Patents

Literature

134results about How to "Adjust the preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

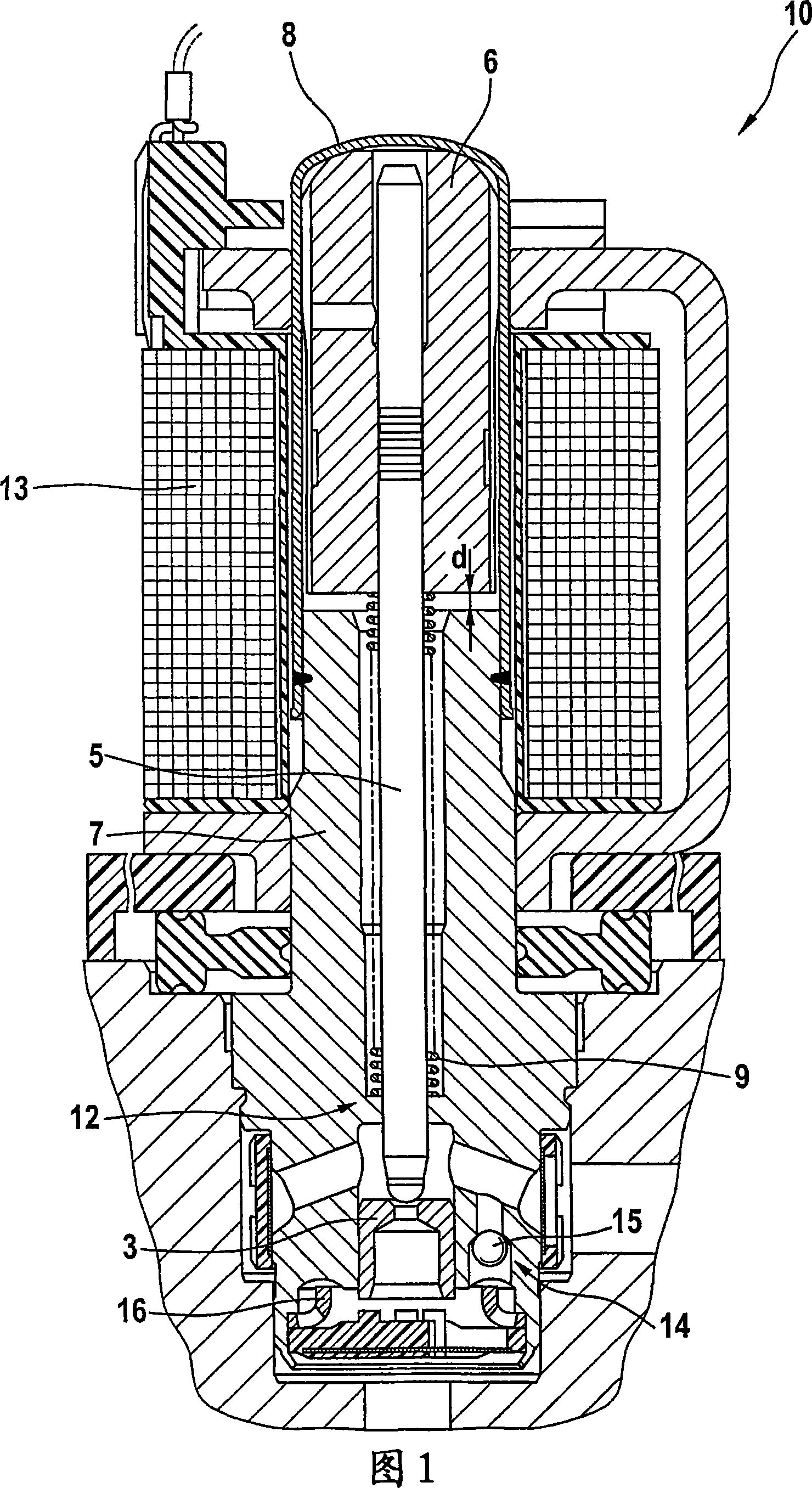

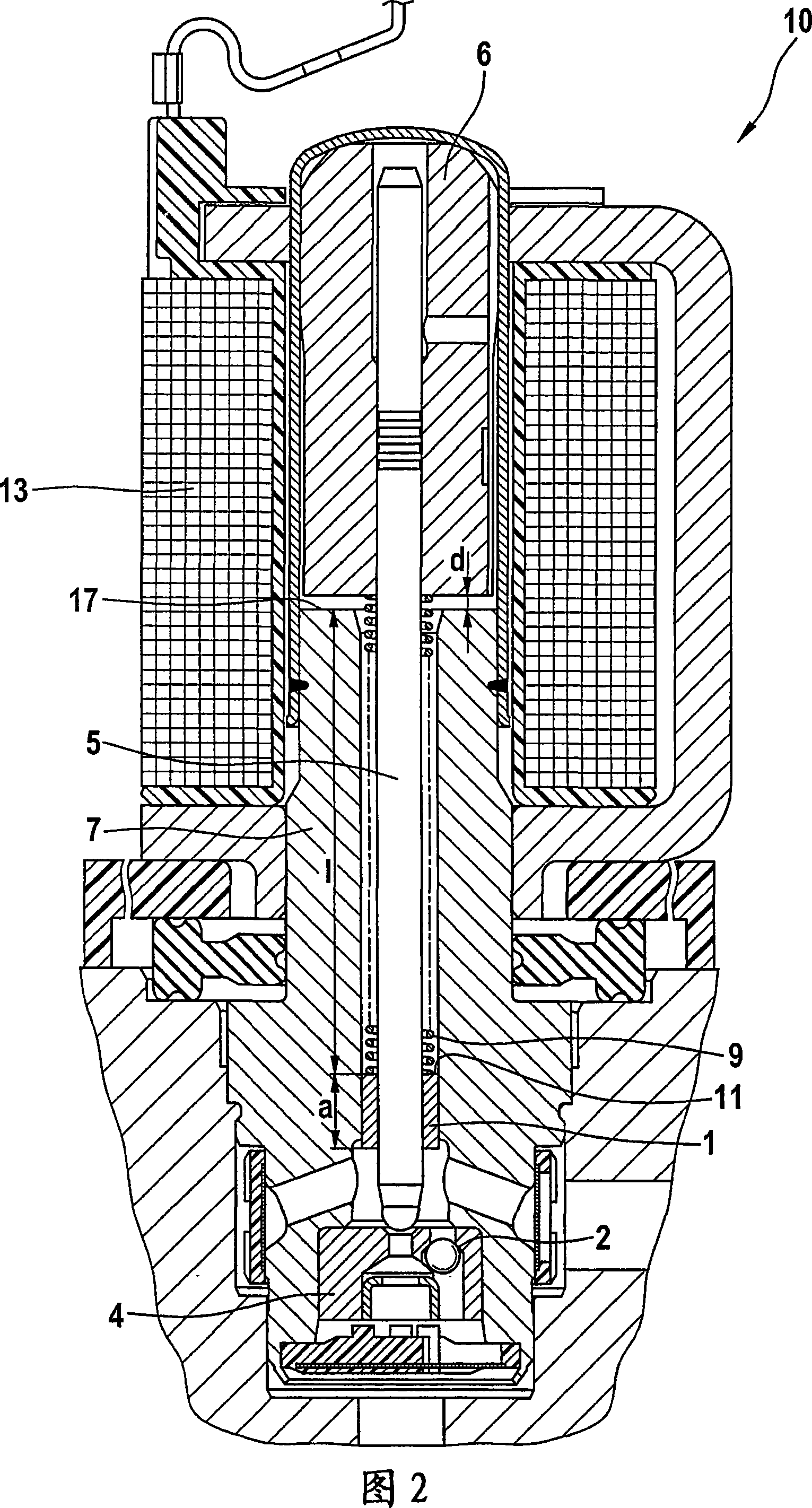

Electromagnetically controllable adjusting device and method for the production thereof and/or rectification

InactiveCN101065276AReduce switching energyReduce magnetic short circuitOperating means/releasing devices for valvesElectromagnets with armaturesSignal onTelecommunications Device

The security device comprises (i) a first connector ( 12 ) for connection to a telecommunications device ( 14; 15 ) such as a land-line telephone, mobile telephone or the modem of a computer, (ii) a second connector ( 16 ) connected to a telecommunications line ( 18 ), and (iii) a normally closed switch ( 20, 21 ) having a closed position in which a signal pathway ( 22, 23 ) within the security device between the first connector ( 12 ) and the second connector ( 16 ) is enabled and an open position in which the signal pathway ( 22, 23 ) is interrupted. A control device ( 24, 25 ) for controls the position of the switch ( 20, 21 ). A programmable memory ( 26, 27 ) stores allowed signal sequences and at least one authorised pass number. A comparator ( 30 ) is in operative connection with the control device ( 24, 25 ) and compares signals on the pathway ( 22, 23 ) with the allowed stored signal sequences. The control device ( 24, 25 ) opens the switch ( 20, 21 ) when a signal on the pathway ( 22, 23 ) does not match one of the stored signal sequences. A programmer ( 32 ) receives pass numbers and programming signals from a remote telecommunications device ( 52 ) via the telecommunications line ( 18 ). The programmer ( 32 ) includes an authorised pass number recognition device ( 34 ) for comparing a received pass number with the authorised pass numbers stored in the memory ( 26,27 ). The memory ( 26, 27 ) can be reprogrammed only when an authorised pass number is received.

