Woven fabric with three-layer three-dimensional effect and production method of woven fabric

A technology of woven fabrics and three-dimensional effects, applied in the field of fabric weaving, can solve the problems of reduced breaking strength and friction resistance of fabric rolling parts, difficulty in meeting customer needs, and poor stability of rolling effects, etc. pleats, avoiding high production costs, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

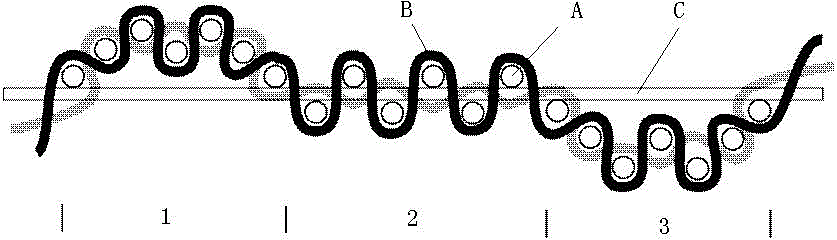

[0032] Such as figure 1 As shown, it is a schematic structural diagram of the three-layer three-dimensional unit of the embodiment of the woven fabric with three-layer three-dimensional effect of the present invention. The woven fabric with three-layer three-dimensional effect of the present embodiment includes a fabric body, and three-layer three-dimensional units are provided on the fabric body. The three-layer three-dimensional unit includes a high convex area 1, a middle layer area 2 and a low concave area 3. 2 is located between the high convex area 1 and the low concave area 3, and the high convex area 1 and the low concave area 3 are respectively located on the upper and lower sides of the middle layer area 2. The warp raw material of the fabric body of this embodiment is colored spinning multi-fiber semi-gloss polyester low-elastic network yarn A; Filament C, color-spun multi-fiber semi-gloss polyester low-elasticity network yarn B and coarse-gauge color-spun polyeste...

Embodiment 2

[0036] The production method of the woven fabric with three-layer three-dimensional effect in this embodiment comprises the following steps:

[0037] 1) Warping: The total number of warps is 4072, the number of barrels is 408, the number of strips is 9.8, the density of warp lines is 26 lines / cm, and the warping speed is 350m / min. Among them, the warp direction raw materials are colored spinning Multi-fiber semi-gloss polyester low-elasticity network yarn A, and the specification of color-spun multi-fiber semi-gloss polyester low-elasticity network yarn A is 340dtex / 96f×2 / 350S;

[0038] 2) Weaving: Arrange the weft raw material color-spun multi-fiber semi-gloss polyester low-elasticity network yarn B and coarse-scale color-spun polyester monofilament C according to the rule of B:C=3:1, and the weft density of the upper machine is 11 pieces / cm Carry out weaving; Concretely, the specification of color-spun multi-fiber semi-glossy polyester low-elastic network yarn B is 500dt...

Embodiment 3

[0042] The production method of the woven fabric with three-layer three-dimensional effect in this embodiment comprises the following steps:

[0043]1) Warping: The total number of warps is 4072, the number of barrels is 408, the number of strips is 9.8, the density of warp lines is 26 lines / cm, and the warping speed is 350m / min. Among them, the warp direction raw materials are colored spinning Multi-fiber semi-gloss polyester low-elasticity network yarn A, and the specification of color-spun multi-fiber semi-gloss polyester low-elasticity network yarn A is 340dtex / 96f×2 / 350S;

[0044] 2) Weaving: Arrange the weft raw material color-spun multi-fiber semi-gloss polyester low-elasticity network yarn B and coarse-scale color-spun polyester monofilament C according to the rule of B:C=3:1, and the weft density of the upper machine is 11 pieces / cm Carry out weaving; Concretely, the specification of color-spun multi-fiber semi-gloss polyester low-elasticity network yarn B is 500dtex / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com