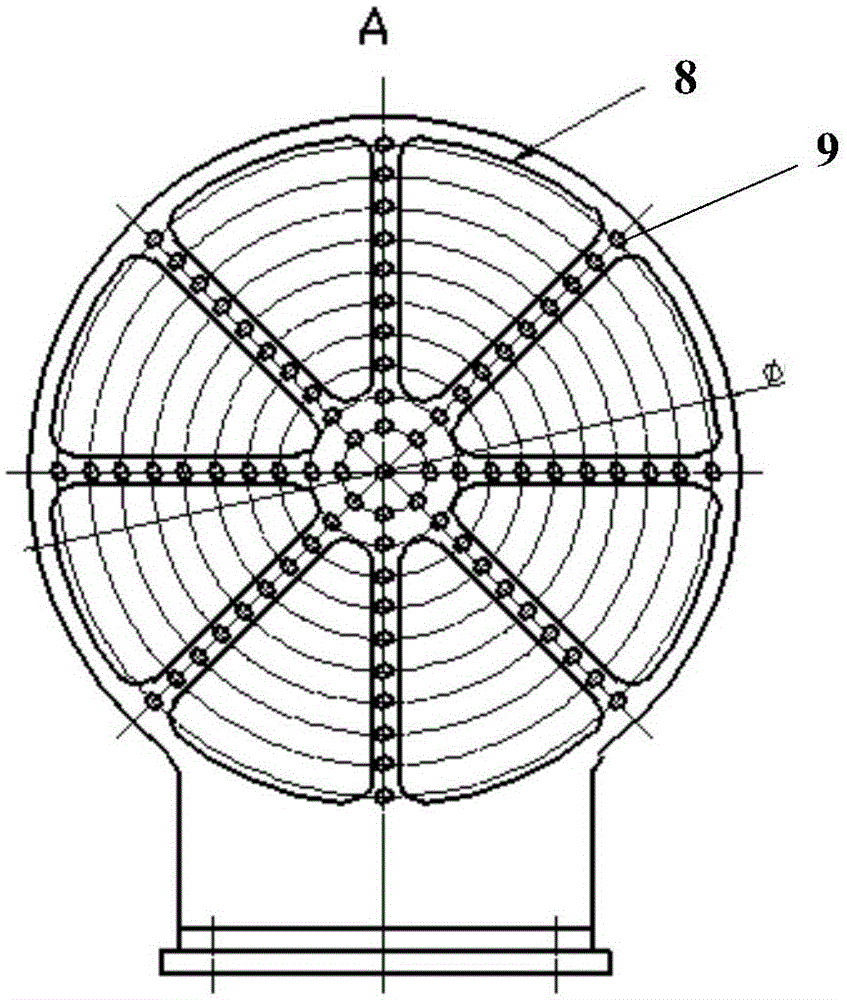

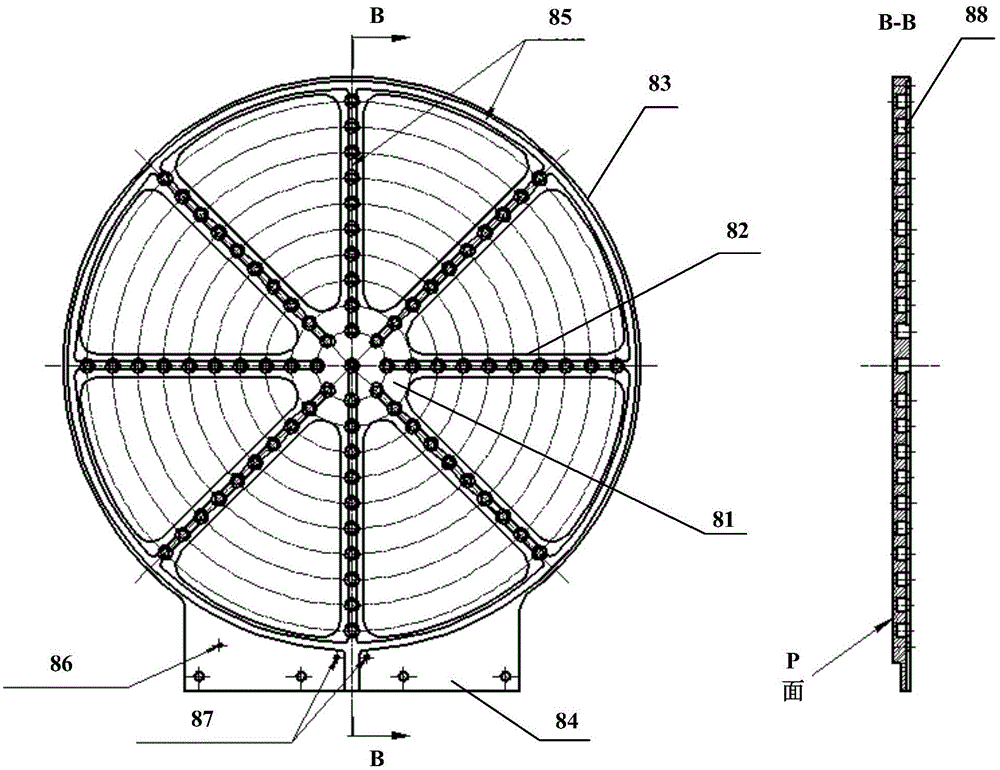

Ion thruster beam test system based on Faraday probe array

ActiveCN105116436ALarge amount of data informationRealize positioning installationX/gamma/cosmic radiation measurmentElectricityIon current

The present invention discloses an ion thruster beam test system based on a Faraday probe array. According to the present invention, the Faraday probes are arranged in a surface array manner, all probe test signals are acquired synchronously, the data information amount is large, and the whole test and the data processing can be finished usually in only several minutes. A shielding outer sleeve is arranged at the outer side of an ion current catch tray of each Faraday probe and is used to shield the stray ions flying to the side surface of the ion current catch tray, thereby guaranteeing that the ions are only collected on the right side of the ion current catch tray. The shielding outer sleeve is directly and electrically connected with a disc-type metal support by the metal contact, so that a bias voltage can be supplied to the disc-type metal support by just one conducting wire, and the biggest advantages of the mode are that: the number of the probe leads is reduced substantially, the structure is simplified, and the reliability is improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

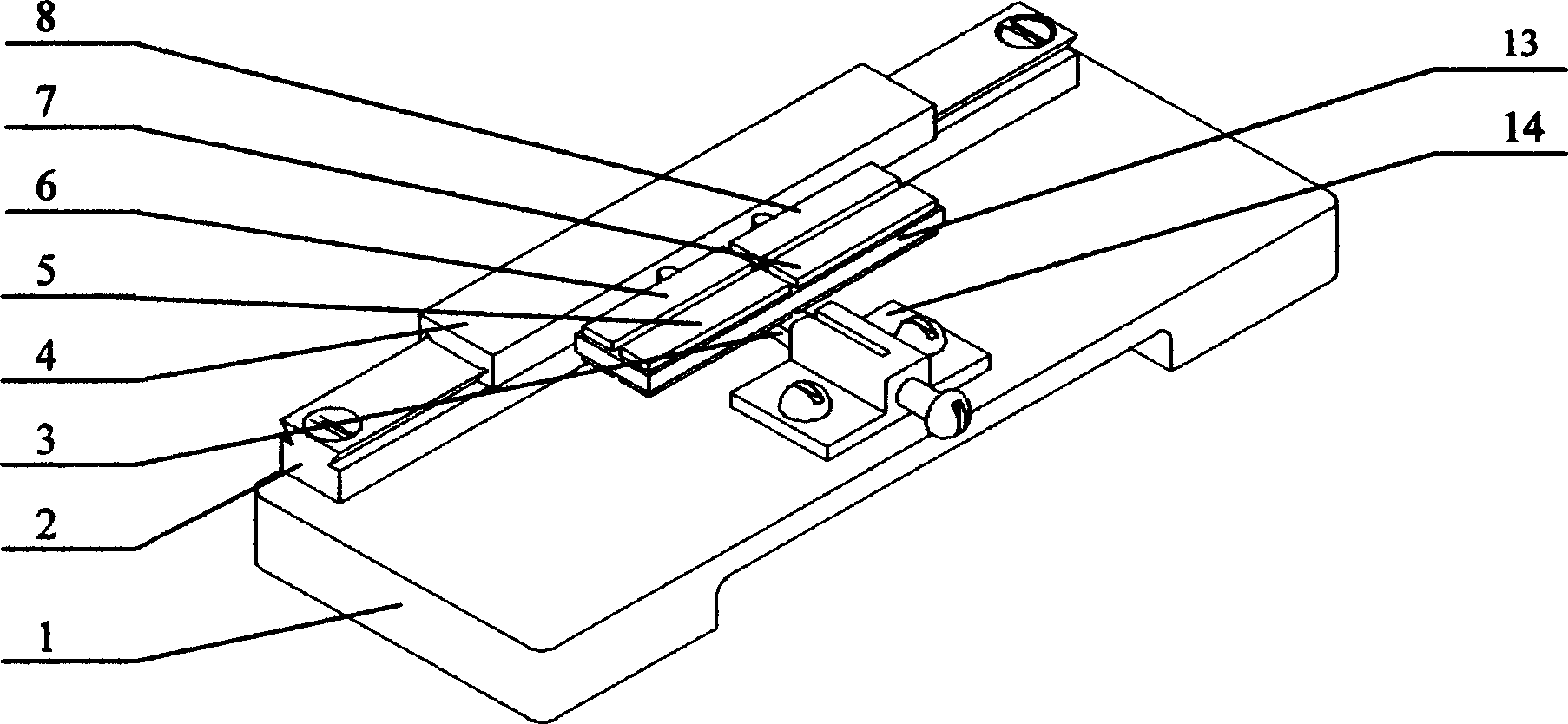

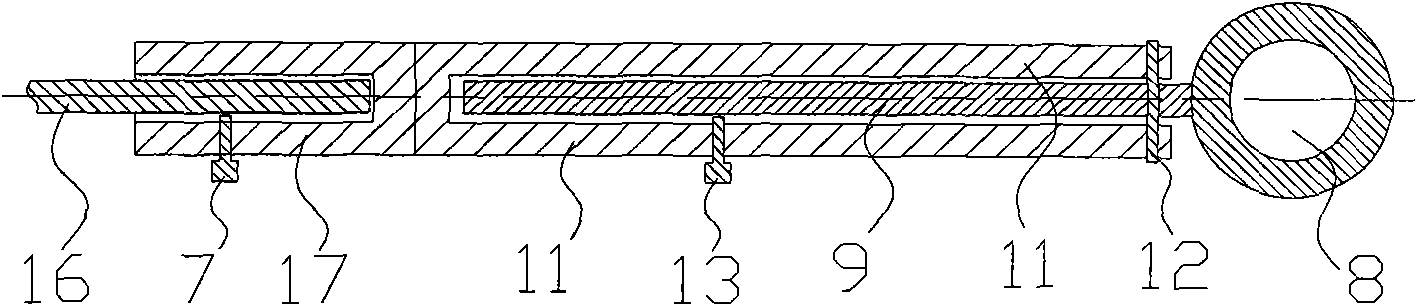

Linear ultrasonic motor

InactiveCN102497130ASimple structureReduced parts countPiezoelectric/electrostriction/magnetostriction machinesElastomerPiezoelectric actuators

The invention discloses a linear ultrasonic motor comprising a pedestal, a guide rail, a slide block, a piezoelectric vibrator, a positioning cantilever, and a positioning support. The pedestal is used for fixing the guide rail and the positioning support. The piezoelectric vibrator is used for generating mechanical oscillation under voltage excitation. The guide rail is used for supporting and constraining movement of the slide block. The positioning support and the positioning cantilever are cooperated with each other and are used for fixing the piezoelectric vibrator. The piezoelectric vibrator contains a metal elastomer that is provided with the set number of holes with a set shape, so that frequency of first-order longitudinal vibration is close to frequency of second-order bending vibration of the piezoelectric vibrator as well as amplitudes of the first-order longitudinal vibration and the second-order bending vibration are increased; and the mechanical oscillation generated by the piezoelectric vibrator drives the slide block to make linear movements. According to the above-mentioned technical scheme provided in the invention, the linear ultrasonic motor has a simple structure as well as can be processed and miniaturized conveniently; and a user demand can also be met.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

