Patents

Literature

65results about How to "Guaranteed buffer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

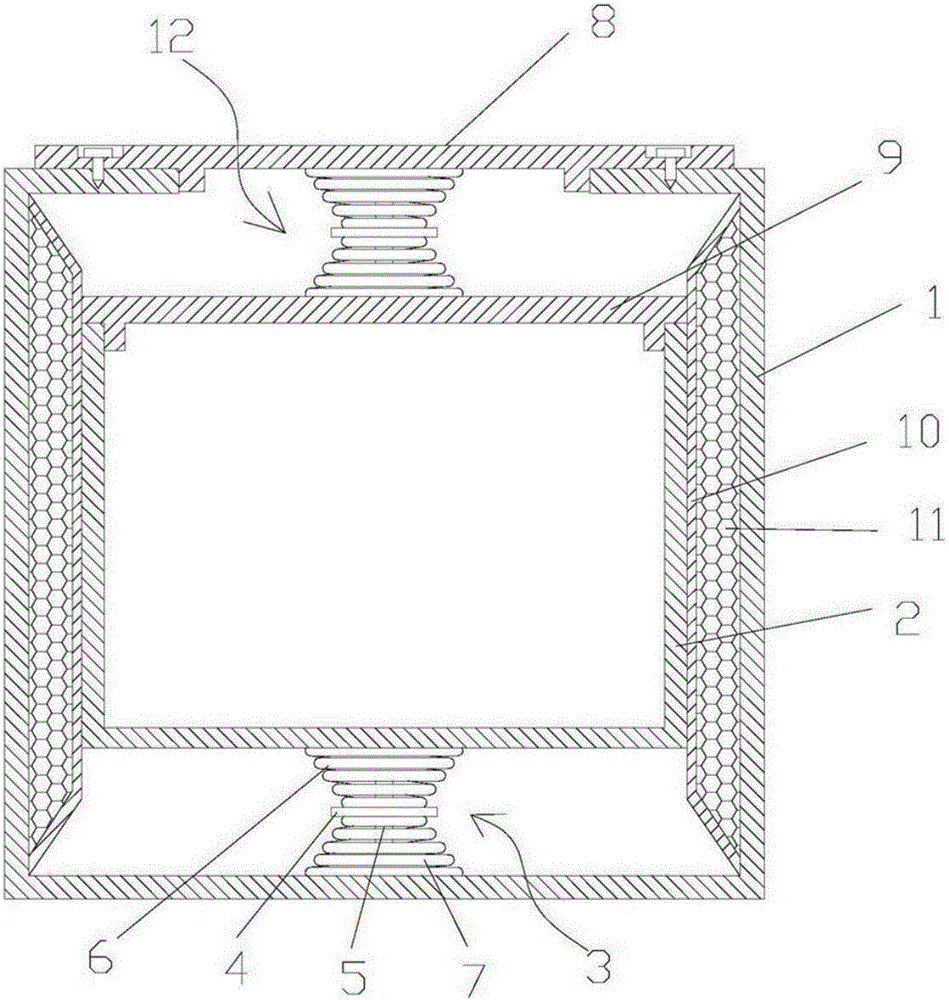

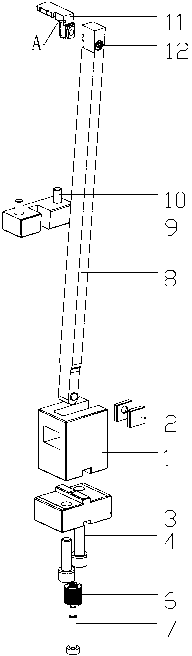

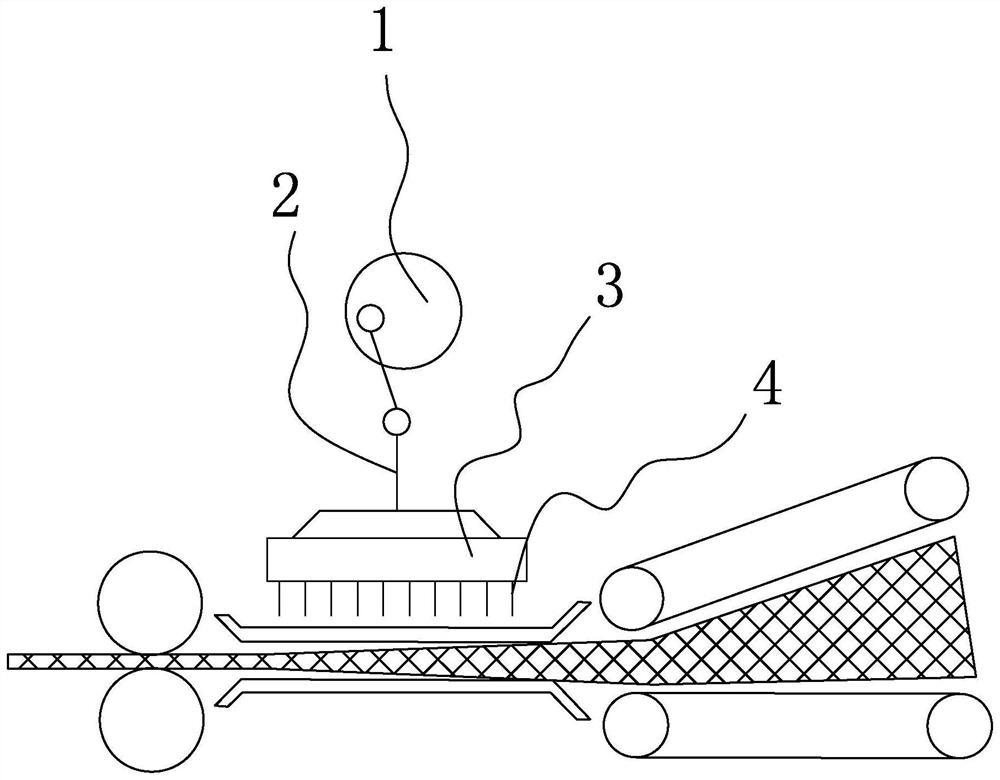

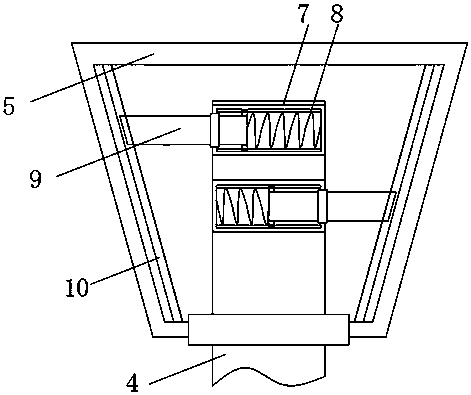

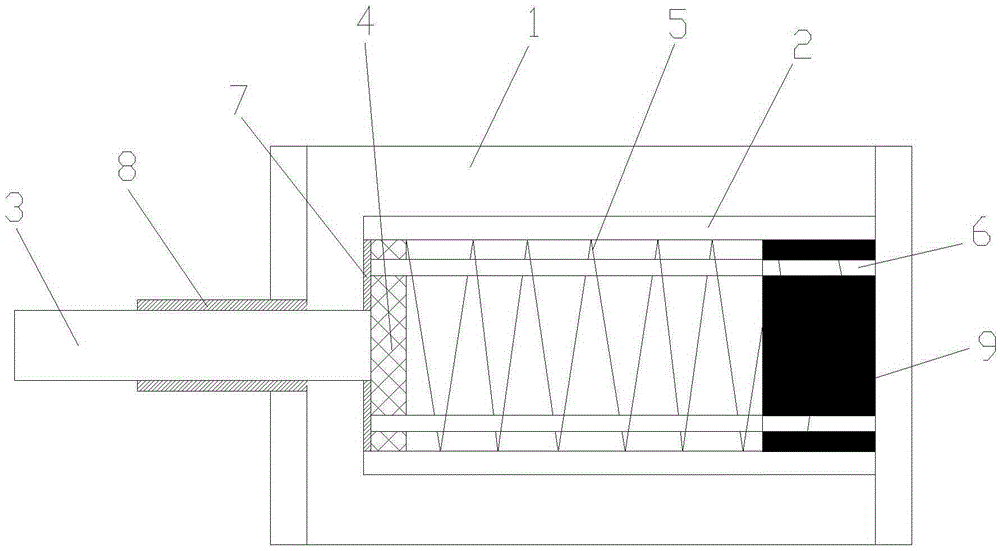

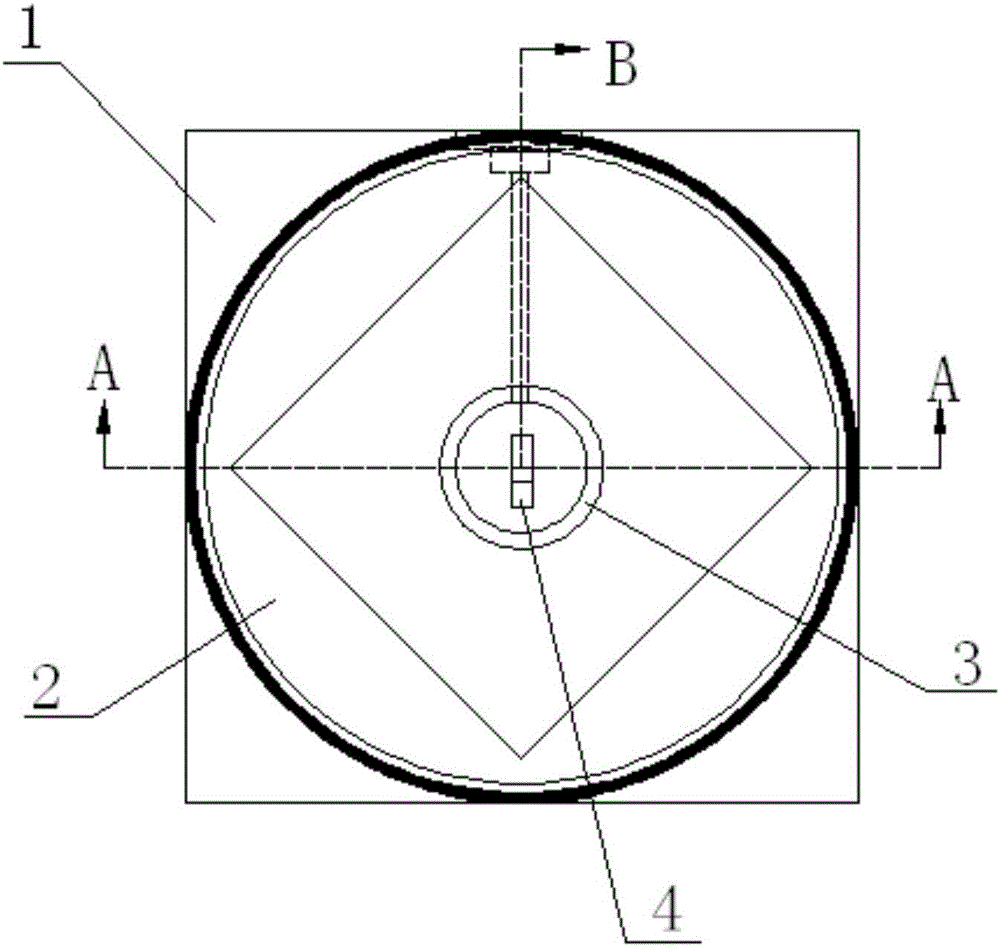

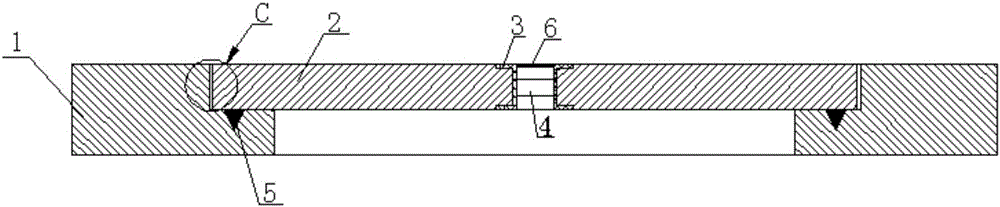

Gripper, in particular a bernoulli gripper

InactiveCN101687322AGuaranteed bufferReduced risk of damageGripping headsSemiconductor/solid-state device manufacturingDevice formRobotic arm

