Assembling positioning jig

A technology for positioning fixtures and positioning holes, which is applied in lamination devices, layered products, lamination, etc., and can solve problems such as deflection, excessive clearance, and assembly deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

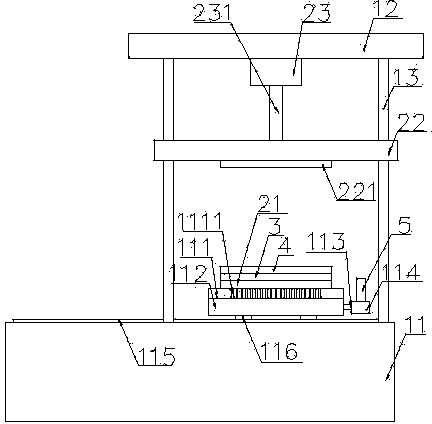

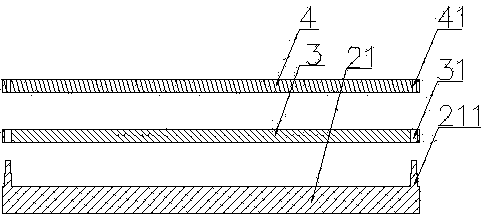

[0021] see figure 1 and figure 2 , as shown in the legend therein, an assembly positioning jig for installing the display protection screen 4 on the display front frame 3, including a frame and a pressing device, the frame includes a base 11, a Top plate 12 and four guide posts 13; the pressing device includes a positioning base plate 21, a pressing plate 22 and a cylinder 23; the guide post 13 vertically connects the base 11 and the top plate 12, and the pressing plate 22 covers It is arranged on the guide post 13 and moves up and down along the guide post 13; the cylinder 23 is fixed on the top plate 12 and connected to the pressing plate 22 through the driving of the cylinder piston 231, and the pressing of the pressing plate 22 A foam buffer gasket 221 is attached to the surface.

[0022] The display front frame 3 and the display protection screen 4 are respectively provided with two first positioning holes 31 and two second positioning holes 41, and the positioning bo...

Embodiment 2

[0029] The rest are the same as the first embodiment, except that the cylinder is a hydraulic cylinder.

Embodiment 3

[0031] The rest are the same as the first embodiment, the difference is that the cylinder is a rotary lifting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com