Owner:CONTINENTAL TEVES AG & CO OHG

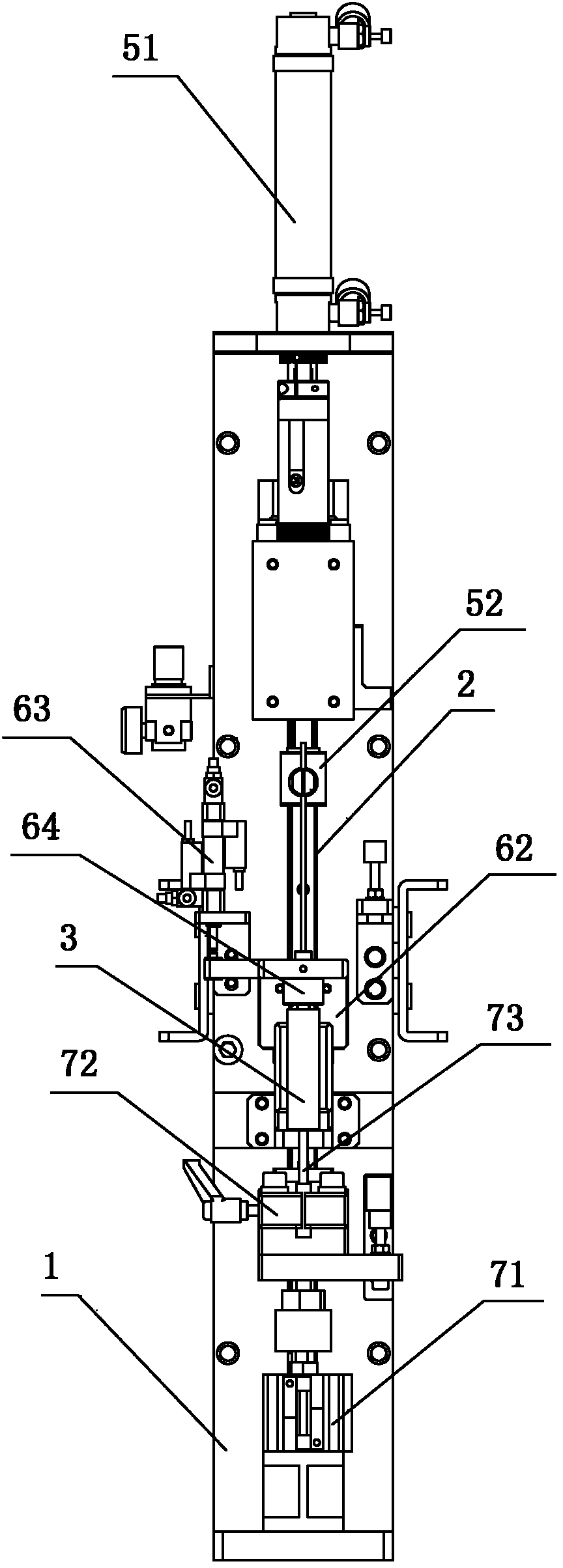

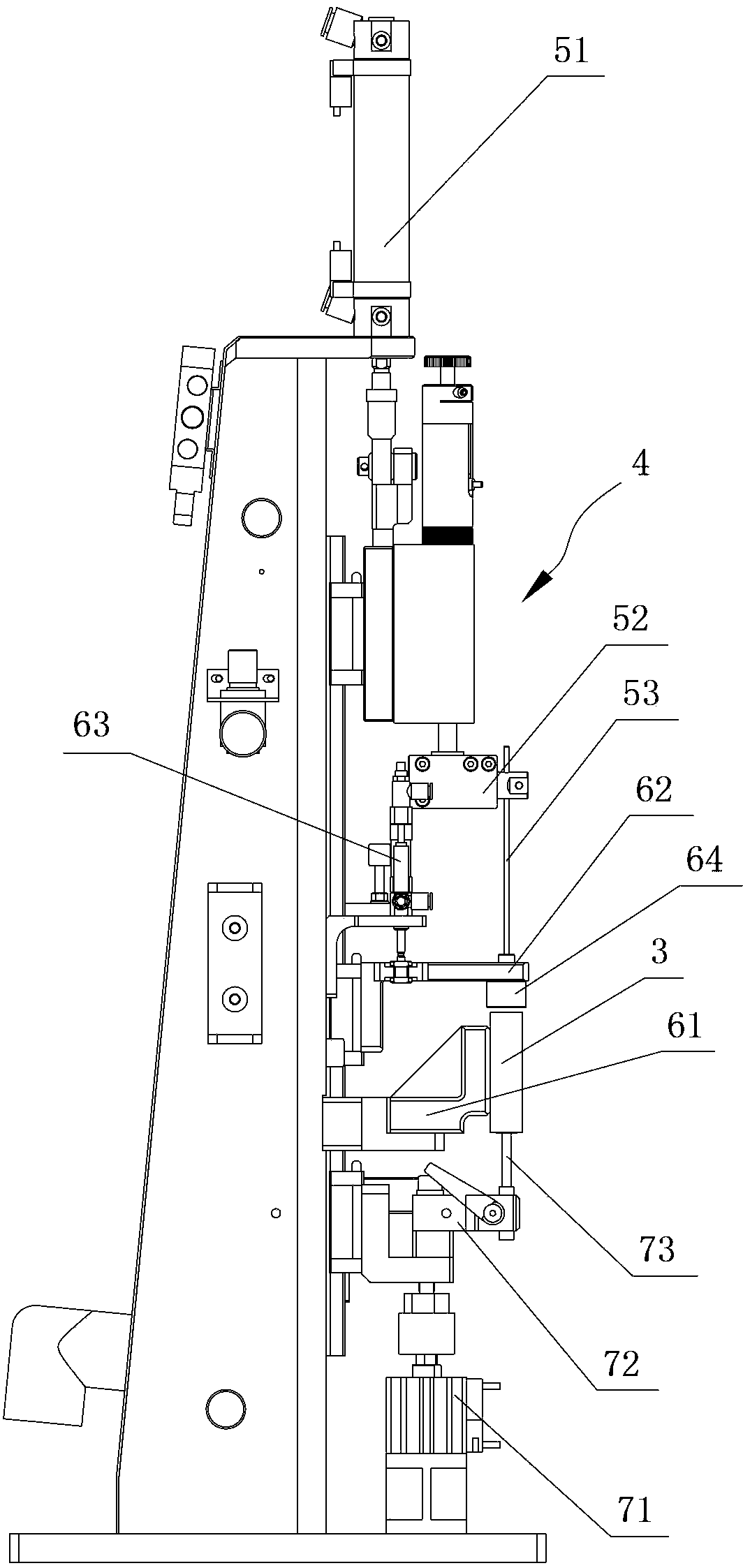

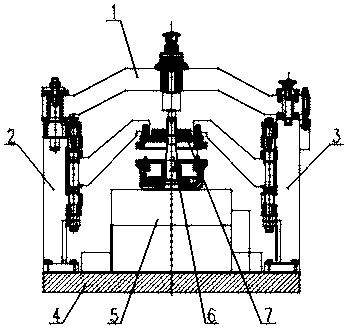

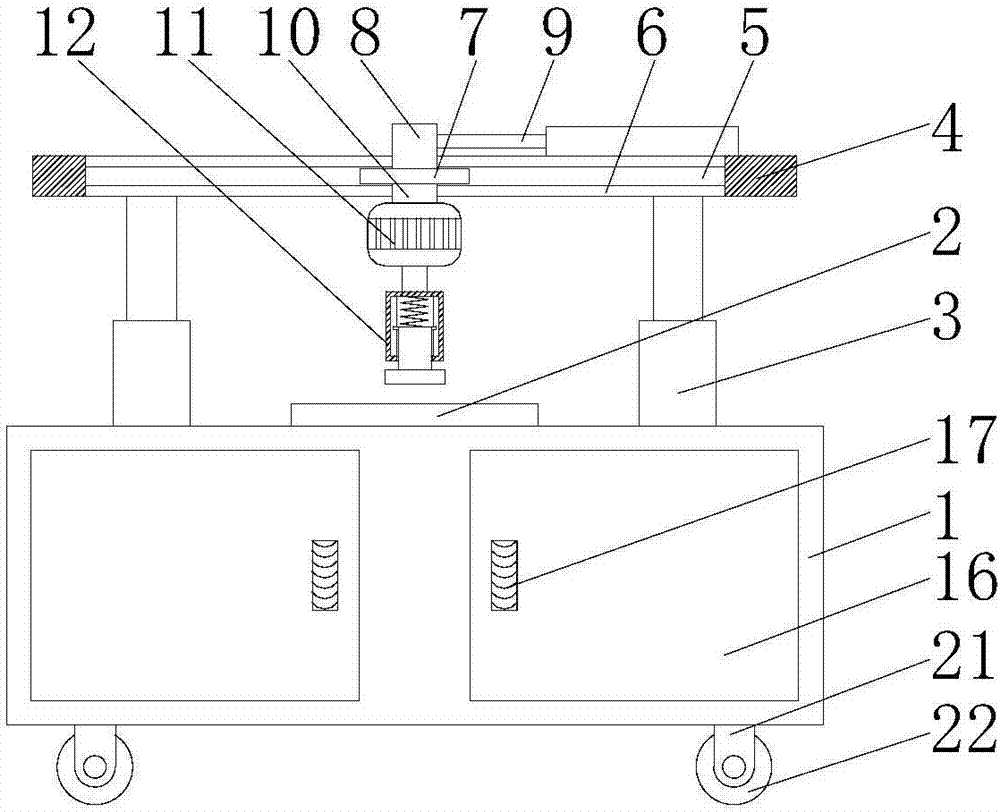

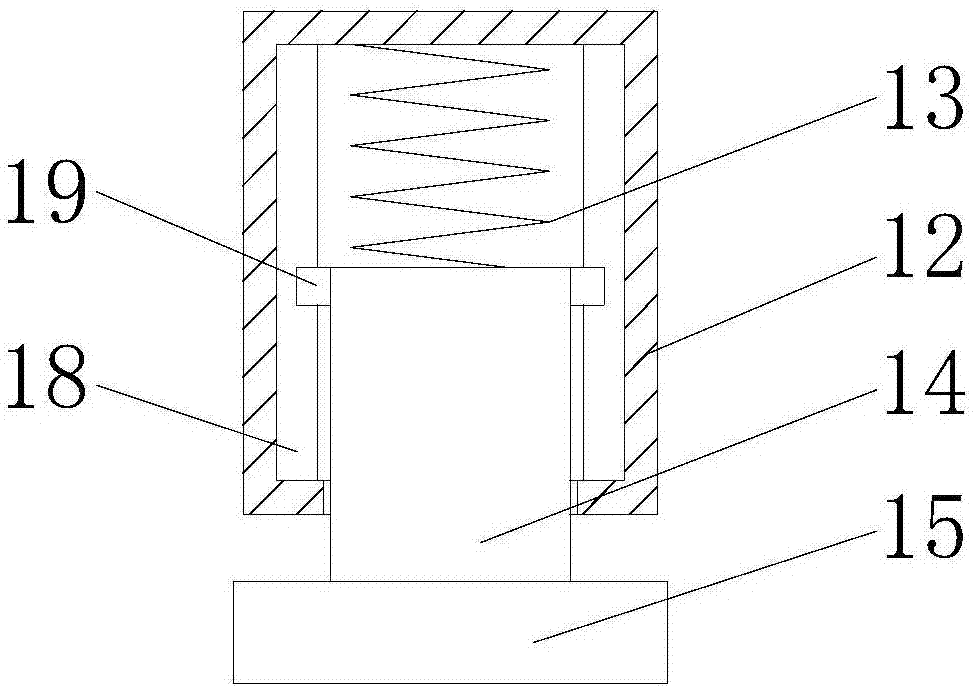

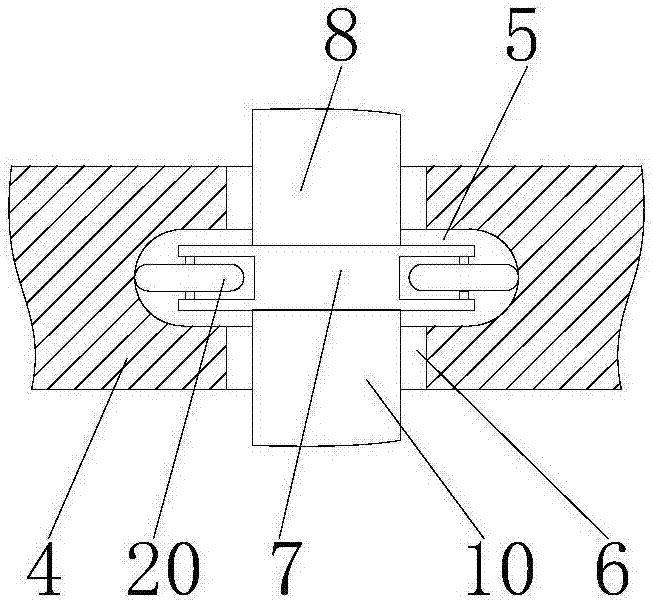

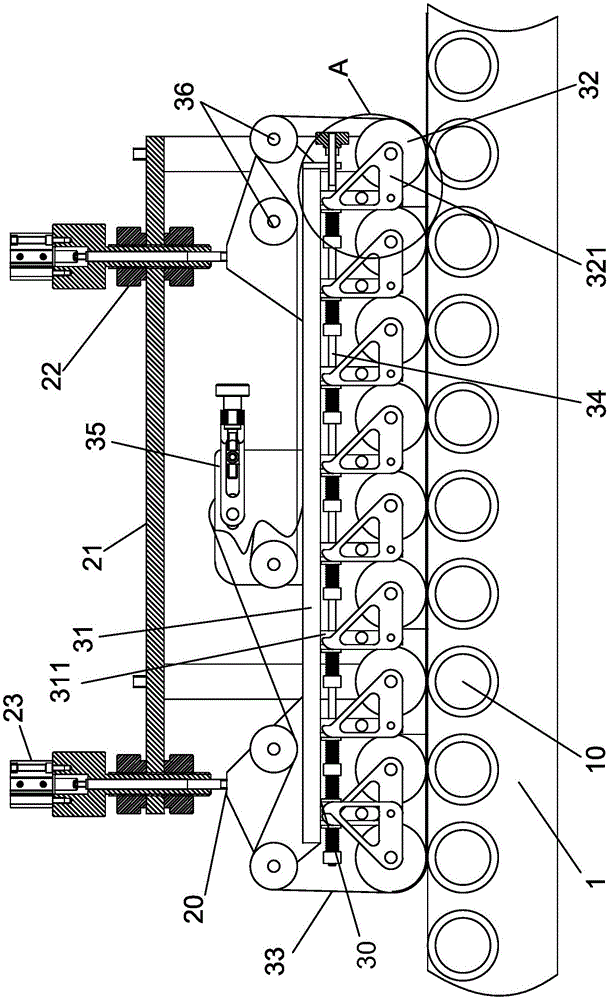

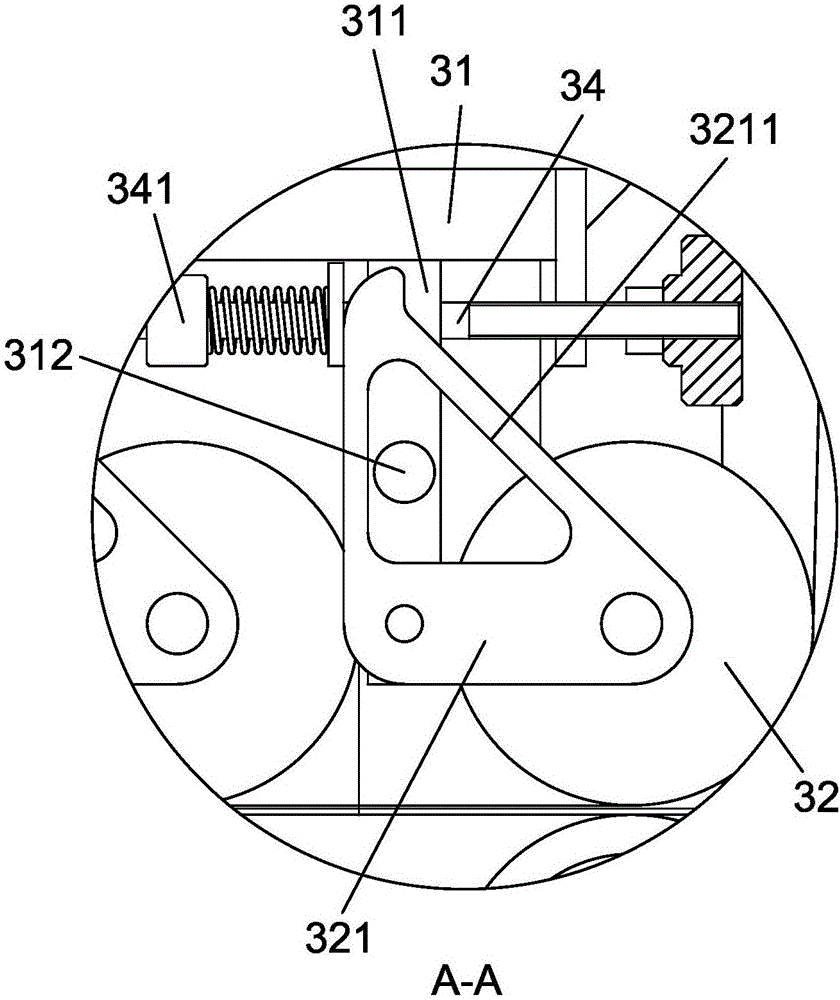

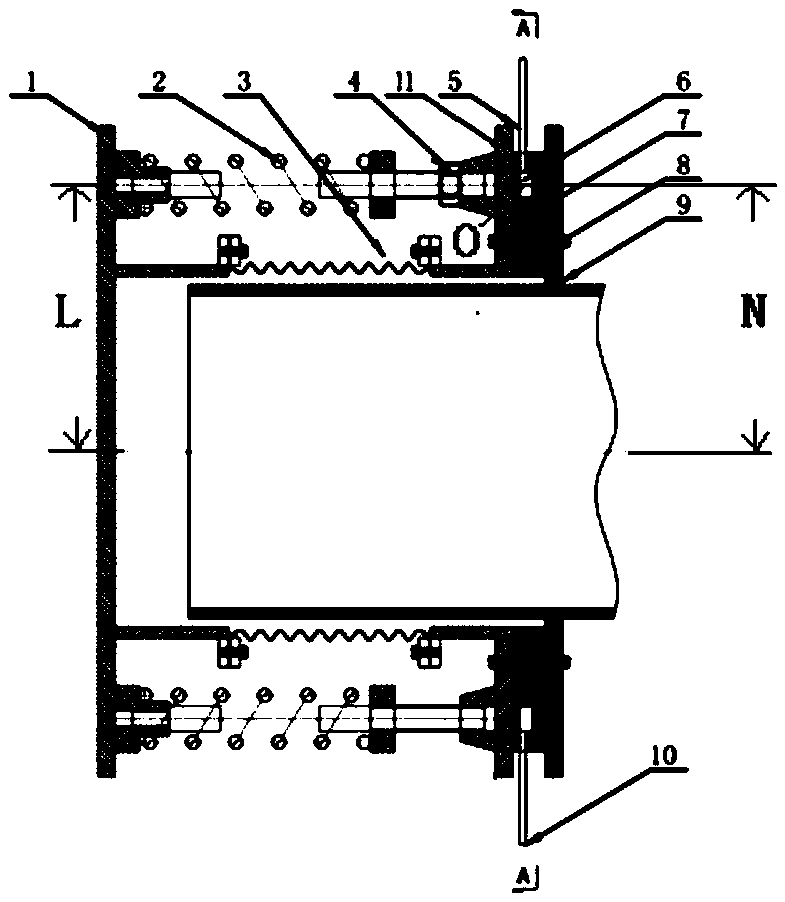

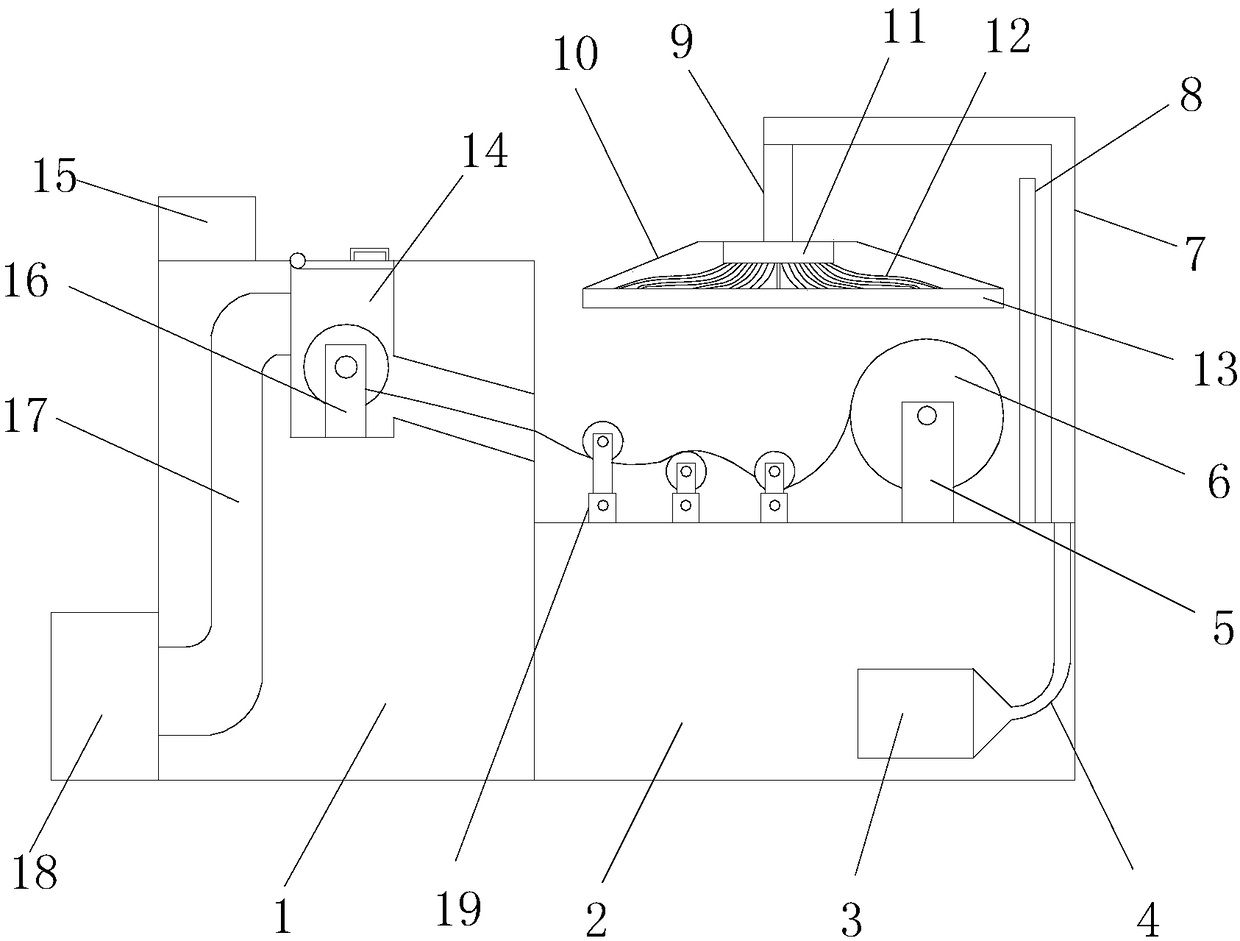

Full automatic tab welding device

ActiveCN103358007AAchieve weldingImprove welding qualityResistance electrode holdersEngineeringMultiple function

The invention provides a full automatic tab welding device, which is used for solving the problems of poor welding quality and low production efficiency of a cathode tab in the prior art. The full automatic tab welding device comprises an engine base, and further comprises an actuating mechanism, wherein guide rails are vertically arranged on the engine base, and a positioning mechanism used for positioning a battery cell is arranged on the guide rails; the actuating mechanism comprises an upper welding electrode movably arranged at the upper parts of the guide rails and a lower welding electrode moveably arranged at the lower parts of the guide rails, and a following mechanism is used for controlling the motion of the upper welding electrode is arranged on the upper welding electrode. The device realizes full automatic mechanization of welding process of the tab during the production technology of cylindrical batteries, saves manpower, greatly improves both production efficiency and welding quality of batteries, is convenient to maintain, is artistic in structure, is accurate in location, is reliable for welding and has multiple functions.