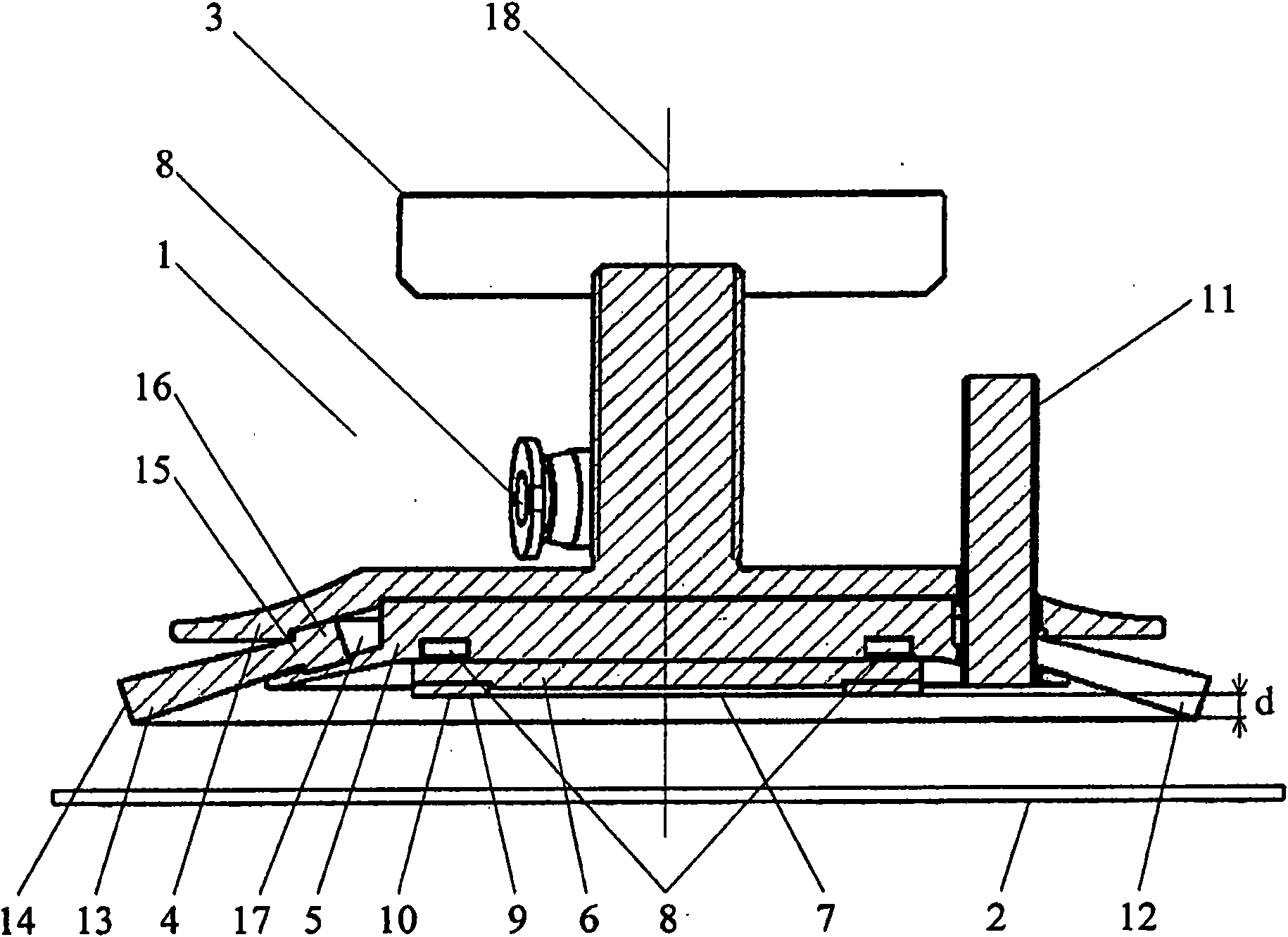

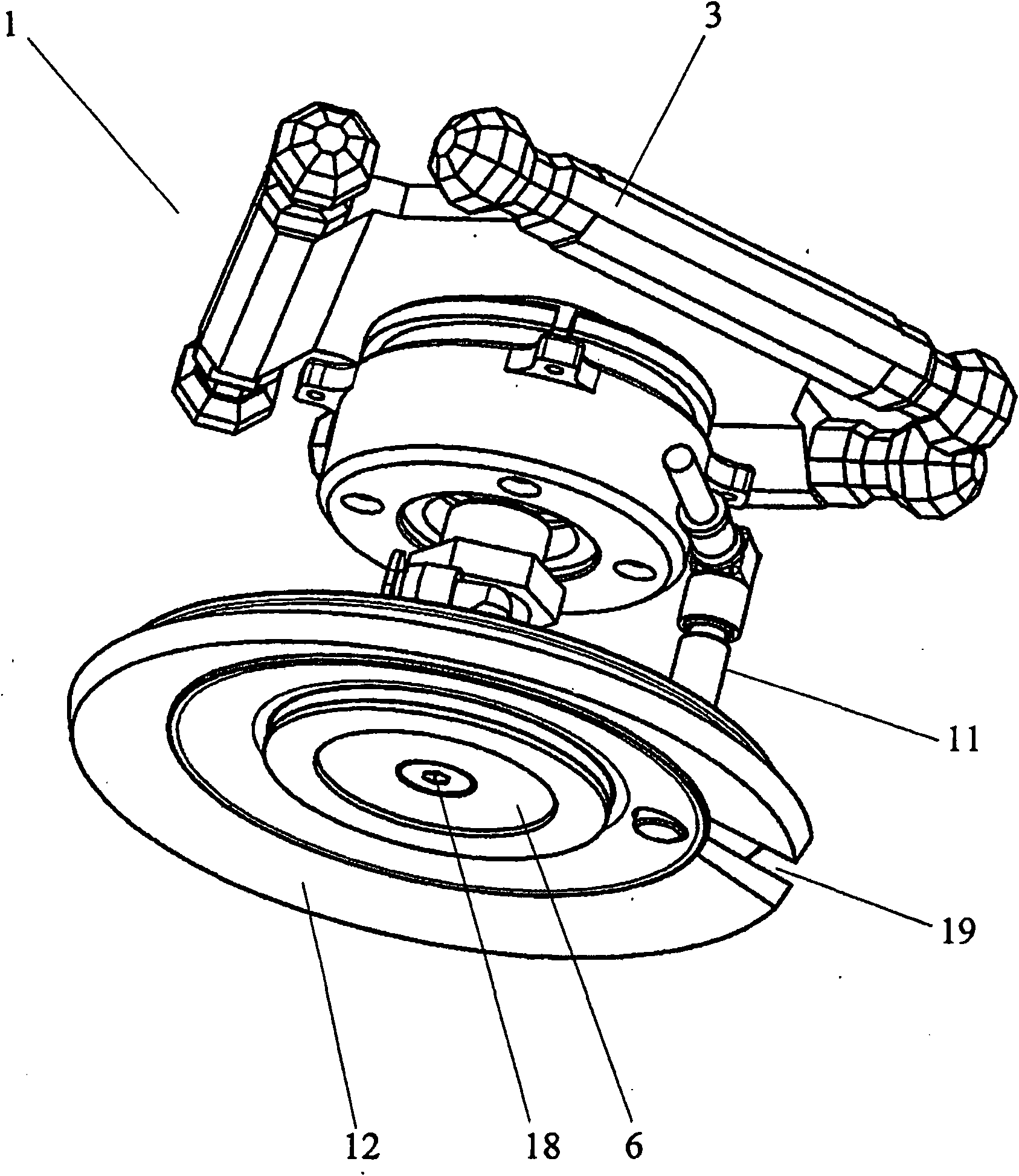

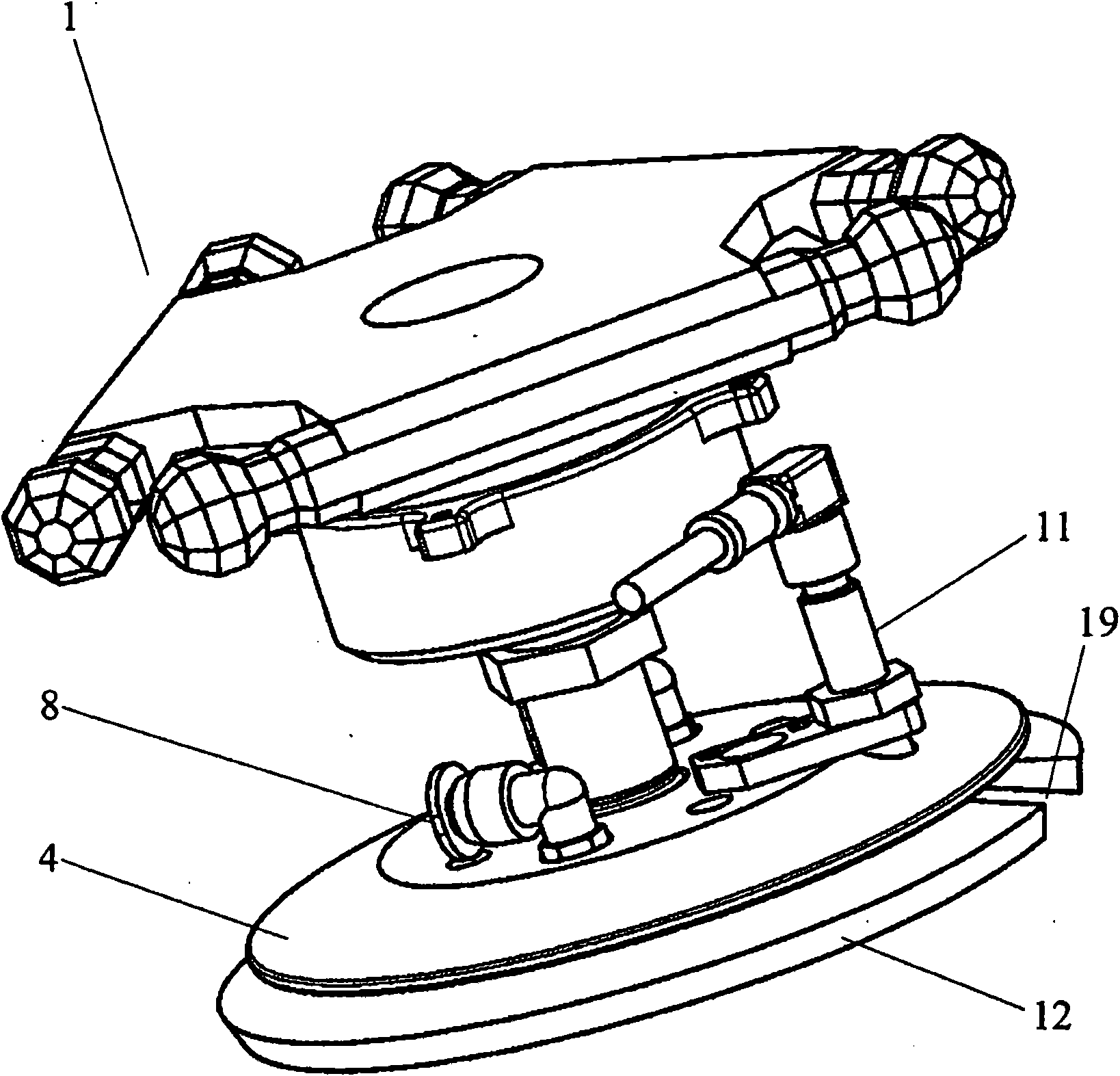

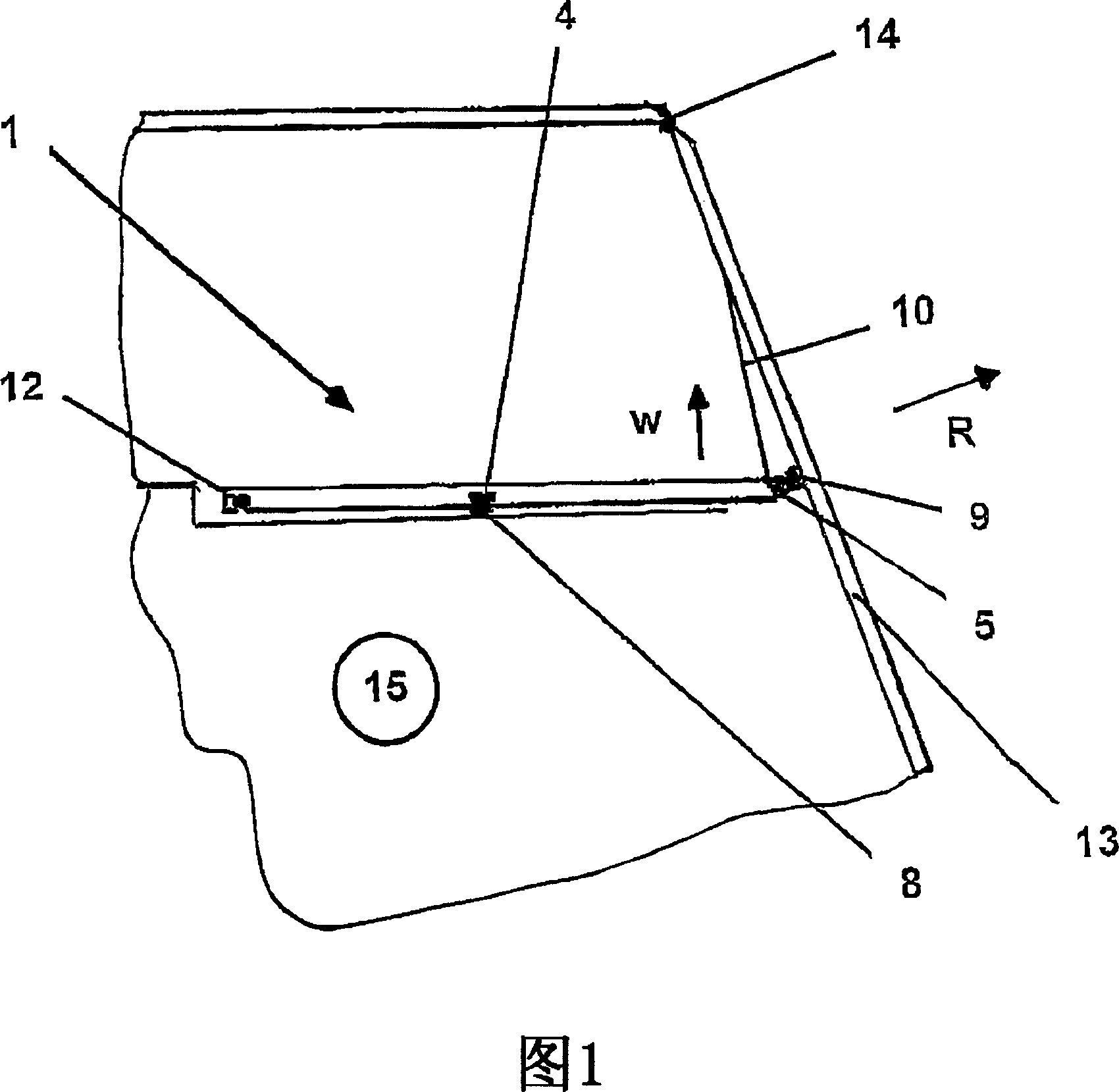

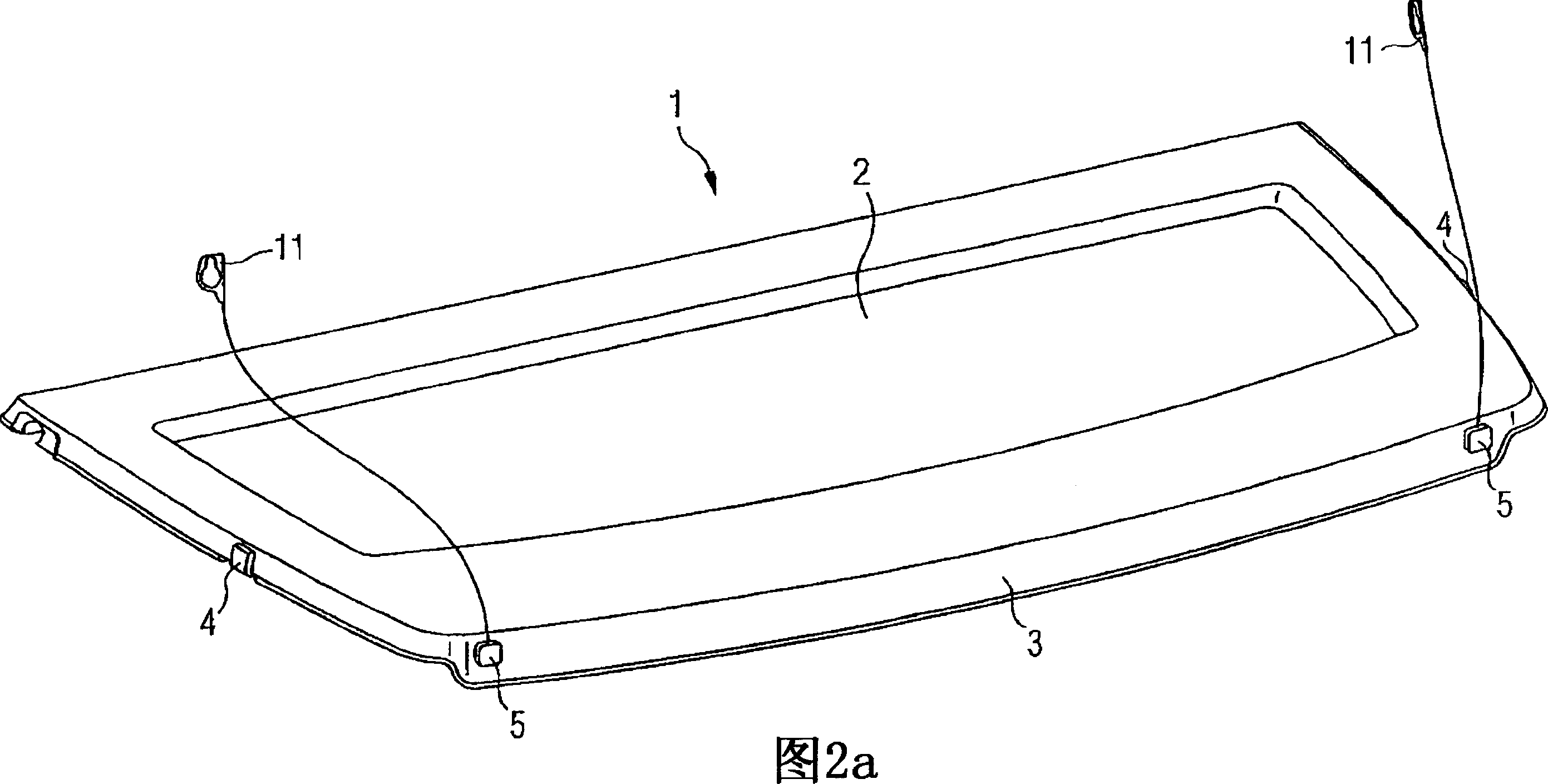

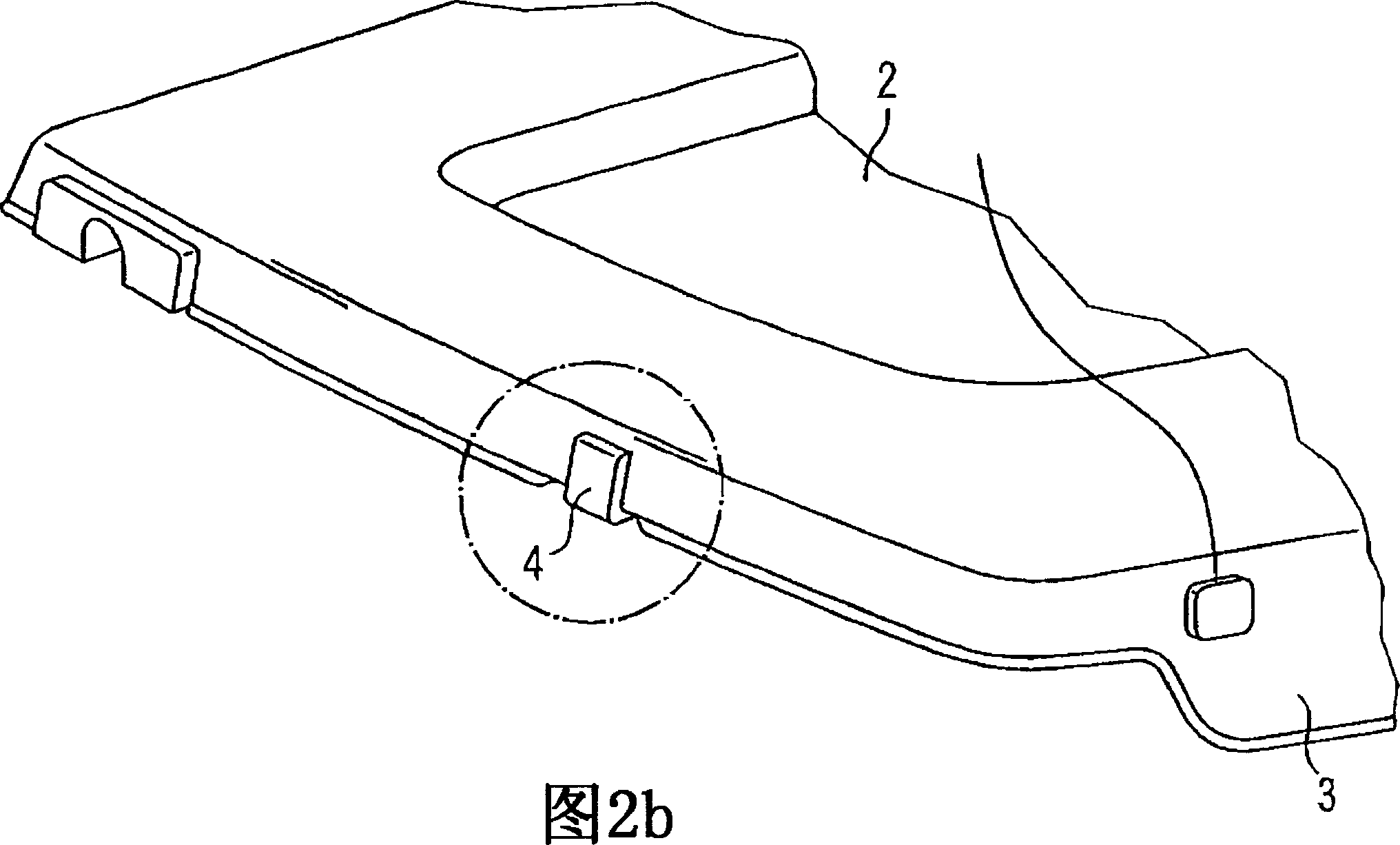

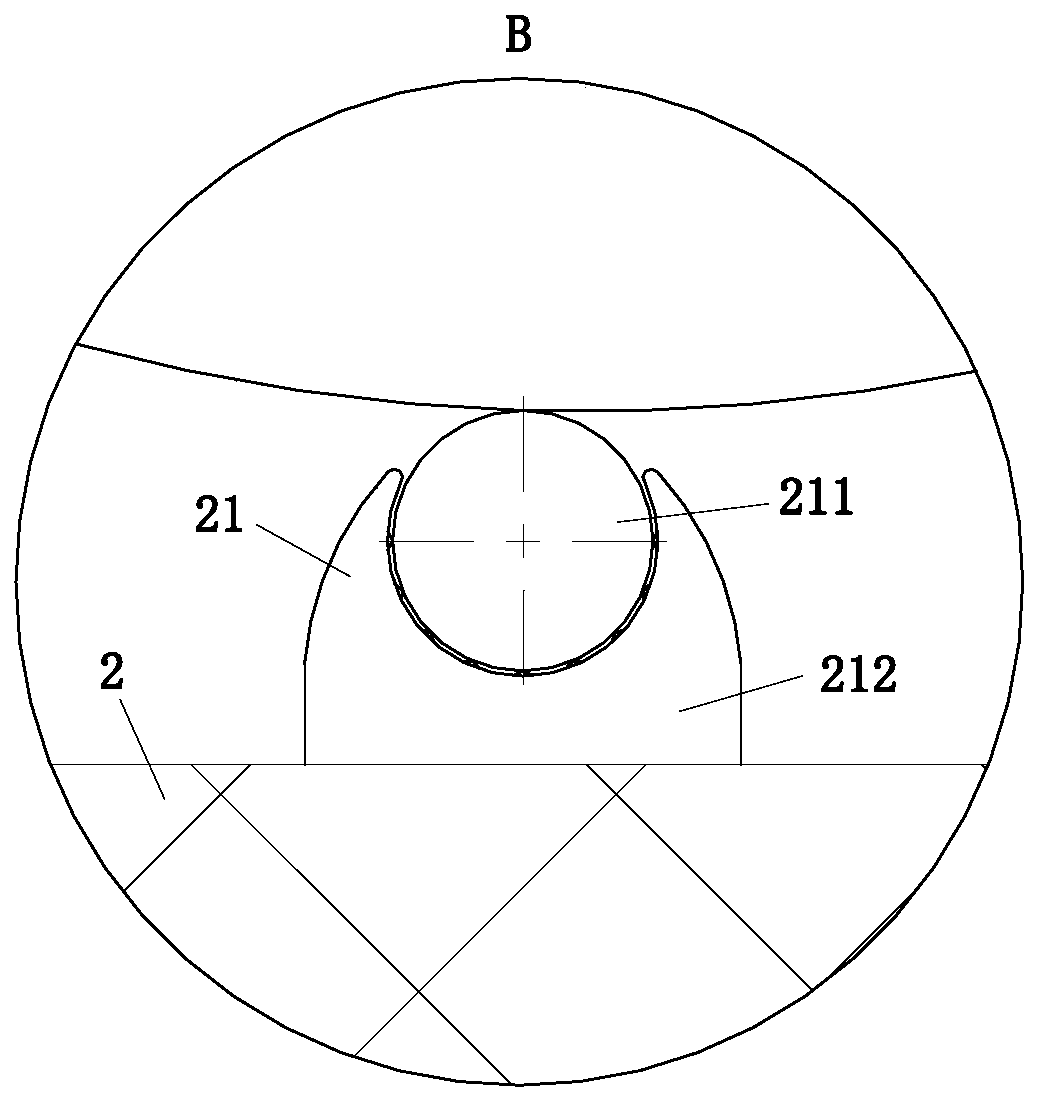

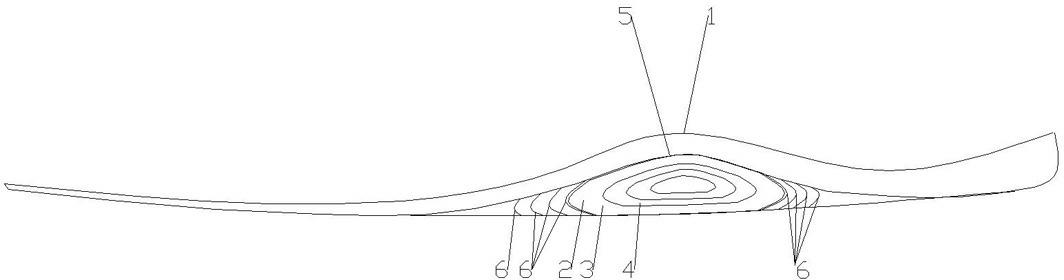

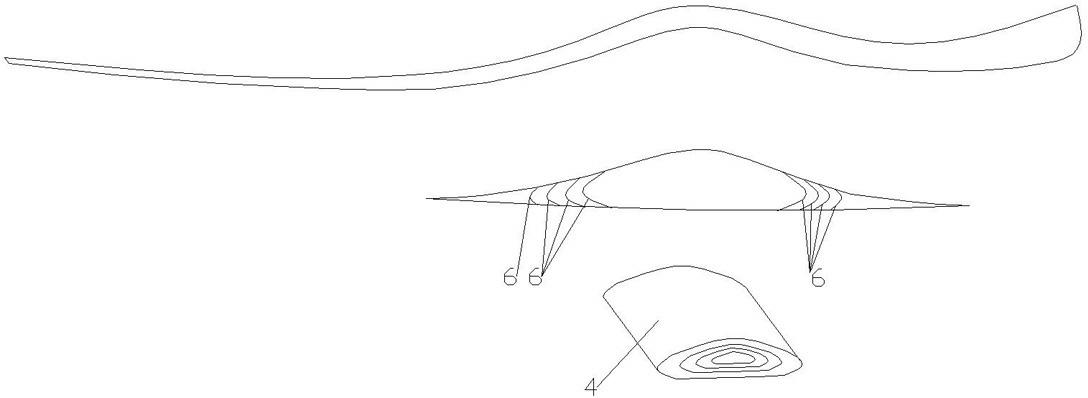

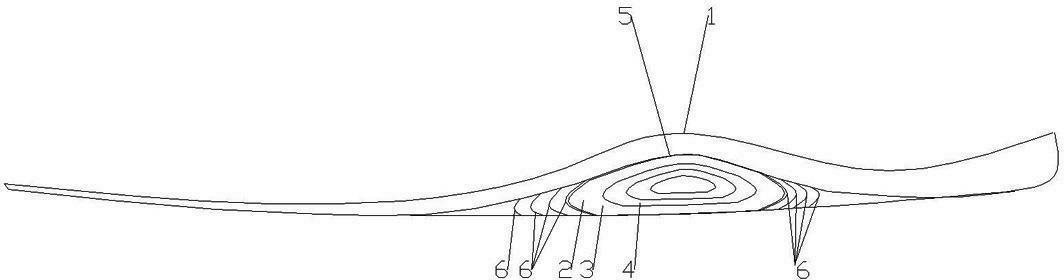

The invention relates to a gripper (1), in particular a Bernoulli gripper for holding two-dimensional components such as silicon-based wafers (2) with a low degree of loading, having a clamping ring (4) connected to a controllable robot arm (3), having a baffle plate (6) which is connected to the clamping ring (4) by means of a funnel-shaped component (5) and has a gripping face (7) which communicates with a flow system (8) which passes through the funnel-shaped component (5) and the baffle plate (6) and by means of which, after an excess pressure has been applied to the Bernoulli gripper (1),a negative pressure is to be produced on the gripping face (7) of the baffle plate (6) in order to attach by suction the wafer (2) to be gripped, having a rubberized bearing surface (9) of a bearingring (10) which is integrated in the gripping face (7) and provides a slip-resistant movement of the wafer (2) attached to the gripping face (7) by suction, and having a sensor (11) for detecting thewafer (2) attached to the gripping face (7) by suction. In order to permit an extremely shock-resistant attachment of the wafer to be gripped on the gripping face of the gripper, the invention provides a damping device (12) which is circumferentially adapted to the gripper (1), the contour of which device, as viewed in the plan view of the gripper (1), protrudes circumferentially above the contourof the latter, and which device forms such a damping resistance for the wafer (2) to be gripped during its suction-induced approach towards the gripping face (7) that the wafer (2) comes to bear in ashock-free manner against the rubberized bearing surface (9) of the bearing ring (10).

Owner:JONAS & REDMANN AUTOMATIONSTECHNIK GMBH

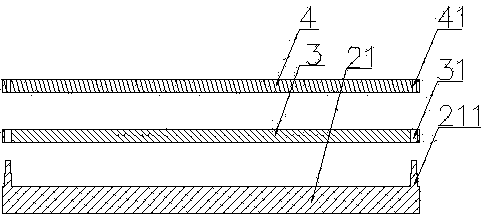

Assembling positioning jig

InactiveCN103419456AEasy to locatePrevent assembly deformationLaminationLamination apparatusEngineeringDisplay device

The invention discloses an assembling positioning jig which is used for installing a protection screen of a display on a display front frame and comprises a machine frame and a pressing device. The assembling positioning jig is high in positioning accuracy and accurate in installation and achieves mechanical automation.

Owner:昆山濡鑫光电科技有限公司

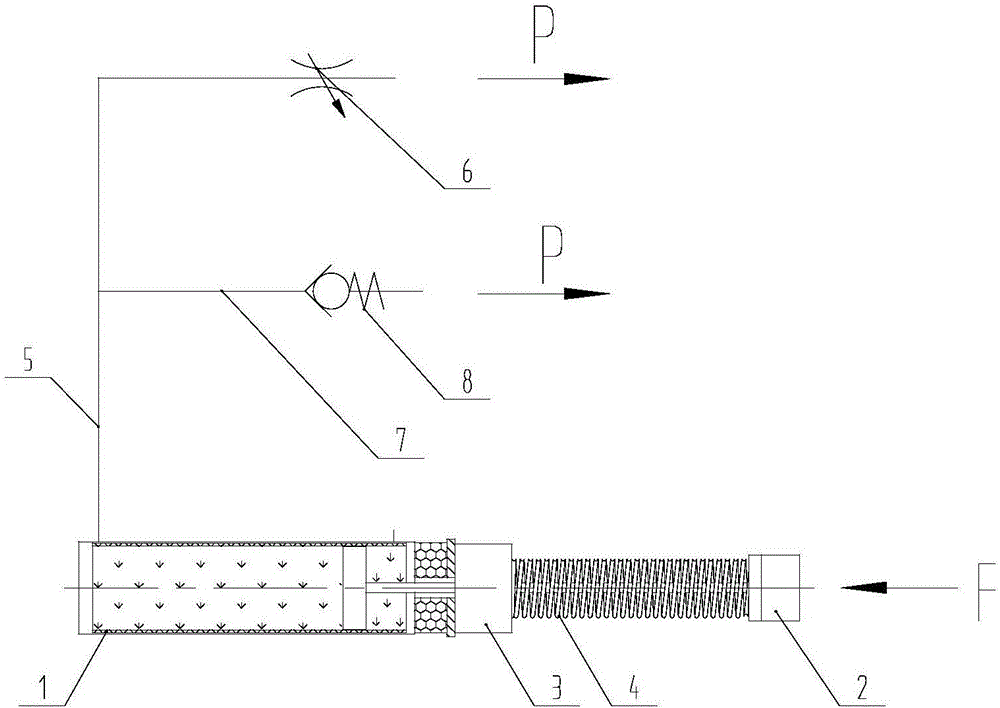

Pressure safety device of elevator

InactiveCN102674104AImprove protectionImprove reliabilityElevatorsBuilding liftsSafety controlEngineering

The invention discloses a pressure safety device of an elevator, which is a device which can protect people from being hurt after the elevator falls under the condition that other safety devices are out of work. By adoption of the pressure safety device, the elevator is supported by air pressure which is brought when the elevator falls at high speed at the last moment and slowly falls, and a protective air cushion can be formed in the elevator, so that a phenomenon that the people in the elevator are hurt because the elevator falls to the ground at high speed is avoided. Therefore, an effective safety control is provided for the masses.

