High-safety lifting elevator

An elevator and high-safety technology, applied in the field of elevators, can solve the problems of falling death and ineffective protection, etc., and achieve the effect of improving the buffering effect, balancing the force, and balancing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

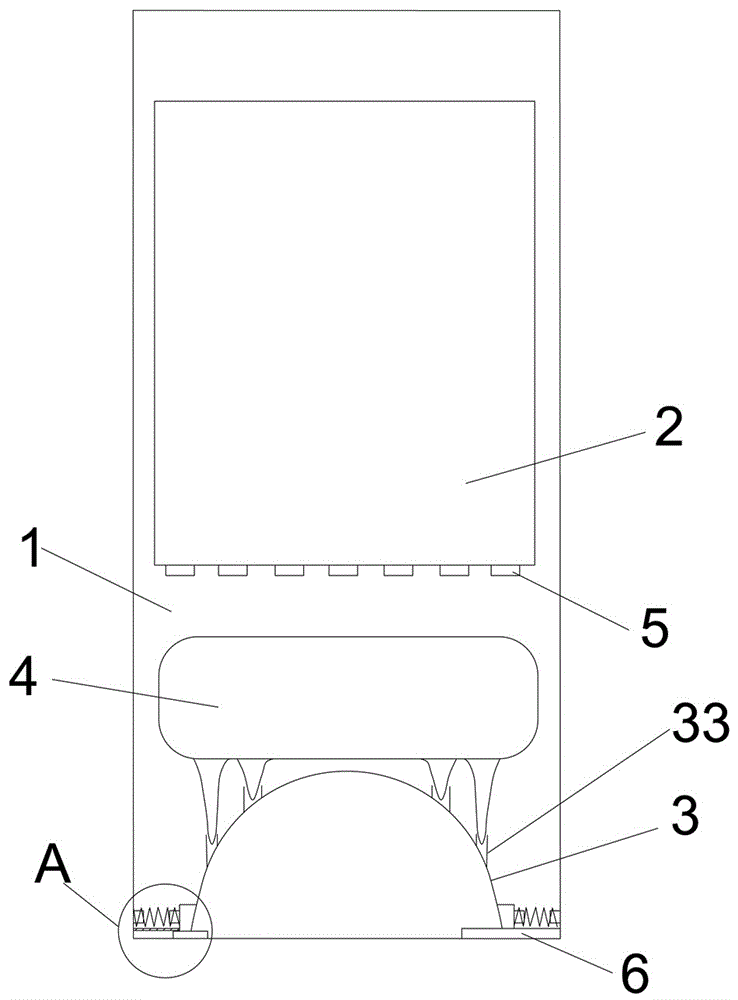

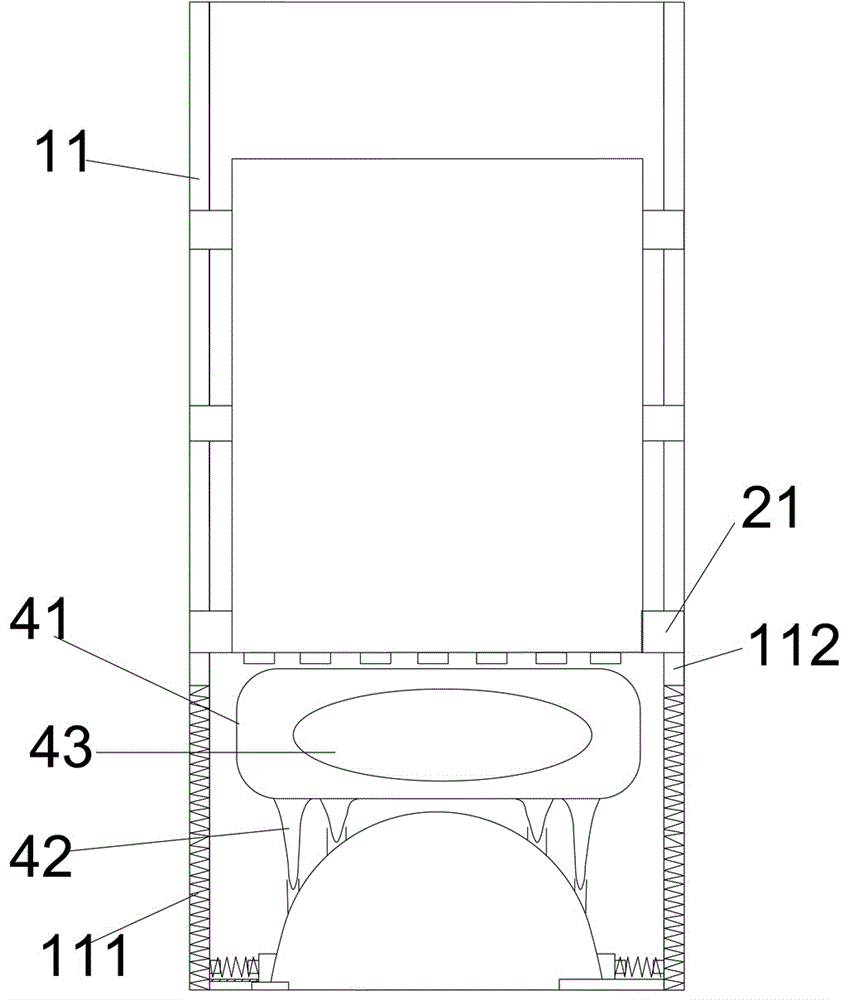

[0035] A high-safety elevator, comprising a shaft 1 and a car 2, the inner bottom of the shaft is provided with an arched buffer plate 3 that arches upwards, and a buffer airbag 4 is placed on the upper surface of the arched buffer plate, and the car A plurality of buffer rubber strips 5 are evenly distributed on the bottom, and both ends of the arched buffer plate are connected to the bottom of the hoistway through arch plate expansion offset components.