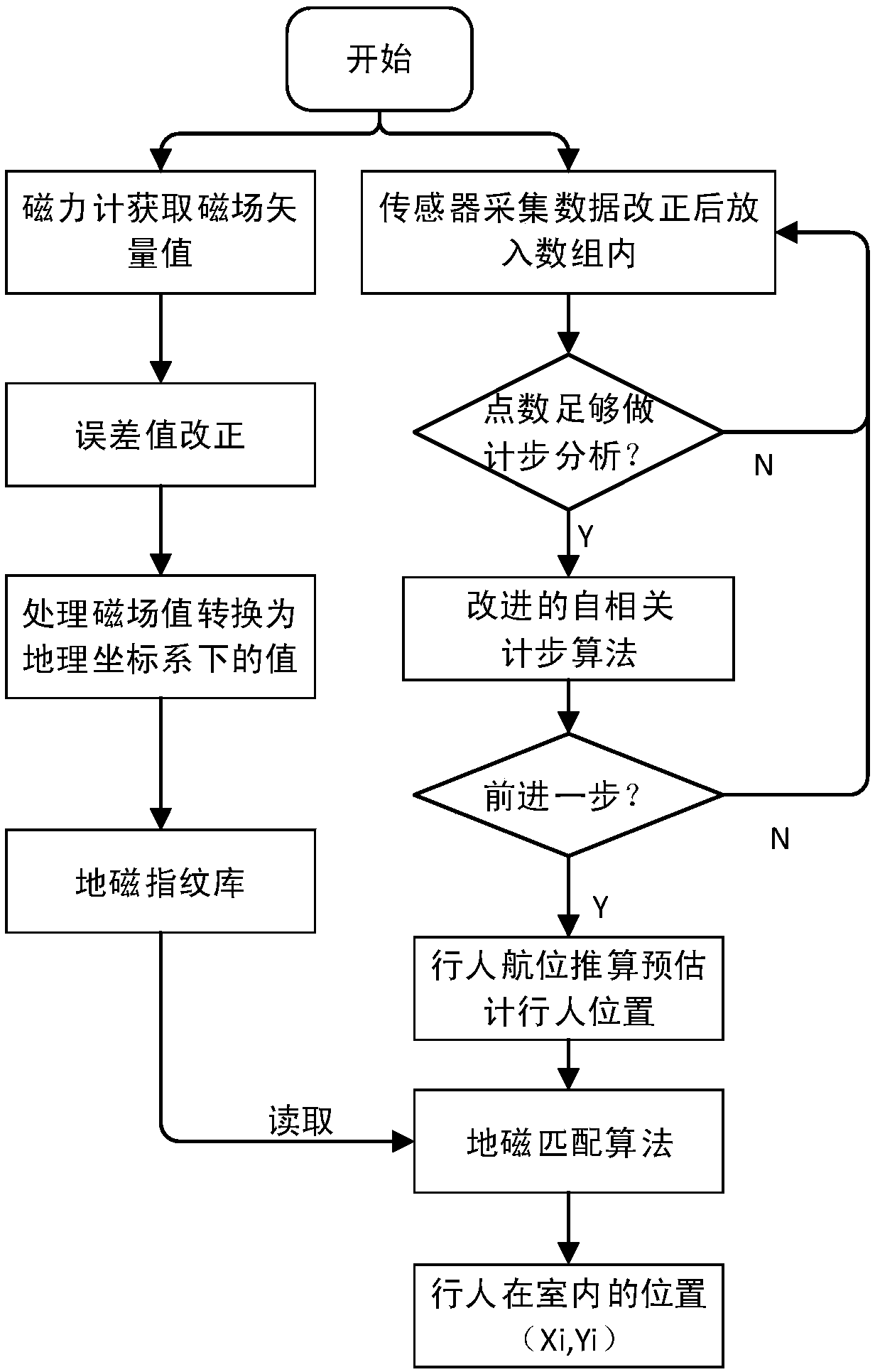

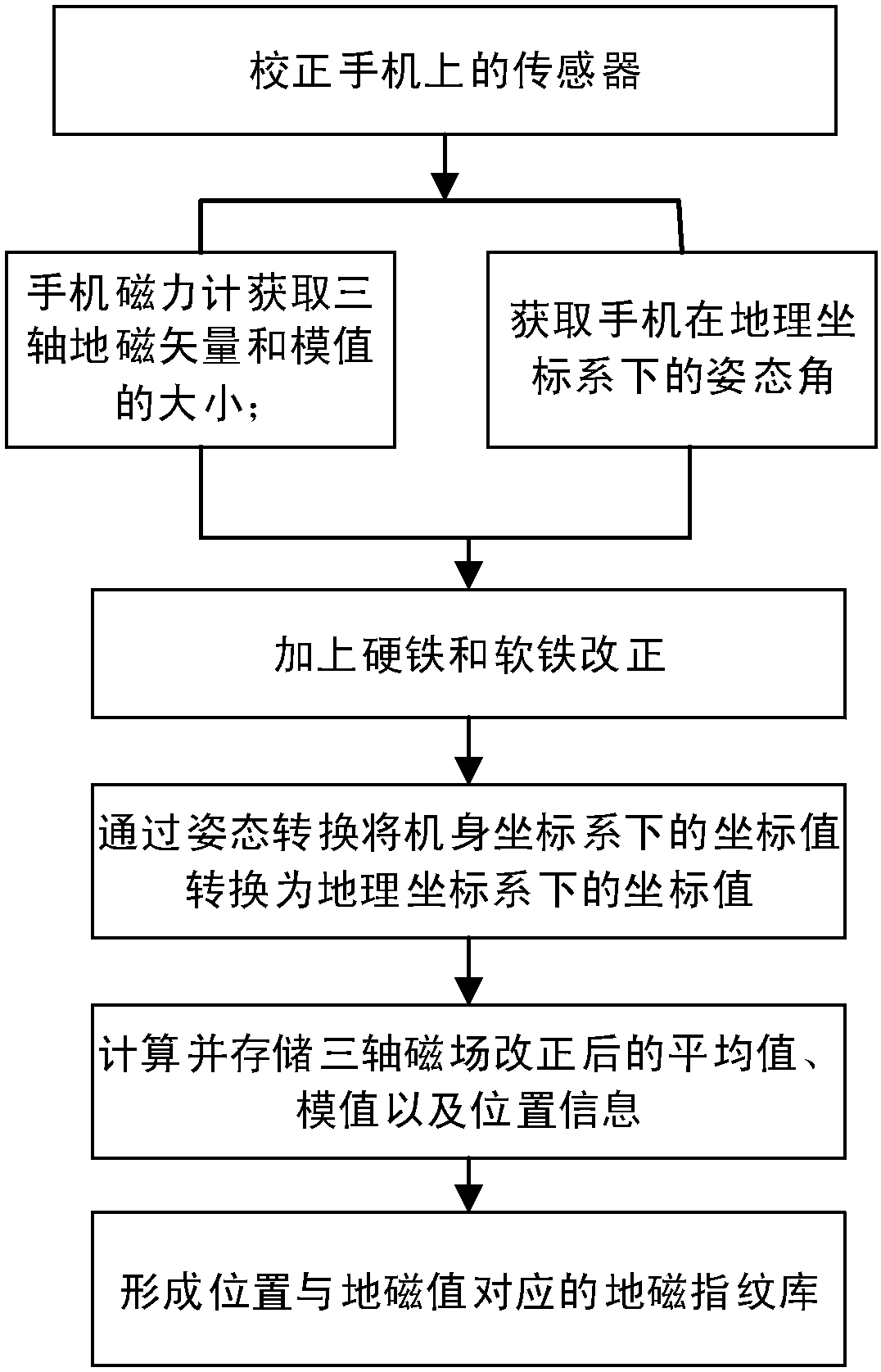

Geomagnetic matching and PDR (Pedestrian Dead Reckoning) fusion indoor positioning method based on intelligent terminal

ActiveCN108225324AHigh precisionImprove efficiencyNavigational calculation instrumentsNavigation by terrestrial meansComputer visionArtificial intelligence

The invention discloses a geomagnetic matching and PDR (Pedestrian Dead Reckoning) fusion indoor positioning method based on an intelligent terminal. A user can realize the positioning only by using the intelligent terminal; the data collection is performed by using a cheap sensor of the intelligent terminal; the additional arrangement of equipment and positioning equipment is not needed; the price is low; the positioning mode is simple. The PDR and geomagnetic matching positing fusion is utilized; the defects of PDR accumulation errors and too long geomagnetic matching time can be overcome; meanwhile, the precision and the efficiency of the single positioning mode are improved.

