Self-walking type concrete coating device special for building wall on construction site

A construction site, concrete technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of affecting the quality of ash spreading, increasing the labor load of workers, and skewing of ash spreading, so as to improve practicality and reduce labor The effect of volume and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

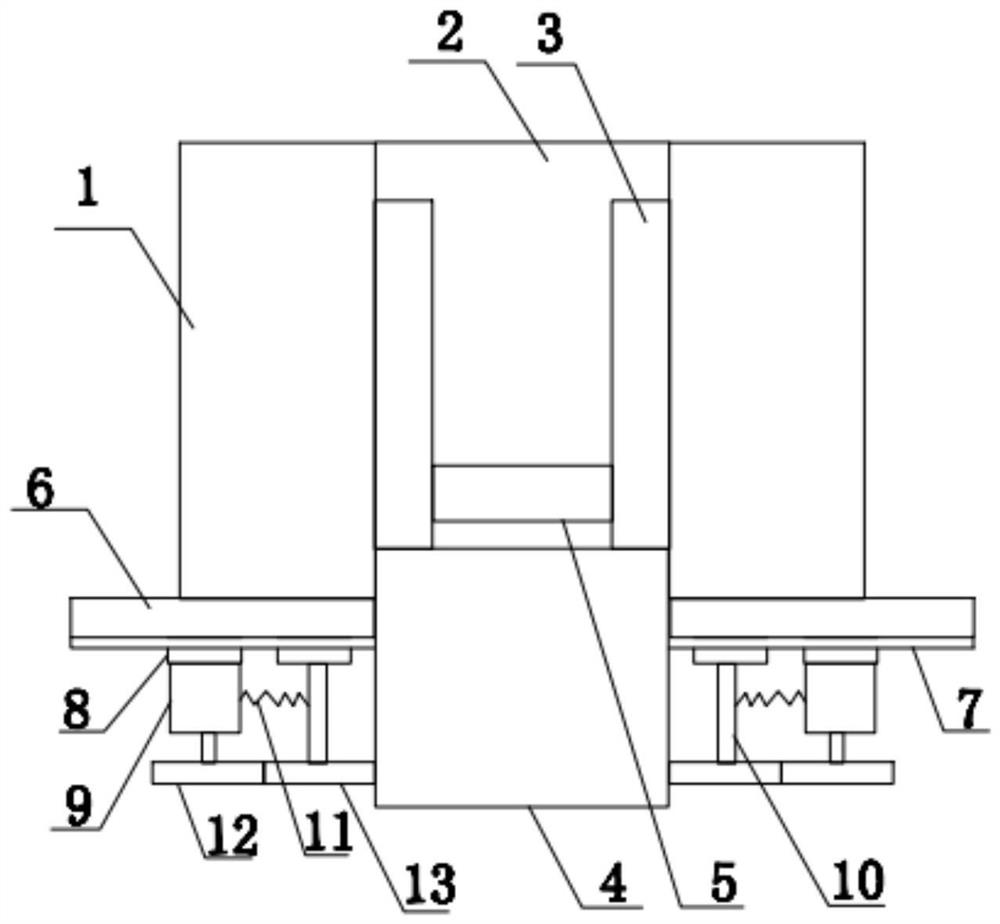

[0030] Such as figure 1 As shown, a special self-propelled concrete coating device for building walls on construction sites includes two correspondingly arranged longitudinal plates 1 and a horizontal plate 2 for connecting the two longitudinal plates 1 to accommodate concrete. area, on the two longitudinal plates 1 there is correspondingly a positioning block 3 for positioning the width of the concrete in the accommodation area and the bottom surface is flush with the bottom surface of the horizontal plate 2, the bottom surface of the positioning block 3 and the longitudinal plate 1 form a In the clamping area clamped with the brick body 4, a scraping plate 5 connecting the two positioning blocks 3 for leveling the concrete in the accommodation area is provided between the two positioning blocks 3, and a fixing plate 5 is respectively provided at the bottom of the two longitudinal plates 1 The plate 6 is provided with a driving mechanism for driving the two longitudinal plate...