Owner:北京商驰科技发展有限公司

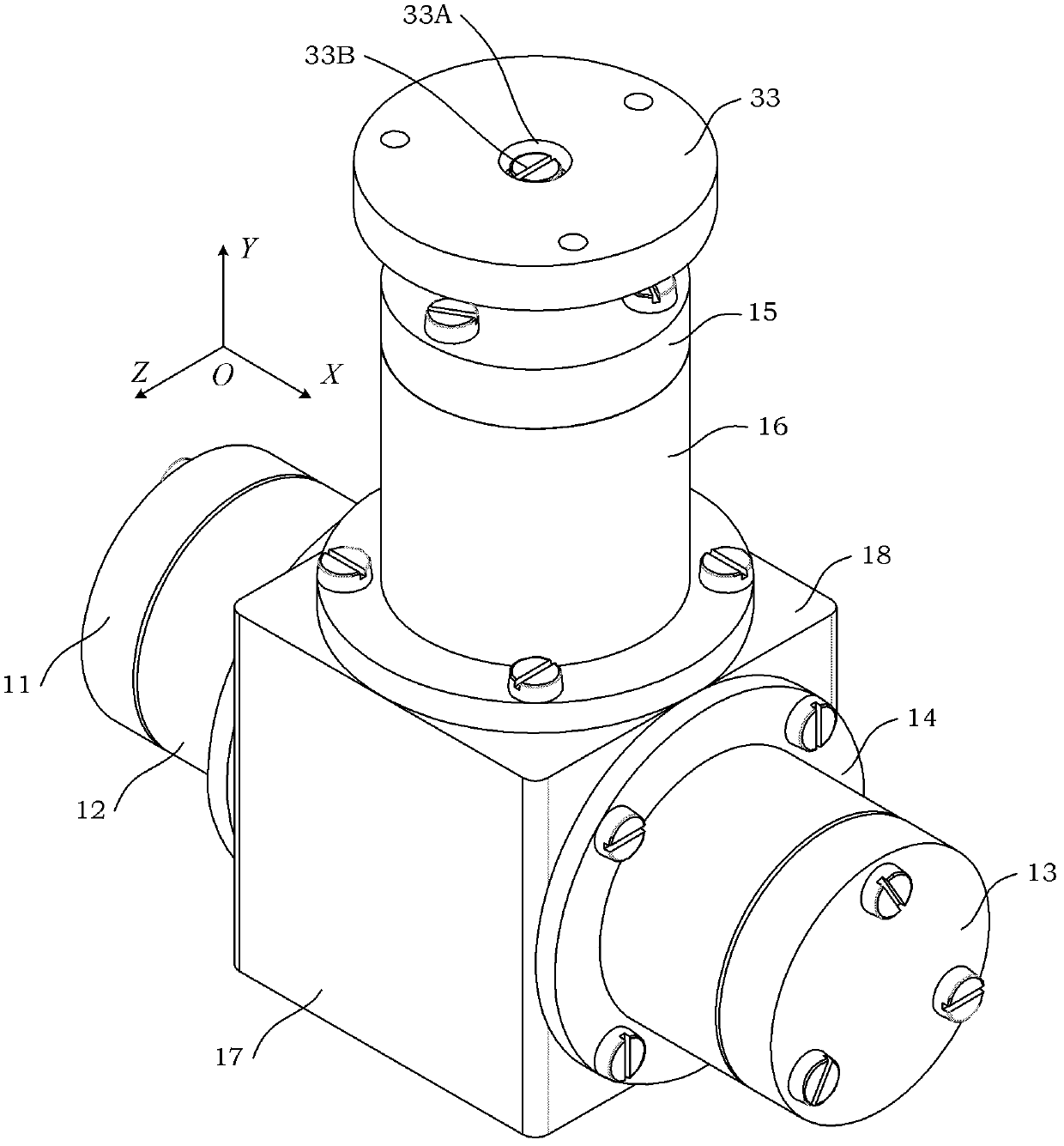

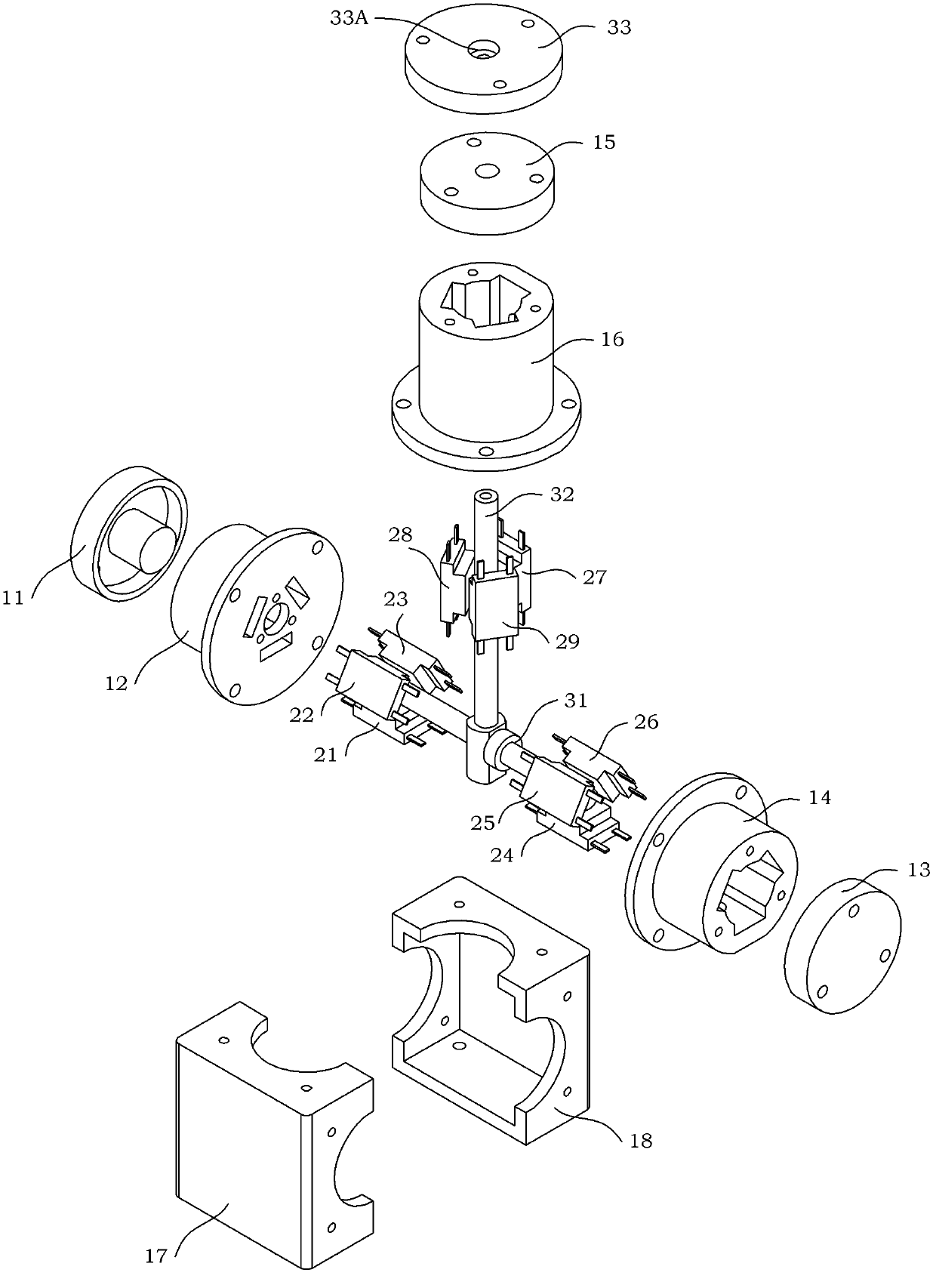

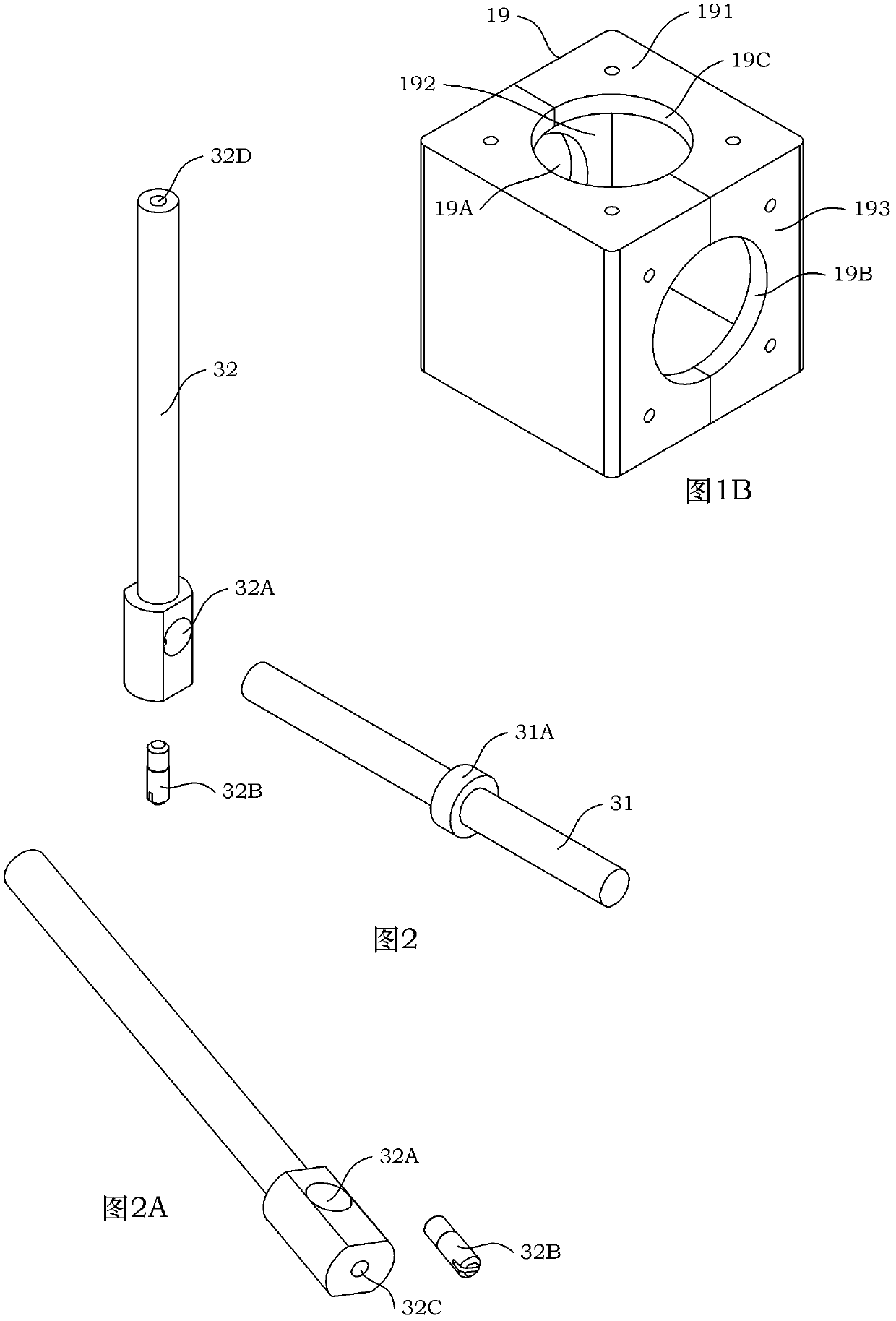

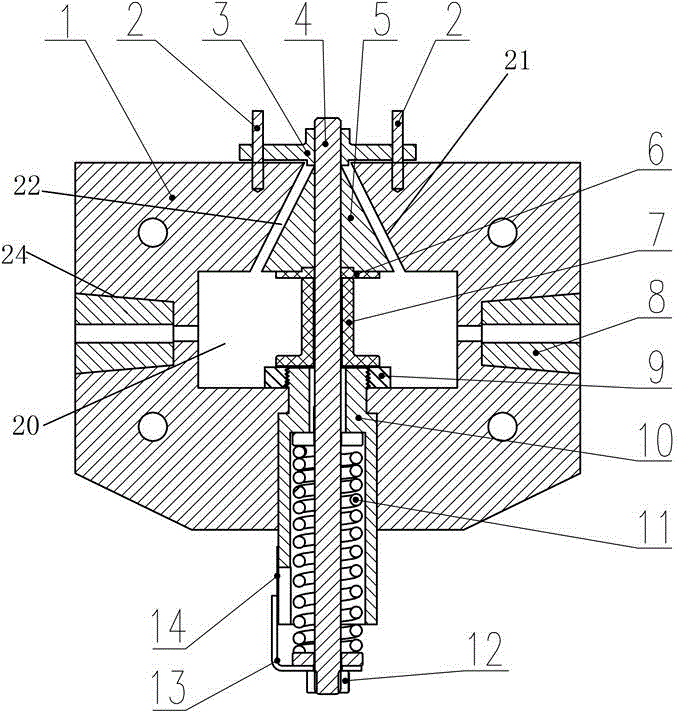

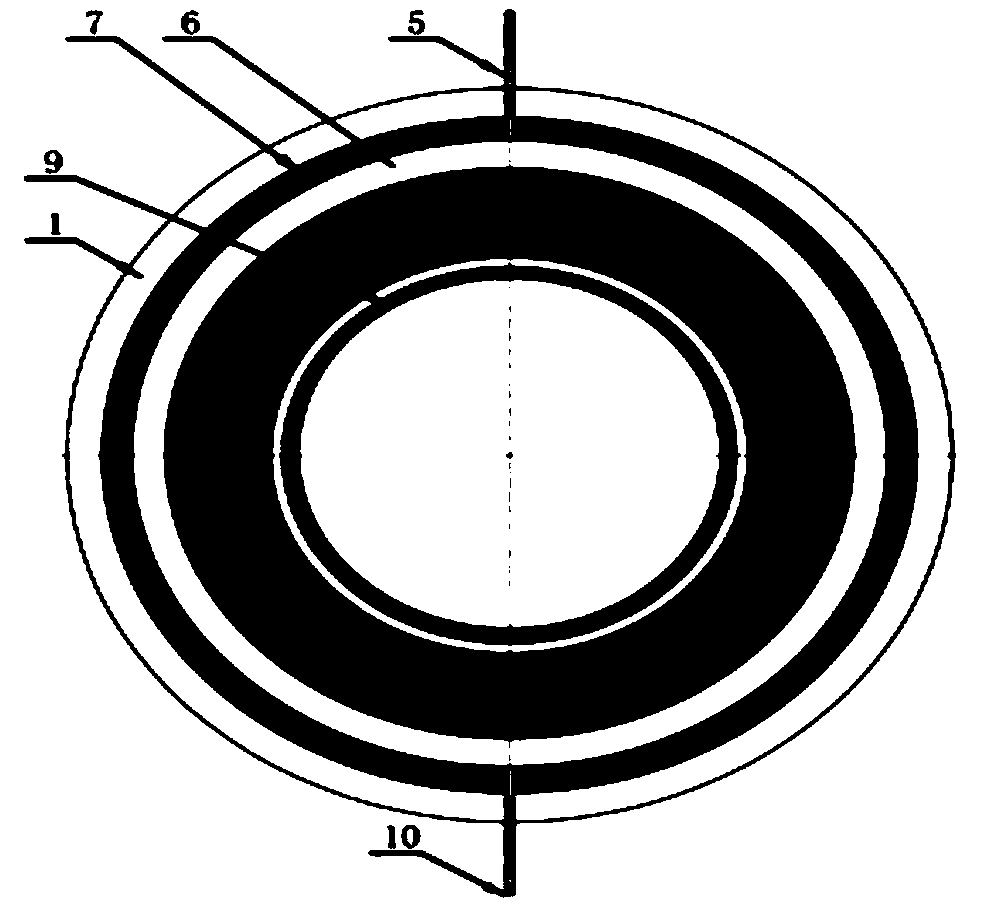

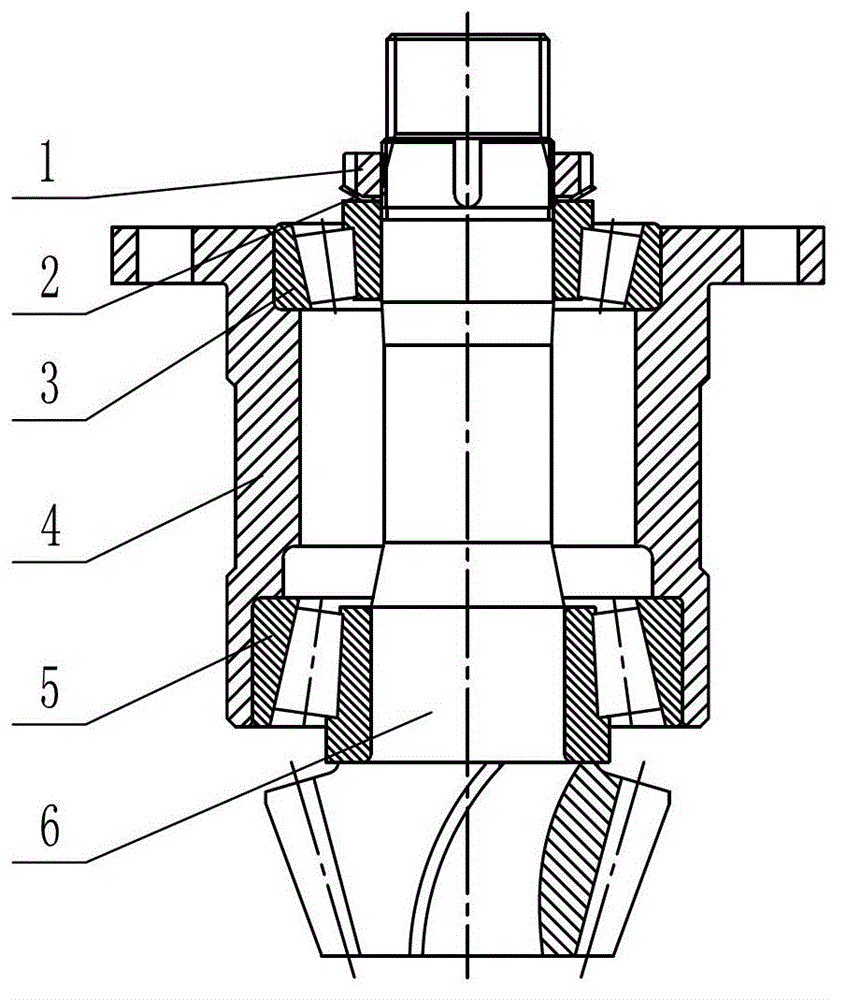

Torque sensor capable of measuring six-dimensional non-coplanar force

ActiveCN102353482ALow costHigh measurement accuracyWork measurementForce measurement using piezo-resistive materialsTorque sensorEngineering

The invention discloses a torque sensor capable of measuring six-dimensional non-coplanar force. In the torque sensor, nine sensors are arranged on three installation bases in three groups respectively; the end parts of the installation bases are connected with end covers; the two ends of an X-axis connecting rod are arranged in through holes of two installation bases respectively; and a Y-axis connecting rod is arranged in a through hole of a third installation base. The torque sensor designed by the invention is arranged on a carrier by using a loading flange. When pressure is applied to the upper end of Y-axis connecting rod, nine one-dimensional sensors which are connected with a T-shaped connecting rod are subjected to force of different magnitudes and have different outputs under the actions of six-dimensional non-coplanar force and three-dimensionalal non-coplanar orthogonal torque. Analysis on the force structure according to the theoretical mechanics indicates that the relation between the output force information of the nine one-dimensional sensors and the applied six-dimensional non-coplanar force is: the magnitude of the six-dimensional non-coplanar force can be obtained by only measuring the output numerical values of the nine one-dimensional sensors.

