Wide-temperature-range hyperelastic titanium-zirconium-niobium-tantalum shape memory alloy and preparation method thereof

A memory alloy, super-elastic technology, applied in the titanium zirconium niobium tantalum shape memory alloy material, the new quaternary Ti-Zr-based shape memory alloy field, to achieve the effect of improving X-ray visibility, easy positioning and tracking, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of a titanium-zirconium-niobium-tantalum shape memory alloy, comprising the following steps:

[0042] The first step: use titanium sponge particles with a purity of 99.7%, zirconium particles with a purity of 99.7%, master alloy Nb-Ti chips with a purity of 99.9%, and master alloy Nb-Ta chips with a purity of 99.9% as raw materials, according to 2 to 4 at.% Ta, 20 at.% Zr, 10 at.% Nb, and the rest are the composition ratios of Ti, and each raw material is prepared.

[0043]Step 2: After mixing all raw materials evenly, press cold isostatic pressing (CIP) into a rod with a diameter of 40mm, and then perform vacuum degassing. The cold isostatic pressing pressure is 280MPa, the holding time is 10 minutes, the vacuum degassing temperature is 750°C, the holding time is 5 minutes, and the vacuum degree is 5×10 -3 Pa.

[0044] Step 3: Weld the bar after vacuum degassing into a consumable electrode with a length of 650 ...

Embodiment 1

[0055] Example 1: Preparation of Ti-20Zr-10Nb-4Ta alloy material with wide temperature range superelasticity;

[0056] The first step: use titanium sponge particles with a purity of 99.7%, zirconium sponge particles with a purity of 99.7%, master alloy Nb-Ti chips with a purity of 99.9%, and master alloy Nb-Ta chips with a purity of 99.9% as raw materials, according to 4at.% Ta, 20 at.% Zr, 10 at.% Nb, and the rest are the composition ratios of Ti to prepare each raw material.

[0057] Step 2: After mixing all raw materials evenly, press cold isostatic pressing (CIP) into a rod with a diameter of 40mm, and then perform vacuum degassing. The cold isostatic pressing pressure is 280MPa, the holding time is 10 minutes, the vacuum degassing temperature is 750°C, the holding time is 5 minutes, and the vacuum degree is 5×10 -3 Pa.

[0058] Step 3: Weld the bar after vacuum degassing into a consumable electrode with a length of 650 mm in a vacuum consumable arc melting furnace and...

Embodiment 2

[0069] Example 2: Preparation of Ti-20Zr-10Nb-4Ta Alloy Material with High Temperature Shape Memory Effect

[0070] According to the preparation method of Example 1, the cooling in air to room temperature in the seventh step is replaced by quenching in water, so as to obtain a titanium-zirconium-niobium-tantalum alloy plate with high-temperature shape memory effect.