Owner:CHINA UNIV OF MINING & TECH

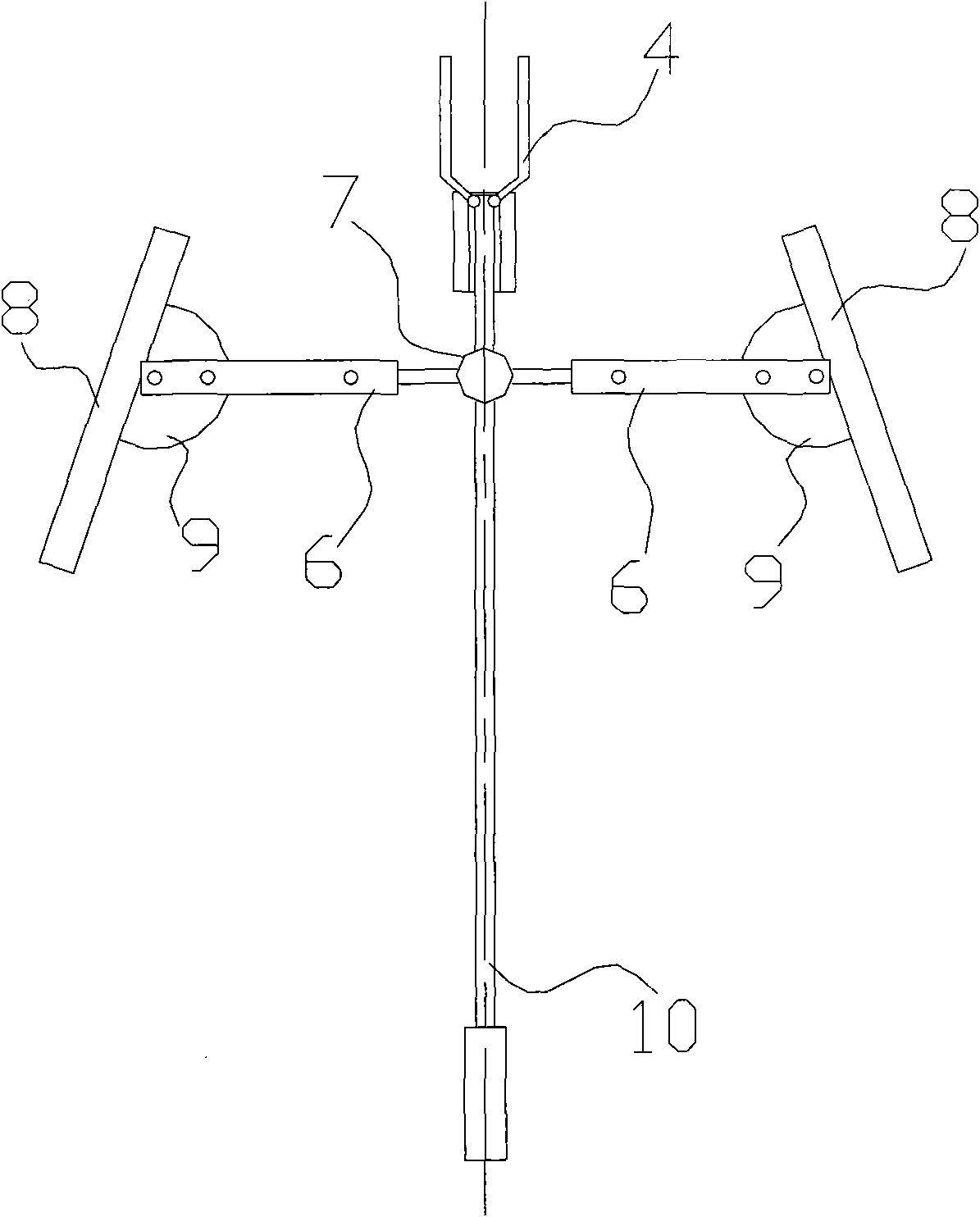

Auxiliary installation device for hydraulic bolt tensioning jack

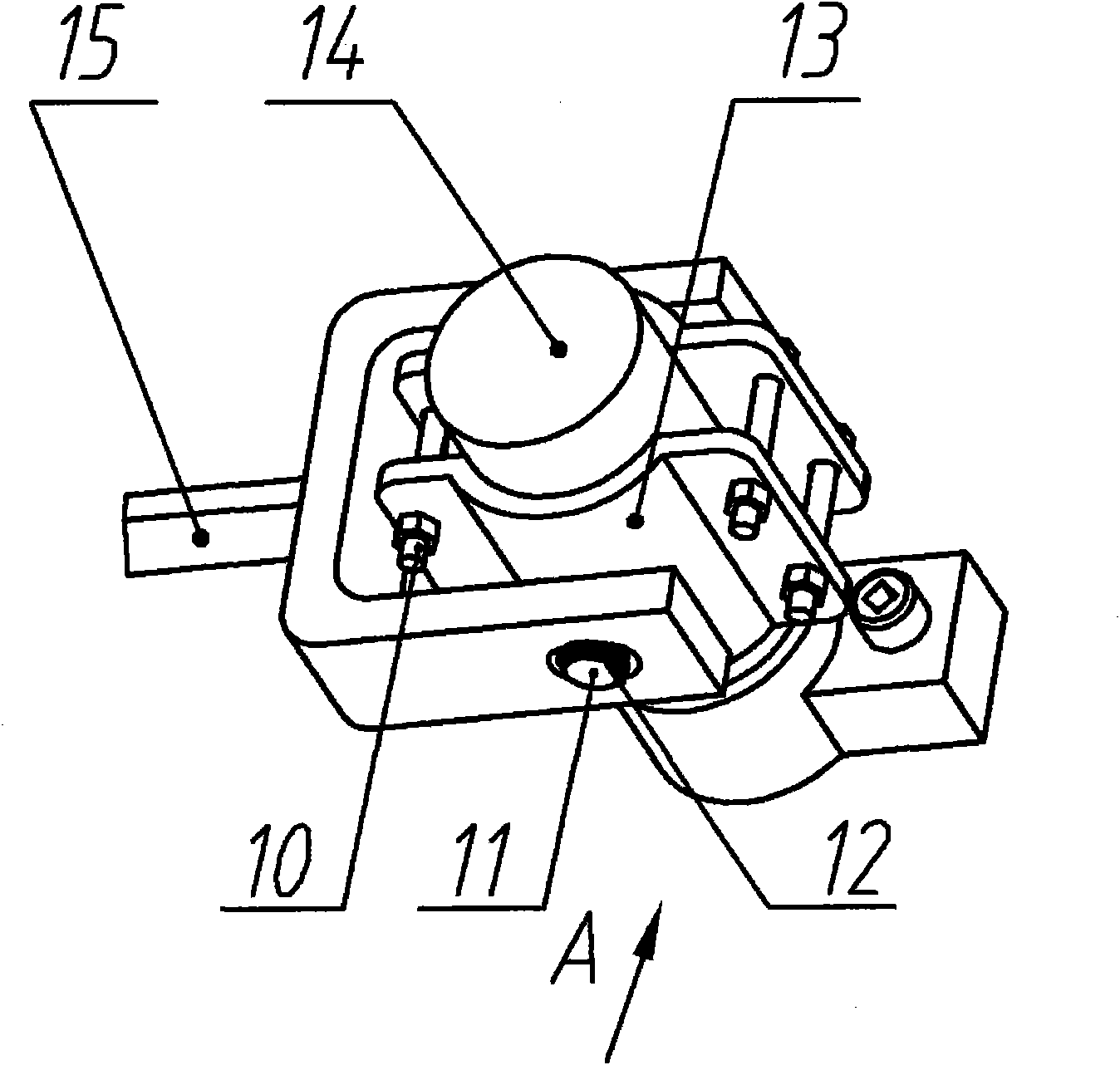

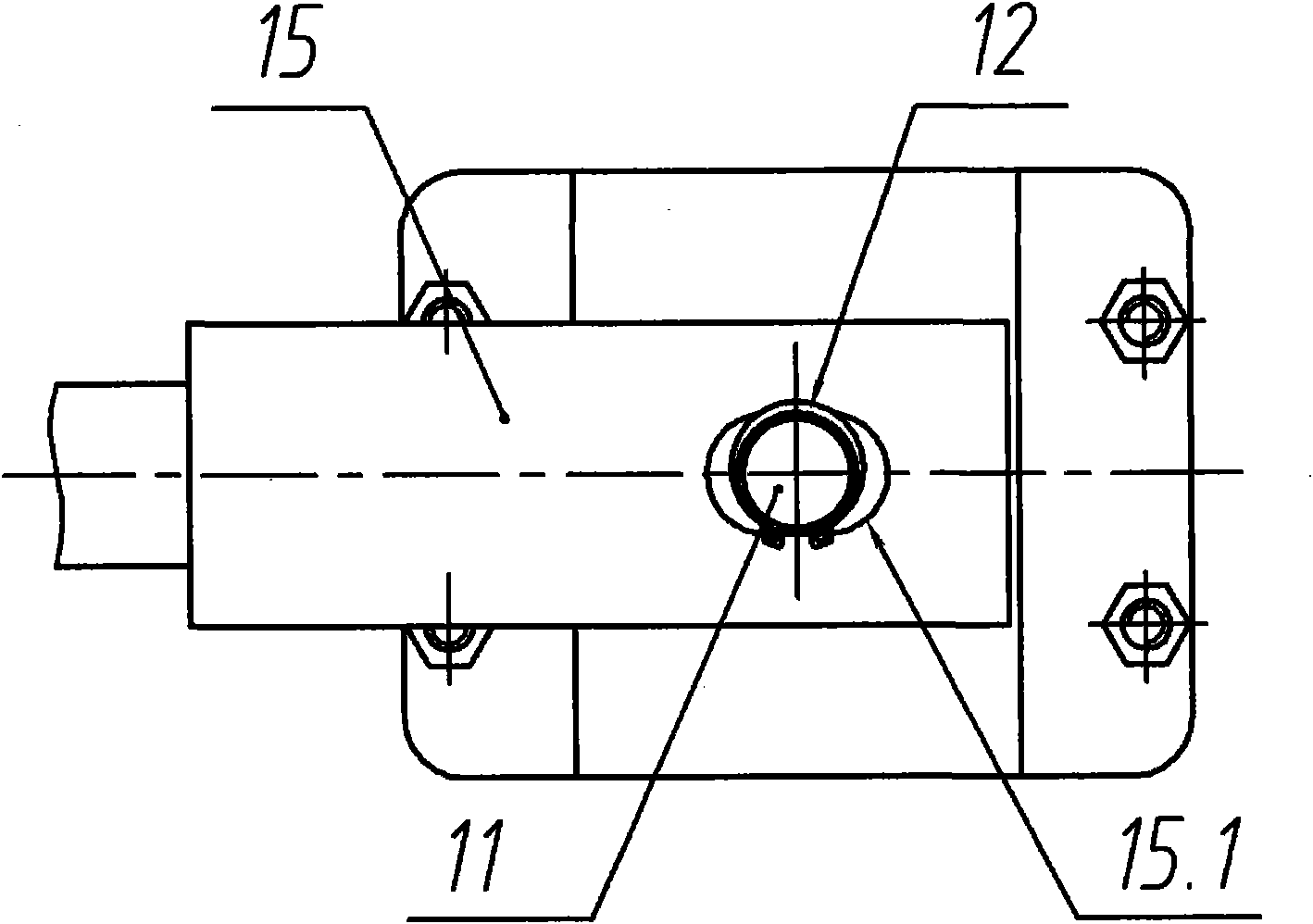

The invention provides an auxiliary installation device for the hydraulic bolt tensioning jack and relates to the technical field of the fastening and disassembling of the bolt. The device comprises a clamping mechanism, a slider-guide rail mechanism and a connecting rod, wherein the clamping mechanism comprises a clamping plate, a pin, clamping plate bolts and nuts and clamp springs, the parts are used to install a plurality of hydraulic bolt tensioning jacks on the device of the invention; the slider-guide rail mechanism comprises a slider, a guide rail, an upper cover plate, a dividing disc and a stop block; and one end of the connecting rod is connected with the pin of the clamping mechanism through a waist-shaped groove, and the other end is connected with the slider of the slider-guide rail mechanism through a hinge. By adopting the device of the invention, the number of workers can be decreased, the work efficiency can be improved; by using the device, the hydraulic bolt tensioning jacks can move flexibly in the axial and circumferential directions and workers can perform the installation and positioning operations fast, accurately and intuitively; and no improvement of theexisting hydraulic bolt tensioning jack is required.

Owner:JIANGSU UNIV

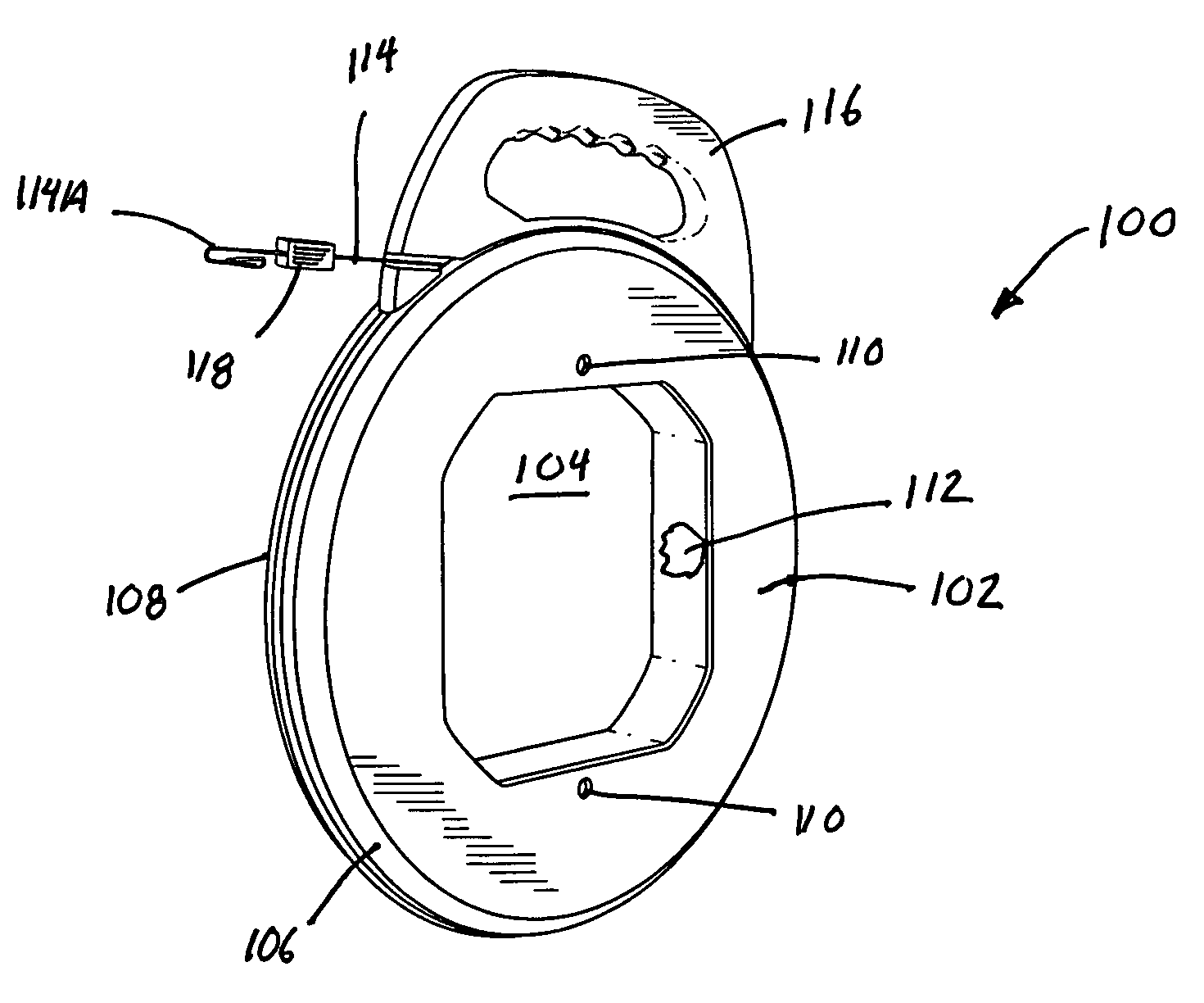

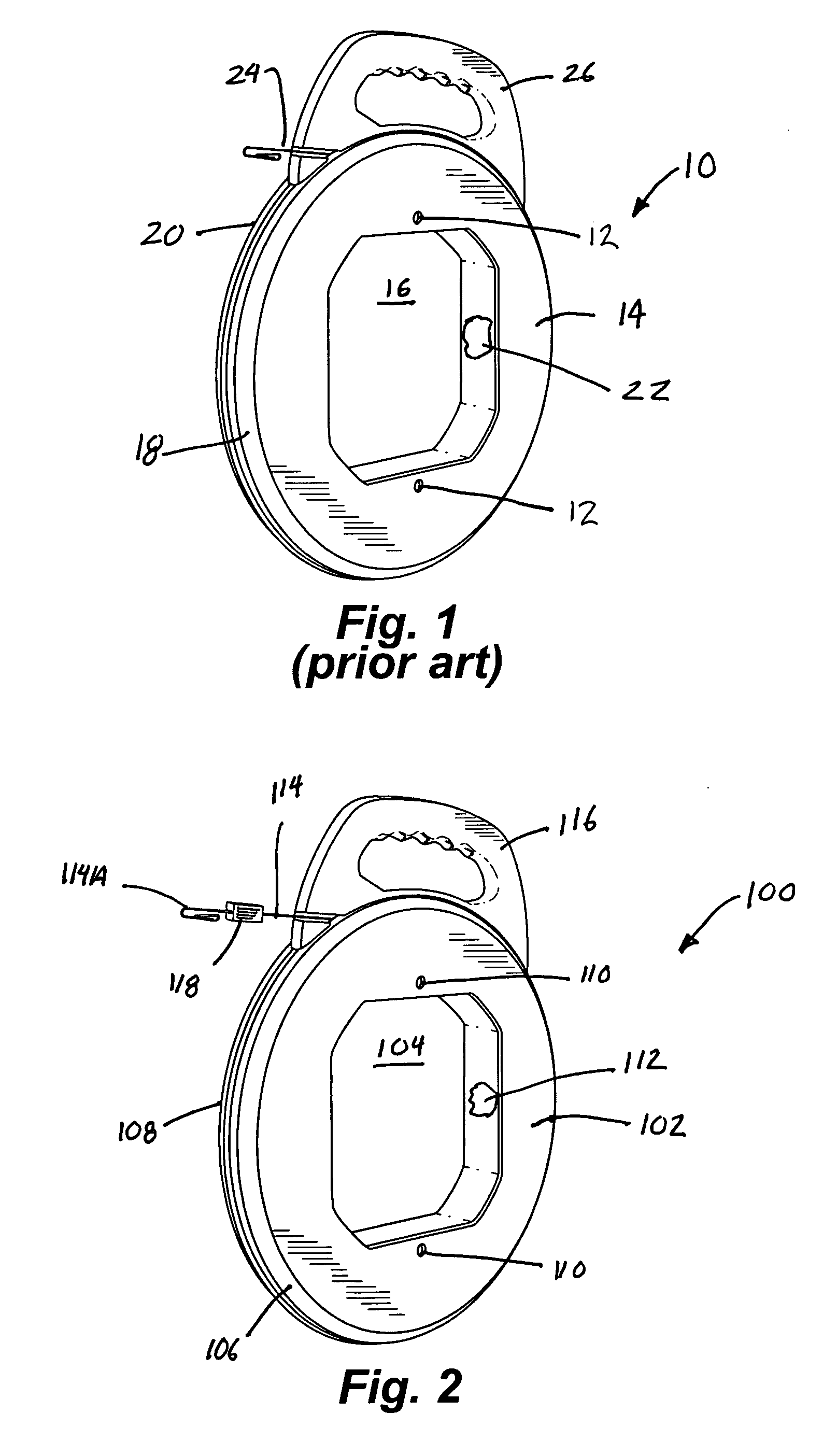

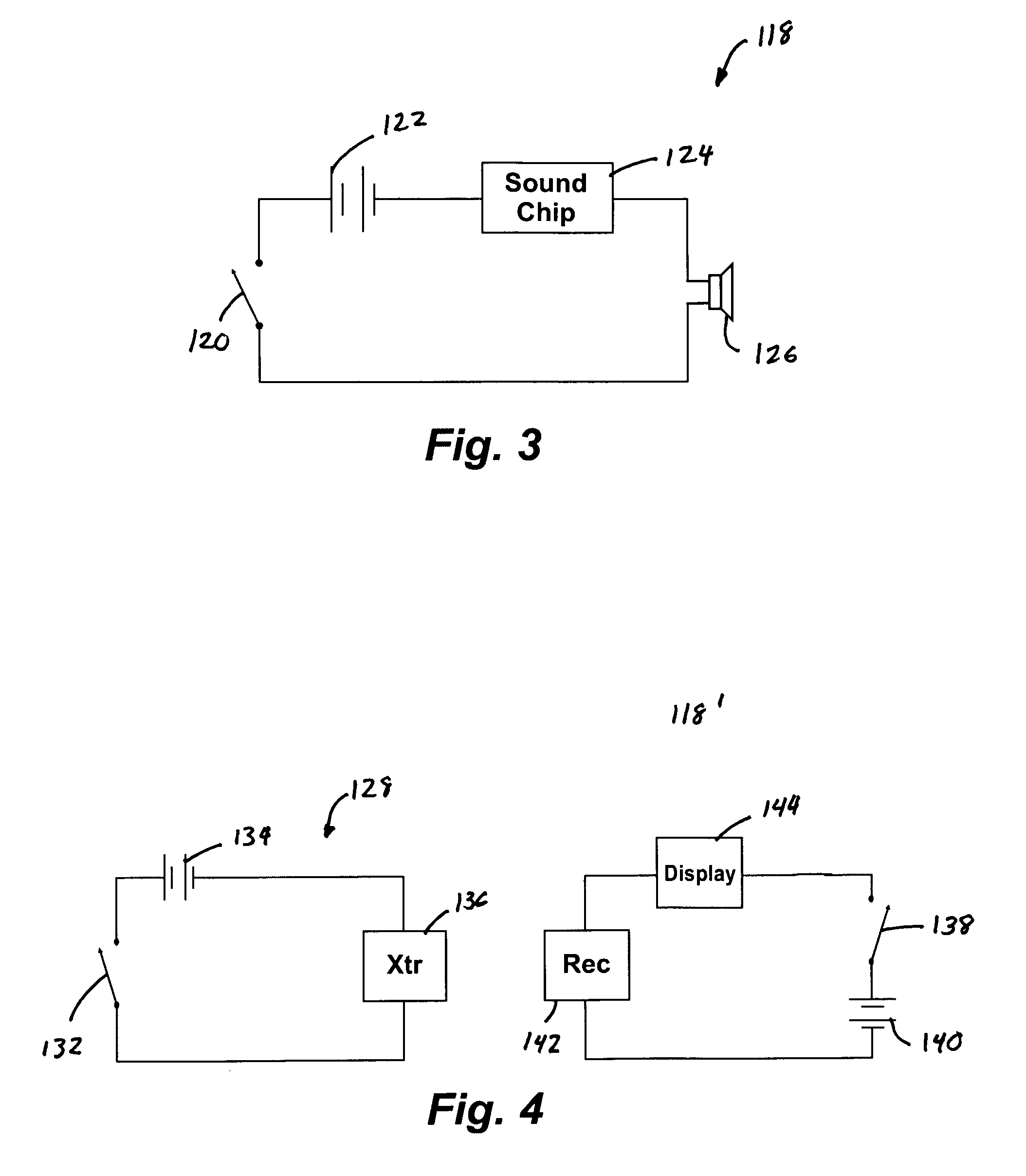

Fish tape having electrical box locator circuit and method therefor

InactiveUS7150448B1Easy to locatePrecise positioningWaterborne vesselsFilament handlingEngineeringFish tape