Owner:BEIHANG UNIV

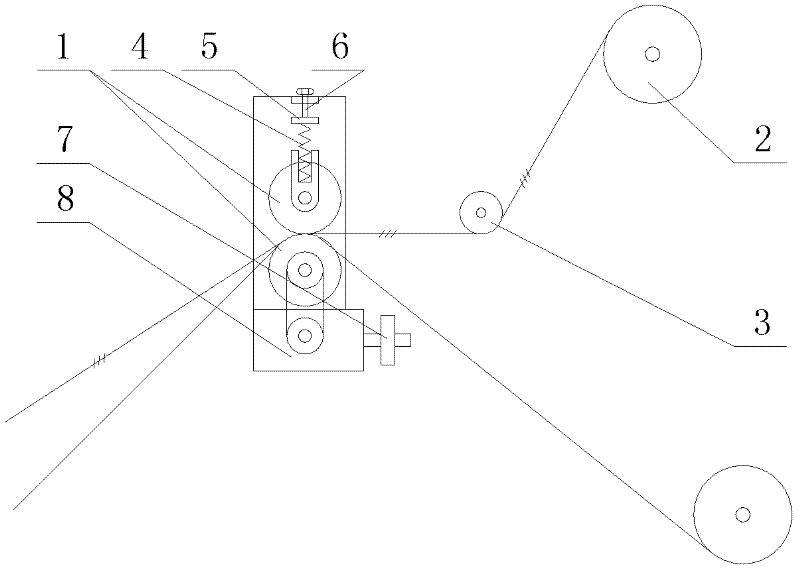

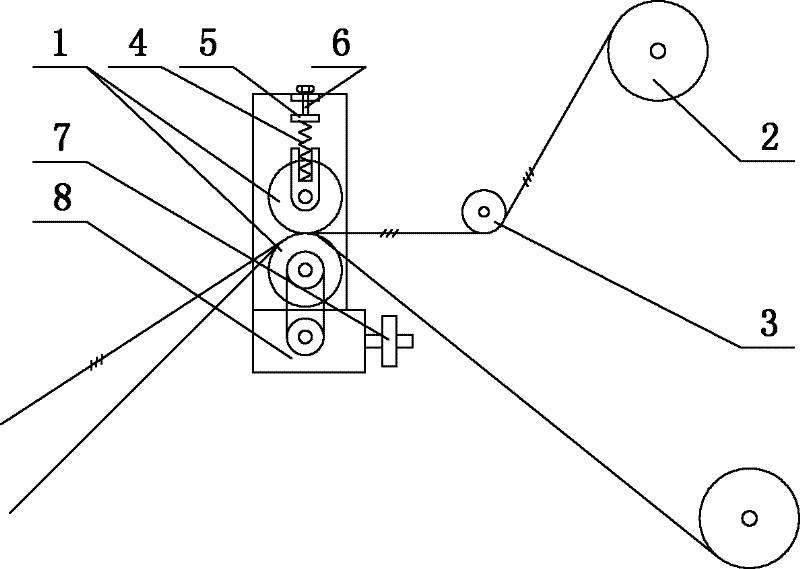

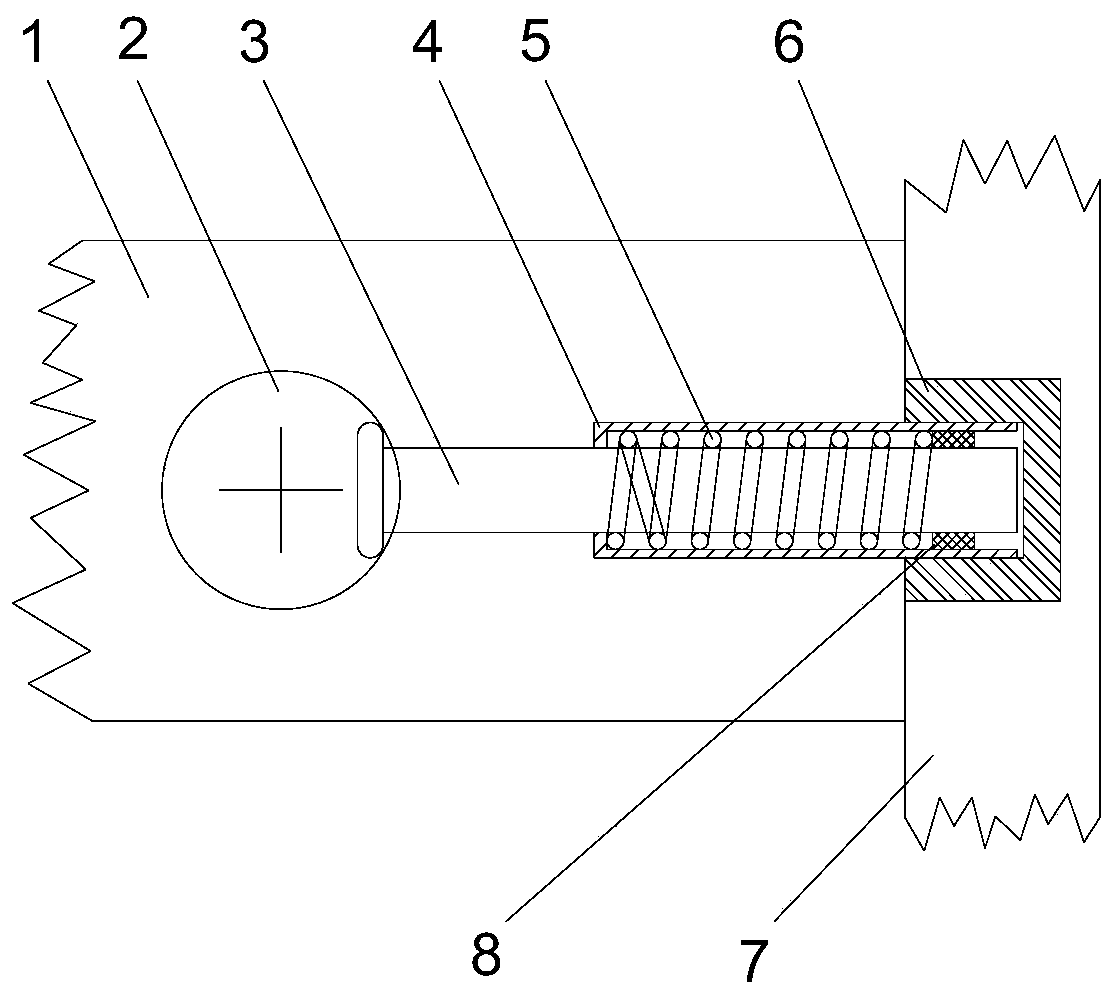

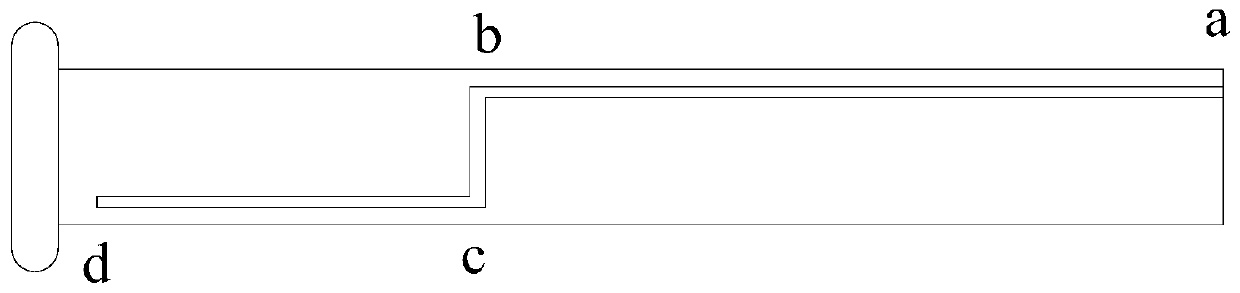

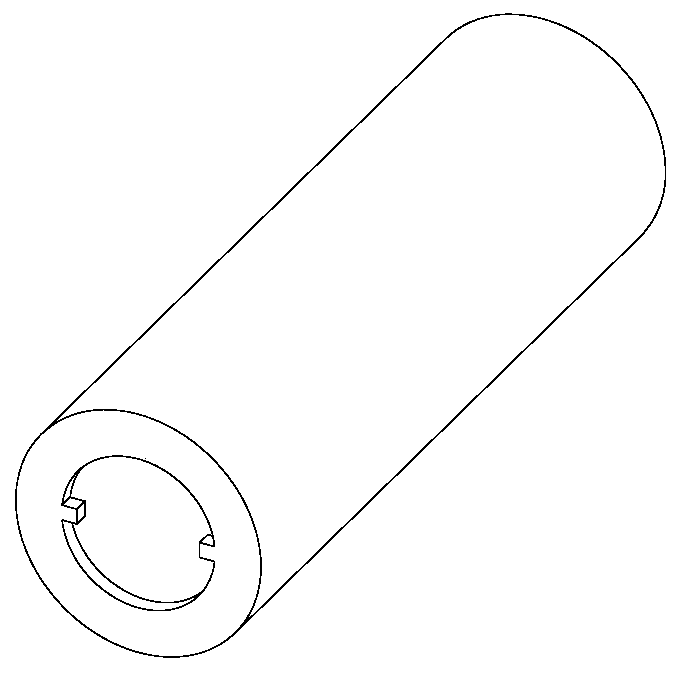

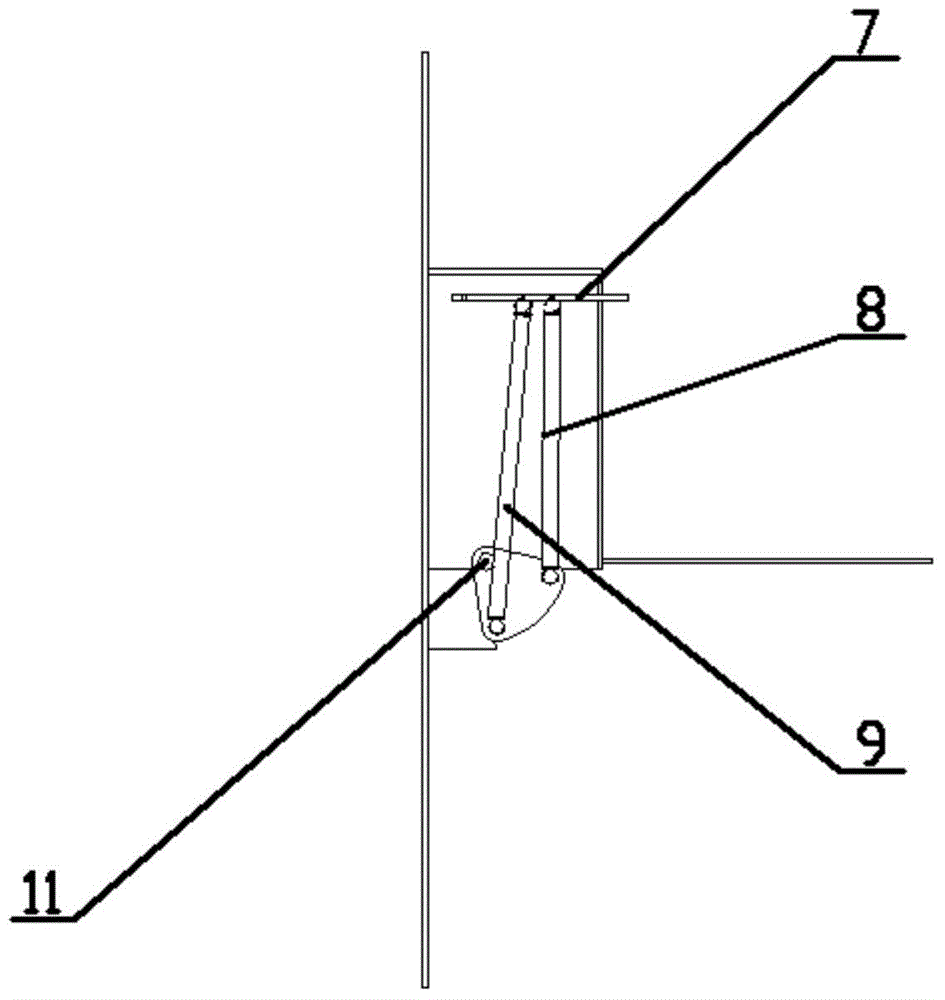

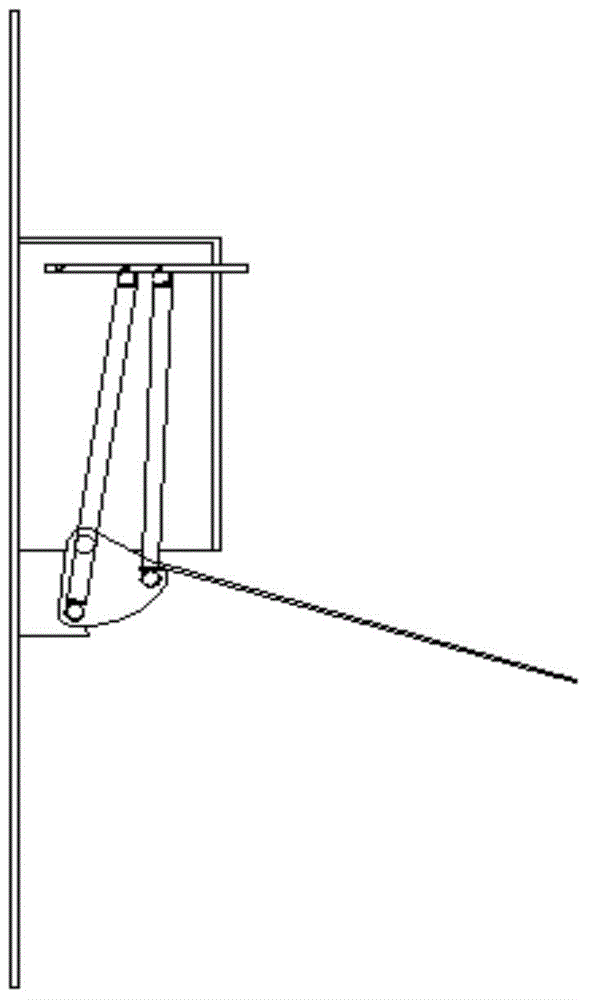

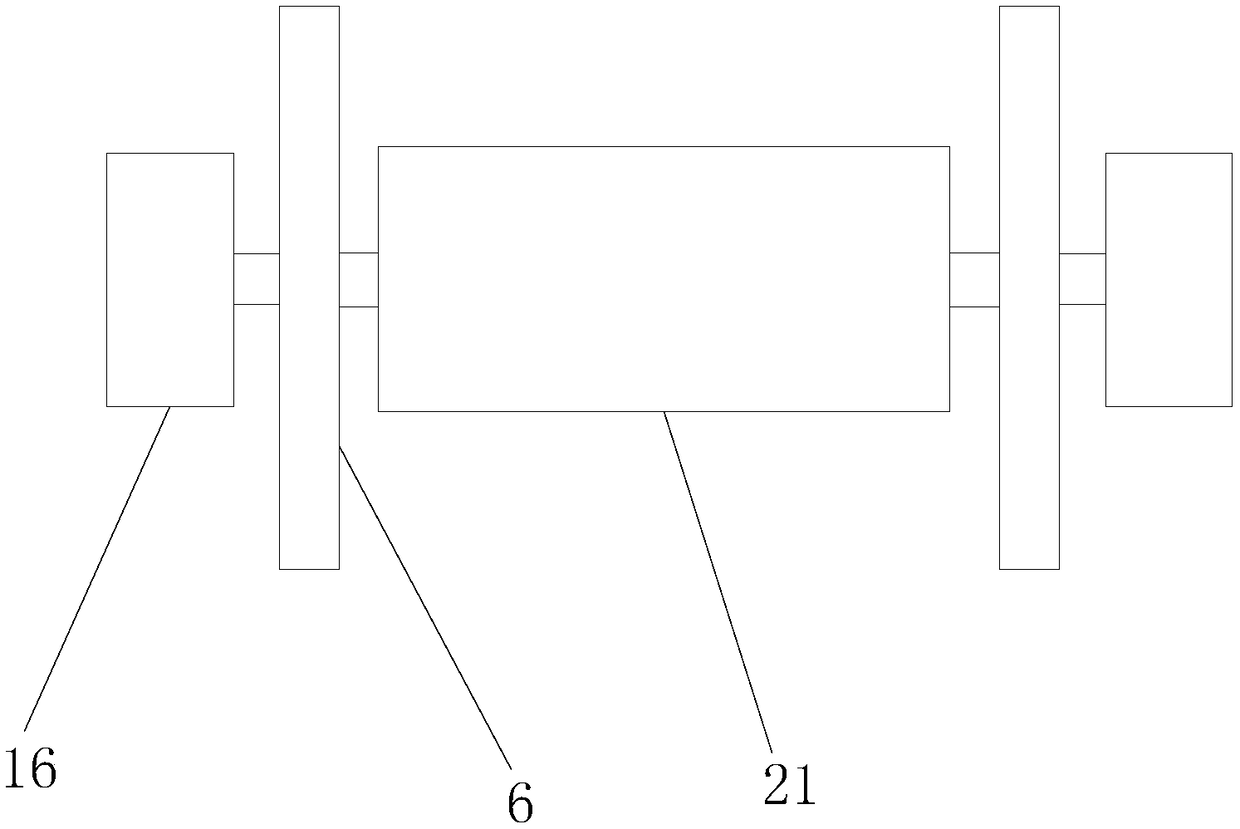

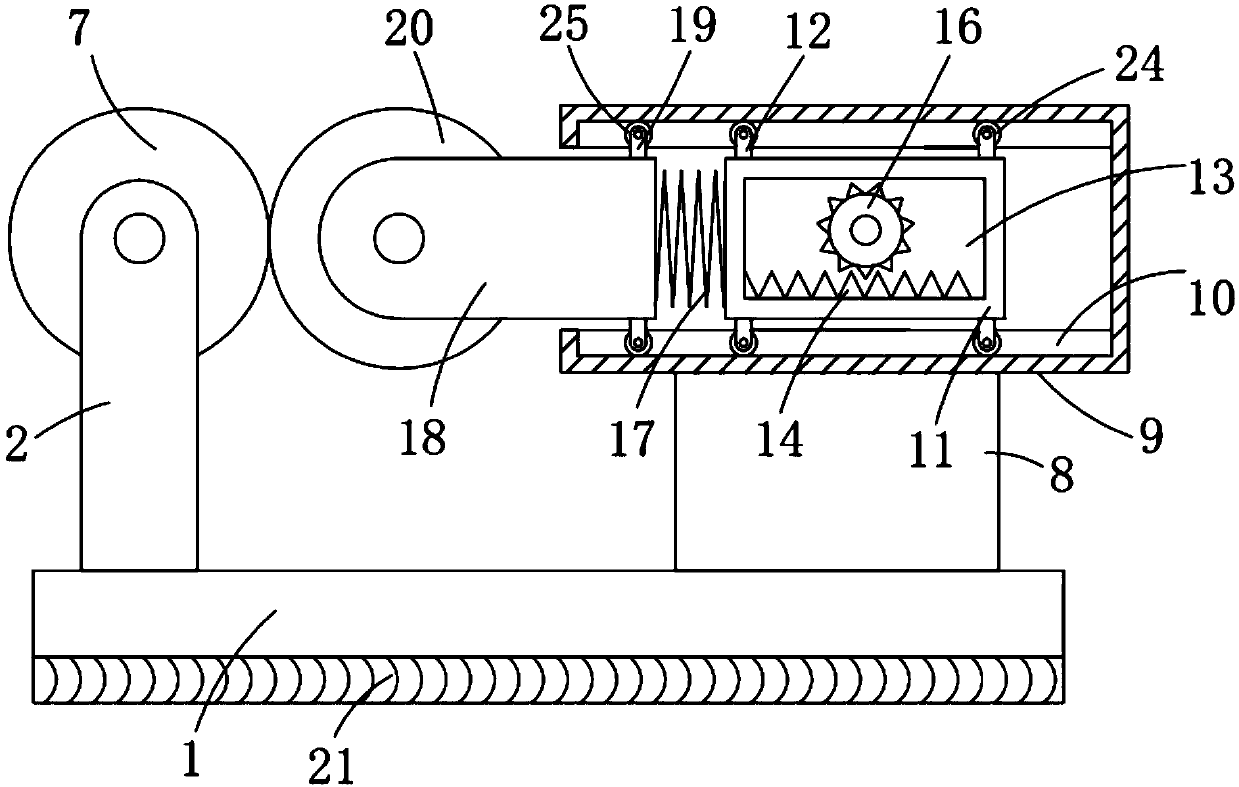

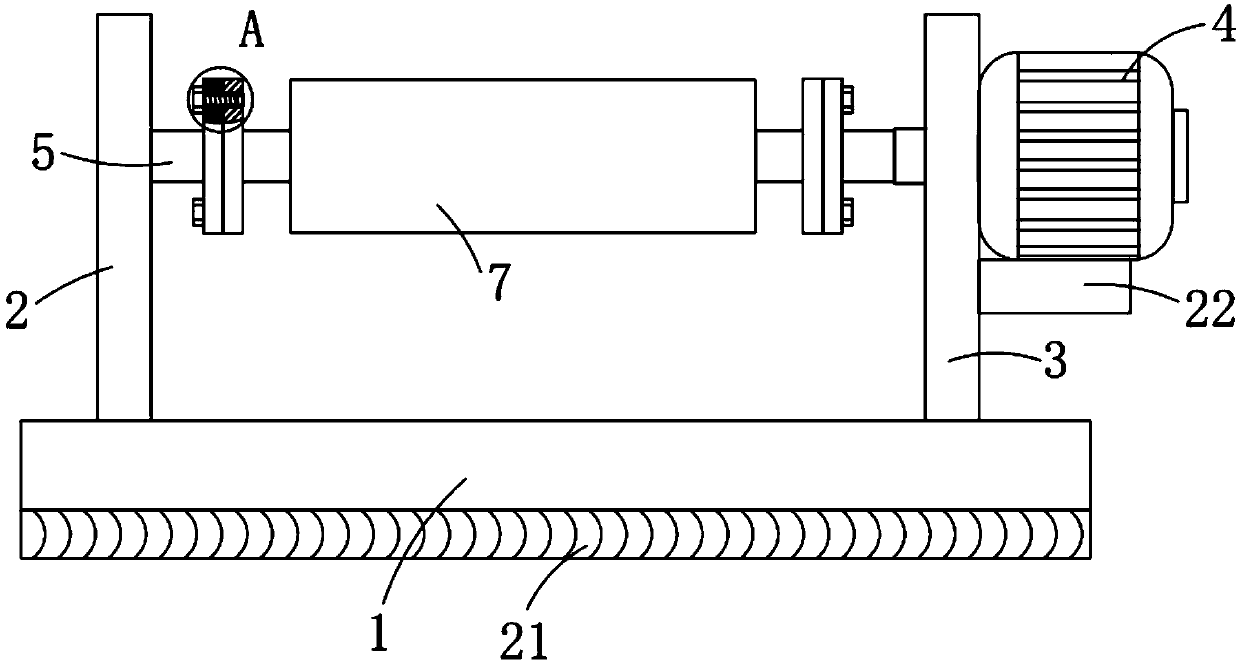

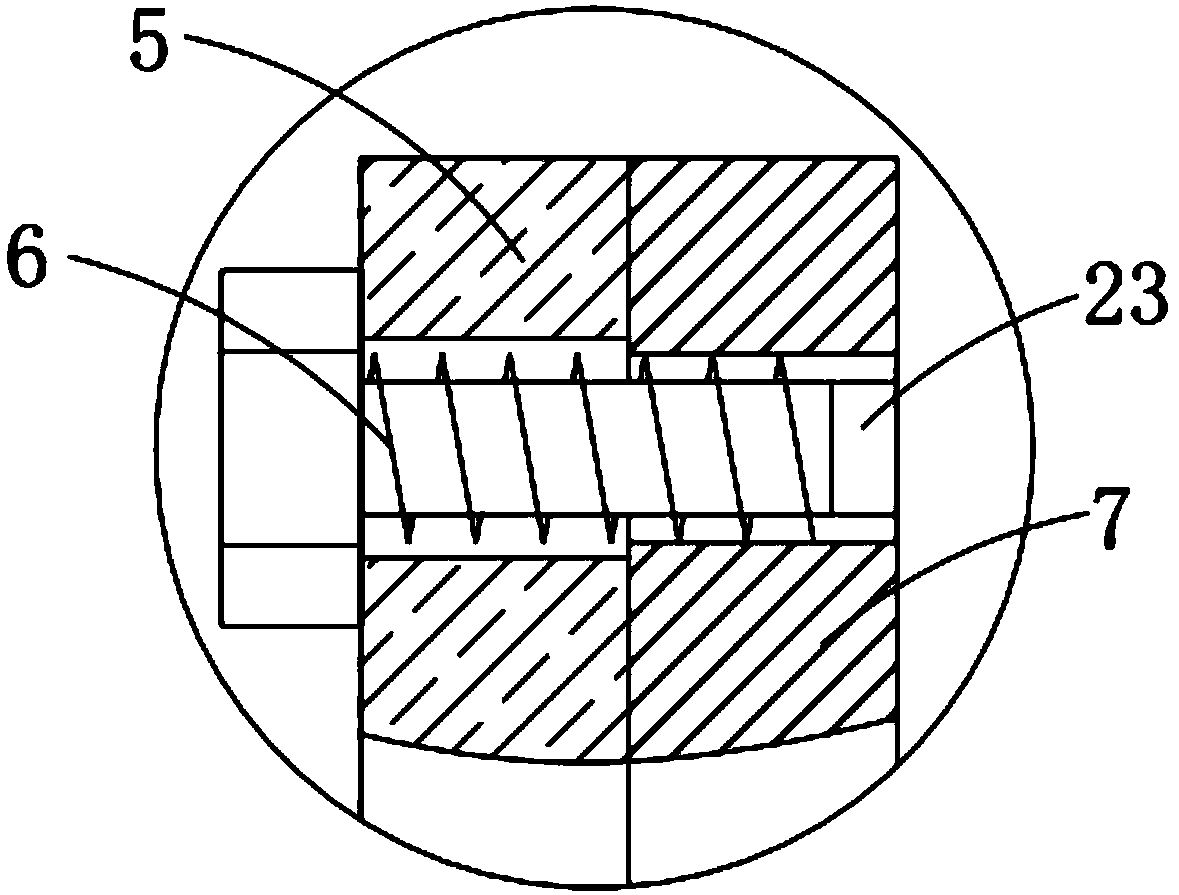

Synchronous feeding mechanism for tongue depressor machine

InactiveCN102407953AAdjust the preloadGuaranteed stabilityWrapping material feeding apparatusWebs handlingEngineeringMechanical engineering

The invention relates to a synchronous feeding mechanism for a tongue depressor machine, which comprises two paired rollers connected in rolling way and two feeding rollers; the lower paired roller is fixed; the roller shaft of the upper paired roller is mounted on a pre-tightening spring; the pre-tightening spring bears against a pushing block; the pushing block is mounted on the shell through screws and can be adjusted in position by the screws; a guide roller is arranged between the upper feeding roller and each of the two paired rollers; and the lower side of the guide roller and the lower side of the upper paired roller are located on the same horizontal height. The synchronous feeding mechanism for the tongue depressor machine provided by the invention has the beneficial effects that: feeding speeds of two material belts are adjusted by the pre-tightening spring to ensure that feeding speeds of two feeding rollers are completely the same. And pre-tightening force of the pre-tightening spring can be adjusted in real time according to different thicknesses, friction coefficients and feeding speeds of material belts, so that better synchronization effect is realized. While the stability of the paired rollers can be better ensured by the arrangement of a guide wheel and the tension force in other directions may not be acted on the paired rollers.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

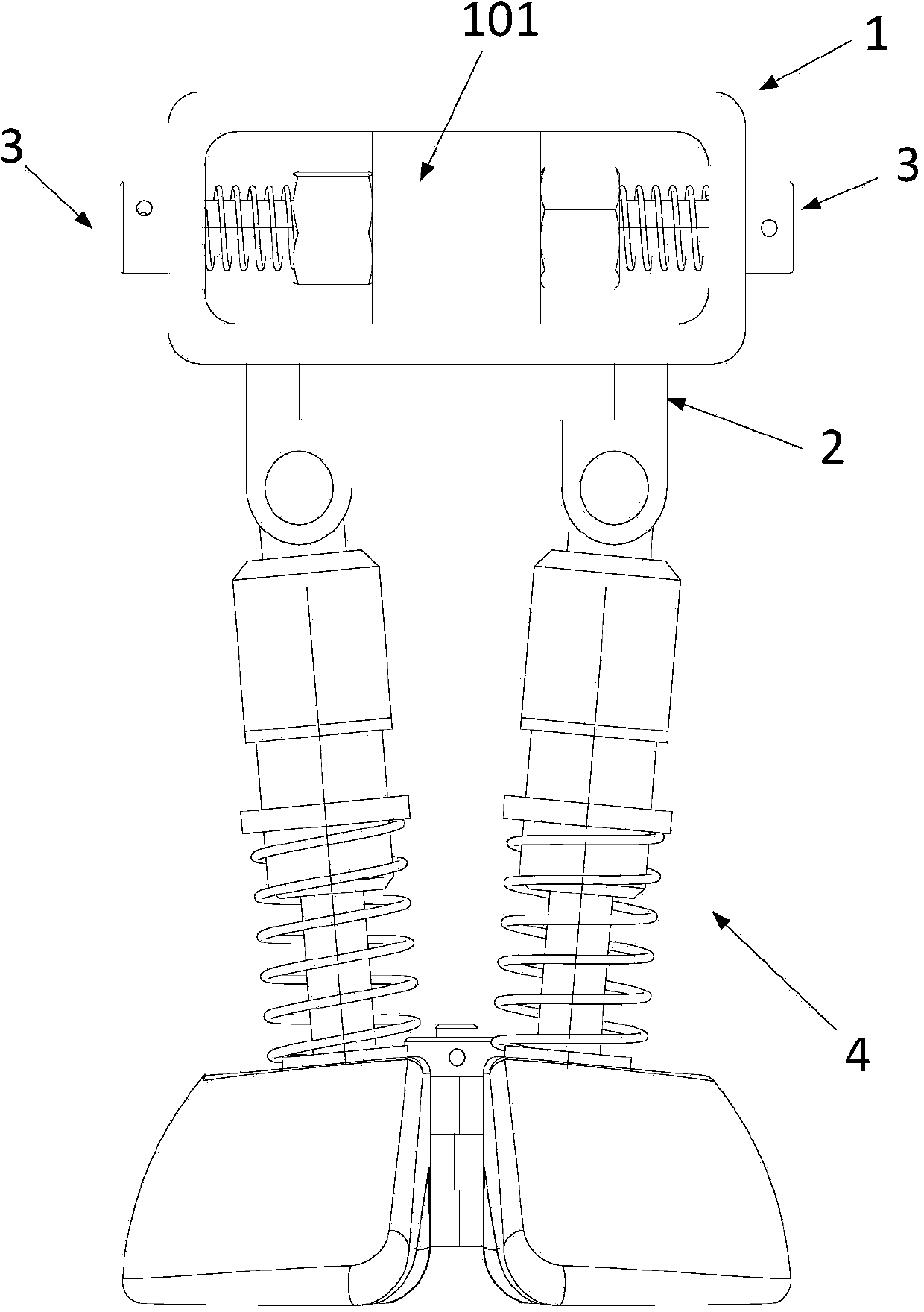

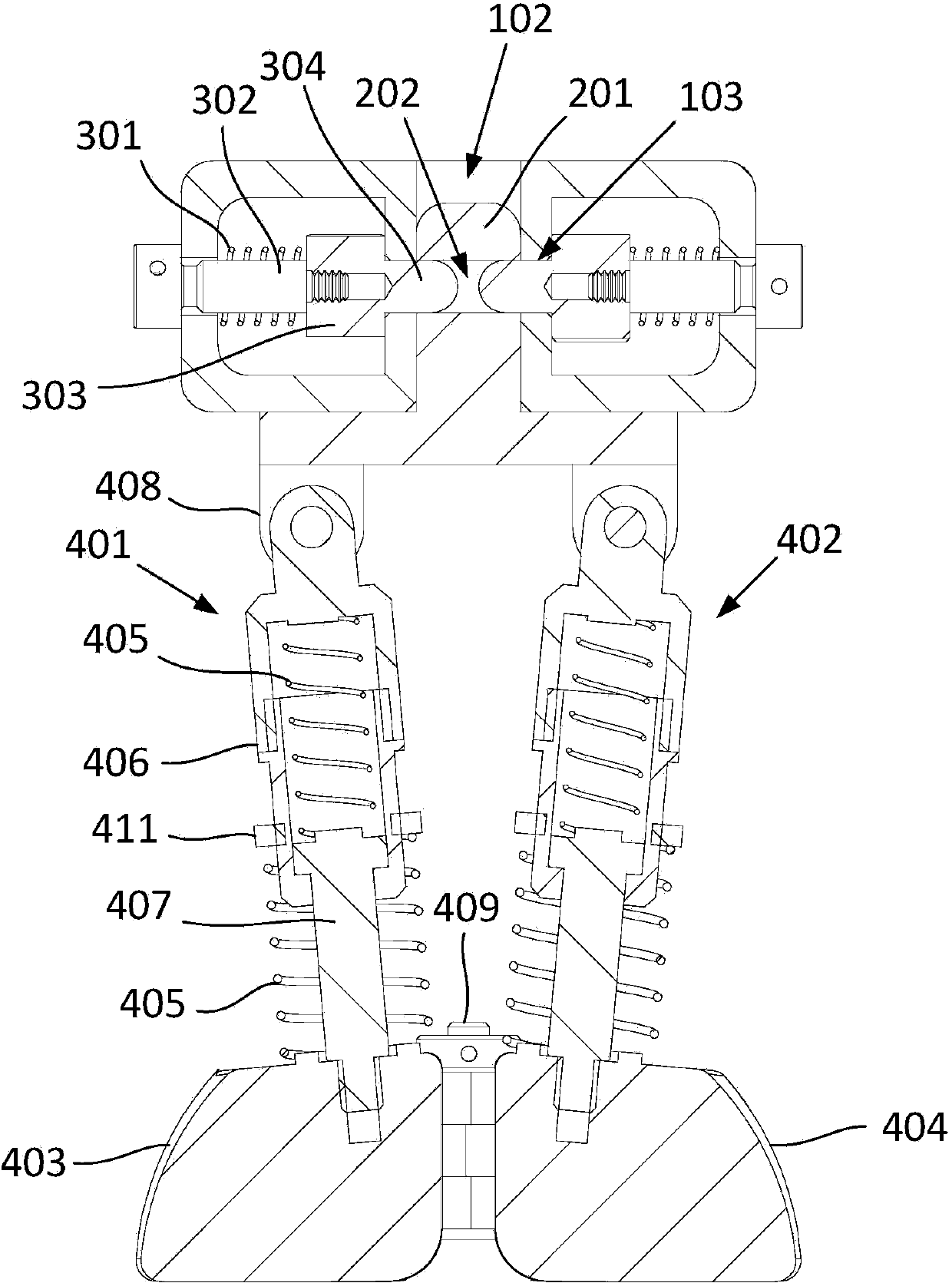

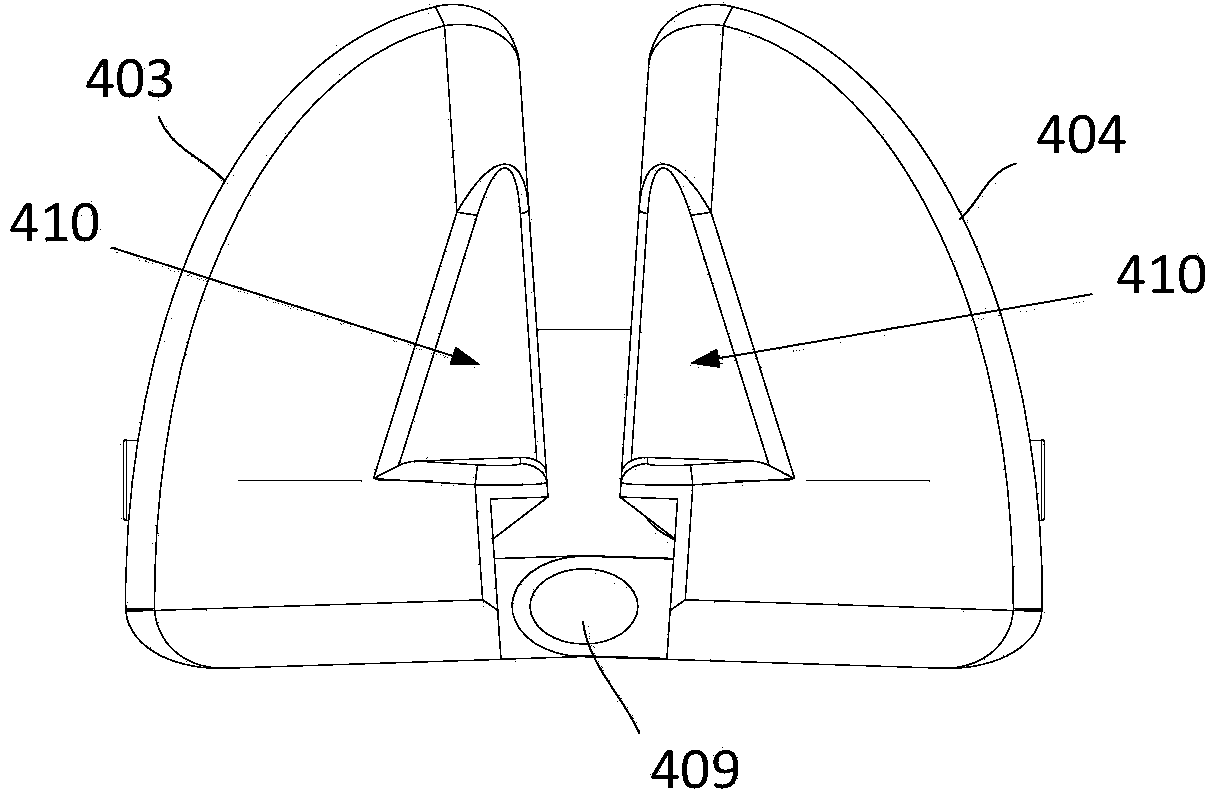

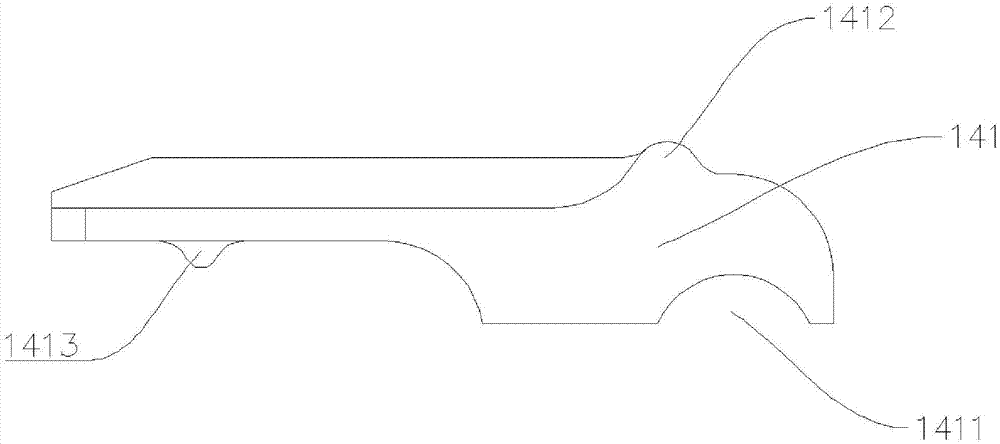

Modularization sheep foot simulation mechanical foot device

The invention discloses a modularization sheep foot simulation mechanical foot device which comprises an interface shell, a foot installation plate, plugging mechanisms and foot mechanisms. The interface shell is internally provided with a connection block. A plugging hole is formed in the connection block in the vertical direction, the top face of the foot installation plate is provided with a plugging shaft, and the bottom face of the foot installation plate is used for installation of the foot mechanisms. The plugging shaft penetrates into the plugging hole, due to the fact that the two sets of plugging mechanisms sequentially penetrate through the connection block from the two sides of the interface shell and the end of each plugging mechanism can be located in the plugging shaft, positioning between the interface shell and the foot installation plate is achieved. Detaching between the interface shell and the foot installation plate is achieved by pulling the plugging mechanisms. The foot mechanisms are designed by simulating the sheep feet and are connected with a left hoof section and a right hoof section through two branch chains respectively. Each branch chain is provided with a buffering and energy storing spring to achieve vibration reducing and energy storing. The modularization sheep foot simulation mechanical foot device has the advantages that fast replacing between the foot mechanisms and legs of a robot can be achieved, and the modularization sheep foot simulation mechanical foot device is suitable for leg type and wheel leg type robots to walk on complicated grounds in the open gas.

