Patents

Literature

45results about How to "Gentle curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

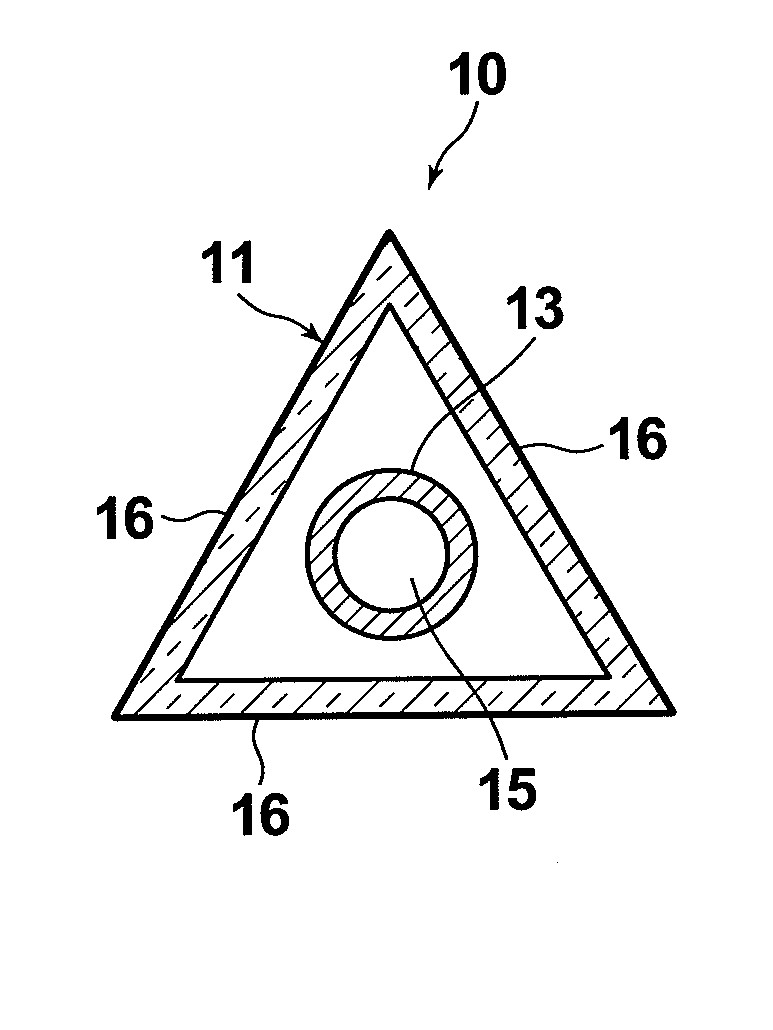

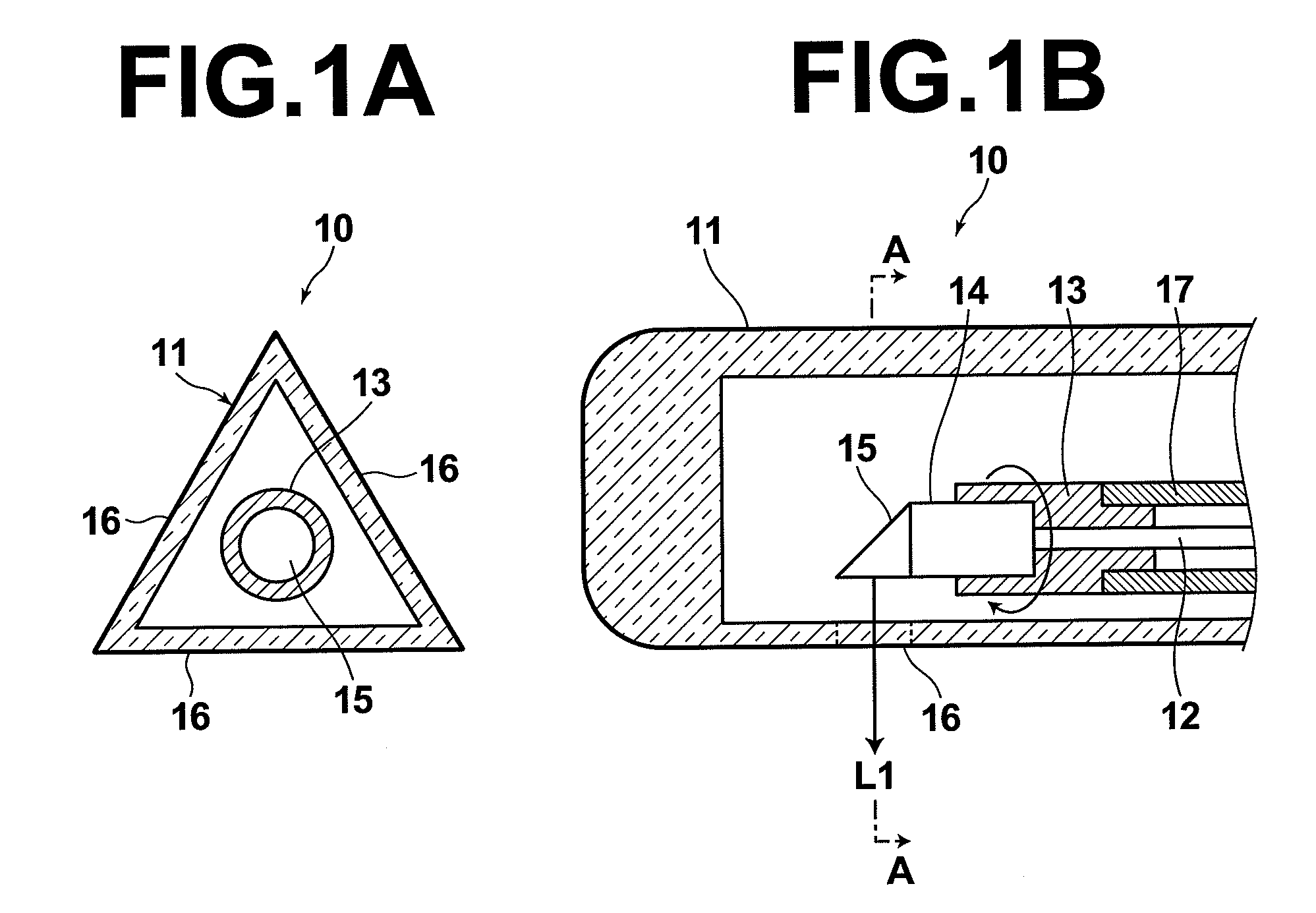

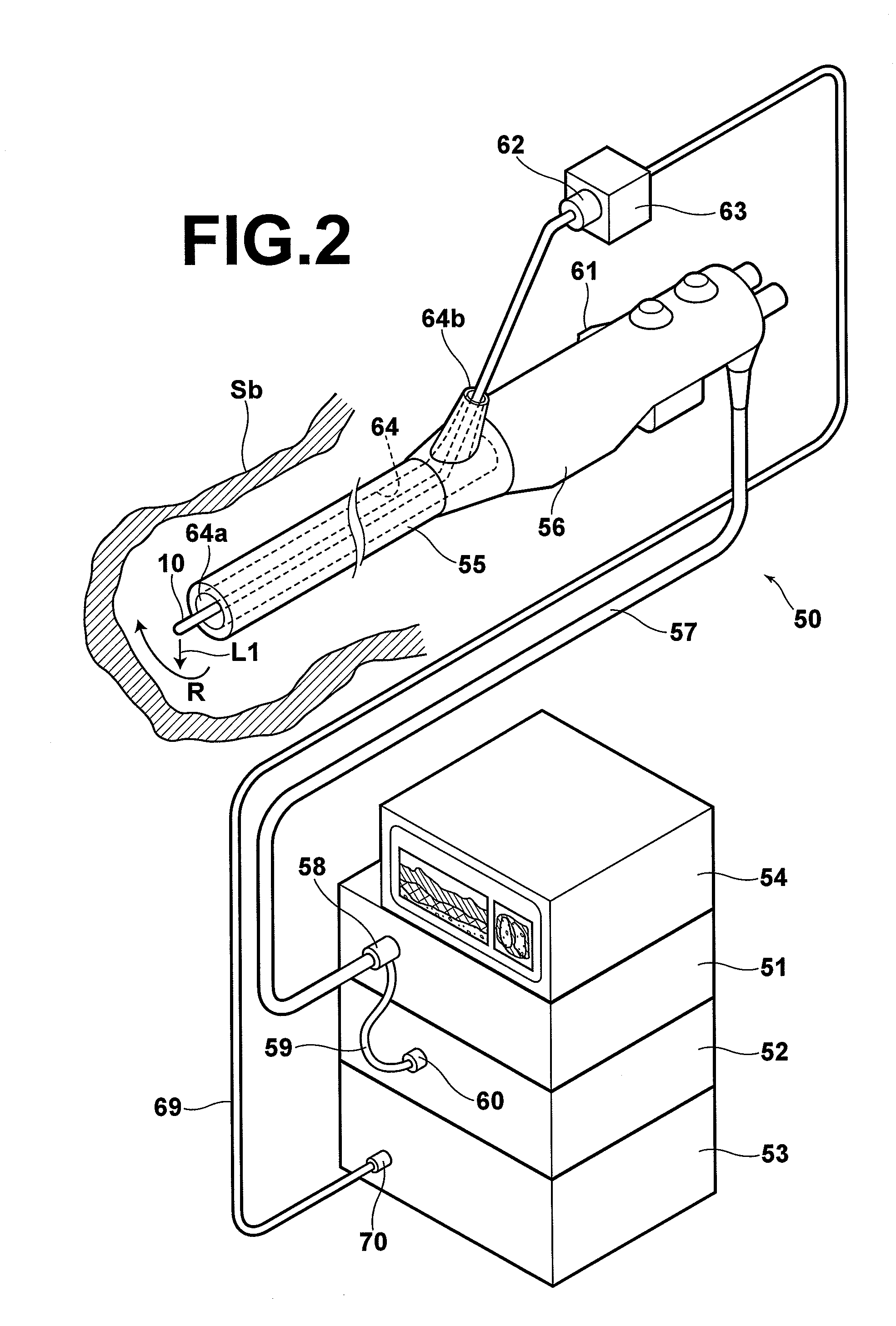

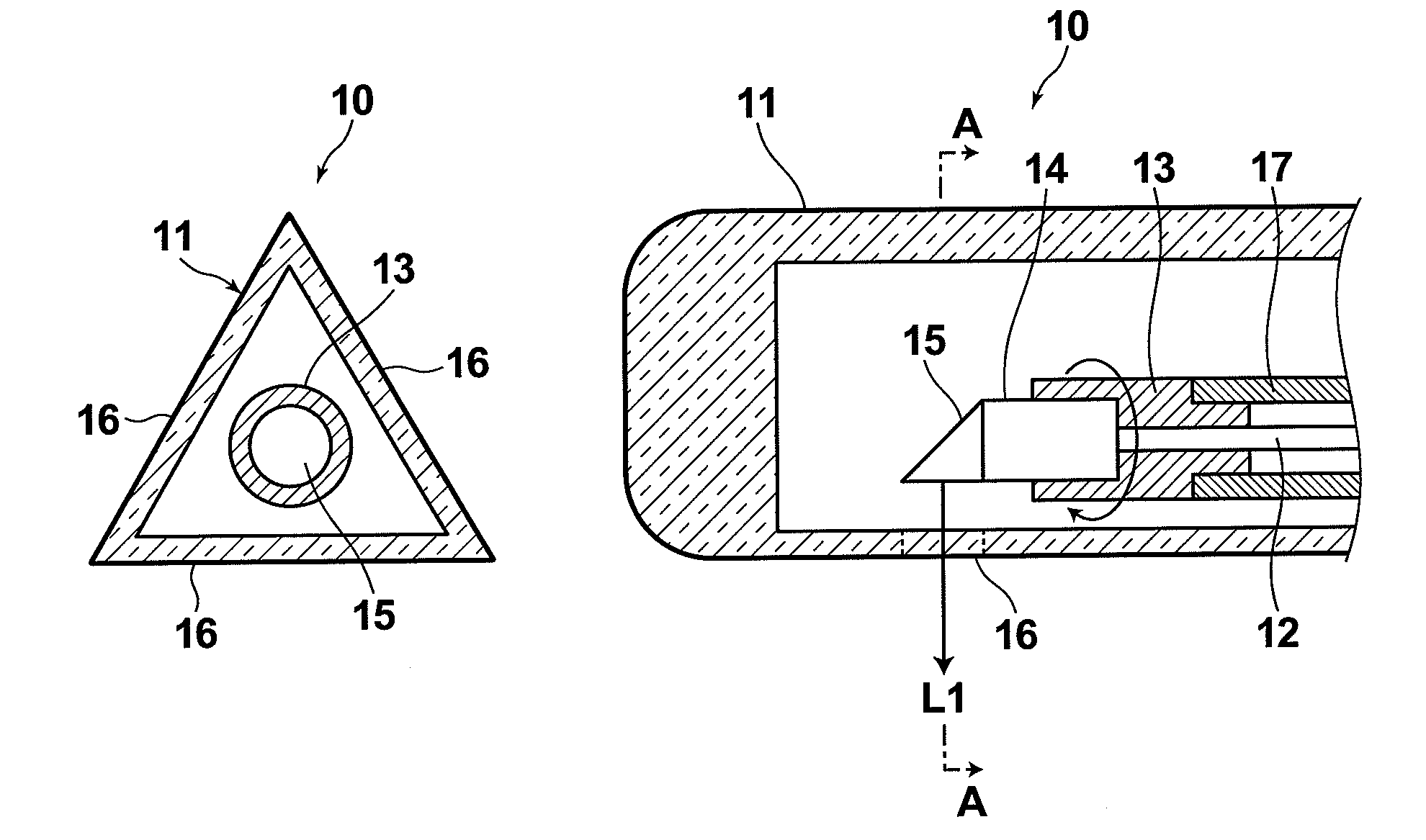

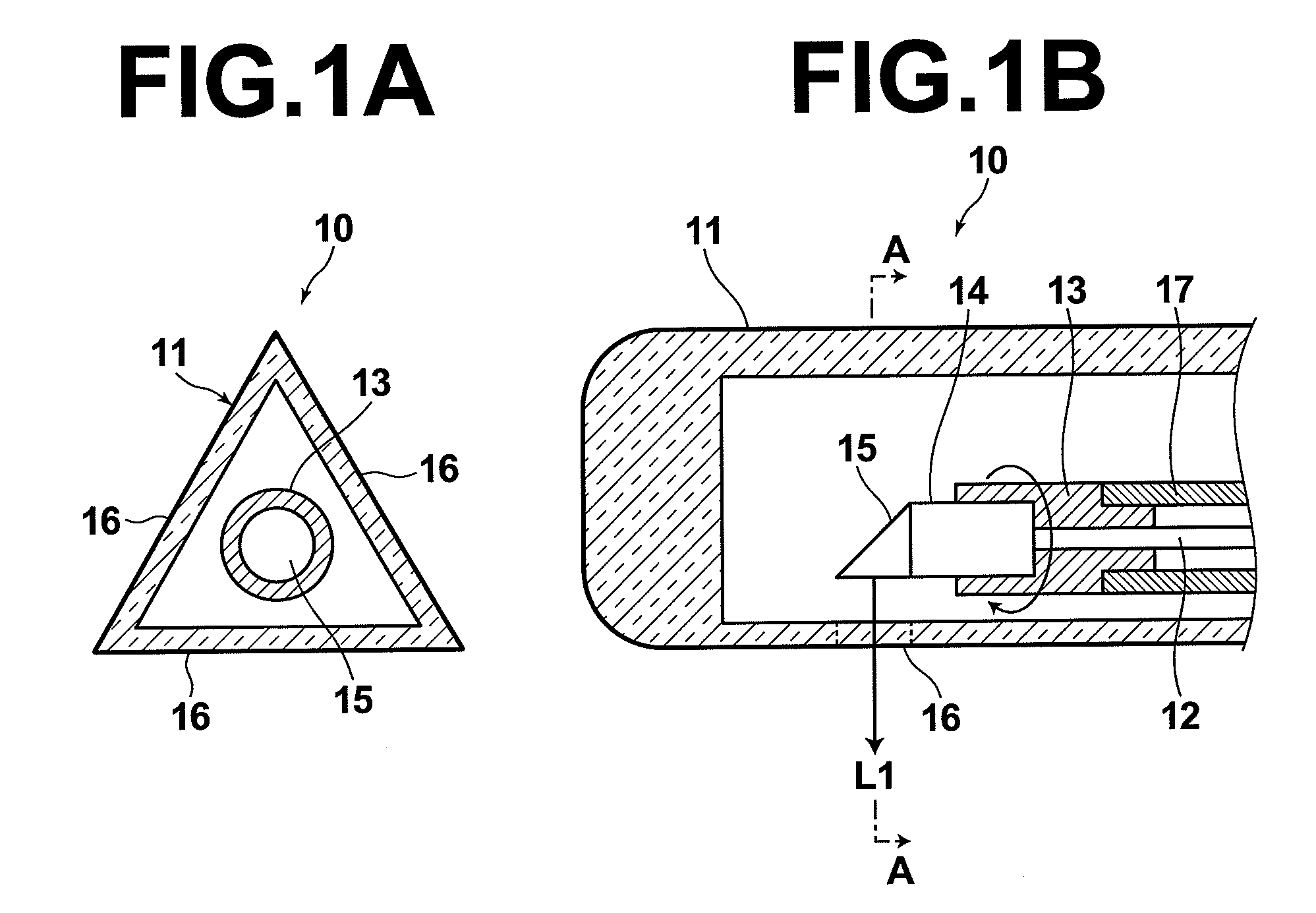

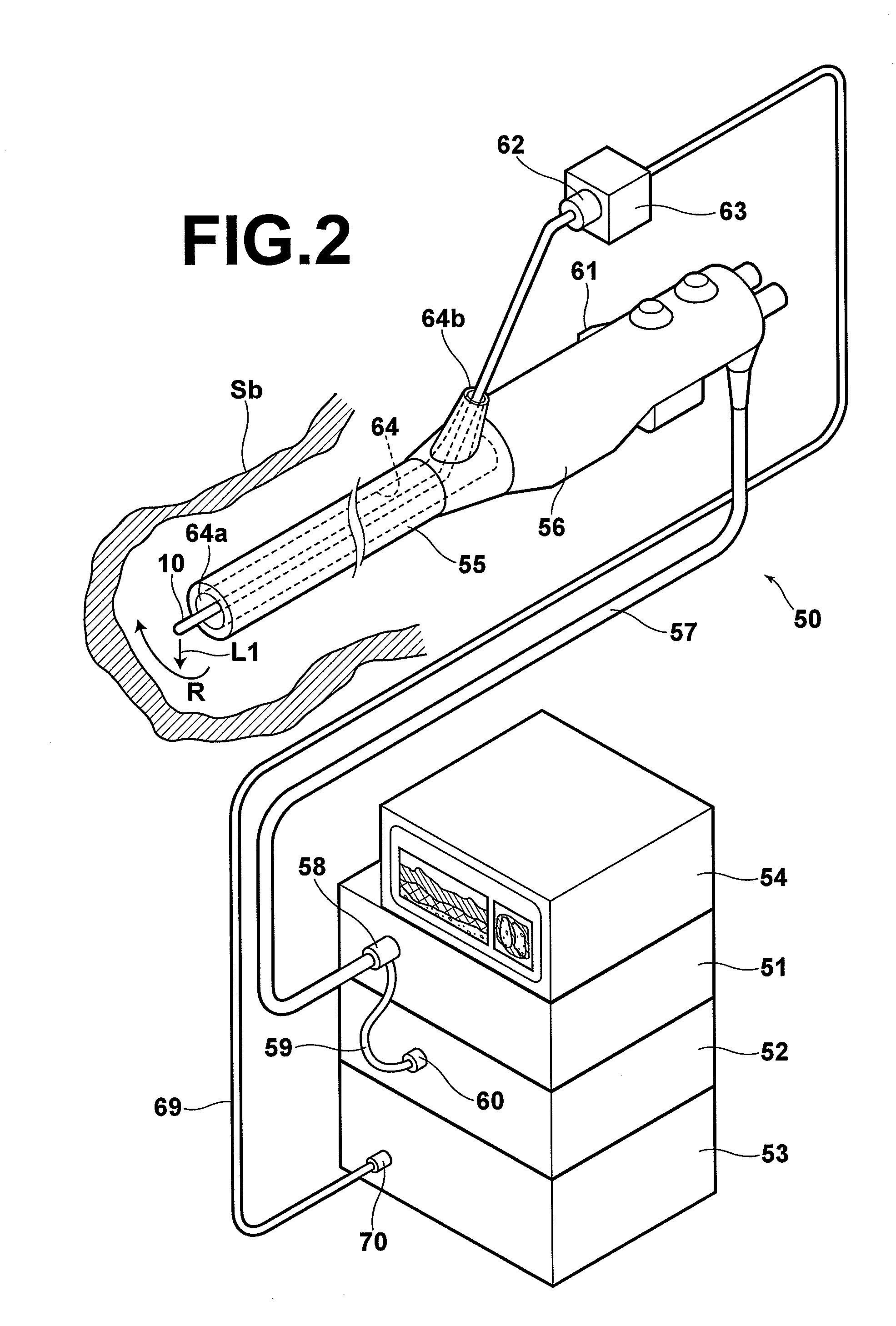

Optical probe and optical tomography apparatus

InactiveUS20080260342A1High quality tomography imageIncrease contact areaSurgeryEndoscopesOptical tomographyEngineering

An elongated probe to be inserted into a tube which is open at a distal end portion of an insertion section of an endoscope includes a sheath constituting the outer circumferential surface of the optical probe, an optical fiber laid in the internal space of the sheath along the longitudinal direction of the sheath, and a deflection scanning means disposed in the internal space of the sheath to deflect light outputted from the optical fiber and is rotated around an axis line extending in the longitudinal direction to scan the deflected light in a circumferential direction of the axis line. A plurality of light transmission sections for transmitting the scanning light is provided, each formed flat on the outer surface, on a side wall of the sheath along the circumferential direction.