Owner:SWIFT RICHARD C

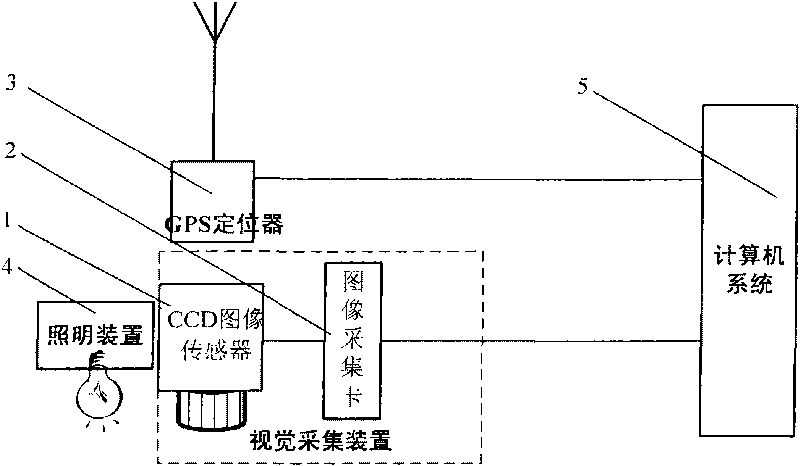

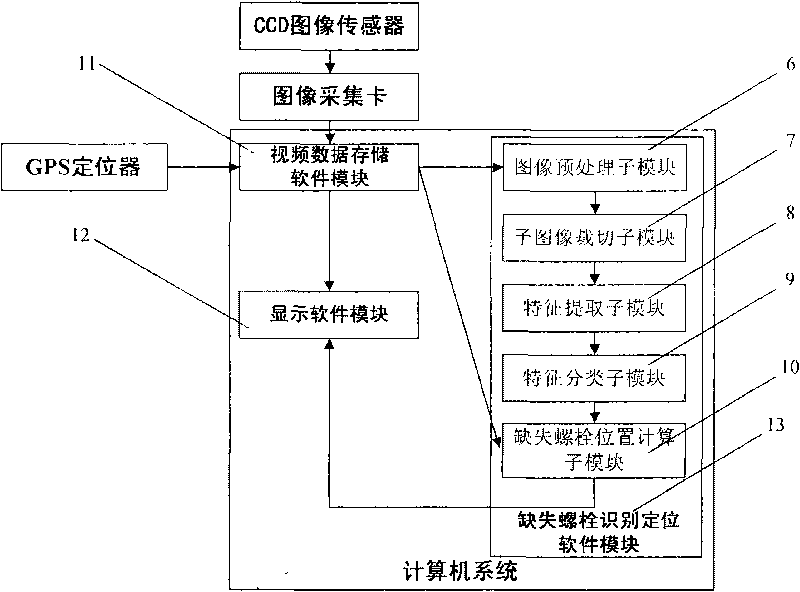

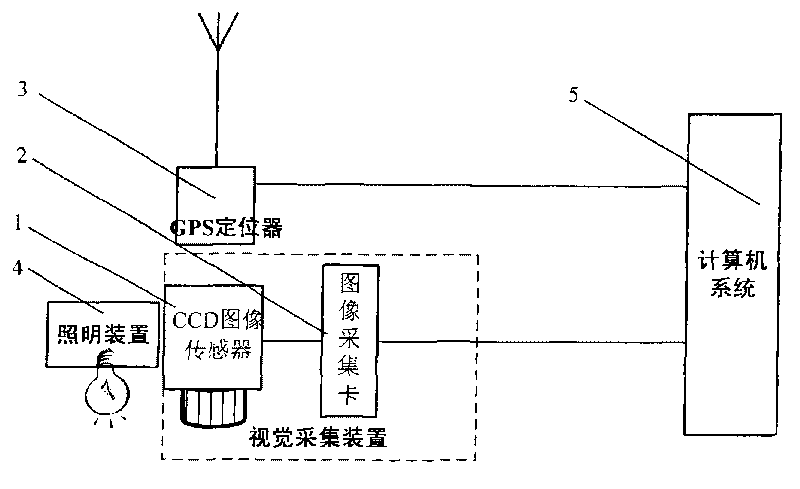

Device for automatically detecting nut loss of rail fastener system

InactiveCN101706274AImprove recognition rateEasy to locateSatellite radio beaconingUsing reradiationFeature extractionComputerized system

The invention relates to a device for automatically detecting nut loss of a rail fastener system, comprising a vision collecting device, a GPS locator, an illumination device and a computer system, wherein nut illumination is added for the illumination device, and the computer system is provided with a video data storage software module, a display software module and a lost nut identifying and positioning software module. The executing steps are as follows: the video data storage software module receives and stores the position information of the device obtained by the GPS locator and continuous video images containing the fastener system nut obtained by the vision collecting device, and records the corresponding time value obtained by the video image and the position data; the lost nut identifying and positioning software module carries out pretreatment, sub-image cutting, feature extraction, feature classification and position calculation to the obtained video image to identify the position the nut loss; and the display software module displays and prints the image and position information of the lost nut. In the invention, the device moves along with the train during operation so as to automatically detect and position the nut loss of the rail fastener system.

Owner:CHINA JILIANG UNIV

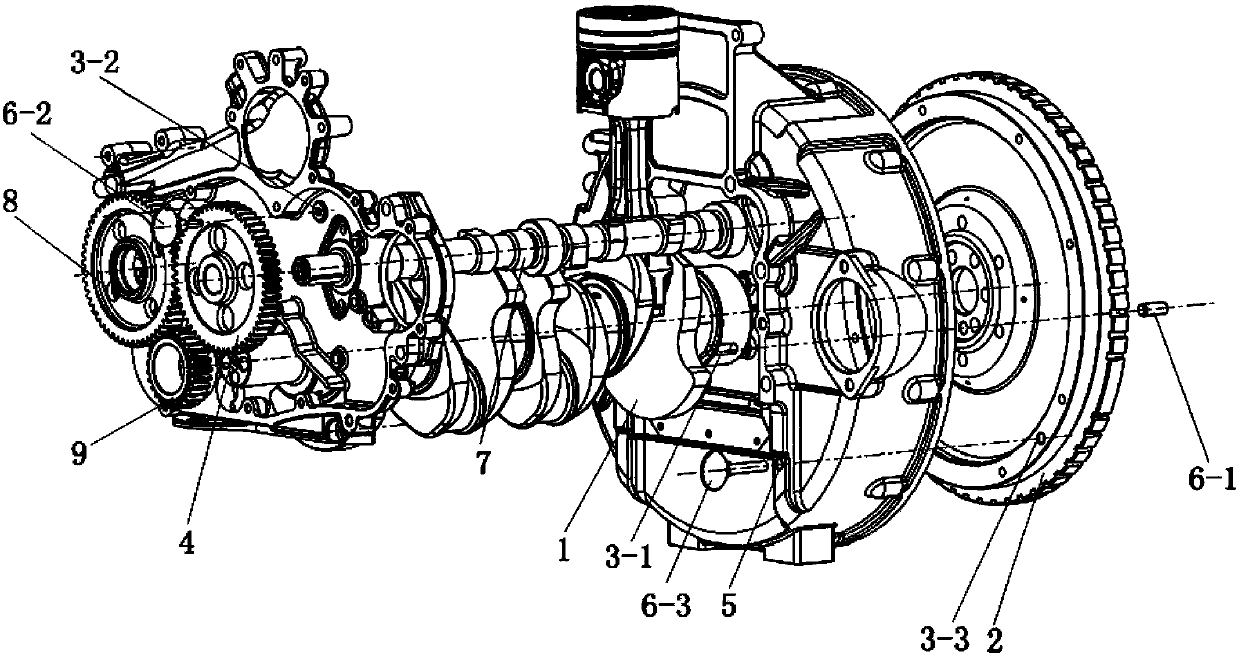

Diesel engine timing locating method

InactiveCN103422928APrecision injectionEliminates assembly steps requiring alignment of mating marksValve arrangementsMachines/enginesGear wheelEngineering

The invention discloses a diesel engine timing locating method. The phase relation among an engine cam shaft, a crankshaft and a first cylinder is measured in advance, three locating pin holes are designed, and timing location is completed through the following four steps that the crankshaft and a flywheel are located through a first pin; a second pin penetrates through a cam shaft gear and is inserted into a second locating pin hole in a gear chamber; a third locating pin penetrates through a flywheel shell and is inserted into a third locating pin hole in the flywheel through the rear end of the engine, so that the cam shaft and the crankshaft opposite to the cam shaft in position are fixed on the upper dead center of the first cylinder; a crankshaft gear and an idler gear are installed, and meshing marks are arranged among the idler gear, the crankshaft gear and the cam shaft gear. According to the diesel engine timing locating method, timing location is very easy and convenient, operation is easy, and errors of determination of the upper dead center of the first cylinder caused by manual timing are avoided. By means of matching between the locating pins and the pin holes, the step that common gear assembly needs alignment of the meshing marks is omitted, the assembly process is simplified, production efficiency is improved, and the application effect is very good.

Owner:东风朝阳朝柴动力有限公司

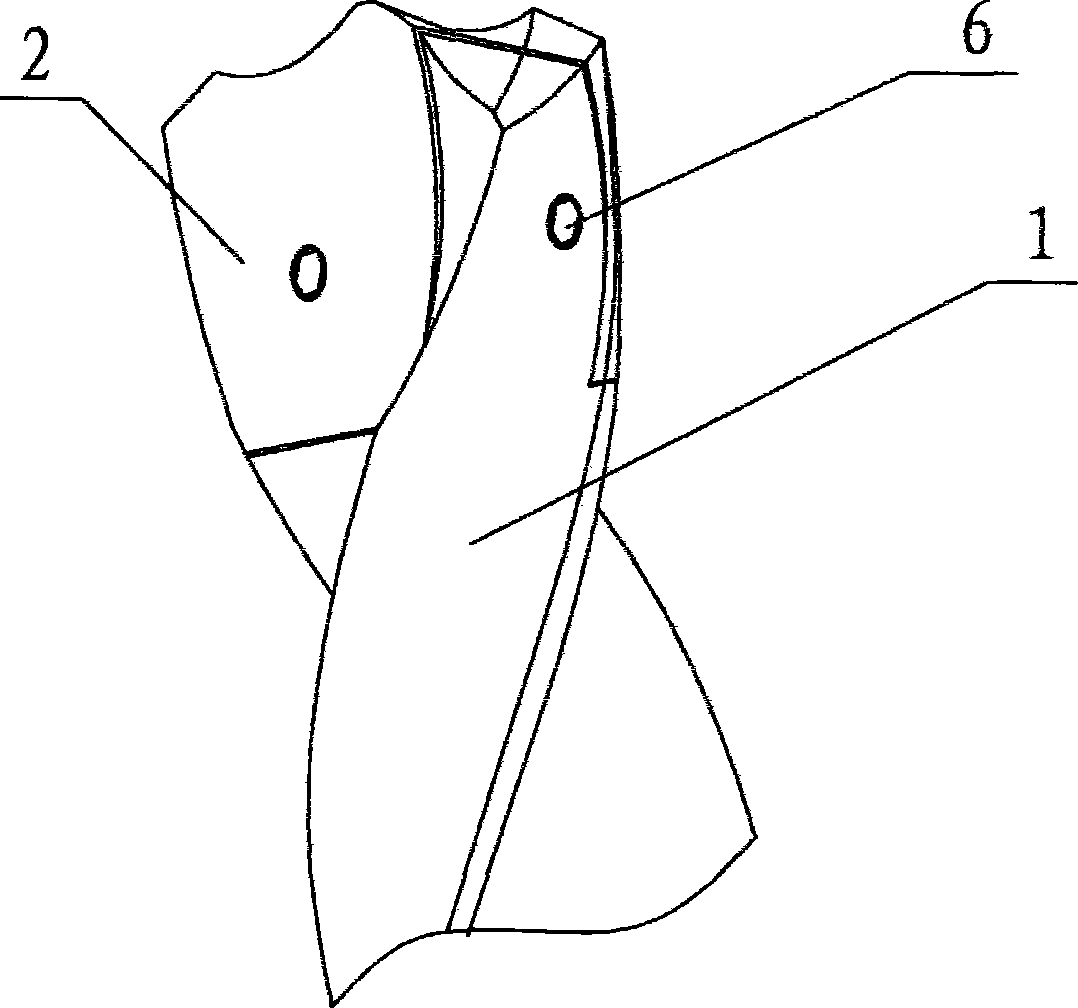

Method for preparing grinding-free drill head and drill head

The invention provides a manufacturing method of a grinding-free drill bit, which comprises a drill body and a detachable cutting blade connected on the front end of the drill body; the manufacturing method is characterized by comprising the following steps: (1) according to the set depth and width, the front end of the drill body is equipped with a spiral groove for holding the cutting blade; both inner side walls of the spiral groove are arcwall faces, and the two arcwall faces are of central symmetry, so that the entire outline of the spiral groove is of S shape; each arcwall surface is a parallelogram after being unfolded; (2) the cutting blade with side walls being two symmetrical arcwall faces and matched with the inner wall shape of the spiral groove is prepared; (3) the cutting blade is placed into the drill spiral groove, and connected to prepare the grinding-free drill bit. No sequence exists between step (1) and step (2). The manufacturing method also provides the grinding-free drill bit prepared by using the method.

Owner:苏茂均

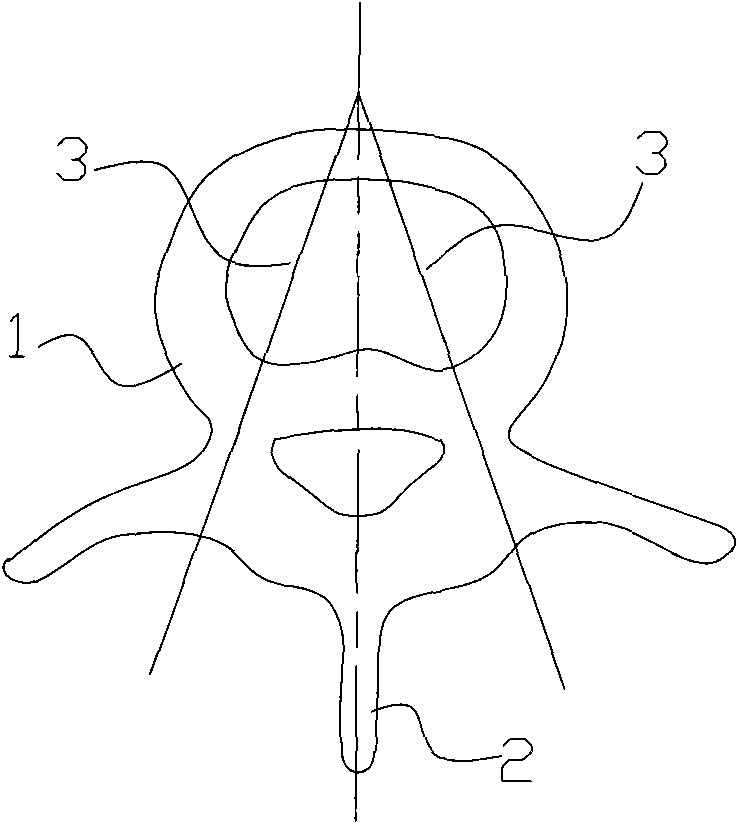

Pedicle screw positioning device and positioning method thereof

The invention discloses a pedicle screw positioning device and a positioning method thereof. The device comprises a spinous process clamp, a connecting rod and two pedicle screw guide pipes, wherein the front end of the spinous process clamp is provided with two opposite clamps, the connecting rod is connected with the spinous process clamp, the two pedicle screw guide pipes are respectively symmetrically arranged at both ends of the connecting rod, and an angular adjustment device is arranged between the both ends of the connecting rod and the two pedicle screw guide pipes. The positioning method at least comprises the following steps: a, adjusting angles of the two pedicle screw guide pipes relative to the connecting rods; b, tightly clamping a spinous process by the spinous process clamp and adjusting an angle of the spinous process clamp relative to a pedicle; and c, respectively inserting pedicle screws into the pedicle screw guide pipes and feeding the pedicle screws under the guide action of the pedicle screw guide pipes. The invention can accurately position the pedicle screws, is more convenient for operative manipulation, lessens hurt to patients and improves the safety and the controllability of operations.