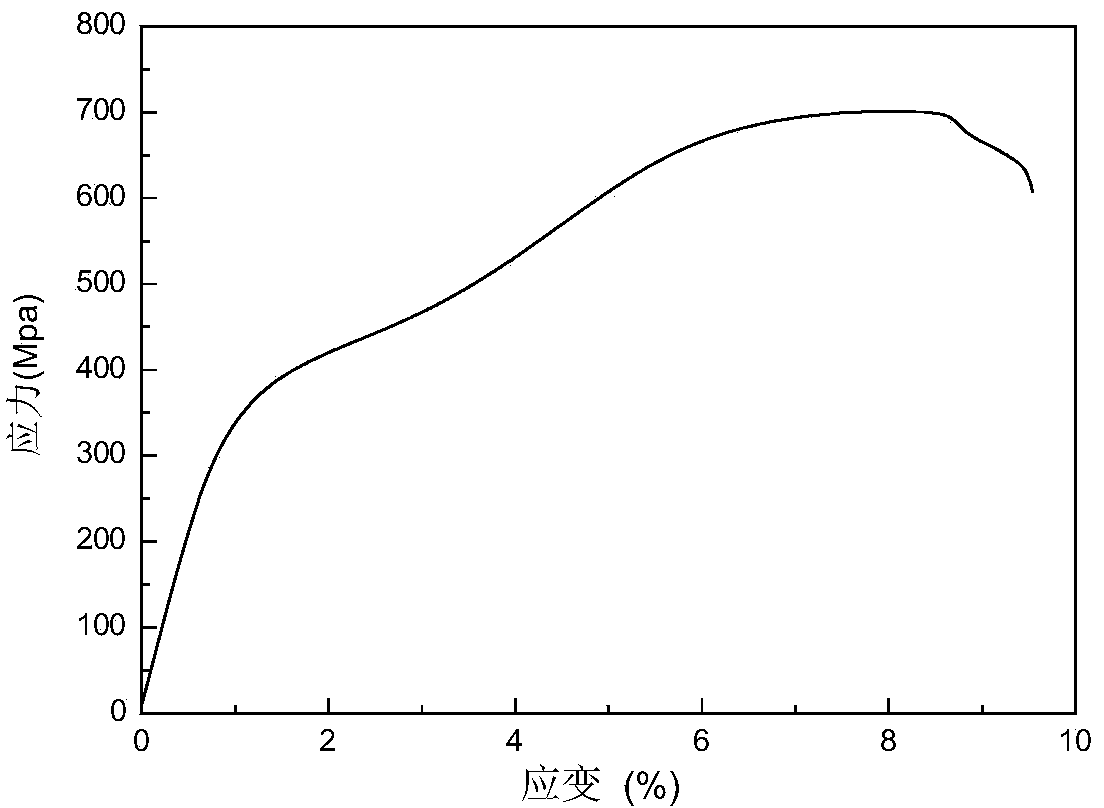

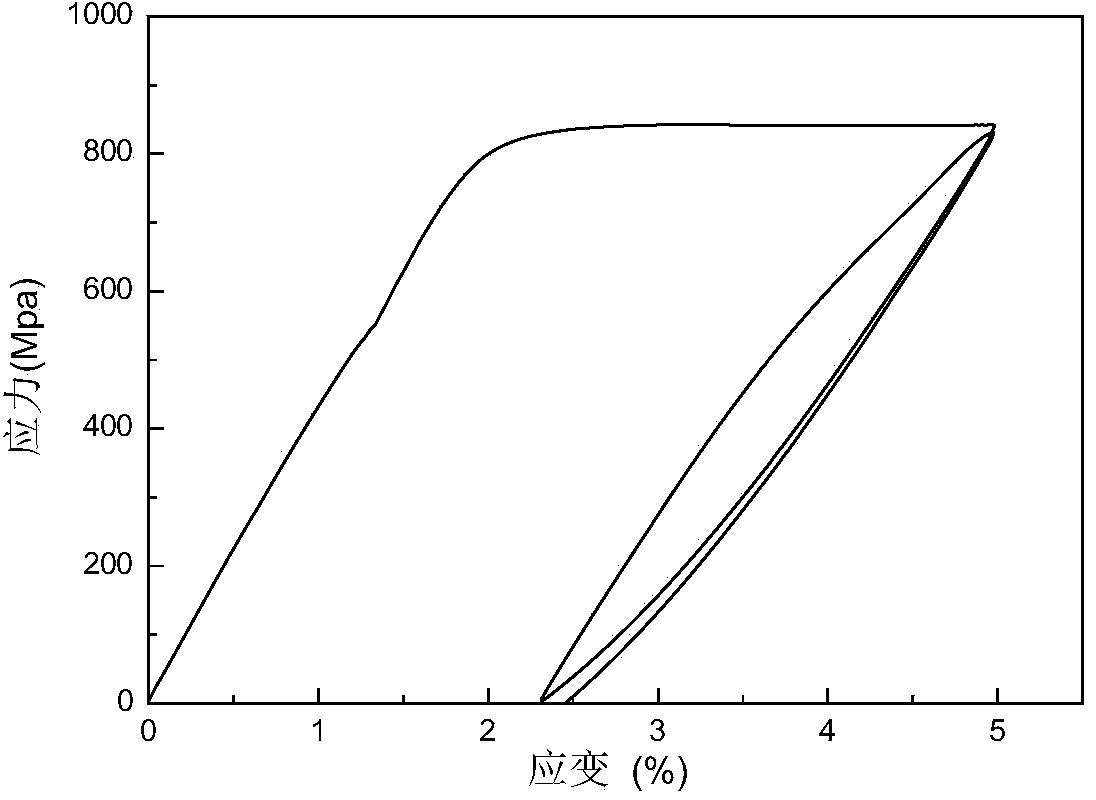

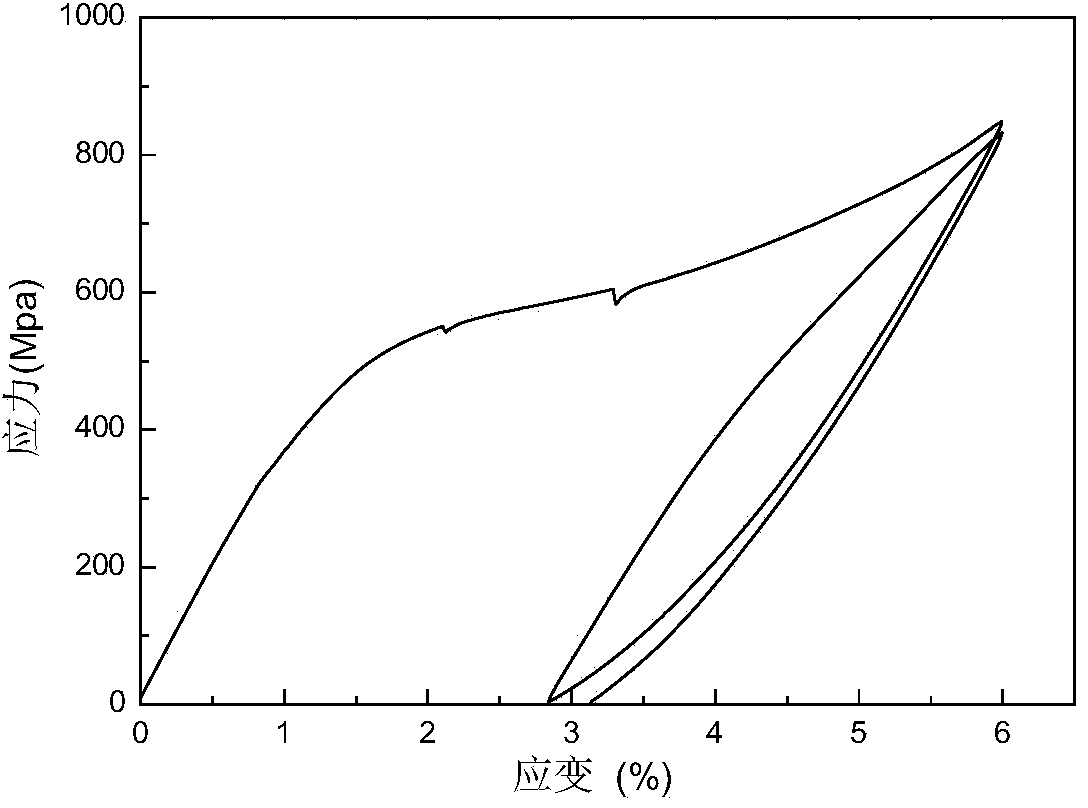

[0071] Use a low-speed cutting saw to cut out the titanium, zirconium, niobium, and tantalum shape memory alloy material with a size of 1×1×1.5 mm. 3 As a phase transition test sample, the martensitic phase transition temperature was measured with a NETZSCH STA449 differential scanning calorimeter; the wire cutting method was used to cut out a tensile gauge section with a length of 30 mm, a width of 1.5 mm, and a thickness of 1 mm. Tensile specimens are used as mechanical performance test samples, and the tensile test is carried out at room temperature using a SANS CMT5504 universal material testing machine wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com