Owner:杨茂亮

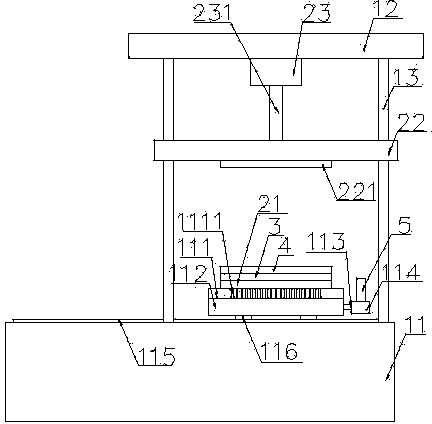

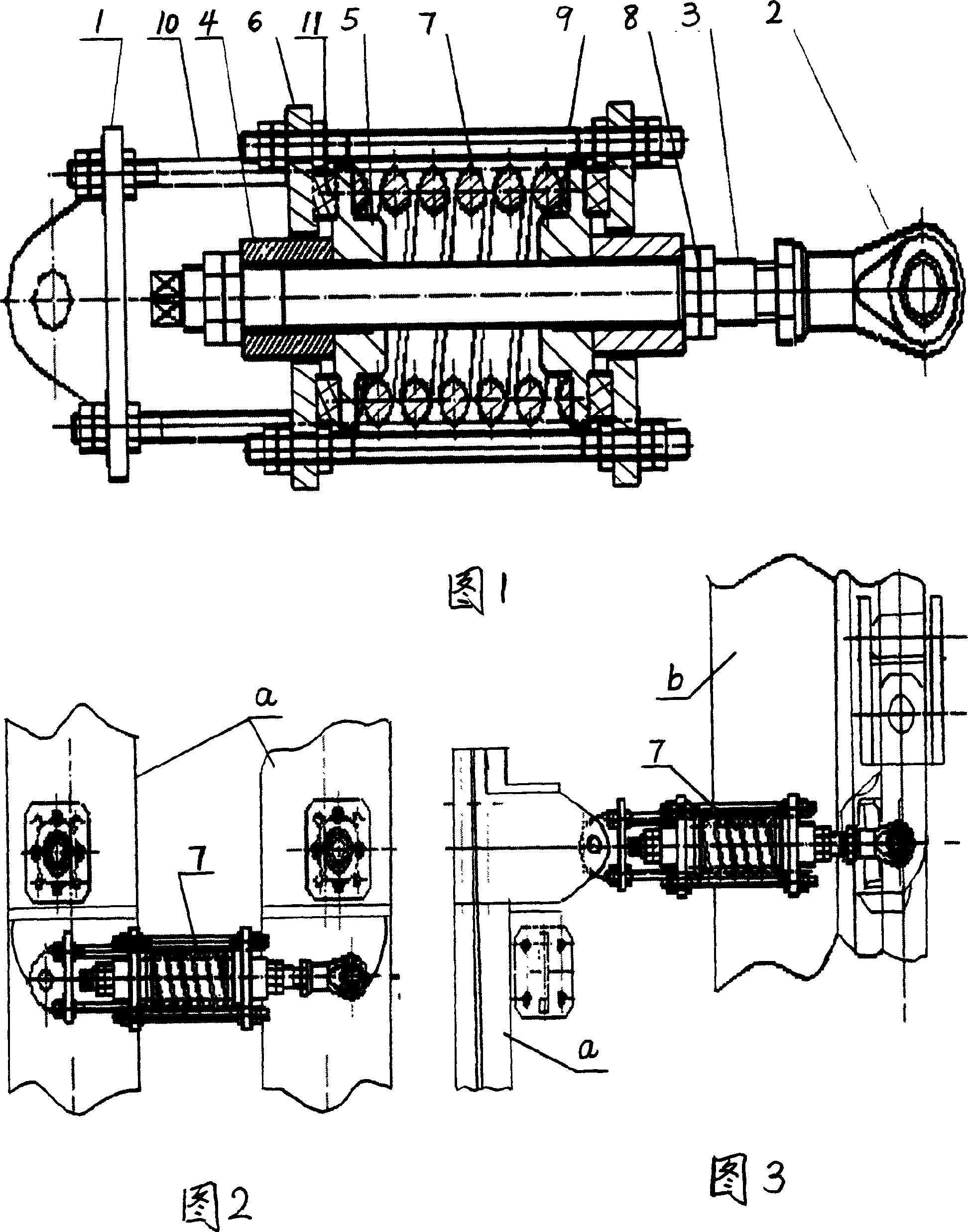

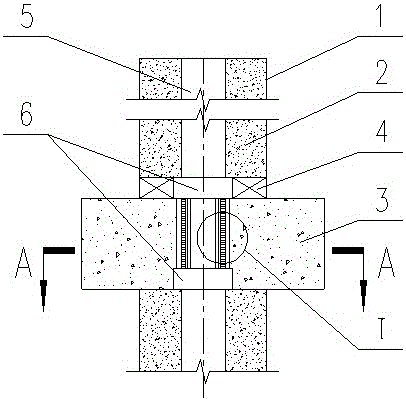

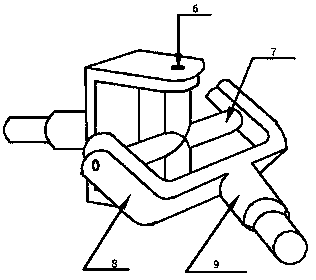

Joining method and apparatus of binode twisting-pulling mechanism and crust breaking mechanism

The present invention is anode twisting-shifting mechanical and breaking mechanism connecting method and unit. Two anode twisting-shifting mechanicals or one anode twisting-shifting mechanical and one breaking mechanism are connected via elastic spring connection. The connecting unit includes one knuckle bearing with one screwed pull rod; and on the pull rod, there are two locking shaft sleeves, two spring seats, two flanges and one spring set between the two spring seats, regulating nut, etc. The present invention has the advantages of convenient use, easy making, simple structure and capacity of replacing two anodes in once operation.

Owner:GUIYANG AL-MG DESIGN & RES INST

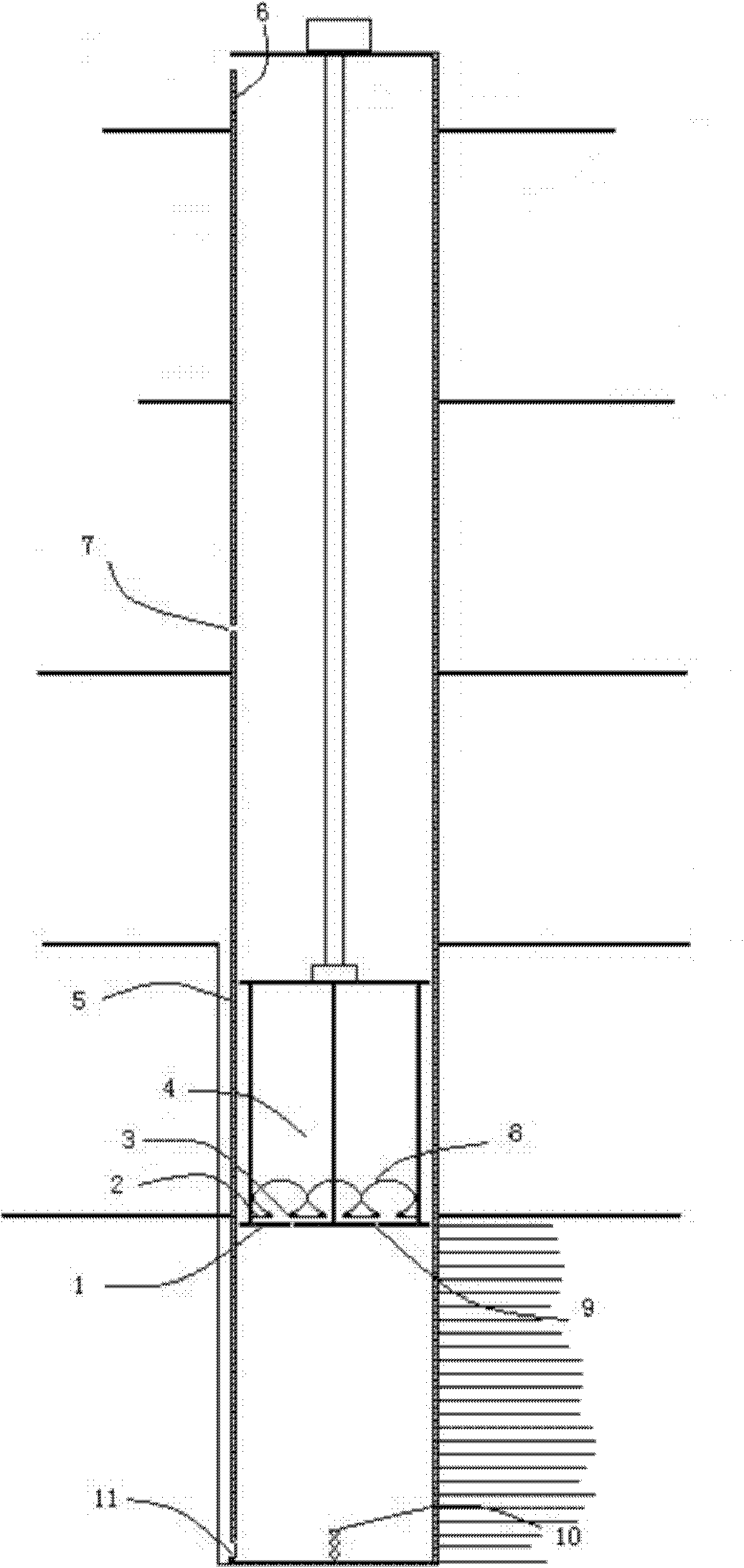

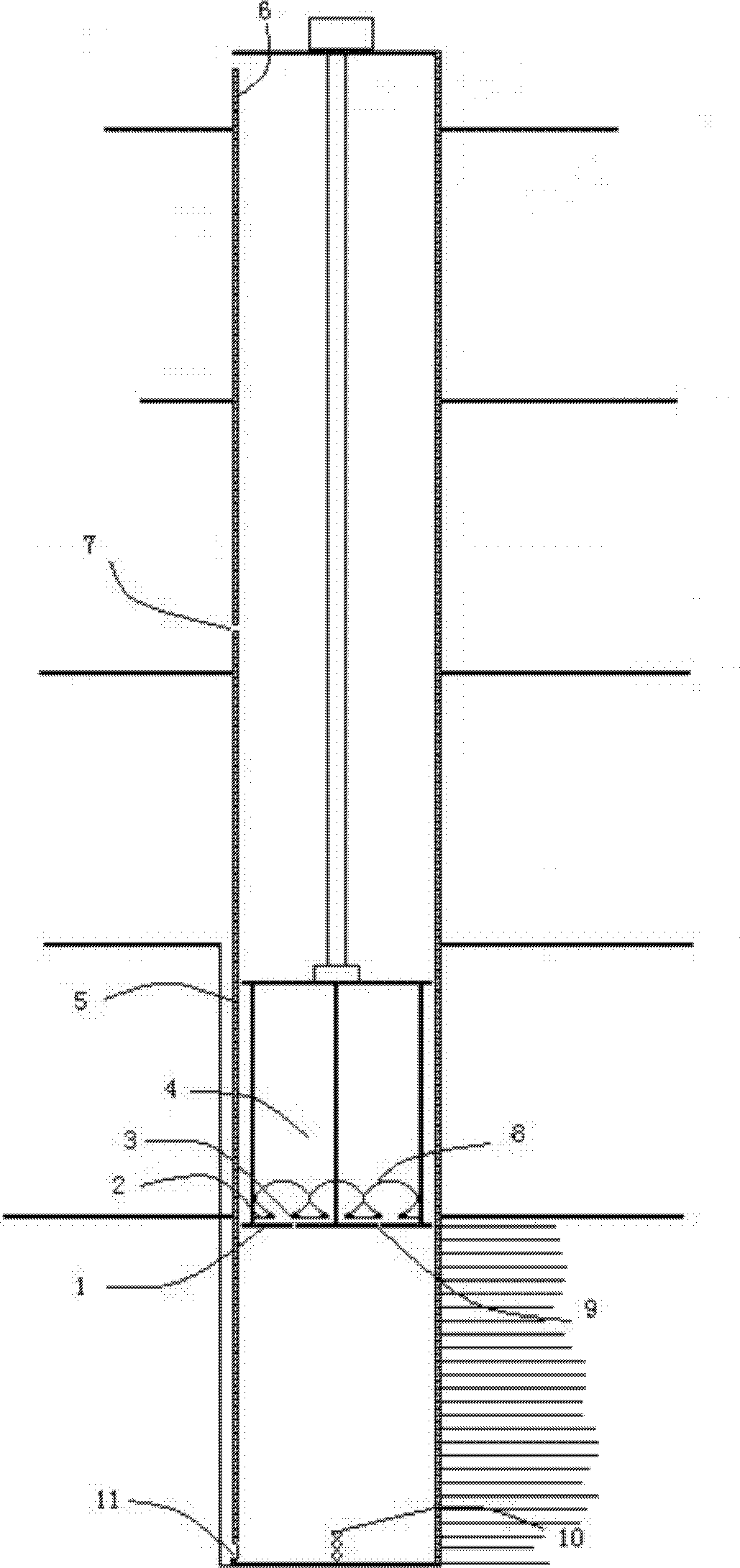

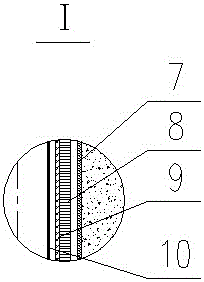

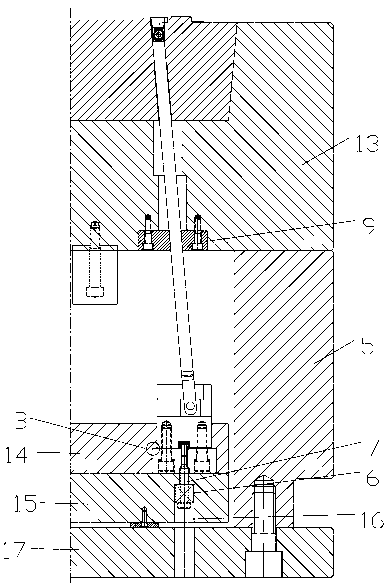

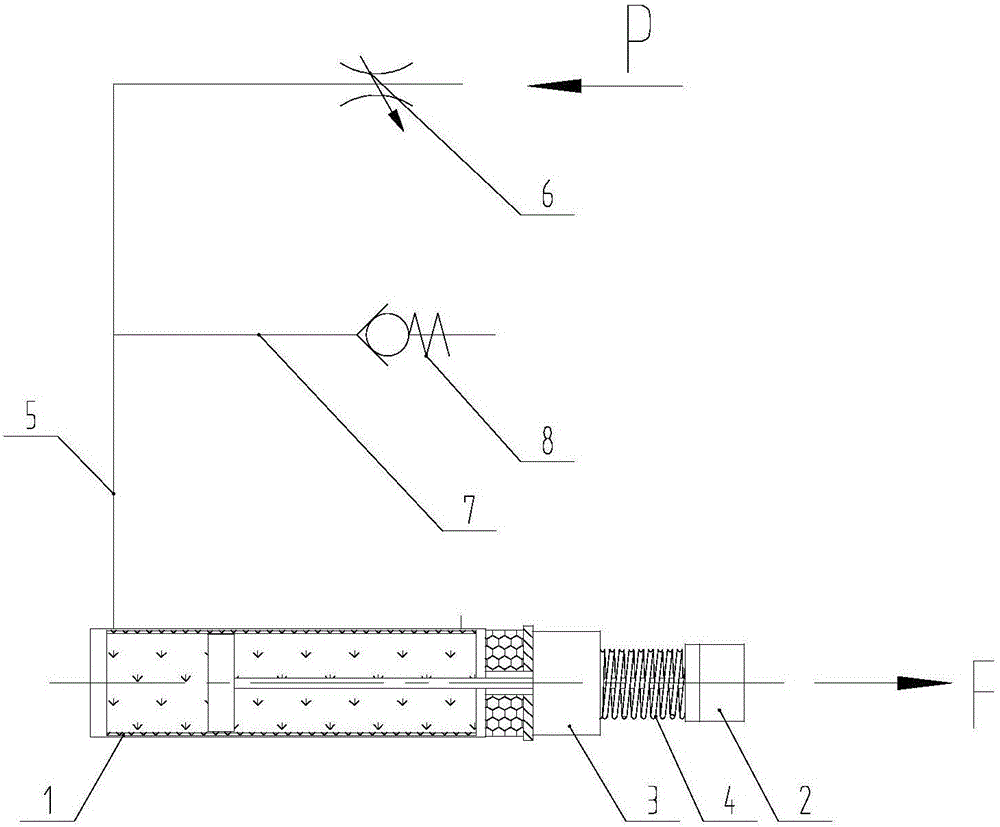

Casing pipe device structure used for oil drilling and capable of preventing casing damage due to fault slippage

ActiveCN105735913AFix damagePrevent impact on oil production operationsDrilling rodsDrilling casingsOil drillingPetroleum

The invention discloses a casing pipe device structure used for oil drilling and capable of preventing casing damage due to fault slippage. The casing pipe device structure is installed in the expanding section of a fault and mainly composed of a movable joint of a four-layer structure. A rigidity followable casing pipe layer of the movable joint is connected with an upstream casing pipe part and a downstream casing pipe part through threaded connecting parts. The four-layer structure of the movable joint is connected into a whole at the two ends of the movable joint. An outer steel wire knitmesh is arranged on the outer side of the rigidity followable casing pipe layer, and an inner steel wire knitmesh and a flexible hose are sequentially and inwards arranged in the rigidity followable casing pipe layer. In the fault zone, displacement caused by fault slippage can be offset by a buffer space between the outer steel wire knitmesh of the movable joint and the stratum, the transverse displacement deformation and confining capacity of the rigidity followable casing pipe layer of the movable joint and a ring-pillar-shaped gap between the inner steel wire knitmesh and the flexible hose in the innermost layer. Meanwhile, mud or sandy soil can be effectively prevented from entering the flexible hose in the innermost layer through the outer steel wire knitmesh and the inner steel wire knitmesh, and the flexible hose can properly deform along with partial displacement deformation of the rigidity followable casing pipe layer, so that the flexible hose does not crack and influence oil recovery operation.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