Owner:FUJIFILM CORP +1

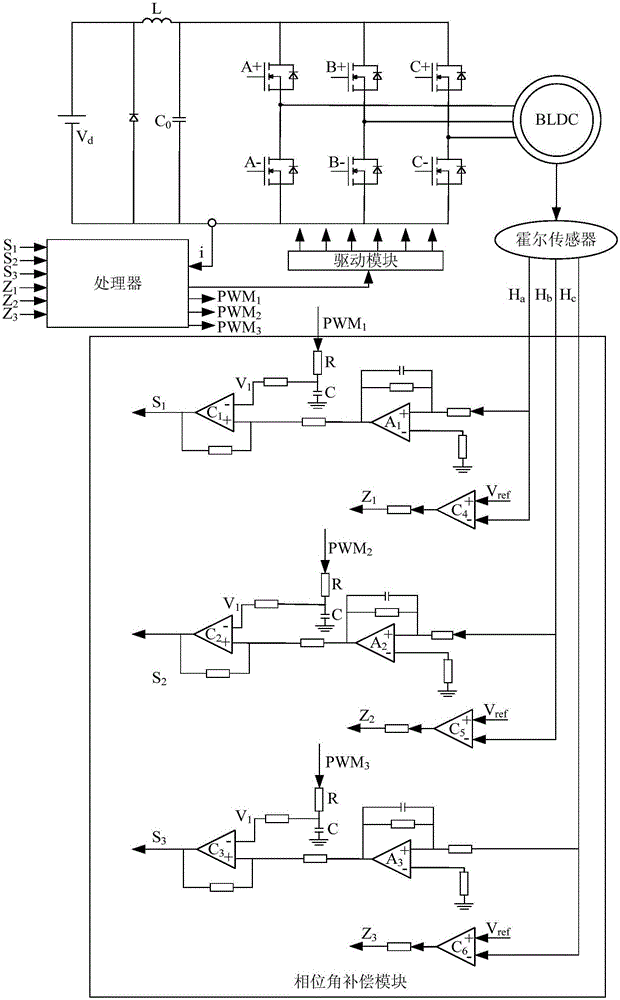

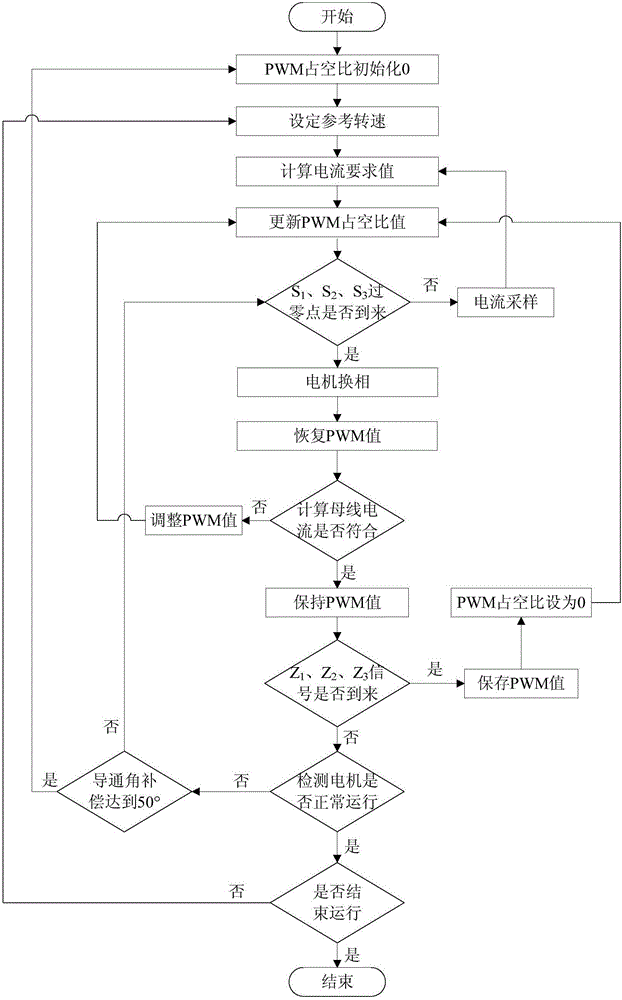

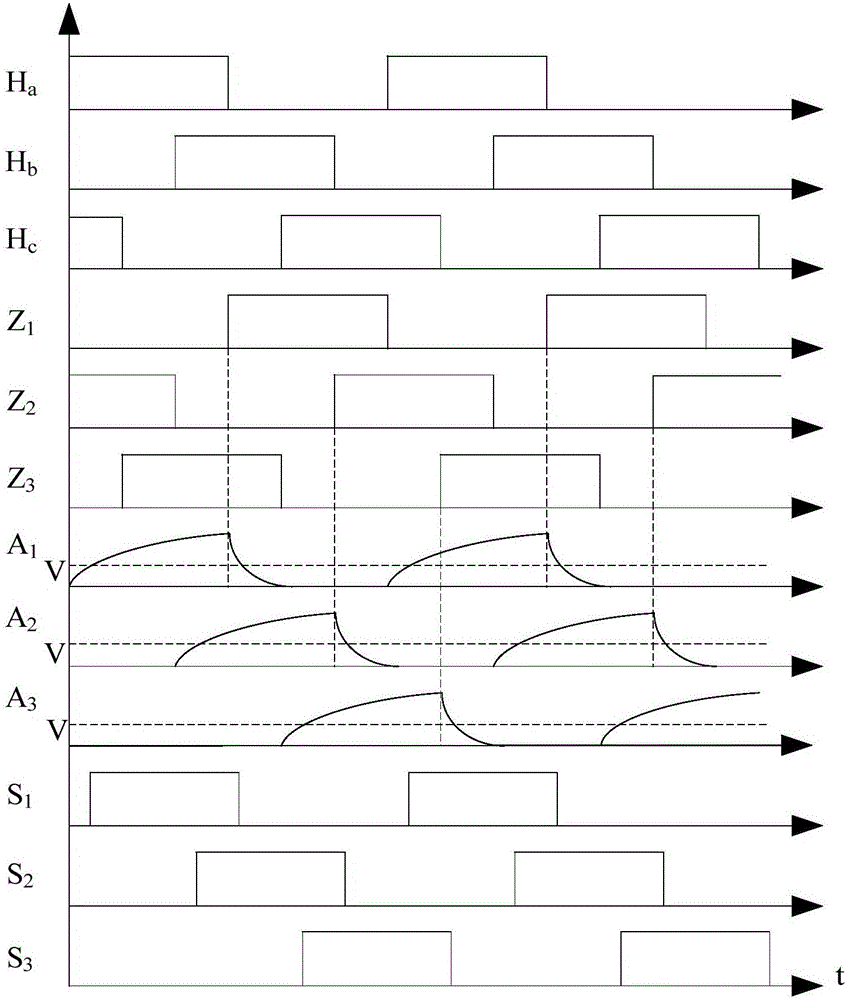

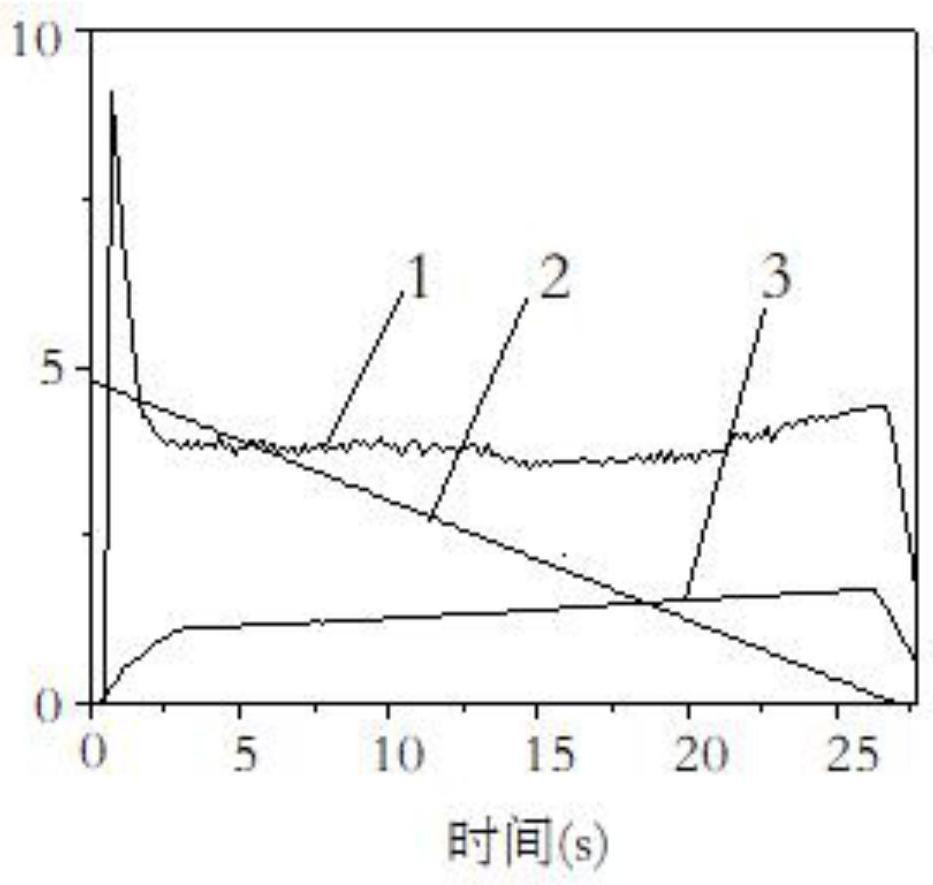

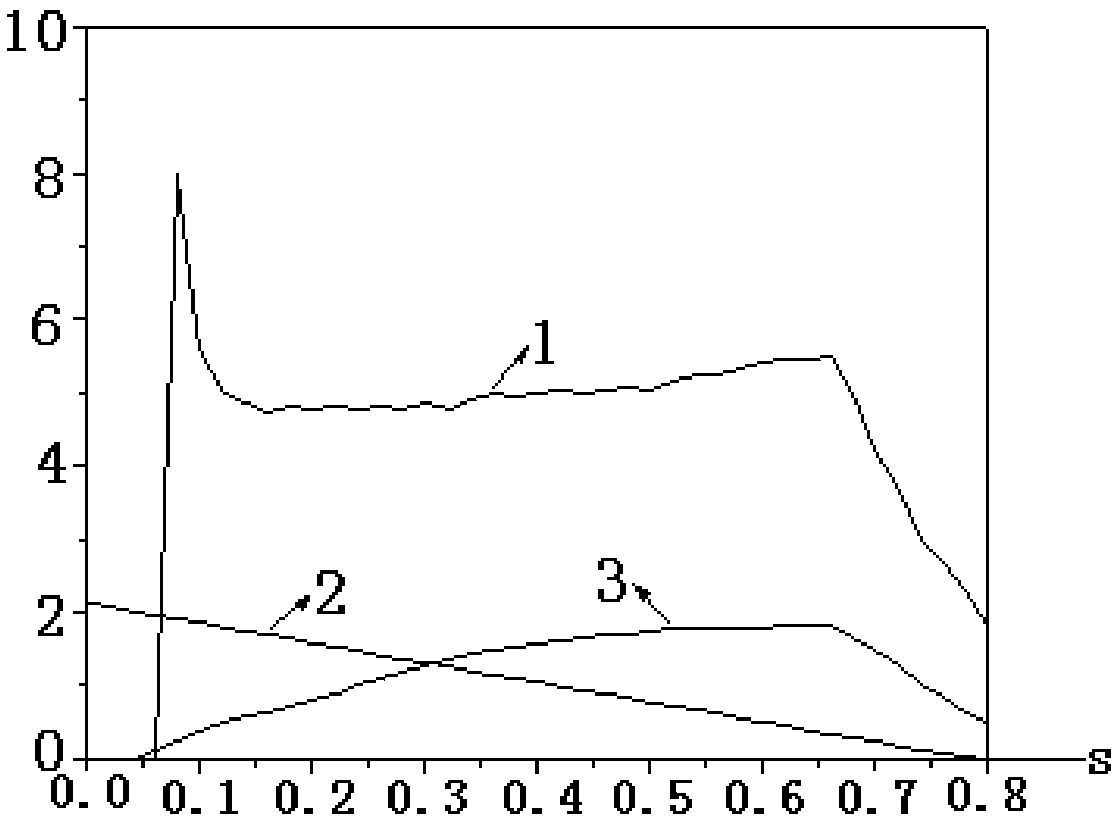

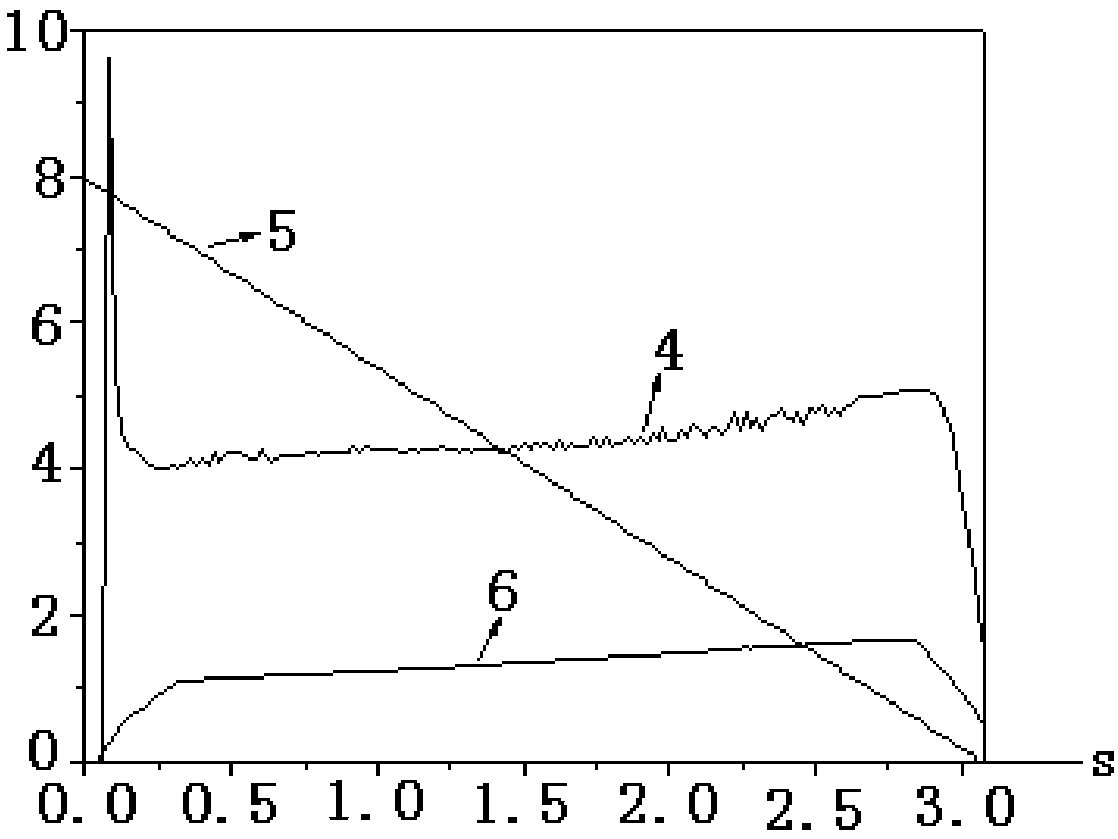

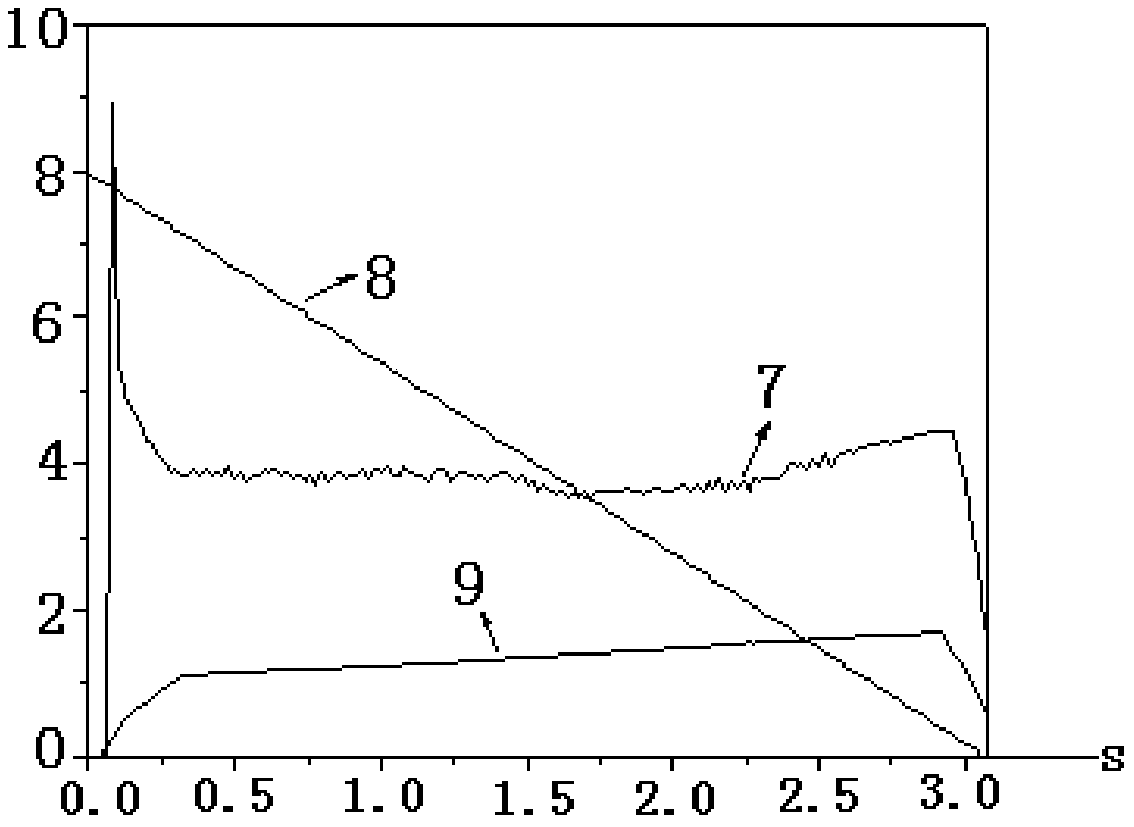

Three-phase brushless direct current motor adaptive commutation angle compensation method

InactiveCN105958874AGuaranteed uptimeEasy to useTorque ripple controlElectronic commutatorsThree-phaseControl theory

The present invention discloses a three-phase brushless direct current motor adaptive commutation angle compensation method. A hardware commutation angle compensation module is added, and the size of the commutation angle compensation is controlled through the PWM signals of the processor. The size of the current of the bus of each phase conduction phase is detected, the current mean value of the bus is calculated, and the current mean value is compared with the reference value to control the increasing and decreasing of the PWM signal duty cycle and reach the purpose of adaptively regulating the commutation angle compensation.

Owner:曹子沛

Optical probe and optical tomography apparatus

An elongated probe to be inserted into a tube which is open at a distal end portion of an insertion section of an endoscope includes a sheath constituting the outer circumferential surface of the optical probe, an optical fiber laid in the internal space of the sheath along the longitudinal direction of the sheath, and a deflection scanning means disposed in the internal space of the sheath to deflect light outputted from the optical fiber and is rotated around an axis line extending in the longitudinal direction to scan the deflected light in a circumferential direction of the axis line. A plurality of light transmission sections for transmitting the scanning light is provided, each formed flat on the outer surface, on a side wall of the sheath along the circumferential direction.

Owner:FUJIFILM CORP +1

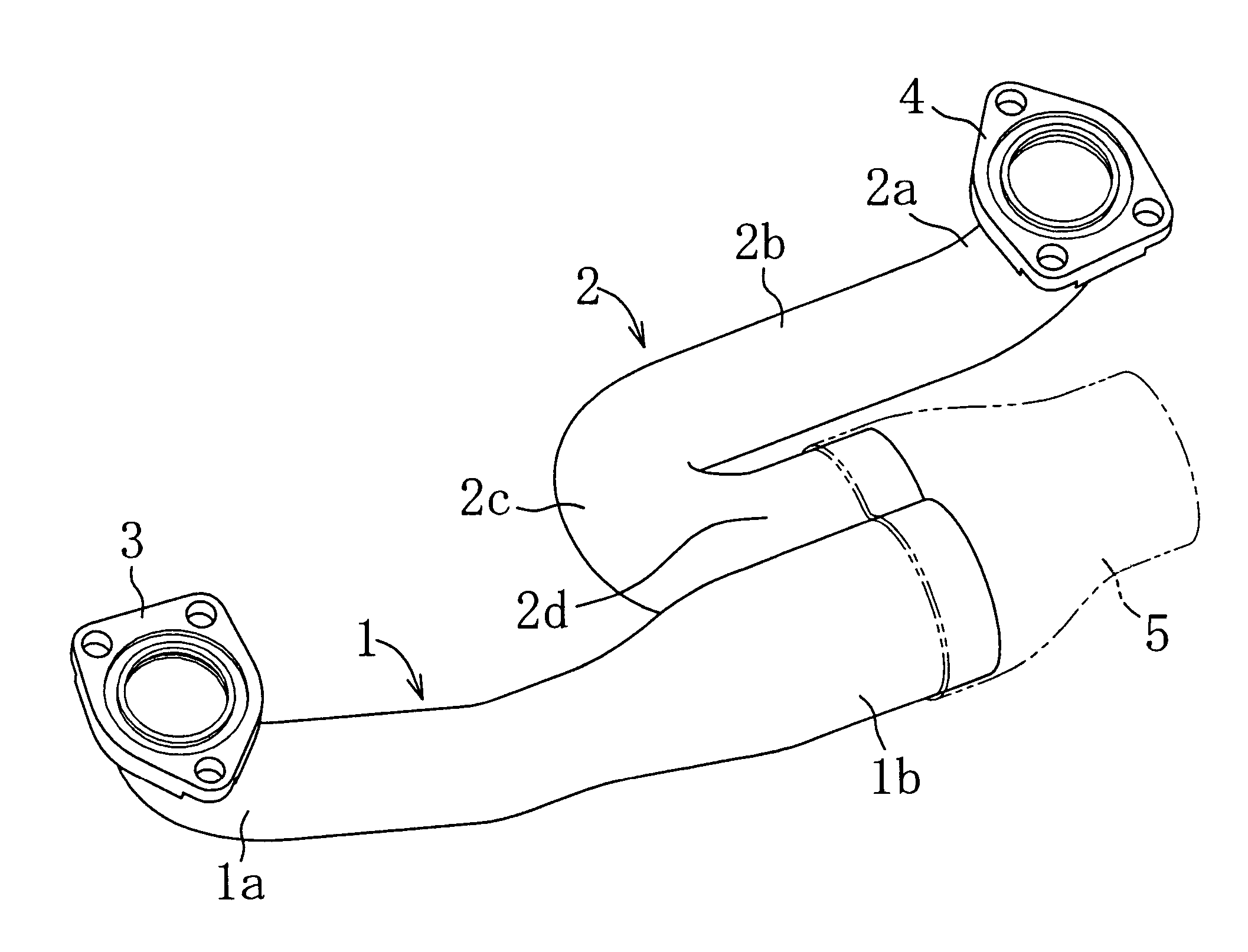

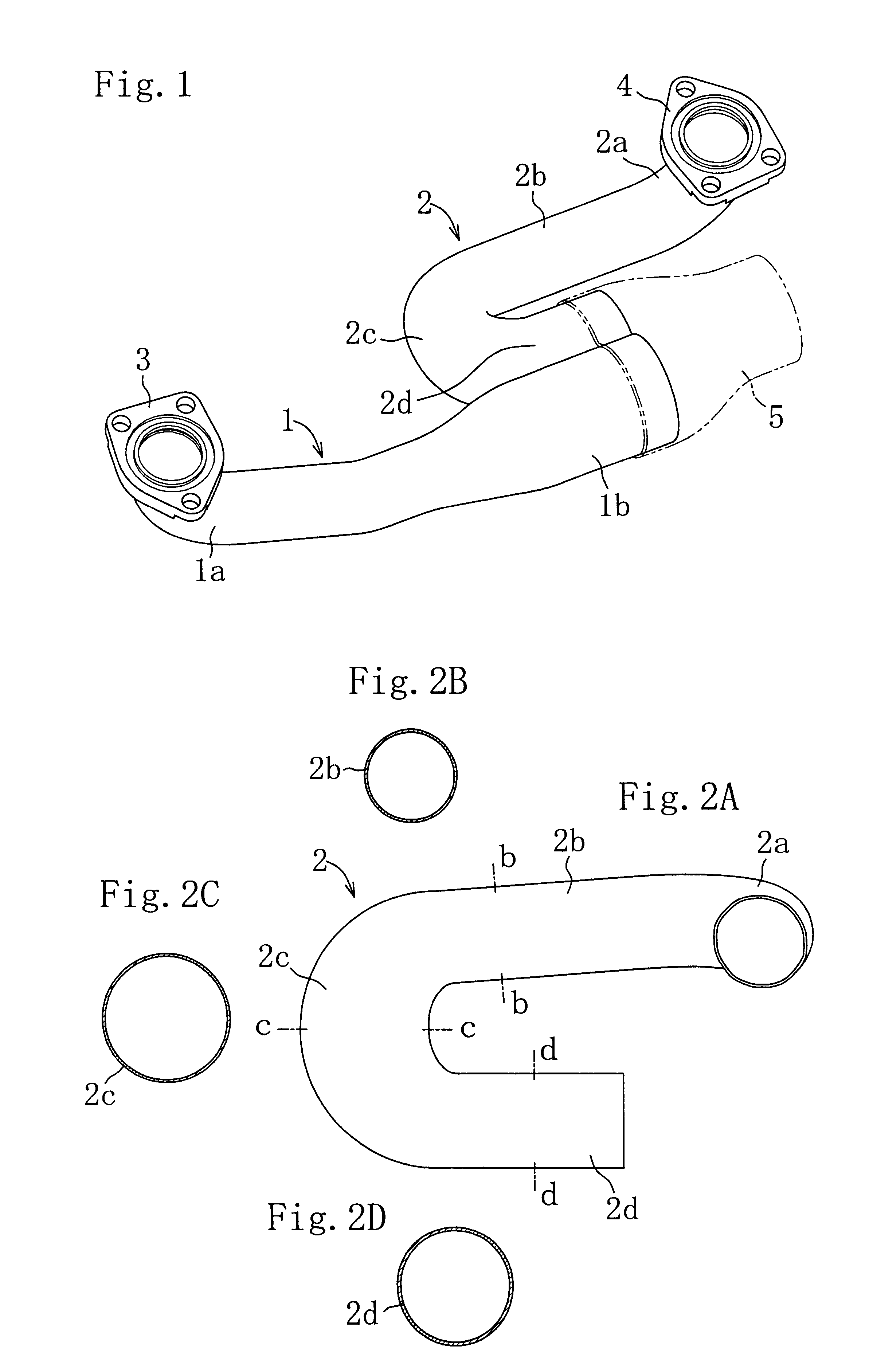

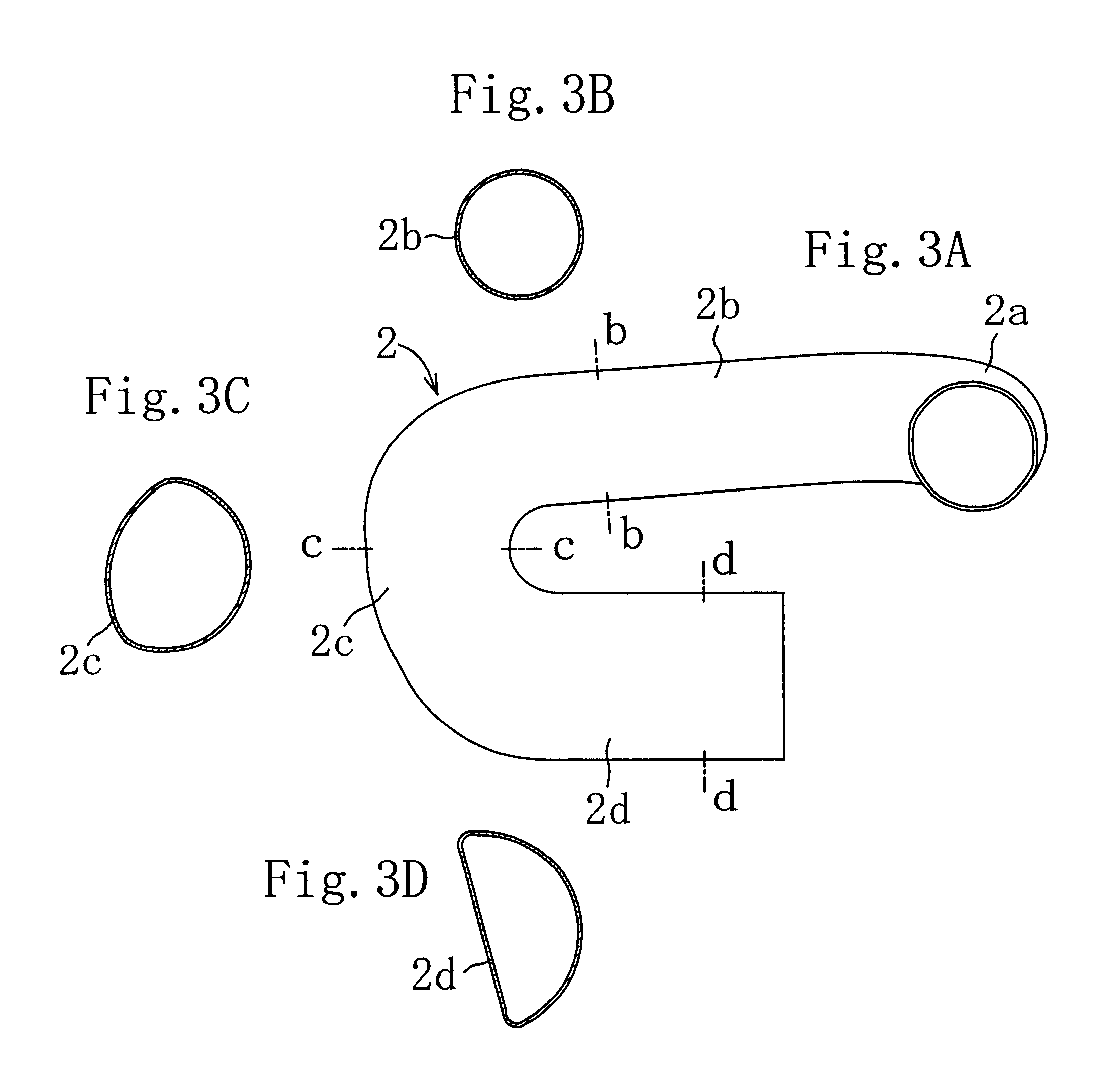

Engine exhaust system

This invention relates to an engine exhaust system for automobiles or the like; and more specifically, to an exhaust system having a crook of a generally U-shape at the mid section of the pipe line constituting the exhaust system. Even when a U-shaped crook is provided at the mid section of the pipe line constituting an exhaust system described above, the flowing resistance of exhaust air can be reduced to a minimum value to prevent the back pressure from being applied to the engine or lowering of the output of the engine. The engine exhaust system is such that the U-shaped crook forms a gentle curve so that the cross sectional area of the internal space of the U-shaped crook near the top portion is at least 1.3 times the minimum cross sectional area of the internal space of the pipe line having the U-shaped crook.

Owner:SANKEI GIKEN KOGYO

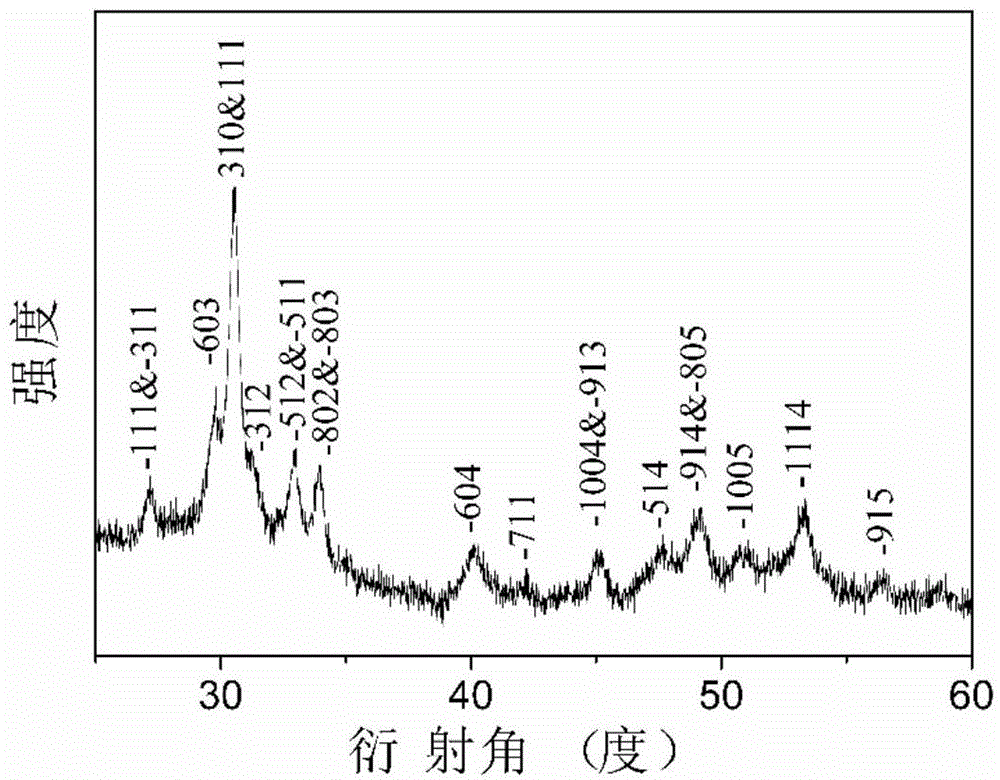

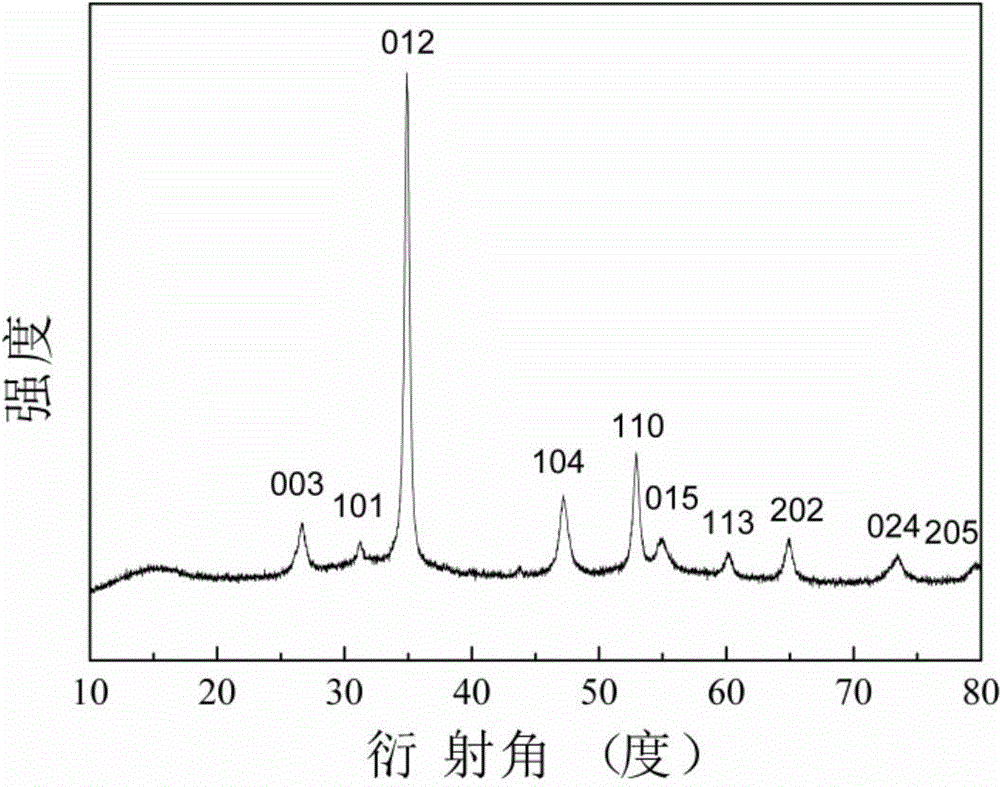

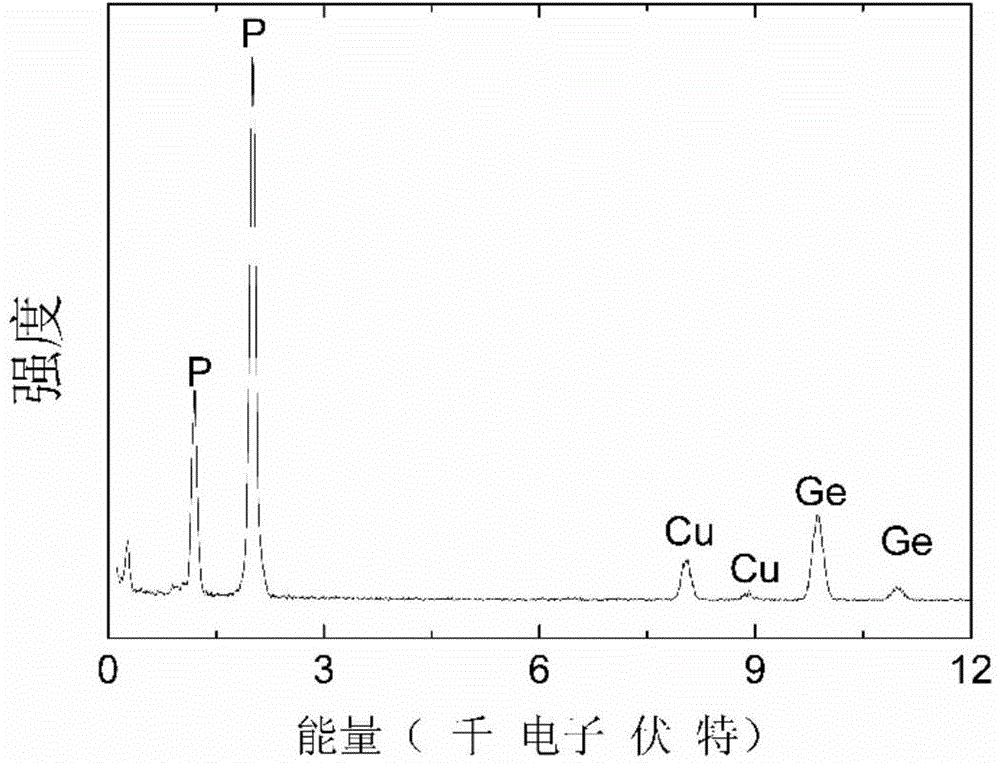

Negative electrode active material for lithium-ion/sodium-ion battery, negative electrode and battery

ActiveCN104600299AHigh lithium/sodium storage capacityHigh lithium/sodium storage activityCell electrodesSecondary cellsLithiumCharge discharge

The invention provides a negative electrode active material for a lithium-ion / sodium-ion secondary battery, a negative electrode and a battery, belonging to the technical field of electrochemistry and batteries. The negative electrode active material comprises a phosphorus-germanium compound, or / and a first complex formed by the phosphorus-germanium compound and elementary P or / and elementary Ge, or / and a second complex formed by the phosphorus-germanium compound and conductive components, or / and a third complex formed by the first complex and conductive components. The negative electrode provided by the invention comprises the negative electrode active material. The negative electrode has the advantages of high specific capacity, high initial Coulomb efficiency, small charge-discharge voltage platform difference and good high-current charge-discharge performance.