Owner:广东好依护医疗科技股份有限公司

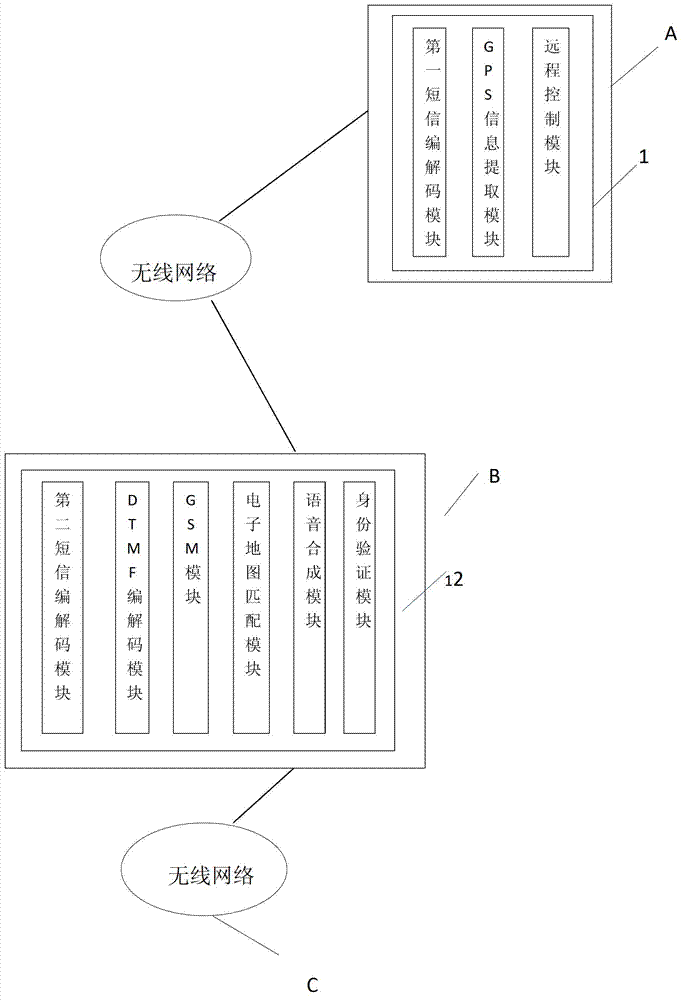

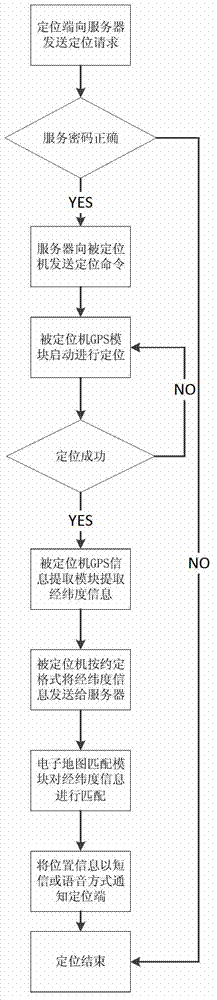

Centralized positioning method and system for the old going outside

InactiveCN103037307AEasy to locateLocation request information diversificationMessaging/mailboxes/announcementsTransmissionInformation extractionText message

Provided is a centralized positioning method and a system for the old going outside. The centralized positioning method and the system for the old going outside comprise the following steps: (1) The locator calls the server or sends messages to ask for positioning. (2) After the server receives the location requests and checks the password, the server sends positioning instructions to the localization machine to be positioned by messages. (3) After receiving the positioning instructions, the localization machine starts the global position system (GPS) module to carry out the positioning and to output the GPS information. (4) The GPS information extraction module of the localization machine extracts the useful latitude and longitude information from the GPS information. The successfully extracted information is sent to the server by text messages according to the agreed format. (5) The server carries out the match with the position information and gets the specific information then tells the locators so as to achieve the positioning for the old. The centralized positioning method and system for the old going outside has the advantages that when you want to know the position of the old, the purpose can be achieved by sending messages to the server or making a call.

Owner:ZHEJIANG UNIV OF TECH

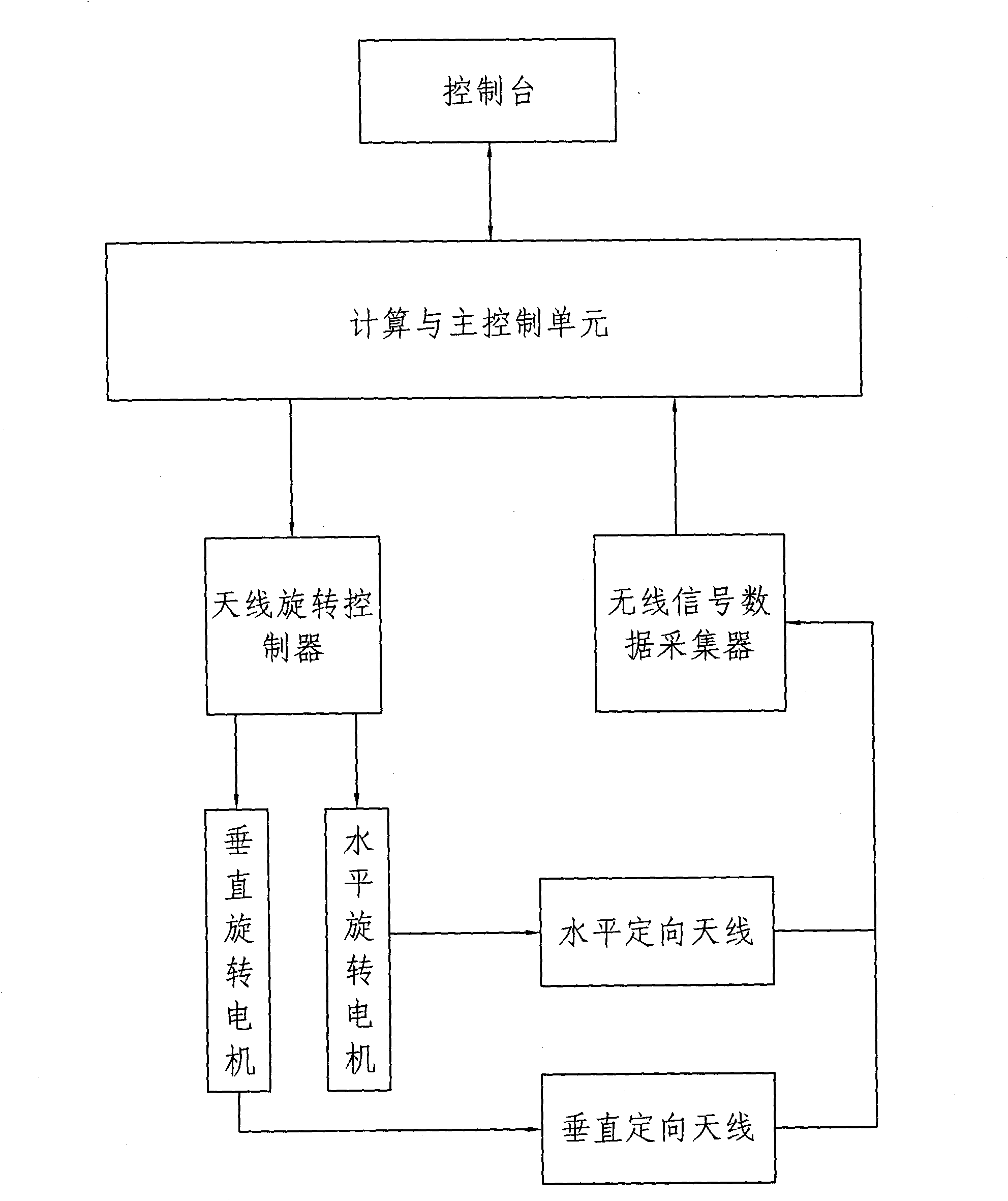

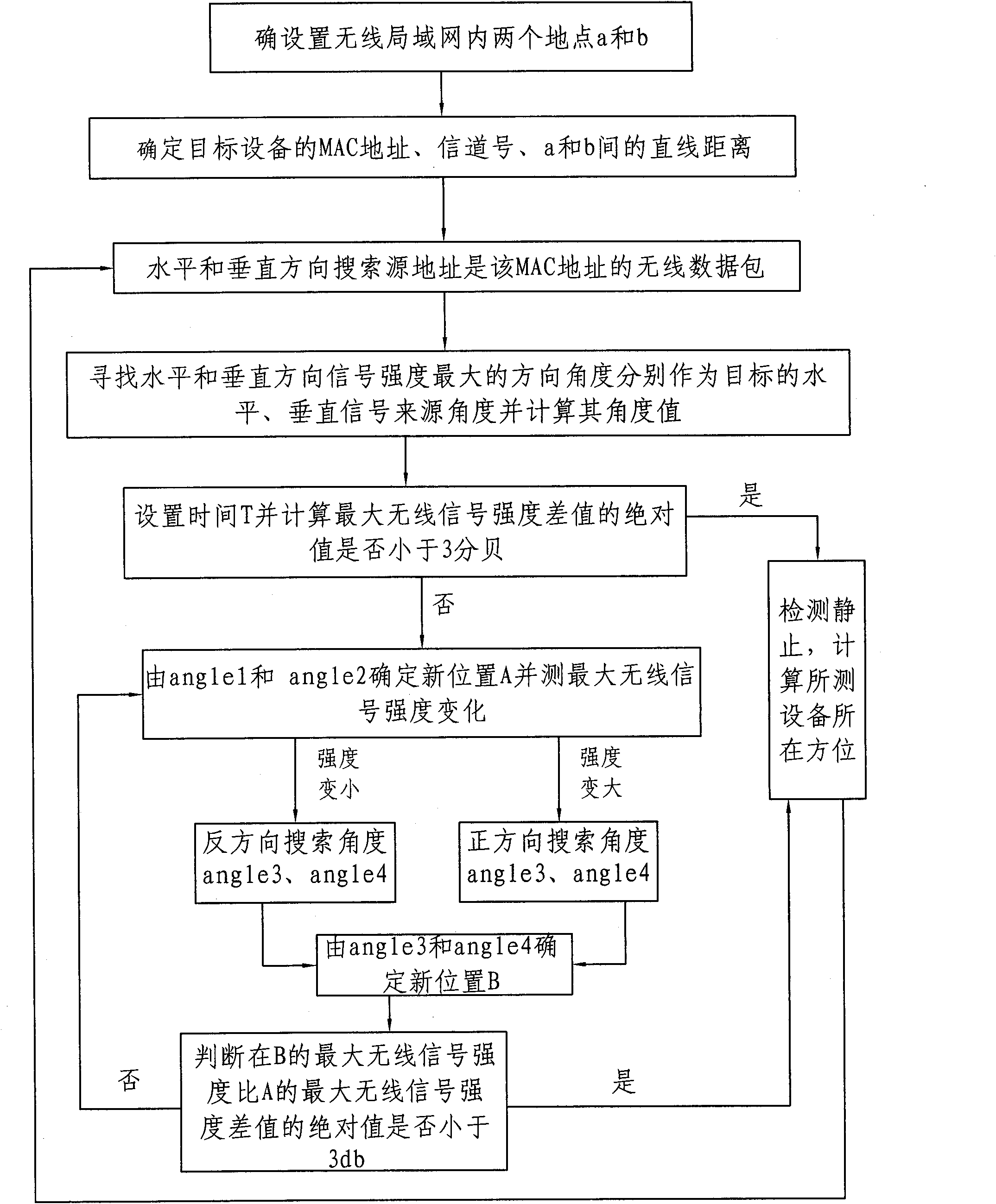

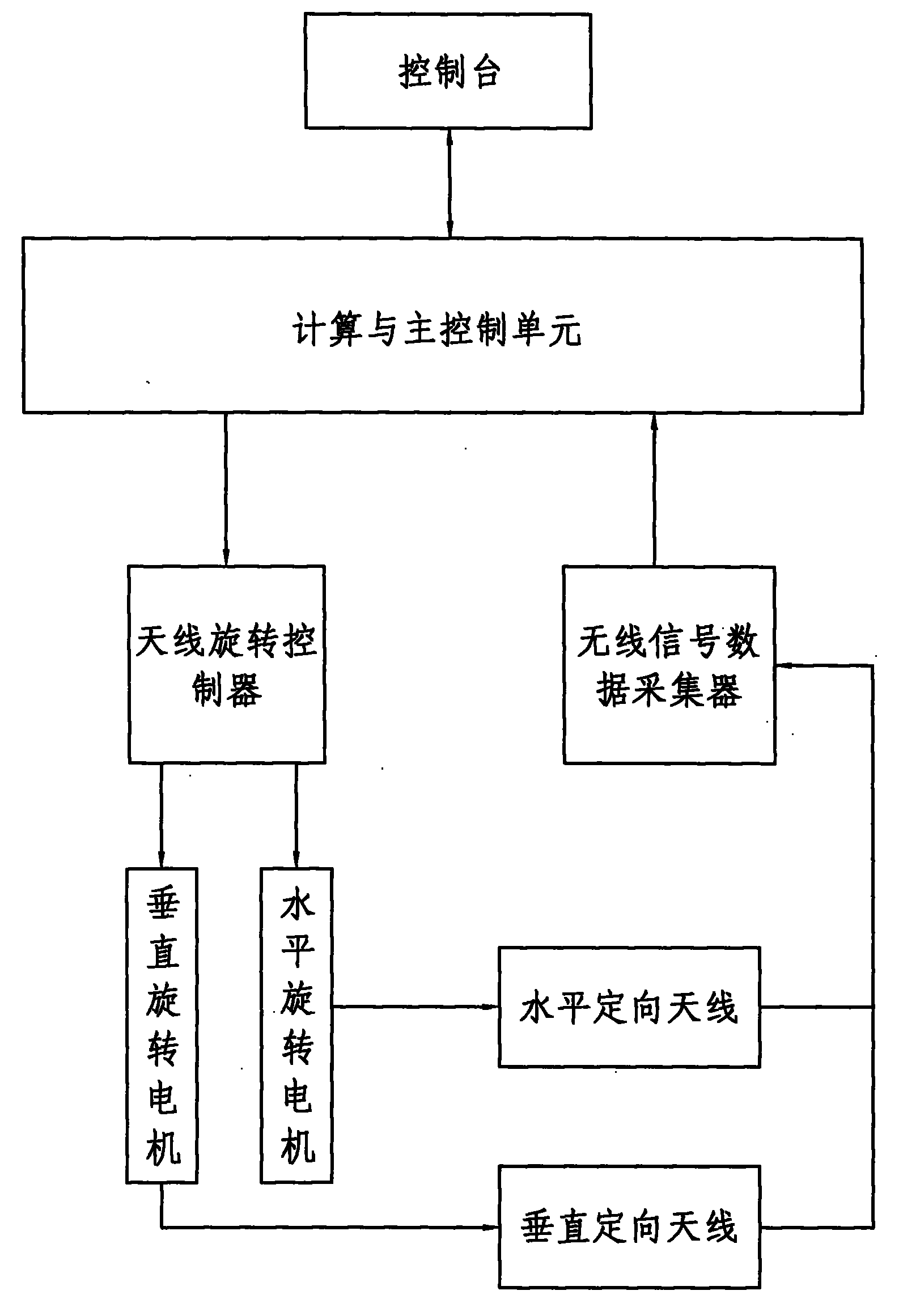

Method and device for positioning and tracking equipment in wireless local land area