Owner:BEIHANG UNIV

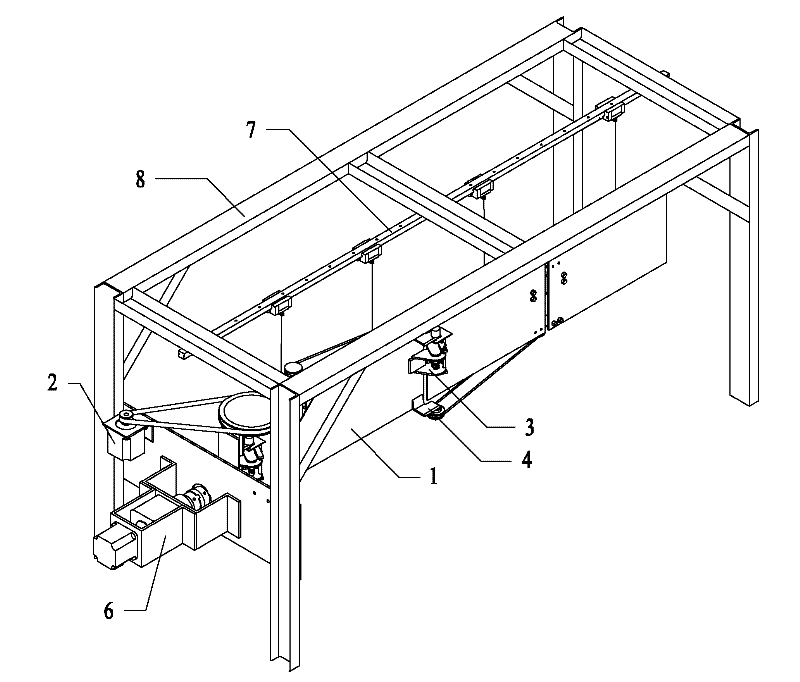

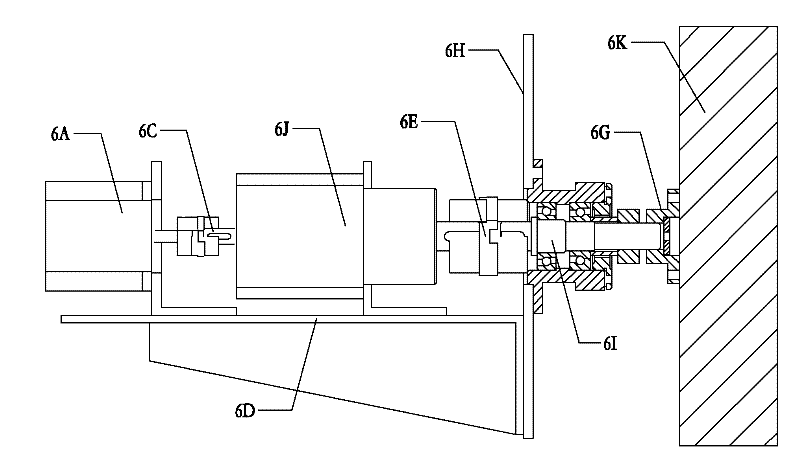

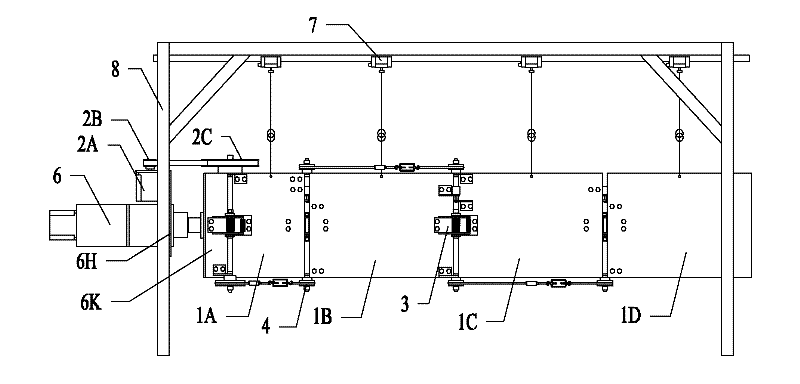

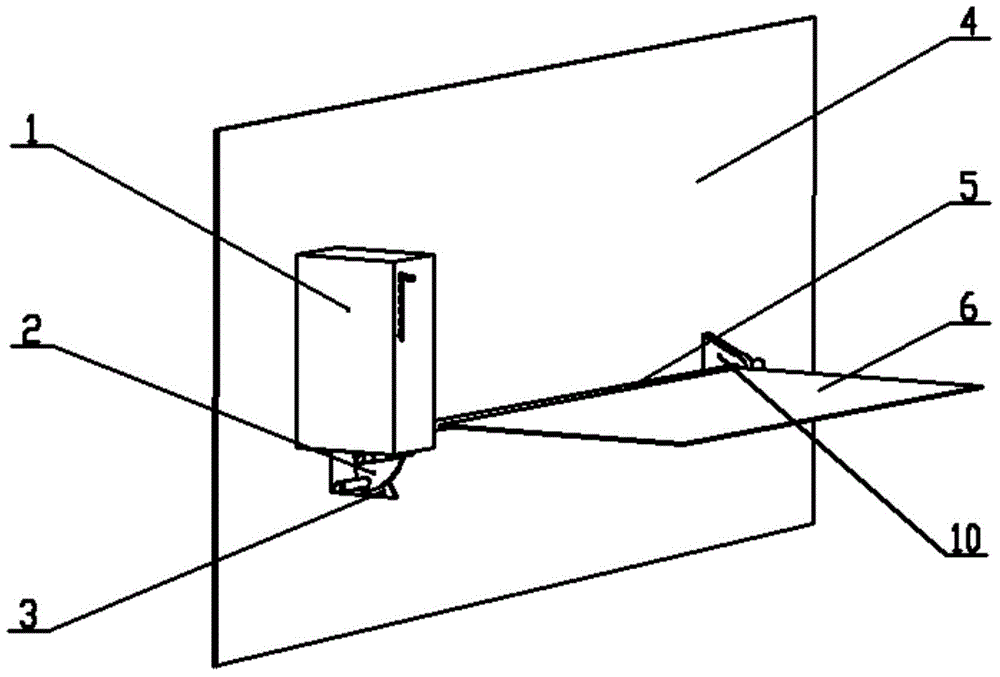

Solar cell array simulation device

InactiveCN102253322AAdjust tensionAdjust the preloadPhotovoltaic monitoringTension measurementEngineeringSolar cell

The invention discloses a solar cell array simulation device comprising a frame, an orientating mechanism, a suspension gear, a gap hinge, solar cell array sailboards, a swinging mechanism and a unfolding mechanism, wherein the orientating mechanism is arranged on the side part of the frame; the swinging mechanism is arranged on the orientating mechanism; the suspension gear is arranged on the top of the frame; the suspension gear and the orientating mechanism are connected with the solar cell array sailboard; the gap hinge is arranged between the solar cell array sailboards; and the unfolding mechanism is arranged on the solar cell array sailboards. According to the solar cell array simulation device, the kinematic characteristics for unfolding a solar cell array under different driving parameters can be tested, and the unfolding of the solar cell array under the conditions of different hinge gaps and various mechanical faults can be simulated.

Owner:TSINGHUA UNIV

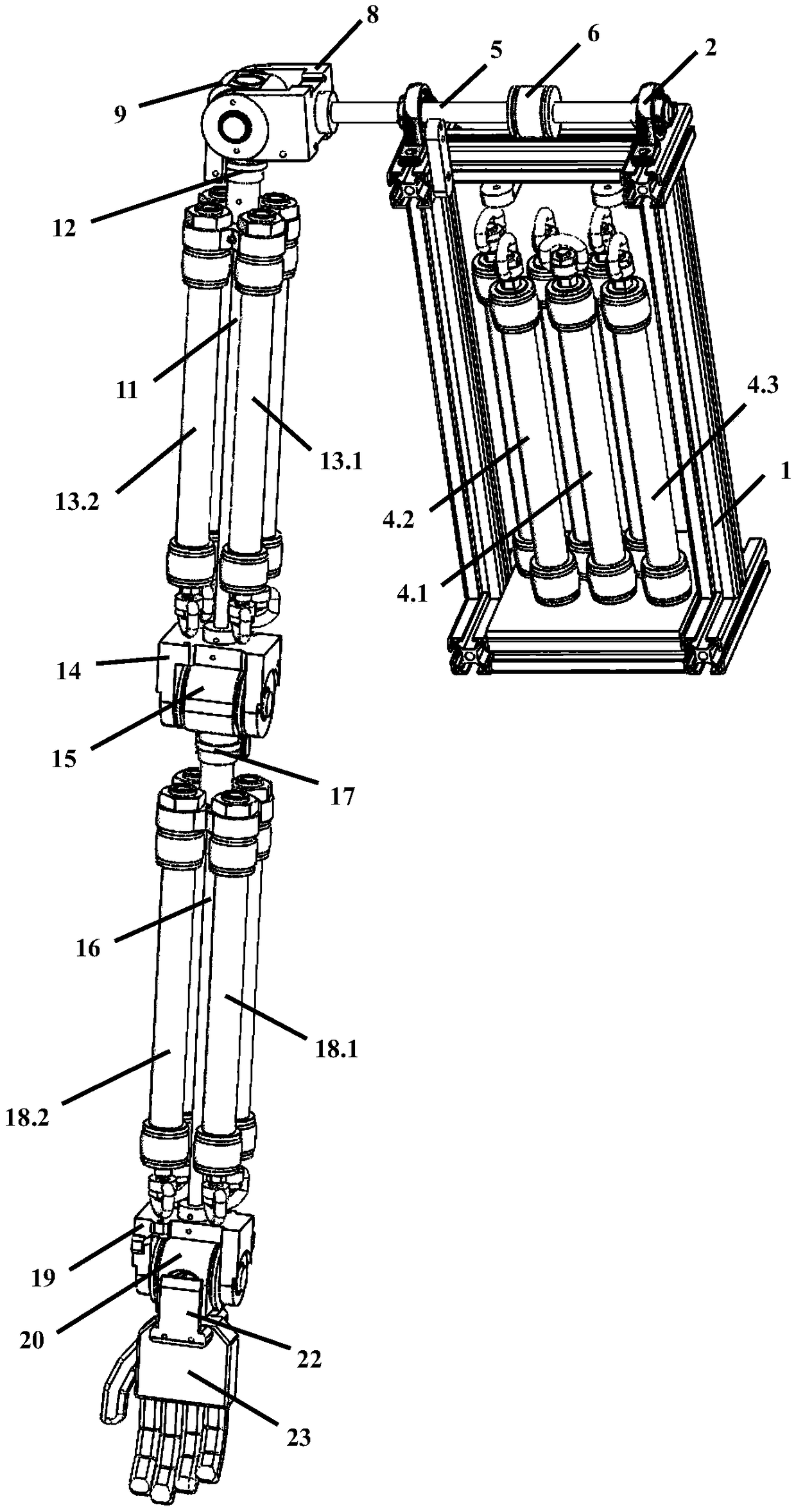

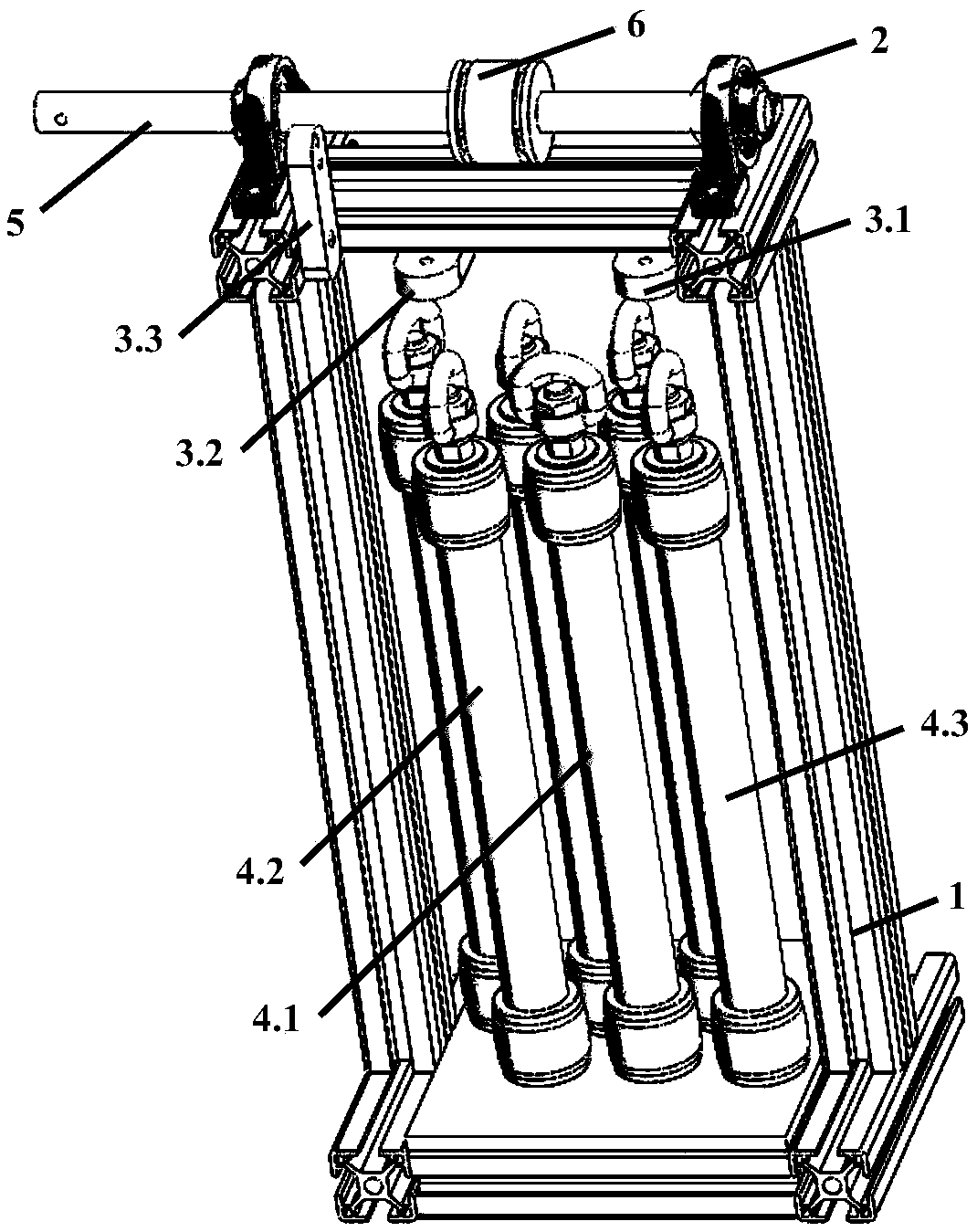

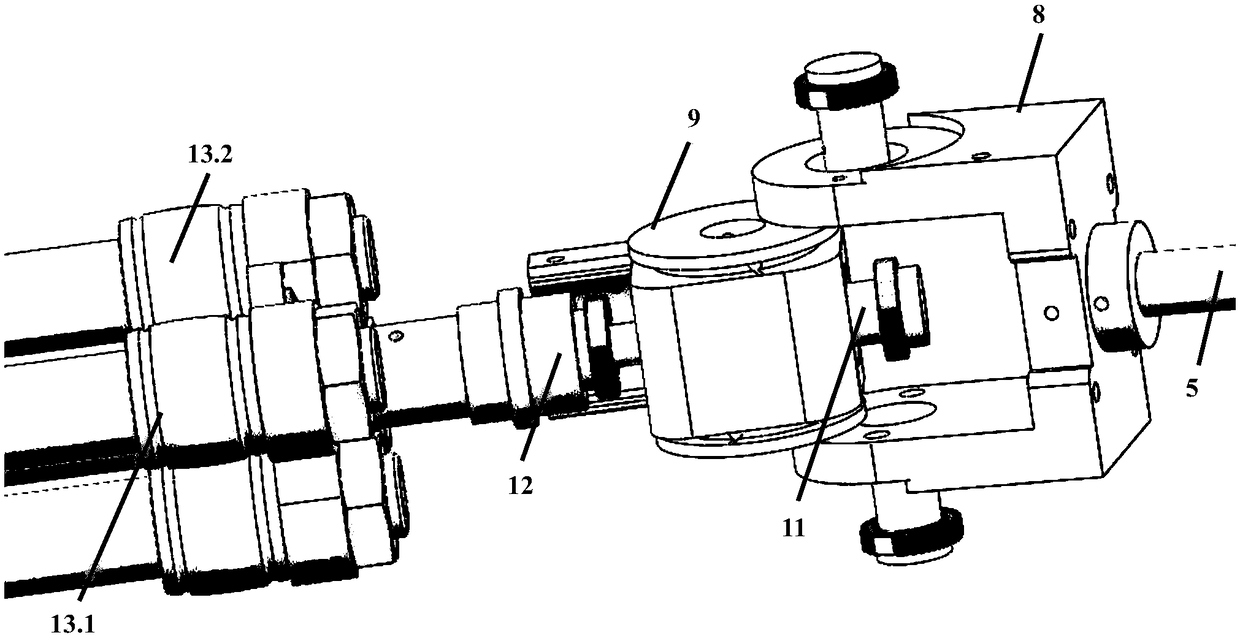

Seven-degree-of-freedom humanoid mechanical arm driven by pneumatic muscle

ActiveCN108724163ASports anthropomorphicSimple structureProgramme-controlled manipulatorShoulder abductionThree degrees of freedom

The invention discloses a seven-degree-of-freedom humanoid mechanical arm driven by pneumatic muscle. The mechanical arm is composed of a fixing support, a shoulder joint, a big arm, an elbow joint, aforearm, a wrist joint and a hand, wherein the shoulder joint is provided with a degree of shoulder buckling stretching freedom, a degree of shoulder abduction freedom and a degree of big arm inner rotation and outer rotation freedom, the axles of the degree of shoulder buckling stretching freedom, the degree of shoulder abduction freedom and the degree of big arm inner rotation and outer rotation freedom intersect at one point, the elbow joint is provided with a degree of elbow buckling stretching freedom, the wrist joint is provided with a degree of elbow-forearm pre-rotation and post-rotation freedom, a degree of wrist buckling stretching freedom and a degree of wrist abduction freedom, the axles of the degree of elbow-forearm pre-rotation and post-rotation freedom, the degree of wrist buckling stretching freedom and the degree of wrist abduction freedom intersect at one point, and the movement of the mechanical arm completely simulates people. Each degree of freedom of the mechanical arm is driven by a pair of pneumatic muscle antagonists, and a bowstring wire and a steel wire rope are used for transmission. According to the seven-degree-of-freedom humanoid mechanical arm driven by pneumatic muscle, the artificial degree is higher, a transmission system is simpler, and the degree of coupling between different pneumatic muscles is lower; and the installation position of the pneumatic muscle is more flexible, the arrangement of the pneumatic muscle is more compact, and the pre-tightening force of the pneumatic muscle is adjustable.

