Enzyme seepage agent for improving performance of guar gum fracturing fluid and application of enzyme seepage agent

A fracturing fluid and seepage technology, applied in the fields of production fluid, drilling composition, wellbore/well components, etc., can solve problems such as difficulty in accurately controlling quantity and activation time, pumping fluctuation, formation residue, etc. Simple, smooth curve, mild gel breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, an enzyme seepage agent for improving the performance of guar gum fracturing fluid is composed of the following substances in parts by weight: 5 parts of α-D-trehalose-6-corynebacterium mycolate are added in proportion to the mixing tank, 5 parts of L-asparagine, 5 parts of aspartic acid, 2 parts of sodium diacetate, 2 parts of protease, 5 parts of mannanase, 3 parts of cellulase, 73 parts of water, stirring at room temperature for 30min-1h Can.

[0041] The prepared enzyme permeation agent can achieve the following indicators:

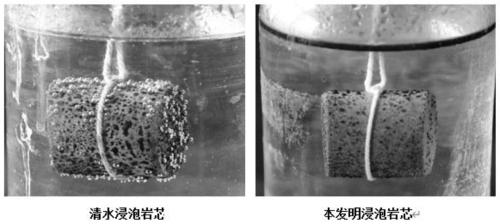

[0042] Crude oil replacement rate: 62%;

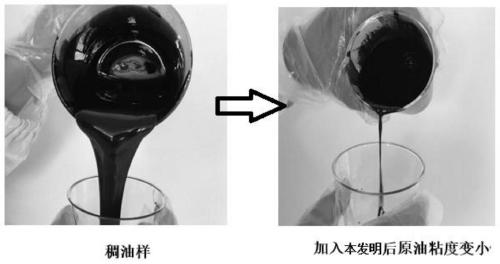

[0043] Viscosity reduction rate: 95%;

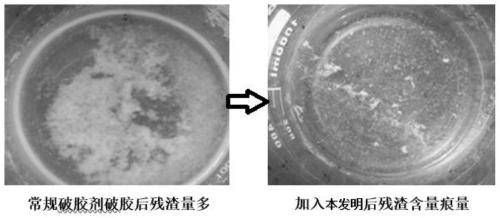

[0044] Residue content reduction rate: 52%;

[0045] Scale inhibition rate: 90%.

[0046] In this example, the application of an enzyme seepage agent to improve the performance of guar gum fracturing fluid is realized through the following steps: add 0.05 parts of enzyme seepage agent to the original 1 part of guar gum fracturing fluid, and...

Embodiment 2

[0049] In this embodiment, an enzyme seepage agent for improving the performance of guar gum fracturing fluid is composed of the following substances in parts by weight: 10 parts of α-D-trehalose-6-corynebacterium mycolate are added in proportion to the mixing tank, 7 parts of L-asparagine, 10 parts of aspartic acid, 5 parts of sodium diacetate, 10 parts of protease, 10 parts of mannanase, 5 parts of cellulase, 43 parts of water, stirring at room temperature for 30min-1h Can.

[0050] The prepared enzyme permeation agent can achieve the following indicators:

[0051] Crude oil replacement rate: 67%;

[0052] Viscosity reduction rate: 98%;

[0053] Residue content reduction rate: 55%;

[0054] Scale inhibition rate: 92%.

[0055] In this example, the application of an enzyme seepage agent to improve the performance of guar gum fracturing fluid is realized through the following steps: Take 0.025 parts of enzyme seepage agent directly into the cross-linking tank and mix with ...

Embodiment 3

[0058] In this embodiment, an enzyme seepage agent for improving the performance of guar gum fracturing fluid is composed of the following substances in parts by weight: 8 parts of α-D-trehalose-6-corynebacterium mycolate are added in proportion to the stirring tank, 6 parts of L-asparagine, 7 parts of aspartic acid, 3 parts of sodium diacetate, 7 parts of protease, 6 parts of mannanase, 4 parts of cellulase, 60 parts of water, and stir at room temperature for 40 minutes.

[0059] The prepared enzyme permeation agent can achieve the following indicators:

[0060] Crude oil replacement rate: 70%;

[0061] Viscosity reduction rate: 98%;

[0062] Residue content reduction rate: 58%;

[0063] Scale inhibition rate: 94%.

[0064] In this example, the application of an enzyme seepage agent to improve the performance of guar gum fracturing fluid is realized through the following steps: Take 0.035 parts of enzyme seepage agent directly into the cross-linking tank and mix with 1 part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com