The invention discloses a method and a device for positioning and tracking equipment in a wireless local land area. The method and the device are not limited to an indoor environment and are also in effect in an outdoor environment in the coverage of the wireless local land area. Through the method for positioning and tracking the equipment in the wireless local land area, the positioning and tracking of the equipment in the wireless local land area are realized by utilizing at least two places to measure the horizontal positioning and vertical positioning of a target. The device for positioning and tracking the equipment in the wireless local land area comprises directional antennae, a wireless network card, a directional antenna rotation controller, a wireless signal data acquirer, a computation and master control unit and a console. In the method and the device, no infrastructure of the wireless local land area is needed, no sensor needs deploying, the target can be positioned only by at least two points in a three-dimensional space and a moving direction of the mobile target can be tracked.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

Clamping cartridge polymer pole ear welding method

InactiveCN1967907AEasy to locateEasy to operateCell component detailsNon-electric welding apparatusCopper foilEngineering

The invention relates to a polymer polar ear welding method, which comprises that: a, cutting the length of polar ear; b, putting cathode polar ear at the middle of copper foil, aligning the sealing film and upper edge of baffle film; c, moving to ultrasonic welding machine, pressing down battery, making upper face of battery horizontal with welding base, and welding; d, putting anode polar ear at middle of copper foil relative to electric corn, aligning the sealing film and the upper edge of baffle film; e, moving to ultrasonic welding machine, pressing down the battery, making upper face of battery horizontal with welding base, welding; f, cutting off abundant copper and aluminum foils; g, bending welding area toward to side of battery for 90degree, keeping two polar ears parallel. The invention can reduce processes and improve welding speed.

Owner:SHENZHEN HAIYING TECH

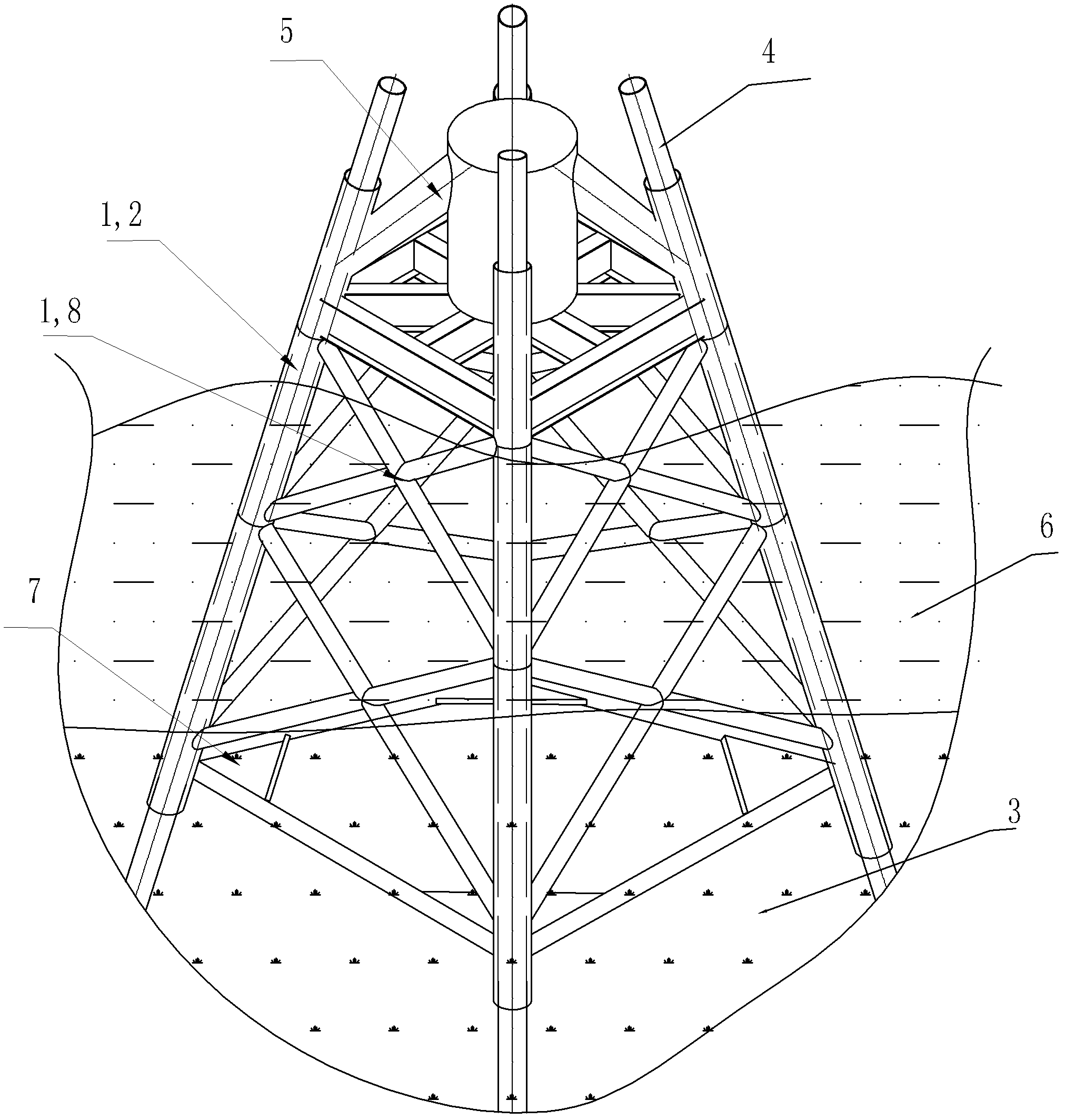

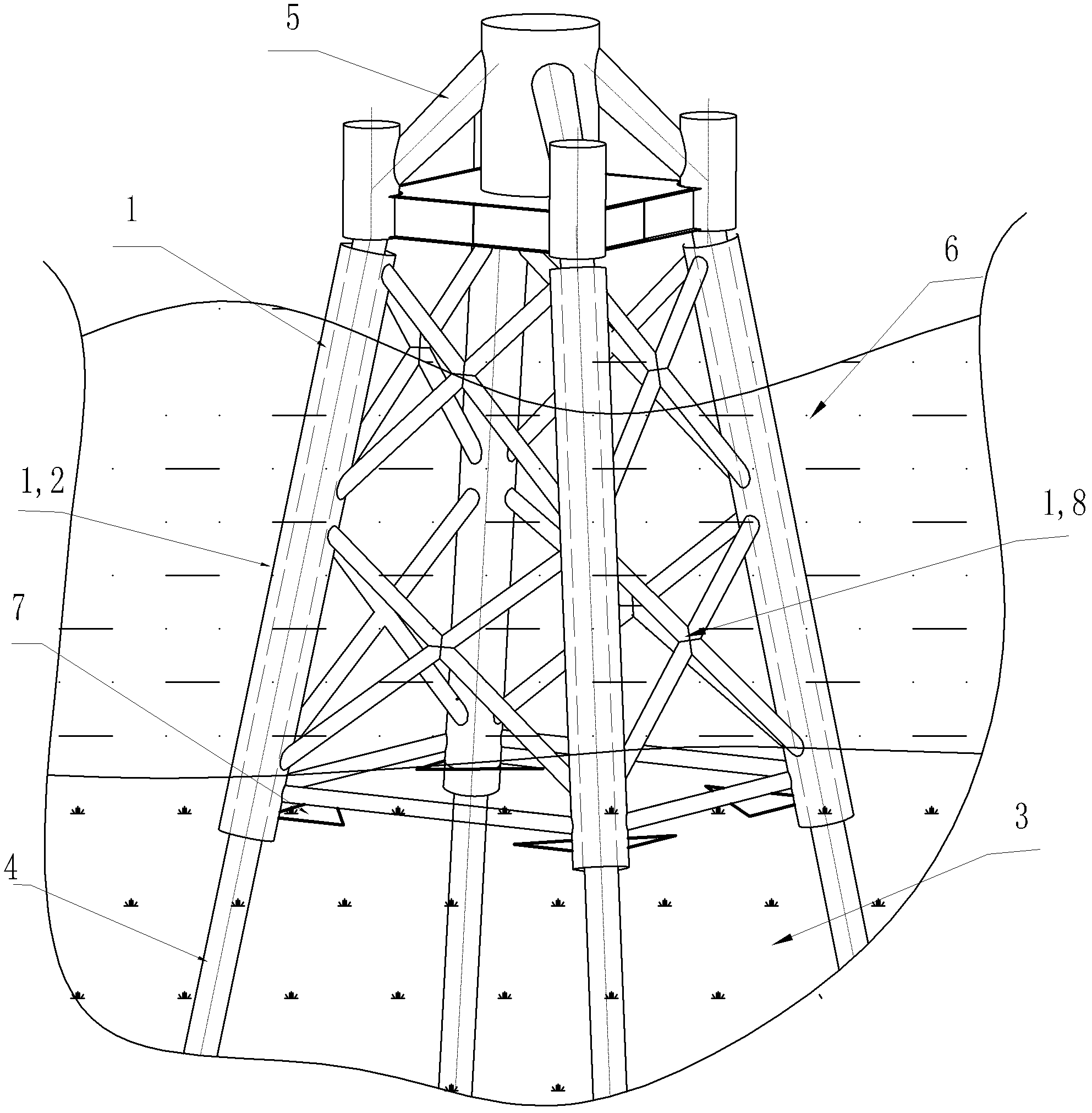

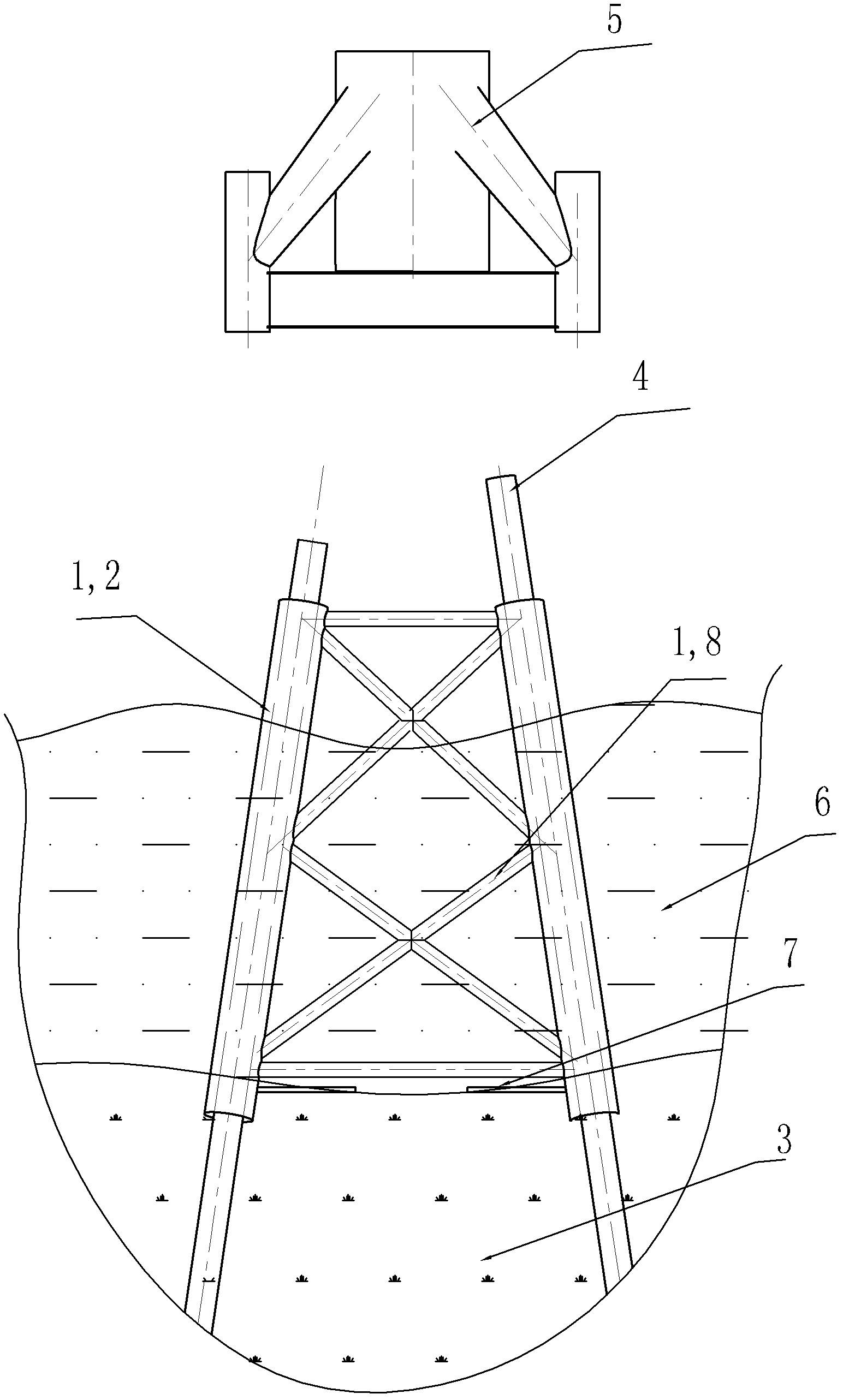

Basic mounting method of offshore fan jacket and integrated jacket device

The invention discloses an integrated jacket device which comprises a jacket body, wherein the jacket body is horizontally arranged on a seabed surface; the jacket body comprises a plurality of jacket legs; a tubular pile which is fixed on the seabed surface is inserted into each of the jacket legs; a jacket platform on which a fan tower cylinder is installed is arranged at the top of the jacket body; and the jacket platform is integrally connected with the jacket body. Besides, the invention discloses a basic mounting method of an offshore fan jacket. The method comprises the following steps: A) mounting the jacket platform: arranging the jacket platform at the upper end of the jacket body and connecting the jacket platform and the jacket body into a whole; B) placing the jacket body: horizontally arranging the jacket body on the seabed; C) piling: inserting the tubular piles into the jacket legs and utilizing a piling machine to firmly fix the tubular piles in the seabed; and D) grouting: after piling the tubular piles, grouting cement plaster into the clearances between the tubular piles and the jacket legs.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