Owner:廊坊市增特科技有限公司

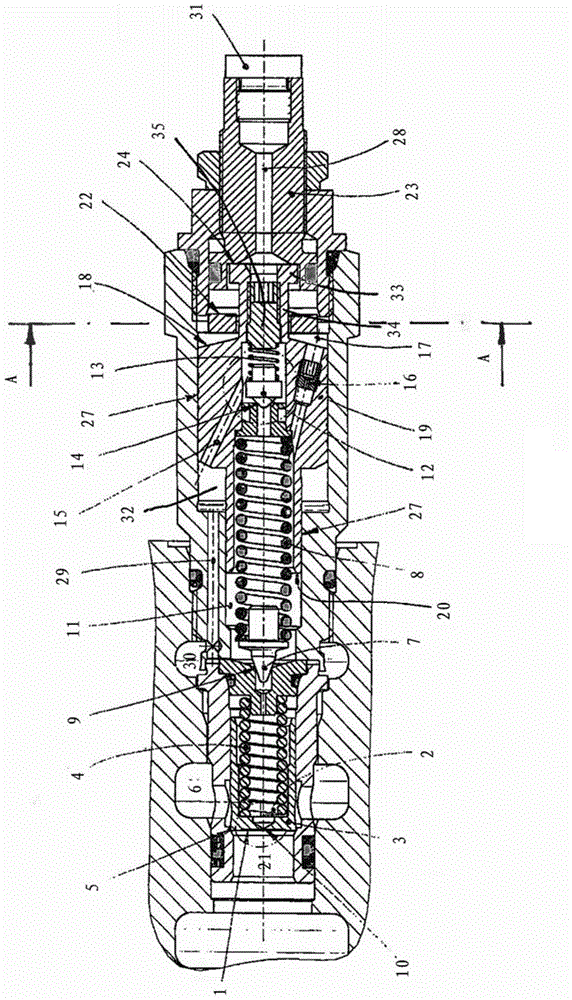

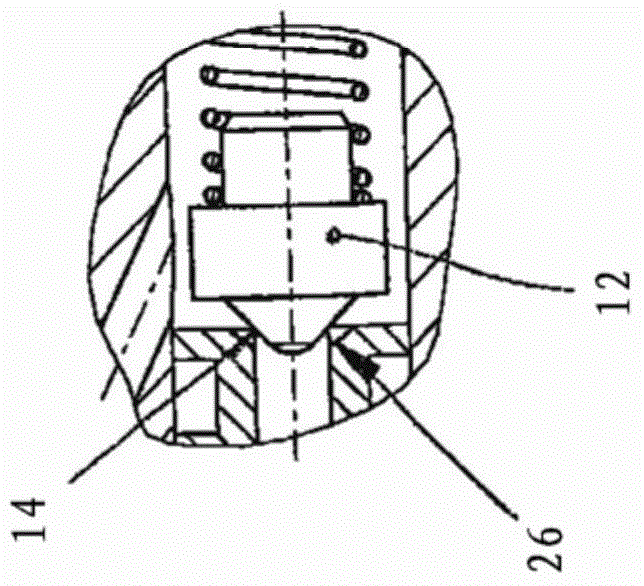

Pressure-limiting valve

InactiveCN104696561AAvoid blockingImprove distributionOperating means/releasing devices for valvesEqualizing valvesEngineeringPiston

The invention relates to a pressure-limiting valve with a master grade and a pre-control grade. The pre-control grade is used for controlling opening movement of the master grade. The pre-control grade has spring elements (8), pre-tightening forces of which are used for determining opening pressure of the pressure-limiting valve. The spring elements are supported on a guide piston (19). The guide piston can be movably arranged in a housing of the pressure-limiting valve and is provided with a guide chamber (17) at the rear portion. The guide chamber is sized depending on the position of the guide piston. A control fluid of the pre-control grade flows into the guide chamber at the rear portion such that pre-tightening forces of the spring elements (8) increased by movement of the guide piston after the pre-control grade is opened. A pressure-relief grade is arranged and used for limiting pressure of the pre-control grade and provided with a valve element (12) pre-tensioned to reverse to a valve seat (14). Hence, at least one outflow opening (26) can be arranged between the valve element and the valve seat when the valve element and / or the valve seat are formed for closing the pressure-relief grade. The fluid can flow out of the outflow opening from the pre-control grade.

Owner:LIEBHERR MACHINES BULLE

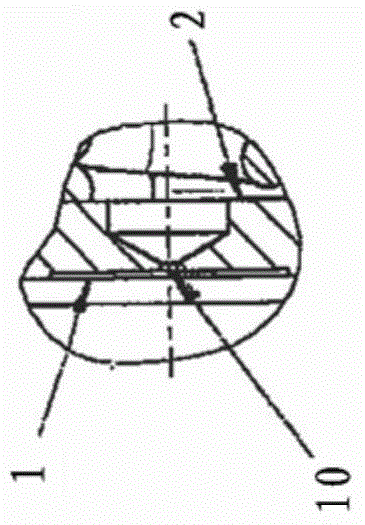

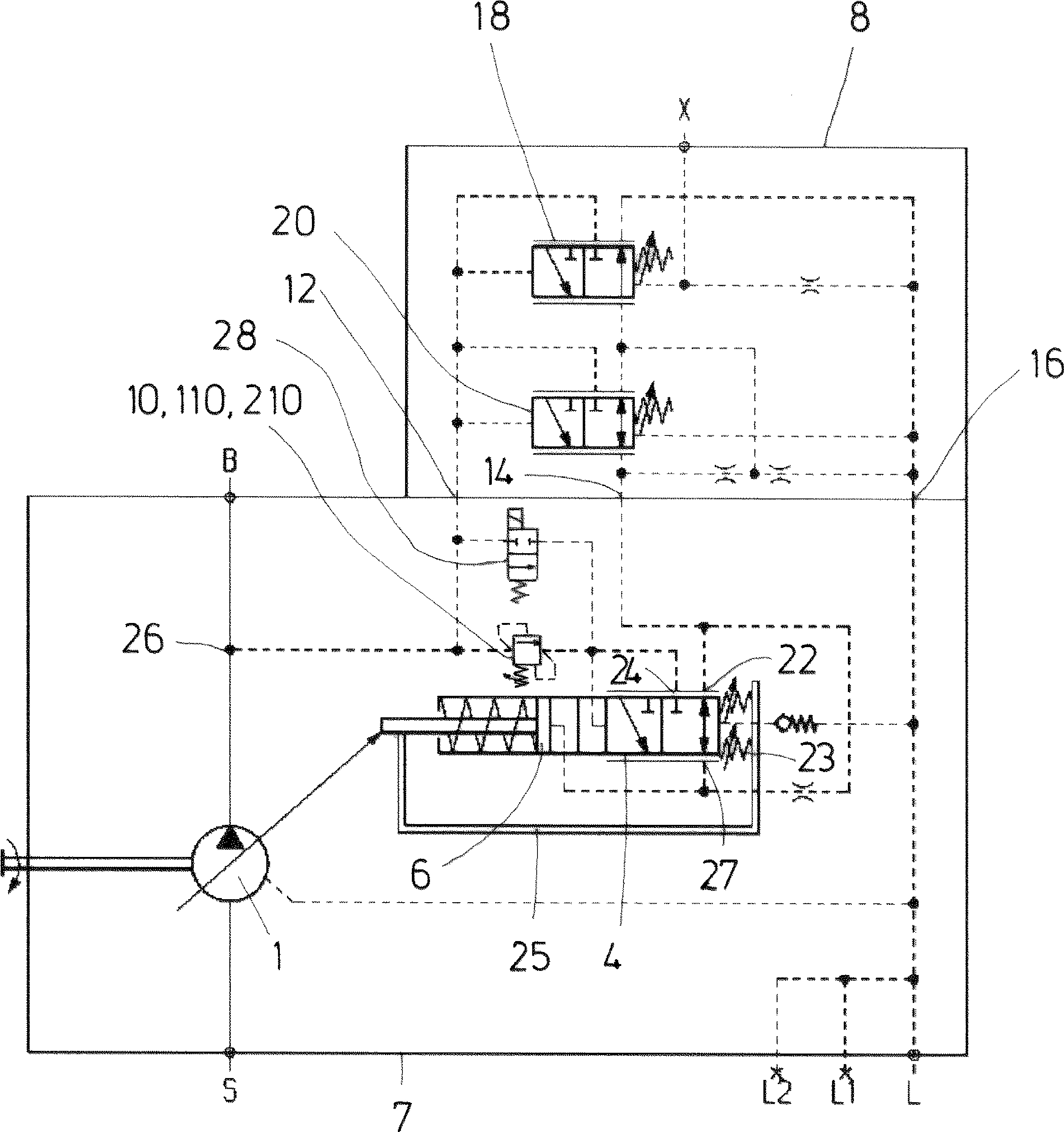

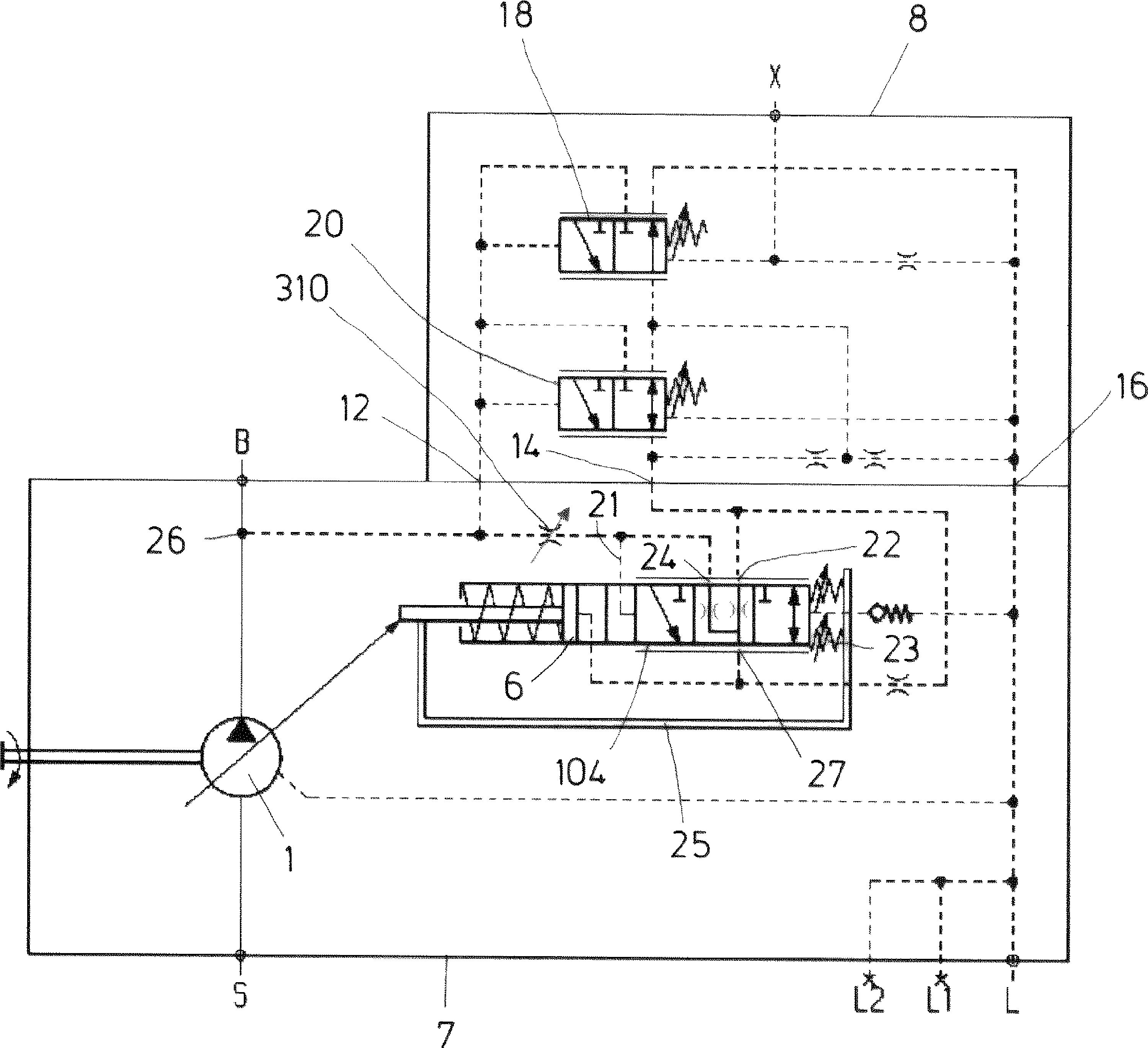

Adjusting device used for fluid static force pump and fluid static force pump

ActiveCN103671058ALow servo pressureSimple device technologyPump controlPositive-displacement liquid enginesPressure decreaseFuel tank

The invention discloses an adjusting device used for adjusting discharge volume of the fluid static force pump and provided with a power adjusting valve. The power adjusting valve is provided with a first port, a second port, a third port and a valve slide block. Hydraulic pressure oil can flow into the first port from a pressure port of the pump. The second port can be connected with an oil tank. The third port is connected with a servo cavity in a servo piston. The valve slide block can be loaded through controlling pressure in a condition when the discharge volume of the pump is decreased and the valve slide block can be loaded with a spring device in a condition that a swing angle is increased. The invention aim at adjusting different power levels by arranging the adjusting device adopting the above structure. The device is realized by that the valve device can load control pressure that is amount to pressure in a pressure port of the pump or can load control pressure decreasing relative to pressure in the pressure port of the pump based on adjustment of the valve slide block of the power adjusting valve.

Owner:ROBERT BOSCH GMBH

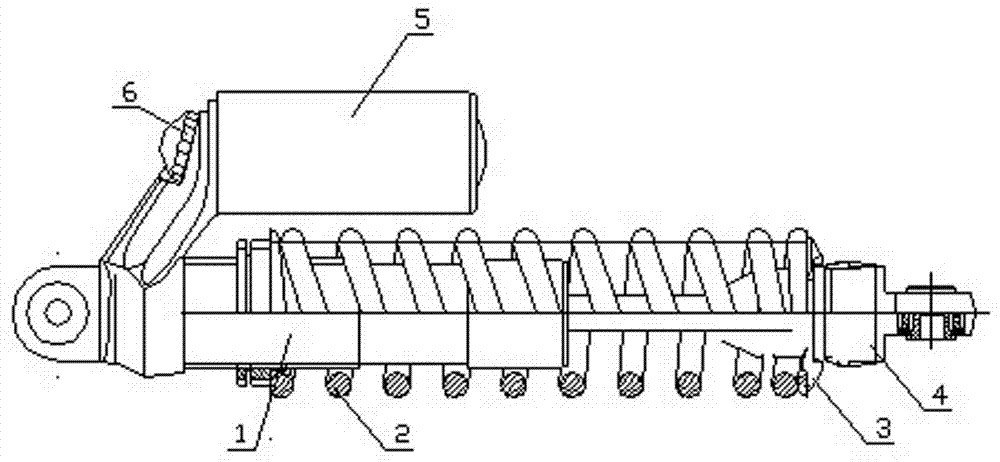

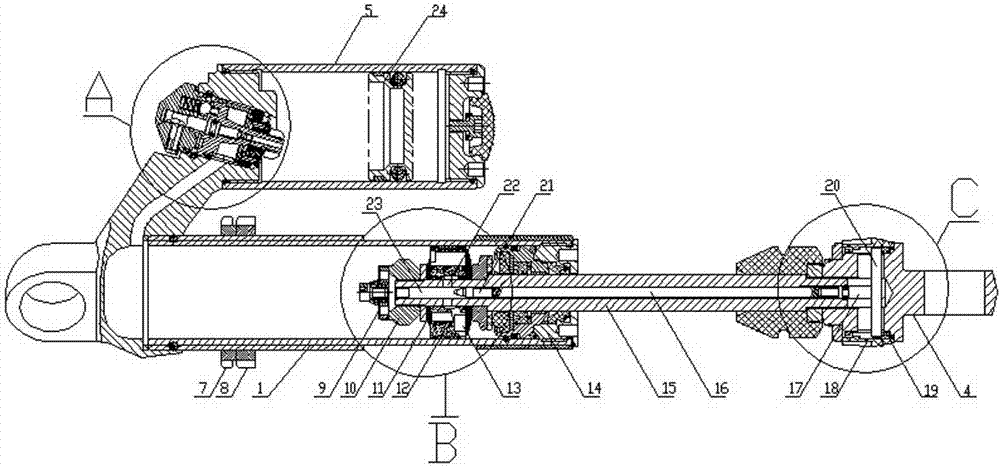

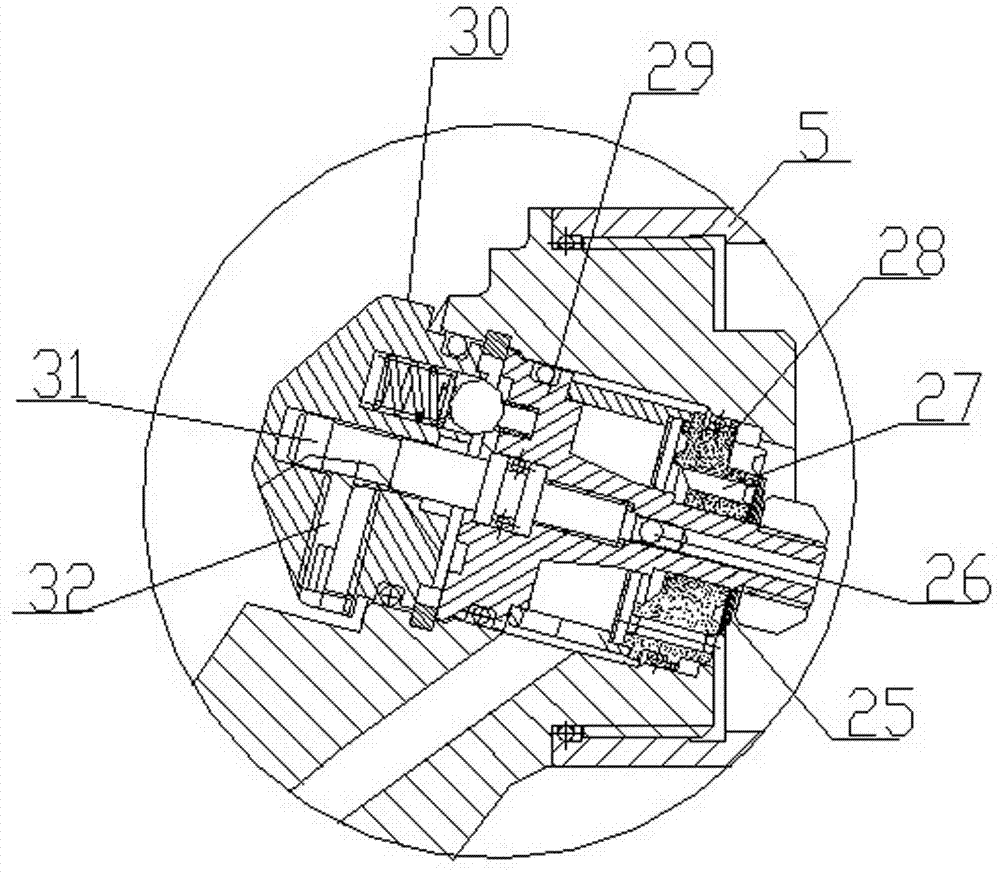

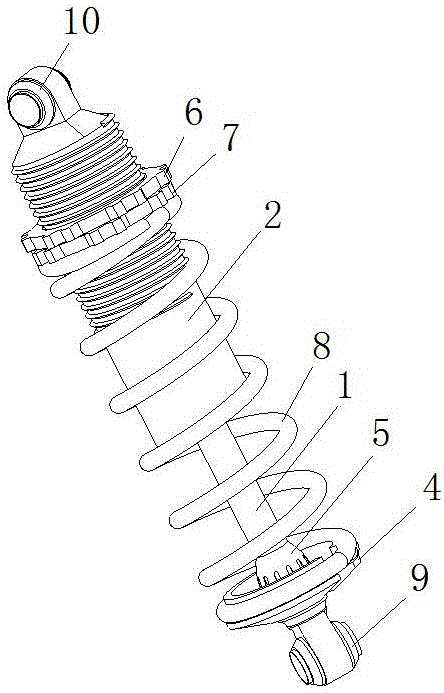

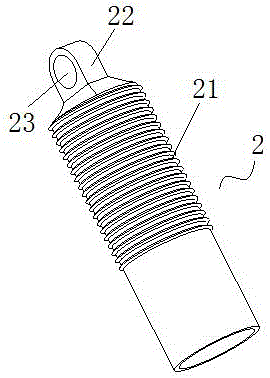

Motorcycle shock absorber with damping force adjustable

InactiveCN103527698AImprove shock absorptionImprove adsorption capacitySpringsLiquid based dampersEngineeringShock absorber

The invention discloses a motorcycle shock absorber with damping force adjustable. The problems that an existing shock absorber is poor in adjusting capacity of damping force, and the damping force cannot be adjusted and restored are solved. The motorcycle shock absorber comprises a piston cylinder, a piston and a piston rod, the piston is provided with a rebound valve, and the rebound valve is communicated with a channel. A radial through hole is formed in the piston rod, and is communicated to the channel, and an ejector pin used for adjusting the flow of the radial through hole is arranged inside the piston rod. The flow of the radial passing of the piston rod is adjusted through the ejector pin, then the flow of the channel of the rebound valve is adjusted, and therefore the damping force is adjusted and restored, the riding feedings of different riders are met, and the shock absorption performance of the shock absorber is improved. The motorcycle shock absorber is suitable for the shock absorption of motorcycles, and especially suitable for the shock absorption of racing motorcycles.

Owner:广东川南减震器有限公司

Telescopic connecting piece used for plate-type solid wood furniture

Wood furniture generates dry shrinkage and wet expansion due to changes of relative humidity in the air. Conventional plate-type solid wood furniture is usually connected by three-in-one connecting pieces, because the three-in-one connecting pieces are in fixed rigid connection, the three-in-one connecting pieces cannot stretch along with a solid wood furniture plate when the solid wood furnitureplate is warped due to dry shrinkage and wet expansion, and splitting of the plate is often caused. The invention provides a telescopic flexible connecting piece which can stretch together when a plate is warped and deformed, thereby effectively avoiding splitting of the plate.