Owner:HUAZHONG UNIV OF SCI & TECH

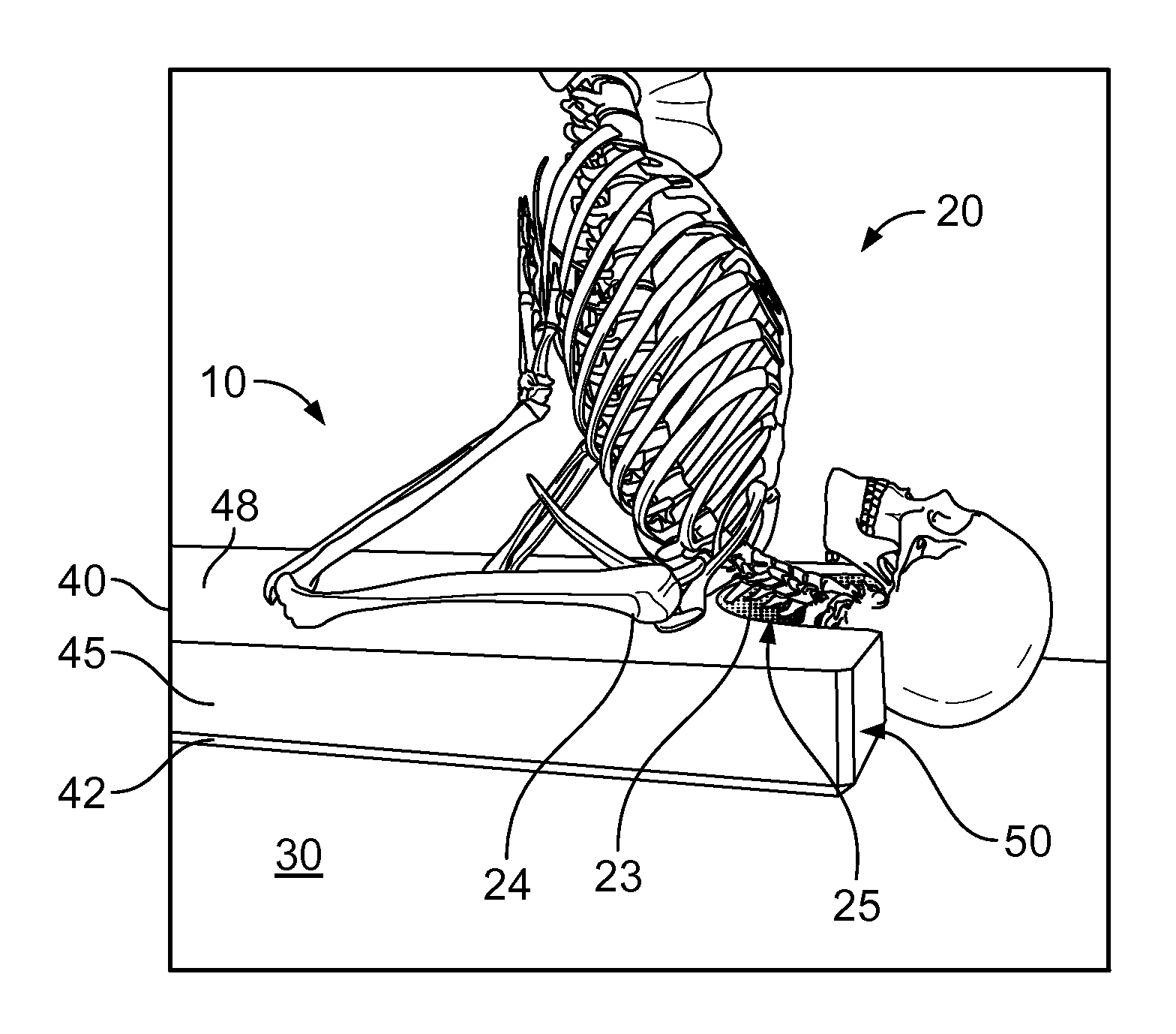

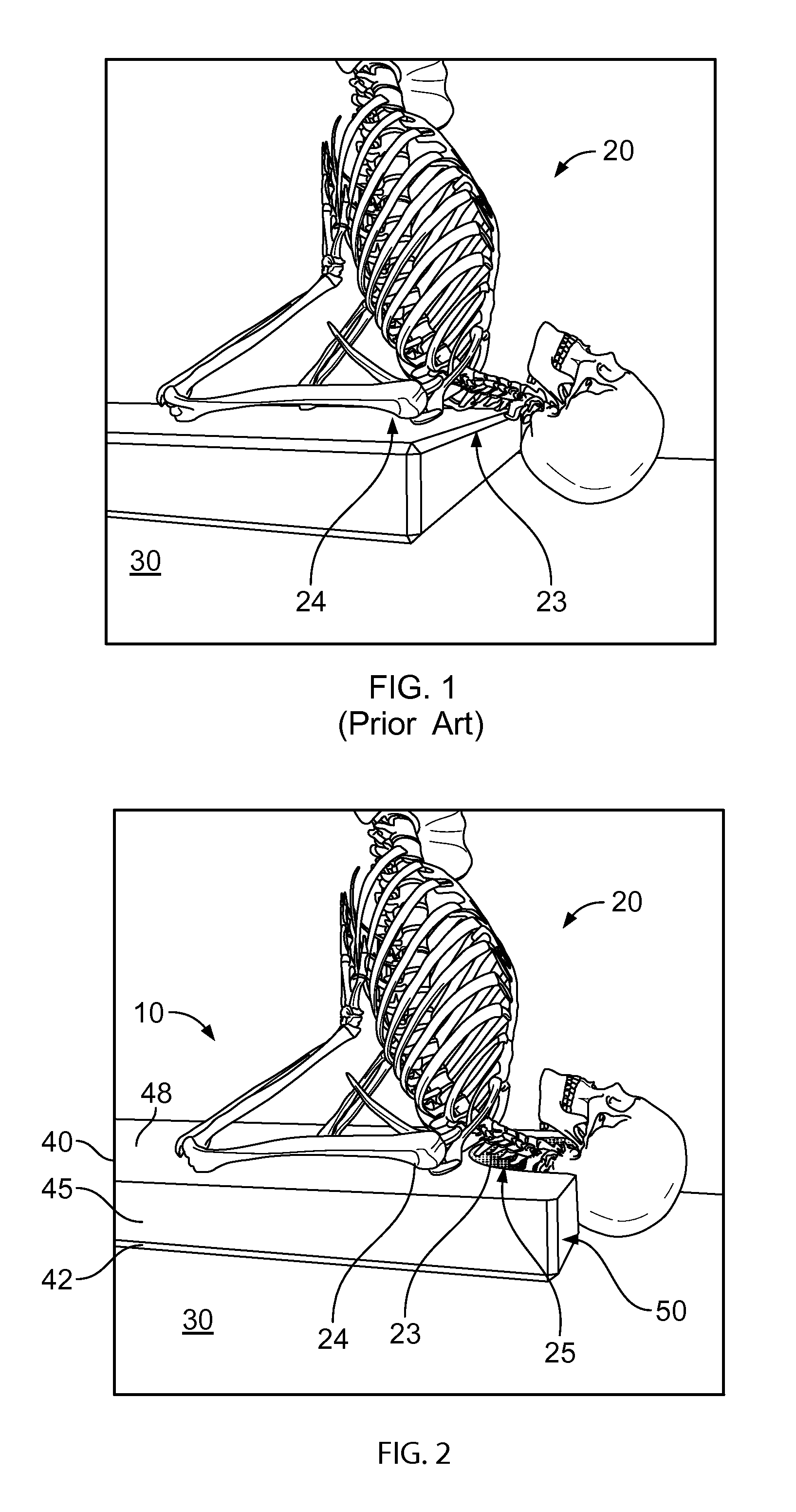

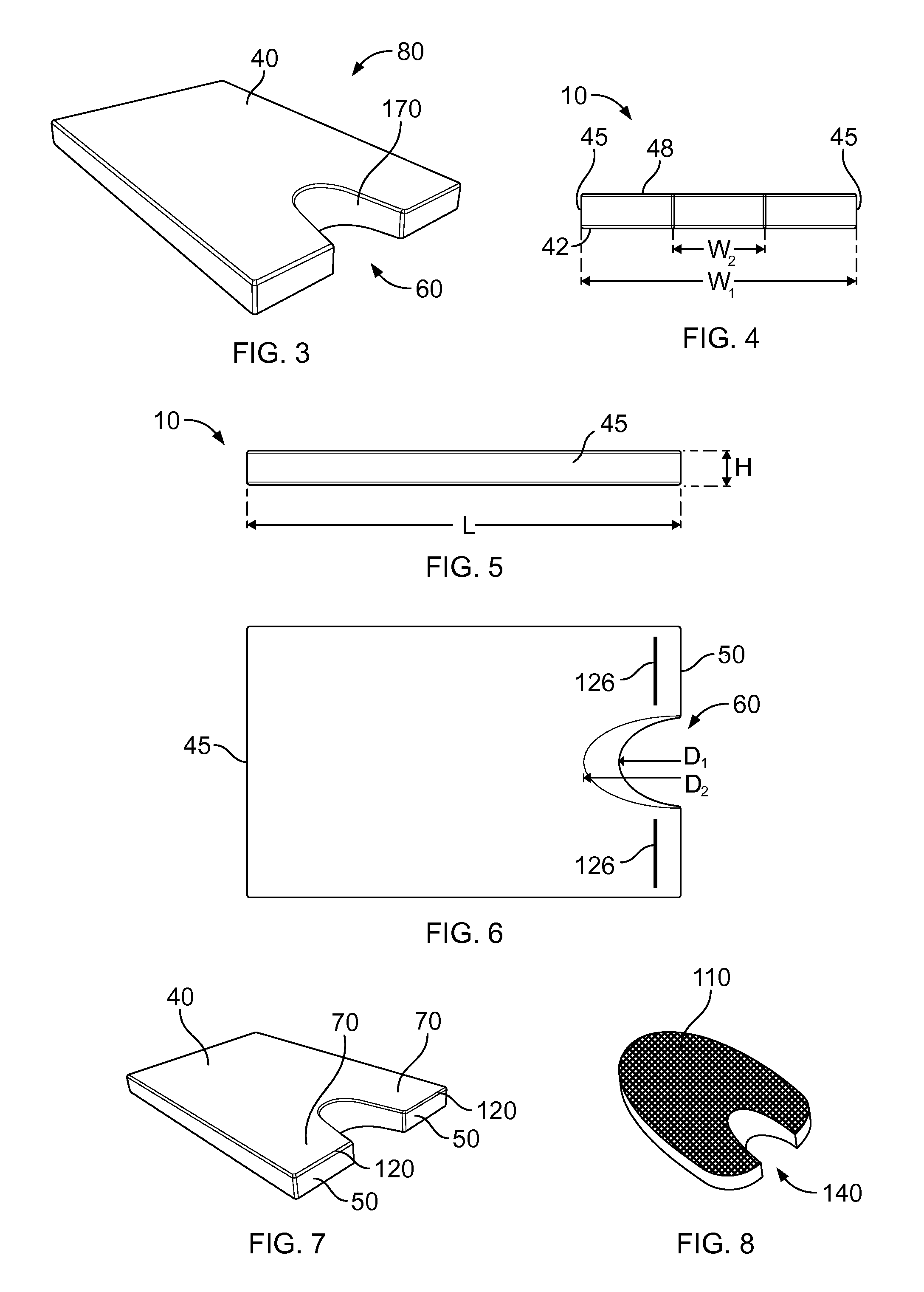

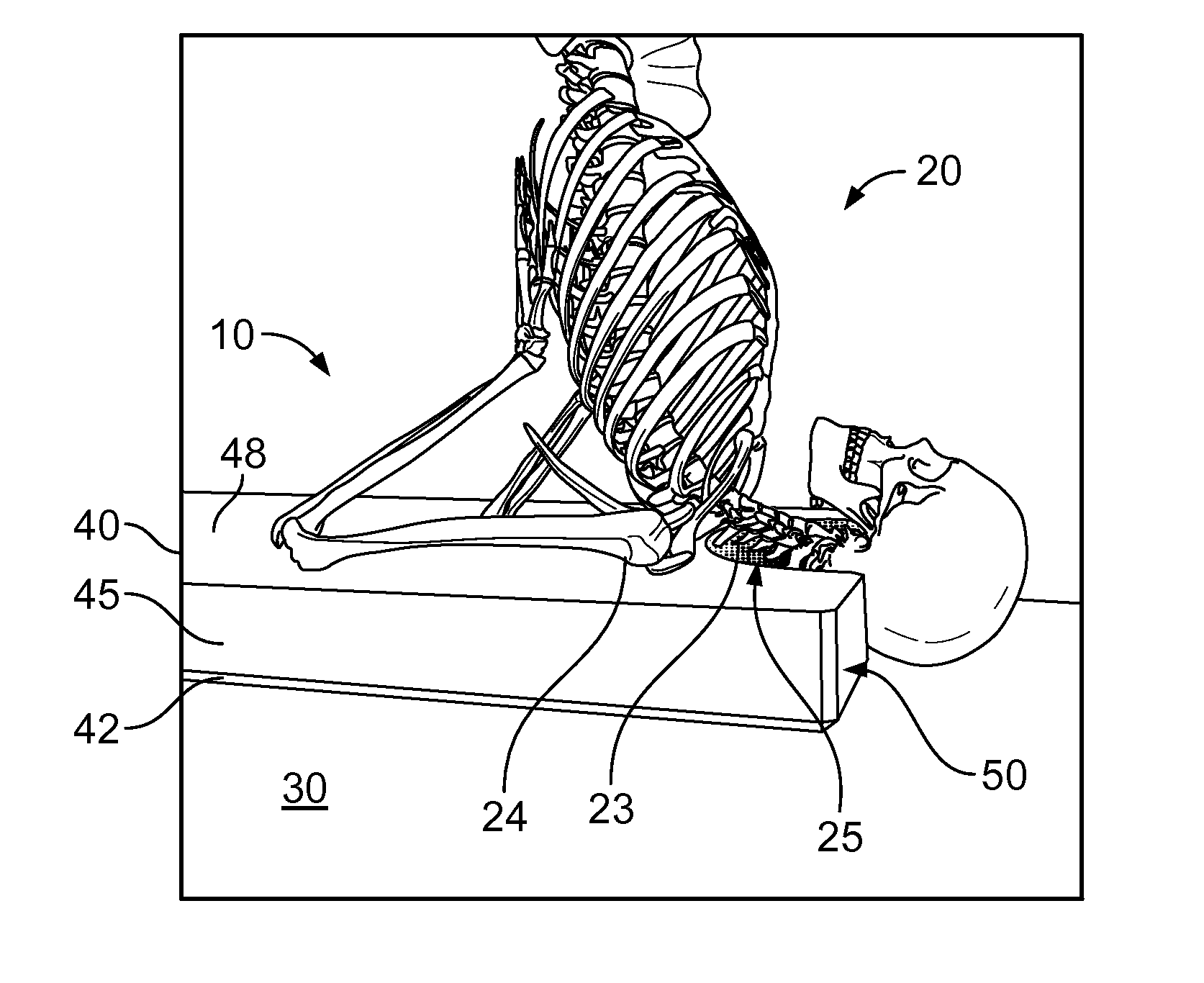

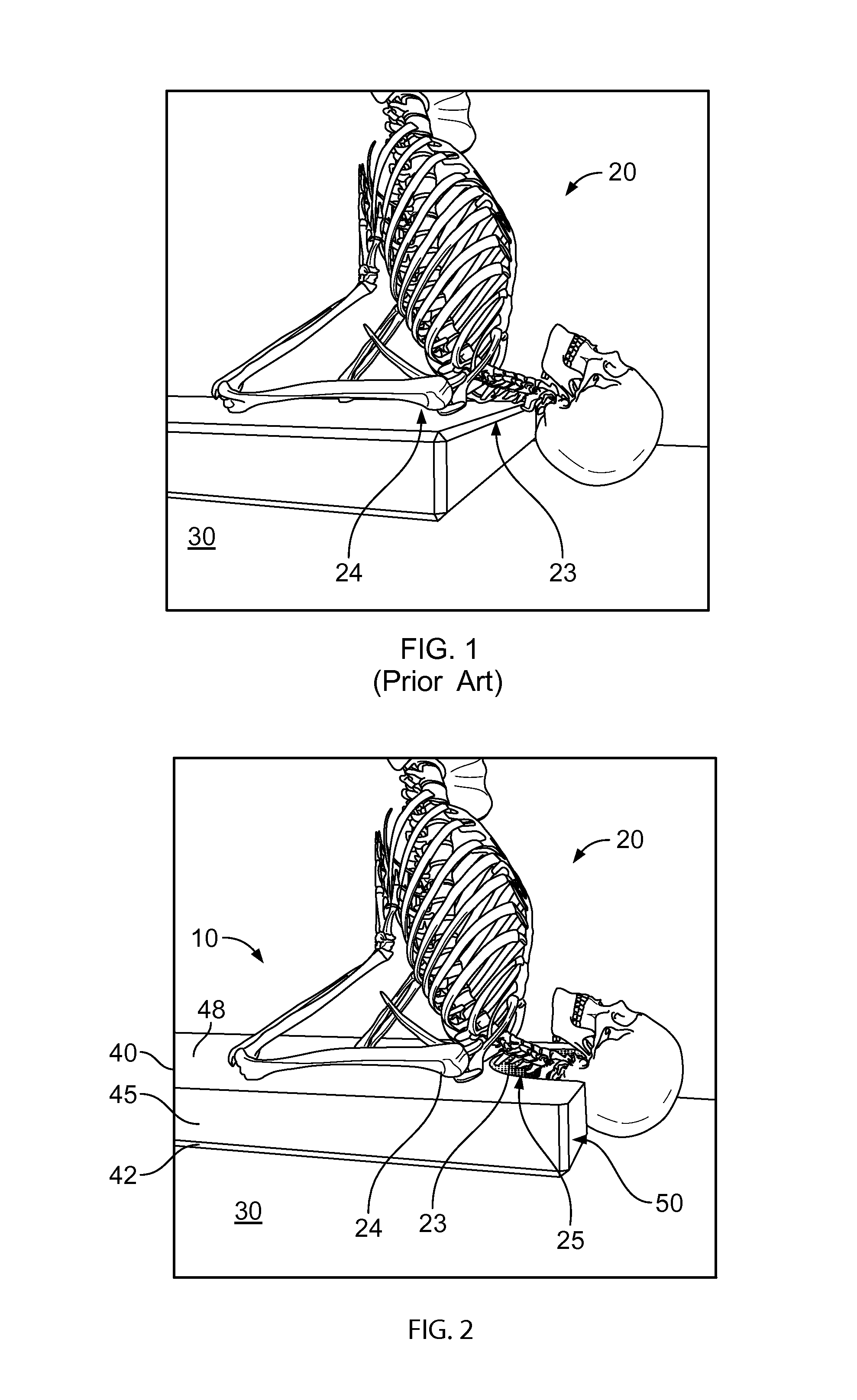

Exercise mat

An exercise mat for a person exercising on a floor surface comprises a pad having a top surface, a bottom surface, and a peripheral edge. A cutout is formed in a first portion of the peripheral edge and sized to accommodate the neck of the person. A high-friction non-slip texture or coating may be applied to either the top surface or the bottom surface of the pad, or both. The top surface may further includes a pair of raised shoulder stops. In use, with the bottom surface of the pad resting on the floor surface and with the person's shoulders supported on opposing sides of the cutout proximate the first portion of the peripheral edge, the person's neck may be positioned within the cutout to allow natural flexion curvature of the cervical spine when the person is performing a shoulder stand on the mat.

