Car body top cover loading device

A body and material rack technology, which is applied to the field of the body top cover feeding device, can solve the problems of difficult positioning and adjustment of the body top cover, short positioning adjustment assistance time, long assistance time and low efficiency, etc., and achieves short positioning adjustment assistance time, Convenient positioning, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

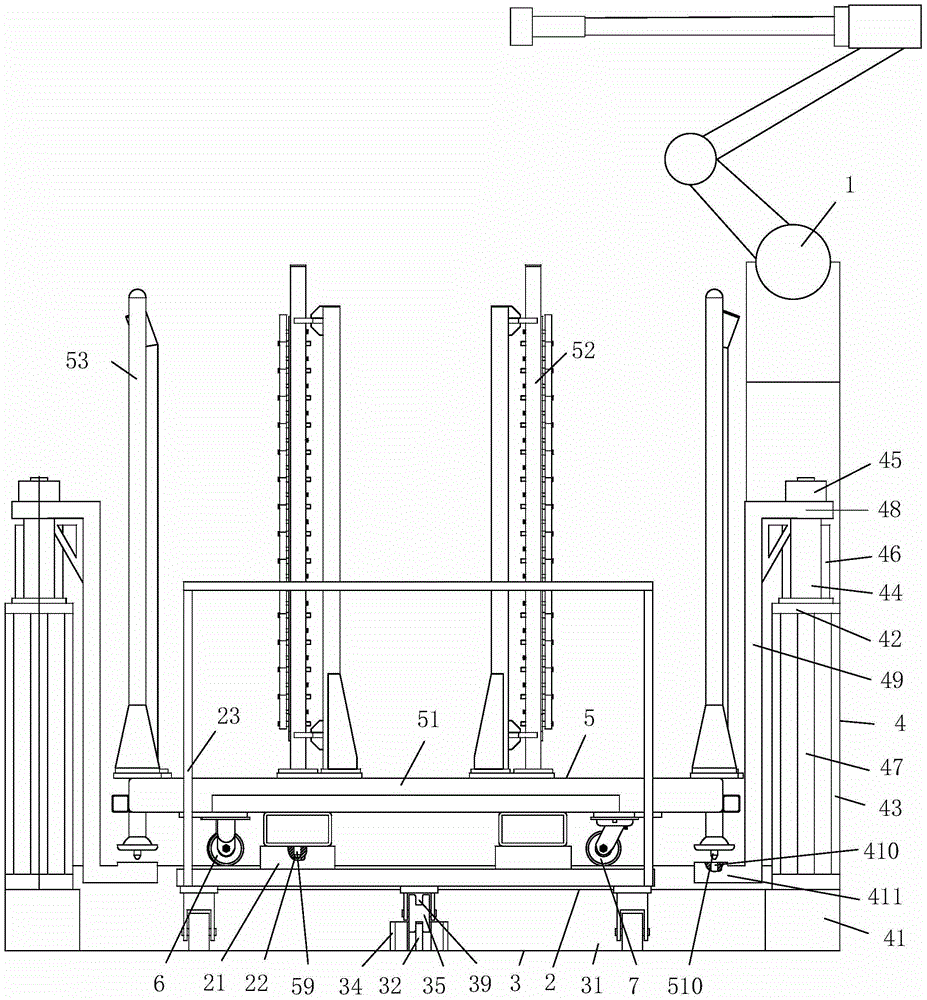

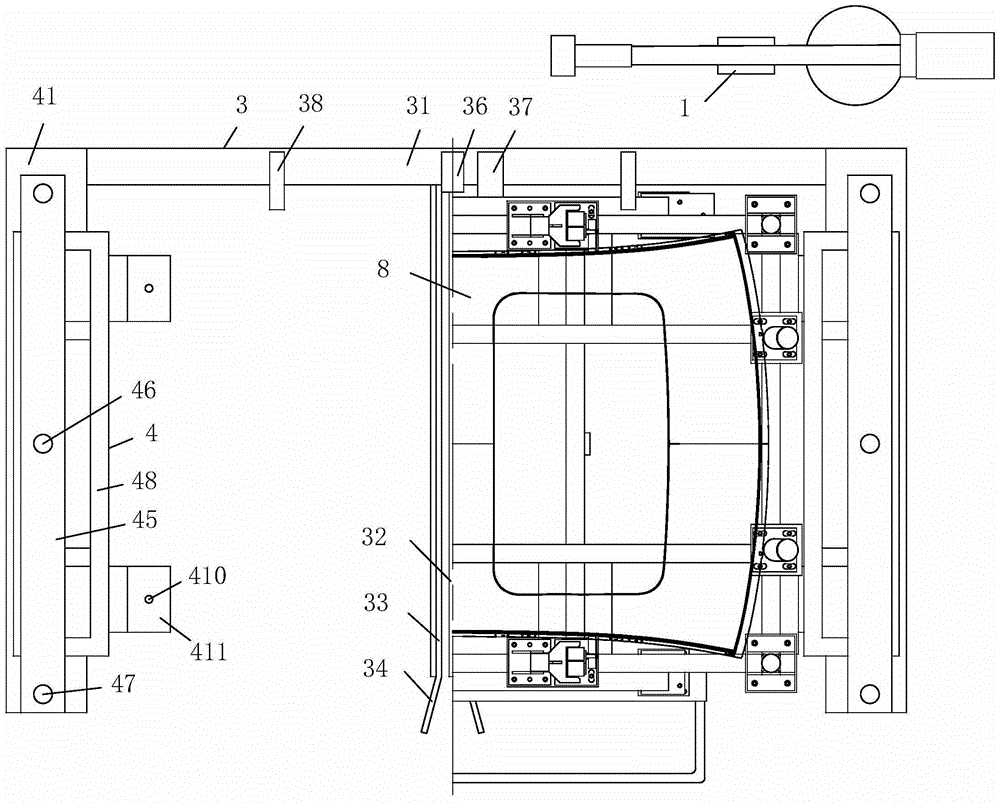

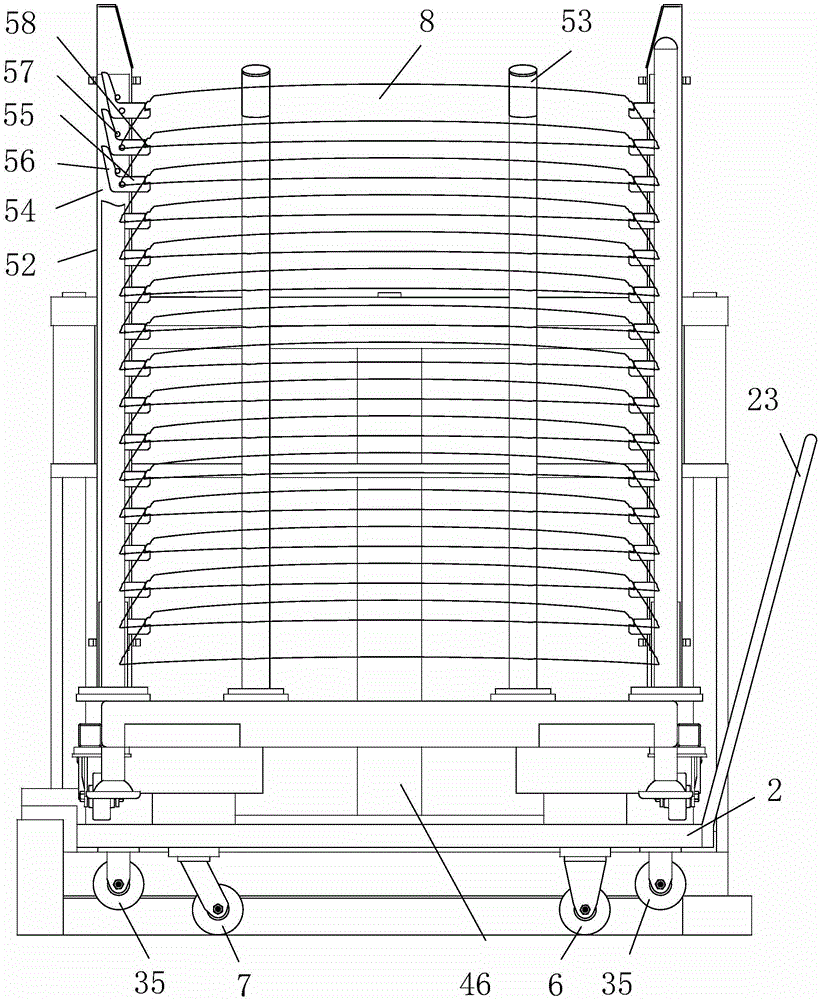

[0018] as attached figure 1 , attached figure 2 , attached image 3 Shown: a vehicle body top cover loading device, including a transfer vehicle 2, a transfer vehicle positioning assembly 3, two material rack lifting mechanisms 4, a material rack 5 and an upper Material industrial robot 1.

[0019] The upper end of the transfer vehicle 2 is provided with a material rack support block 21; the material rack 5 includes a base 51, four supporting vertical rods 52, 12 which are respectively located on the opposite sides of the base 51 and whose lower ends are welded to the upper end of the base 51 respectively. The vertical wall bar 53 that two lower ends are welded with base 51 upper ends respectively; The lower end of base 51 is provided with two material rack positioning pins 59; The material shelf positioning hole 22 that fits in clearance with the material shelf p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com