Owner:BEIJING FORESTRY UNIVERSITY +1

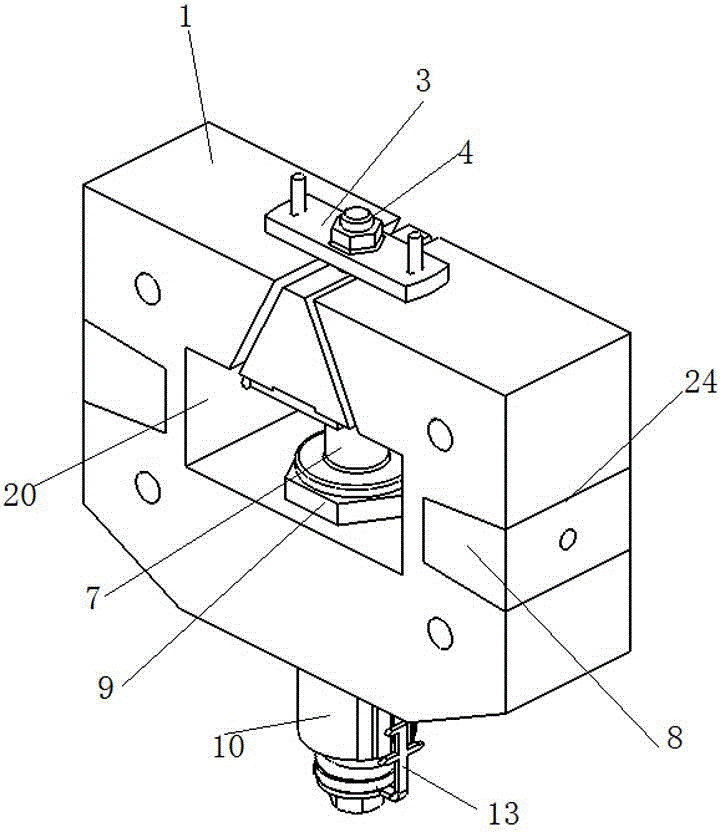

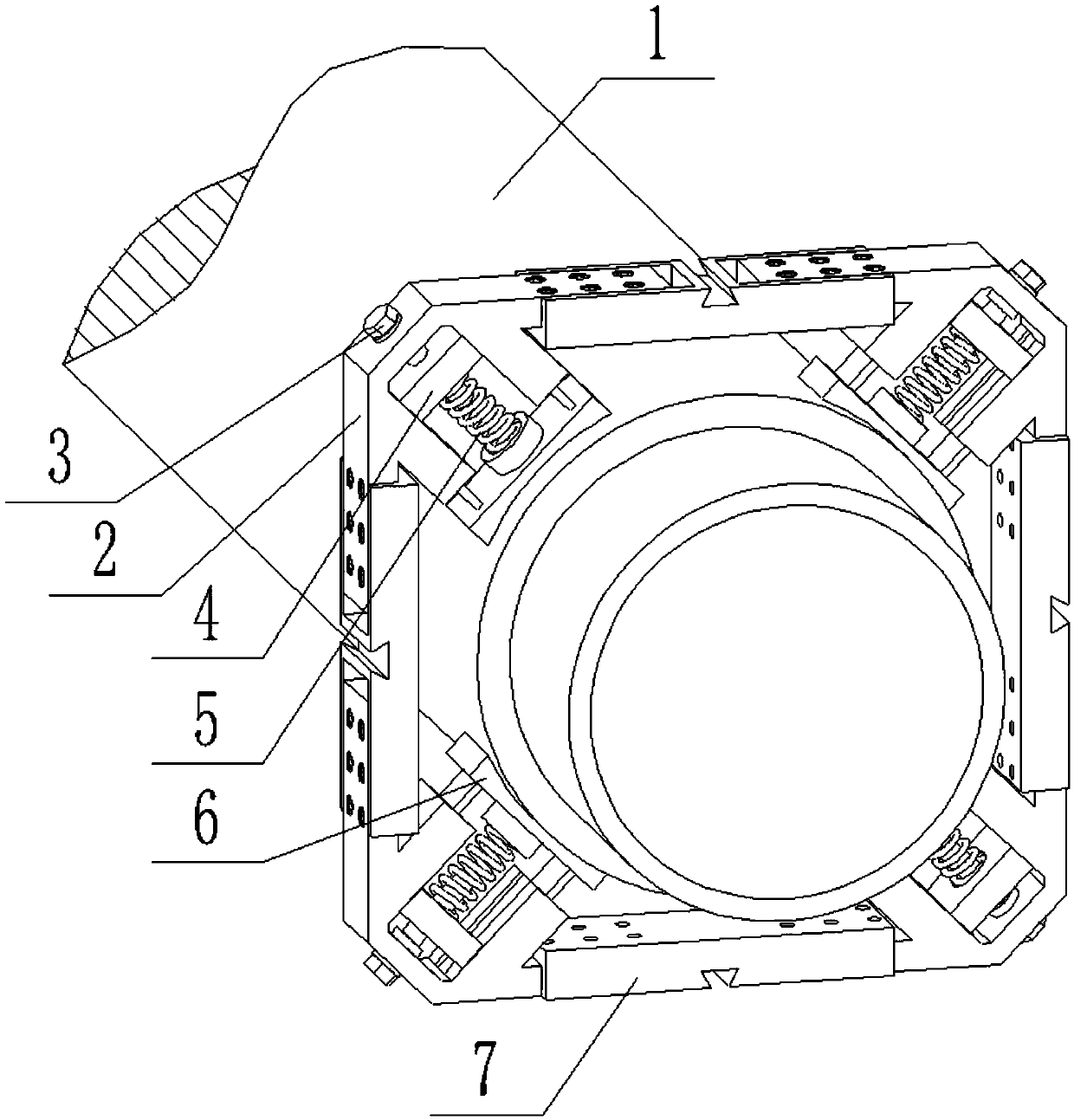

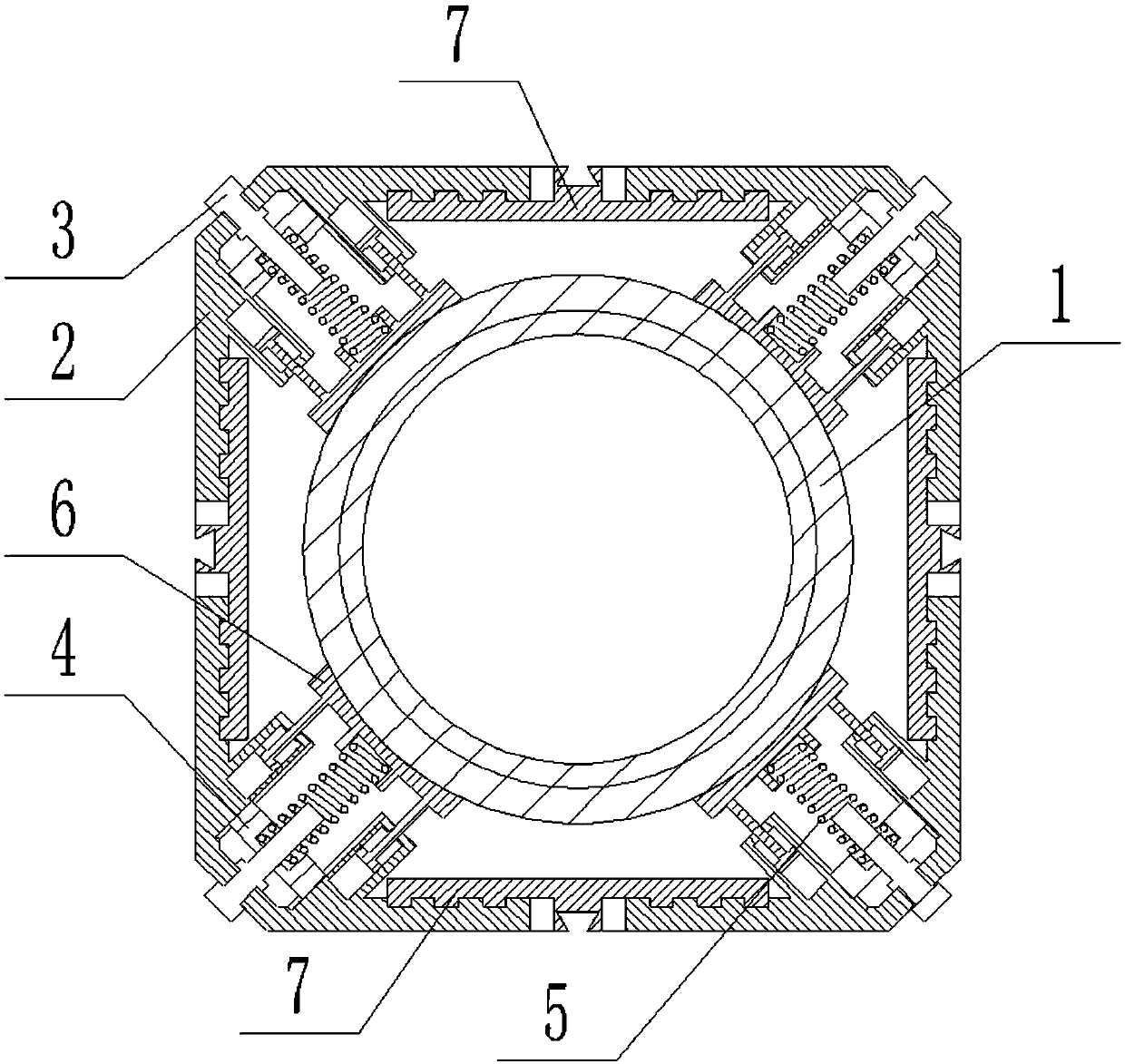

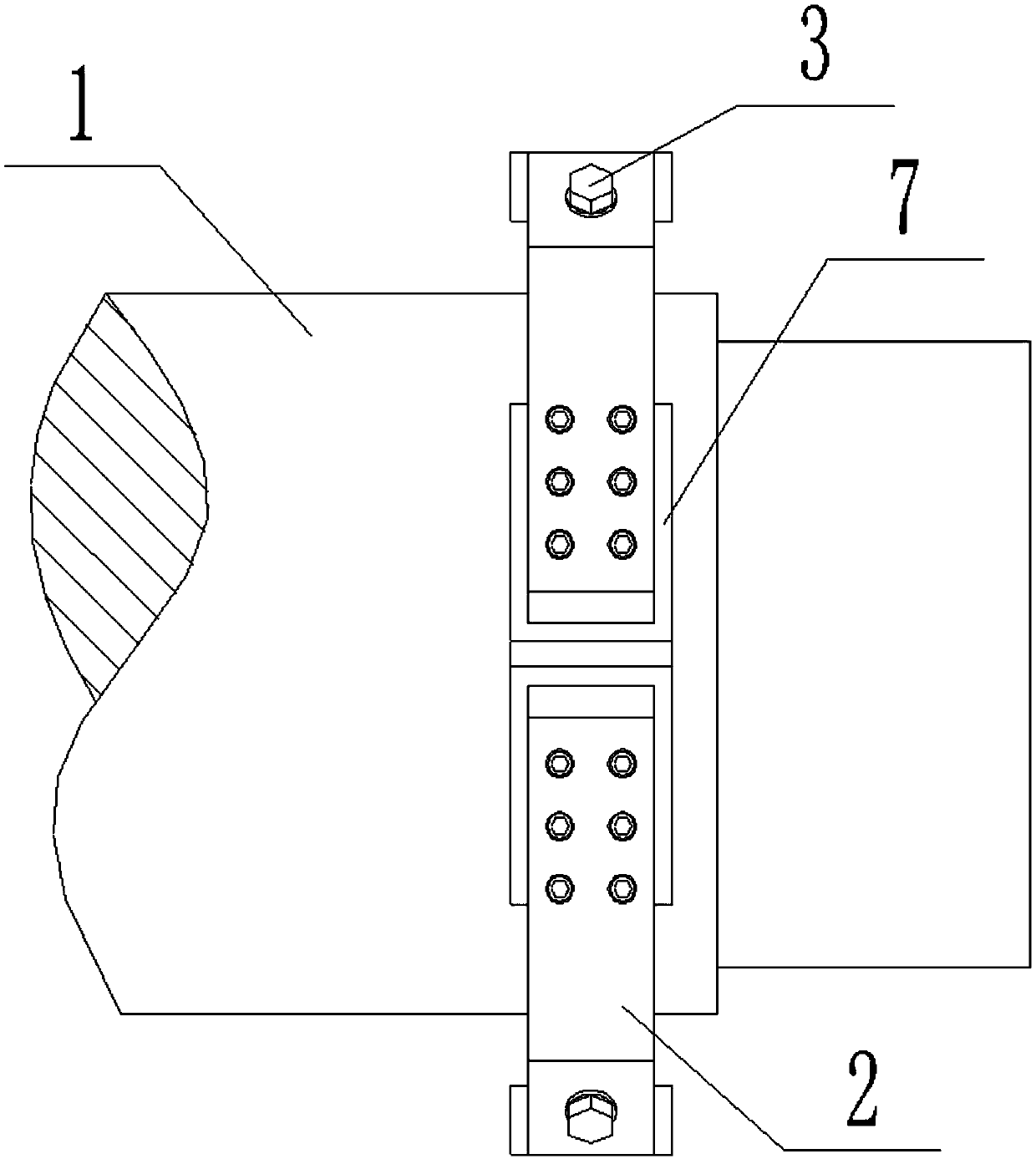

Auxiliary clamping device for disc-hydraulic-type turbine disc tool

ActiveCN111015315AAdjustable positionGuaranteed accuracyPositioning apparatusMetal-working holdersPull forceEngineering

The invention discloses an auxiliary clamping device for a disc-hydraulic-type turbine disc tool. The device comprises a clamp base, a beam, a left column, a right column and two pressure foot adjustment assemblies. The lower ends of the left column and the right column are symmetrically arranged on the clamp base, and the tops of the left column and the right column are fixedly connected with theleft and right ends of the beam. A downward tip is arranged in the middle of the beam, the two pressure foot adjustment assemblies are symmetrically arranged on the inner sides of the left column andthe right column, and each pressure foot adjustment assembly is composed of an oil cylinder, an upper lining, a pull rod, a pressure foot, a spring, a spacer, a lower lining, a nut, a disc spring, anadjustment lock nut and a positioning device. The auxiliary clamping device for the disc-hydraulic-type turbine disc tool applies stable and reliable pressure to the tool or a workpiece with the helpof pull force of the disc springs, the rotation tip is adopted for assisting in supporting and positioning the rotation tool or the workpiece, reinforcement is performed under the condition that processing is not influenced, and a turbine disc is conveniently and quickly clamped.

Owner:BAODING XIANGYANG AVIATION PRECISION MACHINERY

Overcurrent electromagnetic release

InactiveCN104362051AConducive to miniaturization design and productionIncrease electromagnetic attractionProtective switch operating/release mechanismsMiniaturizationEngineering

The invention provides an overcurrent electromagnetic release which comprises a armature, a reset spring and an annular yoke rack. The armature moves upwards to control a corresponding system to release when short circuit currents pass a system circuit. The reset spring drives the armature to move downwards to reset. The yoke rack is provided with a peripheral annular wall and a central hole. The central hole is enclosed by peripheral annular wall, extends along a front-rear direction, and allows the system circuit to penetrate to form an electromagnet. An upper notch is formed in the inner wall surface of the top annular wall of the yoke rack. The armature is assembled into the upper notch in a guide moving manner along an up-down direction. The overcurrent electromagnetic release has the advantages that the yoke rack is added to increase the electromagnetic attractive borne by the armature of the whole release, the application range of the electromagnetic release is expanded, and electromagnetic release miniaturization is benefited.

Owner:PINGGAO GRP +1

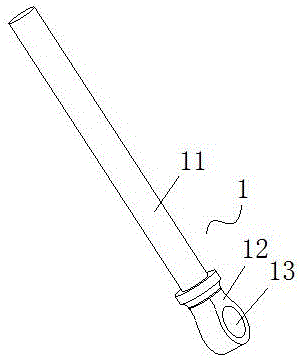

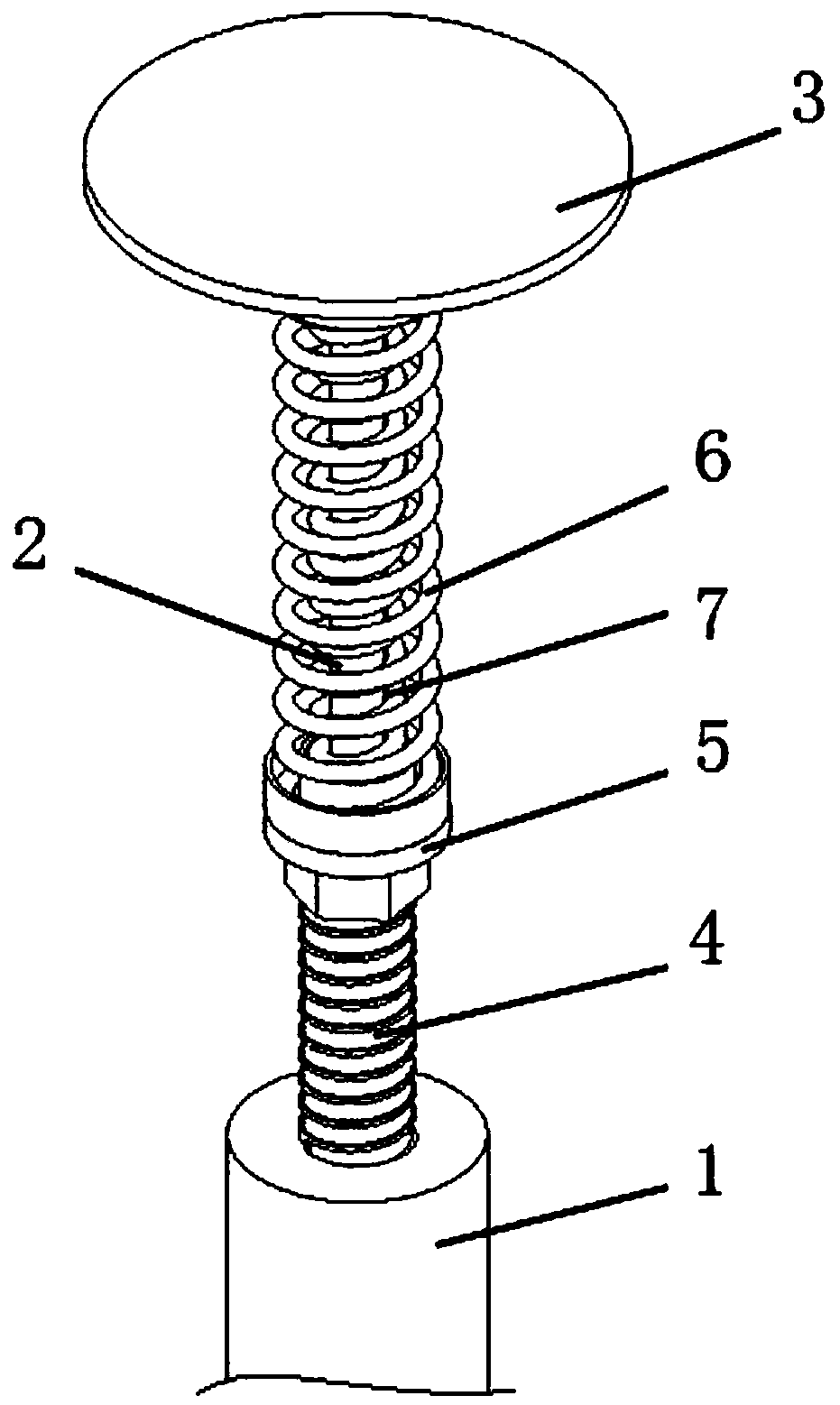

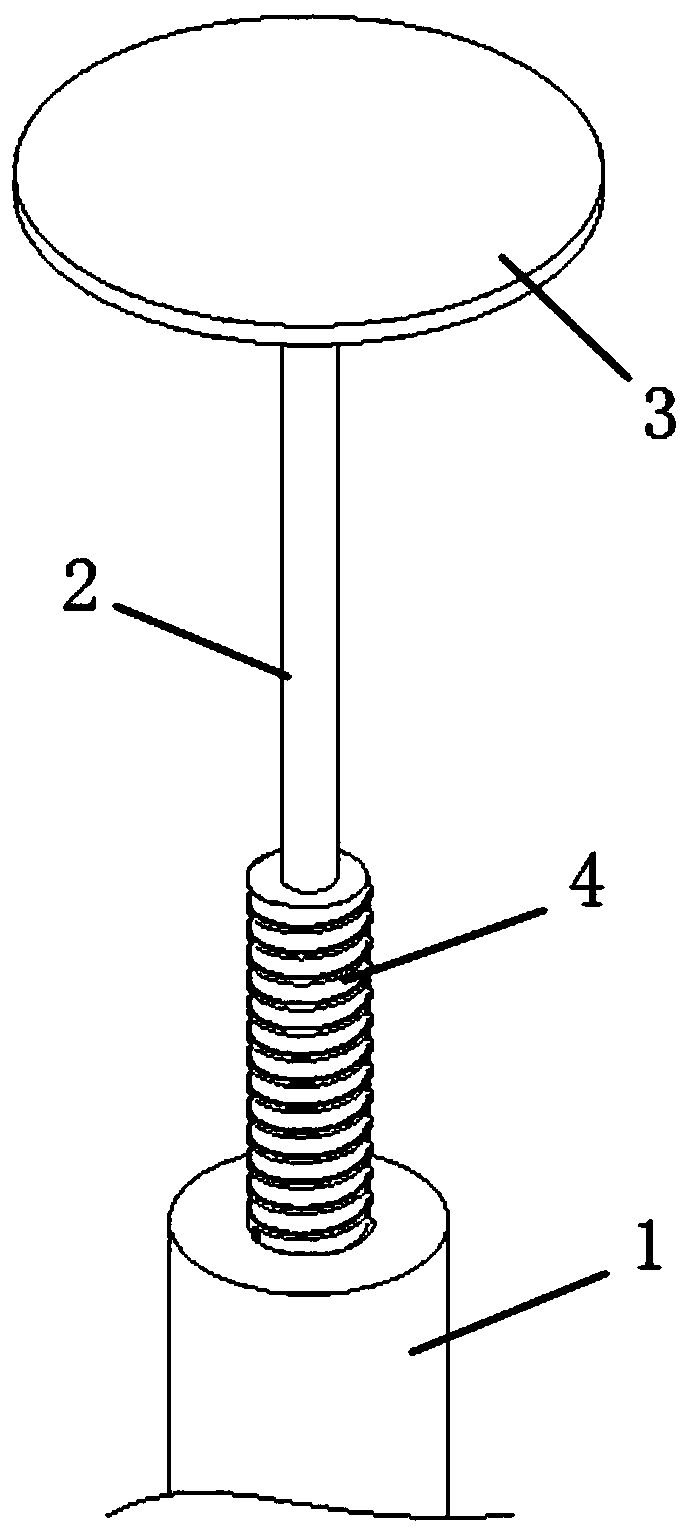

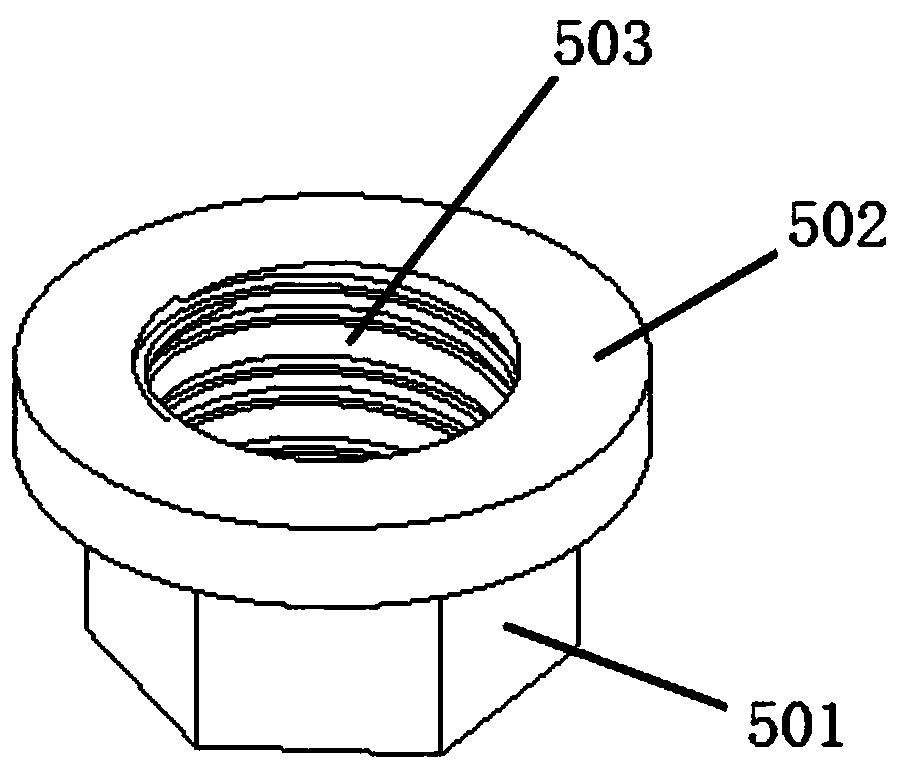

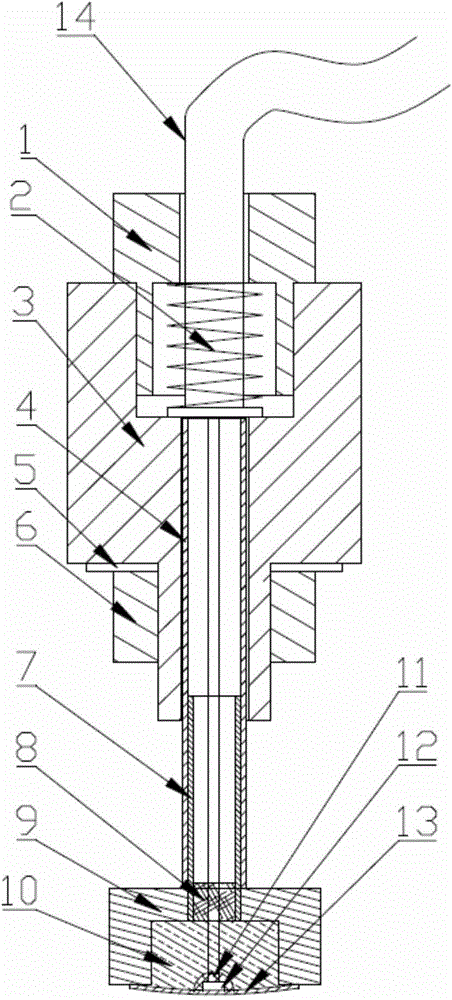

Thread drive based shock absorber

InactiveCN106523587AAdjust the preloadEasy to adjustSpringsSprings/dampers functional characteristicsEngineeringThreaded rod

The invention discloses a thread drive based shock absorber which comprises a shock absorption supporting rod and a threaded supporting rod. A gasket disc is mounted in the threaded supporting rod. The shock absorption supporting rod is mounted in the threaded supporting rod and provided with a spring mounting base. A fastener is mounted on the shock absorption supporting rod and used for fastening the spring mounting base and the shock absorption supporting rod. An upper pressing disc and a lower pressing disc are mounted on the threaded supporting rod through threads. A shock absorption spring is mounted between the lower pressing disc and the spring mounting base. A first connecting piece is mounted in a first unthreaded hole of the shock absorption supporting rod, and a second connecting piece is mounted in a second unthreaded hole of the threaded supporting rod. During use, the upper pressing disc and the lower pressing disc are in threaded connection together and are mounted on a cylindrical threaded rod of the threaded supporting rod through the threads, the shock absorption spring is mounted between the spring mounting base and the lower pressing disc, and therefore the pre-tightening force of the shock absorption spring can be adjusted by adjusting the lower pressing disc, and adjustment is facilitated.

