Angle ejection device for injection mold

A technology of injection mold and inclined roof, which is applied in the field of plastic injection molding to avoid the effect of screw breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

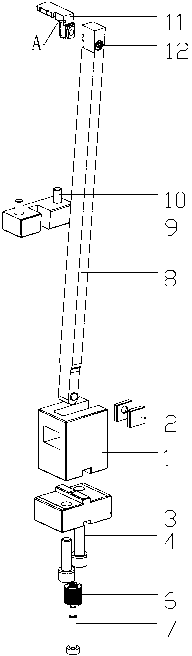

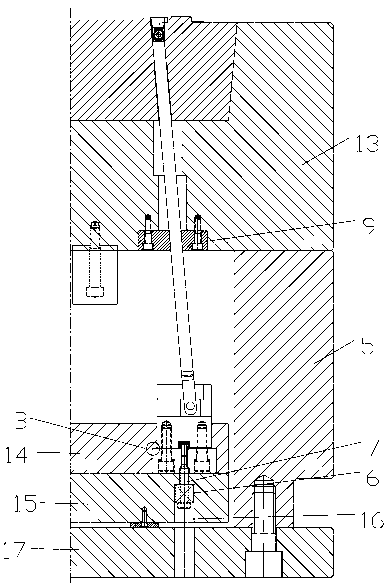

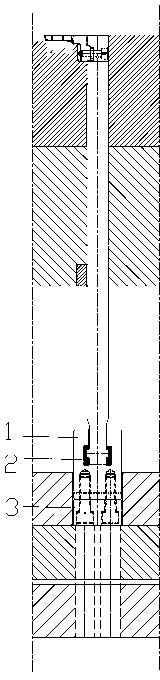

[0023] as attached Figures 1 to 4 As shown, the injection mold generally includes an upper template (not shown in the figure), a lower template 13, a square iron 5 supporting the lower template 13, a bottom plate 17, a bottom needle plate 15 and a face needle plate 14 for installing ejector pins. The inclined roof device disclosed in this embodiment mainly includes two major parts: an inclined roof installation part and an inclined roof 8, wherein the inclined roof installation part includes an inclined roof box 1 and an inclined roof box seat 3, and the inclined roof installation part is divided into an inclined roof box 1 and slanted top box seat 3 are mainly to facilitate processing and assembly. The slanted top box 1 and the slanted top box seat 3 are fixedly connected together by screws 4 . The lower end of the inclined top 8 cooperates with the inclined top box 1 , and the inclined top 8 is rotatable and laterally slidable relative to the inclined top box 1 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com