Owner:LONG RAYMOND

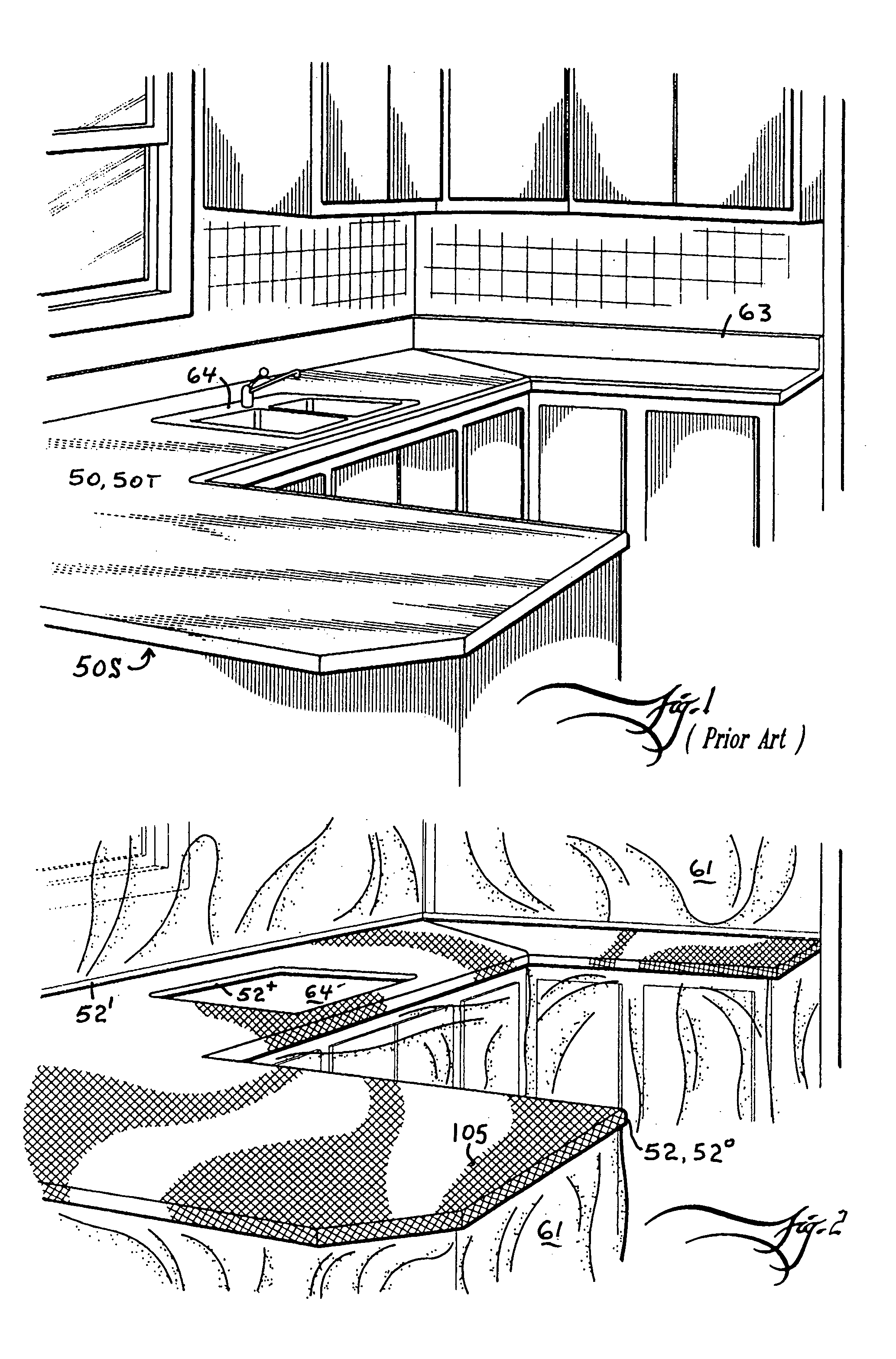

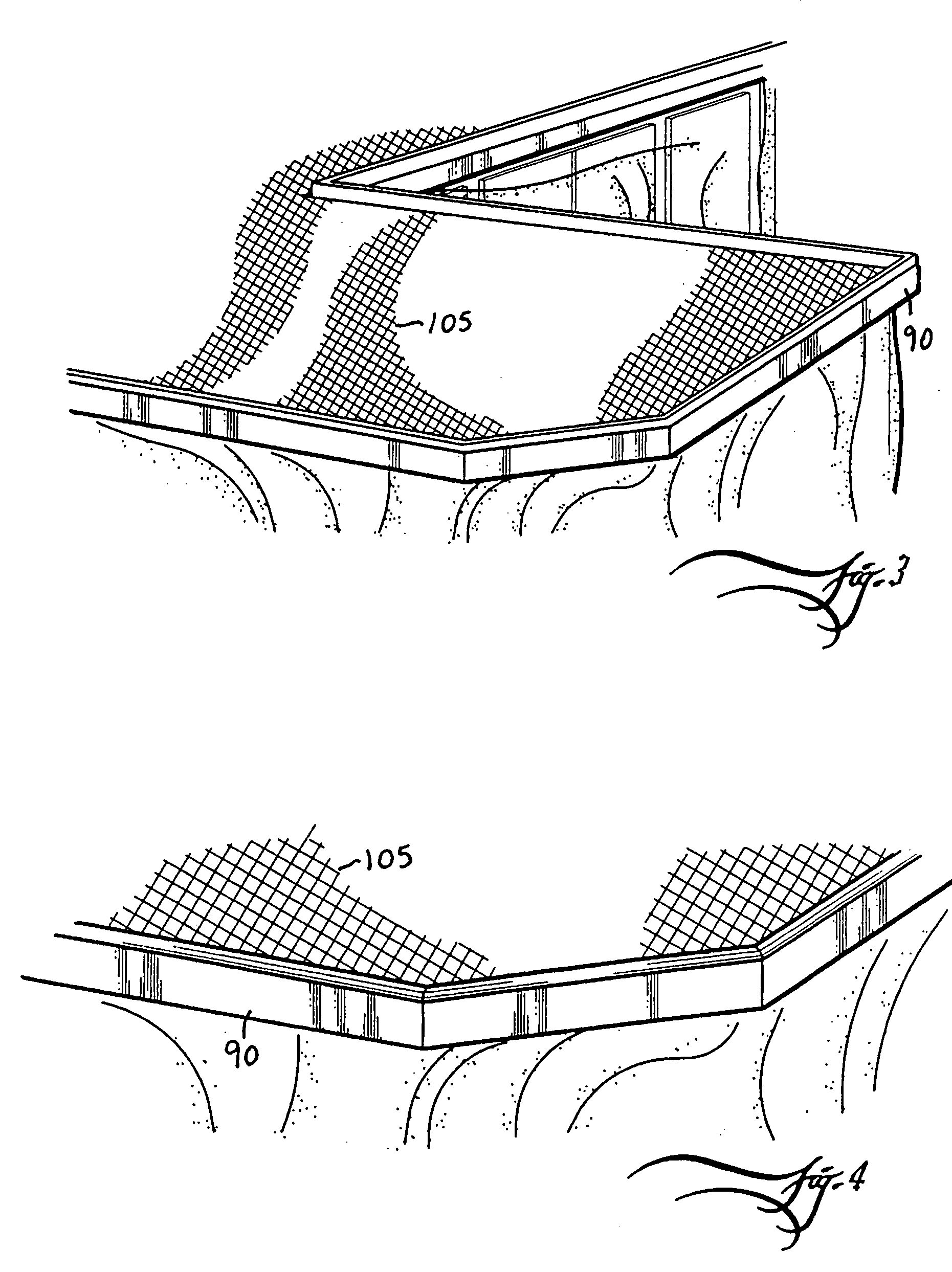

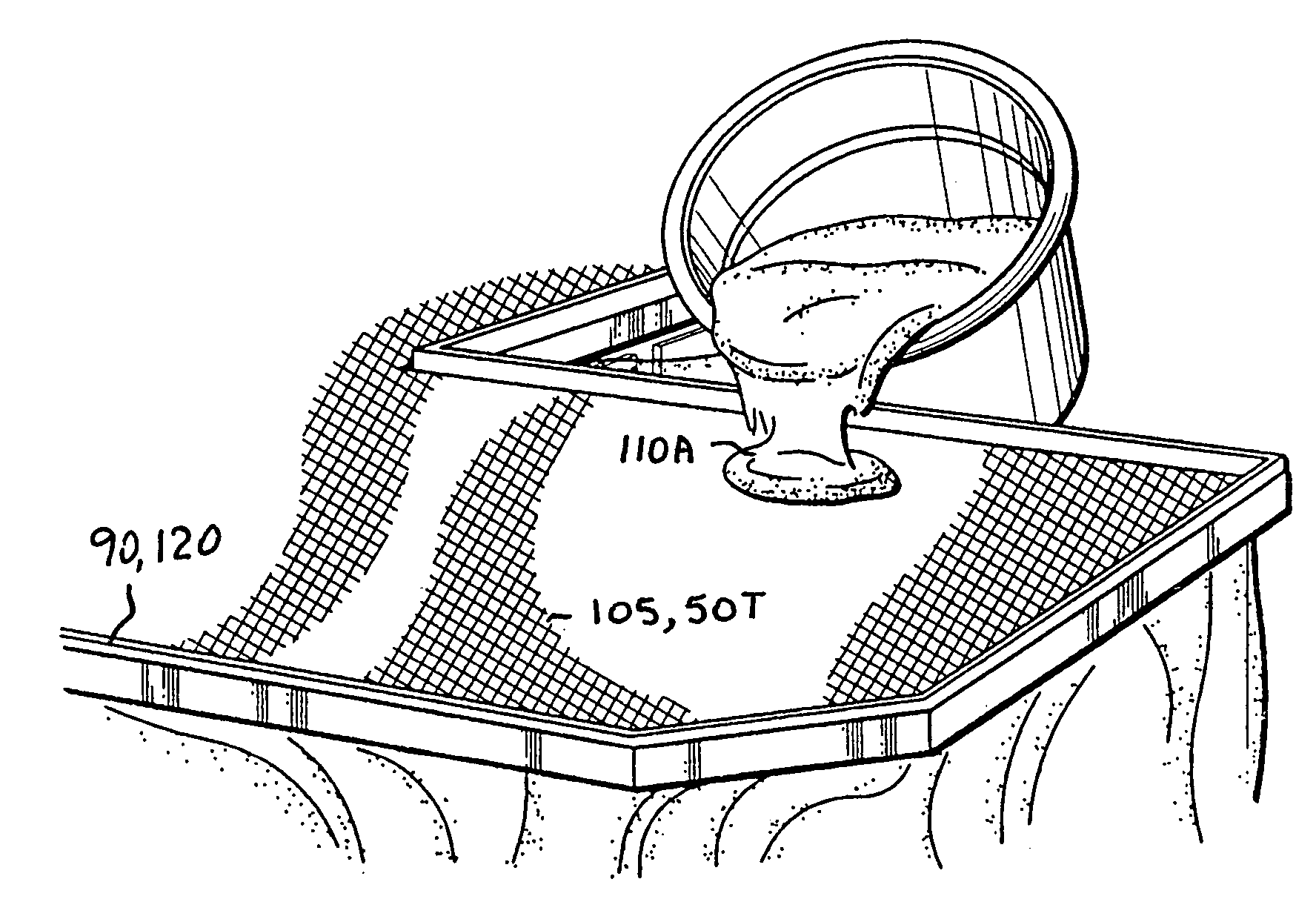

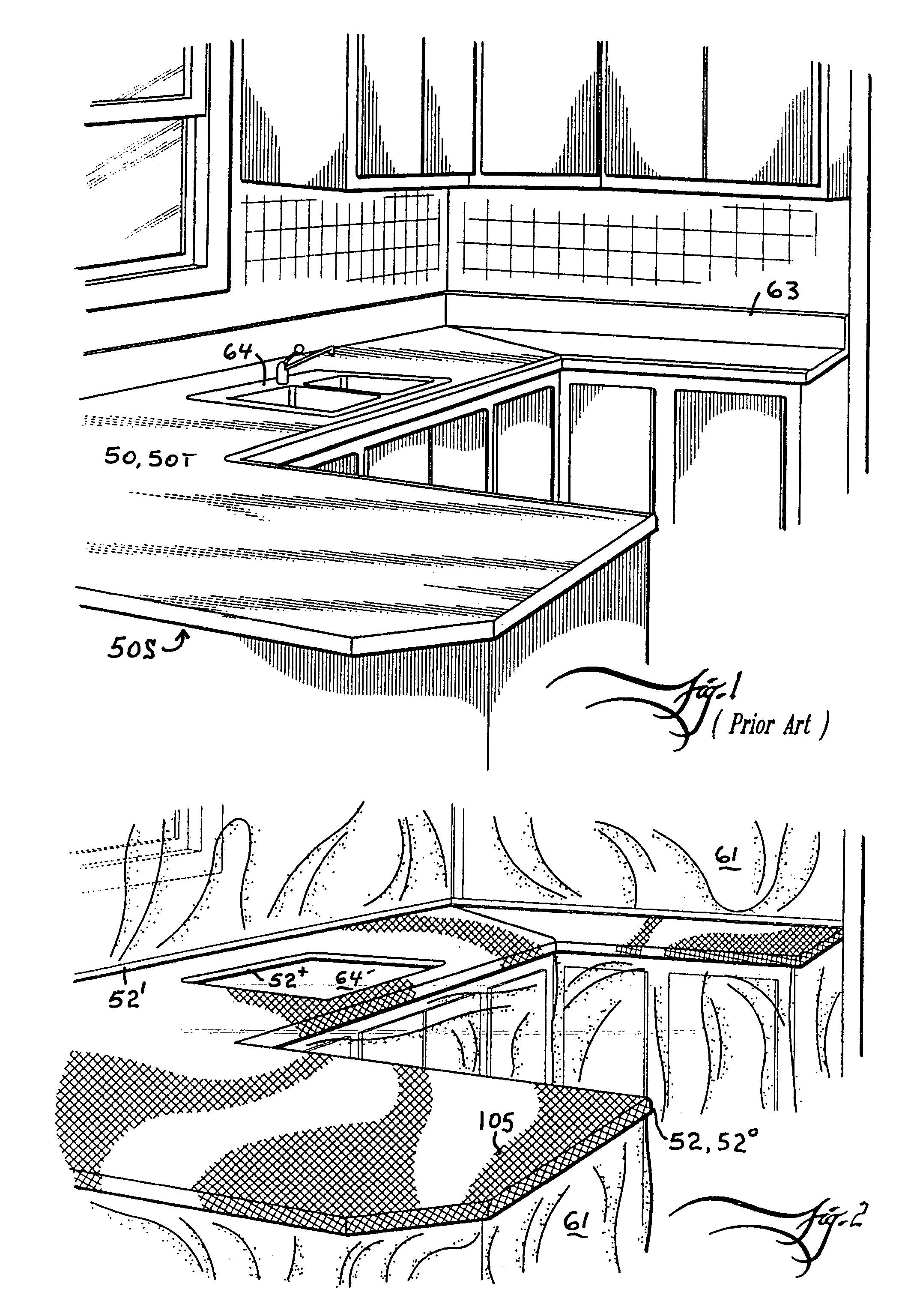

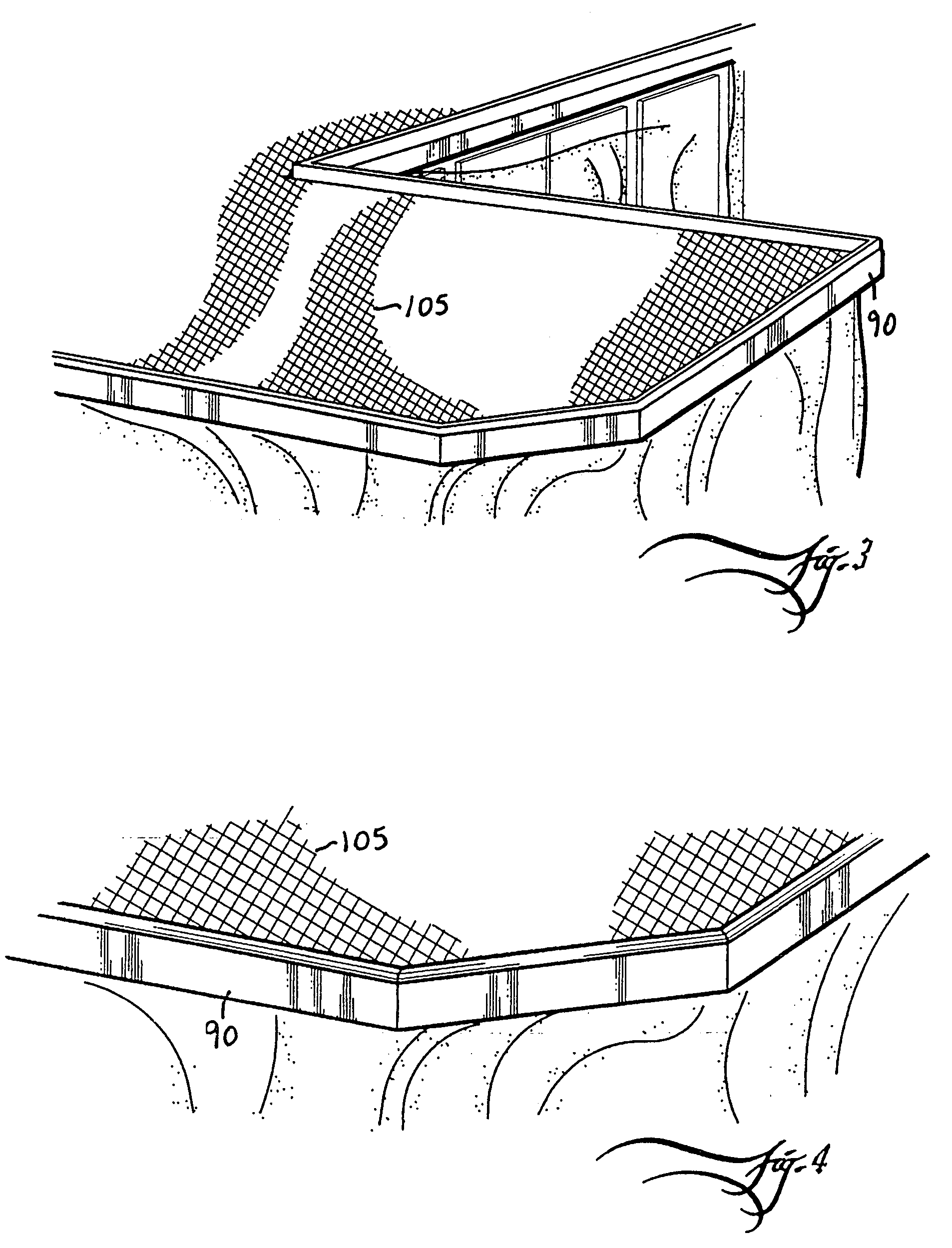

Method of remodeling a countertop

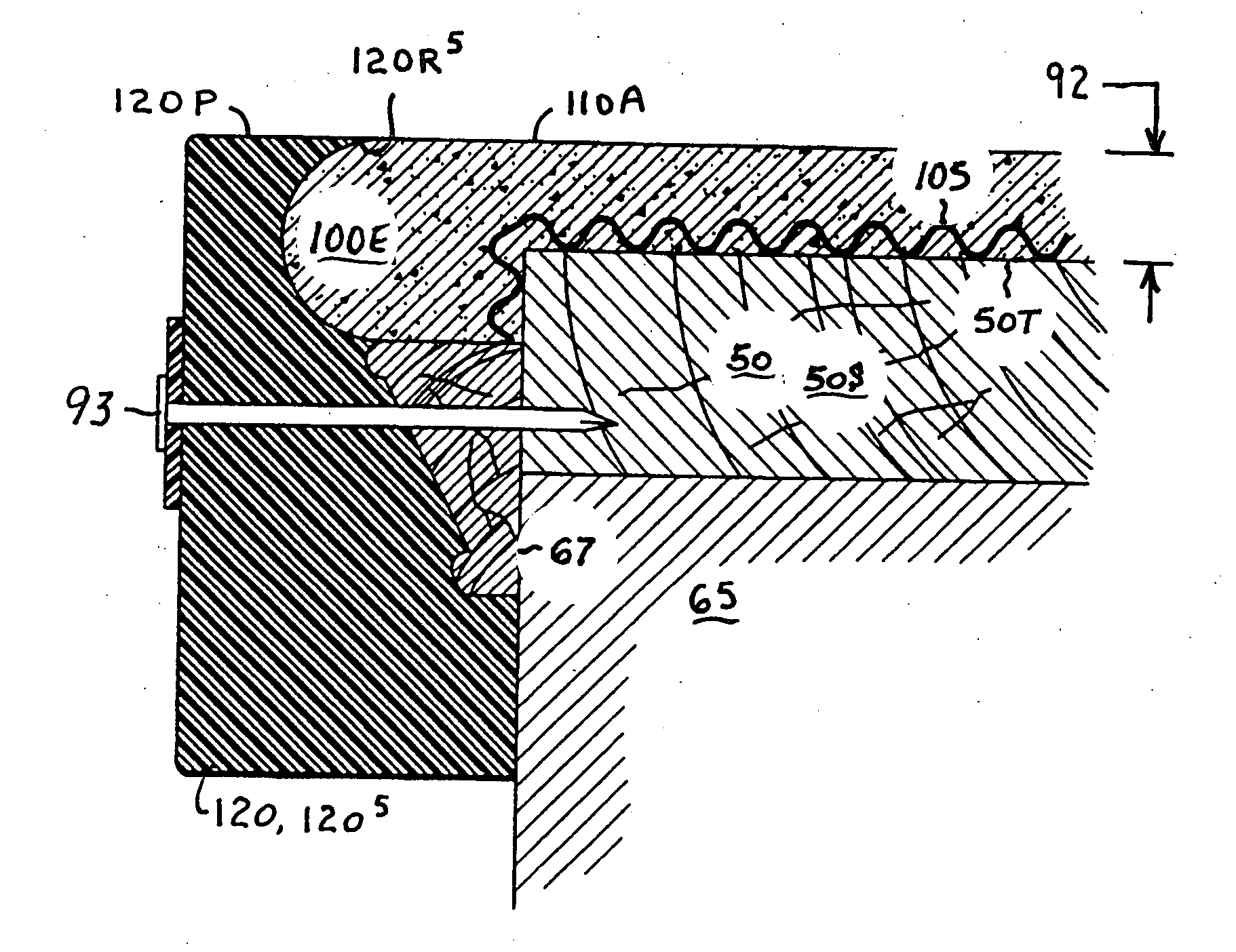

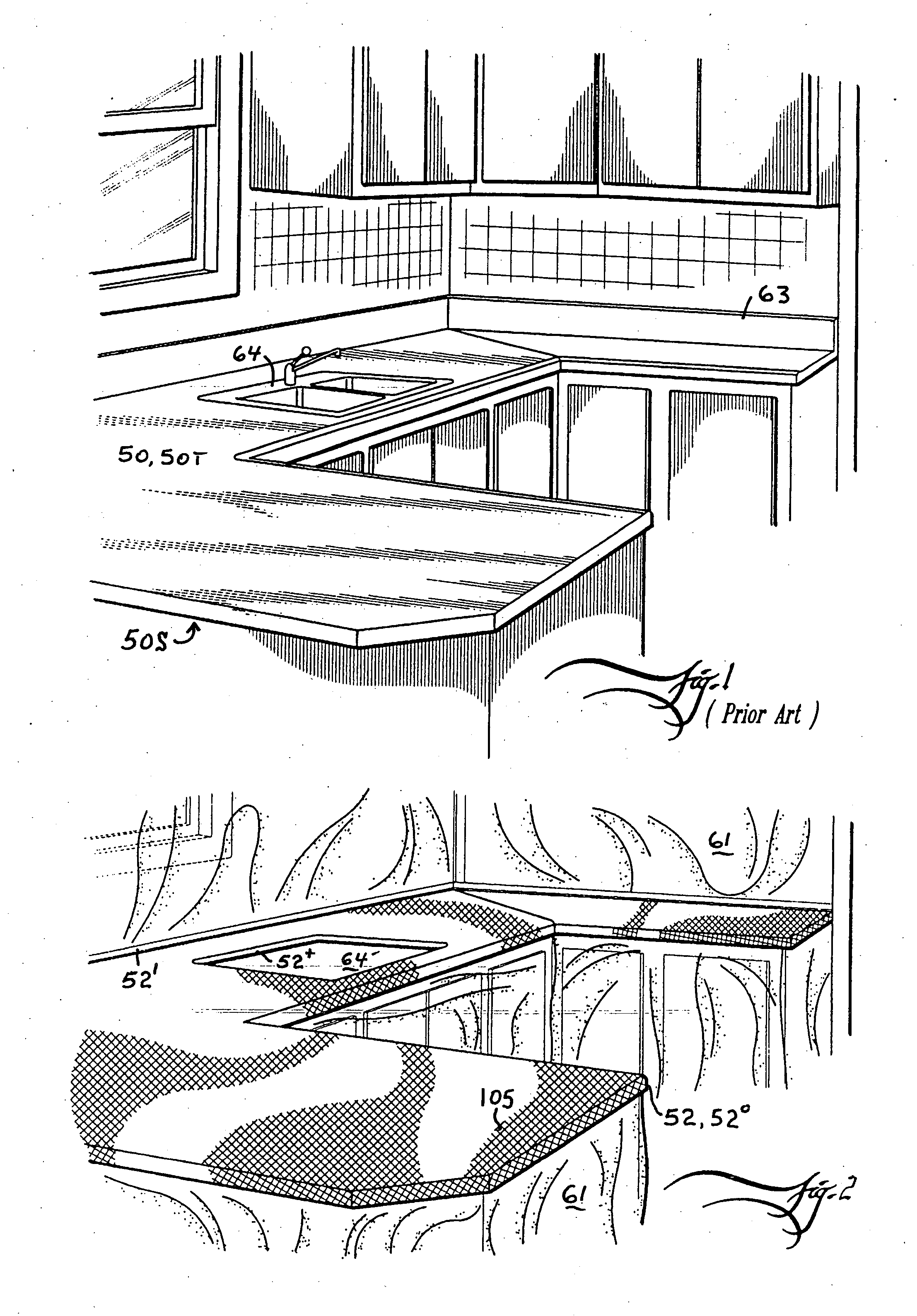

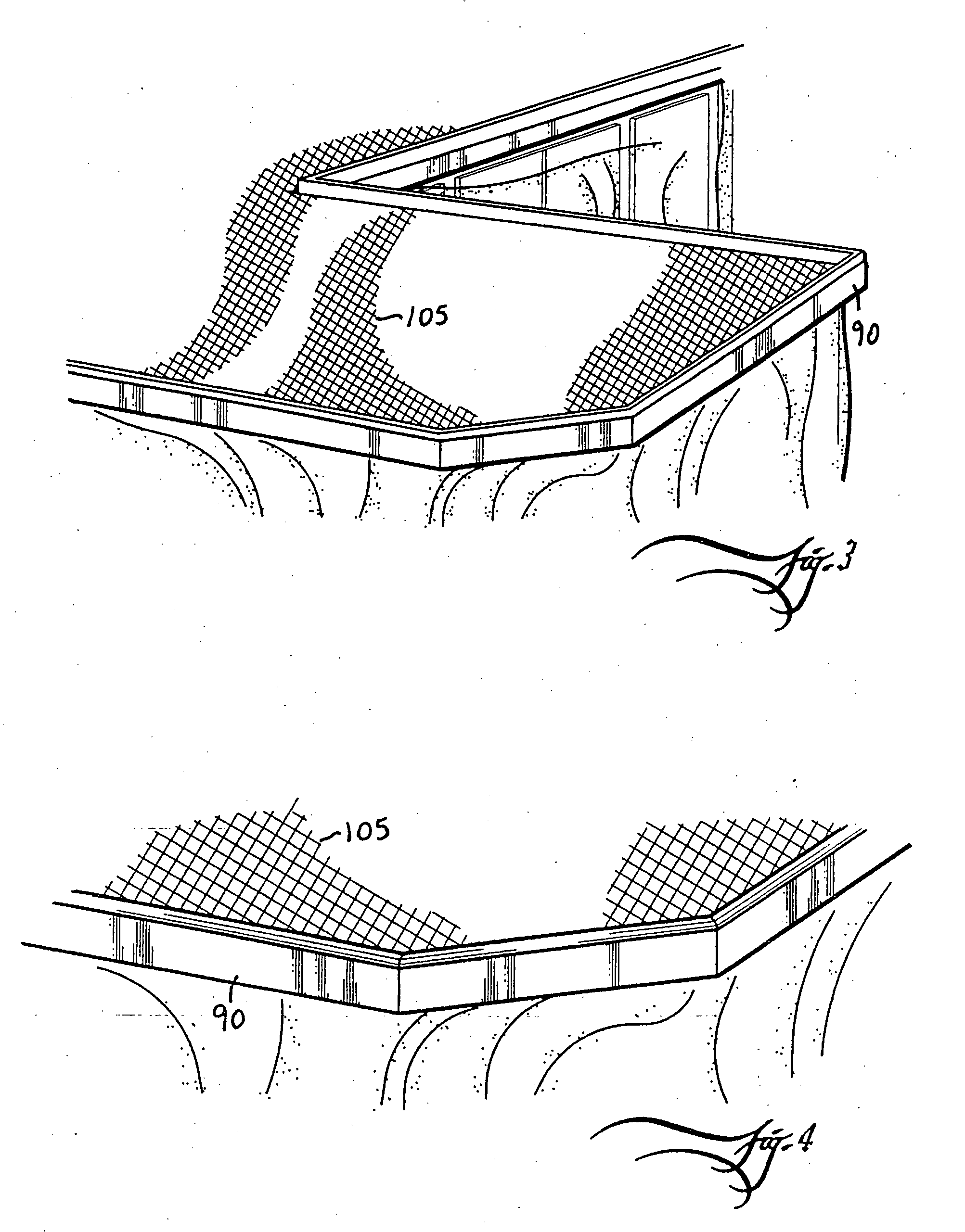

InactiveUS7219409B2Improve bending strengthGentle curveArc welding apparatusCeramic shaping apparatusPolymer modifiedFree edge

A method of remodeling a subsisting countertop by casting a polymer-modified cementitious casting compound thereupon has some of the following steps. Given a subsisting countertop, without altering it, temporarily attaching edging forms or flow checks around all the free edges of the subsisting countertop, both of which forms and flow checks operate to check the flow of the casting compound at least to the height of a given rise. Following that, pouring a polymer-modified cementitious casting compound over the countertop to the height of the given rise and as checked within the edging forms and flow checks. The final step involves optionally removing the forms before the lapse of a full day.

Owner:STONE GRP HLDG

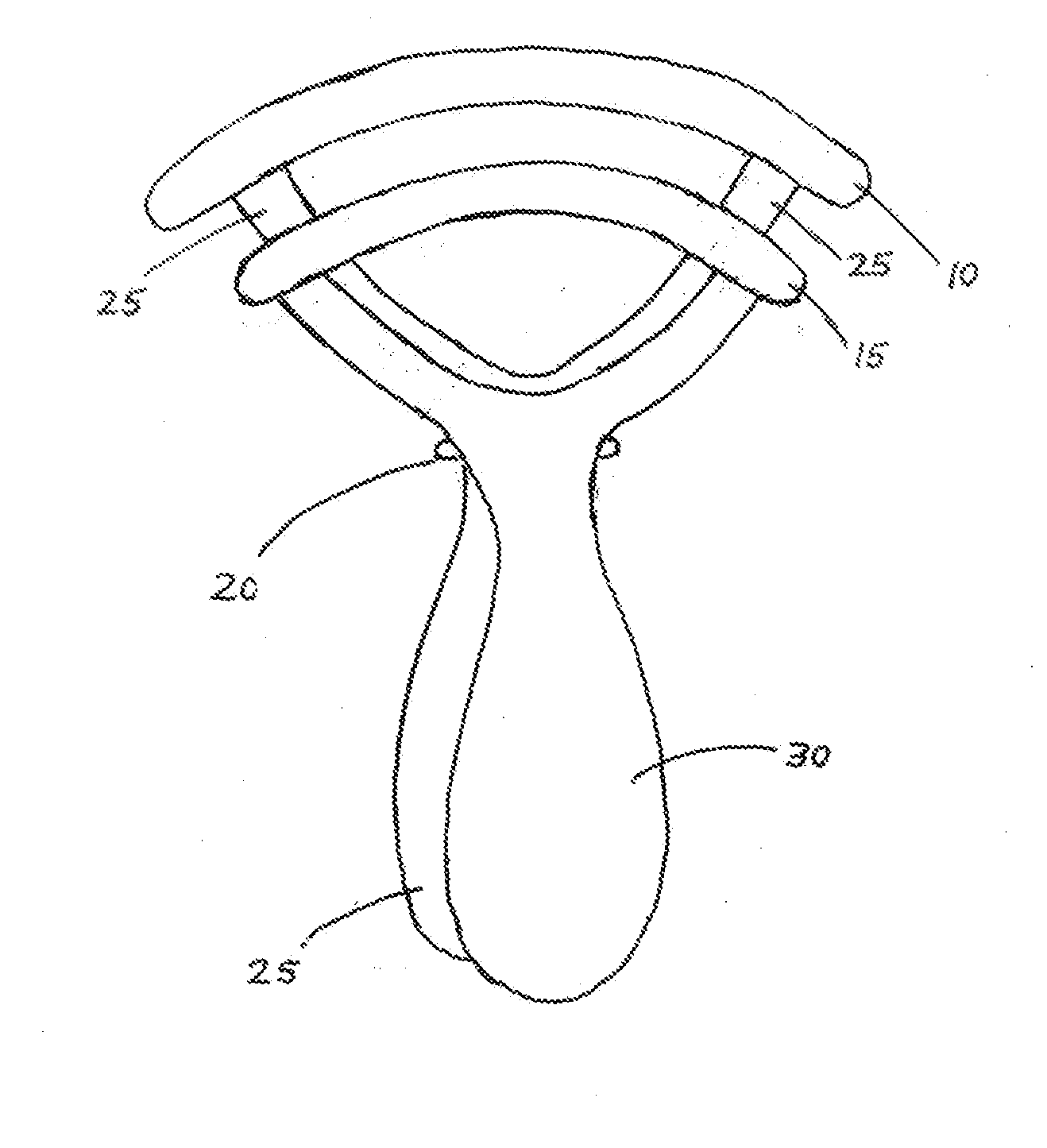

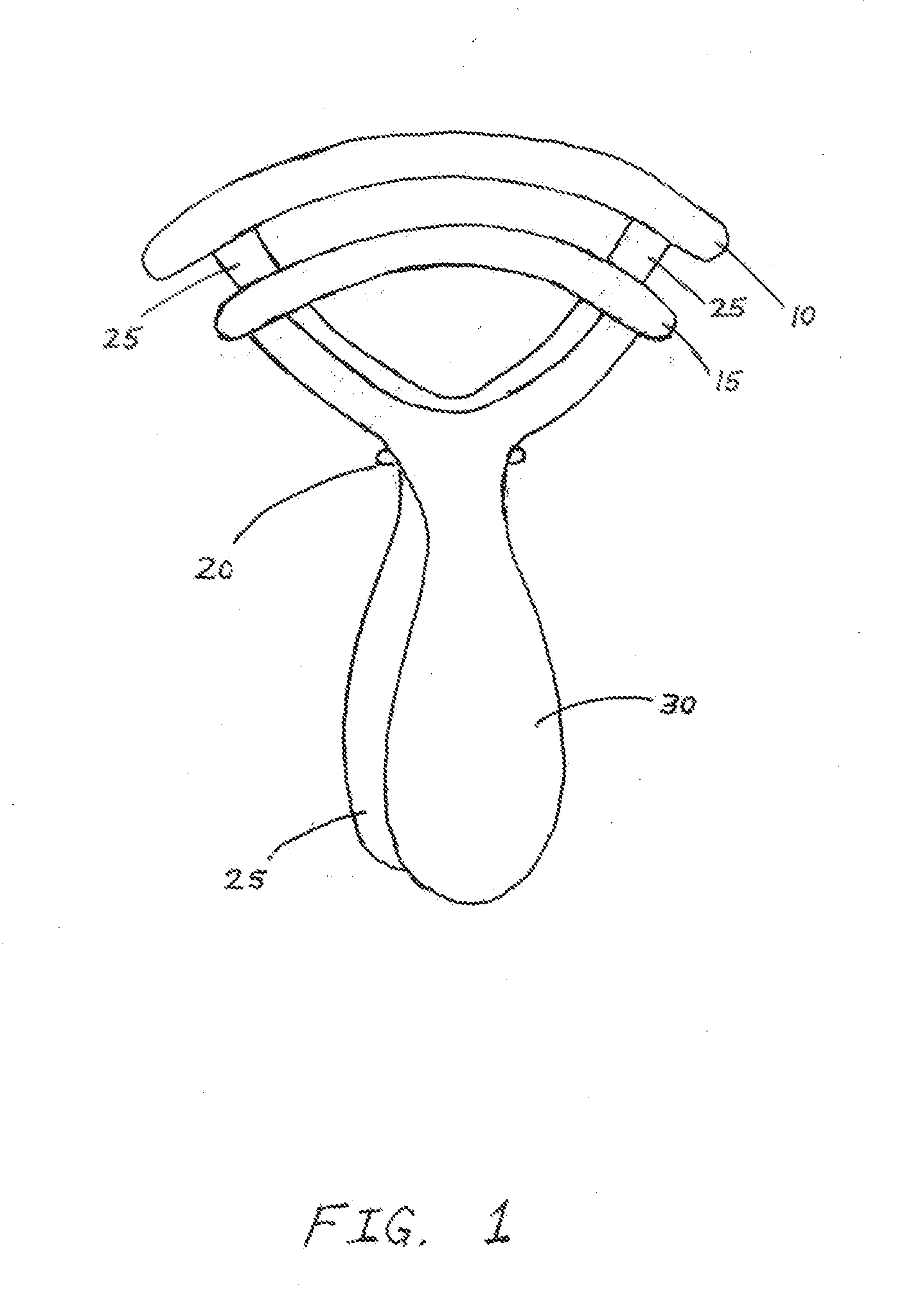

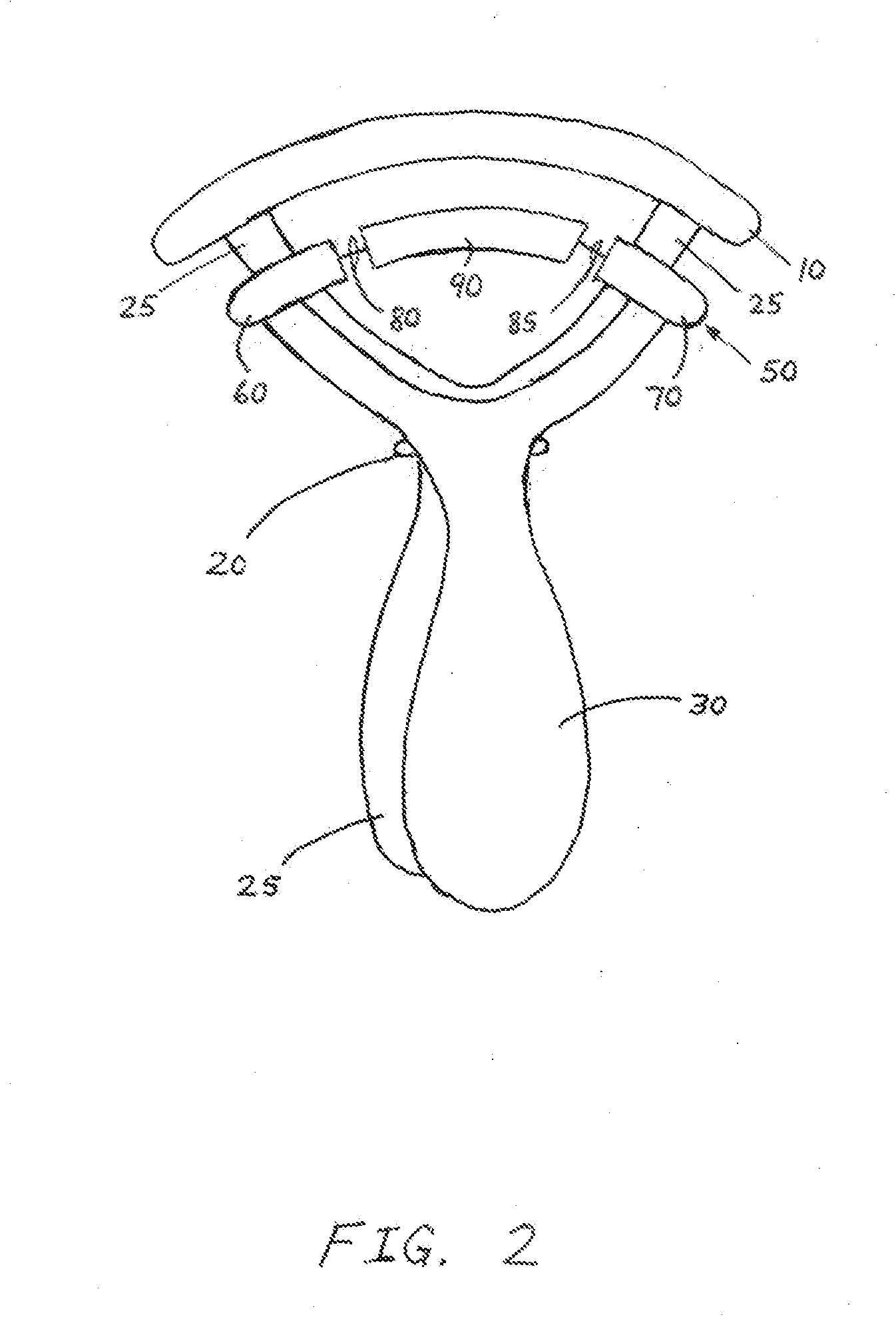

Exercise mat

ActiveUS20130198953A1Prevent slippingAvoid problemsSleeping rugTravelling rugEngineeringShoulder Support

An exercise mat for a person exercising on a floor surface comprises a pad having a top surface, a bottom surface, and a peripheral edge. A cutout is formed in a first portion of the peripheral edge and sized to accommodate the neck of the person. A high-friction non-slip texture or coating may be applied to either the top surface or the bottom surface of the pad, or both. The top surface may further includes a pair of raised shoulder stops. In use, with the bottom surface of the pad resting on the floor surface and with the person's shoulders supported on opposing sides of the cutout proximate the first portion of the peripheral edge, the person's neck may be positioned within the cutout to allow natural flexion curvature of the cervical spine when the person is performing a shoulder

Owner:LONG RAYMOND

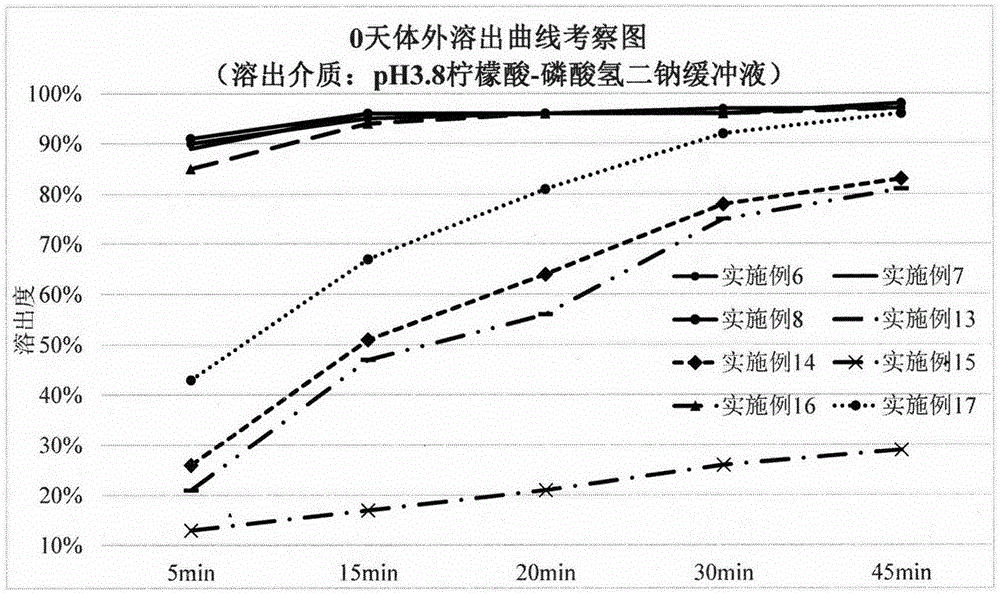

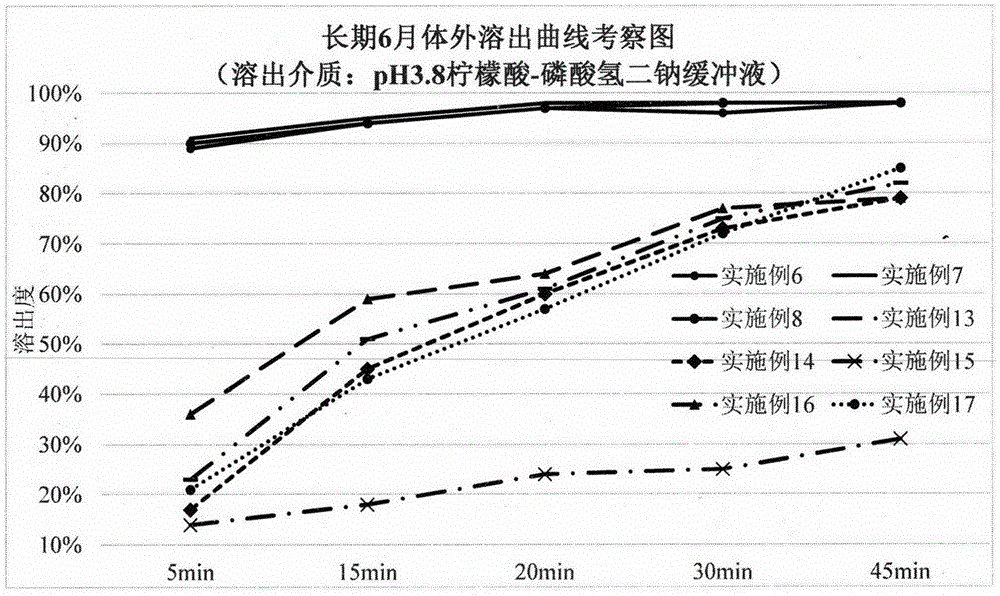

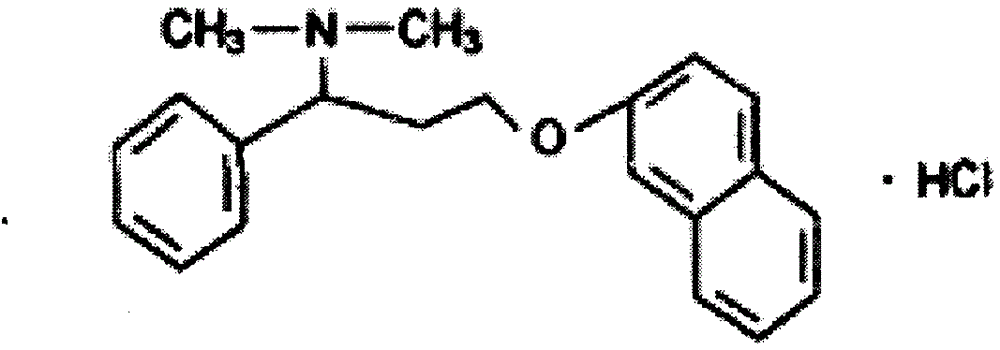

Hydrochloric acid dapoxetine tablet

ActiveCN105232503AReduce the impactGentle curveOrganic active ingredientsNervous disorderAcetic acidOrganic solvent

The invention relates to a hydrochloric acid dapoxetine tablet and belongs to the field of medicine production new technologies, in particular to the hydrochloric acid dapoxetine tablet and a preparation method thereof. Hydrochloric acid dapoxetine serves as the main constituent, and the tablet is obtained through direct tabletting of hydrochloric acid dapoxetine solid dispersion particles and auxiliary materials; a preparation method of the hydrochloric acid dapoxetine solid dispersion particles comprises the steps of mixing hydrochloric acid dapoxetine with organic solvent for forming a clear solution, and then adding the clear solution to dextrin for conducting pelleting. The weight ratio of hydrochloric acid dapoxetine and dextrin is 1 to 2-15, and the organic solvent is one or more out of ethanol, acetic acid, ethyl acetate and acetone. By means of the hydrochloric acid dapoxetine tablet, the influence of crystal form difference on preparations is eliminated, and the obtained hydrochloric acid dapoxetine tablet is good in in-vitro dissolution, safe and stable.

Owner:NANJING ZENKOM PHARMA

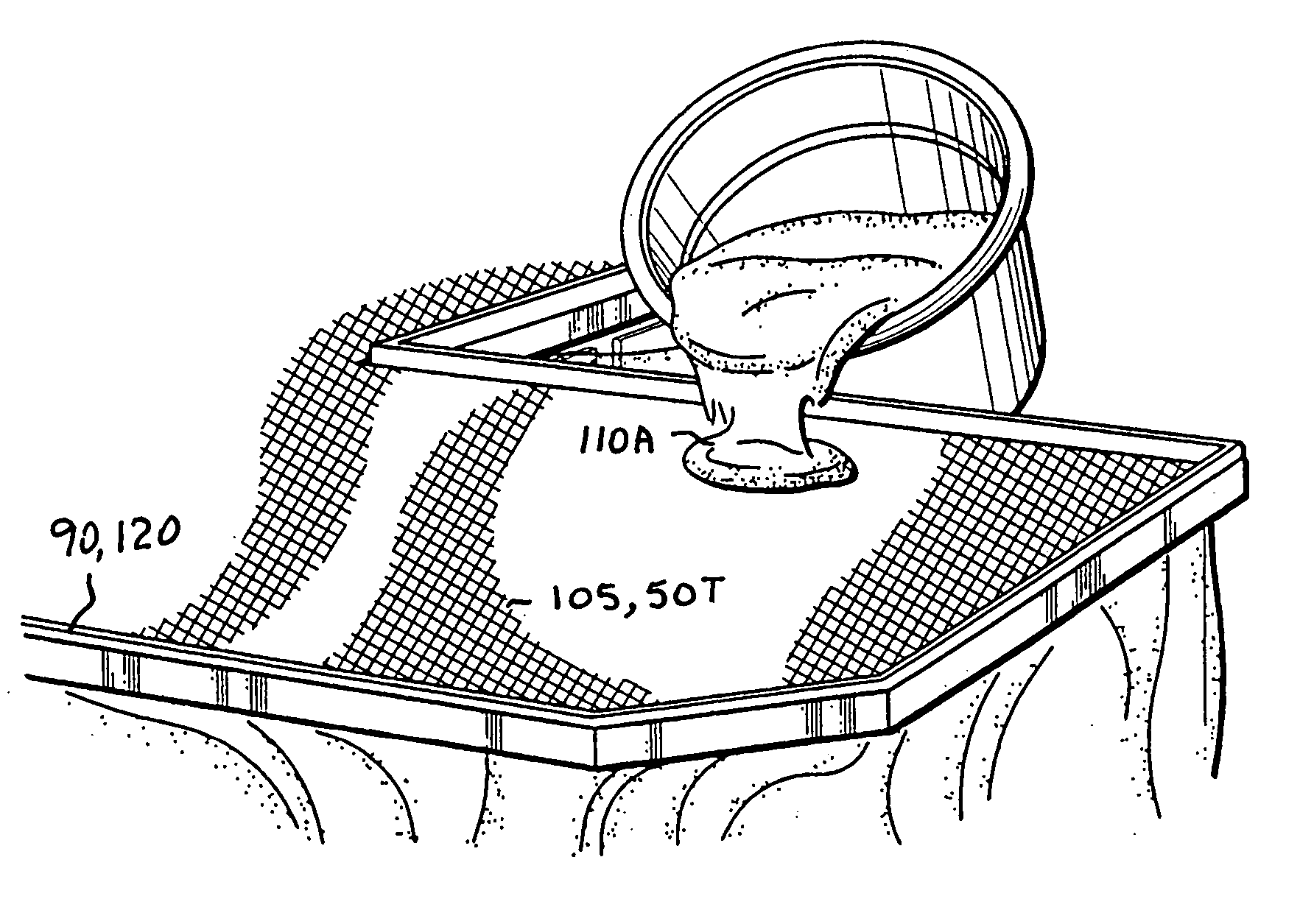

Method of casting a concrete-mix countertop

InactiveUS7685691B2Improve bending strengthGentle curveMetal rolling stand detailsBuilding repairsPolymer modifiedWorkspace

A method of producing a countertop upon a workspace furnishing such as floor cabinets by casting a polymer-modified cementitious casting compound thereupon has some of the following steps. Given the workspace furnishing, temporarily attaching edging forms or flow checks around all the free edges of the top deck thereof, both of which the forms the and flow checks operate to check the flow of the casting compound at least to the height of a given rise. Following that, pouring a polymer-modified cementitious casting compound over the countertop to the height of the given rise and as checked within the edging forms and flow checks. The edging forms have depending-flange relief cavities that descend below the plane of the deck that give the hardened casting compound an appearance of a virtual thickness that disguises in part the actual thinness of the rise over the deck.

