Ceramic pulse capacitor and dielectric material, and preparation methods thereof

A technology of pulse capacitors and dielectric materials, applied in the direction of fixed capacitor dielectrics, capacitors, fixed capacitors, etc., can solve the problems of poor capacitance temperature stability and high dielectric constant, achieve low dielectric loss, large dielectric constant, and improve insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

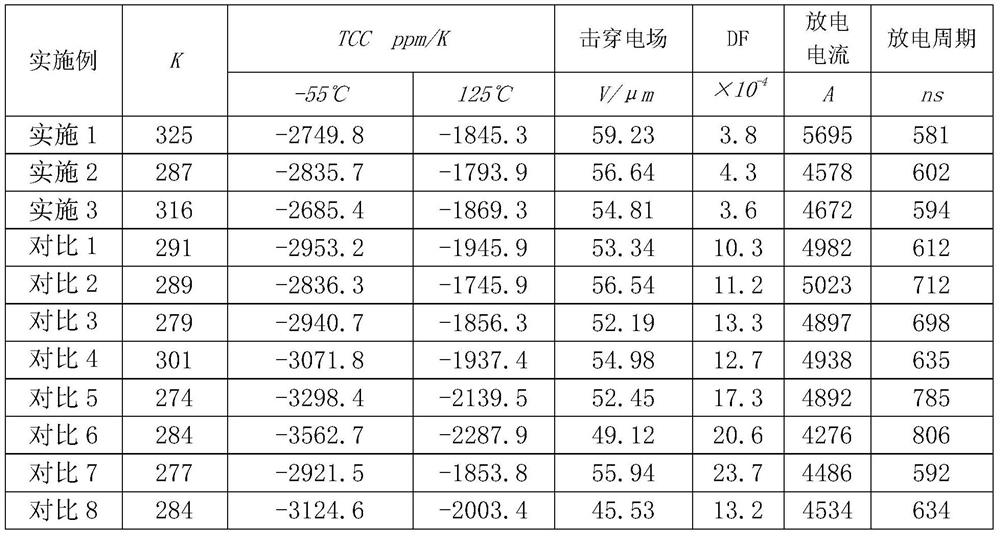

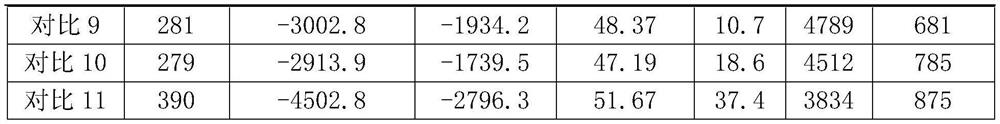

Examples

preparation example Construction

[0029] Its preparation method comprises the following steps:

[0030] Step 1, preparation of SrTiO by molten salt method 3 : According to the molar ratio 1:1: (2-4): (2-4) Weigh SrCO respectively 3 , TiO 2 , NaCl, KCl, add appropriate amount of ethanol and zirconium beads, mix and ball mill for 4-8h, after drying, move the powder into an alumina crucible for calcination at 900°C for 1h, then cool to room temperature naturally; wash and filter until Cl-free - was detected; finally at 120°C, dry to get SrTiO 3 ;

[0031] Step 2, preparation of CaTiO by molten salt method 3 : According to the molar ratio of 1:1: (2-4): (2-4) respectively weigh CaCO 3 , TiO 2 , NaCl, KCl, add an appropriate amount of ethanol and zirconium beads, mix and ball mill for 4-8 hours, after drying, move the powder into an alumina crucible for calcination at 800°C for 1 hour, and cool naturally to room temperature. The calcined product is ultrasonically washed and filtered with deionized water unt...

Embodiment 1

[0038] A ceramic pulse capacitor, made of a dielectric material, specifically, the dielectric material includes the following molar parts of raw materials: 60 parts of SrTiO 3 , 40 parts CaTiO 3 , 0.3 parts of MnCO 3 , 1 part of Sr 0.99 Ca 0.01 sn 0.98 Ti 0.02 o 3 , 3 servings of La 0.02 Bi 1.98 Ti 2 o 7 .

[0039] Among them, SrTiO 3 , CaTiO 3 Synthesized by molten salt method; Sr 0.99 Ca 0.01 sn 0.98 Ti 0.02 o 3 Synthesized by solid-phase method; La 0.02 Bi 1.98 Ti 2 o 7 Synthesized by solid phase method.

[0040] Its preparation method comprises the following steps:

[0041] Step 1, preparation of SrTiO by molten salt method 3 : SrCO was weighed at a molar ratio of 1:1:3:3 3 、TiO 2 , NaCl, KCl, add appropriate amount of ethanol and zirconium beads, mix and ball mill for 6 hours, after drying, move the powder into an alumina crucible for calcination at 900°C for 1 hour, and cool to room temperature naturally; , filtered until no Cl - was detected; ...

Embodiment 2

[0048] A ceramic pulse capacitor, made of a dielectric material, specifically, the dielectric material includes the following molar parts of raw materials: 50 parts of SrTiO 3 , 50 parts CaTiO 3 , 0.5 phr MnCO 3 , 2 parts of Sr 0.99 Ca 0.01 sn 0.98 Ti 0.02 o 3 , 2 parts of La 0.02 Bi 1.98 Ti 2 o 7 .

[0049] Among them, SrTiO 3 , CaTiO 3 Synthesized by molten salt method; Sr 0.99 Ca 0.01 sn 0.98 Ti 0.02 o 3 Synthesized by solid-phase method; La 0.02 Bi 1.98 Ti 2 o 7 Synthesized by solid phase method.

[0050] Its preparation method comprises the following steps:

[0051] Step 1, preparation of SrTiO by molten salt method 3 : SrCO was weighed at a molar ratio of 1:1:3:3 3 、TiO 2 , NaCl, KCl, add appropriate amount of ethanol and zirconium beads and mix ball mill for 6h, after drying, move the powder into an alumina crucible for calcination at 900°C for 1h, then cool to room temperature naturally; the calcined product is ultrasonically washed with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown electric field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com