Basic mounting method of offshore fan jacket and integrated jacket device

An installation method and jacket technology, applied in infrastructure engineering, construction, etc., can solve problems such as difficult operation, and achieve the effects of simple operation, efficient installation, and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

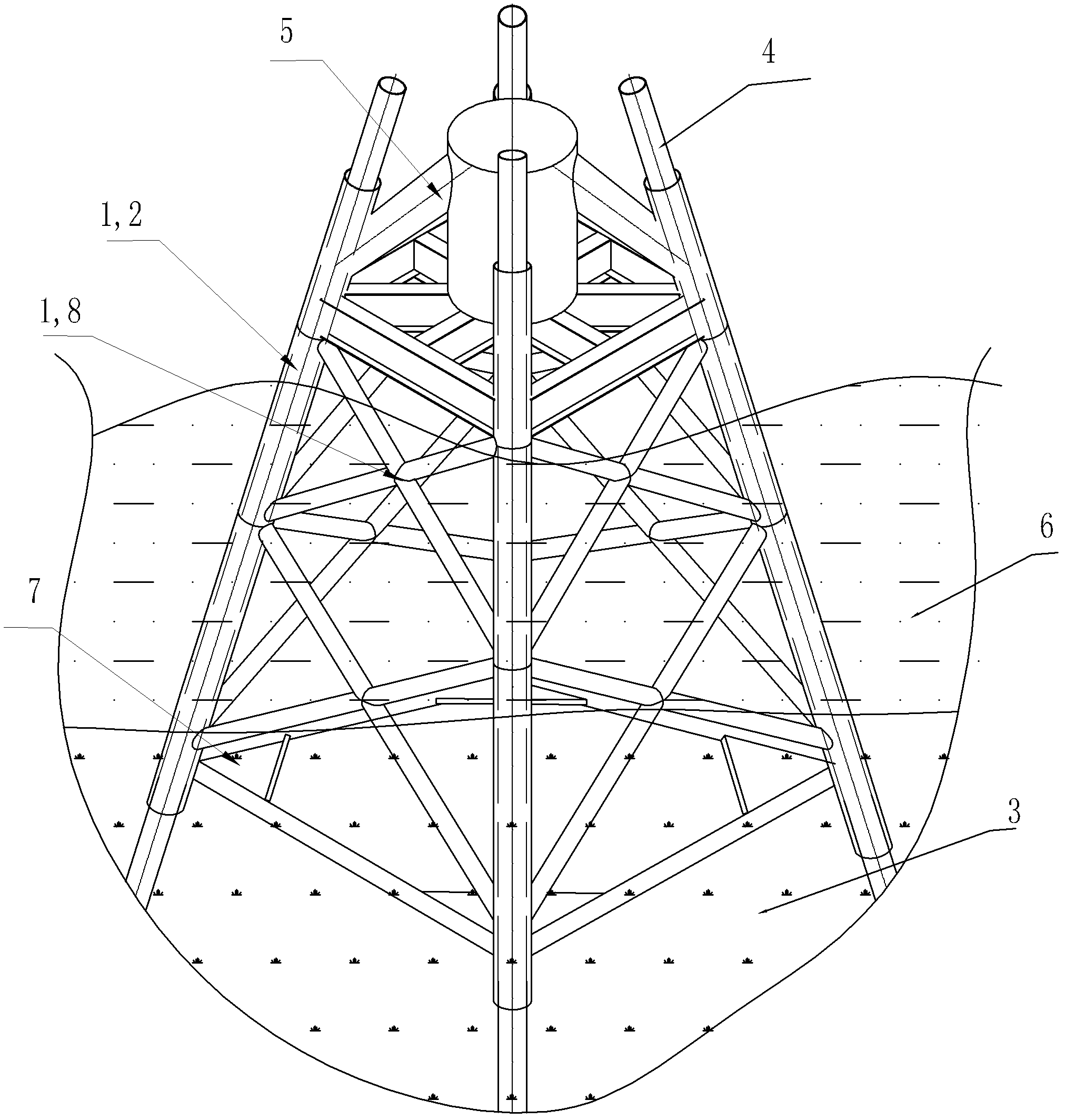

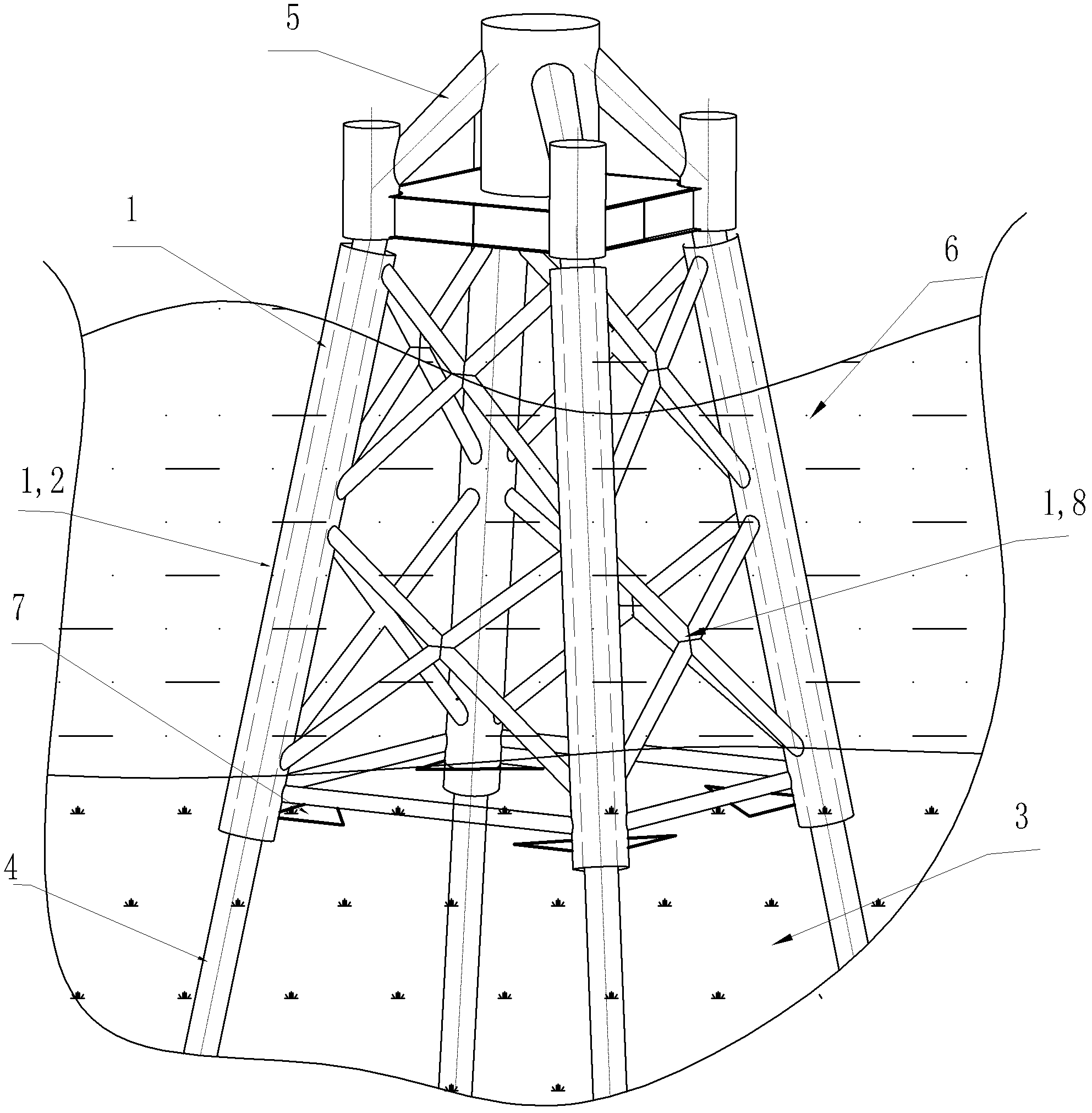

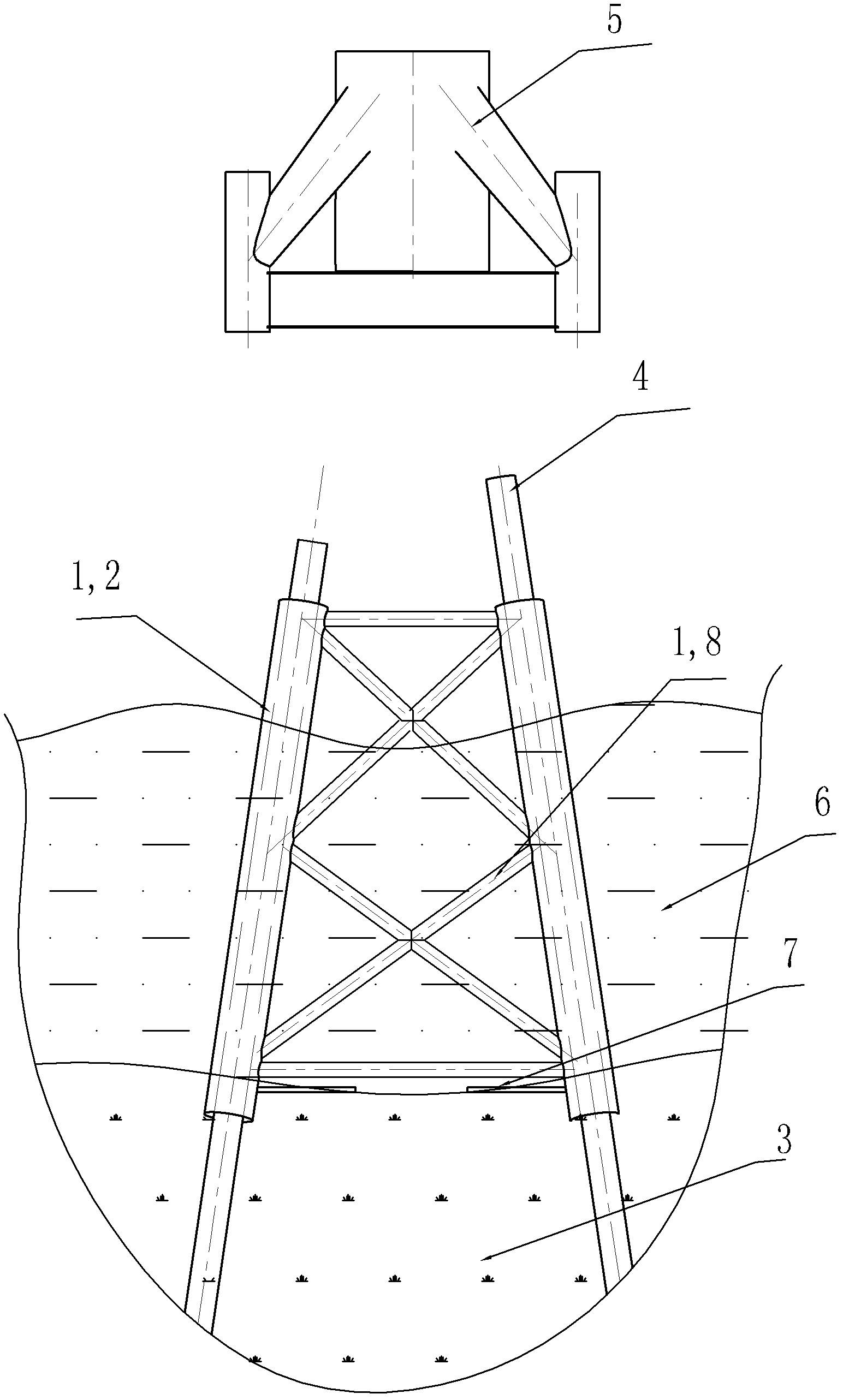

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] As shown in the figure, the integrated jacket device includes a jacket body 1 horizontally arranged on the seabed surface 3 . The jacket body 1 includes multiple jacket legs 2 . A pipe pile 4 fixed to the seabed surface 3 is inserted into each jacket leg 2 . The installation method is as follows: first insert the pipe pile 4 into the jacket leg 2 and protrude from the bottom of the jacket leg and enter into the seabed, and then use a pile driver to drive the pipe pile into the seabed for fixing. With the positioning of jacket legs, the positioning of pipe piles is very accurate. A part of the jacket body 1 is immersed in seawater 6, and the other part is placed above the sea level.

[0026] The top of the jacket body 1 is provided with a jacket platform 5 on which a fan barrel can be installed. The provided jacket platform 5 has two implementations.

[0027] One of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com