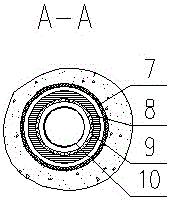

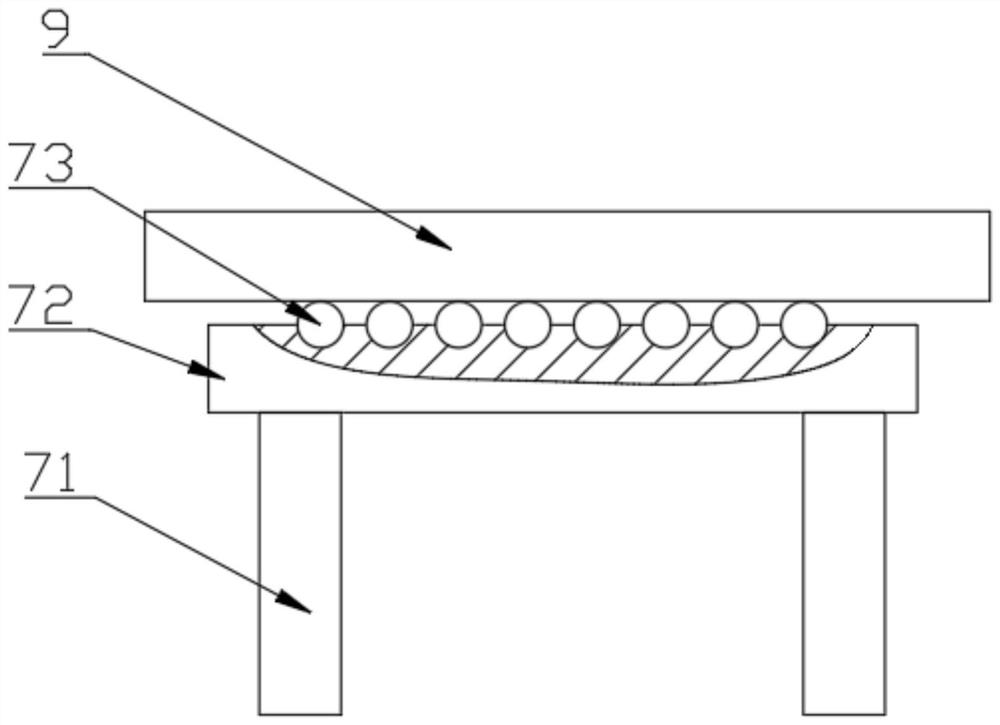

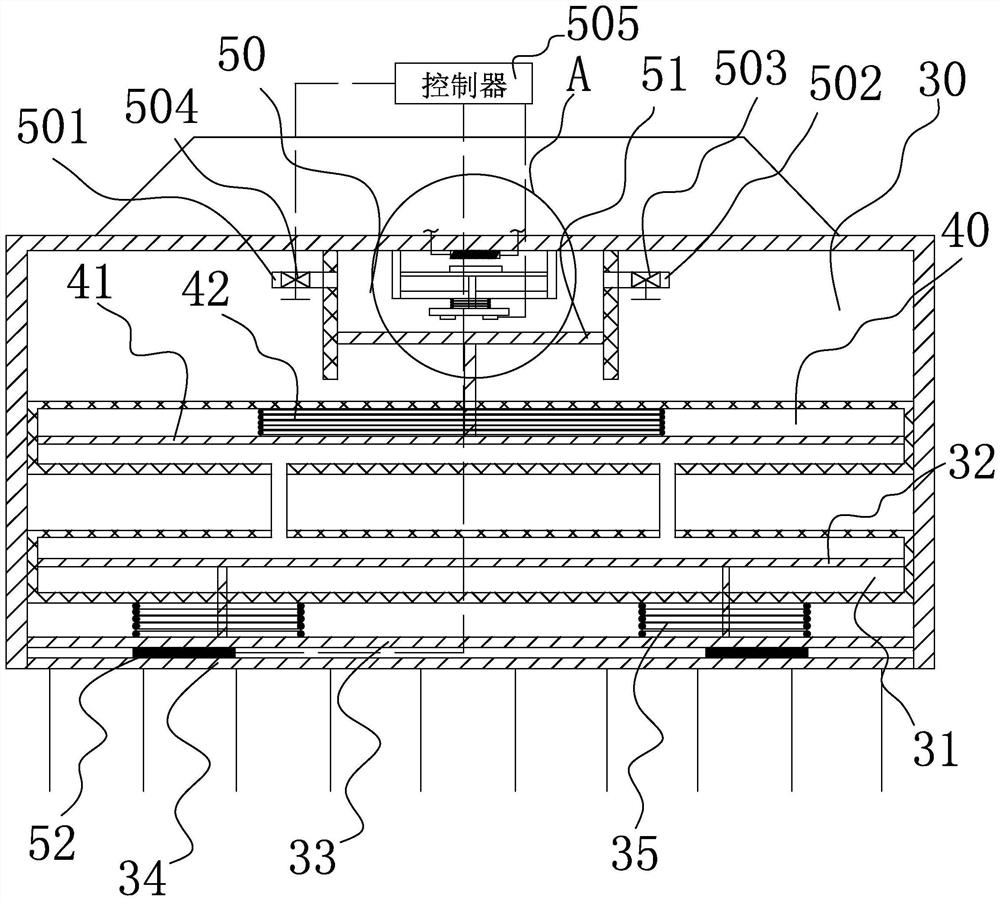

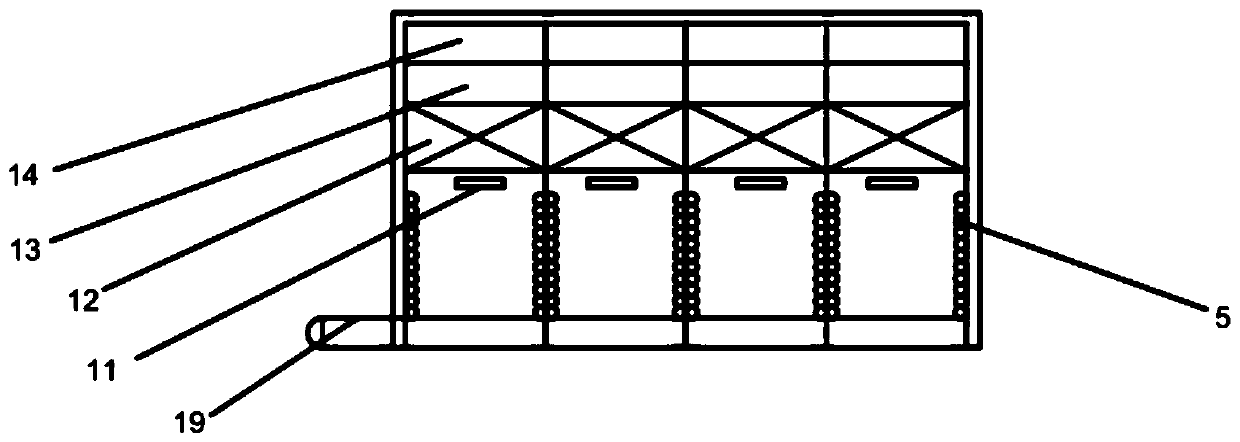

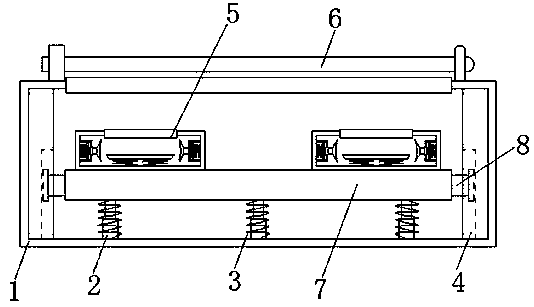

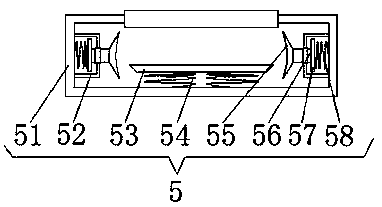

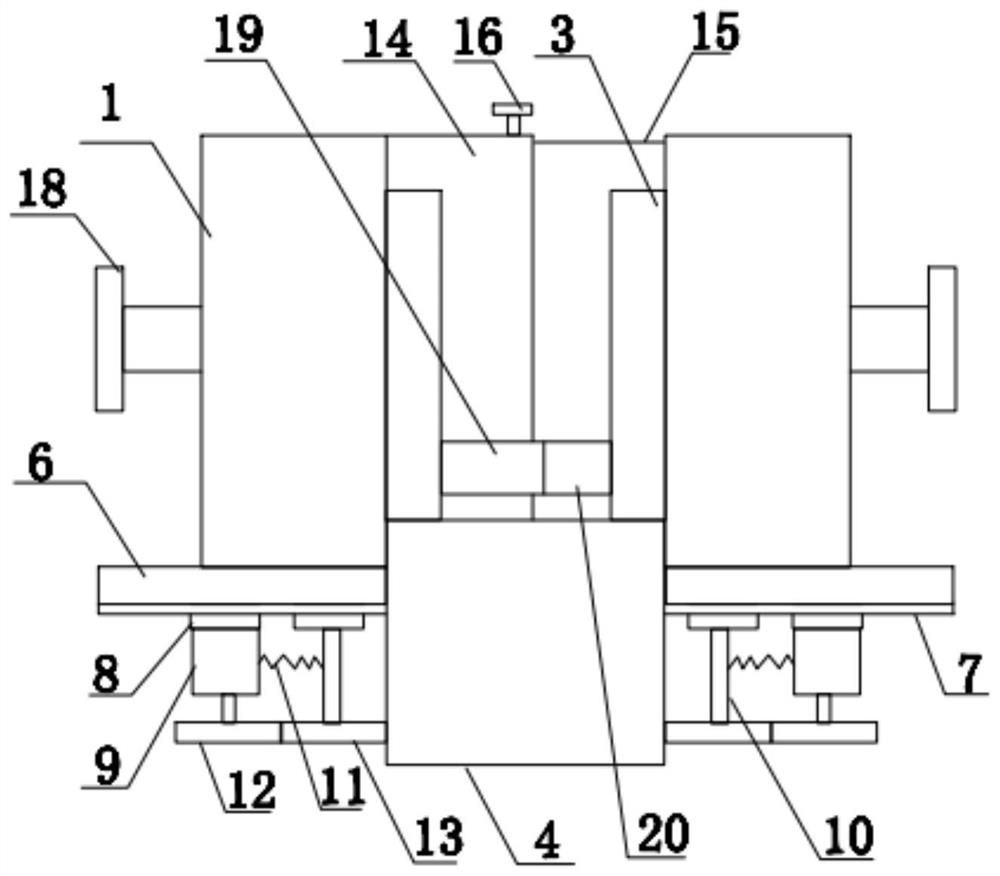

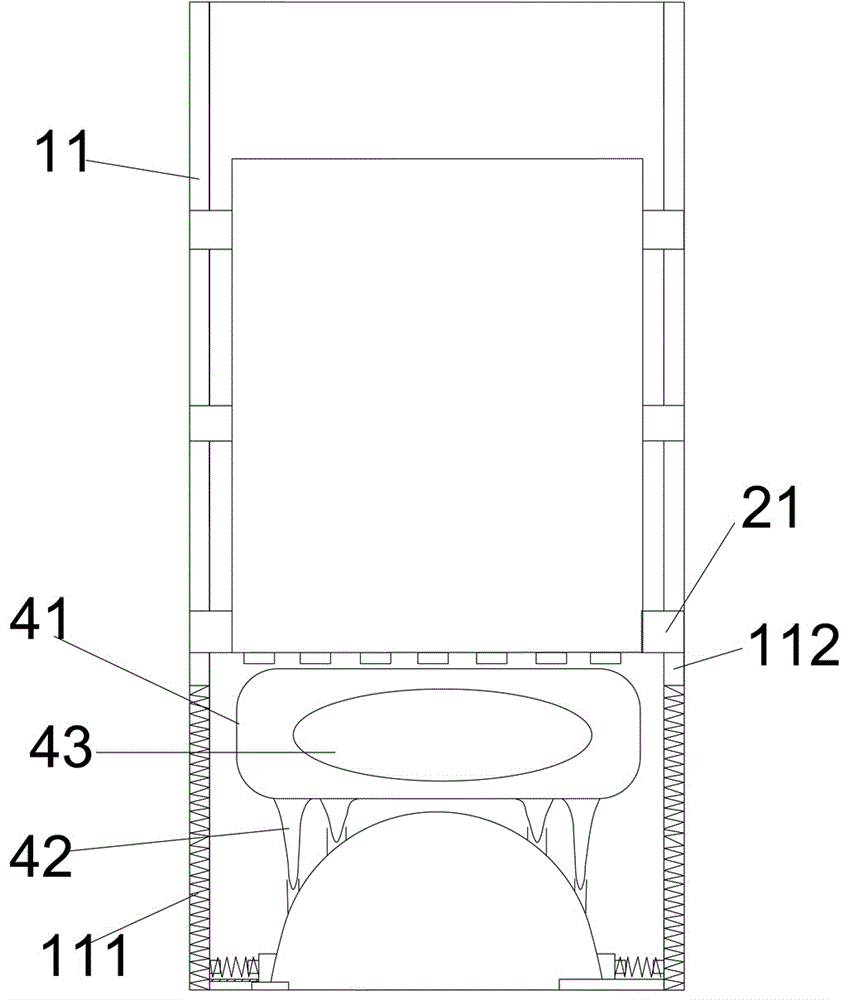

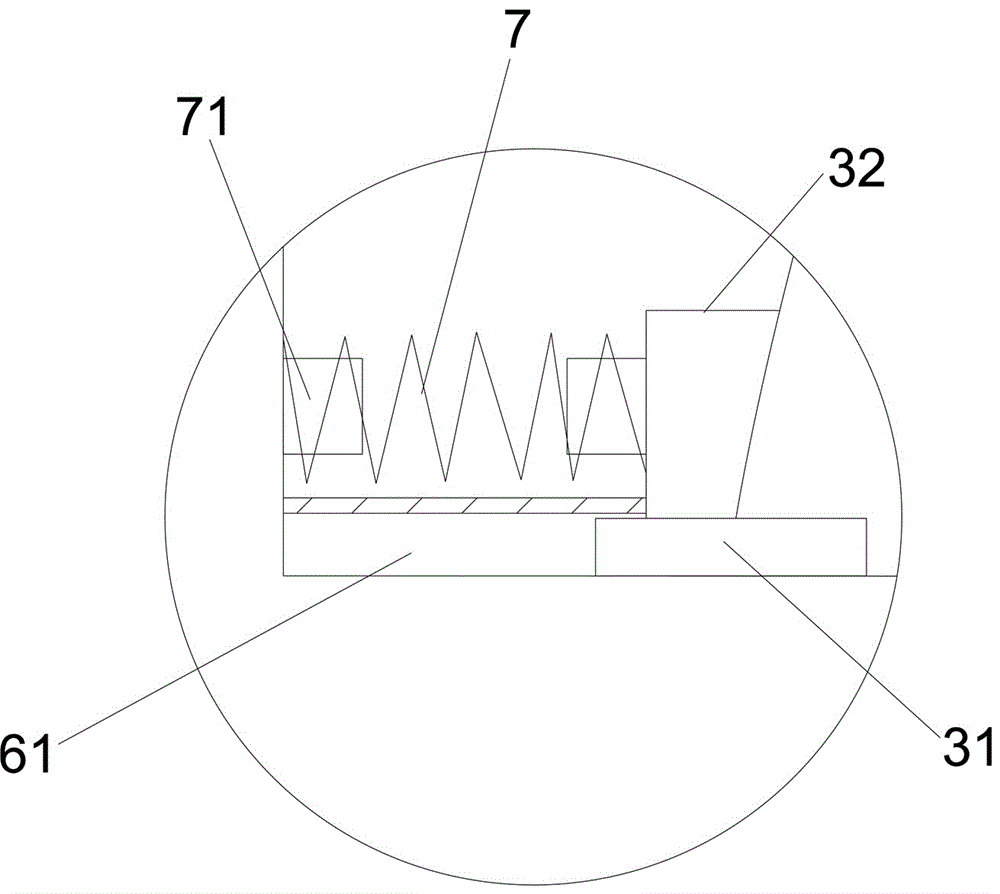

Shockproof buffer device for batteries for electric vehicle

InactiveCN106025128AReduce noiseGuaranteed bufferElectric propulsion mountingCell component detailsElectrical batteryElectric vehicle

The invention provides a shockproof buffer device for batteries for an electric vehicle. The device is provided with an external cabinet protection structure on the basis of a conventional metal box containing a battery pack; the metal box is internally arranged into a cabinet; and the metal box is connected with the inner wall of the cabinet by a spring assembly, so that buffer protection on the battery pack is achieved through the buffer action of springs. On this basis, in order to reduce noise generated by spring expansion in the driving process while the buffer range is ensured, the spring assembly is separated through a rubber plate, so that the noise of the springs is reduced. Meanwhile, a shell filled with a phase change material is arranged in the cabinet and is in contact with the metal box containing the battery pack, so that the heat dissipation effect is improved to a certain extent by the constant-temperature characteristic of the phase change material. An advantageous technical progress is achieved through outstanding technical improvement; and the shockproof buffer device has extremely high promotion potential.