Owner:STONE GRP HLDG

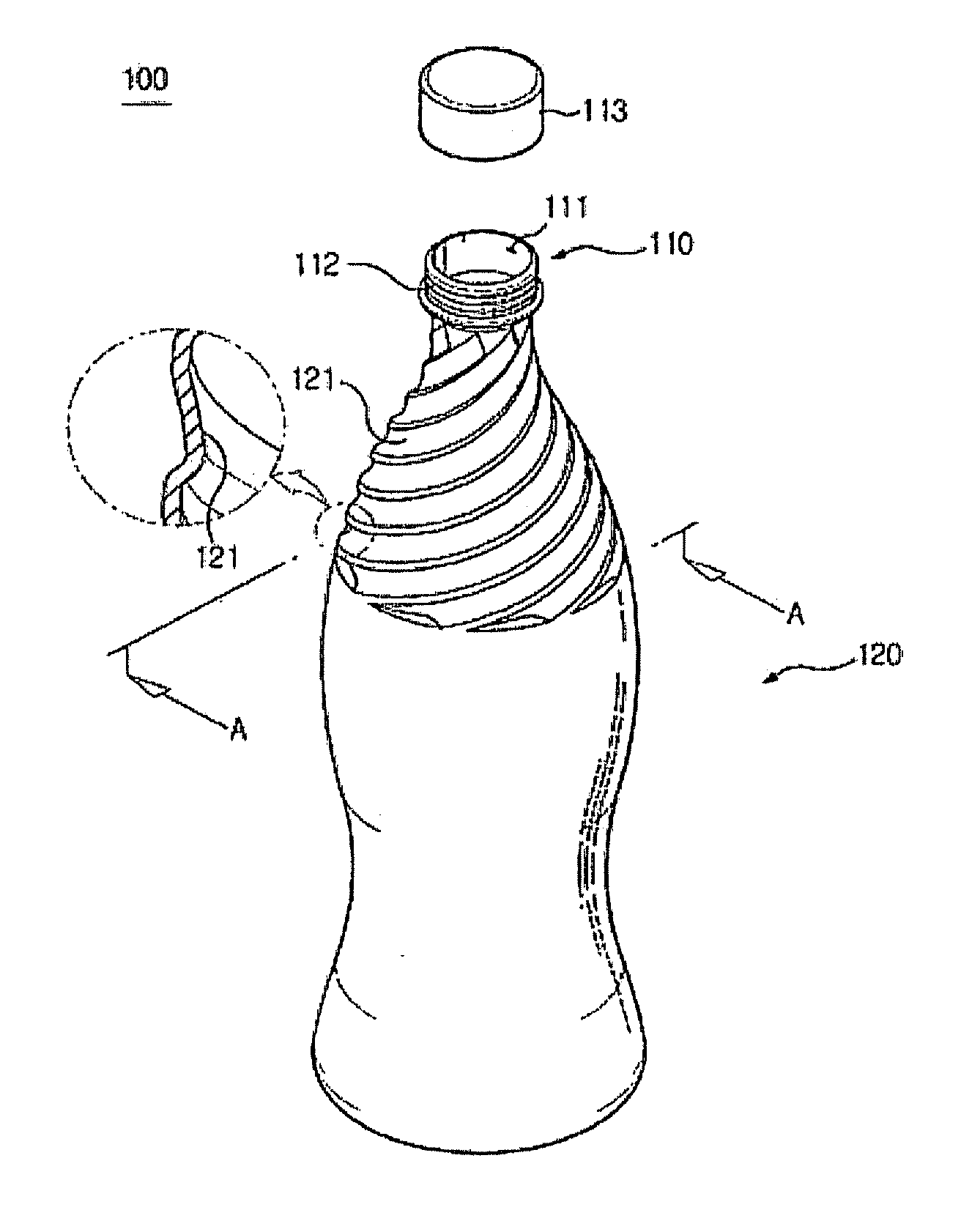

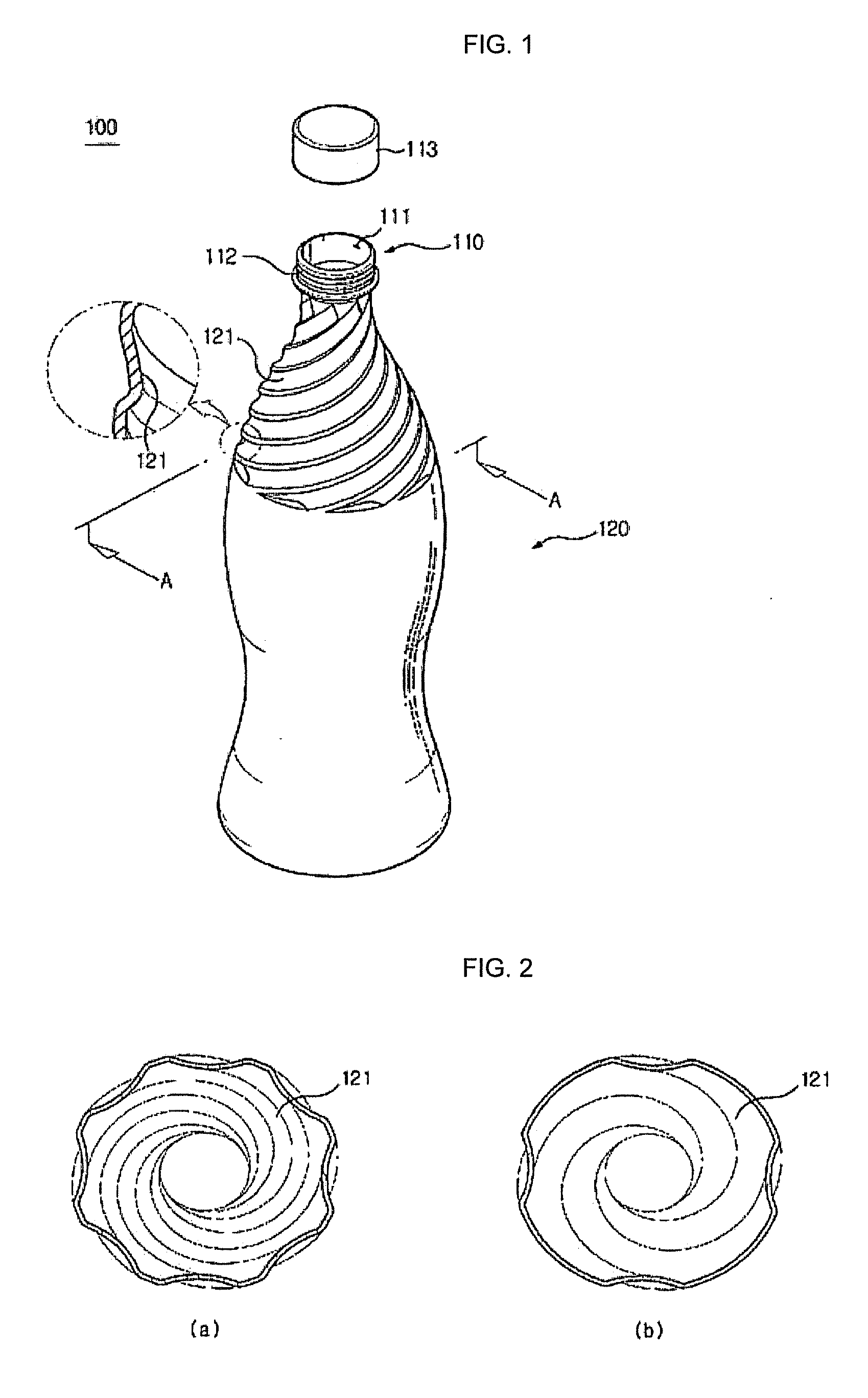

Discharging contents from a container while filling the same with gas

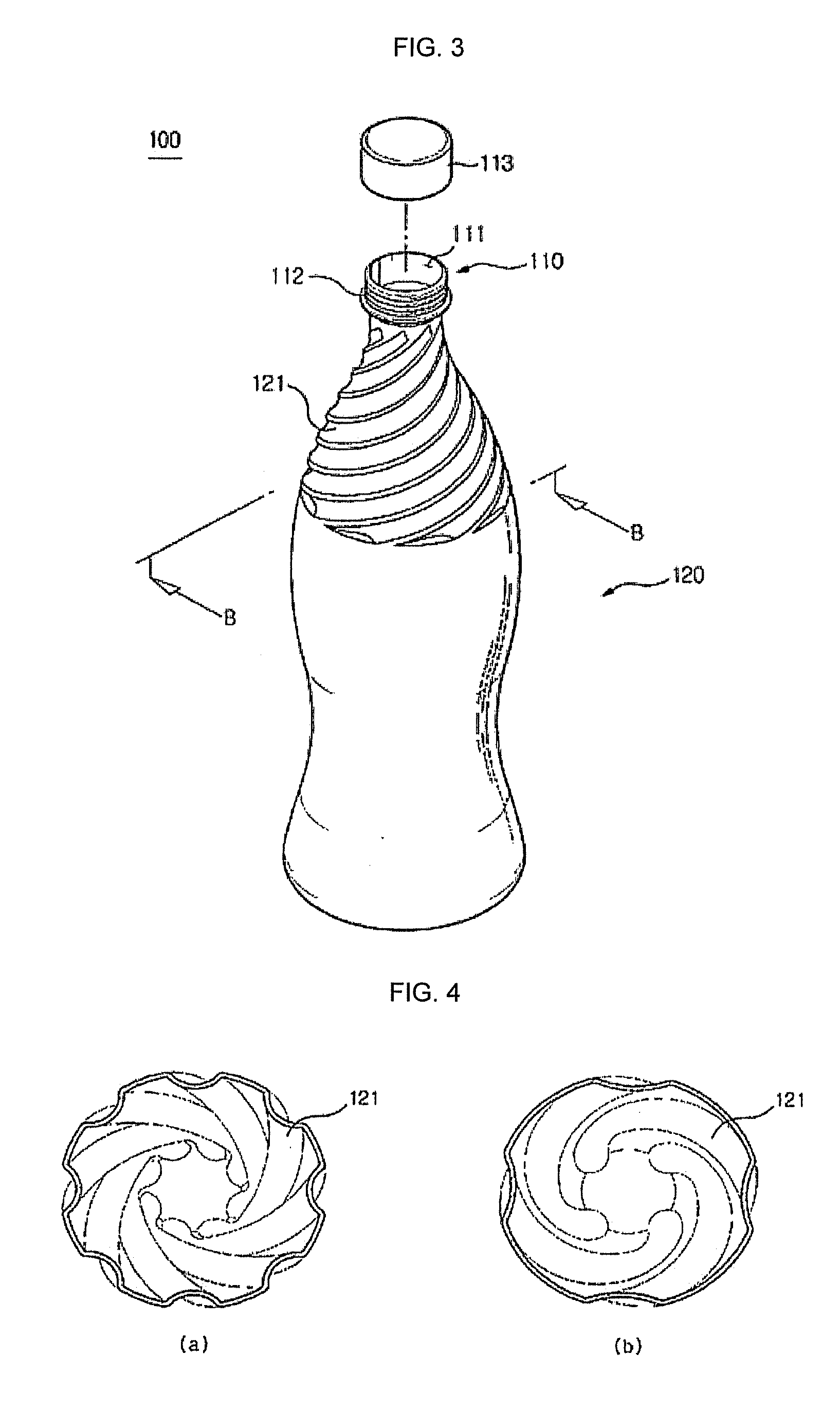

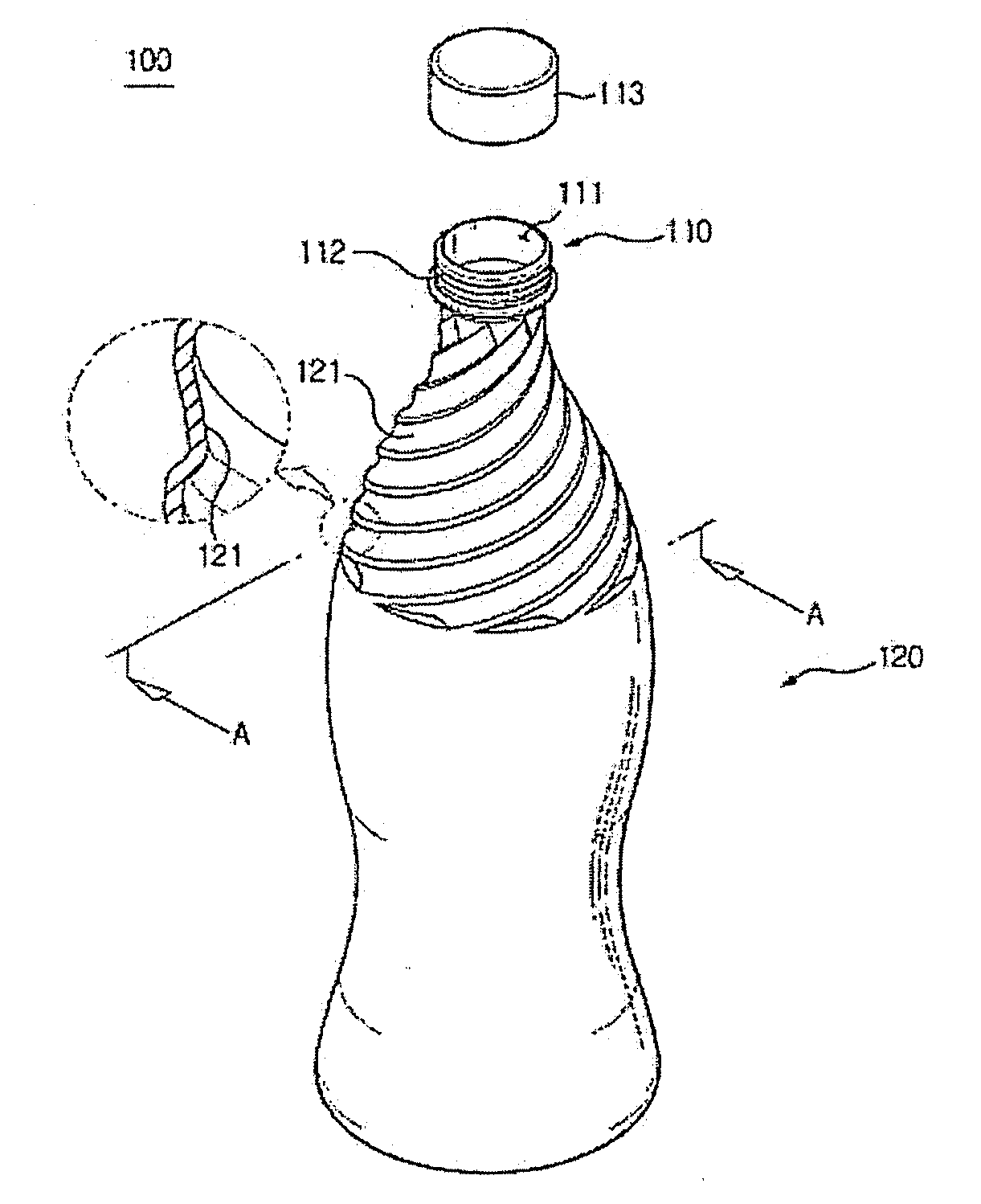

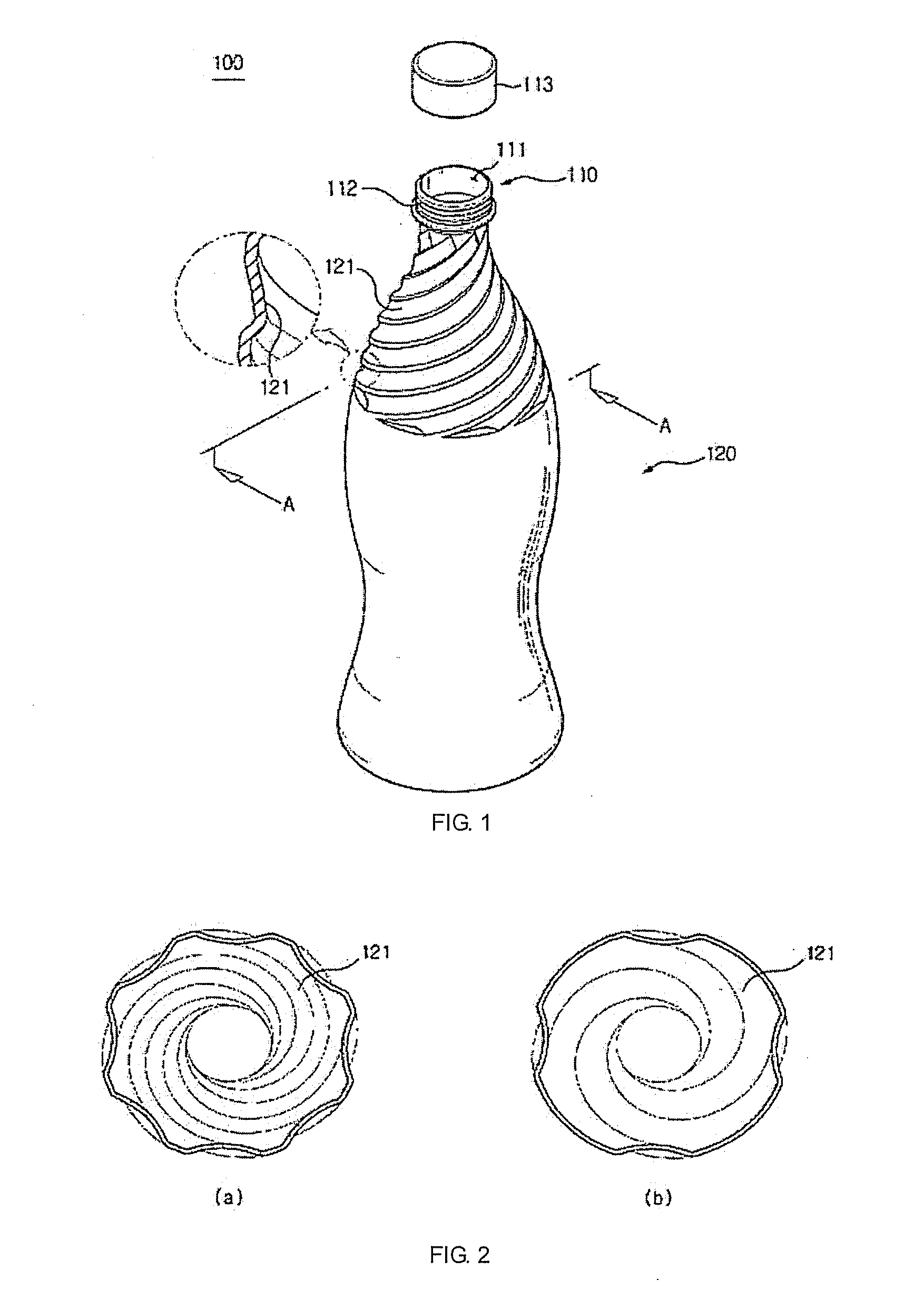

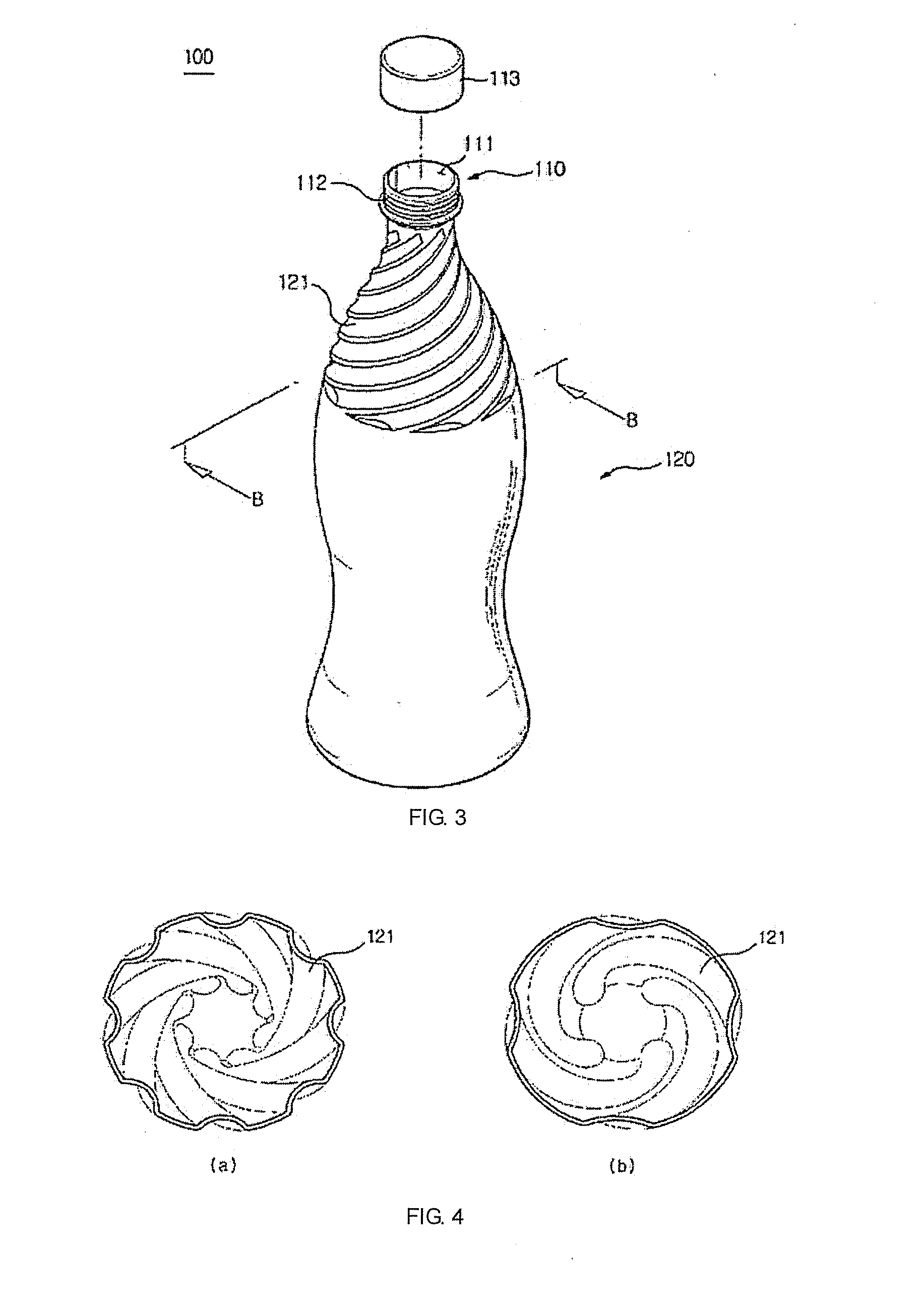

InactiveUS20130048593A1Prevent of liquid contentAvoid accidentsBottlesLarge containersBottleLiquid content

Disclosed is a bottle for containing liquid content including a body portion, at least part or the entire portion of an upper portion of which is provided with a plurality of guides which protrudes inward from an inside surface thereof and is in a spiral pattern so that the liquid content can be guided towards an opening of a neck portion of the bottle while spirally revolving inside the bottle.

Owner:LEE JONATHAN

Discharging contents from a container while filling the same with gas

InactiveUS20130082025A1Prevent of liquid contentAvoid accidentsBottlesLarge containersEngineeringBottle

Disclosed is a bottle for containing liquid content including a body portion, at least part or the entire portion of an upper portion of which is provided with a plurality of guides which protrudes inward from an inside surface thereof and is in a spiral pattern so that the liquid content can be guided towards an opening of a neck portion of the bottle while spirally revolving inside the bottle.

Owner:LEE JONATHAN

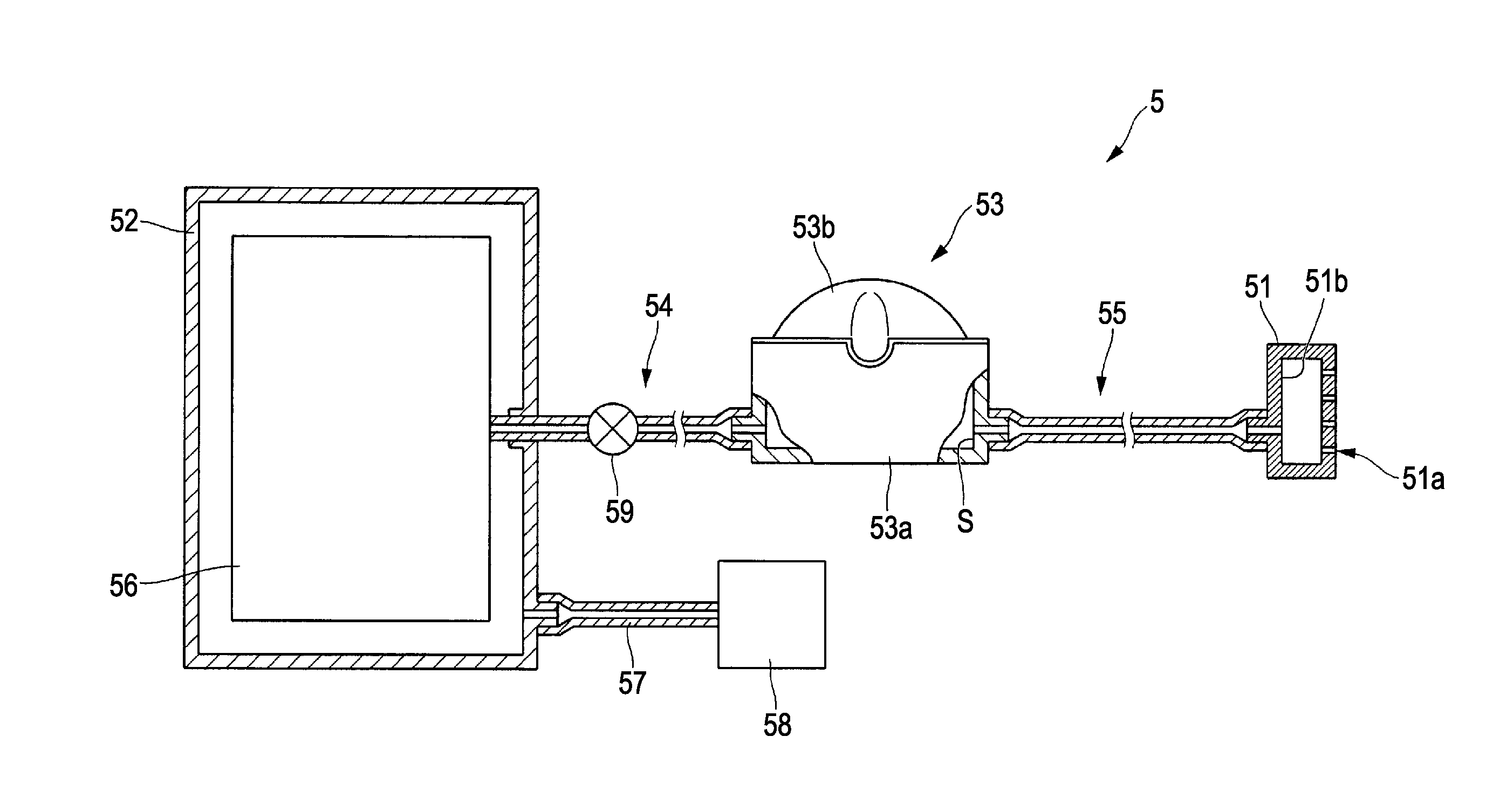

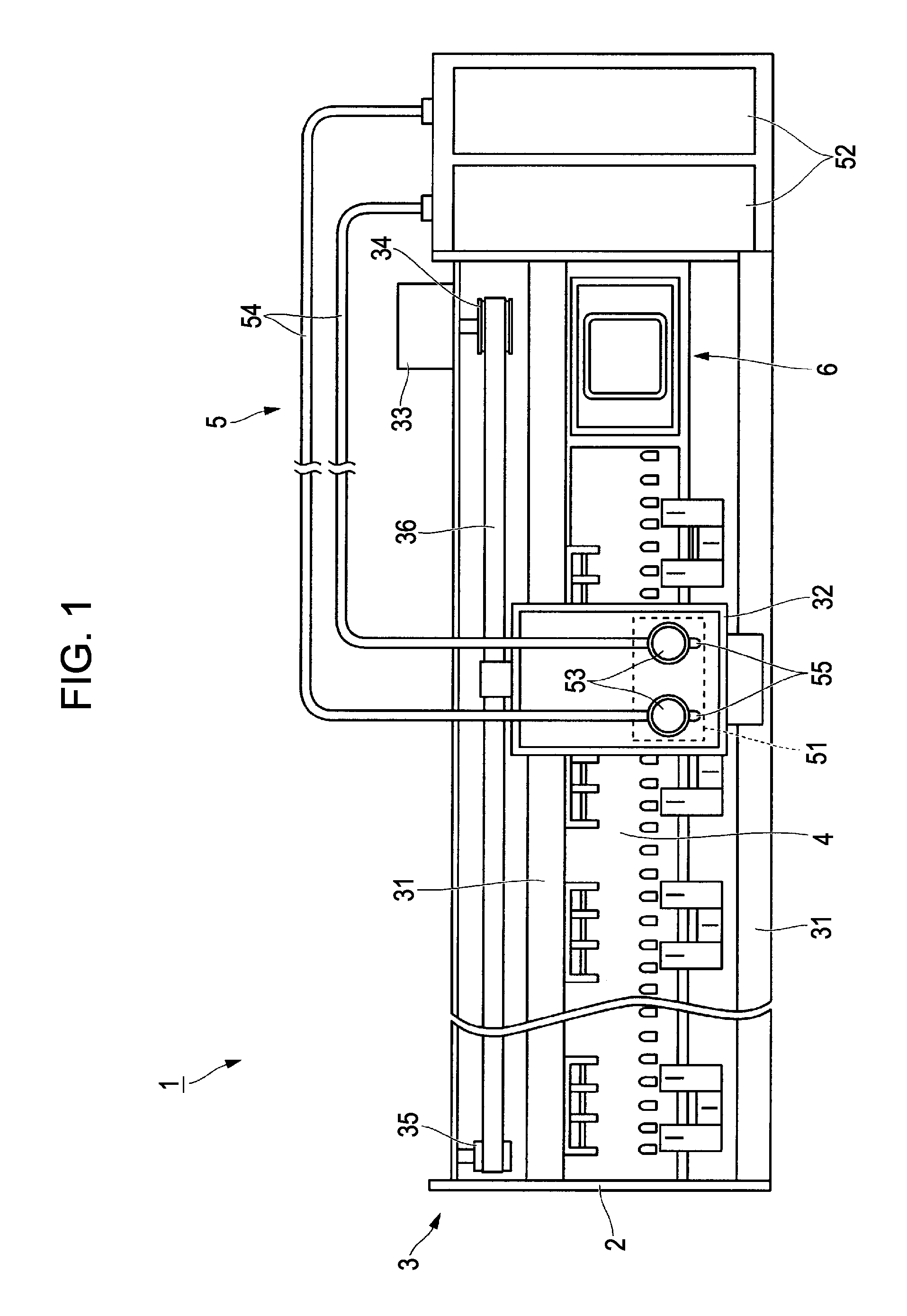

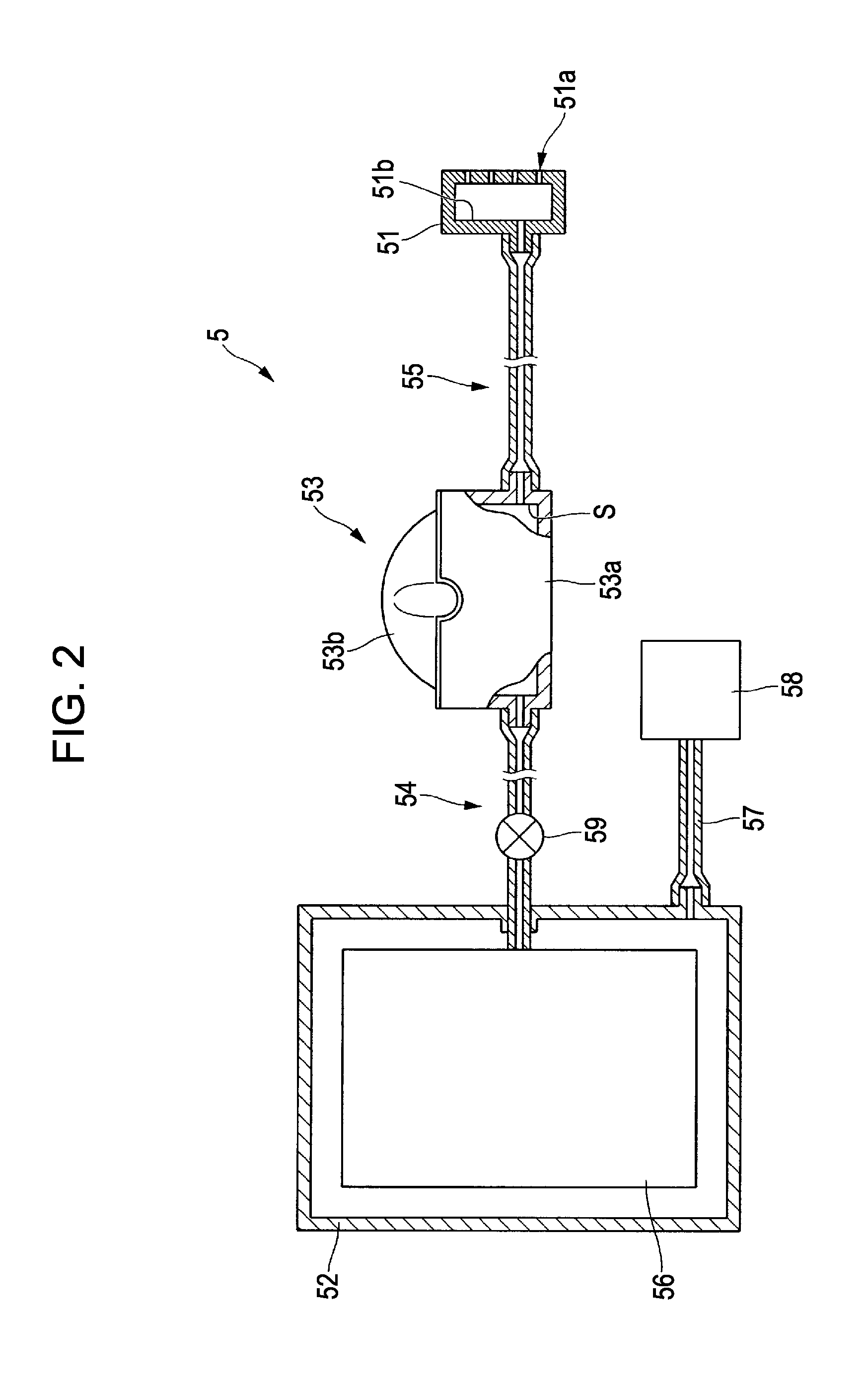

Buffer and liquid ejecting apparatus

InactiveUS20100245497A1Stable supplyExtended service lifeCheck valvesFluid-delivery valvesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

