Copper powder for laser cladding of phosphor copper workpiece and cladding method

A laser cladding and workpiece technology, applied in metal material coating process, coating, etc., can solve problems such as cooling overspeed, changing the comprehensive performance of cladding layer, easy cracking of weld bead, etc., and achieves smooth curve and compact structure , with similar performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

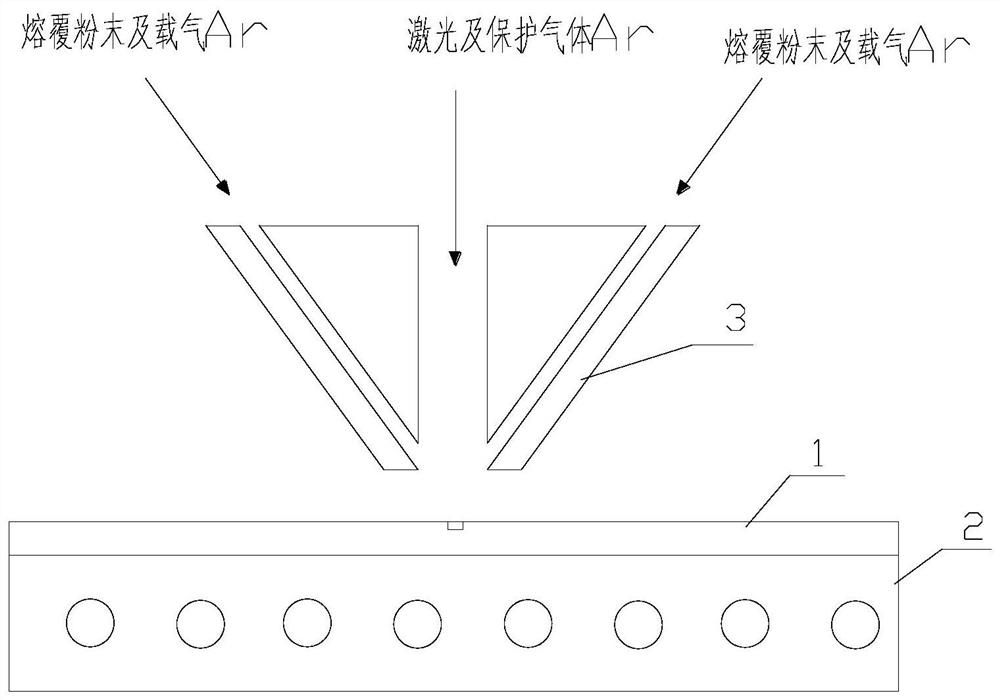

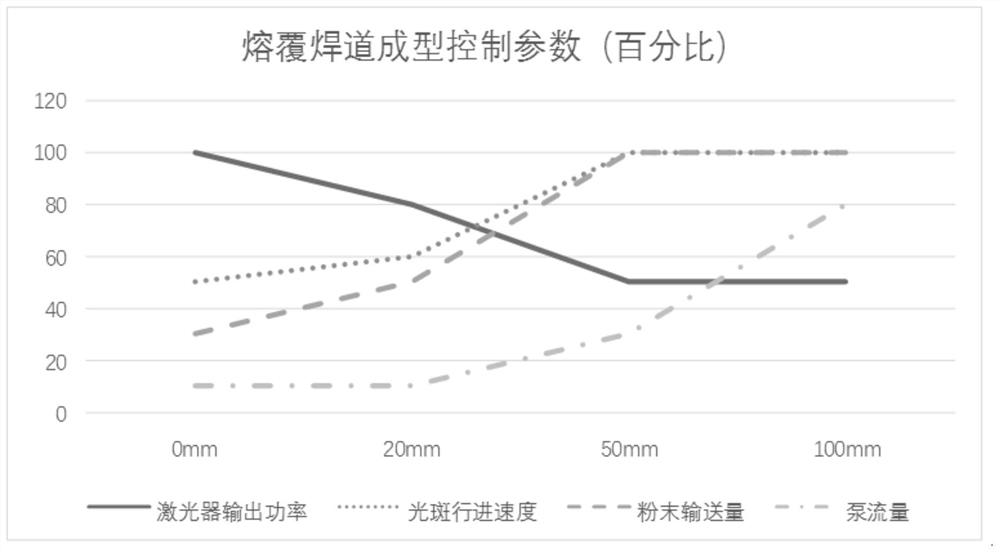

Method used

Image

Examples

Embodiment

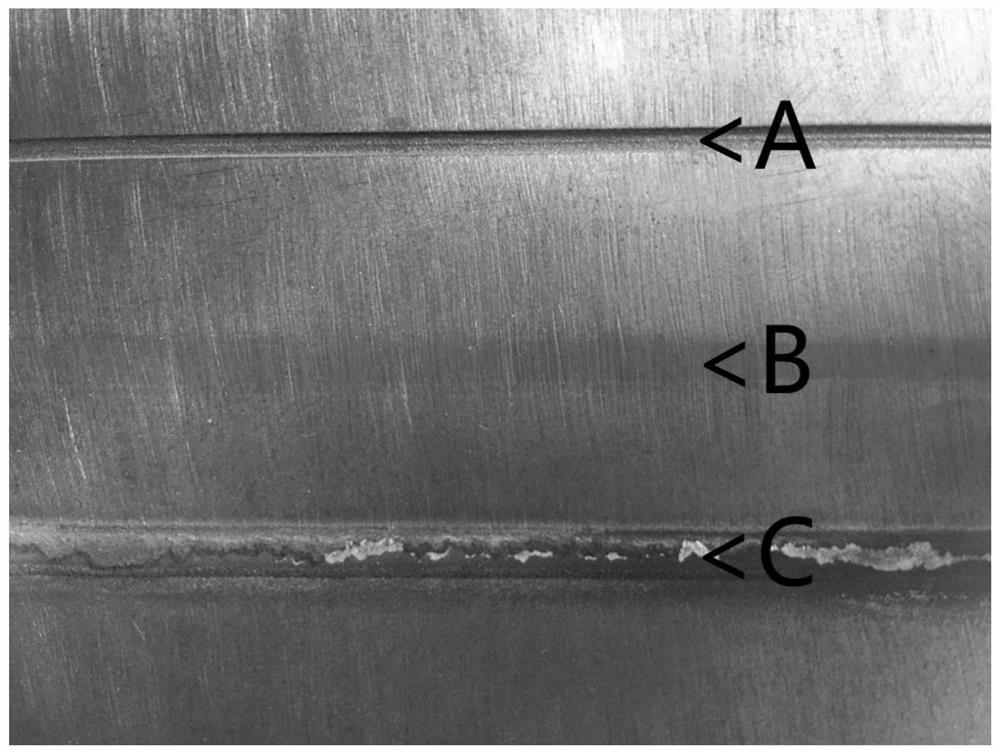

[0043] refer to image 3 and Figure 4 , select the base material of a piece of phosphor bronze workpiece, draw three grooves on the base material, and one groove is used as a control without treatment ( image 3 and Figure 4 number A position), the other two grooves ( image 3 and Figure 4 The numbering B, C position) utilizes the method of the present invention to carry out laser cladding, and the cladding step is:

[0044] 1) Surface pretreatment, including the following processing steps:

[0045] 101) use acetone to wash away the large area oil stains on the cladding surface of the workpiece, and wash with water;

[0046] 102) Ultrasonic removal of oil stains in the pores of the workpiece, washing with water;

[0047] 103) Utilize the dilute hydrochloric acid of 8-13% concentration to wash off the oxide on the workpiece surface, wash with water;

[0048] 104) polishing, washing twice;

[0049] 105) Micro-etch the surface of the workpiece with a micro-etching liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com