Owner:天津中科先进技术产业有限公司

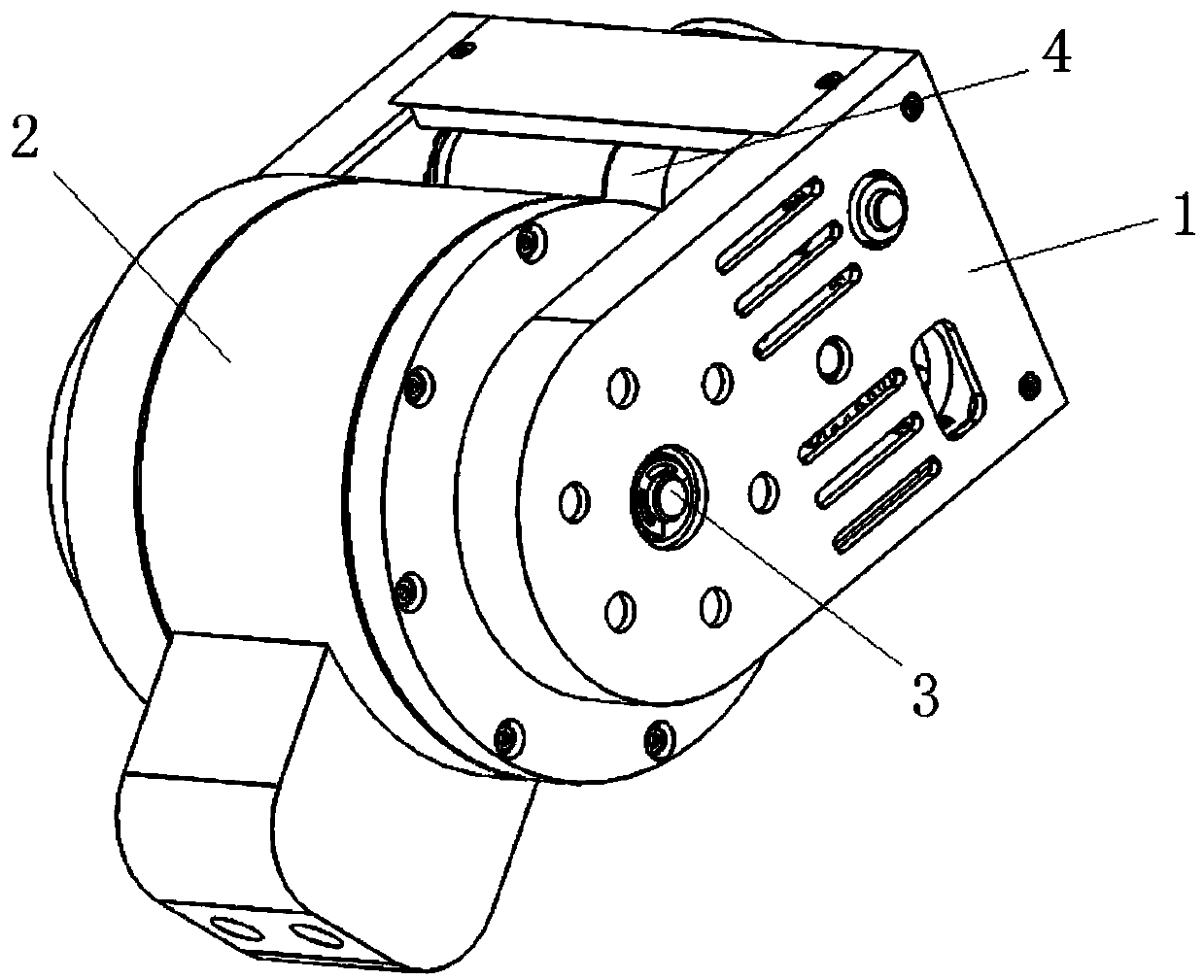

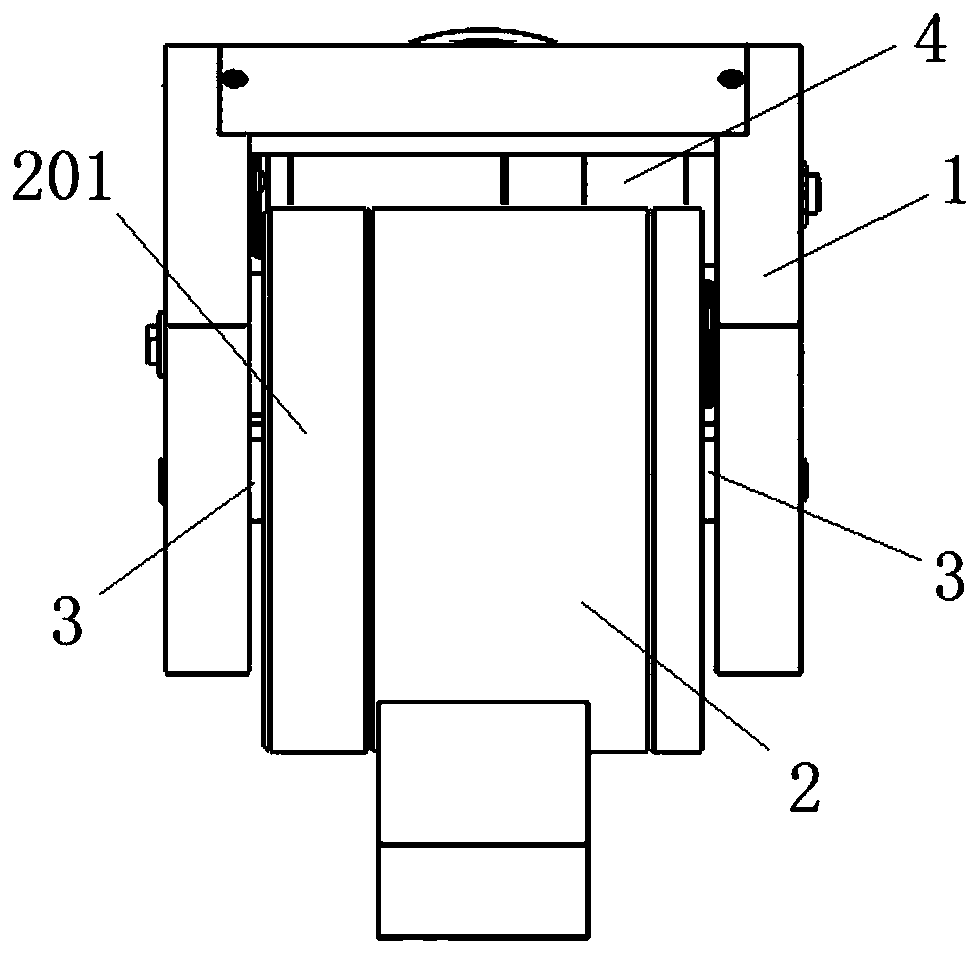

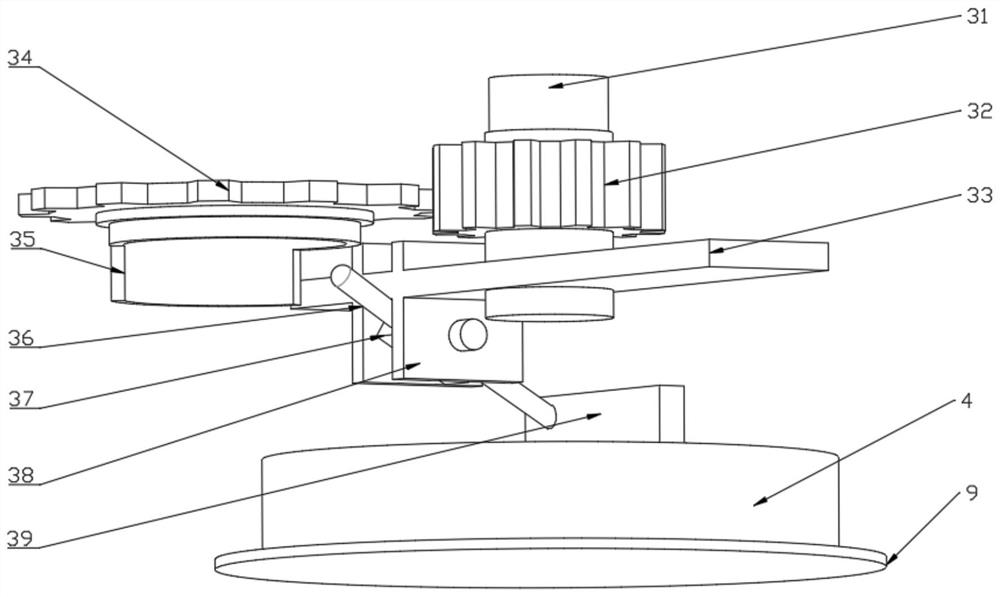

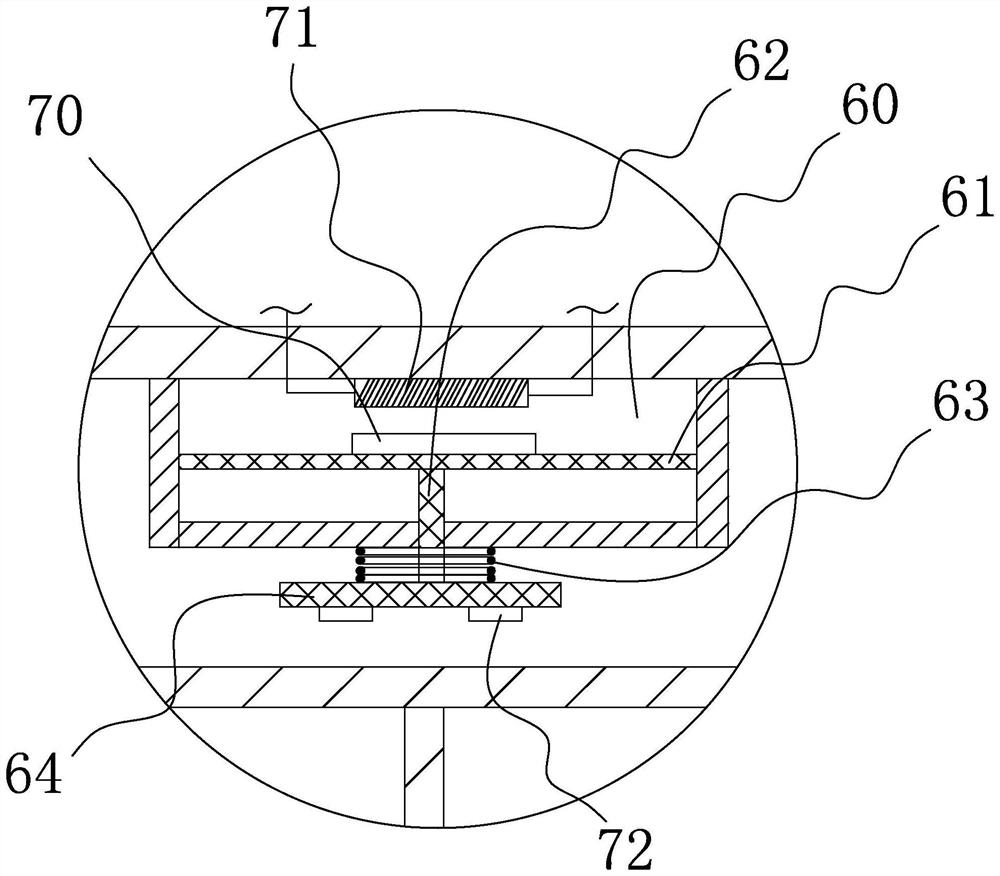

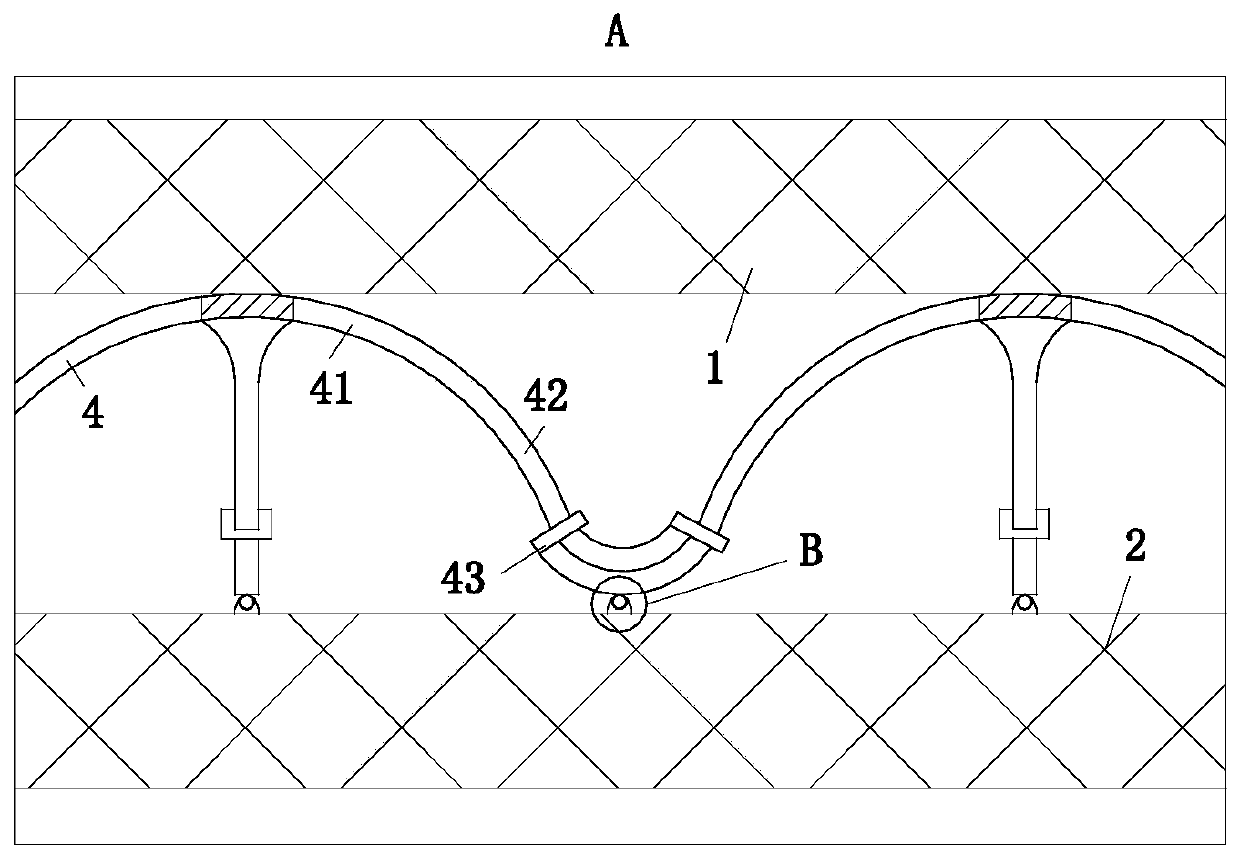

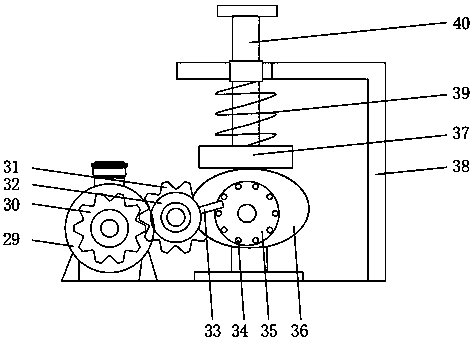

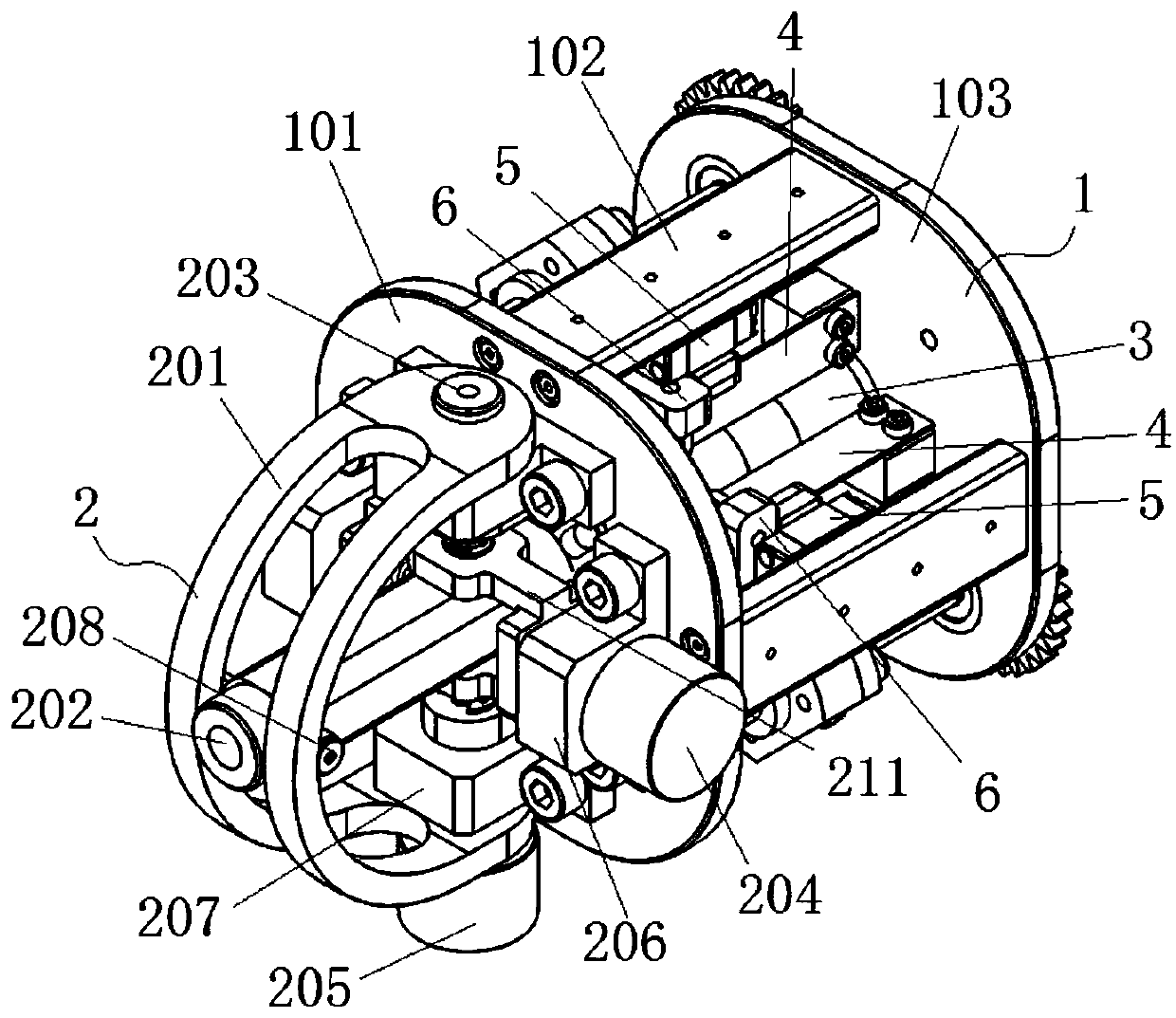

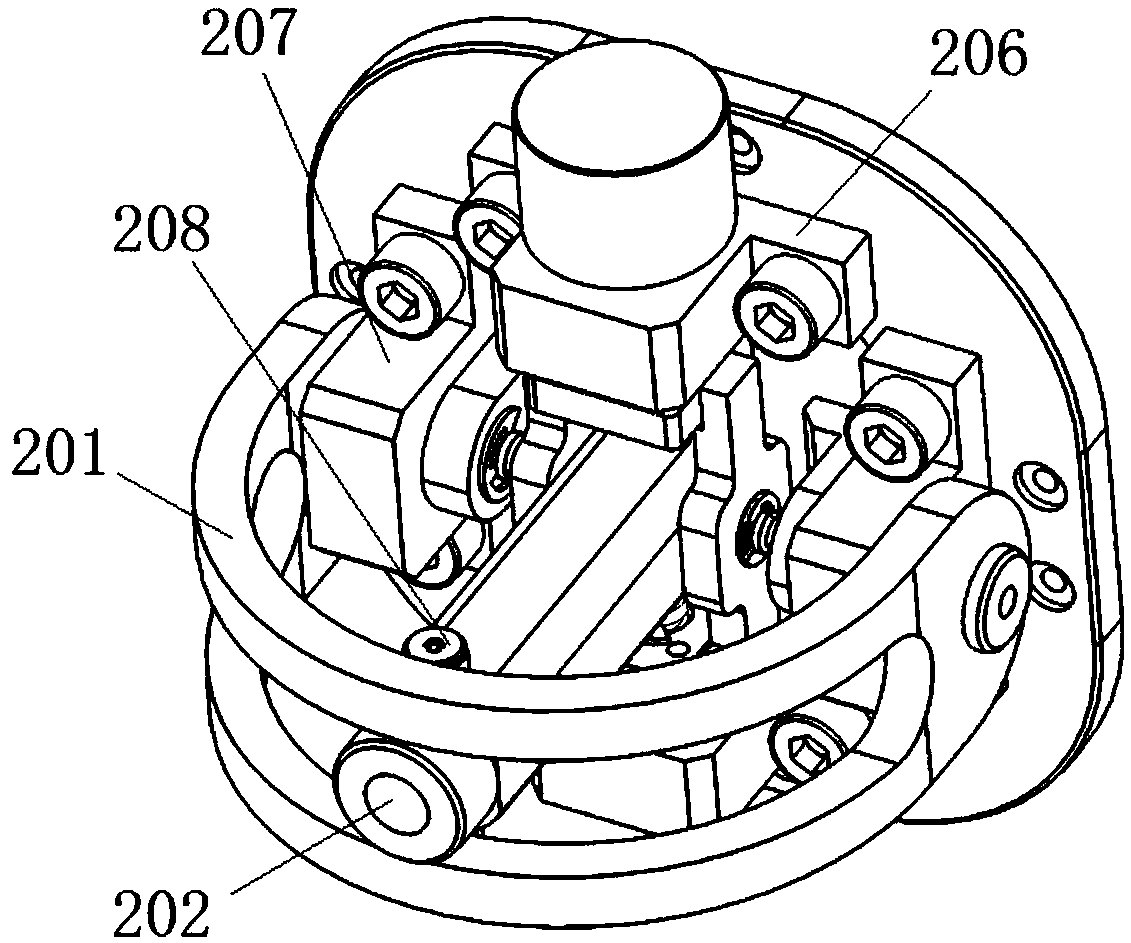

Variable-stiffness joint of robot

The invention relates to the field of robots, in particular to a variable-stiffness joint of a robot. The variable-stiffness joint comprises a supporting frame, a rotating connection seat, a rotatingdriving mechanism, a blade spring mechanism and a stiffness adjustment mechanism; the rotating connection seat is rotationally connected with the supporting frame; the rotating driving mechanism is arranged in the supporting frame; the rotating connection seat is driven by the rotating driving mechanism to rotate; the blade spring mechanism and the stiffness adjustment mechanism are arranged inside the rotating connection seat; the blade spring mechanism comprises a cam follow-up block and two blade springs; the cam follow-up block is driven by the stiffness adjustment mechanism to move; two cams are arranged on the cam follow-up block; the two blade springs are arranged between the two cams; a rotatable side cover is arranged on one side of the rotating connection seat; a side cover pressing column is arranged on the inner side of the side cover; and the side cover pressing column is arranged between the two blade springs. According to the variable-stiffness joint, energy buffering ofthe robot during jumping or collisions can be guaranteed, the cam follow-up block can be driven by the stiffness adjustment mechanism to move to change the radian of the blade springs, and nonlinearadjustment of the stiffness is realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

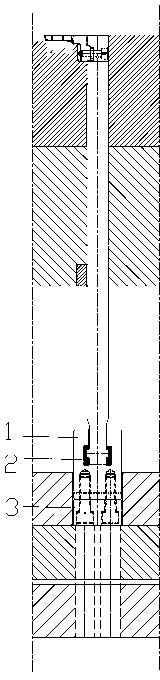

Angle ejection device for injection mold

InactiveCN102729416AGuaranteed bufferMake sure the lifter has cushioningMechanical engineeringOptics

The invention discloses an angle ejection device for an injection mold. The angle ejection device comprises an angle ejection and an angle ejection mounting portion. The angle ejection slides relatively to the angle ejection mounting portion and is rotatablely arranged on angle ejection mounting portion; the angle ejection mounting portion is arranged between a face needle plate and a bottom needle plate of the injection mold; the bottom needle plate is provided with a light hole and a limit screw passing through the light hole, and the front end of the limit screw is fixedly connected to the angle ejection mounting portion; and a polish rod of the limit screw is sleeved with a compression spring, which is positioned between the bottom of the light hole and the head of the limit screw, or positioned between the bottom of the bottom needle plate and the head of the limit screw. According to the angle ejection device for the injection mold provided by the invention, the compression spring is sleeved on the limit screw to exert certain pretension on the angle ejection mounting portion; and when the angle ejection device can not reset accurately due to thermal expansion and cold contraction, certain buffer of the angle ejection device can be ensured, so as to avoid problems of screw snap or angle ejection breaking.

Owner:毅昌金型(东莞)五金制品有限公司

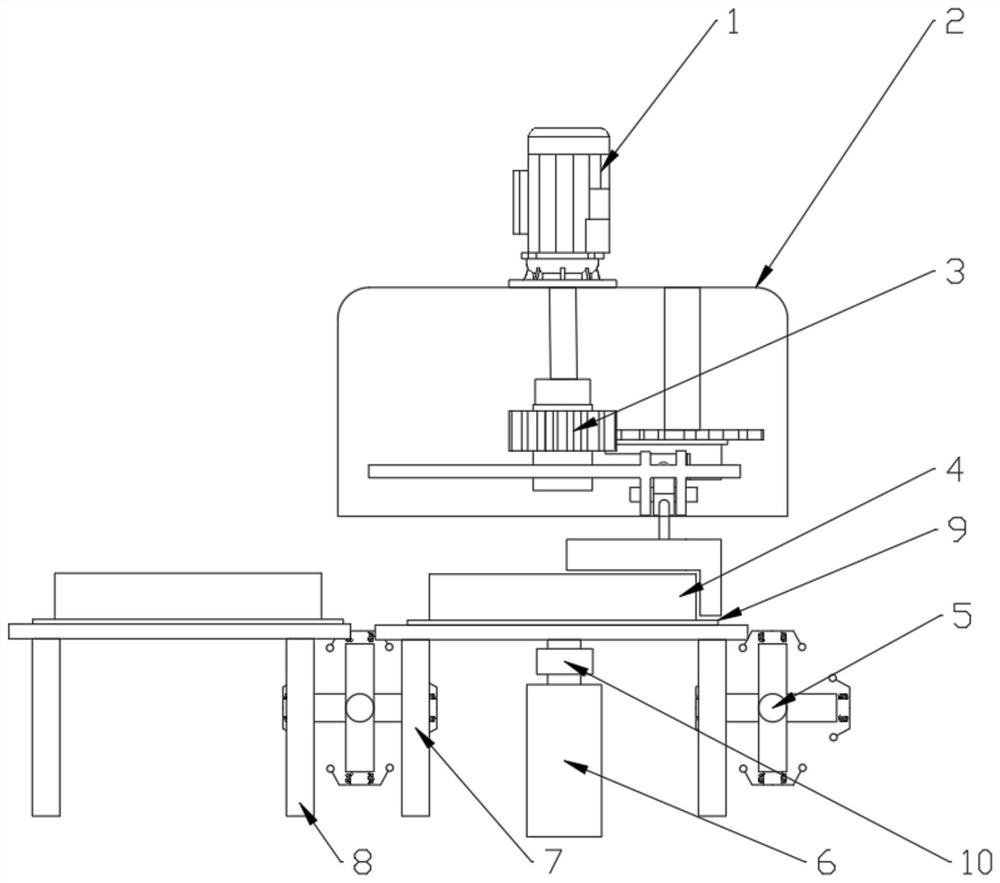

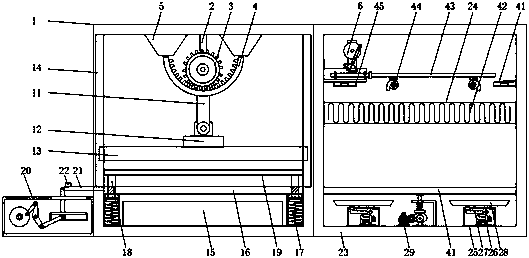

Cake cream flattening device for food processing

InactiveCN111838248AGuaranteed thicknessThickness hasBaked articles handlingGear wheelElectric machinery

The invention discloses a cake cream flattening device for food processing, which comprises a flattening pressing plate, a base plate and a shell, and a flattening mechanism is arranged in the shell;the flattening mechanism comprises the flattening pressing plate and a driving module, the flattening pressing plate does flattening motion on the cake through the driving module, one end of an adjusting rod is in sliding fit with an adjusting pressing block, and the other end of the adjusting rod is detachably connected with the flattening pressing plate; a second motor used for driving the baseplate to rotate is further connected to the lower portion of the base plate. During use, a first motor drives a first gear to rotate through the rotating shaft; furthermore, a second gear is driven torotate, due to the fact that one end of the adjusting rod is in sliding fit with an adjusting pressing block, when the adjusting pressing block rotates, the adjusting rod can be driven to rotate around the rotating point of the adjusting rotating block and the supporting block, and then the flattening pressing plate located at the other end of the adjusting rod can be driven to be matched with the second motor to do cream flattening motion attached to the cake and lifting motion during material changing.

Owner:陈玲

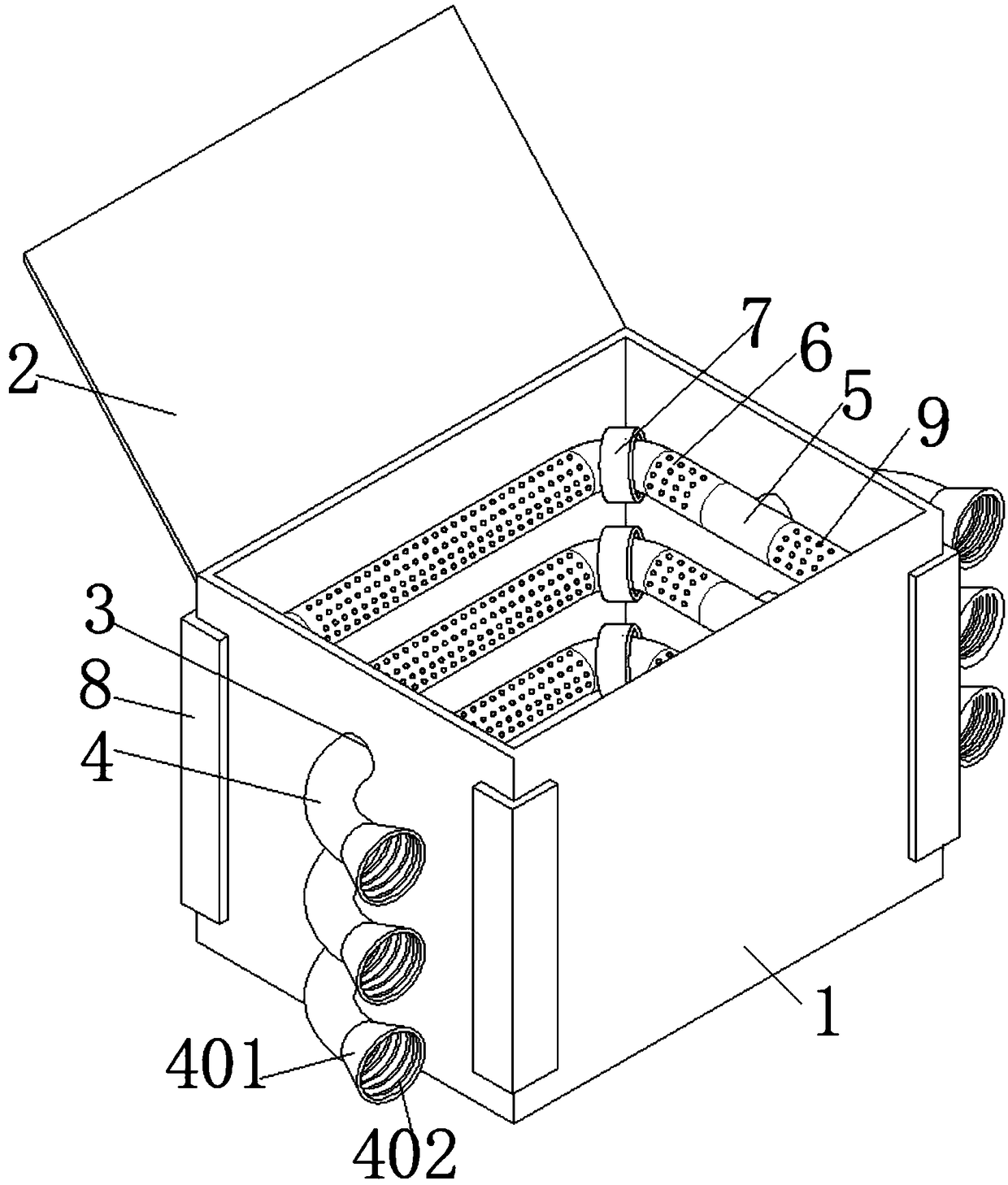

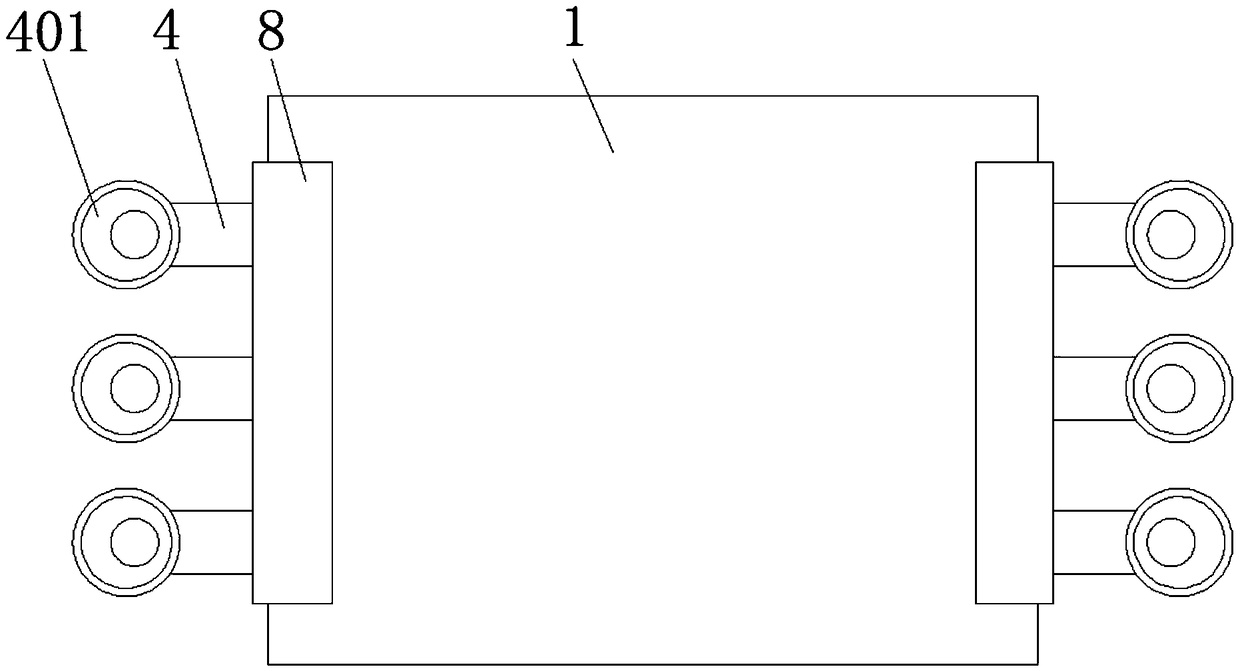

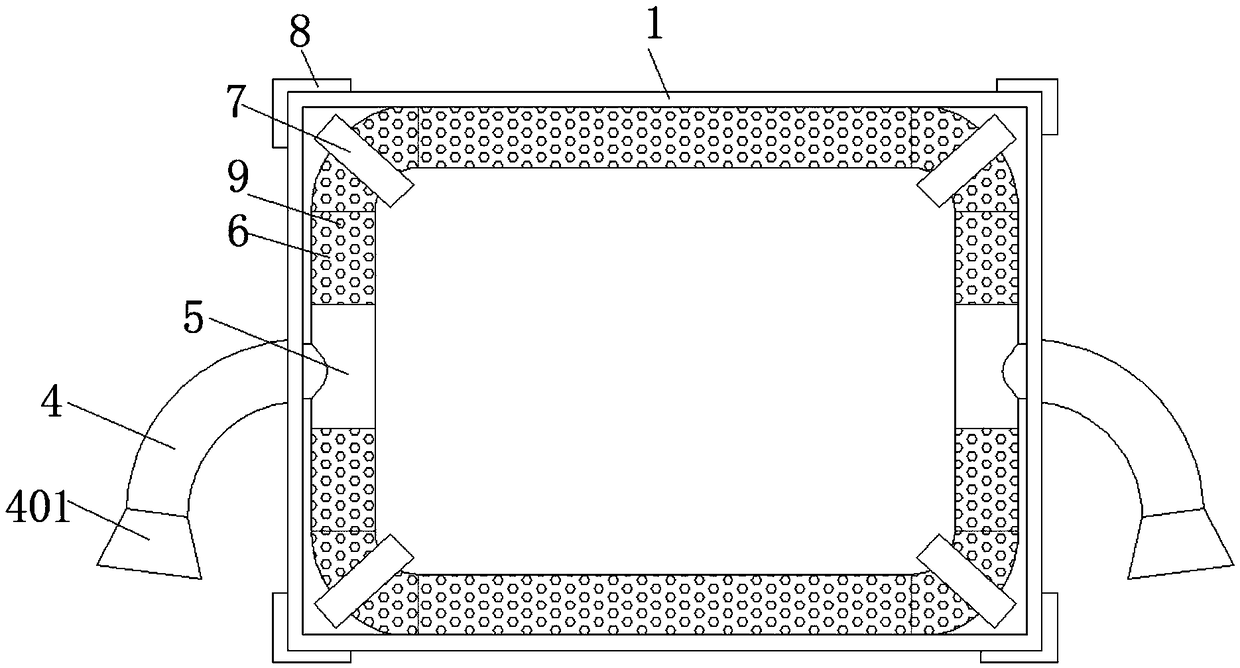

Inflatable anti-collision take-out food box

InactiveCN109229898AGuaranteed stabilityEasy to adjustContainers to prevent mechanical damageAirflowEngineering

The invention relates to the technical field of take-out food equipment and in particular to an inflatable anti-collision take-out food box, comprising a take-out food box body, wherein the back sideof the take-out food box body is hinged to a box cover through a hinge; the top of the take-out food box body is provided with an opening; each of left and right sides of the take-out food box body isprovided with three groups of air inlets; and the left and right sides of the take-out food box body are in threaded connection with airflow inlet pipes communicating with the air inlets. The inflatable anti-collision take-out food box solves the problem that because of fast driving speed, food containers in the take-out food box are likely to repeatedly collide with the inner side of the take-out food box such that soup in the food containers is likely to splash out and causes inconvenience to diners. The inflatable anti-collision take-out food box is ingeniously designed. When a deliverer drives fast, airflow is generated inside a U-shaped air bag so as to ensure that the food containers are buffered during the collision process, and the soup in the food containers is unlikely to splashout in order for the diners to eat.