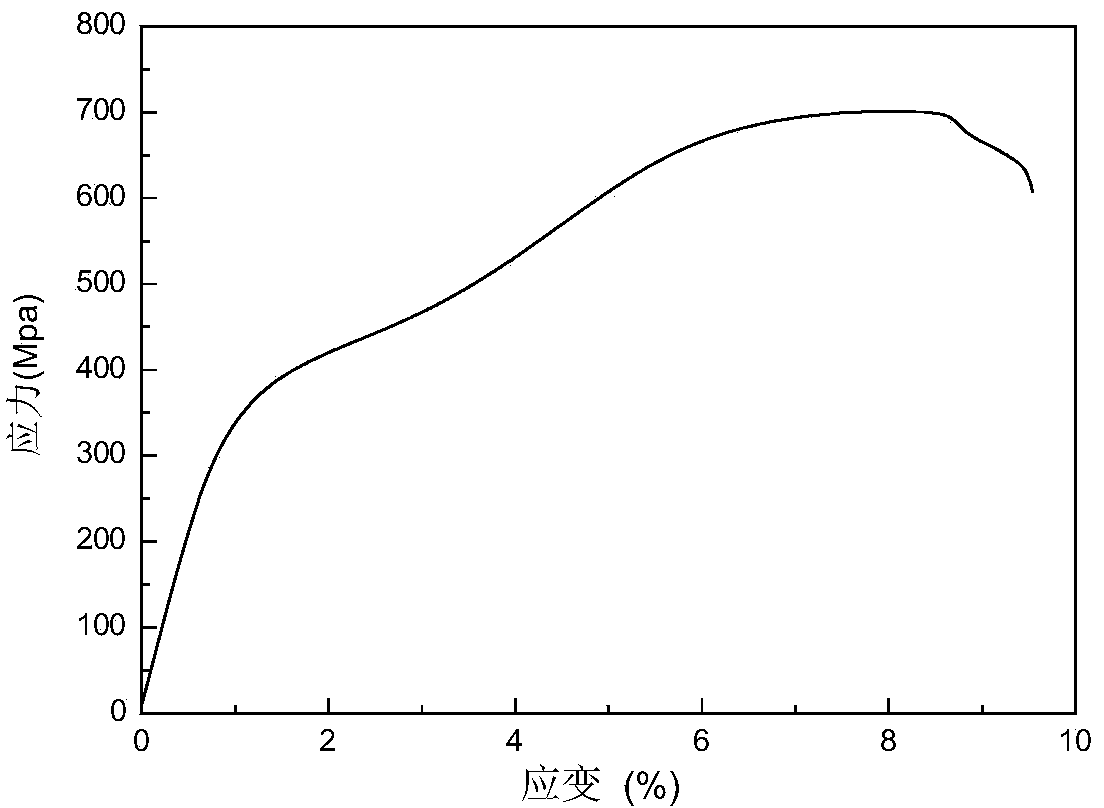

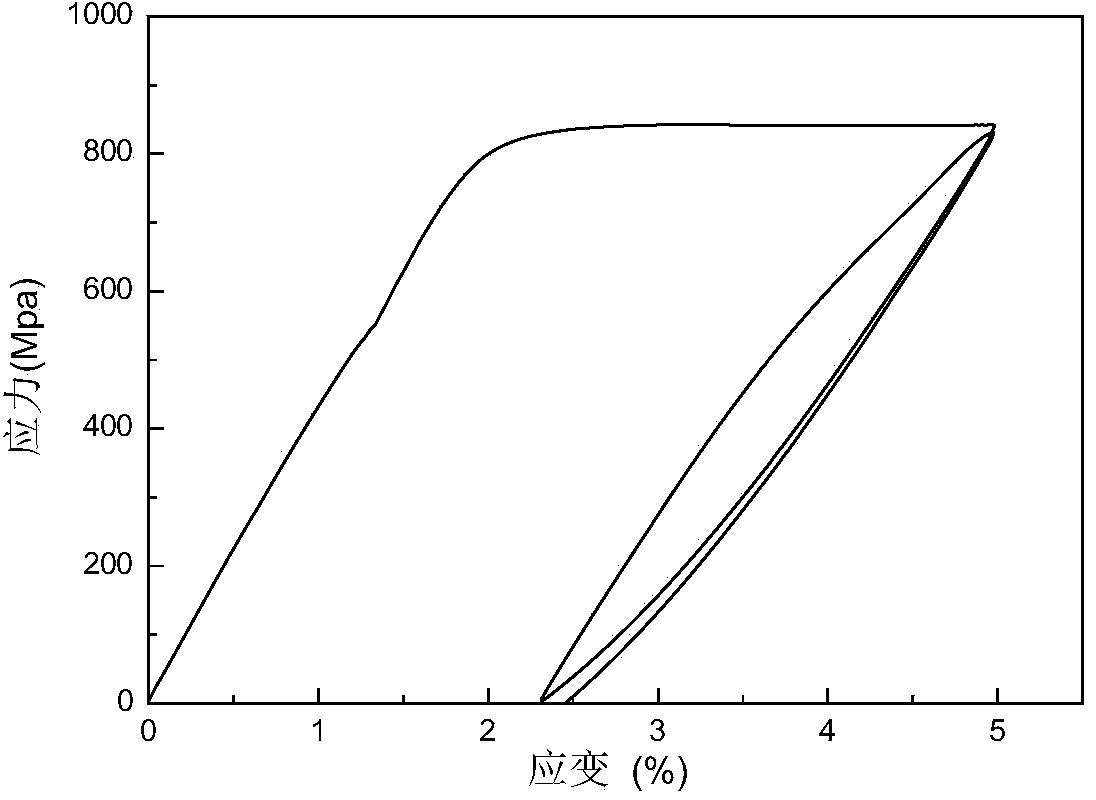

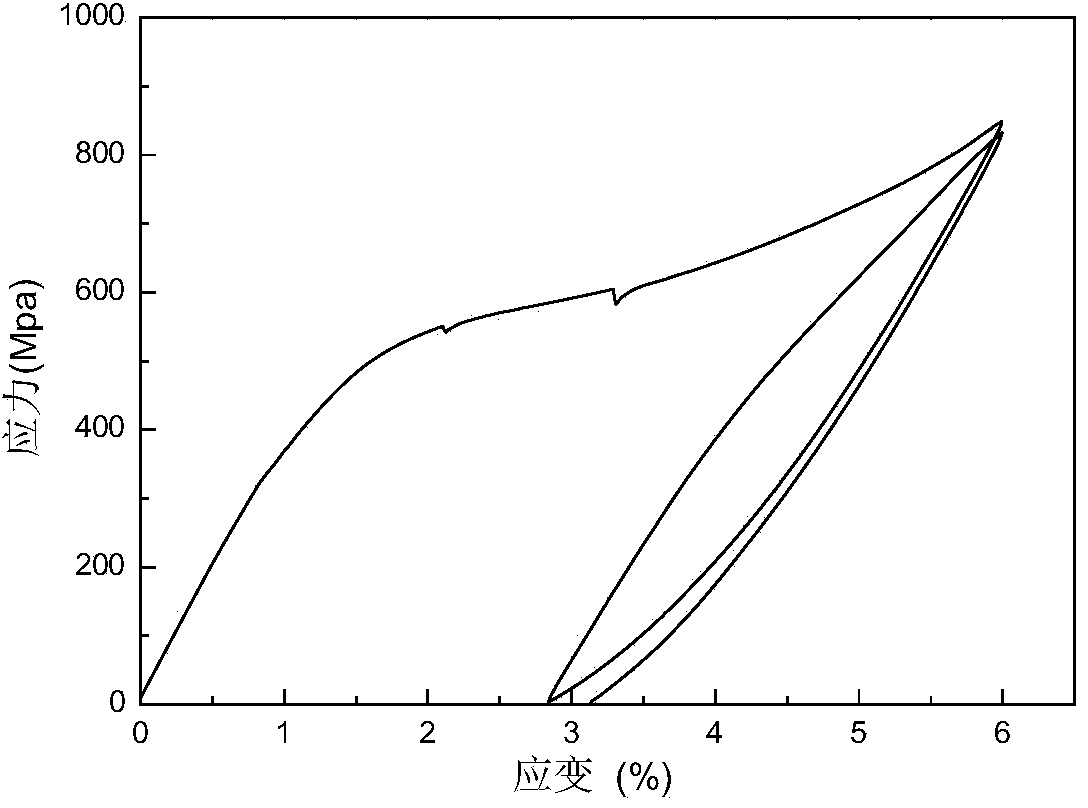

Wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy and preparation method thereof

ActiveCN104032188ABreakthrough featureBreak through limitationsElemental compositionTitanium zirconium

The invention discloses a wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy and a preparation method thereof. The wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy consists of the following biosafety elements in percentage by atom: 20% of zirconium (Zr), 10% of niobium (Nb), 2-4% of tantalum (Ta) and the balance of titanium (Ti). Through different thermal treatment processes, the alloy has different functional characteristics of wide-temperature-range hyperelasticity and high-temperature shape memory effect, namely, the Ti-20Zr-10Nb-(2-4)Ta is of a beta phase at room temperature after annealing at 600 DEG C and air cooling and has a wide temperature range (from -196 DEG C to 135 DEG C) and hyperelasticity, and the maximum room-temperature hyperelasticity is 4.9%, and the highest hyperelasticity is obtained at 50 DEG C and reaches 5.0%; the Ti-20Zr-10Nb-(2-4)Ta is of an alpha phase at room temperature after annealing at 600 DEG C and quenching in water and has a high-temperature shape memory effect, the peak temperature of inverse martensite phase transformation is 97-130 DEG C, and the maximum shape memory effect is 3.34%.

