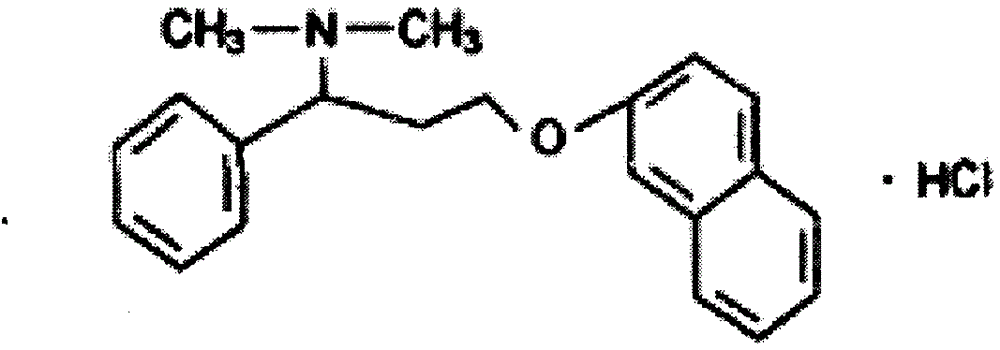

Hydrochloric acid dapoxetine tablet

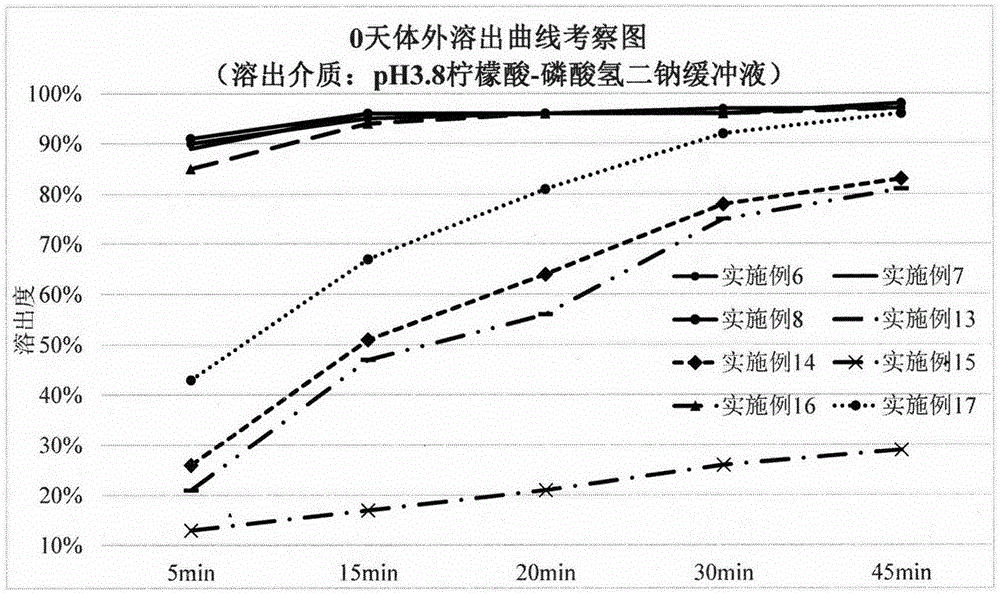

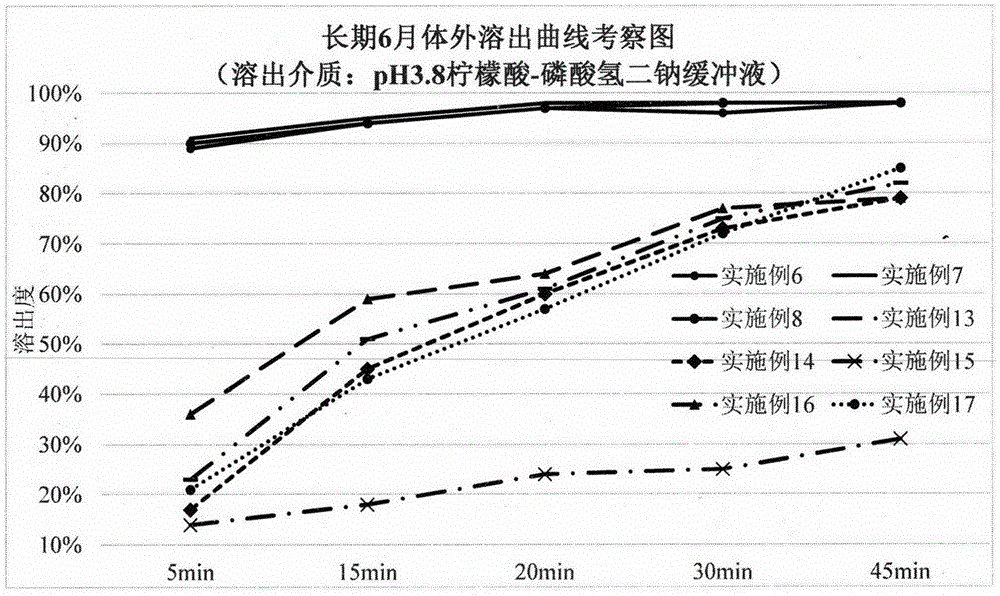

A technology for dapoxetine hydrochloride and cetine tablets, which is applied in the fields of pill delivery, organic active ingredients, non-effective ingredients of polymer compounds, etc., and can solve the problem of high manufacturing cost and use cost, crystal form A and crystal form B Poor stability, poor stability of amorphous substances, etc., to achieve the effect of stable in vitro dissolution curve, small environmental impact, and no decrease in dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] prescription:

[0023]

[0024]

[0025] Preparation method: Mix dapoxetine hydrochloride and ethanol to form a clear solution, then add it to dextrin to granulate, dry, mix with mannitol, micro-powder silica gel, and magnesium stearate, and then directly compress into tablets.

Embodiment 2

[0027] prescription:

[0028] prescription:

[0029]

[0030] Preparation method: Mix dapoxetine hydrochloride and ethanol to form a clear solution, then add it to dextrin to granulate, dry, mix with mannitol, micro-powder silica gel, and magnesium stearate, and then directly compress into tablets.

Embodiment 3

[0032] prescription:

[0033]

[0034] Preparation method: Mix dapoxetine hydrochloride and ethanol to form a clear solution, then add it to dextrin to granulate, dry, mix with mannitol, micro-powder silica gel, and magnesium stearate, and then directly compress into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com