Device for automatically detecting nut loss of rail fastener system

An automatic detection device and nut technology, which is applied in the direction of measuring device, radio wave measurement system, satellite radio beacon positioning system, etc., can solve the problems of unstable training results, large errors in nut location results, applicability and workability of visual recognition systems Reliability needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

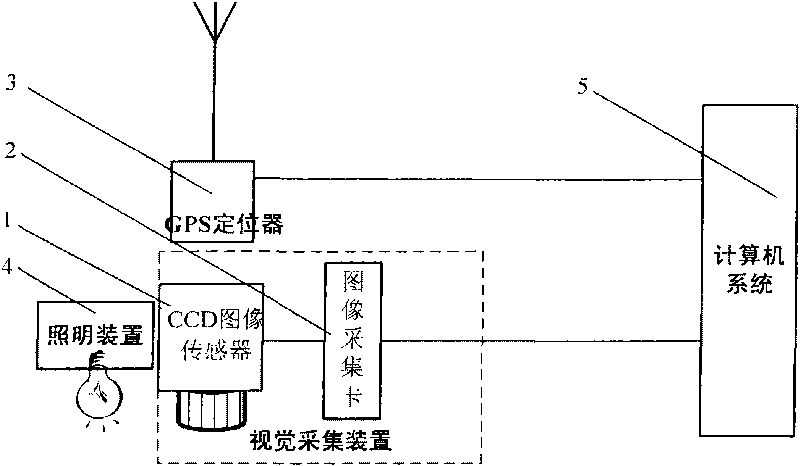

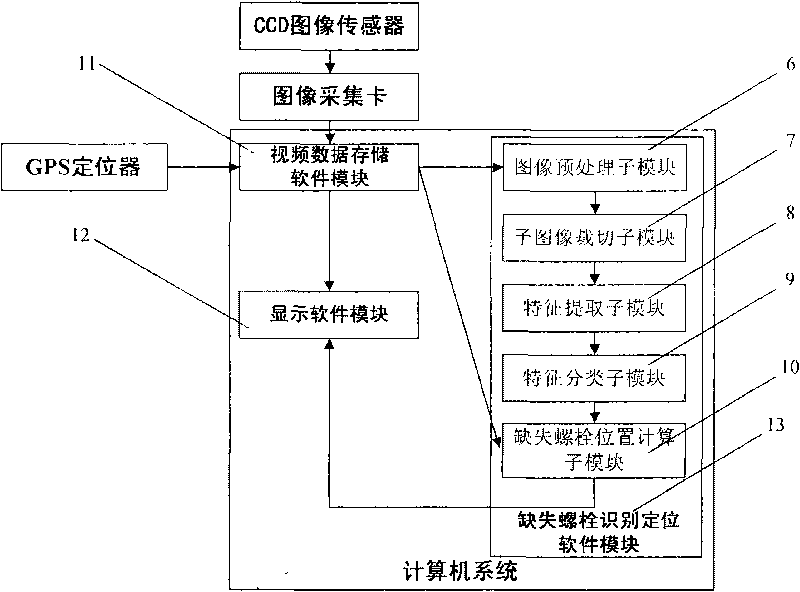

[0028] Such as figure 1 As shown, the present invention includes four components: a visual acquisition device, a GPS locator 3 , an illumination device 4 and a computer system 5 . The visual acquisition device includes a CCD image sensor 1 and an image acquisition card 2 . The visual collection device is used to collect continuous video images including the fastener system nuts on both sides of the rail at the bottom of the train, and transmit the obtained continuous video images to the computer system 5 .

[0029] The GPS locator 3 determines the geographic location of the visual acquisition device at each moment according to the GPS positioning principle, the geographic location data includes longitude and latitude values, and transmits the geographic location information of each moment to the video data storage software module 11 in the computer system 5 At the same time, the video data storage software module 11 also stores the corresponding time value when each geographi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com