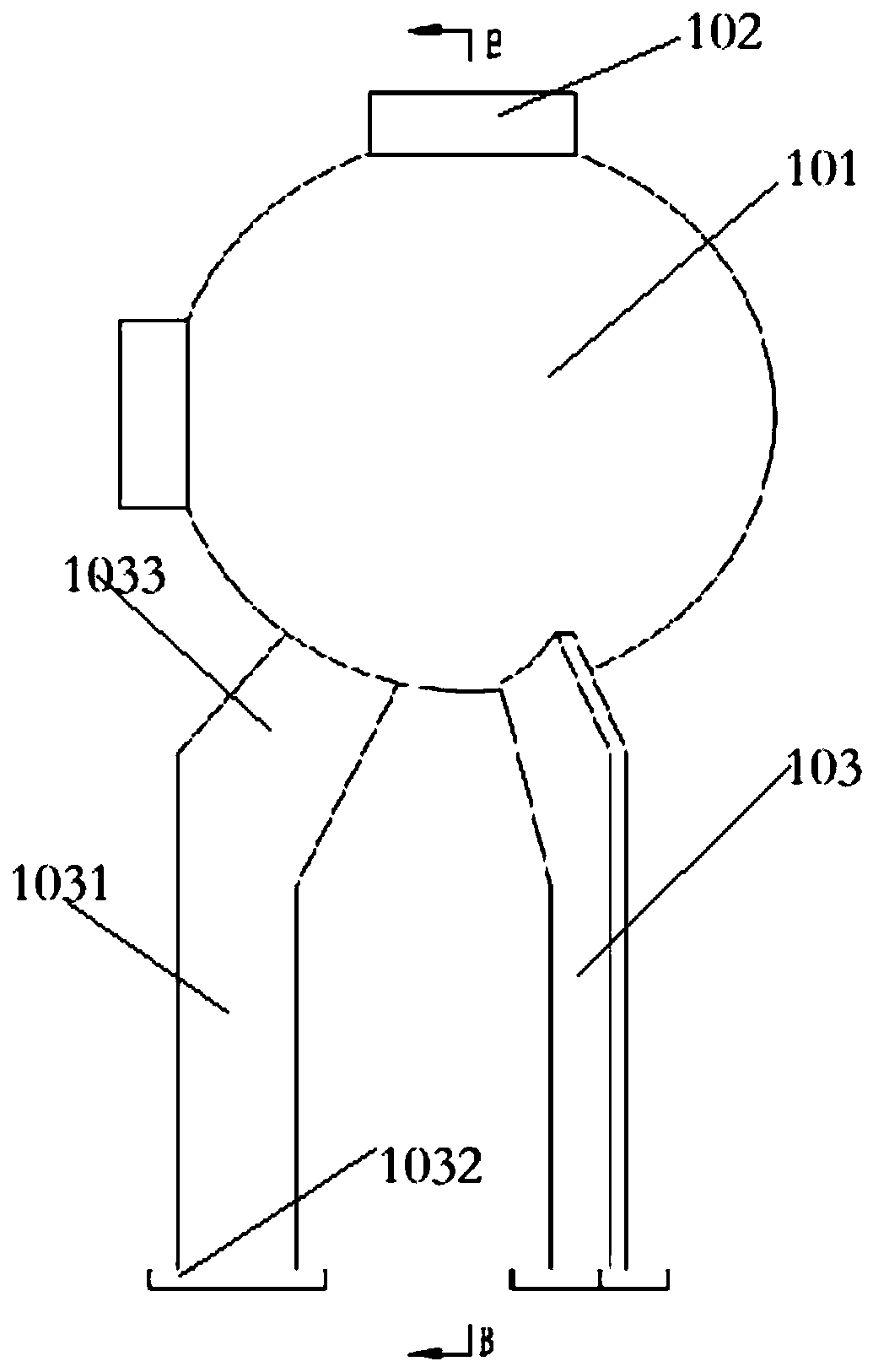

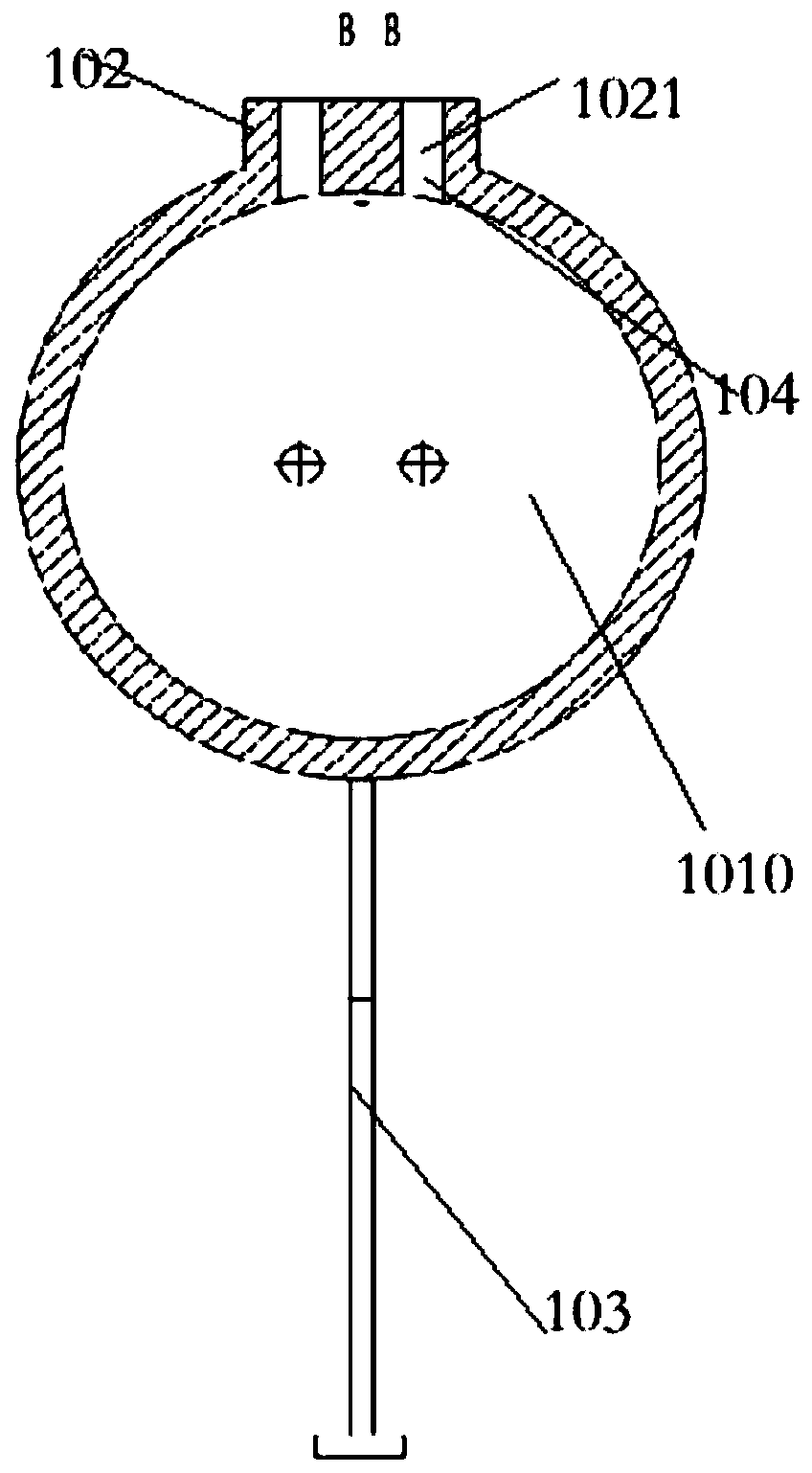

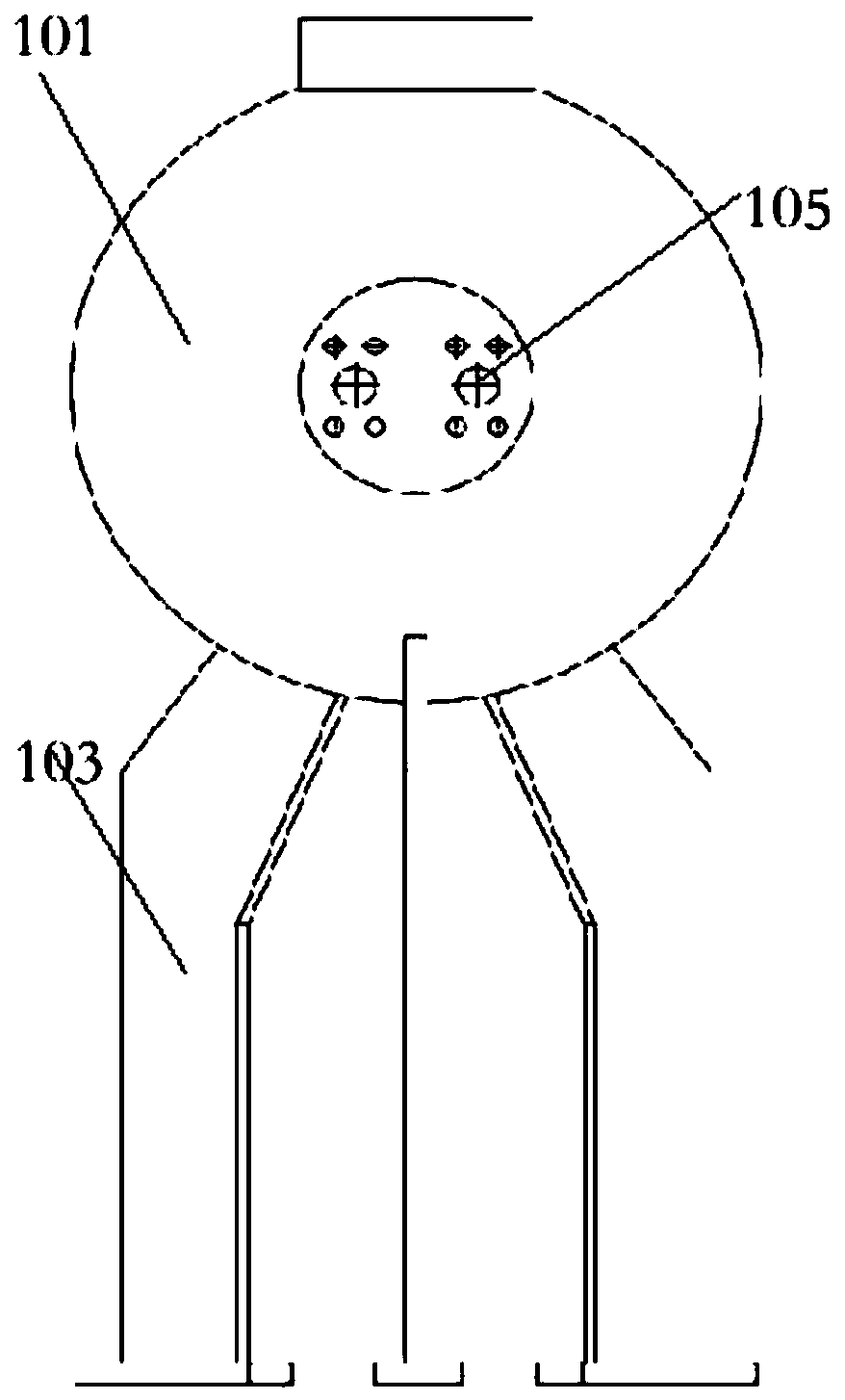

High-pressure shock absorber and high-pressure descaling system adopting same

PendingCN109737047AImprovement in pulsationReduce peaks and troughsPositive displacement pump componentsLiquid fuel engine componentsInternal cavityEngineering

The invention relates to the field of high-pressure shock absorbers, in particular to a high-pressure shock absorber and a high-pressure descaling system adopting the same. The high-pressure shock absorber comprises a spherical shock absorber, a storage cavity is formed in the spherical shock absorber, a liquid inlet channel used for feeding liquid and a liquid discharging channel used for discharging the liquid are arranged on the spherical shock absorber, the liquid inlet channel and the liquid discharge channel are arranged in an intersected mode, and the liquid inlet channel and the liquiddischarge channel are communicated with the storage cavity. According to the high-pressure spherical shock absorber disclosed by the invention, the internal cavity of the spherical shock absorber isoptimized, meanwhile, the distribution positions of the liquid inlet channel and the liquid discharge channel are optimized, so that the liquid inlet channel and the liquid discharge channel are not collinear, water flow impact direction can be changed, high-pressure water flow enters to impact spherical inner walls from the top of the high-pressure spherical shock absorber, the reflected high-pressure water flow and pulsating high-pressure water flow from behind are converged together to weaken the pulsation wave peak of the high-pressure water, and the pulsation condition of the high-pressure water flow passing through the high-pressure shock absorber is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

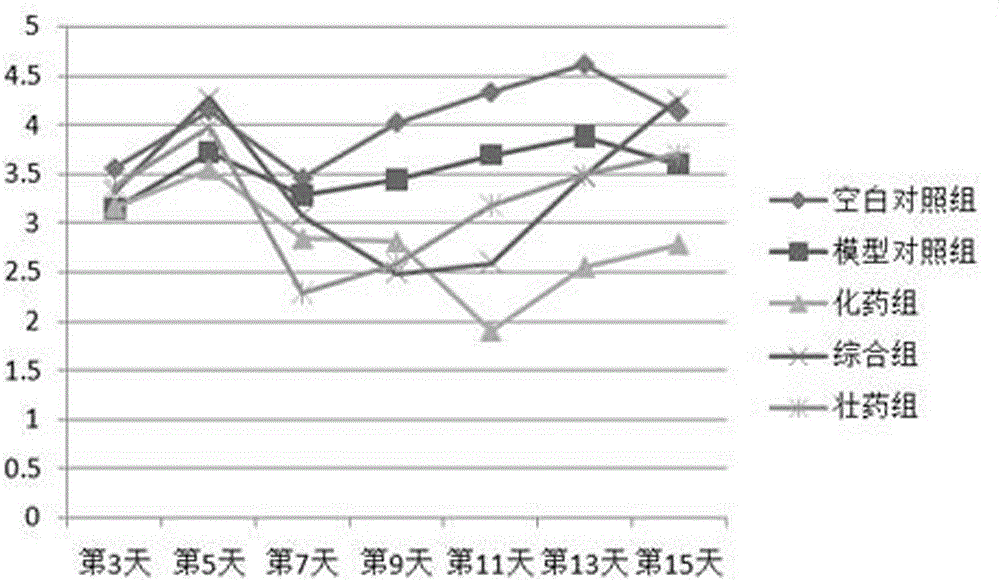

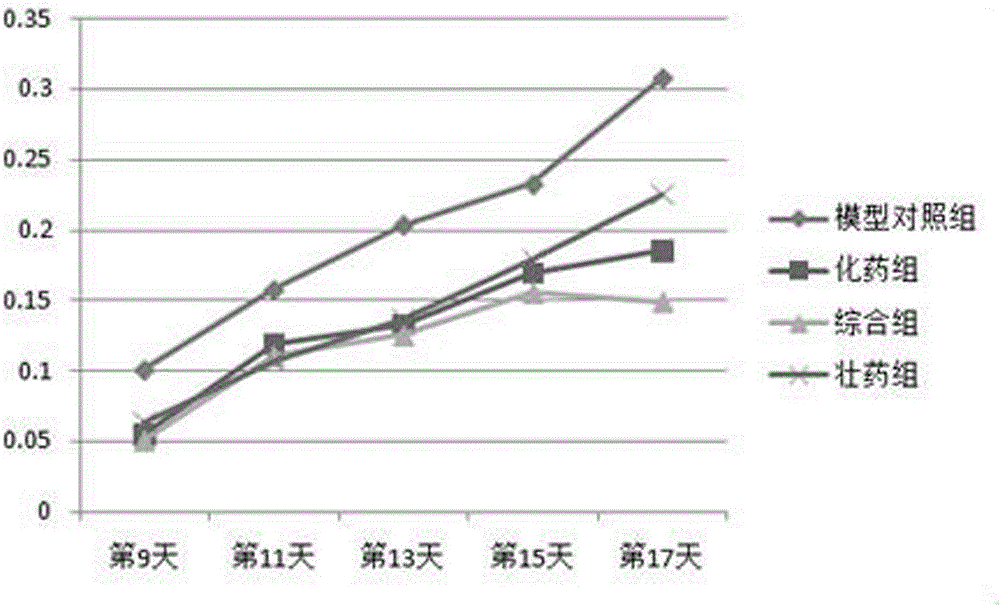

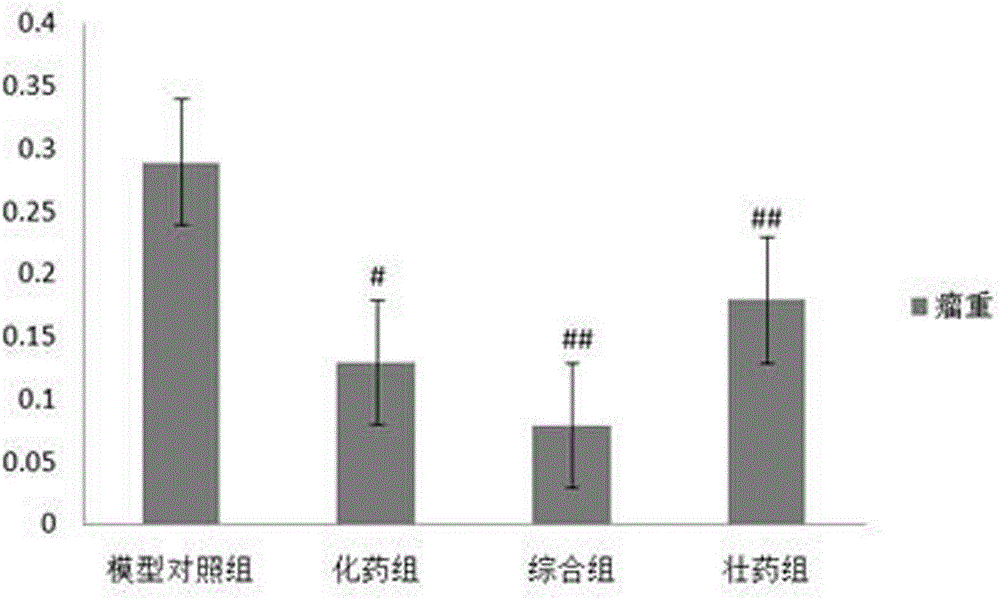

Zhuang medicine composition assisted in resisting lung cancer

ActiveCN105126030AReduce appetite side effectsReduce inhibitionAntineoplastic agentsPlant ingredientsMedicinal herbsBlood platelet counts

The invention discloses a Zhuang medicine composition assisted in resisting lung cancer. The Zhuang medicine composition is characterized by being prepared from the following Zhuang medicinal materials: Nyarinngoux (Chinese name: baihuasheshecao), Gaeubwnhgauh (Chinese name: baiying), Byaekloekhauj (Chinese name: longkui), Buenqcilienz (Chinese name: banzhilian), Ginghgun (Chinese name: guangxi eshu), Fouxndoengz (Chinese name: shishangbai), Swnjgyaeujhenj (Chinese name: huanghuadaoshuilian), Raggongox (Chinese name: lugen), GO gyauhgujlanz (Chinese name: jiaogulan) and Lozhangoj (Chinese name: luohanguo). The Zhuang medicine composition is combined with chemical drugs for curing lung cancer, can reduce the toxic and side effects of inappetence caused by the chemical drugs, reduce the damage of the chemical drugs to immune organs, increase white blood cell count, blood platelet count, red blood cell count and hemoglobin count to reduce the inhibiting effect on myelosuppression, reduce the content of glutamic-pyruvic transaminase and glutamic oxalacetic transaminase to alleviate the damage to liver functions and increase the tumor suppression function of the chemical drugs. Namely, the Zhuang medicine composition is combined with the chemical drugs for curing the lung cancer and has the effects of toxicity reducing and efficacy enhancing.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Eyelash Curler

An eyelash curler used to shape an upper eyelash so as to make it appear longer and more full. The eyelash curler employs a “roller system” that curls an upper eyelash, rather than a “pressing system” that bends or crimps an upper eyelash to achieve a curled effect as with conventional eyelash curlers. The forming members of the eyelash curler, in all the embodiments of the present invention, are cylindrical and curved like the upper eyelash line to help achieve curling, and are less likely than conventional eyelash curlers to damage an eyelash.

Owner:TEXEN BEAUTY PARTNERS EURO SAS

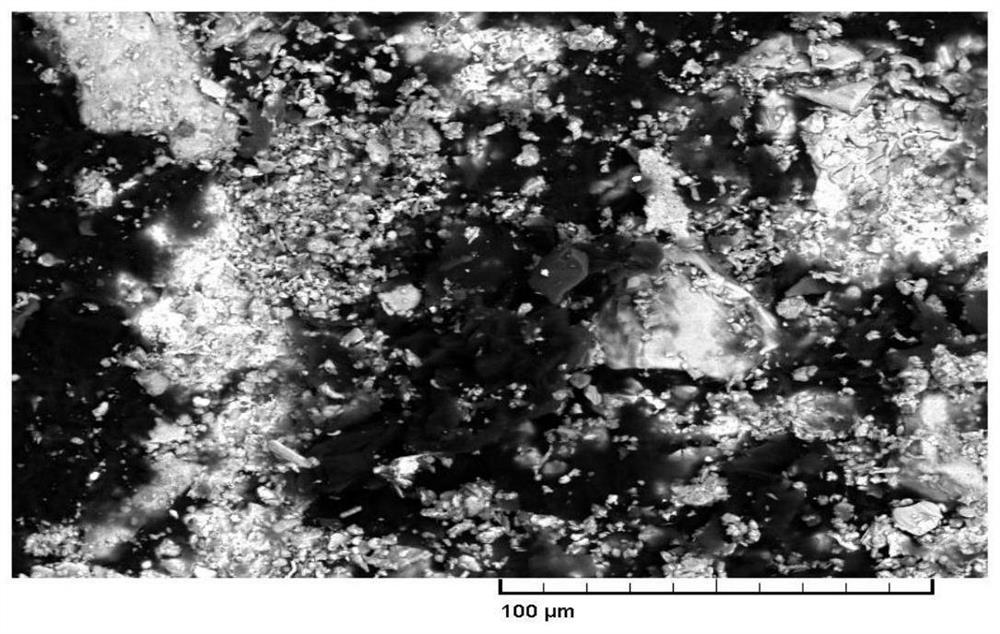

Copper-based powder metallurgy friction material with high-stability friction coefficient and preparation method

PendingCN114210966AHigh mechanical strengthHigh strengthTransportation and packagingMetal-working apparatusSolid componentUltimate tensile strength

According to the copper-based powder metallurgy friction material with the high stable friction coefficient and the preparation method, the components and the preparation process of the material are optimized, the system matching effect of a copper alloy matrix, a lubricating component and a solid component is exerted, and the obtained copper-based powder metallurgy friction material has the advantages of being high in strength, low in expansion rate, small in deformation amount and good in abrasion resistance; the fluctuation range of the friction coefficient of the friction material does not exceed + / -5%, the average friction coefficient mu cp is larger than or equal to 0.31 and smaller than or equal to 0.34, the fluctuation range of the friction coefficient does not exceed + / -5% of the average friction coefficient, and the linear abrasion loss of the friction material is smaller than or equal to 0.0038 mm / face per time. The obtained friction material has good mechanical strength, is suitable for the working conditions that the positive pressure is 2.032 KN and the speed is 75 m / s, has the advantages of being high in strength, low in expansion rate, small in deformation amount, good in abrasion resistance and the like, does not have the phenomena of friction layer falling, chipping, clamping stagnation, bonding and the like in the using process, and is stable in braking curve and stable and reliable in braking process.

Owner:XIAN AVIATION BRAKE TECH

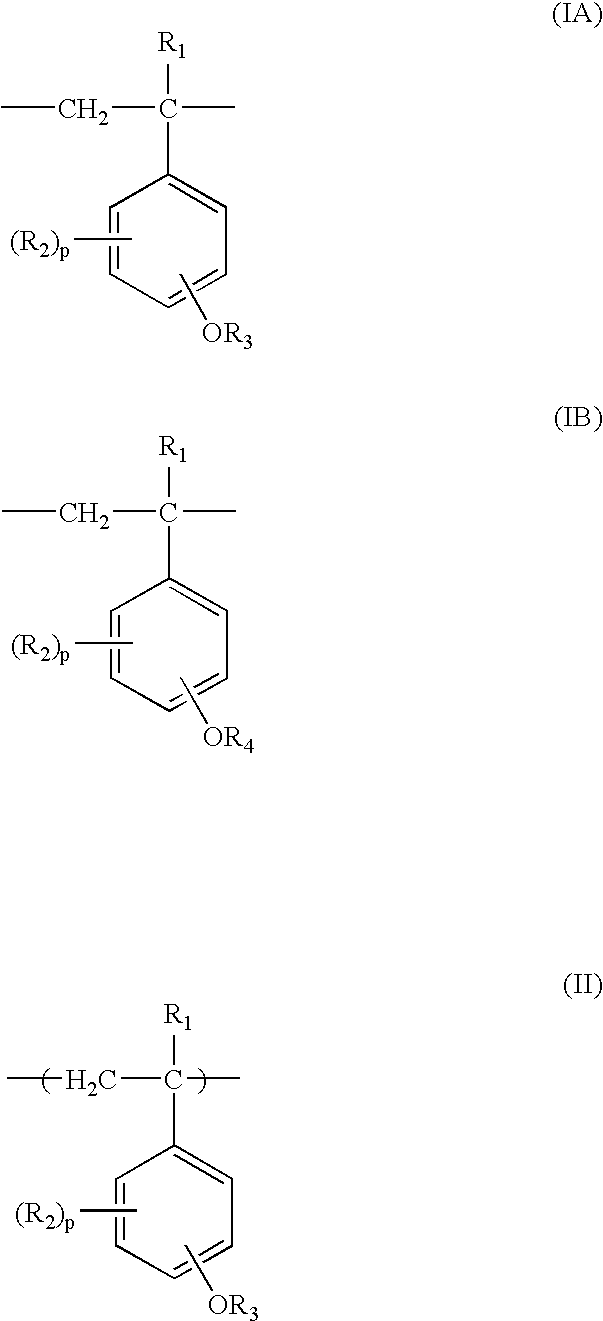

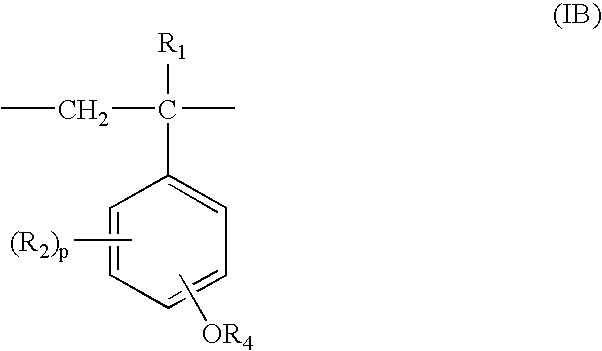

Process for production of partially protected poly(hydroxystyrene)s

A process for making poly(hydroxystyrene)s whose phenolic hydroxyl groups are partially protected by acid-decomposable or -eliminable groups, by which the degree of deblocking of the phenolic hydroxyl groups is controlled. Namely, the production of a polymer containing, in the molecule, repeating units of the general formula (IA) and those of the general formula (IB), comprising adding an acid to polymer (B) containing in the molecule repeating units of general formula (II) in an organic solvent with the molar ratio of the acid to the OR3 group being 0.0001 equivalent or above but below 0.05 equivalent, and reacting the polymer with the acid. In the general formulae, R1 is hydrogen or methyl; R2 is C1-6 alkyl; R3 is an acid-decomposable or -eliminable group; R4 is hydrogen or a group derived from R3 by decomposition with acid; and p is 0, 1, or 2, with the proviso that the IB / IA molar ratio ranges 98 / 2 to 30 / 70.

