Three-phase brushless direct current motor adaptive commutation angle compensation method

A technology of brushed DC motor and commutation angle, which is applied in the direction of electronic commutator, torque ripple control, etc., can solve the problem of high calculation cost, and achieve the effect of low economic cost, convenient use, and stable operation of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

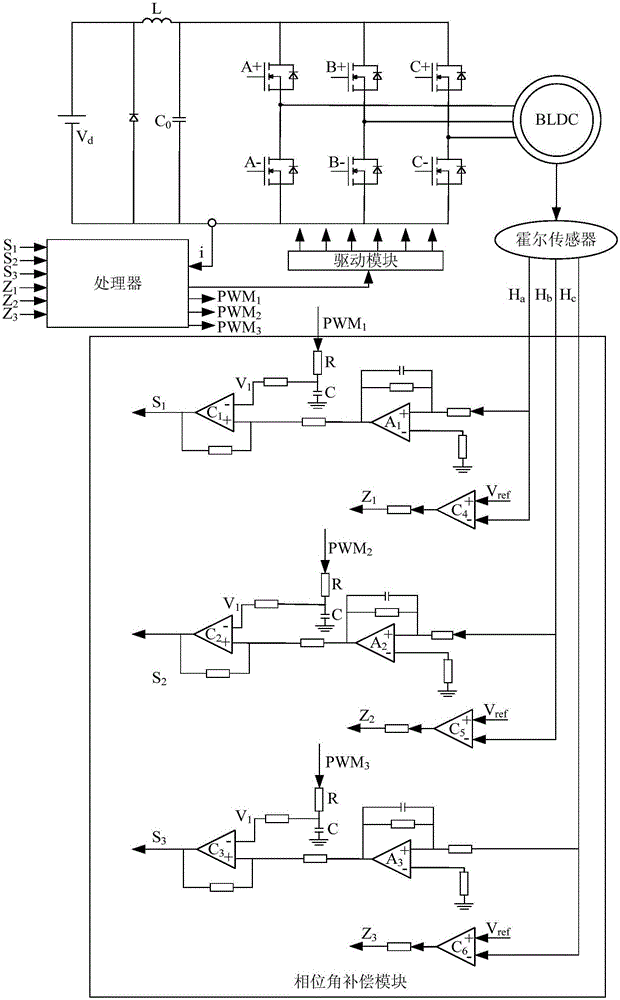

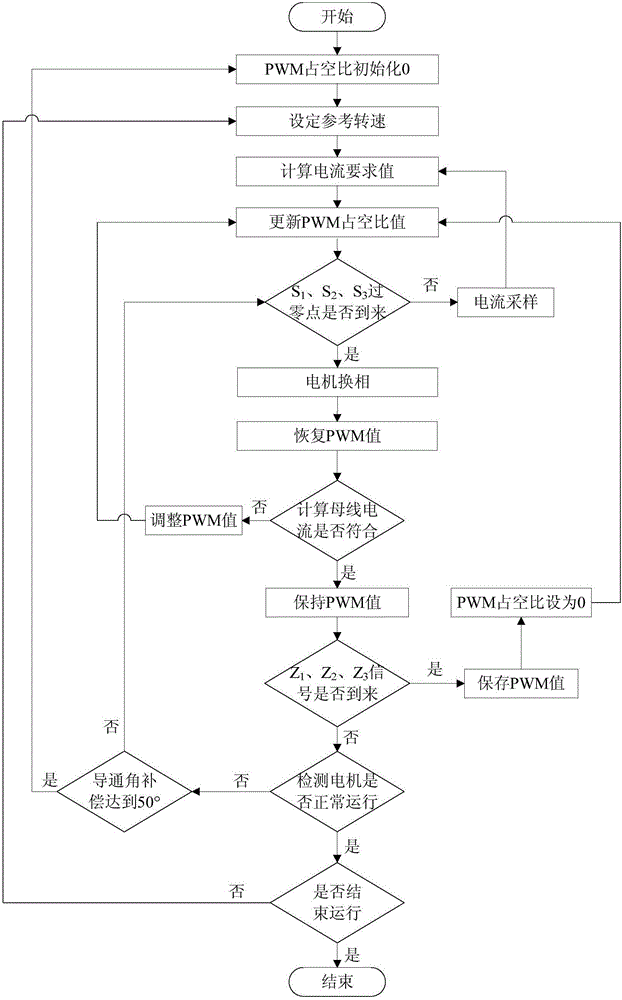

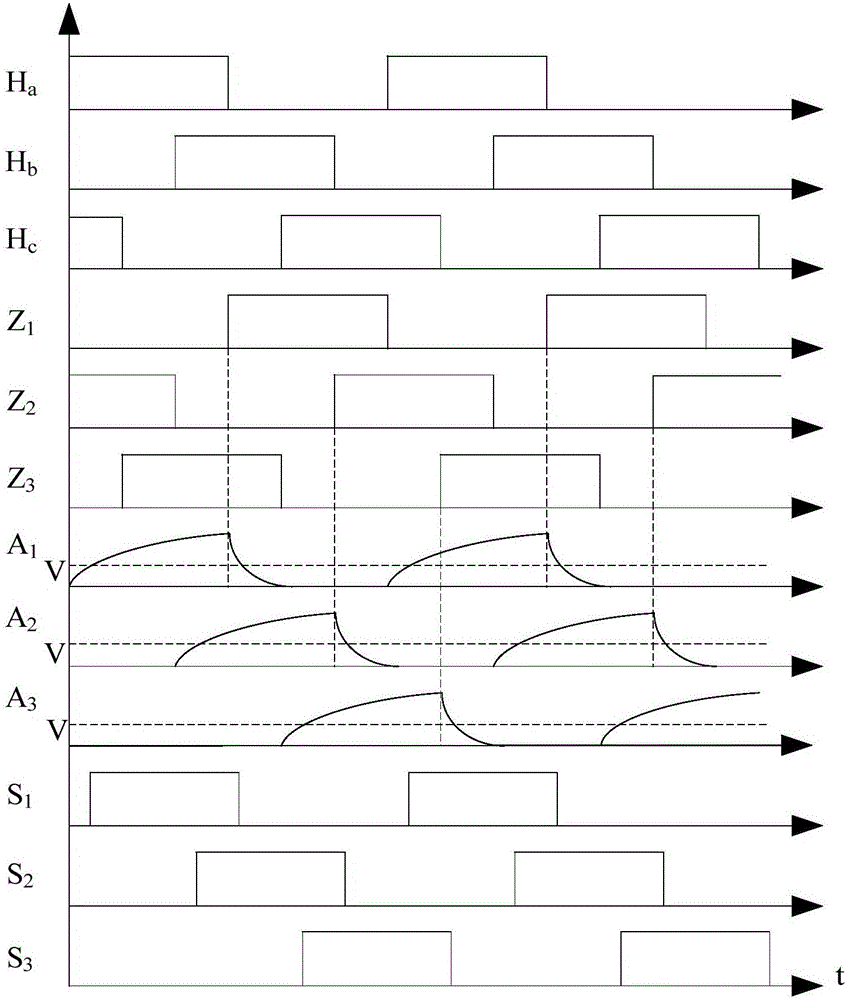

[0017] An adaptive commutation angle compensation method for brushless DC motors, the principle block diagram of adaptive commutation angle compensation is shown in figure 1 As shown, this method is completed through the combination of software and hardware. The commutation angle compensation circuit is composed of three delay circuits. Each delay circuit completes the delay function through the combination of an integrating circuit and a comparator. The delay time is input by the processor. The PWM duty cycle of the phase angle compensation circuit is determined by the size, the delay time increases when the PWM duty cycle is large, and the delay time decreases when the PWM duty cycle is small. The Hall signal is delayed by the commutation angle compensation circuit and enters the processor. The delay time does not exceed 50° electrical angle, and the processor performs commutation according to this signal. In each conduction stage, the processor detects the bus current, calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com