Owner:田飞标

Overturning device for motor vehicle

The invention relates to a flap arrangement for motor vehicles, whereby the flap arrangement (1) includes a locking surface (2) with one essentially perpendicularly to a side surface (3) of the locking surface and at least one buffer (4,5), which has a first range as well as a second range, where the first range (4a, 5a) is formed by a mechanically resistant material and equips a click-stop device (6,7), which behind-seizes the side surface and the second range for the absorption, noise reduction and way limitation between the flap arrangement on the one hand and an edition range on the other hand from a soft material exists and / or with a section of the edition range in connection, consisting of a soft material, is bringable.

Owner:FAURECIA INNENRAUM SYST

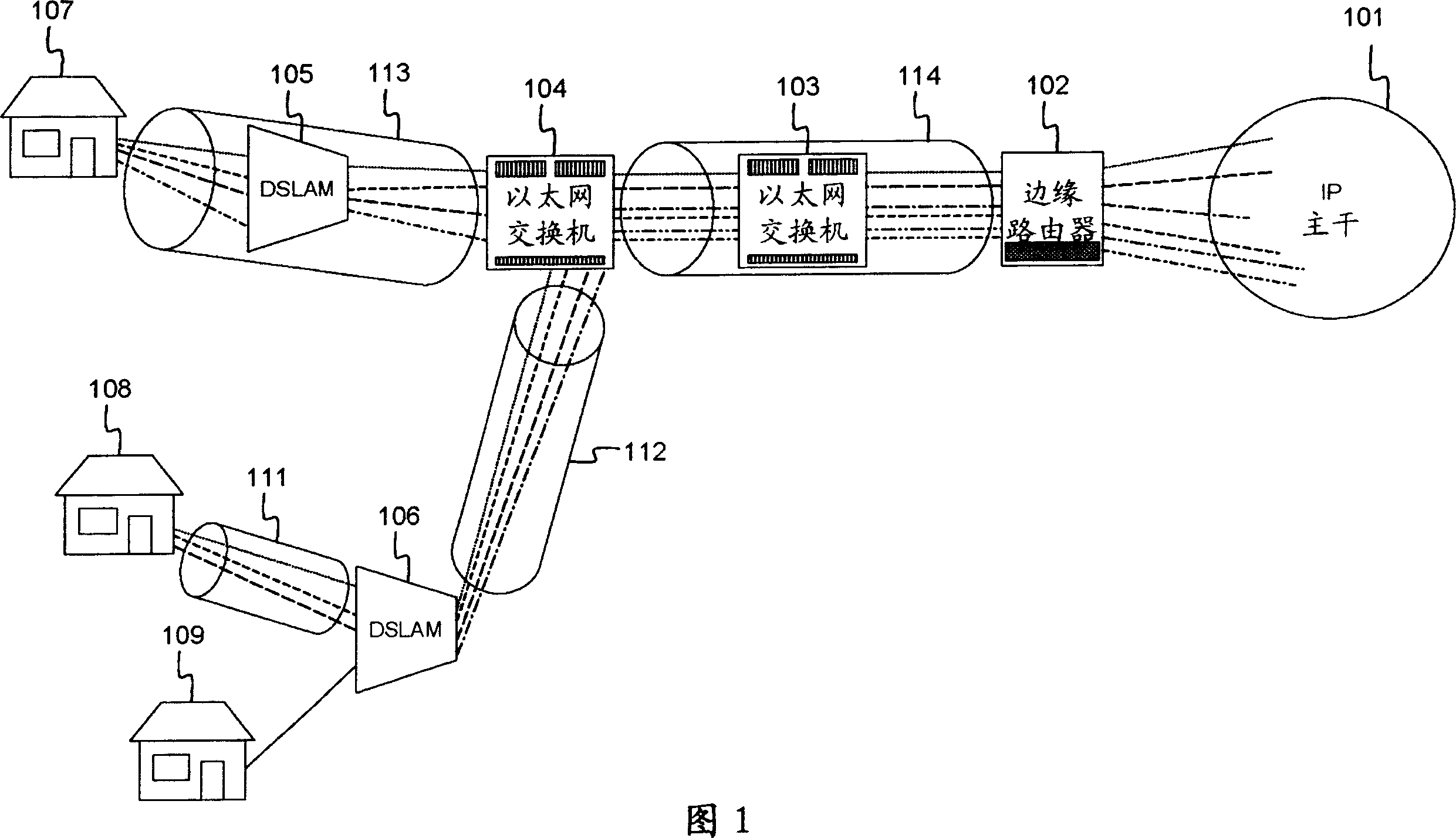

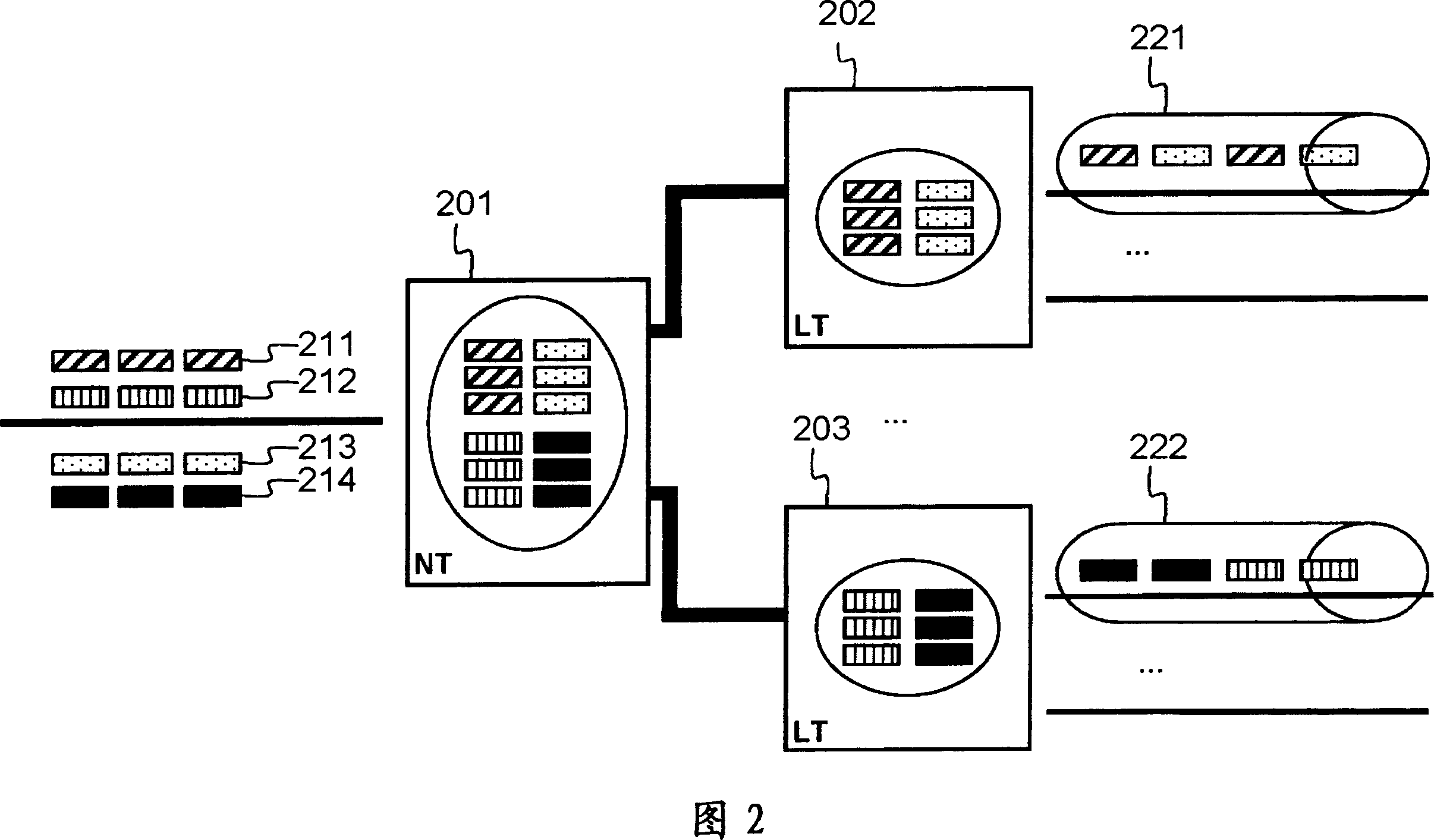

Transmission control protocol host with transmission control protocol convergence module

InactiveCN1984080ATransparent and easy to useEasy to implementData switching networksComputer scienceNetwork segment

A sending transmission control protocol (TCP) host is used in a first network node (106) to transmit TCP flows over a network segment to a receiving TCP host in a second network node (104). The sending TCP host comprises a TCP convergence module for aggregating all TCP flows through the network segment between the first network node (106) and the second network node (104) into an aggregate TCP flow (112). The receiving TCP host comprises a TCP convergence module for disaggregating the TCP flows from the aggregate TCP flow (112).

Owner:ALCATEL LUCENT SAS

Production process of polyester bag-pasting-preventing needled felt

ActiveCN114457507AImprove acupuncture effectGuaranteed structural strengthSynthetic resin layered productsTextile/flexible product manufacturePolyesterPolymer chemistry

The invention discloses a production process of a terylene bag-pasting-preventing needled felt, and aims to provide a production process which is used for coating a terylene needled felt, finishing and constructing a multi-component mixed structure, has a good bag-pasting-preventing effect, brings chopped fibers into the thickness direction of a filter material through a felting needle by virtue of a low-damage needling forming technology, and improves the bag-pasting-preventing performance of the terylene bag-pasting-preventing needled felt. According to the technical scheme, the production process is characterized in that the polyester needled felt is subjected to film covering after finishing and multi-component mixed structure construction, the water spraying grade is larger than the fourth grade, the oleophobic grade is larger than the third grade, the bag pasting prevention effect is good, and the production efficiency is improved. The chopped fibers are brought into the thickness direction of the filter material through a pricking needle through a low-damage needling forming technology, the interlayer strength of a fiber web is improved, and the method is suitable for the technical field of needled felt production processes.

Owner:浙江华基环保科技有限公司

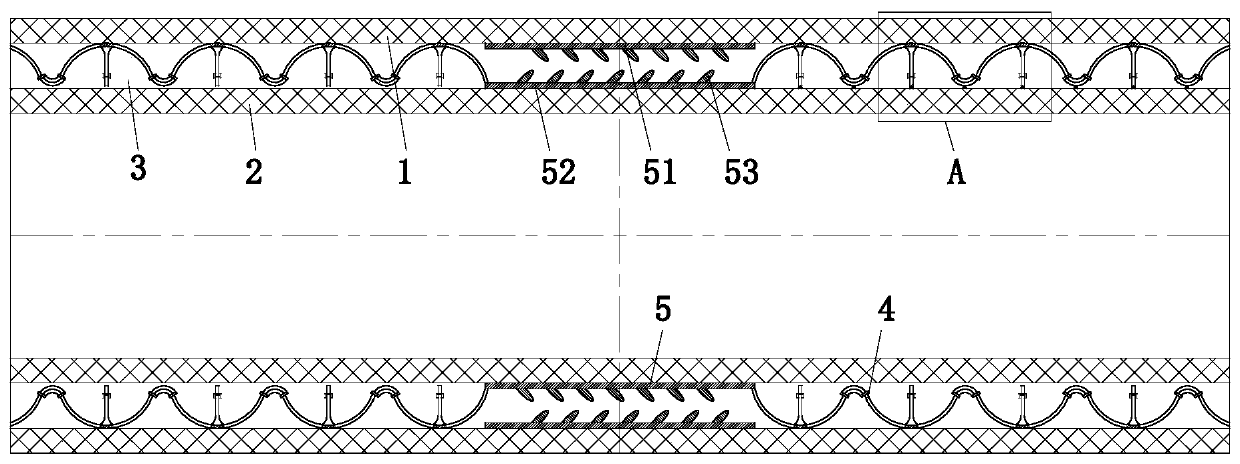

Brake buffering device of air flotation type suspending device of solar wing plates

ActiveCN106122363AAvoid influencePrevent direct reboundNon-rotating vibration suppressionProduct gasEngineering

The invention discloses a brake buffering device of an air flotation type suspending device of solar wing plates. The brake buffering device comprises a buffering air cylinder, an air cylinder fixing base, an electromagnet, a buffering pad and a buffering spring, wherein the buffering air cylinder is fixed to the air cylinder fixing base, and the buffering pad and the buffering spring are installed on a piston rod of the buffering air cylinder in a sleeving mode; an air inlet is formed in the end, away from the electromagnet, of the buffering air cylinder and is connected to an air inlet pipeline, the air inlet pipeline is provided with a throttling valve and an air outlet pipeline, and the air outlet pipeline is provided with a one-way pressure regulating valve; and the inner wall of a cylinder barrel of the buffering air cylinder is made of cellular materials. The brake buffering device can effectively absorb the energy generated by inertia in the braking process of the suspending device, and the phenomenon that the suspending device influences the solar wing plates due to inertial motion can be prevented; and in the motion process of a piston of the buffering air cylinder, air cavities in two sides of the piston can communicate with each other through the cellular materials of the inner wall of the cylinder barrel of the buffering air cylinder, the phenomenon that the piston is directly rebounded under the effect of the spring is prevented, gas is prevented from being transferred too fast, and therefore the buffering effect is better.

Owner:ZHEJIANG UNIV OF TECH

High-strength polyethylene pipe for building

ActiveCN109780374AAvoid damageSo as not to damagePipe protection against damage/wearArchitectural engineeringHigh intensity

The invention belongs to the technical field of polyethylene pipes, and specifically discloses a high-strength polyethylene pipe for a building. The high-strength polyethylene pipe for the building comprises an outer pipe body, an inner pipe body, a support module and a buffer module, wherein the outer pipe body sleeves the outer side of the inner pipe body, and an annular cavity is formed betweenthe inner wall of the outer pipe body and the outer wall of the inner pipe body; the support module and the buffer module are arranged at the inner side of the annular cavity; and the support modulecomprises a first annular steel sheet, a second annular steel sheet and insertion-connection teeth; the first annular steel sheet is arranged on the inner wall of the middle part of the outer pipe body; the second annular steel sheet is arranged on the outer wall of the middle part of the inner pipe body; and the insertion-connection teeth are arranged on the adjacent sides of the first annular steel sheet and the second annular steel sheet separately. According to the high-strength polyethylene pipe for the building, the outer pipe body and the inner pipe body are supported through the co-action of the buffer module and the support module, so that the buffer efficiency is effectively increased; and force relief is carried out between the outer pipe body and the inner pipe body by virtue of a cross elastic frame or an elastic packing auger, so that the damage probability of the outer pipe body due to local stress is lowered, and the service life of the polyethylene pipe is prolonged.

