Coal-rock interface identifying method and system based on image

A recognition system and recognition method technology, applied in the direction of image communication, character and pattern recognition, TV system components, etc., can solve the problem of increasing the labor intensity and danger of the driver of the coal mining machine, aggravating the wear of the pick, and adjusting the position of the drum Inappropriate and other problems, to achieve the effect of reliable coal-rock interface information, strong adaptability, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

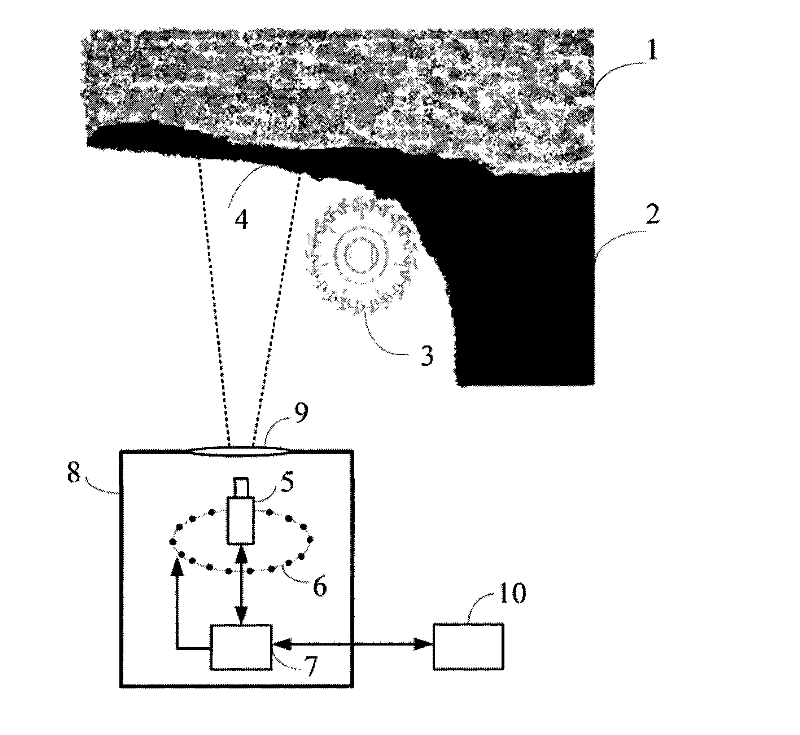

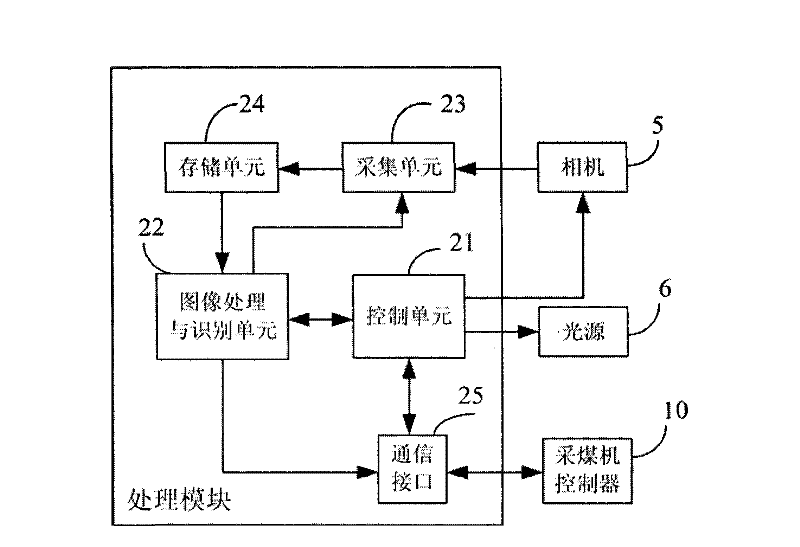

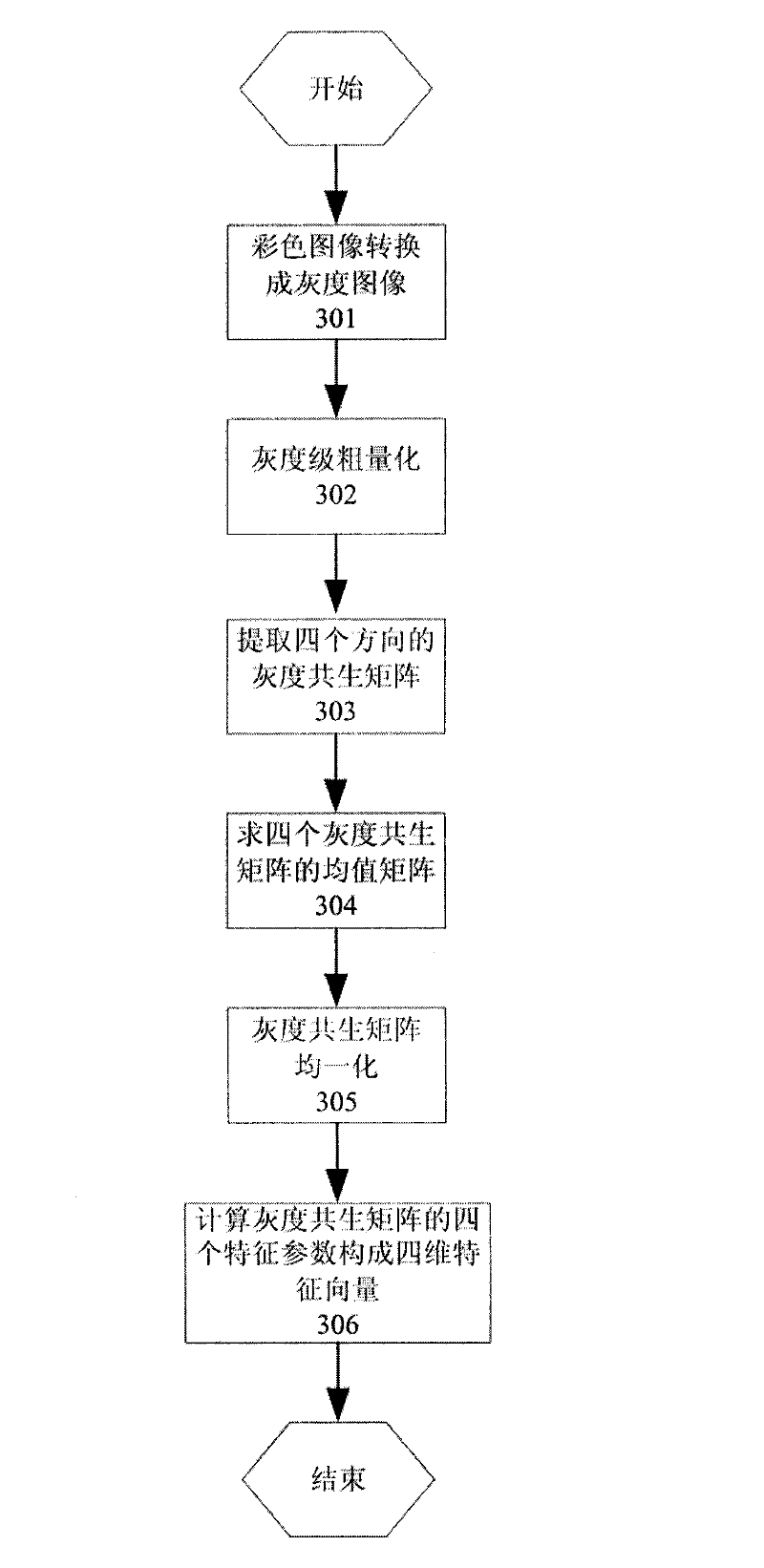

[0038] First, the working principle of the image-based coal-rock interface recognition system is described. Reference figure 1 , In the coal mining face, the shearer drum 3 cuts the coal wall formed by the rock layer 1 and the coal seam 2, and the coal rock recognition system collects the image of the coal and rock cut section 4 cut by the drum in real time, according to the different texture characteristics of the image To identify whether the current cutting object is a coal seam or a rock layer. The coal and rock identification system consists of a light source module 6, an imaging module 5, a processing module 7 and an explosion-proof housing 8. The light source module 6 is a high-brightness ring-shaped white light illuminating lamp composed of multiple groups of LED arrays, and the number of LED array lights is controlled by the processing module 7 to provide suitable illumination for collecting coal and rock images. The imaging module 5 is a charge-coupled device (CCD) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com