Embodiment 2

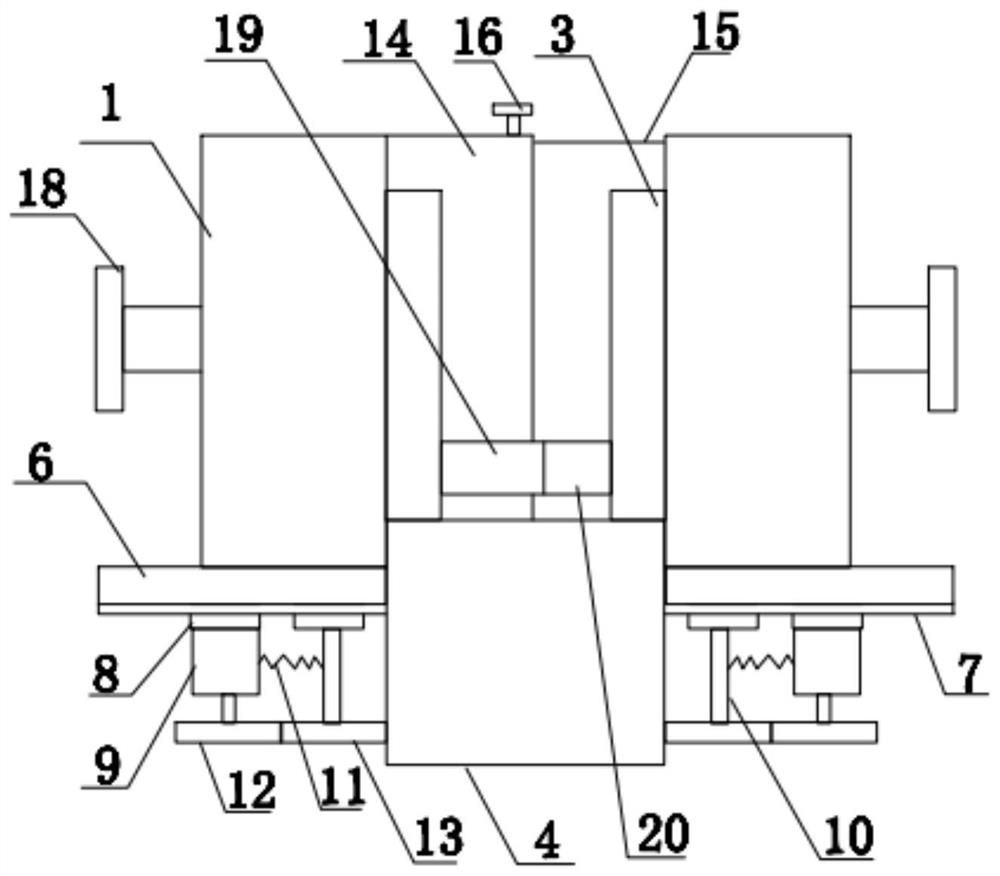

[0033] The same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is that, as Figure 2-6 As shown, the horizontal plate 2 includes a first plate body 14 connected to a vertical plate 1, and an insertion cavity opened on the first plate body 14, and another vertical plate 1 is provided with a socket for insertion into the cavity. The second plate body 15 is provided with a positioning screw hole on the top of the first plate body 14 , and a tightening bolt 16 for tightening the second plate body 15 is provided on the positioning screw hole. It can meet the bricks of different specifications to spread dust, and tighten the bolts to prevent the concrete from propping up and separating the spreading device.

[0034] A second accommodating cavity 17 for accommodating the positioning block 3 is provided on the two longitudinal plates 1 respectively, and an adjusting assembly for adjusting the distance between the two positioning blocks is respective...

Embodiment 3

[0038] The same parts of this embodiment and Embodiment 2 will not be repeated, and the difference is that, as Figure 7 , 8 As shown, it also includes a fine-tuning mechanism for adjusting the height of the first and second scrapers. The fine-tuning mechanism includes an adjustment cavity 25 respectively opened on the front facade of the two positioning blocks 3, and a first adjustment cavity 25 is provided in the adjustment cavity 25. Three slide rails 26, a third slide block 27 is provided on the third slide rail 26, an adjustment screw barrel 28 is provided at the top of the adjustment chamber 25, an adjustment bolt 29 is arranged in the adjustment screw barrel 28, and an adjustment screw 29 is arranged on the third slide block 27 The top is provided with a third bearing 30 where the inner ring is connected to the bottom of the adjusting bolt 29 , and the first scraper 19 and the second scraper 20 are respectively connected to the sides of the two third sliders 27 . The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com