Owner:哈尔滨金凌科技有限公司

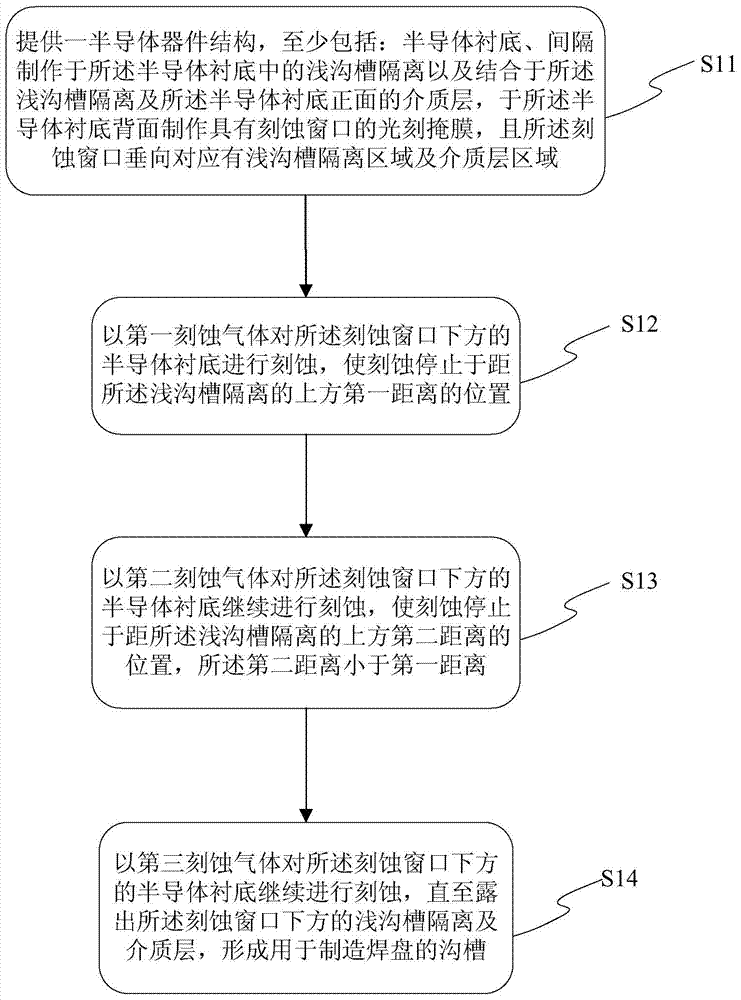

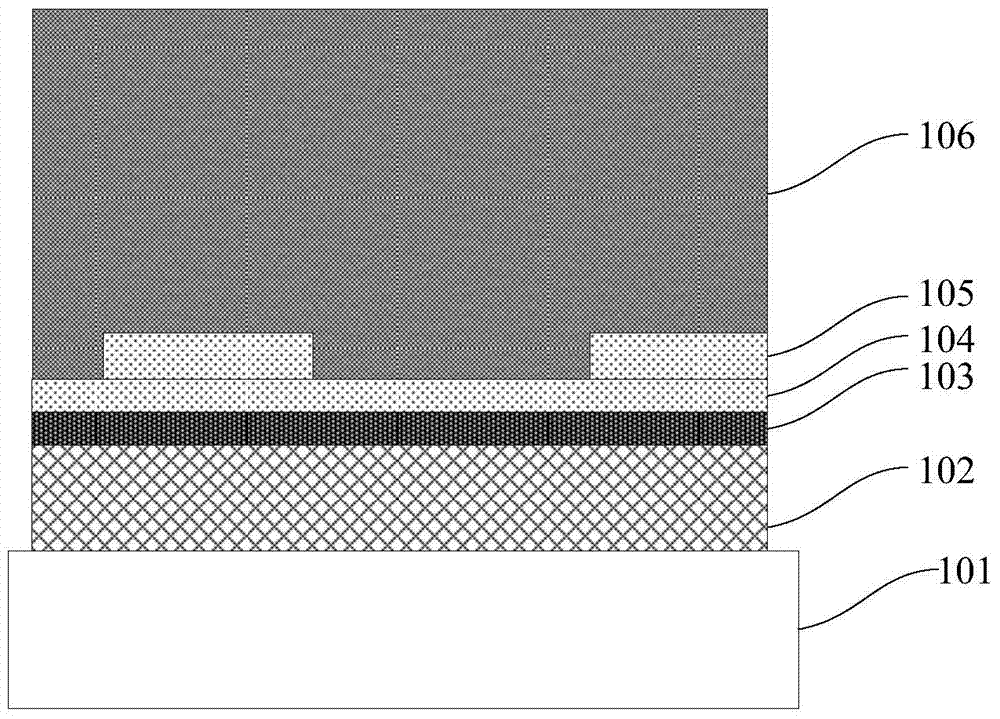

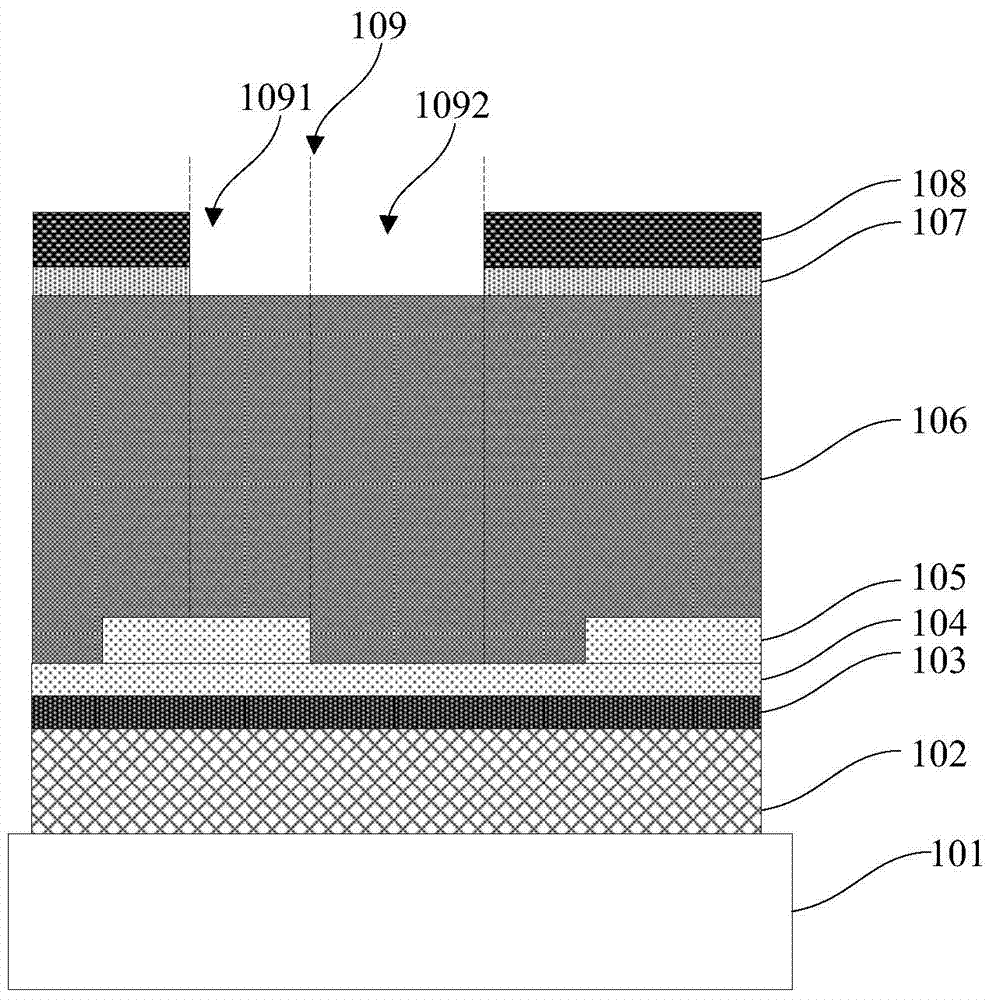

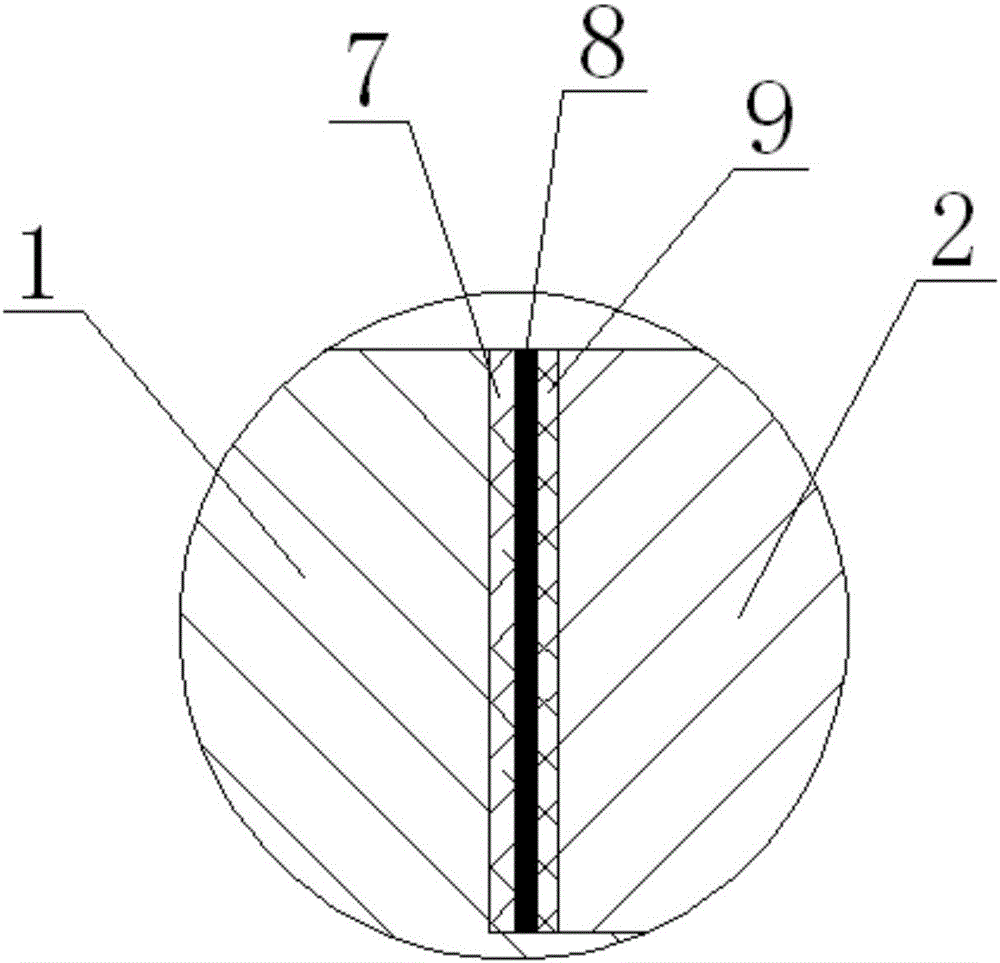

Manufacturing method of semiconductor device

ActiveCN104517975AGuaranteed bufferGuaranteed smoothRadiation controlled devicesPower semiconductor deviceEngineering

The invention provides a manufacturing method of a semiconductor device. The manufacturing method includes the following steps that: 1) a semiconductor device substrate including a semiconductor substrate, shallow trench isolation and a dielectric layer is provided, and a photolithographic mask with an etching window is manufactured on the back surface of the semiconductor substrate; 2) the semiconductor substrate is etched with first etching gas, and etching is performed until etching reaches a position which is located above the shallow trench isolation and is separated from the shallow trench isolation by a first distance; 3) the semiconductor substrate is further etched with second etching gas, and etching is performed until etching reaches a position which is located above the shallow trench isolation and is separated from the shallow trench isolation by a second distance; and 4) the semiconductor substrate is further etched with third etching gas until the shallow trench isolation and the dielectric layer located below the etching window are exposed, so that a trench for manufacturing a pad can be formed. With the manufacturing method of the semiconductor device of the invention adopted, the trench of which the surface is flat and of which the semiconductor substrate, the shallow trench isolation and the dielectric layer are not excessively etched, can be obtained, so that subsequent metal pad manufacture can be benefitted, and therefore, the performance of the device can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Shoe pads capable of adjusting buffering power

The invention discloses a pair of shoe pads capable of adjusting buffering power, comprising shoe pad surface layers and buffering cushions, wherein the arches of the shoe pad surface layers are provided with upwards-concaved concave parts, the buffering cushions and the concave parts are fit with each other and fixed with each other by disassemble fixing devices, the buffering cushions are internally provided with filling cavities, the filling cavities are internally provided with elastic filling materials, and each shoe pad is provided with the plurality of elastic filling materials with different rigidities. The shoe pads capable of adjusting buffering power provided by the invention can be adjusted according to the requirement of various foot shapes.

Owner:ZHEJIANG RED DRAGONFLY FOOTWEAR

Preparation method of epoxidized solution polymerized styrene-butadiene rubber coating

InactiveCN104530837ASolve instabilityPlay the role of protection and beautification decorationRubber derivative coatingsPolyamide coatingsPolymer sciencePolyamide

The invention discloses a preparation method of an epoxidized solution polymerized styrene-butadiene rubber coating. The preparation method comprises the following steps: carrying out epoxidizing modification on solution polymerized styrene-butadiene rubber by virtue of H2O2 and HCOOH peracid system to prepare an epoxidized solution polymerized styrene-butadiene rubber, dissolving the synthesised epoxidized solution polymerized styrene-butadiene rubber in a certain amount of solvent, placing the mixed solvent in a sand mill together with pigments and fillers, an antiager and the like, and grinding and dispersing, discharging when the fineness reaches 20mu m to obtain the component A of the epoxidized solution polymerized styrene-butadiene rubber coating, dissolving polyamide resin in a certain amount of a solvent, adding a curer and a curing accelerator, placing in the sand mill for grinding and dispersing, discharging when the fineness reaches 20mu m to obtain the component B of the epoxidized solution polymerized styrene-butadiene rubber coating, mixing the component A and the component B of the epoxidized solution polymerized styrene-butadiene rubber coating, uniformly stirring and ageing, and then coating a plate with the epoxidized solution polymerized styrene-butadiene rubber coating, so that the performances of the coating can be detected.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Automatic car washer adopting photoelectric sensing technology

PendingCN111497794ASave waterAvoid pollutionVehicle drying apparatusCleaning apparatus for vehicle exteriorsElectric machineryLeather belt

The invention provides an automatic car washer adopting a photoelectric sensing technology. The car washer comprises a rack and a base, wherein the rack is mounted above the base; a moving device is mounted in the base; the moving device comprises a first bearing, a second bearing, a belt and a motor; the motor is connected with the first bearing; the first bearing and the second bearing are connected through the belt. A sewage collecting device is mounted above the base; a clamping groove is formed in the upper part of the sewage collecting device; an inlet is formed in the lower portion of the left side of the rack. An outlet is formed below the right side of the rack; a first photoelectric sensor is mounted above the inlet; a second photoelectric sensor is arranged above the outlet, a storage device, a cleaning chamber, an atomizing device, a drying device and a drying chamber are arranged in the rack, the cleaning chamber and the drying chamber are distributed above the sewage collecting device left and right, the storage device is installed above the cleaning chamber, and the drying device is installed above the drying chamber.

Owner:SHANGHAI GUBOT AUTO TECH CO LTD

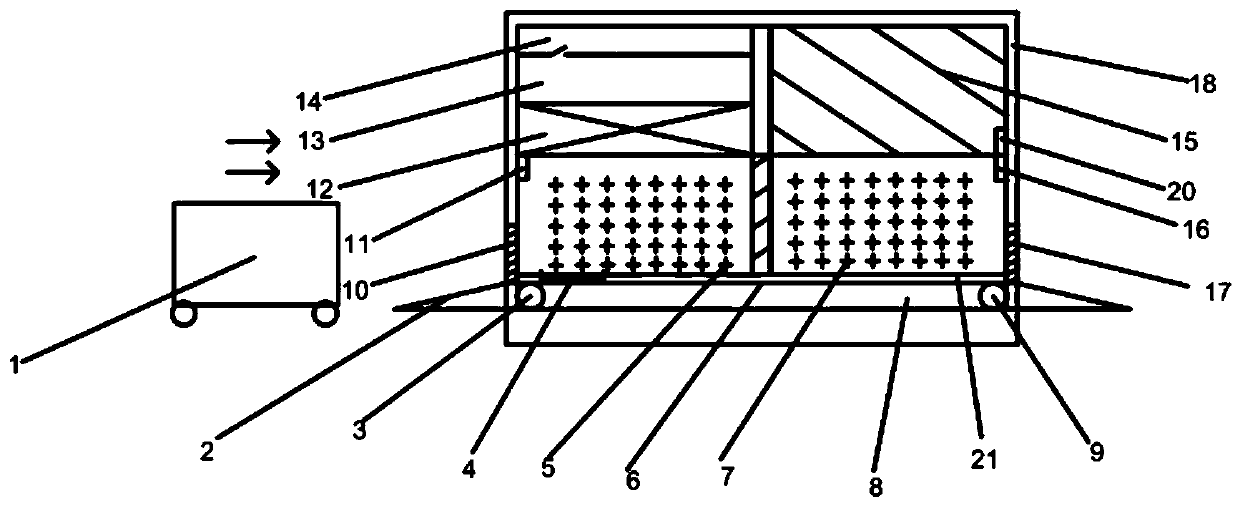

Wood board gluing pressing and drying device

InactiveCN107677086AReach deliveryAchieve the purpose of extrusionDrying gas arrangementsDrying machines with progressive movementsPulp and paper industryWood plank

The invention discloses a drying device for wood glue pressing, which comprises an extruding work box, the top of the inner wall of the extruding work box is fixedly connected with a connecting push rod, and the bottom end of the connecting push rod is rotatably connected with a power gear. The bottom of the gear is meshed with a half-gear, and the top of both ends of the half-gear is fixedly connected with a fixed auxiliary frame. Both ends of the half-gear pass through the fixed auxiliary frame and extend to the inside. A spring is fixedly connected to one side of the inner wall of the groove, and a sliding link is fixedly connected to the end of the spring away from the inner wall of the sliding groove. The invention relates to the technical field of wood product processing. The wood glue pressing drying device solves the problem of conveying and extruding wood boards and drying glued wood boards, ensuring the power output of the glue pressing machine during the wood board glue pressing process. Automatic feeding can liberate labor and improve automation. process, to ensure the uniformity and quality of wood drying, and to improve the yield rate.

Owner:湖州南浔丽学木制品厂

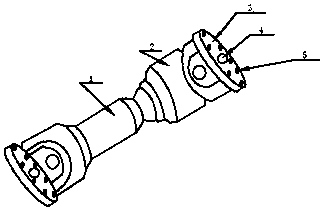

Coupler for car

The invention discloses a coupler for a car. The coupler comprises a connecting shaft, conversion parts, connecting pieces, center holes, positioning holes, pins, driven shafts, buckles and driving shafts; the conversion parts are arranged on the left side and the right side of the connecting shaft, the driving shafts are arranged on the outer sides of the conversion parts, the buckles are arranged on the outer sides of the driving shafts, the driven shafts are arranged in the buckles, the pins are arranged at the two ends of each driven shaft, the connecting pieces are arranged on the front ends of the conversion parts, the center holes are formed in the center portions of the connecting pieces, and the positioning holes are formed in the end faces of the connecting pieces. The coupler iseasy and convenient to mount, safety is higher, machining cost is low, the mounting, dismounting and maintaining process is simple and convenient, the coupler can ensure higher centering of two shafts, transmission torque is large, buffering is ensured, vibration is reduced, during work, deforming or thermal expansion is not prone to happening, and therefore the occurrence probability of axial shifting and the like caused by reasons of deforming, or thermal expansion and the like during work is low.

Owner:常州海洛轴承制造有限公司

Storage apparatus for hardware products

InactiveCN109533656AGuaranteed stabilityAvoid shakingContainers to prevent mechanical damageRigid containersFixed frameEngineering

Owner:江苏新宝得换热科技有限公司

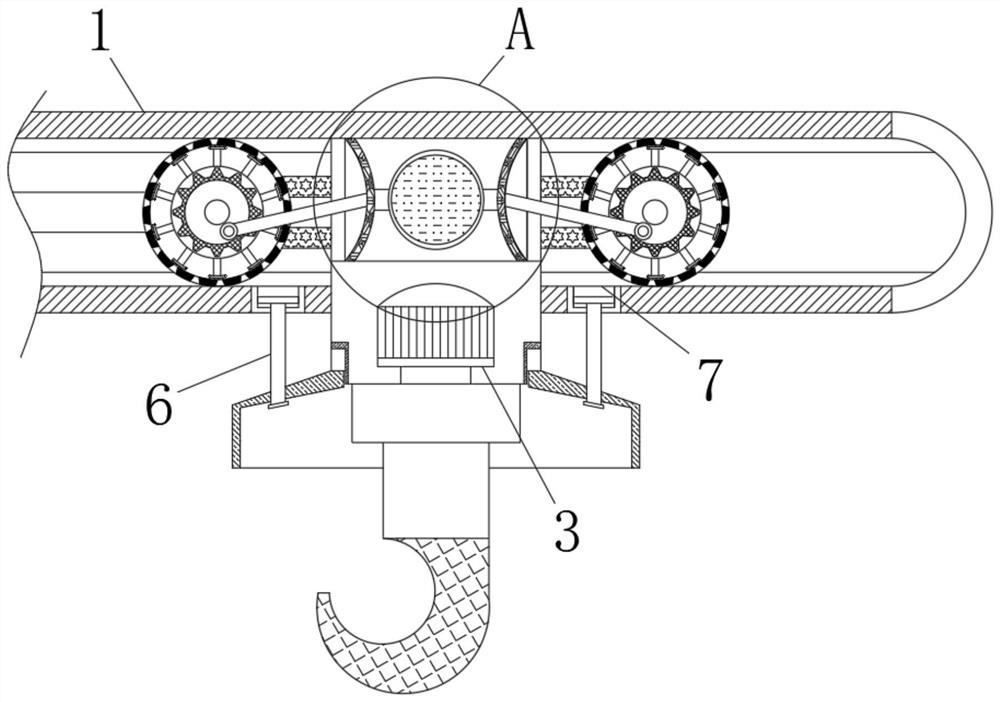

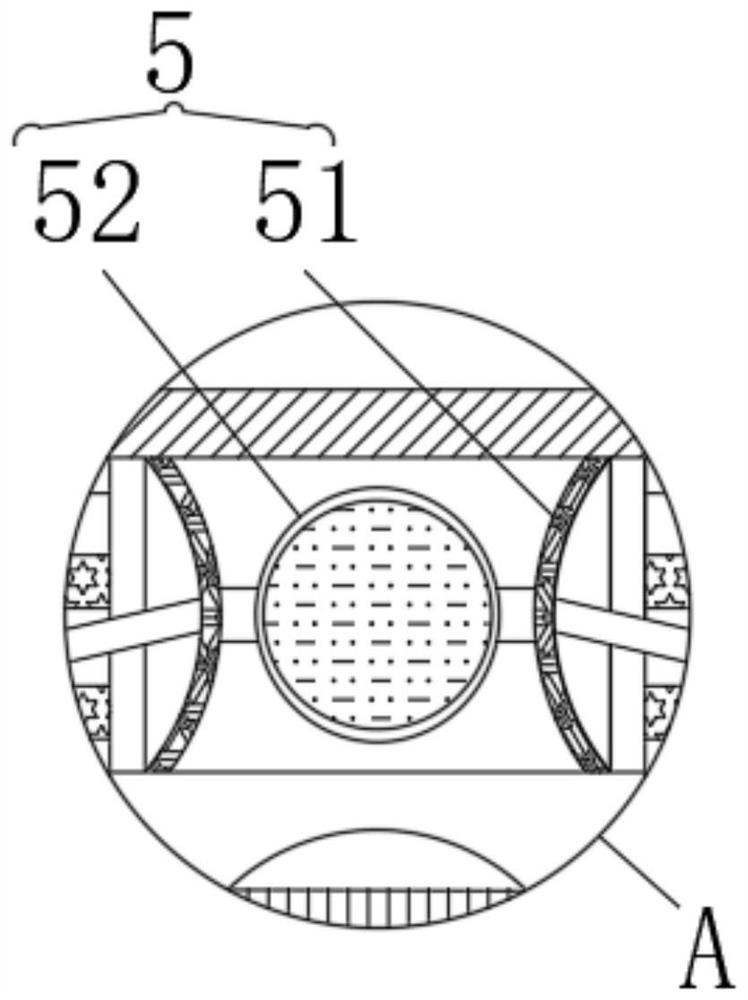

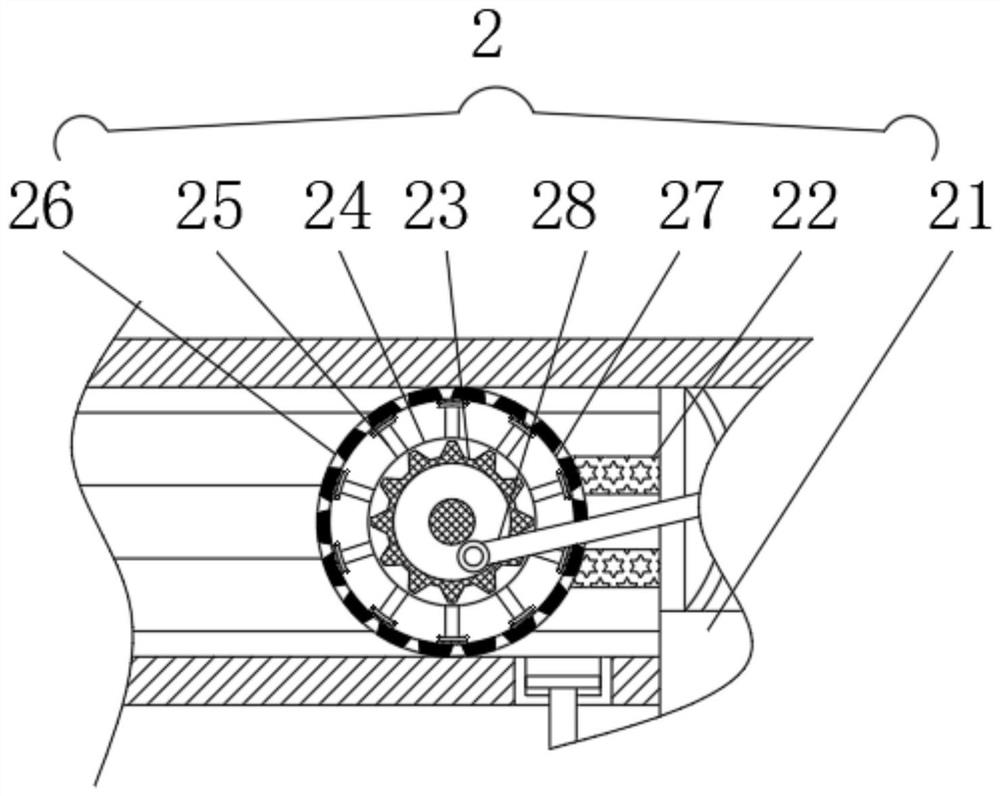

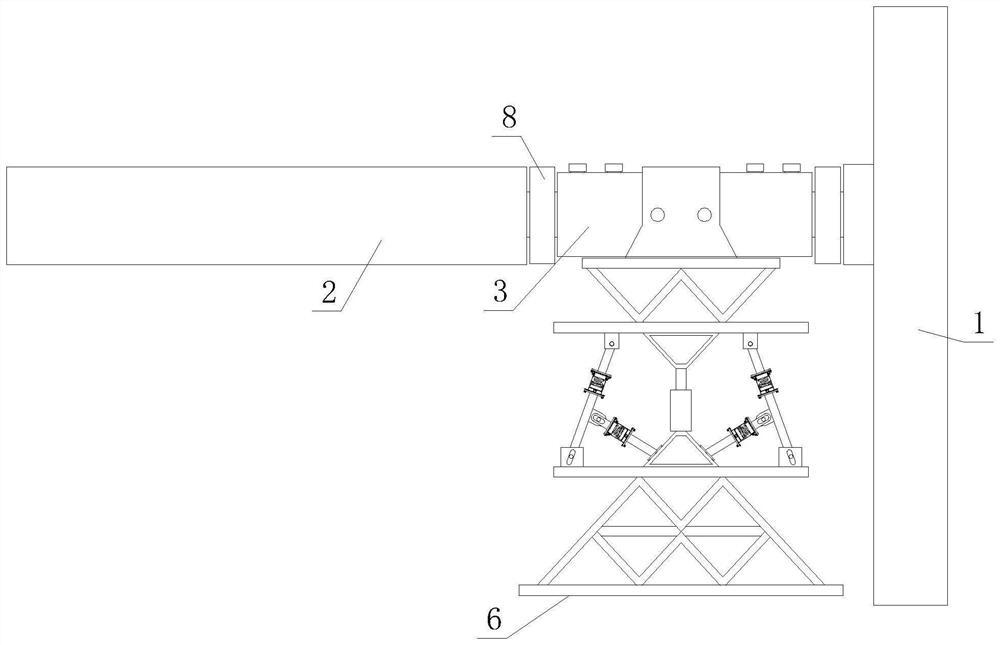

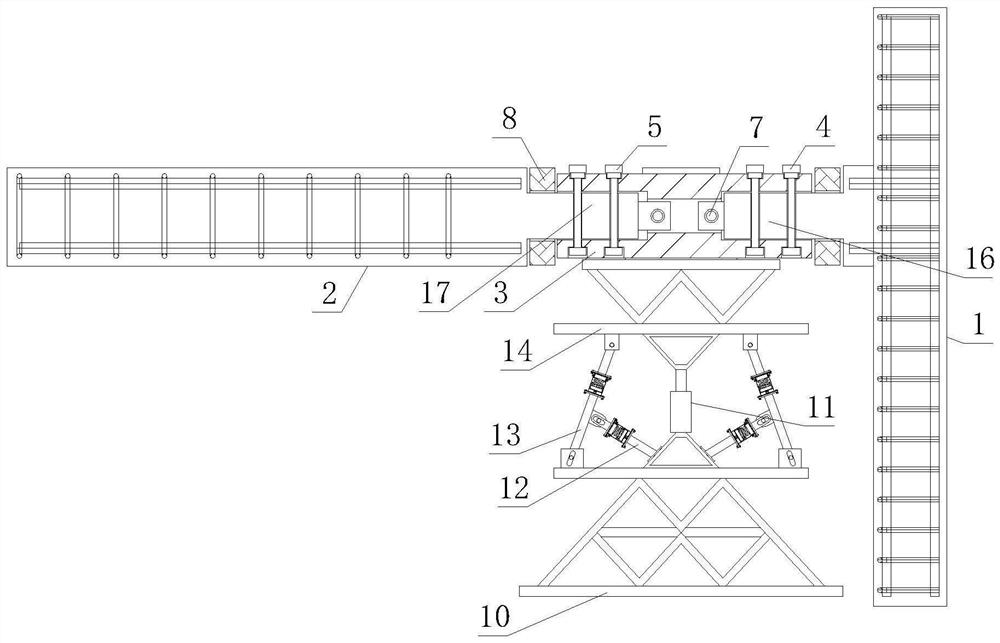

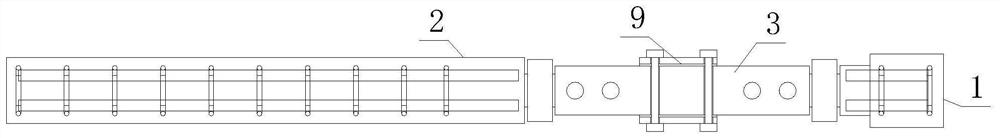

Cantilever beam crane

InactiveCN113734969ABrush evenlyTo achieve the effect of filling lubricating oilLubricant transferConduits/junctionsCantilevered beamClassical mechanics

The invention relates to the technical field of cranes, and discloses a cantilever beam crane which comprises a fixing plate. A liquid injection mechanism is fixedly mounted in the fixing plate, a driving device is fixedly mounted at the lower end of the fixing plate, and an adjusting mechanism is rotatably connected to the lower end of the driving device. According to the cantilever beam crane, in the process that a connecting plate slides in the fixing plate, a lifting hook can be driven to move left and right in the fixing plate, meanwhile, a rotating wheel is driven to rotate, then the rotating wheel can drive a fixing ring to rotate in a liquid storage ring in the rotating process, an upper brush rod acts at the same time, and therefore lubricating oil in the liquid storage ring can be evenly brushed away. Meanwhile, the rotating wheel can be matched with the action of a guide rod in the rotating process to apply pressure to an elastic plate, the elastic plate continuously extrudes the liquid storage bag, so that the lubricating oil in the liquid storage bag can be extruded into the liquid storage ring, then the actions are repeated, and the effect of filling the lubricating oil is achieved.