Owner:BEIHANG UNIV +1

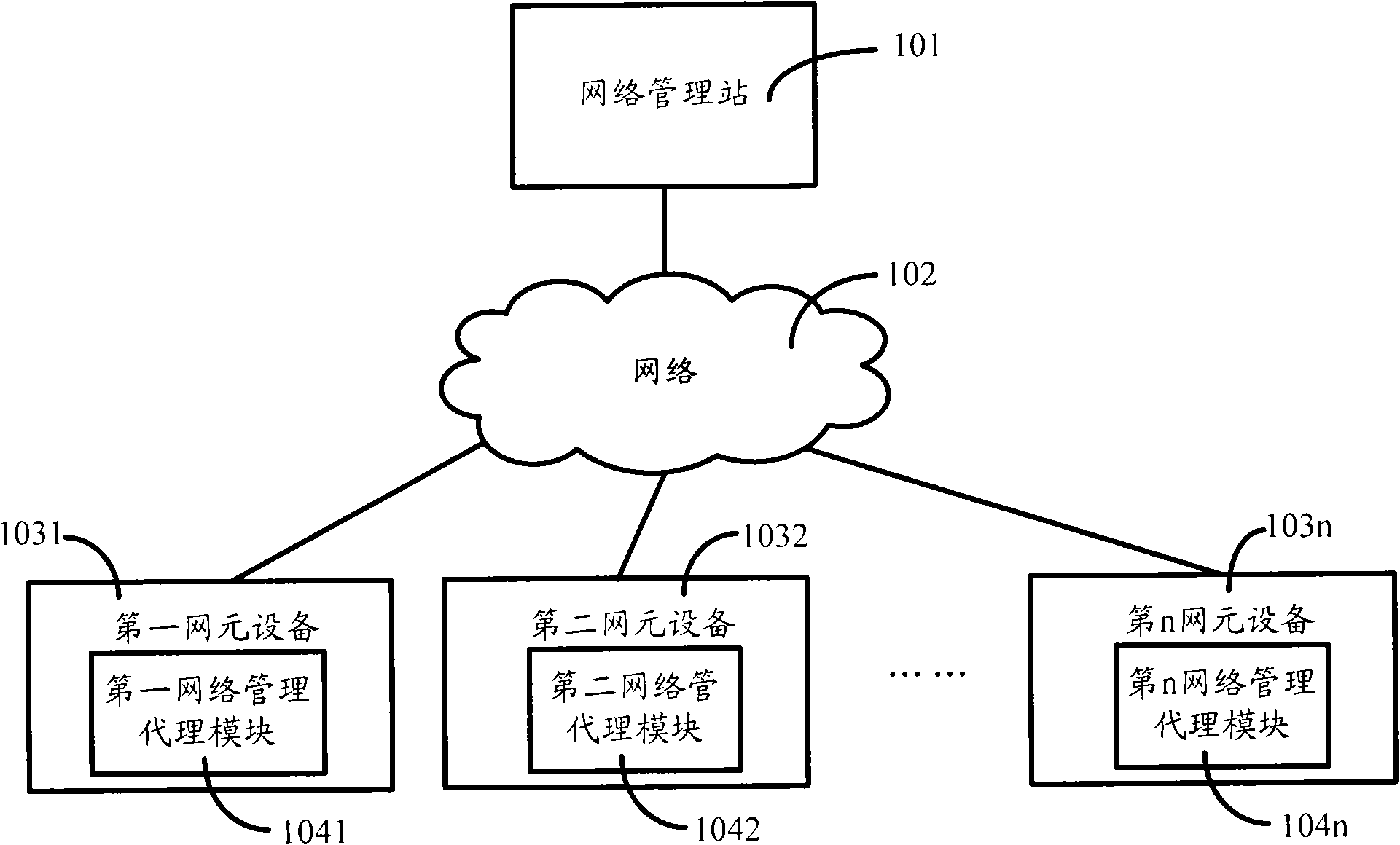

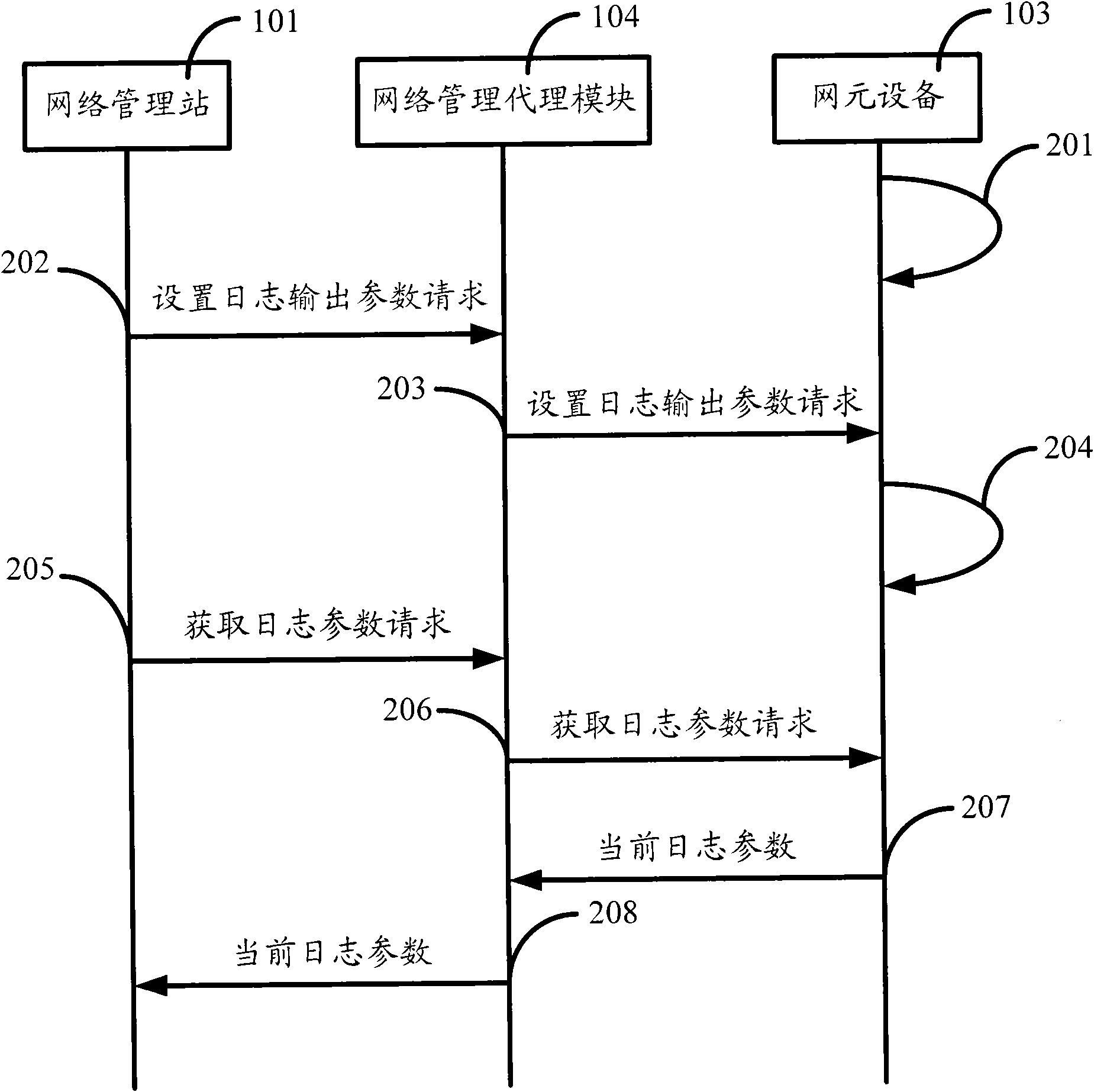

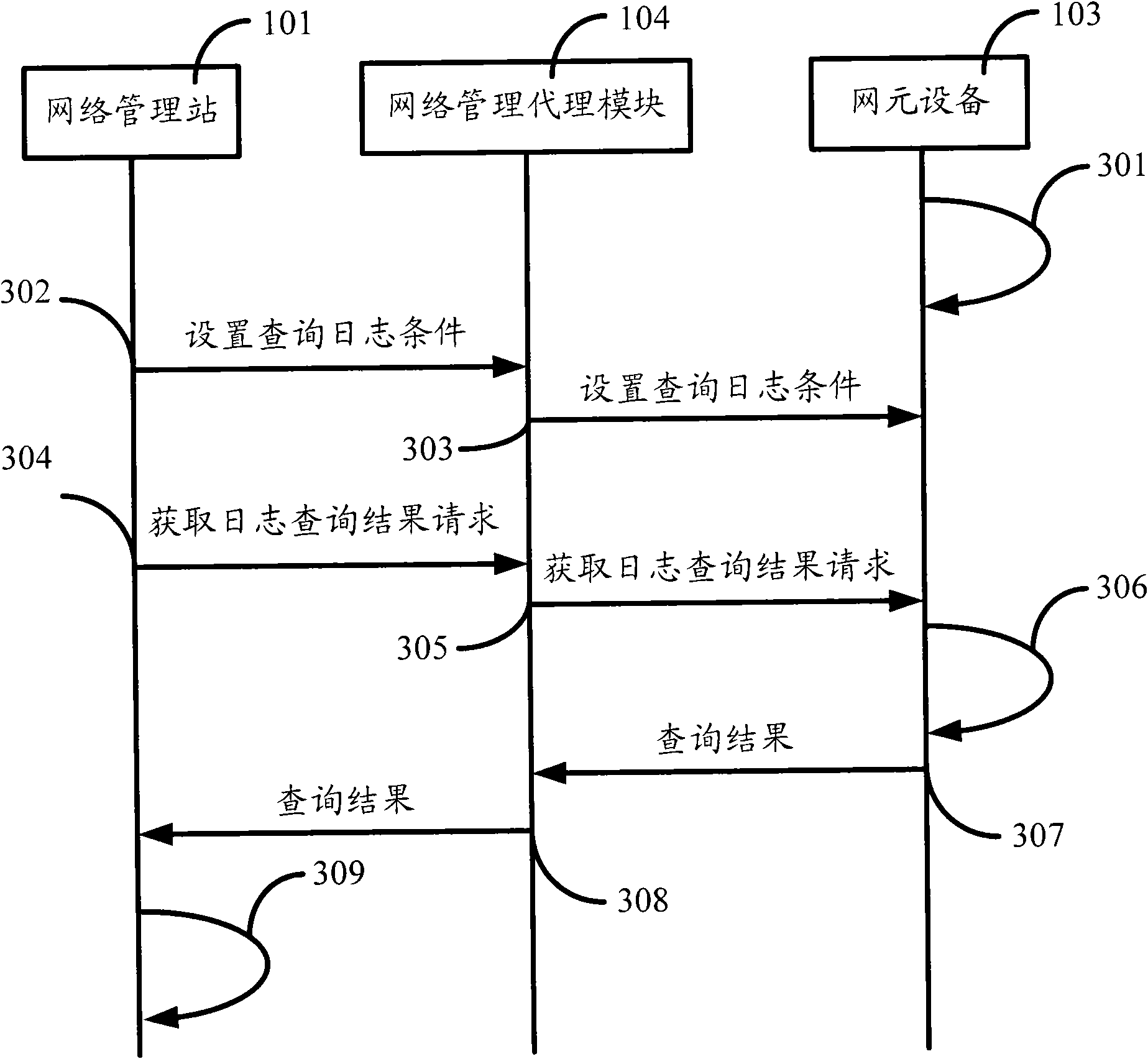

Method of network element equipment log management and device

ActiveCN101667932AEasy to locateRealize dynamic managementData switching networksNetwork managementService information

The invention discloses a method of network element equipment log management and a device; the method comprises the following steps: at least one log processing request is generated by a network management station, the log processing request is transmitted to at least one network element equipment by a network management agent module; the network element equipment receives the log processing request, and the network element equipment log is managed according to the log processing request. By adopting the invention, a plurality of network element equipment logs can be dynamically managed in a concentrating way by the network management station without re-designing special log management software, and the operation of setting and searching the network element equipment log can be realized easily by a setting / acquiring interface based on an SNMP protocol, thereby meeting insistent demands of a user and being convenient for administers and developers to locate faults of the network elementequipment and recall service information.

Owner:ZTE CORP

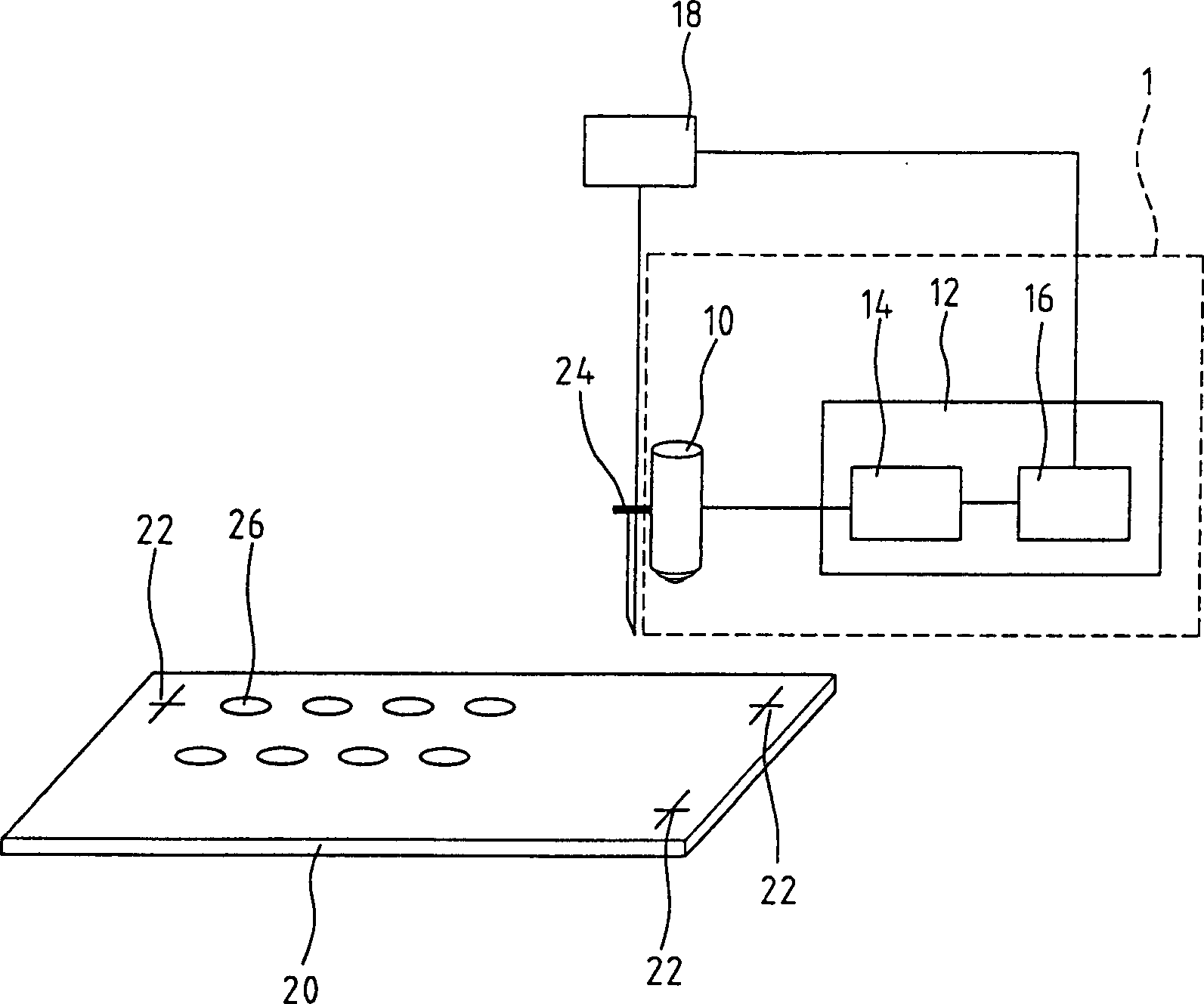

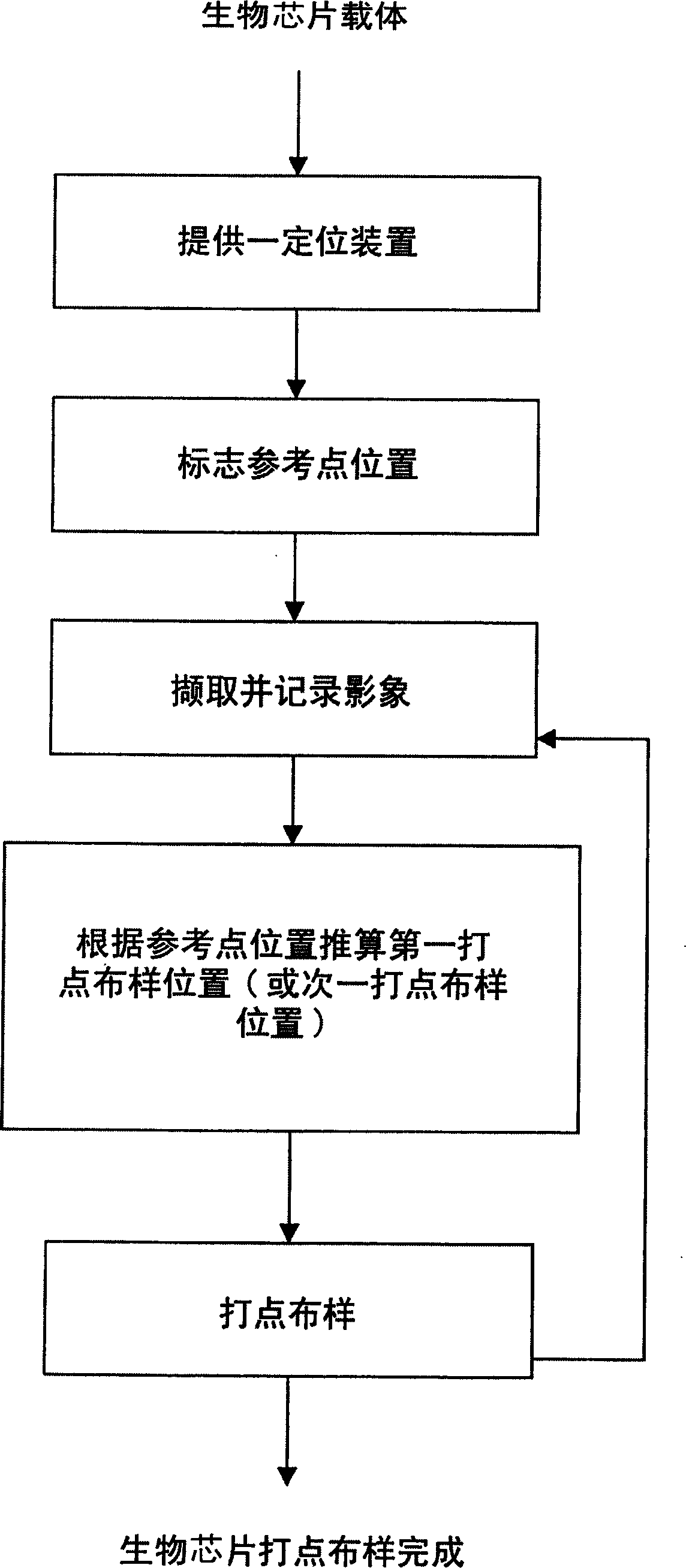

Locating device and its locating method for biochip

InactiveCN1782707ASolve sizeSolve the errorMaterial analysis by optical meansBiological testingComputer visionArtificial intelligence

The present invention provides locating device and method for biochip sample application. The locating device includes one image pick-up device and one locating regulation system. The method of locating the biological probe in the biochip carrier accurately includes the following steps: A. providing a biochip sample application locating device including one image pick-up device and one locating regulation system; B. marking the reference point on the biochip carrier before sample application; C. picking up and recording the image of the reference point with the image pick-up device; D. calculating the first sample applying position with the locating regulation system and applying sample; E. picking up the image of the sample applying position; F. performing feedback operation and correcting the next sample applying position and applying sample; and G. repeating the steps E and F until completing all the sample application.

Owner:KAIWOOD TECH

Powder quantitative weighing and die throwing integrated production equipment and work method thereof

PendingCN107283913ASolve the problems of high labor intensity and low production efficiencyEasy to locateWeighing apparatus with automatic feed/dischargeShaping pressEngineeringMechanical engineering

The invention discloses powder quantitative weighing and die throwing integrated production equipment and a work method thereof. The powder quantitative weighing and die throwing integrated production equipment is composed of feeding mechanisms, storage bins, a charging mechanism, a split charging and weighing mechanism, a conveying mechanism, an unloading mechanism and a controller, all of which are arranged on an equipment frame. Through coordinated cooperation of the multiple feeding mechanisms, the multiple storage bins, the charging mechanism and the split charging and weighing mechanism, all of which are sequentially arranged on the equipment frame, die throwing of two or more kinds of powder raw materials in sequence can be achieved, double-box one-time automatic weighing of each powder can be achieved, and the production efficiency of a pressing machine is improved in a multiplied manner.

Owner:泰安市泰山九鼎称重系统设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com