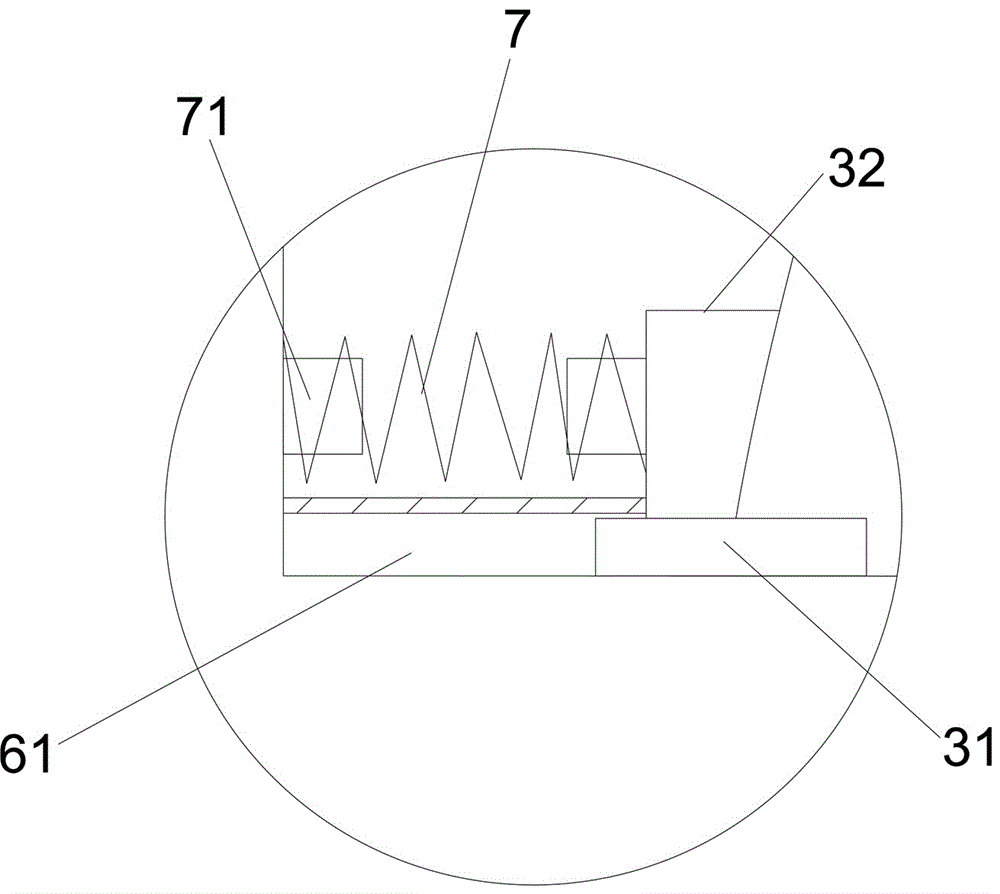

[0036] The arch plate expansion counteracting part includes a slide track track plate 6 fixed at the bottom of the hoistway and having a track groove 61, and an arch plate integrally connected to the outer sides of both ends of the arch buffer plate and set in the track groove Shrink slide bar 31, the right-angle flap 32 that is fixedly connected on described arched buffer plate and slideway track groove plate and the buffer spring 7 that both ends are connected between the side of right-angle flap and hoistway inner wall. ...

Embodiment 2

[0040]The difference from the above embodiment is that the rail groove plate of the slideway is provided with a plurality of track grooves perpendicular to the two sides of the arched buffer plate, and the retractable slide bars of the arch plate are adapted to the track grooves. The two ends of the shrinking slide bar of the arch plate exceed the two sides of the arched buffer plate, and the right-angled folded plate and the inner wall surface of the well are correspondingly provided with two ends of the buffer spring. Limiting guide post 71.

[0041] The cooperation of the right-angle folding plate, the limit guide post and the buffer spring ensures the stable cooperation between the buffer spring and the arch plate, improves the effectiveness and order of the buffer, and ensures the stability of the structure.

Embodiment 3

[0043] The difference from the above-mentioned embodiment is that the buffer airbag includes a main bladder 41 at the top and several support leg bladders 42 connected to the bottom of the main bladder.

[0044] The foot capsules are divided into two groups symmetrically arranged on both sides of the symmetrical center on the top of the arched buffer plate, and each set of foot capsules includes at least two rows that gradually lengthen from the symmetrical center of the arched buffer plate top to the inner wall of the hoistway. Columns of leg capsules, each column has at least two leg capsules.

[0045] Through the setting of the foot capsule, it is ensured that the entire cushioning airbag is matched with the arch plate, and the force on the bottom of the cushion airbag is balanced, and the force surface at the bottom will not be too small due to the arch plate, and the pressure is strong and vulnerable, and the support foot capsule is in accordance with the corresponding arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com