Owner:吴法海

Damping cushion valve rod

The invention discloses a damping cushion valve rod which comprises a shell, a valve seat and a valve rod body. The valve seat is installed in the shell. One end of the valve rod body is connected to the valve seat, and the other end of the valve rod body stretches out of the shell. A limiting block is welded to the bottom of the valve rod body and arranged in the valve seat and can move along the inner wall of the valve seat. A damping spring is arranged between the limiting block and the valve seat. A guiding pillar is arranged between the valve seat and the shell. The limiting block can move along the guide pillar. A wear resistance cushion is further arranged between the valve rod body and the valve seat. A cushion block is arranged at the position, in the valve seat, at the other end of the limiting block. According to the scheme, the valve seat is installed in the shell, the limiting block is welded to the bottom of the valve rod body, the damping spring is arranged between the limiting block and the valve seat, so that when the damping cushion valve rod is used and the valve rod body is stressed, the pressure exerted on the valve rod body is relieved and reduced through the damping spring, the valve rod body vibrates to cushion unloading force to collide with the cushion block, it is ensured that the valve seat is cushioned, and the service life of the valve rod body is greatly prolonged.

Owner:SUZHOU SONGSHUN HARDWARE

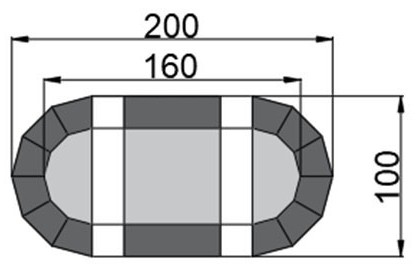

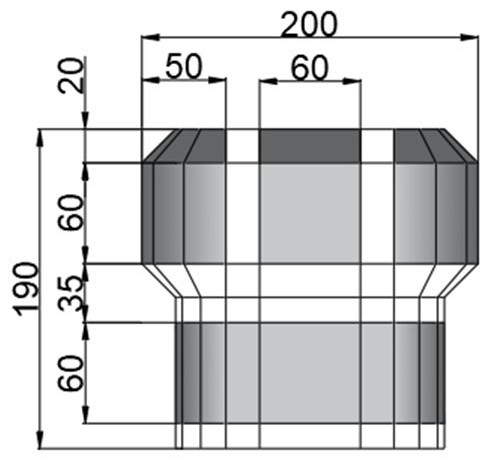

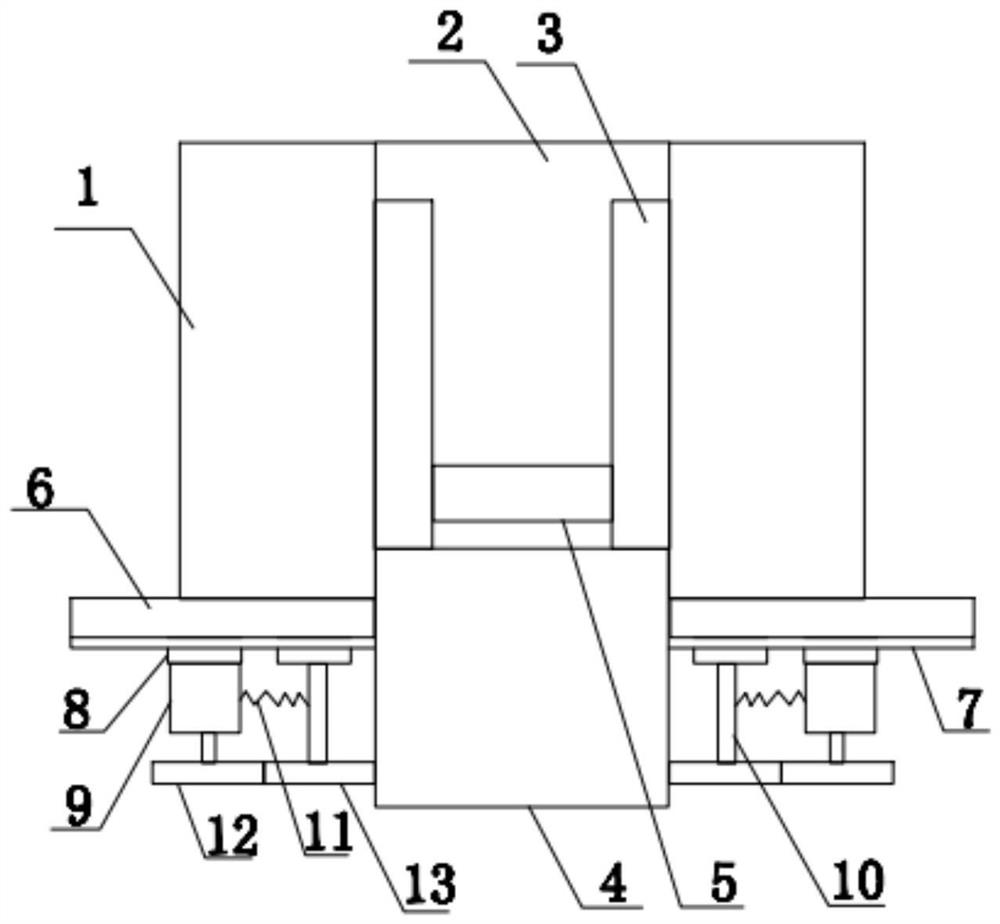

A kind of installation structure and design method of wedge cutter of boulder formation earth pressure balance shield

The invention discloses an installation structure and a design method of a wedge hammer for a boulder stratum earth pressure balance shield. The whole has a large upper part and a small lower part, including the enlarged cutter head of the upper part and the cylindrical cutter body of the lower part, and the cutter head and the cutter body are arranged with alloy blocks; A buffer reset mechanism is arranged between the bottom of the tool and the bottom of the tool box, and the buffer reset mechanism includes an outer shape structure of the bottom of the wedge knife and a buffer and rebound device. The invention provides an installation structure and a design method of a wedge hammer for an earth pressure balance shield in boulder stratum. By designing the wedge hammer installation structure, an earth pressure balance shield that can be applied in a stratum rich in large-sized boulders can be obtained. Wedge striker. The application field of earth pressure balance shield construction is expanded, and the excavation efficiency of earth pressure balance shield construction in boulder formation is improved.

Owner:BEIJING URBAN CONSTR GROUP +1

Self-walking type concrete coating device special for building wall on construction site

PendingCN113216660ARealize automatic operationImplement bufferingBuilding material handlingBrickArchitectural engineering

The invention relates to the technical field of construction tools, in particular to a self-walking type concrete coating device special for building a wall on a construction site. The self-walking type concrete coating device comprises an accommodating area consisting of two longitudinal plates which are correspondingly arranged and a transverse plate; the two longitudinal plates are correspondingly provided with positioning blocks which are used for positioning the width of concrete in the containing area, and the bottom faces of the positioning blocks are flush with the bottom faces of the transverse plates; the bottom faces of the positioning blocks and the longitudinal plates form clamping areas used for being connected with brick bodies in a clamped mode; a scraping plate is arranged between the two positioning blocks, and the bottoms of the two longitudinal plates are each provided with a fixing plate; a driving mechanism is arranged on each fixing plate, so that automatic operation of concrete coating is achieved, the labor amount of workers is reduced, operation on bricks is stable, skew of the mortar laying length is prevented, and uneven brick surfaces are prevented from hindering operation; meanwhile, the mortar laying thickness is adjustable, and the concrete coating device can be suitable for laying bricks with different widths; and the flatness of the bricks in the horizontal direction is guaranteed, and relatively high practicability and popularization value are achieved.

Owner:青岛东建建设有限公司

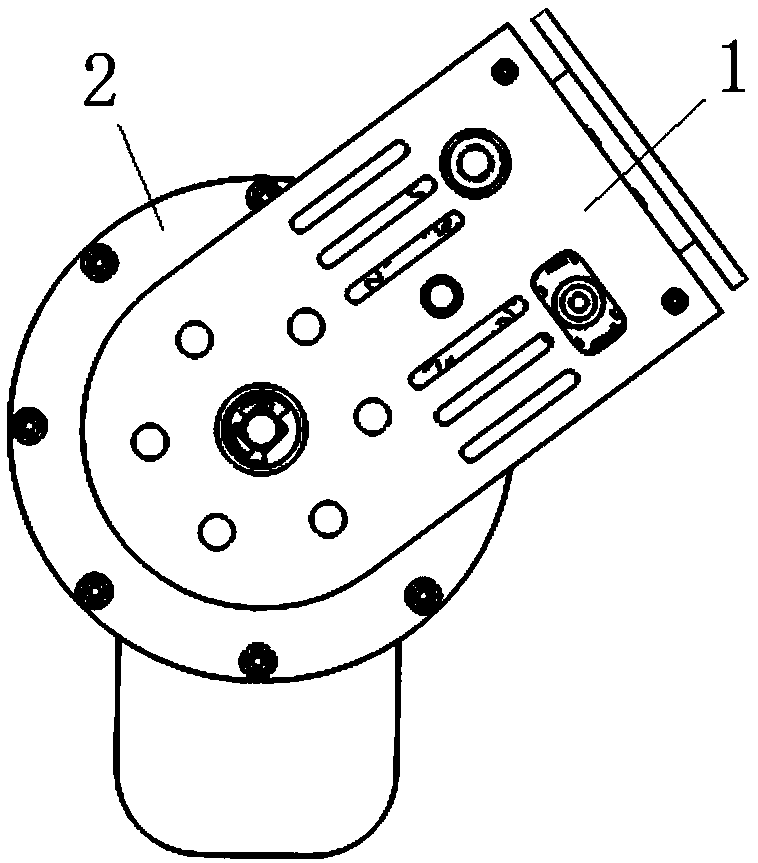

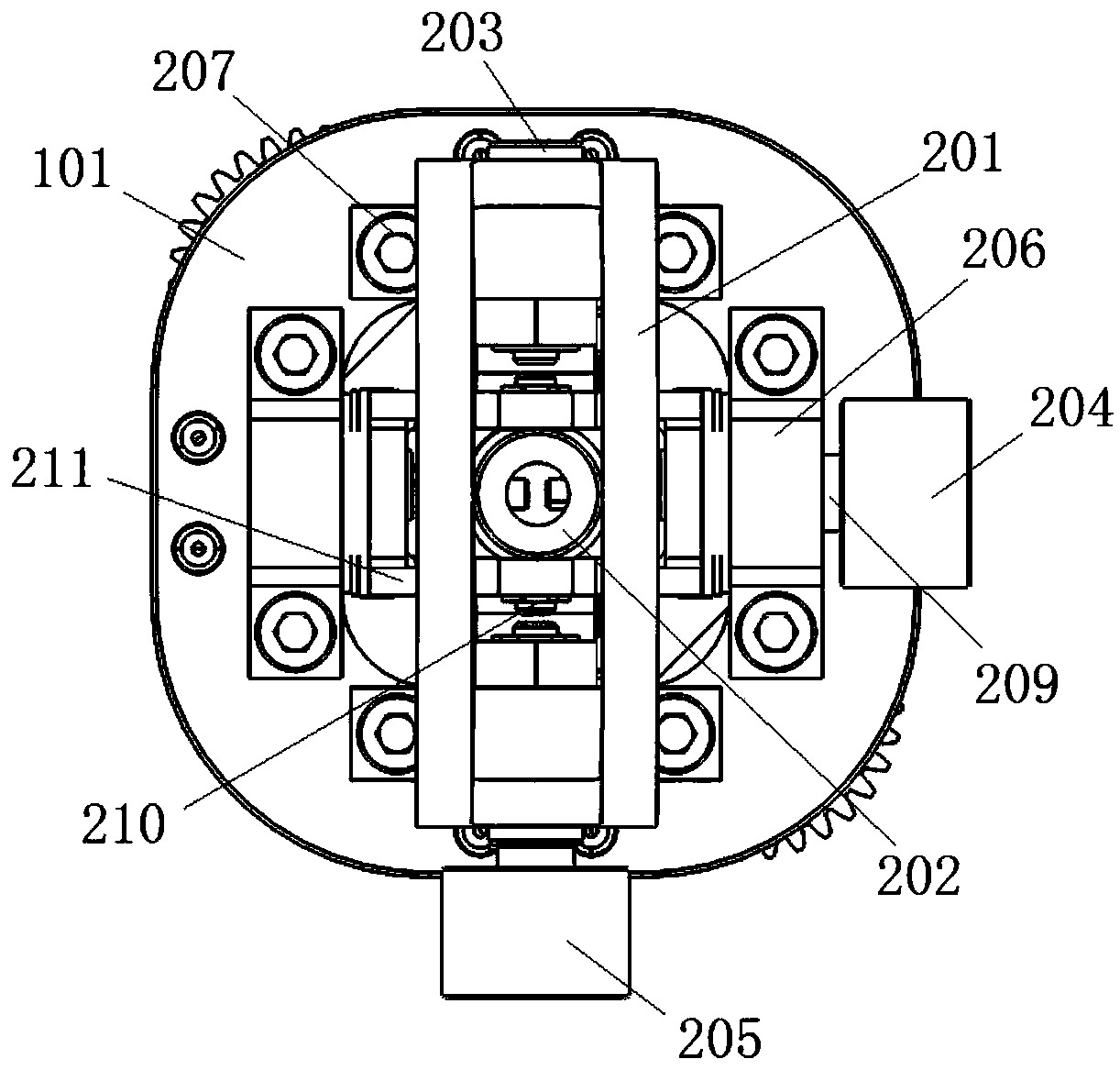

Two-degree-of-freedom variable-rigidity ball-and-socket joint of robot

The invention relates to the field of robots, and particularly relates to a two-degree-of-freedom variable-rigidity ball-and-socket joint of a robot. The two-degree-of-freedom variable-rigidity ball-and-socket joint of the robot comprises a supporting frame, a ball-and-socket mechanism, a leaf spring mechanism and a rigidity adjusting mechanism, wherein a front plate of the supporting frame is provided with the ball-and-socket mechanism; the supporting frame is internally provided with the rigidity adjusting mechanism and the leaf spring mechanism; the leaf spring mechanism comprises a cam following block and two leaf springs; the cam following block is provided with two cams, and two leaf springs are arranged between the two cams; the cam following block is driven to move by the rigidityadjusting mechanism; both ends of a limiting groove semi-ring of the ball-and-socket mechanism and both ends of a power rod seat are hinged on the front plate of the supporting frame through rotatingshafts; a power rod is arranged on the power rod seat, and the front end of the power rod seat is arranged in a groove of the limiting groove semi-ring; each rotating shaft is provided with a spring pressing column; and each spring pressing column is arranged between the front ends of the two leaf springs of the leaf spring mechanism on the corresponding side. The two-degree-of-freedom variable-rigidity ball-and-socket joint of the robot has two characteristics of active rigidity adjustment and passive rigidity adjustment, and realizes large load bearing under the condition of a smaller corner.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Anti-theft, waterproof, dustproof and noise-proof well lid

ActiveCN106638703AAvoid the risk of theftExtended service lifeArtificial islandsUnderwater structuresLocking mechanismEngineering

The invention discloses an anti-theft, waterproof, dustproof and noise-proof well lid. The well lid comprises a base and an upper well lid; the upper well lid is embedded in the base, the upper surface of the upper well lid and the upper surface of the base are located in the same plane, an elastic steel ring and a sealing ring are arranged between the base and the upper well lid and concentric with the upper well lid, the elastic steel ring is fixed on the base, the sealing ring is fixedly connected with the elastic steel ring, a V-shaped sealing ring which is in communication with the upper well lid is embedded in the surface, in contact with the bottom of the upper well lid, of the base, and the upper well lid is further provided with a locking mechanism which is used for locking the upper well lid and the base tightly; the well lid can be effectively prevented from being stolen, and dust or rainwater is prevented from entering a well and causing unnecessary damage to equipment in the well; the arranged V-shaped sealing ring has a certain elasticity and can ensure that a cushion effect is generated between the base and the upper well lid when vehicles pass through the well lid, the noise is reduced, and meanwhile, the service life of the well lid is prolonged.

Owner:STATE GRID CORP OF CHINA +1

End point supporting frame structure applied to house steel structure

InactiveCN112627618AEasy to operateImprove supportProtective buildings/sheltersShock proofingEarthquake resistantSteel columns

The invention discloses an end point supporting frame structure applied to a house steel structure, and relates to the technical field of steel structures. The end point supporting frame structure comprises prefabricated steel columns, prefabricated steel beams, joint connecting members, first high-strength bolts, second high-strength bolts, joint supporting members and third high-strength bolts. One ends of the joint connecting members are connected with the prefabricated steel columns and fixedly connected with the prefabricated steel columns through the first high-strength bolts in a locked mode, the other ends of the joint connecting members are connected with the prefabricated steel beams and fixedly connected with the prefabricated steel columns through the second high-strength bolts, and buffer sleeves are arranged between the joint connecting members and the prefabricated steel columns and between the joint connecting members and the prefabricated steel beams. According to the end point supporting frame structure applied to the house steel structure, telescopic sleeve joints, first buffer pieces and second buffer pieces are arranged in the joint supporting members, energy dissipation can be effectively carried out, damage to the structure under the earthquake action is reduced, and compared with a simple supporting structure, the effect of the end point supporting frame structure applied to the house steel structure is better, so that the anti-seismic effect of a steel structure end point is improved.

Owner:澧县红似火新型建材有限责任公司

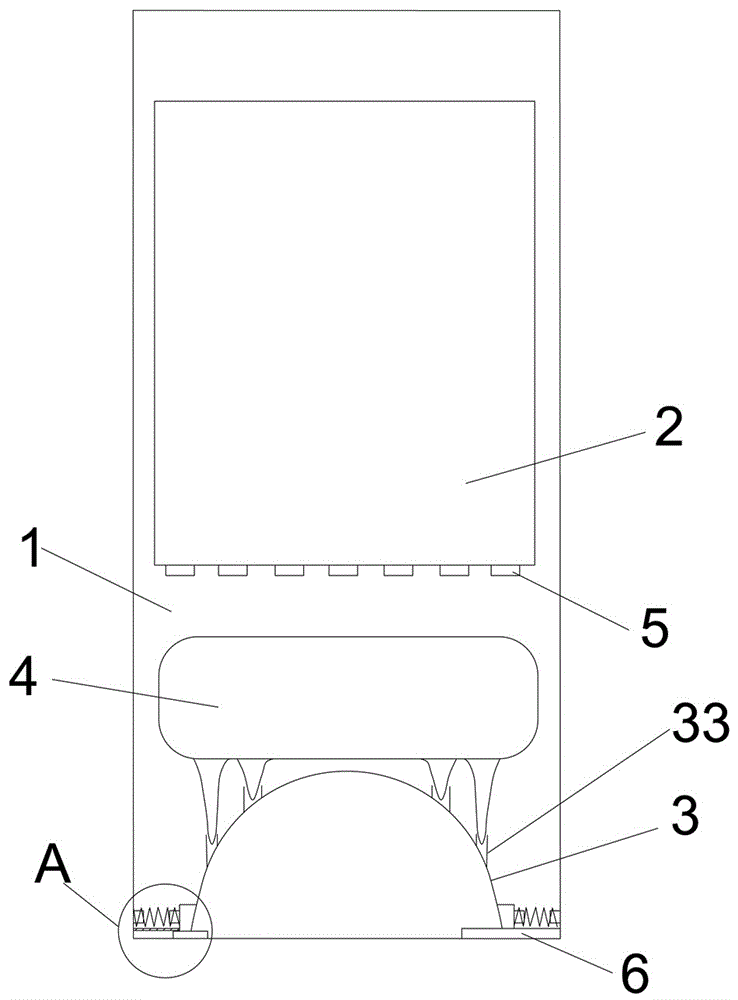

High-safety lifting elevator

ActiveCN106800230AEffective bufferImprove buffering effectElevatorsMechanical engineeringEngineering

The invention belongs to the field of elevators and particularly relates to a high-safety lifting elevator. The high-safety lifting elevator comprises a shaft and an elevator car. An arch-shaped buffer plate is arranged at the bottom in the shaft. An upper buffer air bag is arranged on the upper surface of the arch-shaped buffer plate. Multiple buffer rubber strips are evenly distributed at the bottom of the elevator car. The two ends of the arch-shaped buffer plate are connected with the bottom of the shaft through arch plate unfolding offset components. Each arch plate unfolding offset component comprises a slideway track groove plate fixedly arranged at the bottom of the shaft and provided with track grooves, arch plate contracting sliding strips integrally connected to the outer sides of the two ends of the arch-shaped buffer plate and arranged in the track grooves, a right-angled folding plate fixedly connected to the arch-shaped buffer plate and the slideway track groove plate and a buffer spring with the two ends connected between the side portion of the right-angled folding plate and the inner side wall of the shaft. According to the high-safety lifting elevator, arch plates cannot move freely due to the arch plate unfolding offset components and only can contract in the two-end direction, it can be guaranteed that the arch plates are buffered to the best effect, the buffer capacity of the arch plates is improved due to the buffer springs, the buffer effect is improved, and the protection function on the arch plates is played.

Owner:LEAD BOSCH ELEVATOR SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com