Owner:NIPPON SODA CO LTD

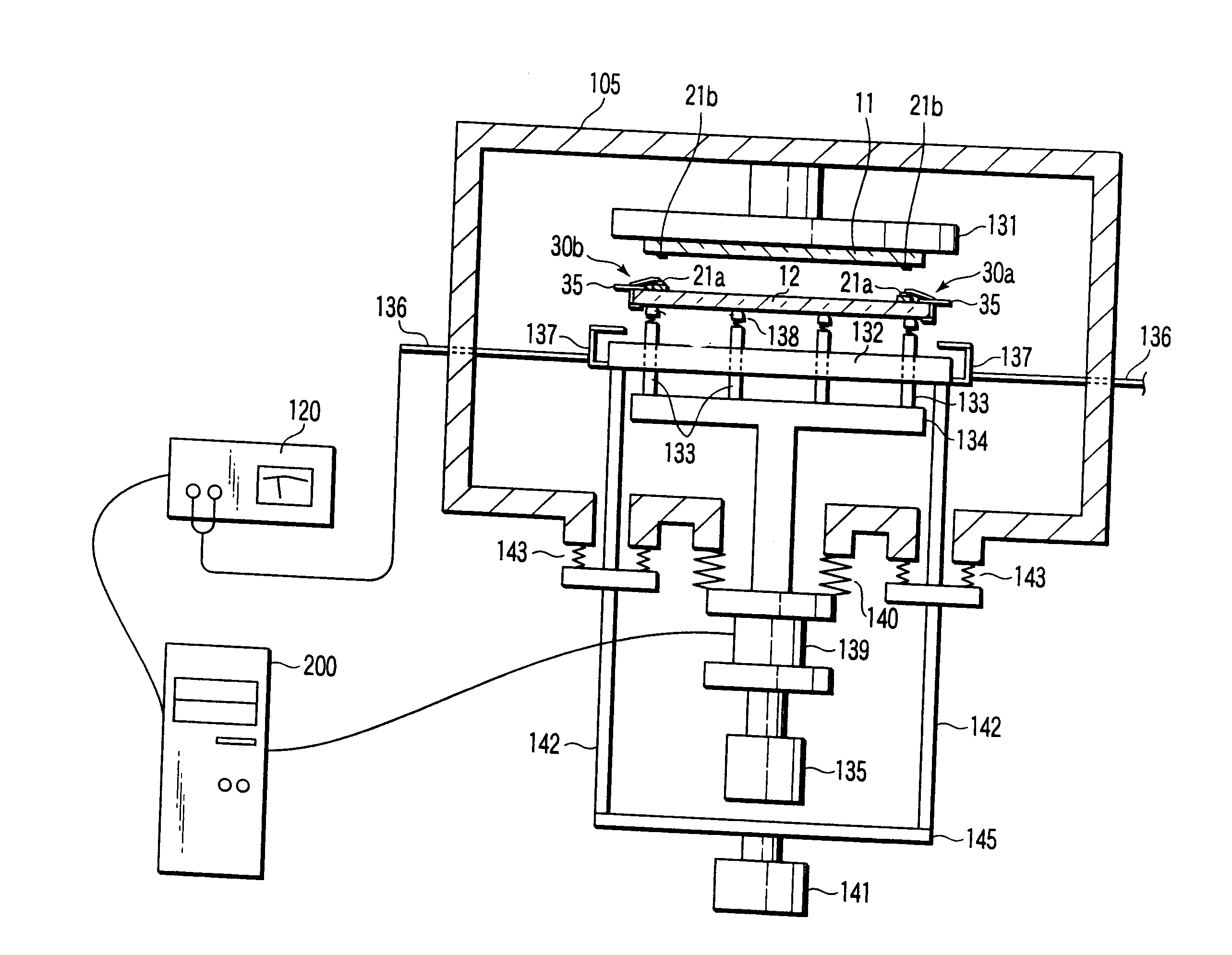

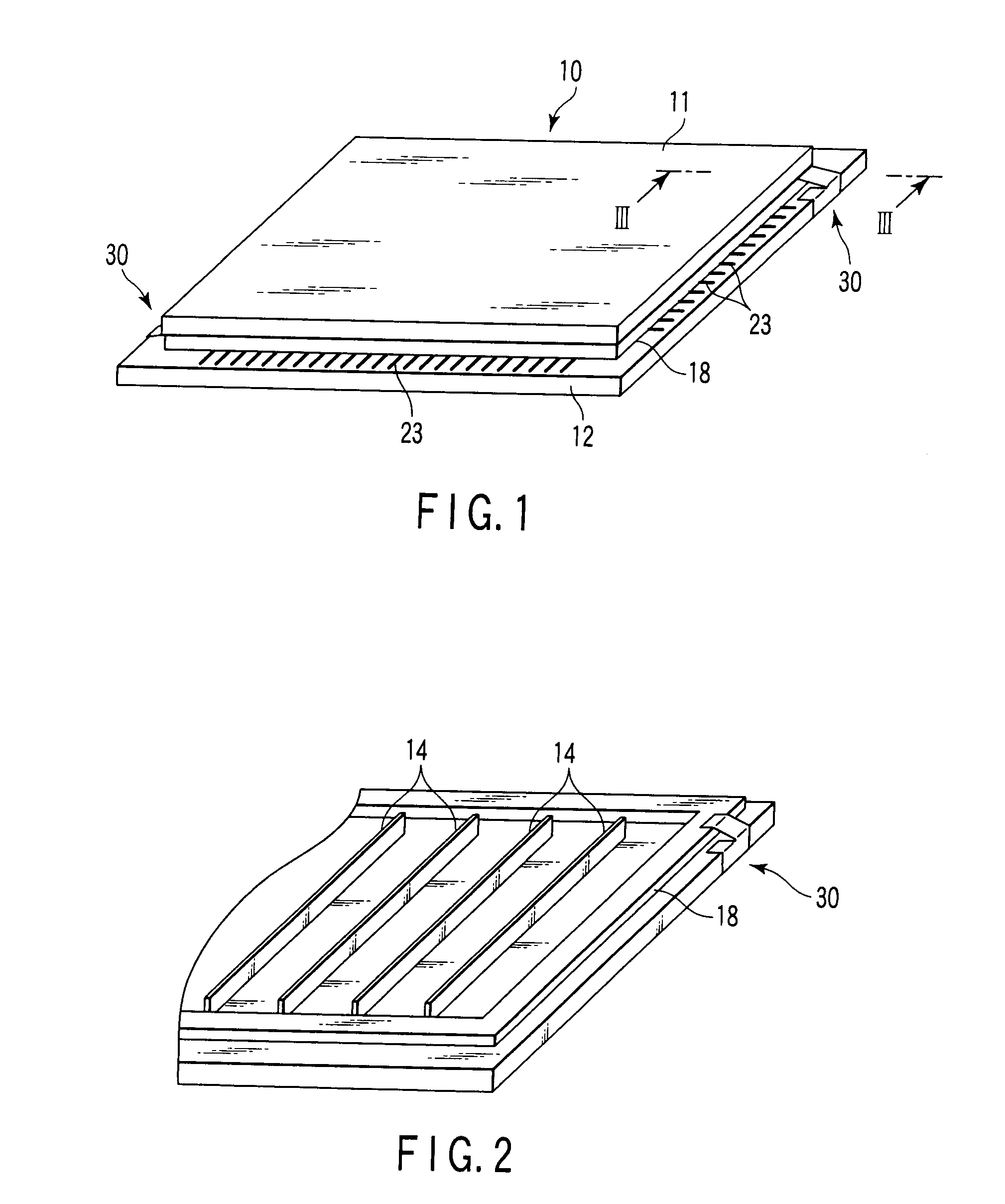

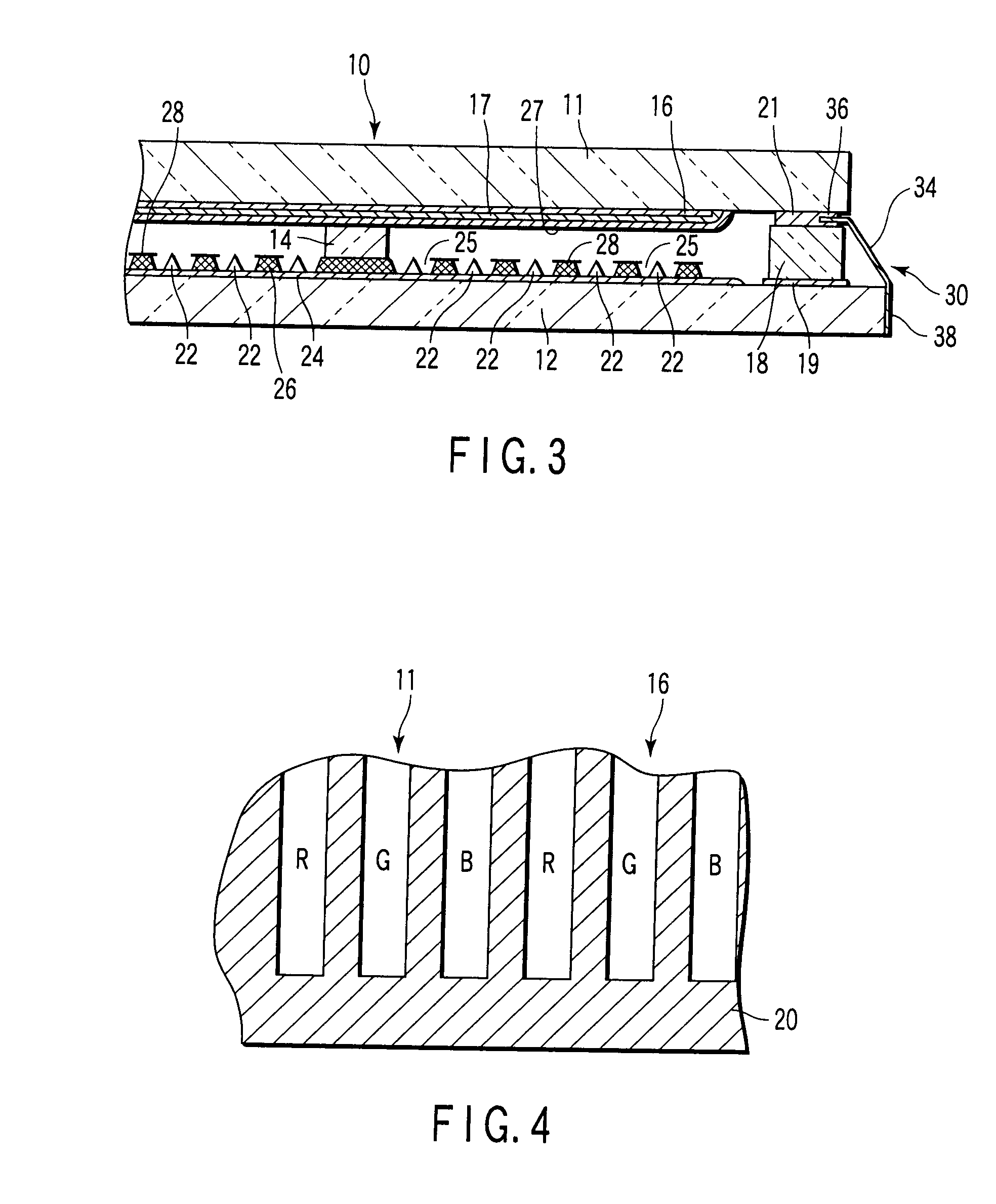

Manufacturing method and manufacturing apparatus for image display device

InactiveUS20070259587A1Quick and stable workShorten the timeCathode-ray/electron-beam tube vessels/containersElectroluminescent light sourcesEngineeringElectric current

After sealing layers are formed on peripheral edge parts of a front substrate and a rear substrate, the front substrate and the rear substrate are disposed to be opposed to each other. Current paths are formed in the sealing layers, and power supply is begun. An electric current, which reaches a maximum current value after a current-increasing period of 10% or more of an entire power-supply time, is supplied for a predetermined time period. The sealing layers are heated and melted by the power supply, and peripheral parts of the front substrate and rear substrate are joined.

Owner:ENOMOTO TAKASHI +2

Concrete mix countertop production and products

InactiveUS20070216052A1Improve bending strengthGentle curveMetal rolling stand detailsBuilding repairsPolymer modifiedFree edge

A method of producing a countertop upon a workspace furnishing such as floor cabinets by casting a polymer-modified cementitious casting compound thereupon has some of the following steps. Given the workspace furnishing, temporarily attaching edging forms or flow checks around all the free edges of the top deck thereof, both of which the forms the and flow checks operate to check the flow of the casting compound at least to the height of a given rise. Following that, pouring a polymer-modified cementitious casting compound over the countertop to the height of the given rise and as checked within the edging forms and flow checks. The edging forms have depending-flange relief cavities that descend below the plane of the deck that give the hardened casting compound an appearance of a virtual thickness that disguises in part the actual thinness of the rise over the deck.

Owner:STONE GRP HLDG

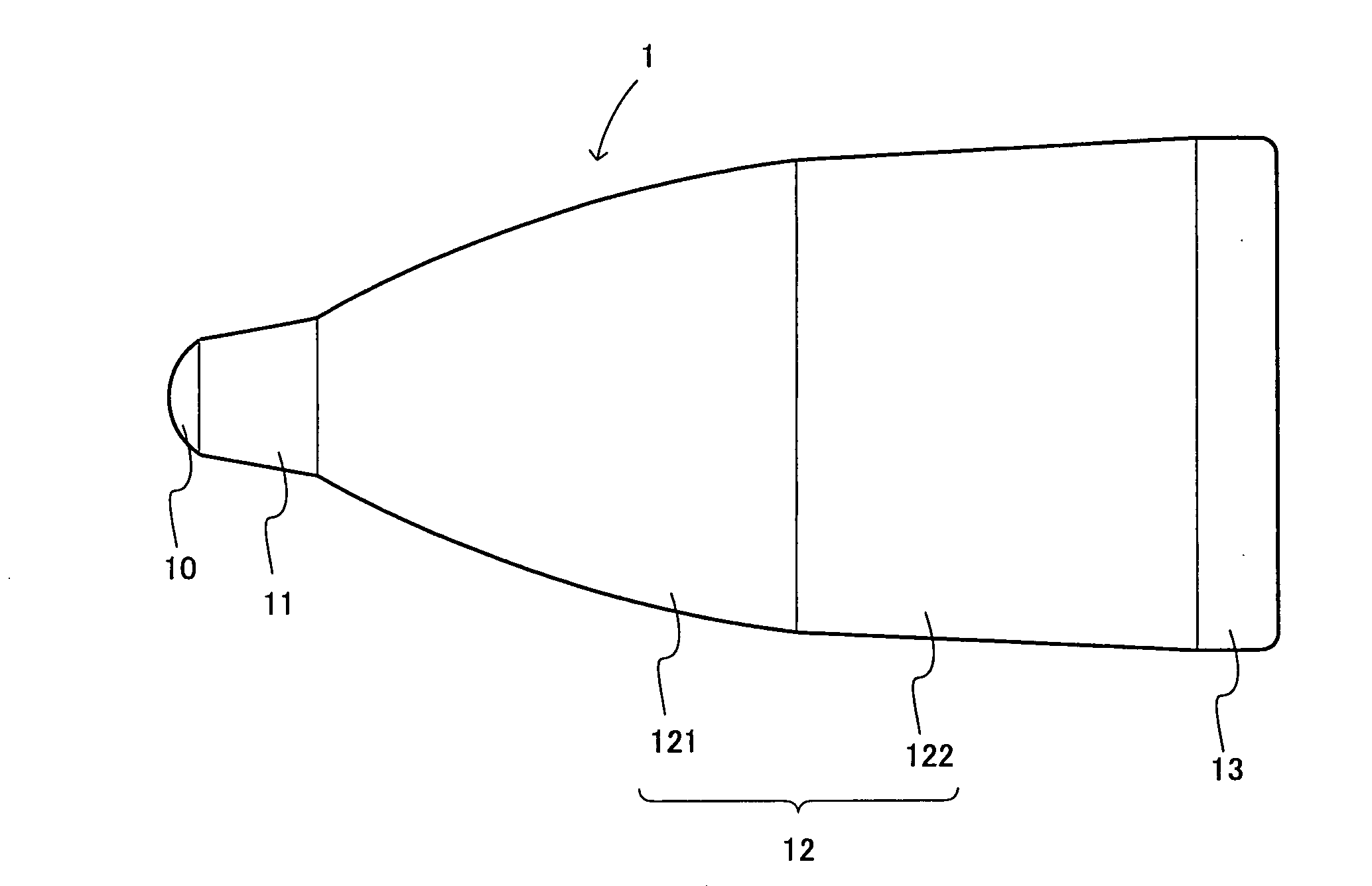

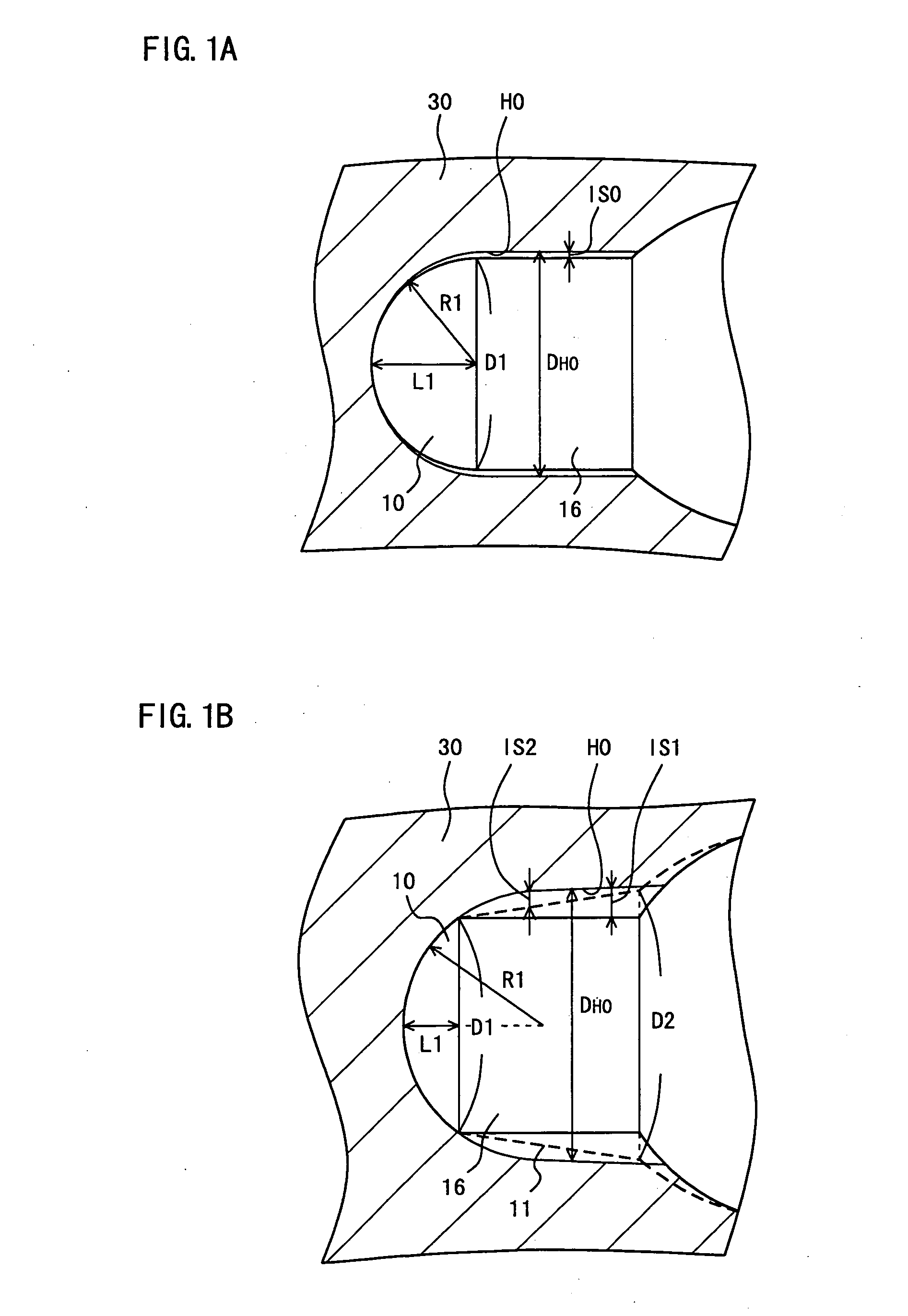

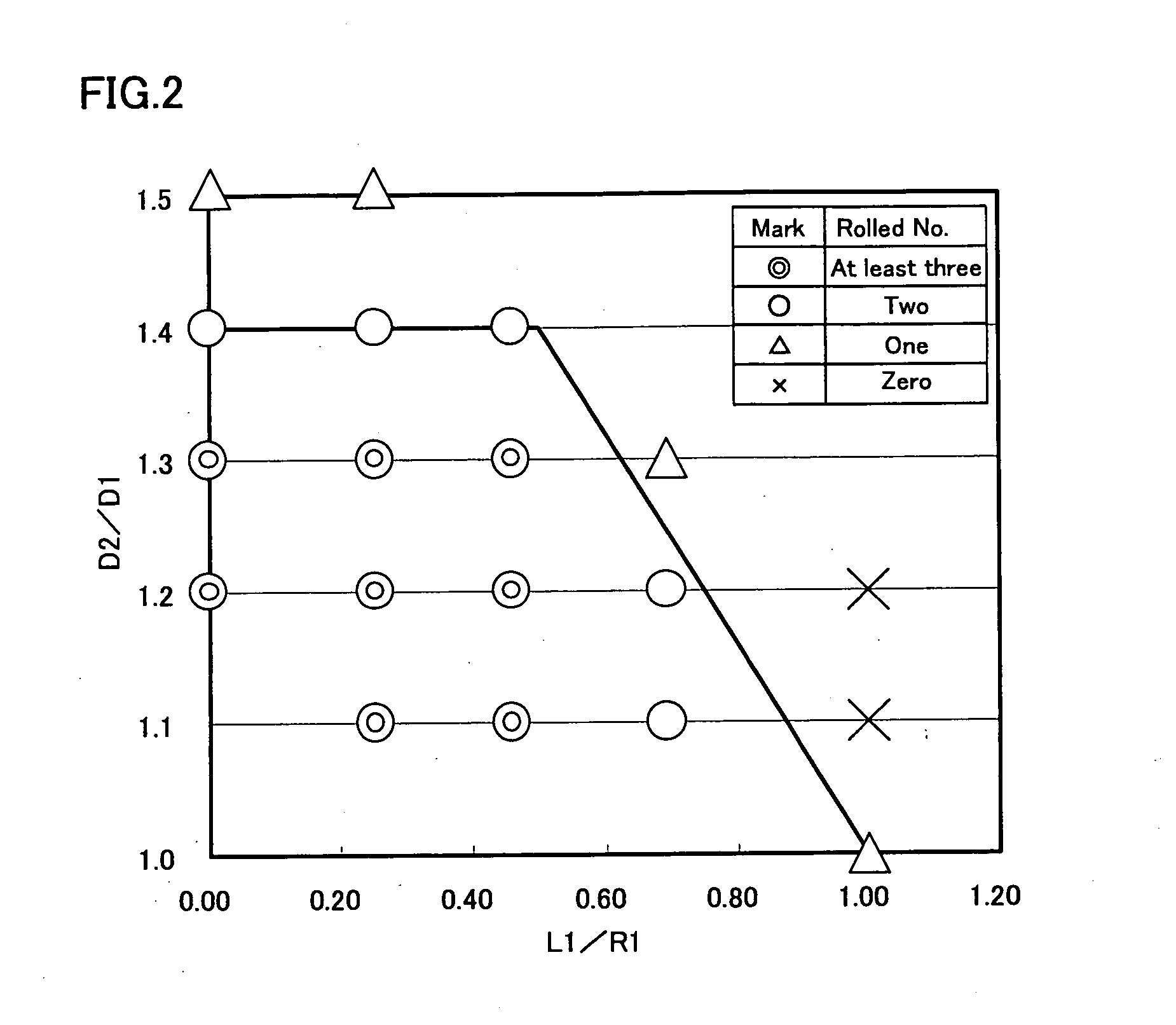

Plug for use in piercing mill

ActiveUS20080314109A1Avoid erosionLarge apertureMandrelsMetal rolling arrangementsOphthalmologyStructural engineering

A plug has a tip end portion, a taper portion, and a middle portion. The surface of the tip end portion is a spherical surface whose radius of curvature is R1 and length is L1 that is shorter than R1. The outer diameter of the taper portion on the front end side is D1, and the outer diameter on the back end side is D2 that is larger than D1, and the length is L2. The plug satisfies Expression (1), Expression (2) if 0<L1 / R1<0.5 and Expression (3) if 0.5≦L1 / R1<1. The curve of the spherical surface of the tip end portion is gentler than that of the semi-spherical surface, and the diameter of a hole formed in a billet by the tip end portion is larger than that in the case of the semi-spherical surface. Therefore, the taper portion does not contact with the billet.0.5D1<L1+L2≦2.5D1 (1)1.0<D2 / D1≦1.4 (2)1.0<D2 / D1<1.8−0.8L1 / R1 (3)

Owner:NIPPON STEEL CORP

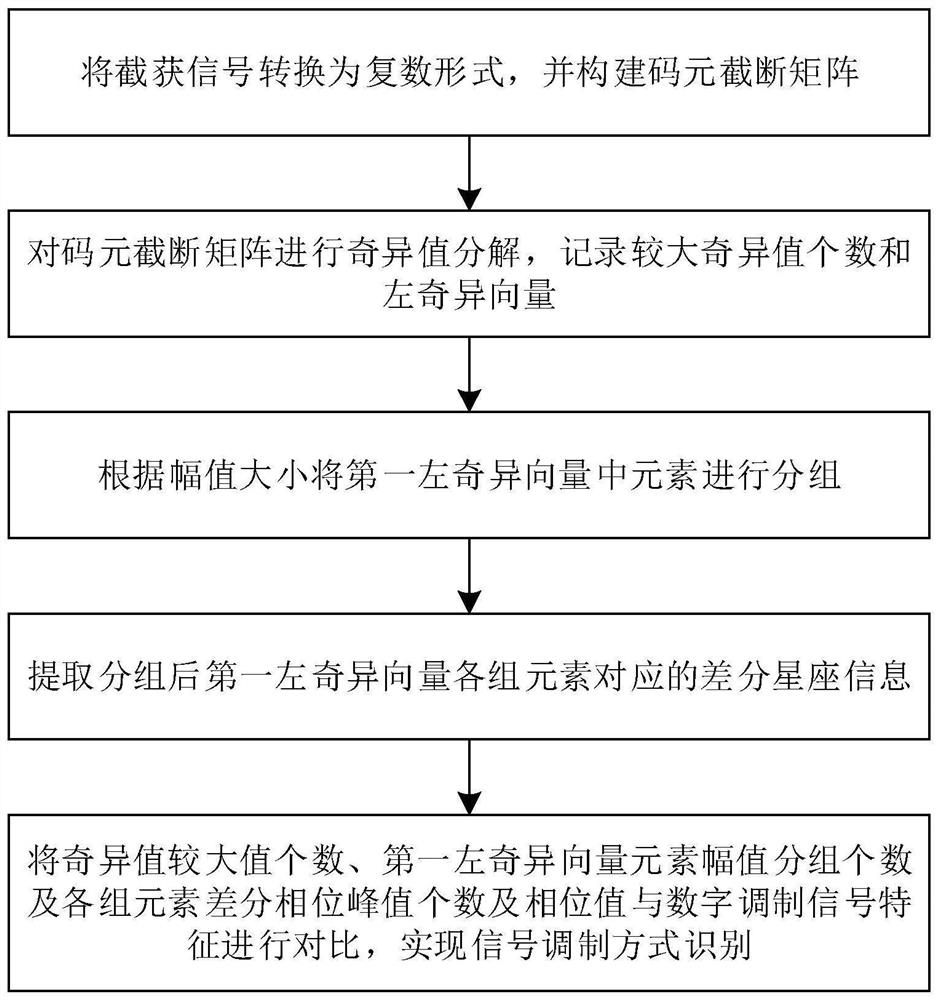

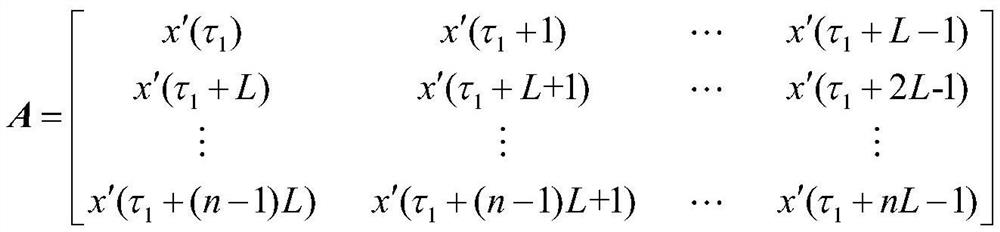

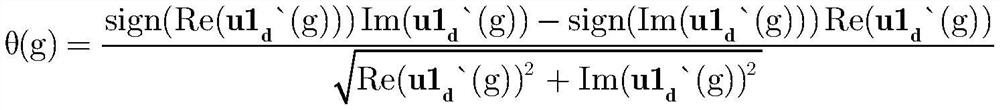

Digital modulation signal differential constellation diagram information extraction and modulation identification method

ActiveCN113542169AHigh degree of automationImprove recognition accuracyModulation type identificationHigh level techniquesSingular value decompositionAlgorithm

The digital modulation signal differential constellation information extraction and modulation identification method disclosed by the invention has strong anti-noise energy and is not influenced by carrier frequency estimation deviation. According to the technical scheme, the method comprises the following steps: firstly, converting an intercepted signal into a complex form, constructing a code element truncated data matrix A, performing singular value decomposition on the A, and counting the number of larger singular values; secondly, grouping the elements in the first left singular vector according to module values; then, extracting differential constellation information corresponding to each group of module value elements; and finally, according to the number of larger singular values, the number of module value groups of the first left singular vector elements, and the number of differential phase peak values and phase values of each group of elements, completing extraction of modulation information such as amplitude and phase contained in the intercepted data, and realizing identification of a signal modulation mode. According to the invention, the defects of limited identification types and inconvenient expansion are avoided. Besides, automation degree of the receiver can be improved, and the real-time interception capability is enhanced.

Owner:10TH RES INST OF CETC

Preparation method of morpholine

The invention discloses a preparation method of morpholine in the technical field of chemical synthesis. A chemical reaction equation is shown as follows. The preparation method particularly includes steps: dewatering: adding concentrated sulfuric acid into a dewatering tank, stirring while dropwise adding diethanolamine liquid, increasing temperature after reaction, controlling the temperature within a range of 190-210 DEG C and reaction time to 80-100min, and water-cooling to 60 DEG C after dropwise adding is finished, wherein a feeding ratio of the concentrated sulfuric acid to the diethanolamine liquid is 1.8:1-1.9:1; neutralizing: dropwise adding 20% sodium hydroxide solution into the dewatering tank to obtain neutralizing liquid; putting the neutralizing liquid in a horizontal distillation kettle, stirring sodium sulfate at the bottom of the distillation kettle, and vacuum-evaporating out morpholine; scraping out sodium sulfate in the distillation kettle by stirring, collecting for recycling, and putting filtrate and kettle washing water into a recycling tank for treatment. By the preparation method, raw materials can be saved to greatest extent (consumption of the diethanolamine liquid is reduced), the process is simple, and wastewater is washing filtration water only and can be recycled, so that influence on environment is avoided; the preparation method is higher than 85% in yield, thereby being more convenient for industrial application.

