High-pressure shock absorber and high-pressure descaling system adopting same

A shock absorber and high-pressure technology, which is applied to components of pumping devices for elastic fluids, machines/engines, variable displacement pump components, etc., can solve the problem of short service life of high-pressure energy storage shock absorbers, spare parts costs and Problems such as large manpower input, to achieve the effect of reducing the peak and trough, the curve of water pressure-time is gentle, and the water pressure of descaling is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

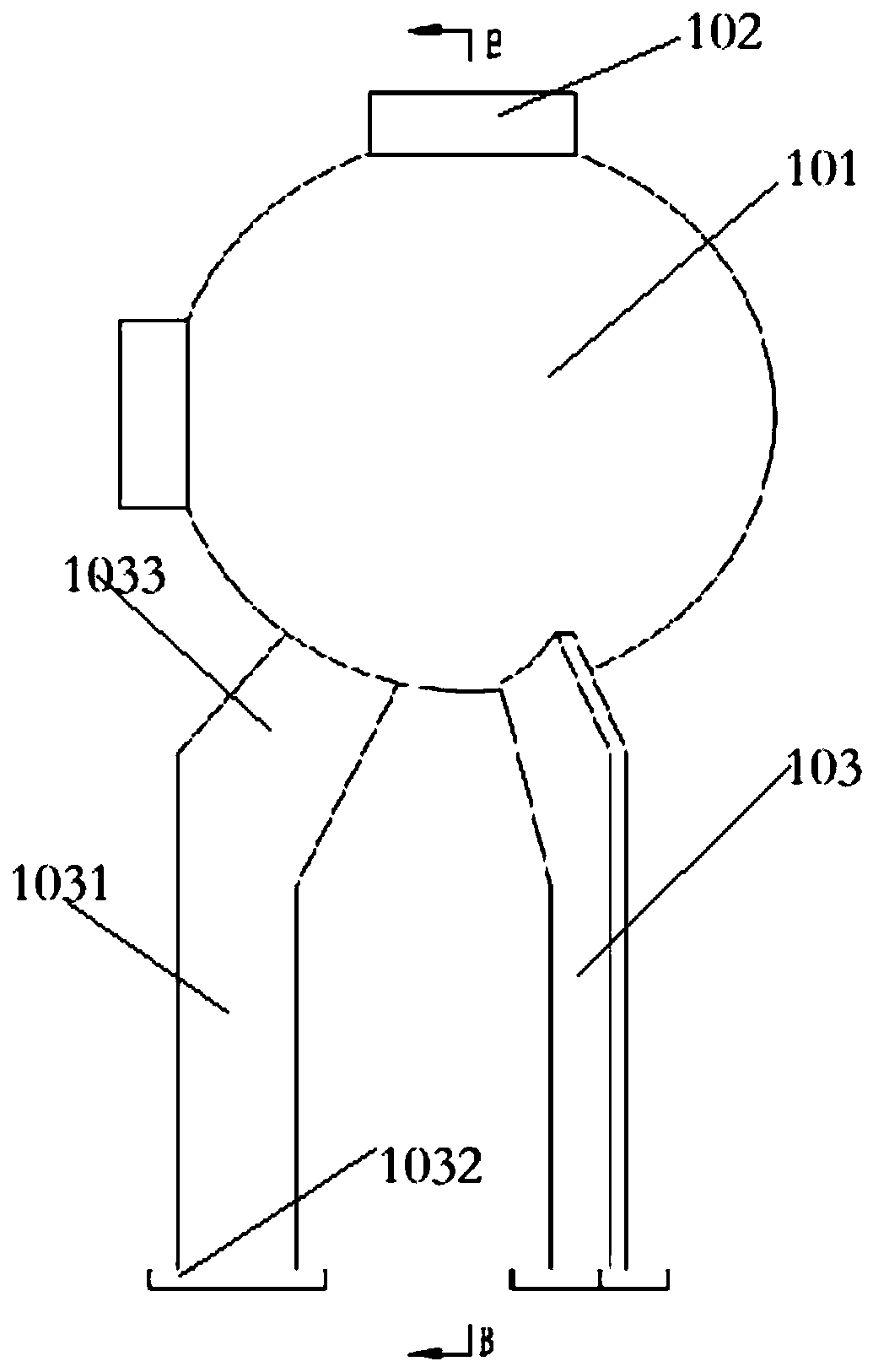

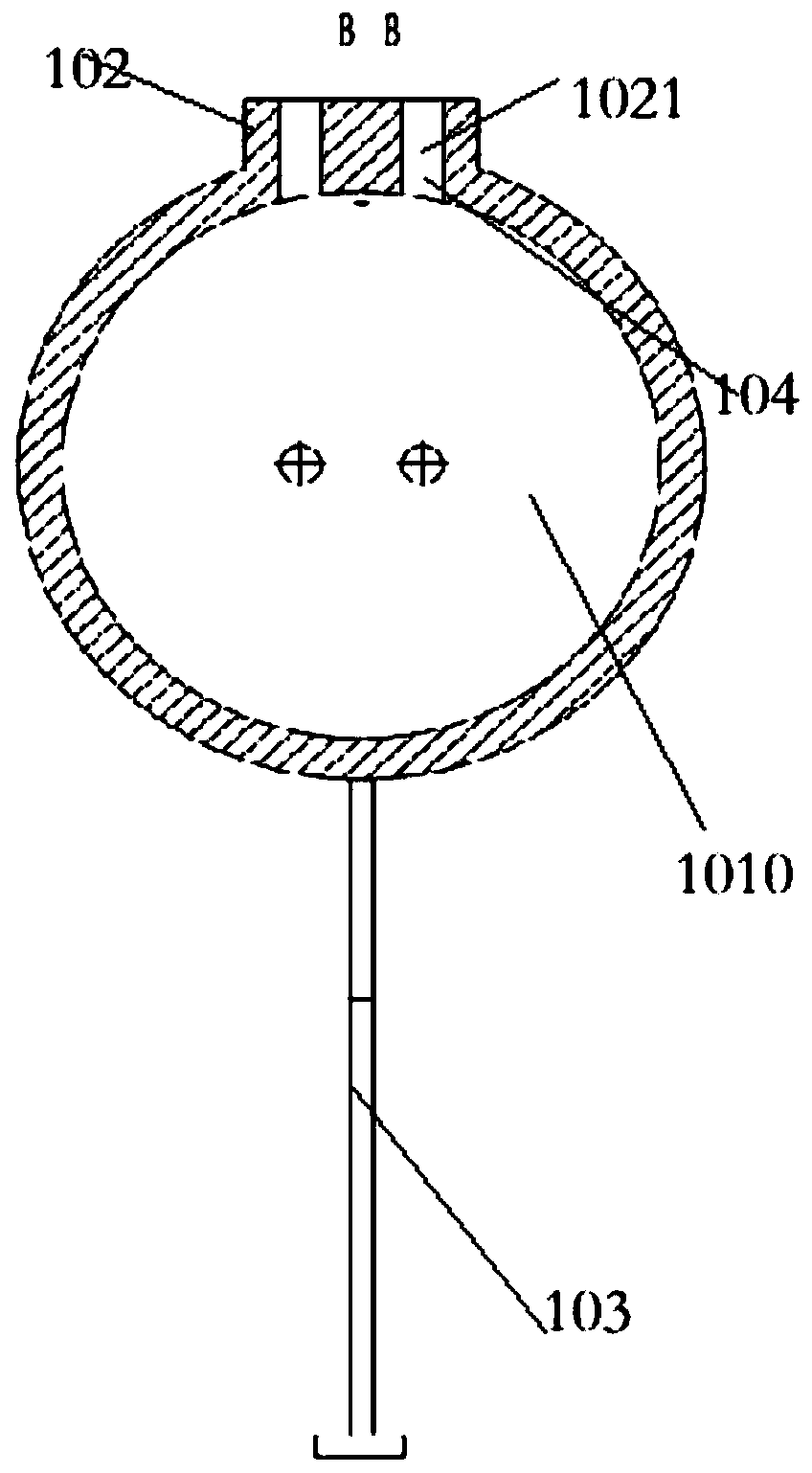

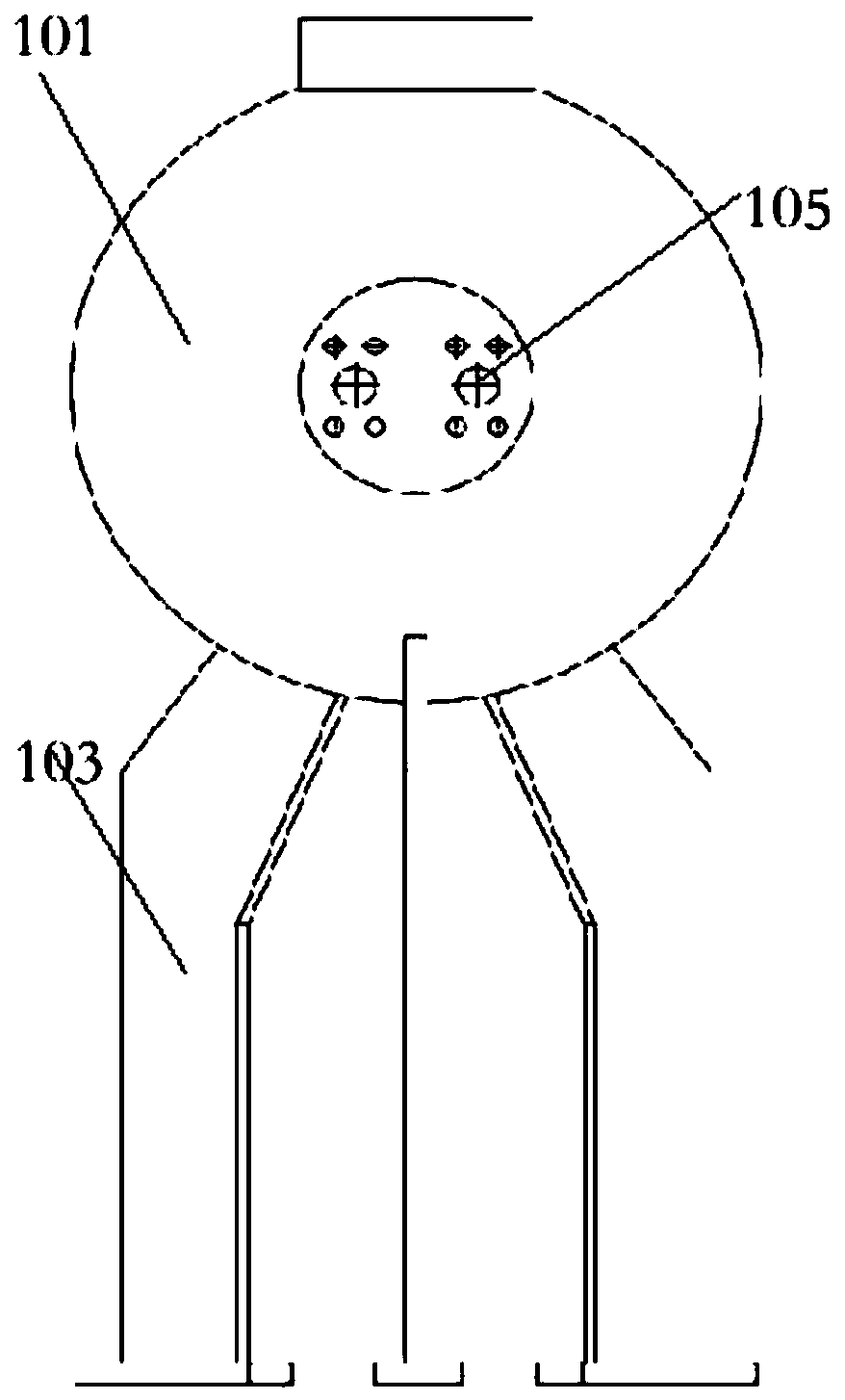

[0032] A high-pressure shock absorber, the high-pressure shock absorber 1 includes a spherical shock absorber 101, the interior of the spherical shock absorber 101 is provided with a storage cavity 1010, and the spherical shock absorber 101 is provided with an inlet for liquid The liquid channel 104 and the liquid discharge channel 105 for liquid discharge, the liquid inlet channel 104 and the liquid discharge channel 105 are intersected and arranged; the liquid inlet channel 104 and the liquid discharge channel 105 are all communicated with the storage cavity 1010; the present invention A new type of high-pressure shock absorber 1 structure is disclosed, which can be well applied to high-pressure phosphorus removal systems. The high-pressure spherical shock absorber 101 disclosed in the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com