Owner:王显权

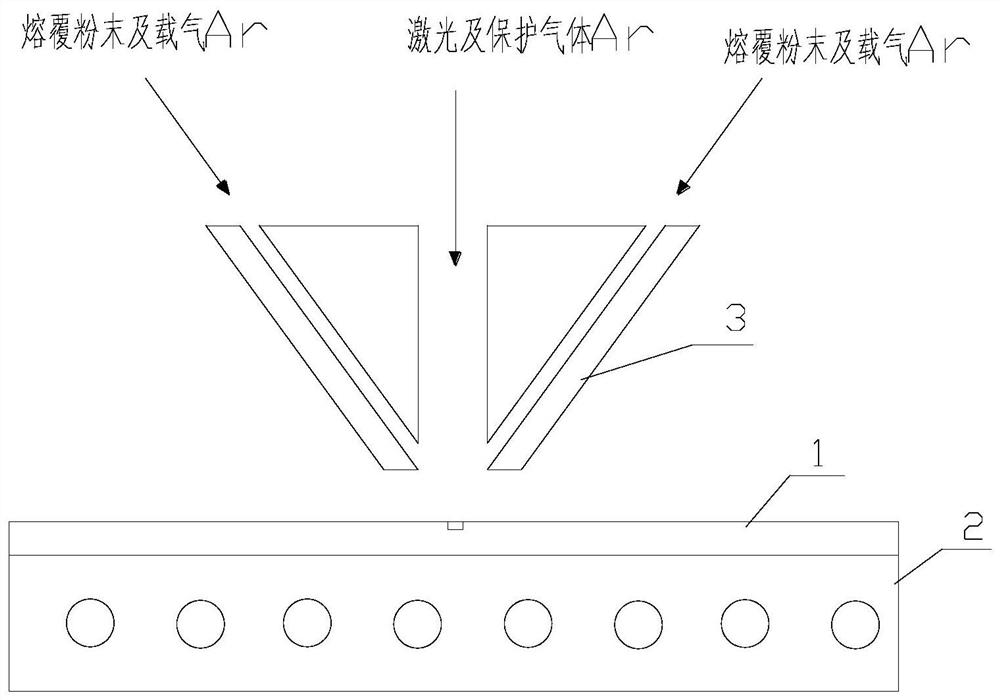

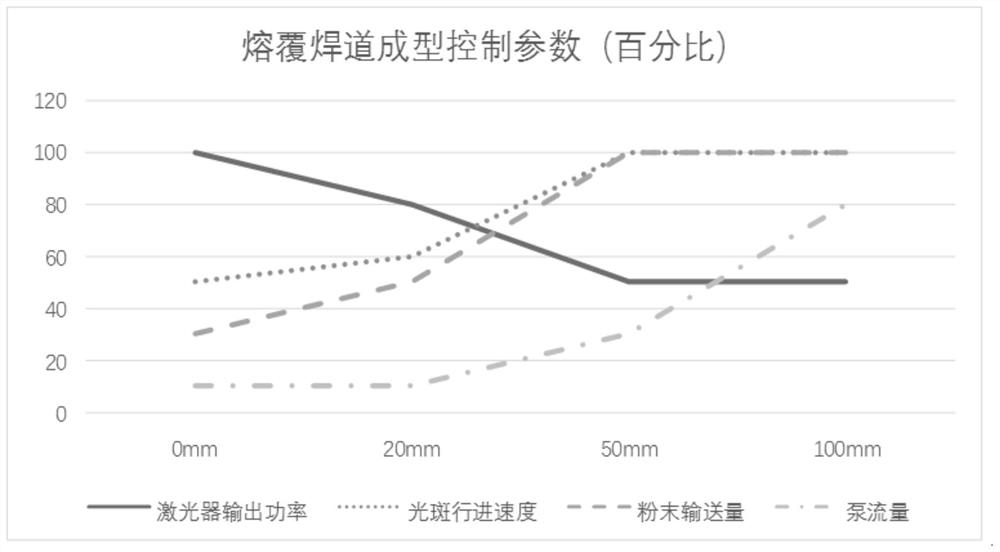

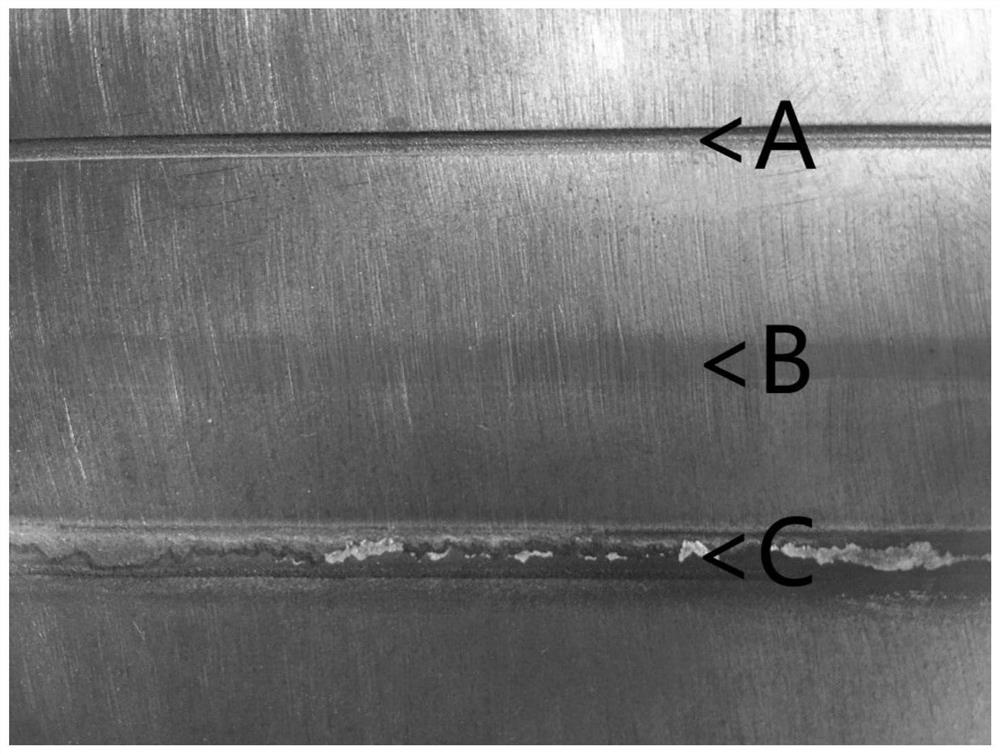

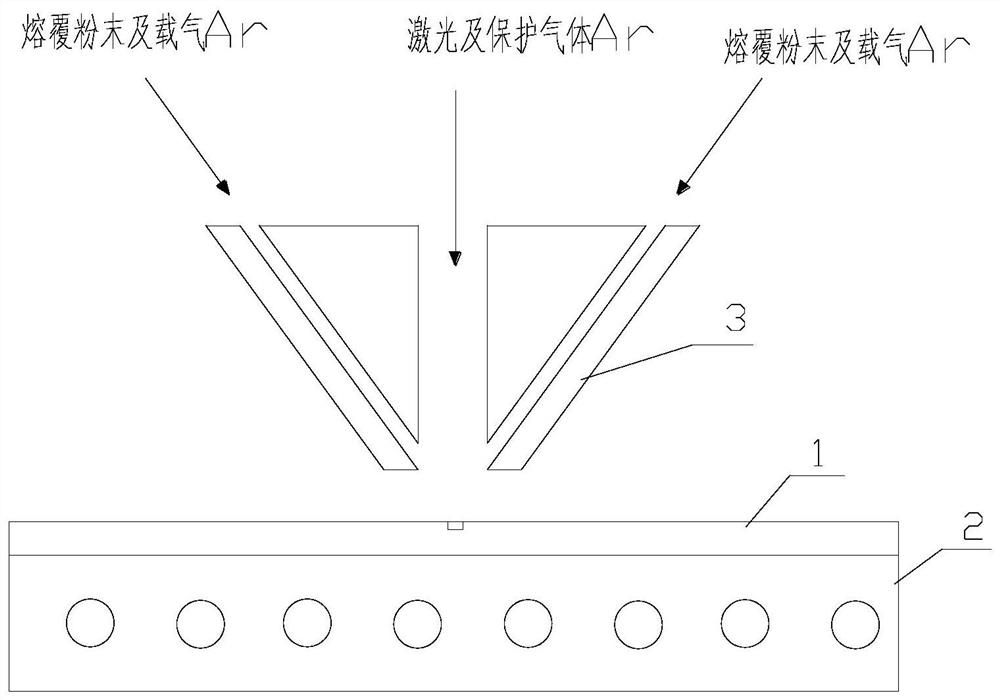

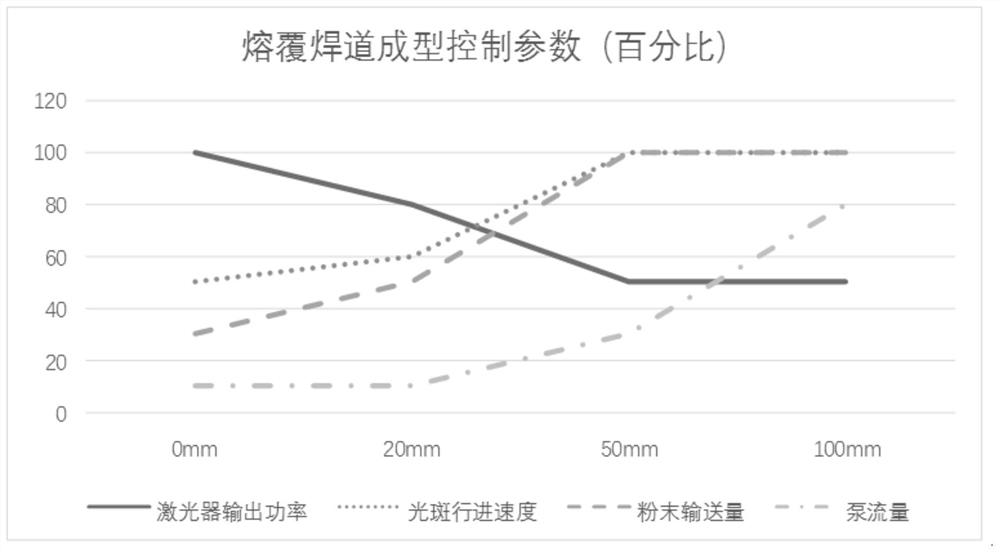

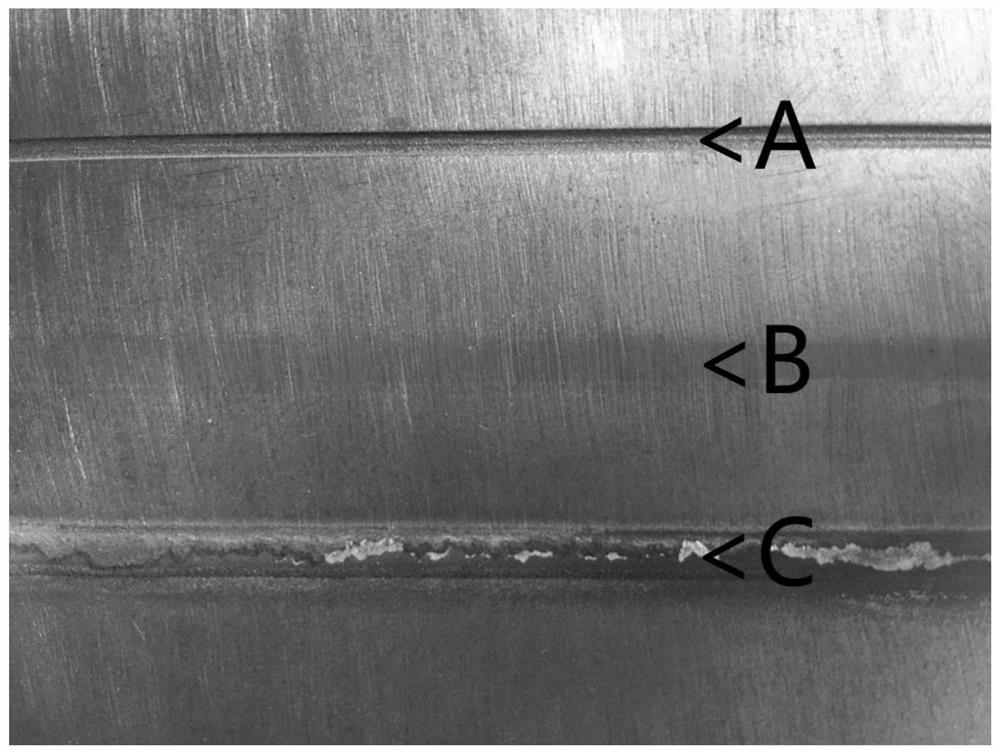

Cu powder applied to laser cladding of P-Cu work piece, and cladding method

ActiveCN111687407ASmooth transitionSimilar performanceMetallic material coating processesAbrasive blastingTinning

The invention belongs to the technical field of laser cladding and particularly relates to Cu powder applied to laser cladding of a P-Cu work piece, and a cladding method. The Cu powder comprises thefollowing components: 2.5-9% of Sn, 0.05-0.6% of P, 0.01-0.05% of Pb, 0-0.5% of Ce, 0-1% of Y, 0-0.2% of Sm and the balance being Cu and inevitable sundries. The method comprises the following steps:carrying out pre-processing on the surface of the work piece; carrying out tinning on the surface of the work piece; manufacturing a work piece cooling supporting base for a cladding process; preparing the Cu powder applied to laser cladding of the P-Cu work piece and drying the Cu powder; fixing the work piece above the cooling supporting base, carrying out cooling in the cladding process, irradiating a cladding position on the surface of the work piece by a laser, feeding the Cu powder to the cladding position on the surface of the work piece by a synchronous powder feeding machine, and carrying out laser cladding on the surface of the work piece; carrying out abrasive blasting on the surface of the cladding position; and carrying out processing and shaping of the work piece. According to the invention, metallurgical bonding of a cladding layer and a work piece base material is presented, and the organizational structure is compact without gas holes or cracks. Results of hardness, wear resistance and corrosion prevention experiments show that transition between the cladding layer and the work piece base material is natural, performance is simple, and curves are steady.

Owner:鞍山大族激光技术有限公司

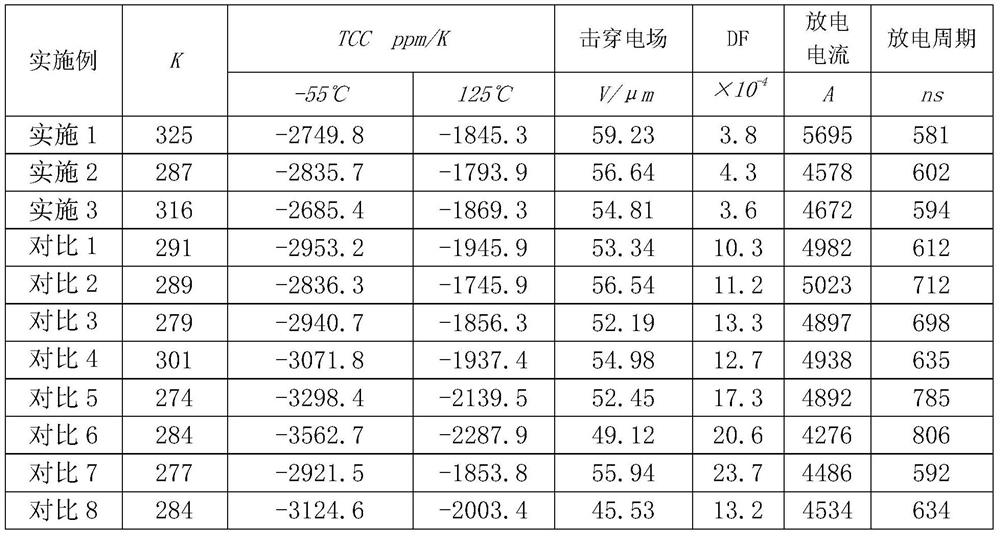

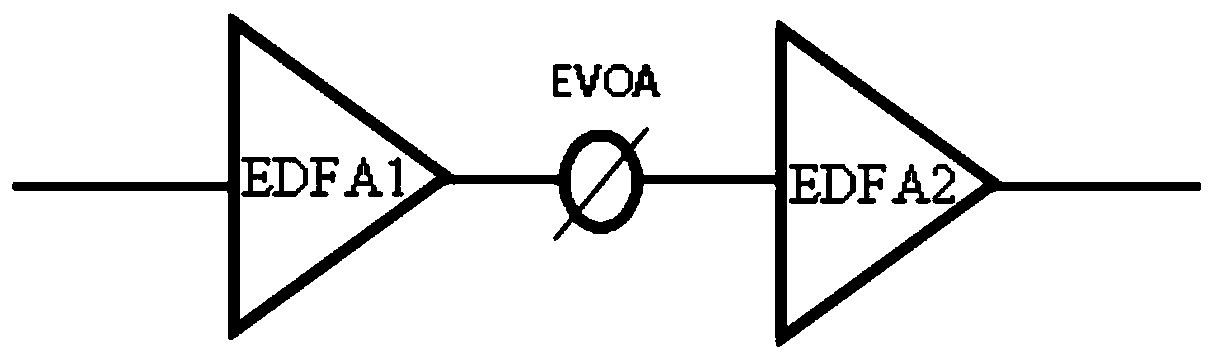

Ceramic pulse capacitor and dielectric material, and preparation methods thereof

ActiveCN113248251AHigh densityHigh dielectric constantFixed capacitor dielectricDielectric lossComposite material

The invention relates to a ceramic pulse capacitor and a dielectric material, and preparation methods thereof. The dielectric material for the ceramic pulse capacitor comprises, by mole, 40-60 parts of SrTiO3, 60-40 parts of CaTiO3, 0.1-0.5 part of MnCO3, 1-2 parts of Sr1-xCaxSn1-yTiyO3 and 2-3 parts of LazBi2-zTi2O7, wherein x is greater than 0 and less than 0.05, y is greater than 0 and less than 0.05, and z is greater than 0 and less than 0.05. The dielectric material prepared by the invention is high in density, large in dielectric constant and low in dielectric loss, and is suitable for ceramic pulse capacitors.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

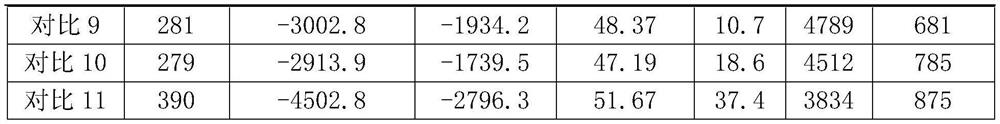

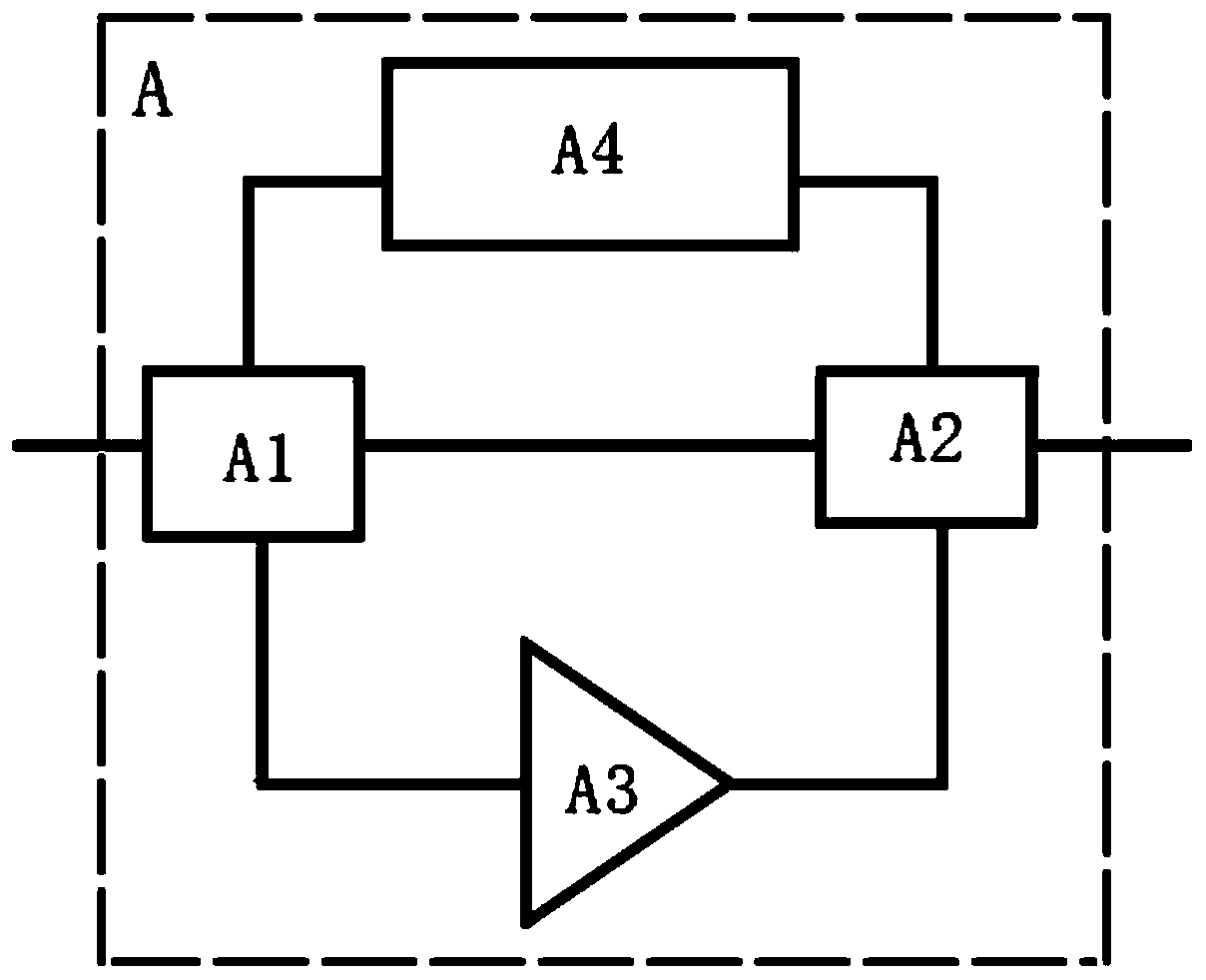

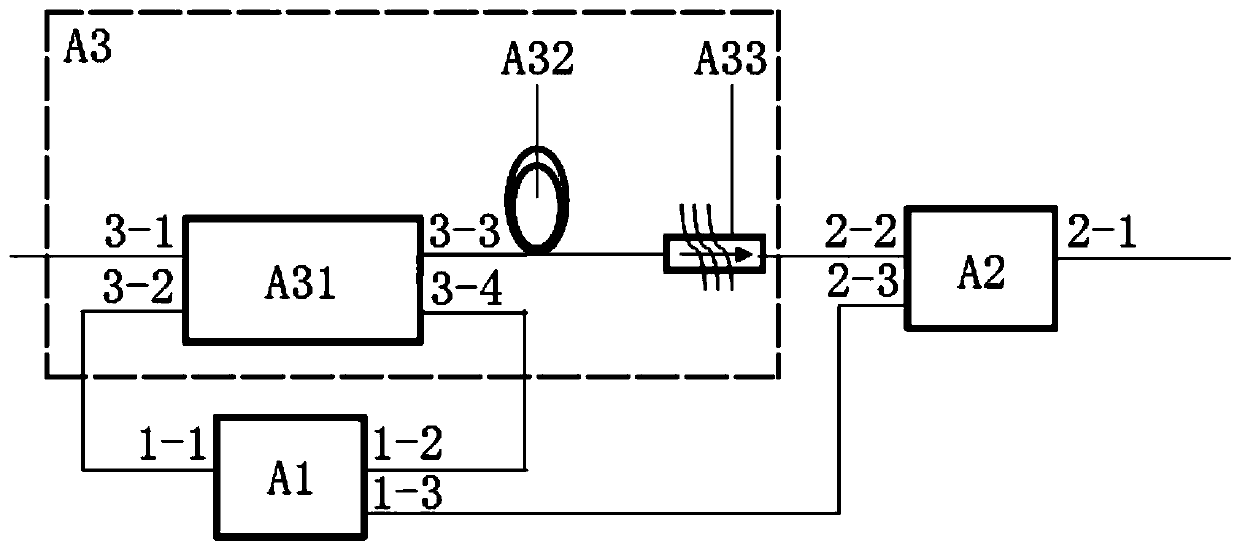

An Erbium-doped Fiber Amplifier Optical Circuit with Adjustable Gain Range

ActiveCN110061407BLow powerWide gain rangeActive medium shape and constructionOptical propertyOptical fiber amplifiers

The invention relates to the technical field of optical signal amplification, and provides an erbium-doped optical fiber amplifier light path with an adjustable gain range. The erbium-doped optical fiber amplifier light path comprises a gain switch unit, wherein the gain switch unit comprises two optical switches, an erbium-doped optical fiber unit and a controller, wherein the two optical switches include a first optical switch and a second optical switch; one end of the first optical switch is connected with one end of the second optical switch, and the other end of the first optical switchand the other end of the second optical switch are connected with the erbium-doped optical fiber unit separately; and the two optical switches are connected with the controller. The erbium-doped optical fiber amplifier optical path provided by the invention can provide a relatively wide gain range and ensure relatively high optical characteristics.

Owner:AOC TECH (WUHAN) CO LTD

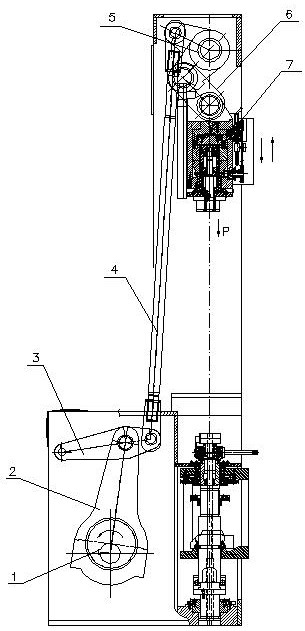

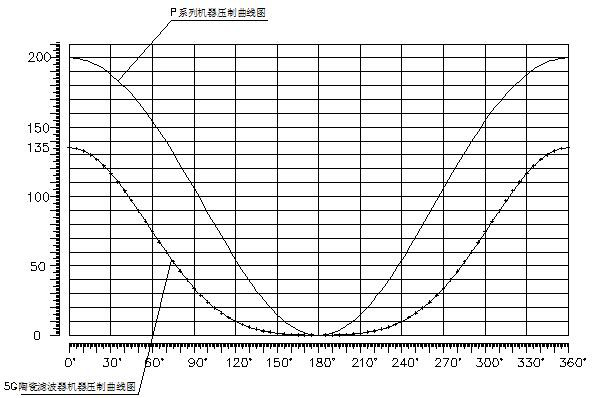

Pressing principle and mechanism of powder pressing machine special for 5G ceramic filter forming

PendingCN112720791AGentle curveThe suppression range is largeAuxillary shaping apparatusPunchingCrank

The invention relates to a pressing principle and mechanism of a powder pressing machine special for 5G ceramic filter forming. A pressing structure comprises an eccentric cam, a first connecting rod, a lever, a pull rod, an upper crank, a second connecting rod and an upper punching seat, wherein the eccentric cam is arranged at the bottom of the pressing mechanism, connected with an external motor and a speed reducer and driven by the external motor and the speed reducer to rotate anticlockwise, the upper part of the eccentric cam is connected with the first connecting rod, and the upper part of the first connecting rod is connected with the lever; and one end of the lever is connected with the lower end of the pull rod, the upper end of the pull rod is connected with the upper crank, the second connecting rod is arranged below the upper crank and connected with the upper crank, and the upper punching seat is arranged below the second connecting rod and connected with the second connecting rod. Through the design of a whole machine pressing forming toggle rod mechanism, the eccentric cam special for 5G and a demolding cam, the functions of large pressing interval and long pressure maintaining time required for forming a 5G ceramic filter are achieved.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Copper-based powder metallurgy friction material for high-speed linear brake and preparation method thereof

The invention discloses a copper-base powder metallurgy friction material for high-speed linear brake and a preparing method of the copper-base powder metallurgy friction material. The copper-base powder metallurgy friction material is composed of electrolysis copper powder, reduced iron powder, graphite, a silicon-chromium alloy, molybdenum disulfide, silicon dioxide, lanthanum oxide, ferrochromium and copper fiber. The percent is the mass percent. Through adjustment on the formula of the copper-base powder metallurgy brake material, the lanthanum oxide is used for modifying the ferrochromium powder and the silicon-chromium alloy to enhance friction components, the chemical reaction is accelerated with carboxymethylcellulose as a particle bonding agent, brake materials meeting the requirements for high energy loads, high speed, high impact force, corrosion resistance and other work conditions are obtained, and the beneficial effects of the stable friction coefficient and good corrosion resistance are achieved. Through the test, the average friction coefficient mucp is larger than 0.35, the friction material linear abrasion loss is smaller than or equal to 0.0195 mm / face.time, and the copper-base friction material is suitable for high-speed linear brake.

Owner:XIAN AVIATION BRAKE TECH

Copper powder for laser cladding of phosphor copper workpiece and cladding method

ActiveCN111687407BSmooth transitionSimilar performanceMetallic material coating processesPhosphor bronzePhosphor

The invention belongs to the technical field of laser cladding, in particular to a copper powder for laser cladding of phosphor copper workpieces and a cladding method. The copper powder comprises the following components: Sn 2.5-9%, P 0.05-0.6%, Pb 0.01-0.05 %, Ce 0-0.5%, Y 0-1%, Sm 0-0.2%, and the rest are Cu and inevitable impurities. The method includes the following steps: pretreatment on the surface of the workpiece; tin plating on the surface of the workpiece; making a cooling support seat for the workpiece during the cladding process; preparing copper powder for laser cladding of the phosphor bronze workpiece, drying the copper powder; fixing the workpiece on the cooling support seat, The cladding process is cooled, the laser irradiates the cladding position on the surface of the workpiece, and the synchronous powder feeder is used to send copper powder to the cladding position on the workpiece surface to carry out laser cladding on the surface of the workpiece; the surface of the cladding position is sandblasted; the workpiece is processed and formed. The cladding layer of the invention presents metallurgical bonding with the workpiece base material, the structure is compact, and there are no pores and no cracks. The hardness, wear resistance and anticorrosion experiments show that the transition between the cladding layer and the workpiece substrate is natural, the performance is similar, and the curve is stable.

Owner:鞍山大族激光技术有限公司

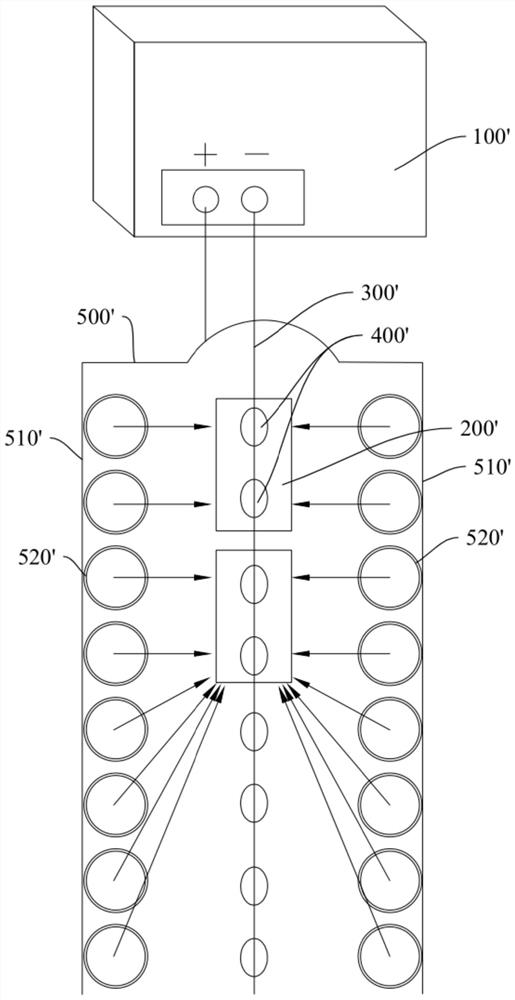

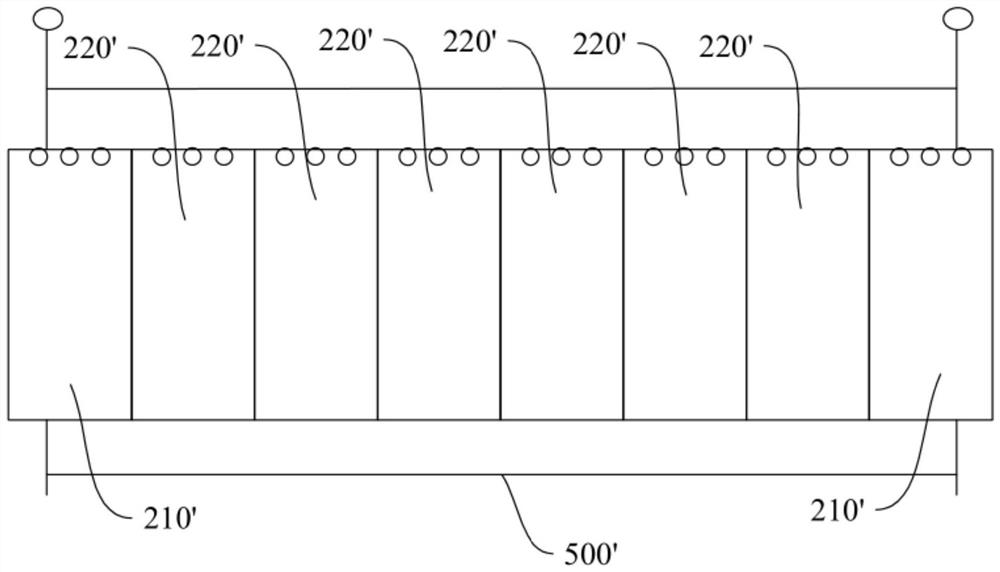

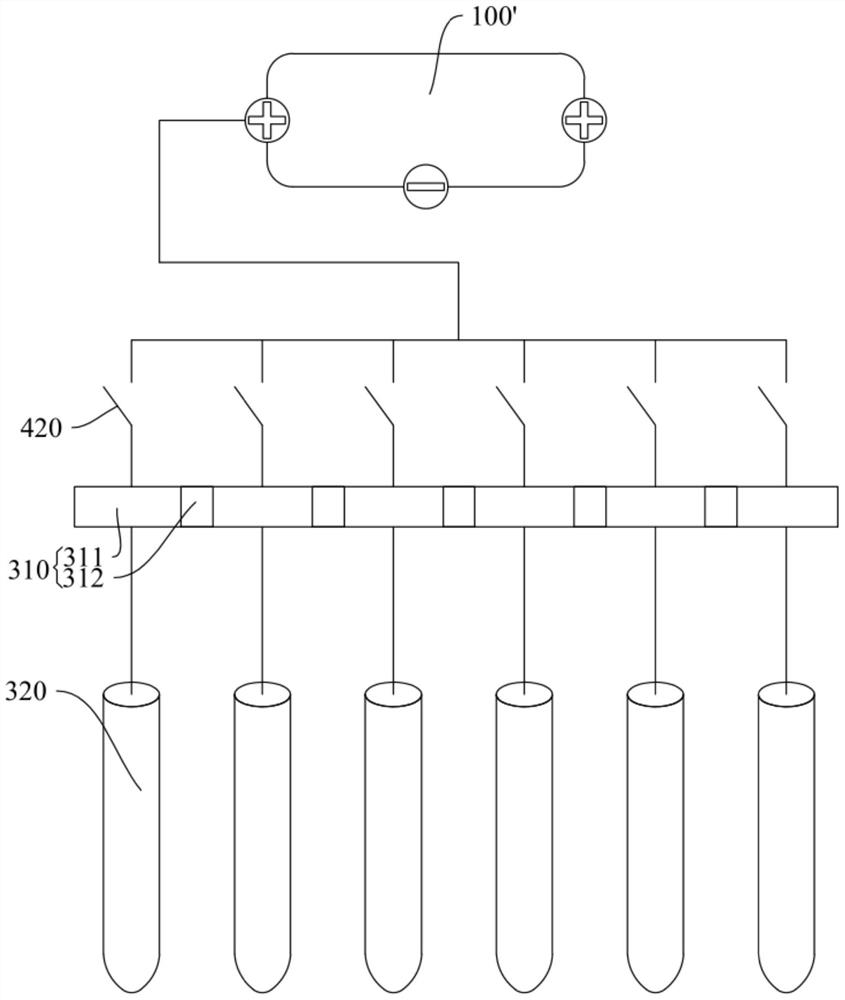

Vertical Continuous Plating Equipment

ActiveCN112760701BGentle curveReduce usageCellsCurrent conducting devicesElectrical connectionControl cell

The invention relates to the field of circuit board production, and provides a vertical continuous electroplating equipment, which includes a cathode conveyor belt, a clamp, an electroplating tank and an anode on-off assembly. The anode insulation section connected between two adjacent anode conductive sections, each anode conductive section is connected to the positive pole of the rectifier in parallel; the anode on-off assembly includes a first inductor, a first control unit electrically connected to the first inductor, and multiple An anode switch electrically connected to the first control unit, the first control unit is used to calculate the time for the plate to pass through each anode conductive section according to the speed of the plate when the plate passes the first sensor, and to control the anode switch on the plate Closed when passing the anode conductive section, and open when no plate passes the anode conductive section. The vertical continuous electroplating equipment can achieve precise electroplating on the board, basically avoid the use of accompanying plating boards, increase production capacity, reduce costs, improve electroplating quality, and reduce the difference in copper plating thickness of each board.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com