Owner:桐城市湃腾机械设计有限公司

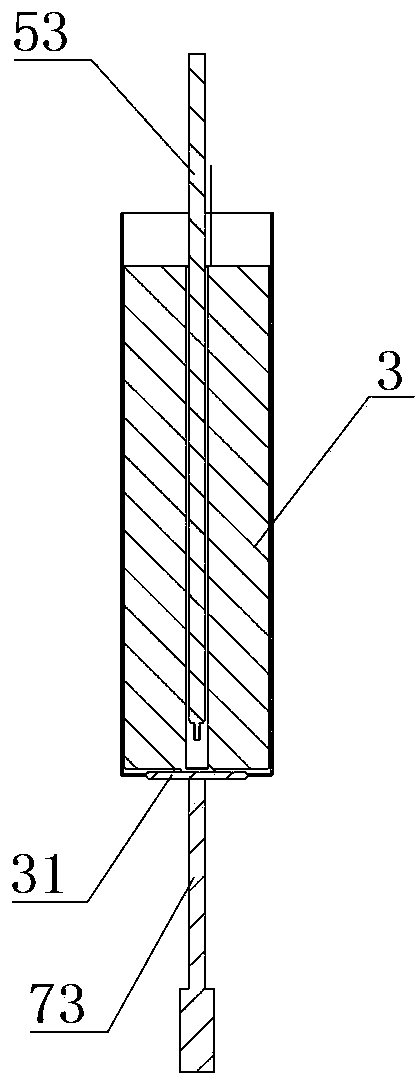

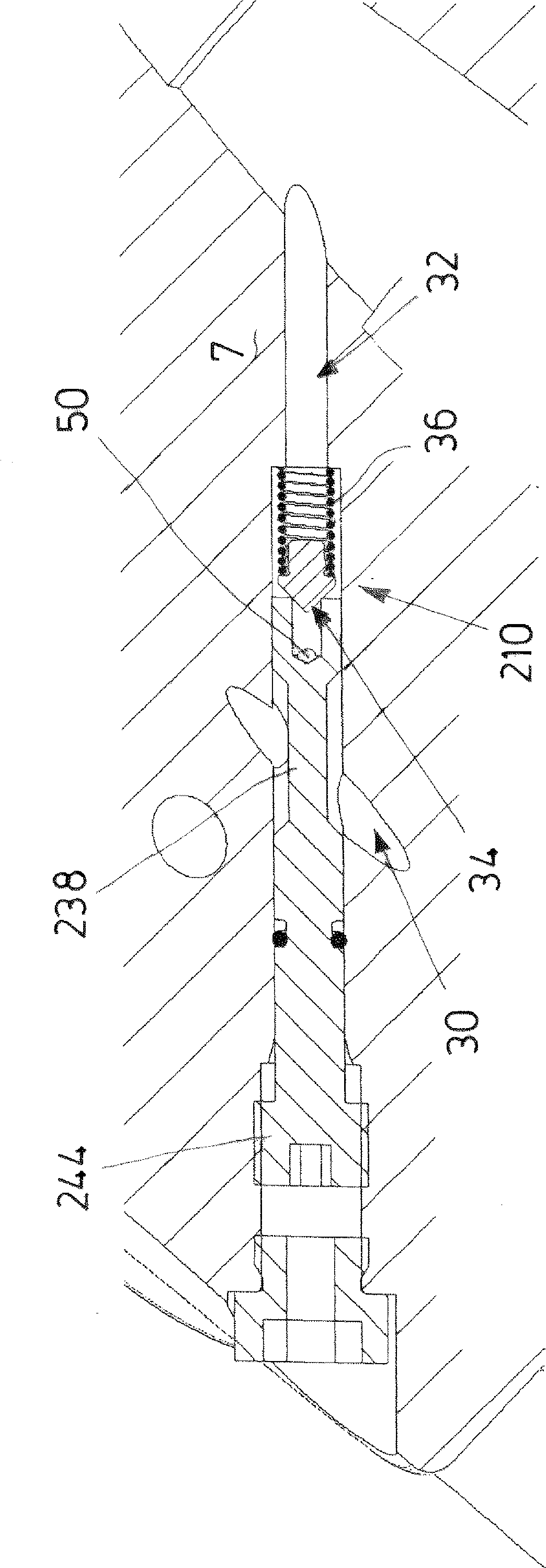

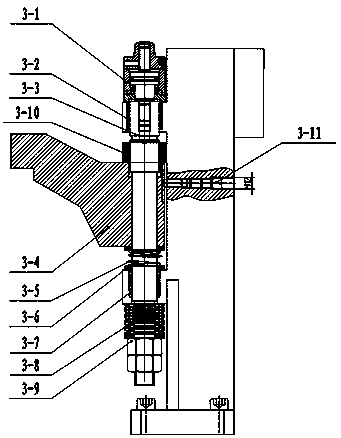

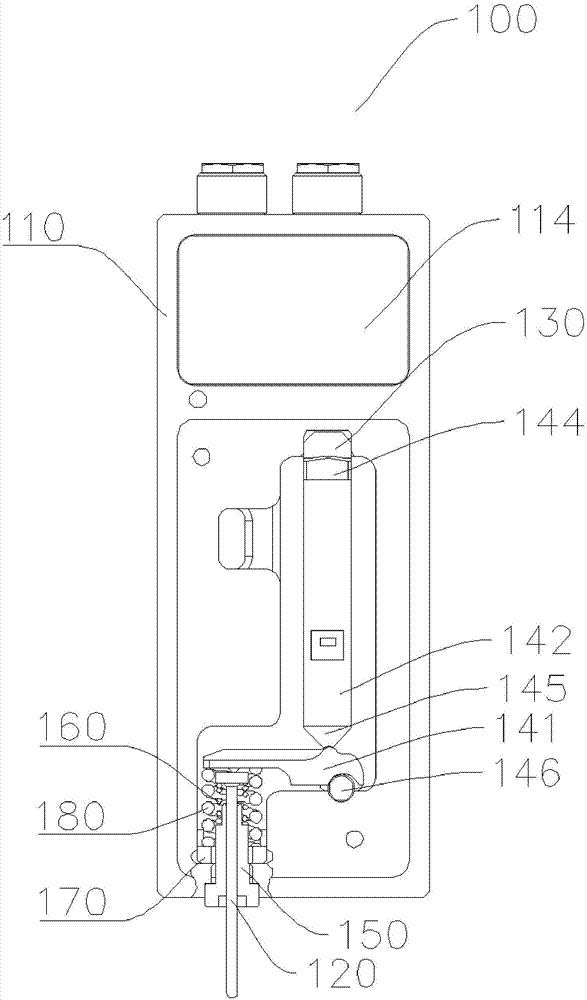

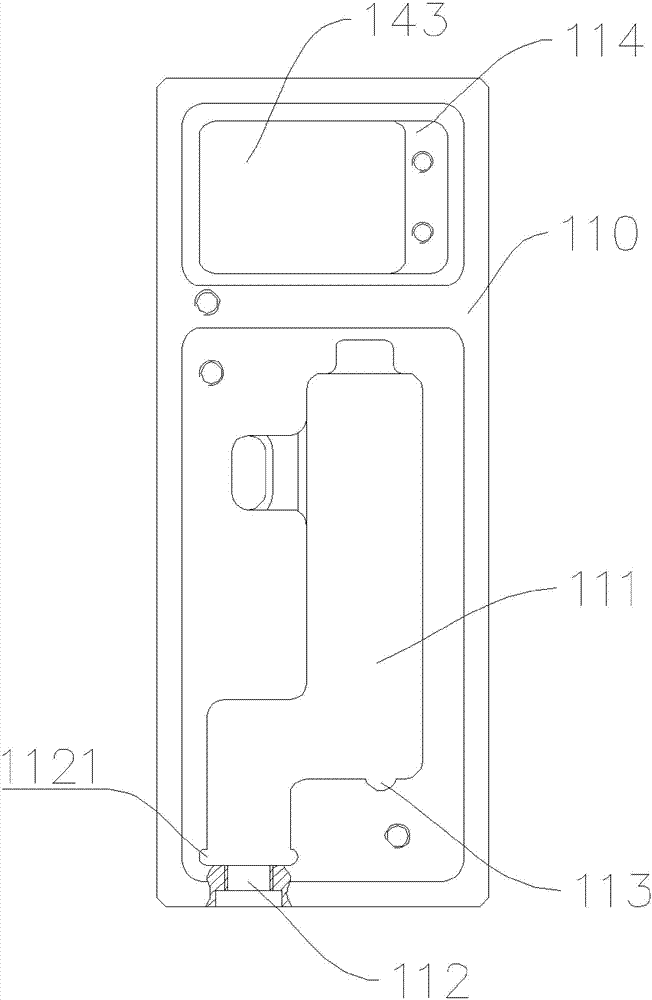

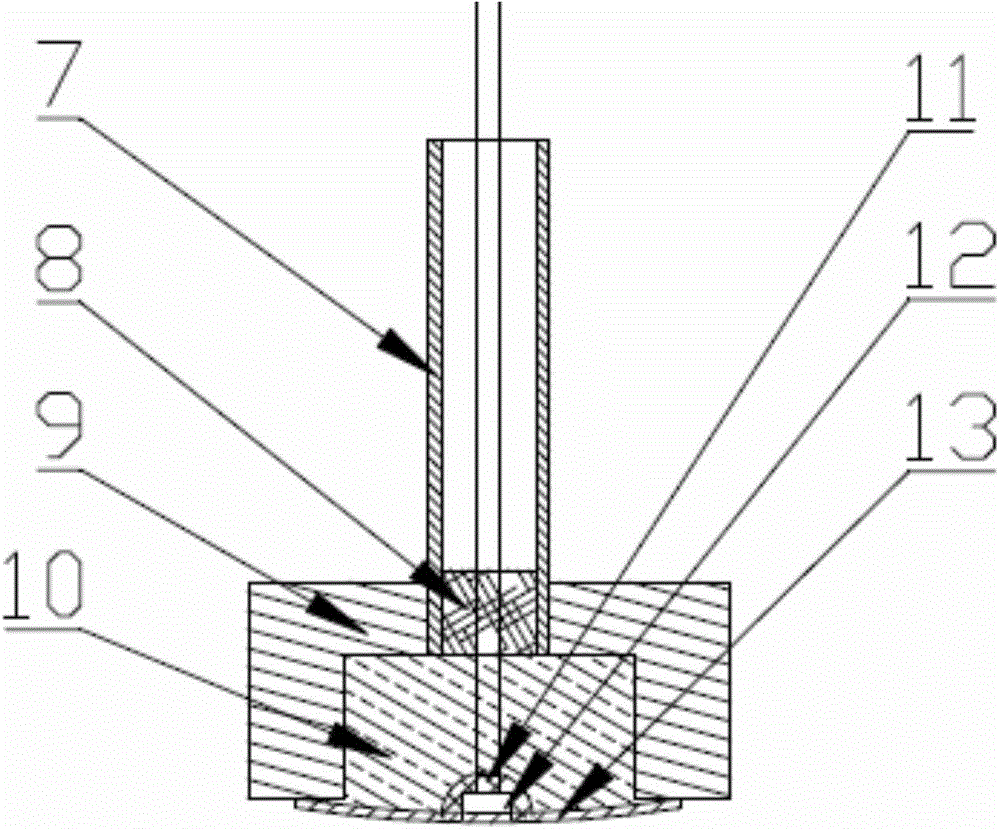

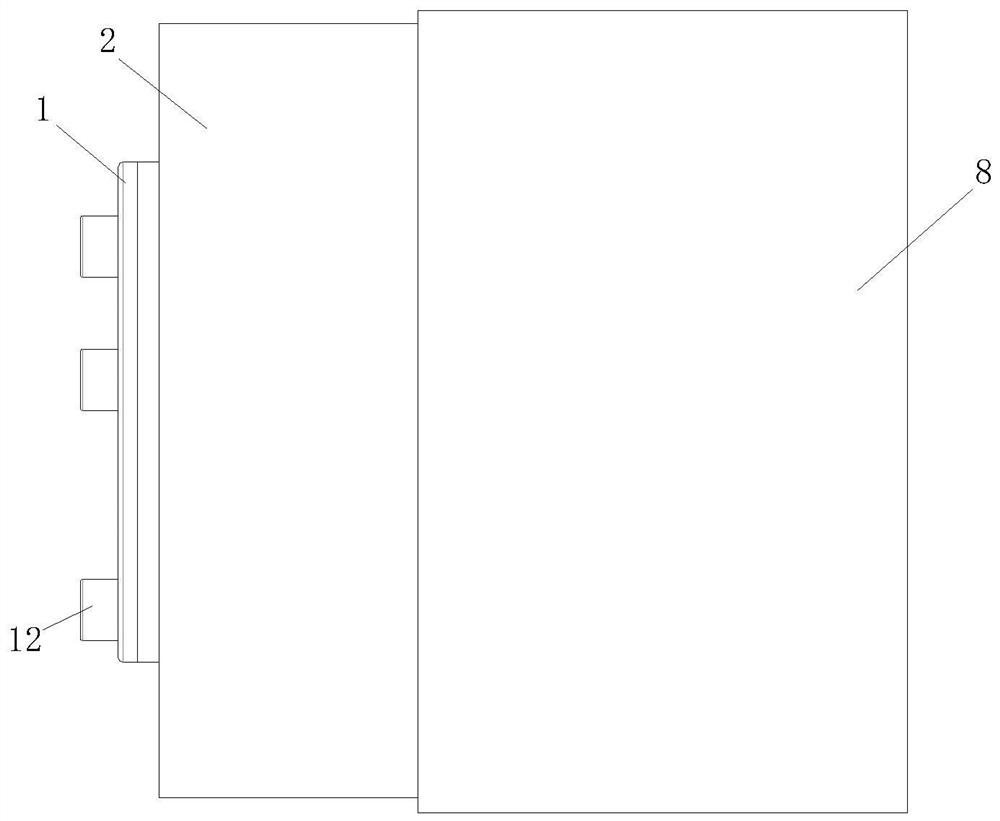

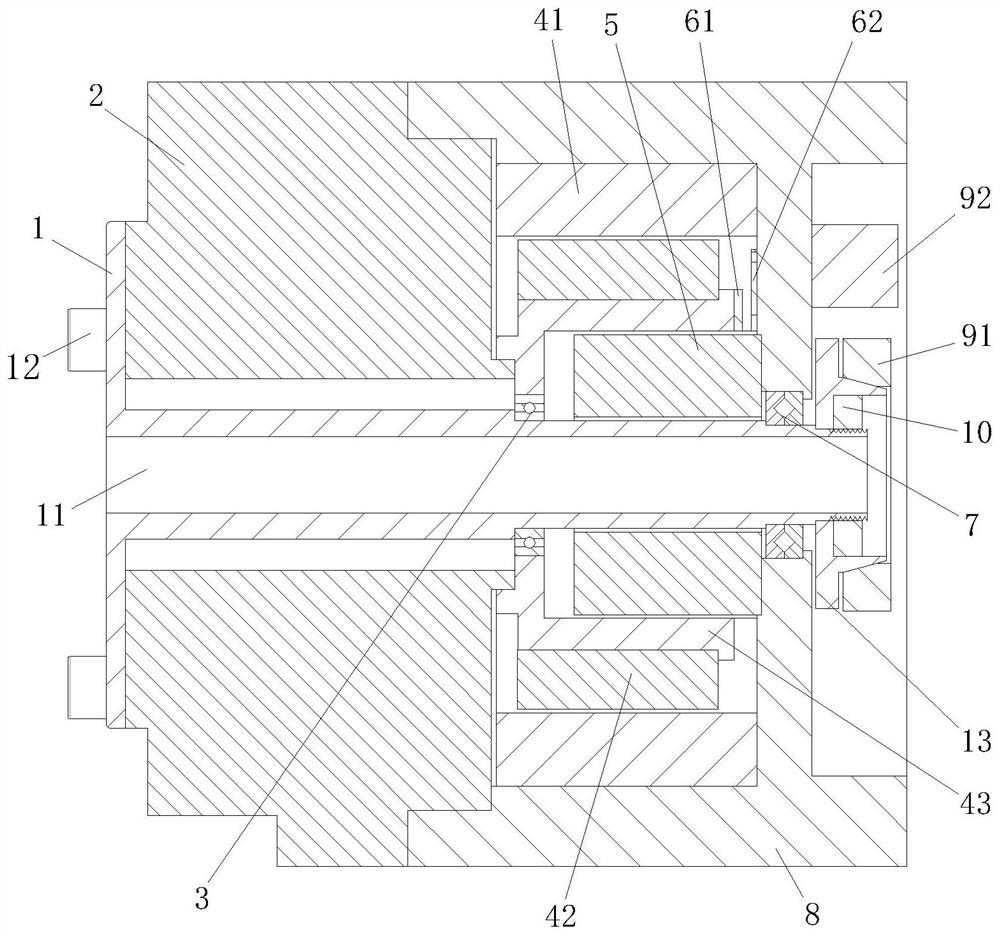

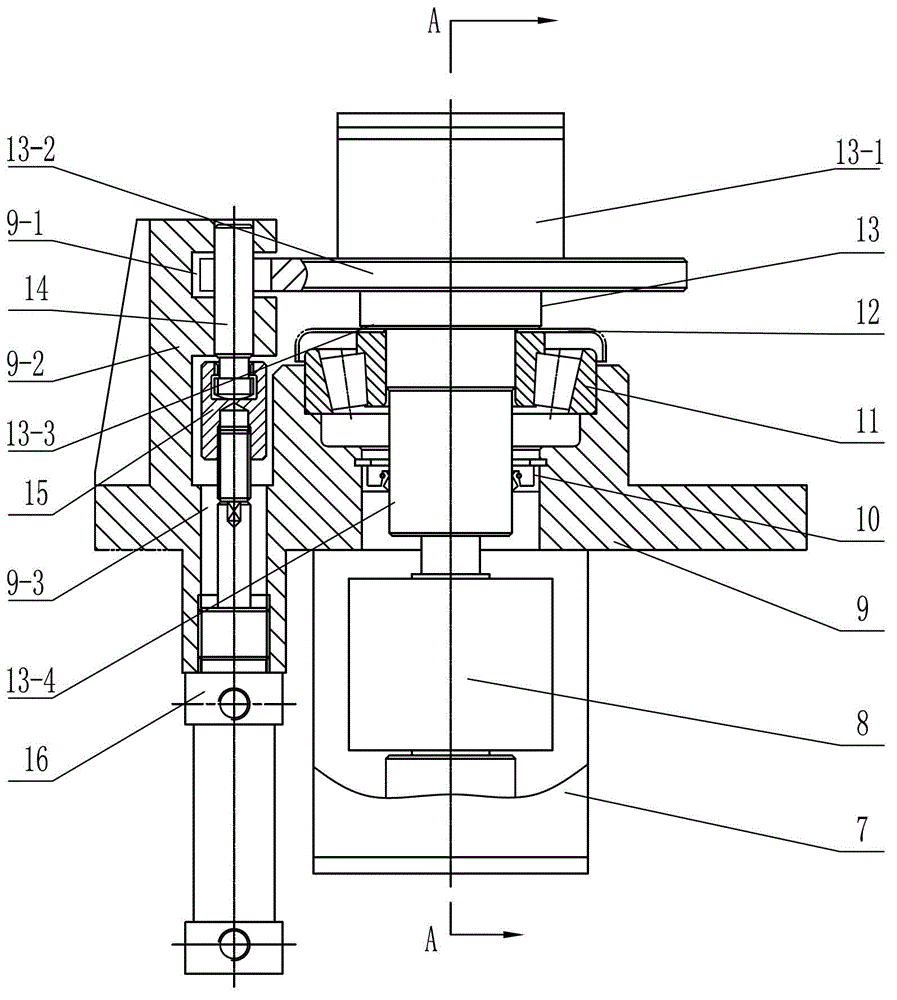

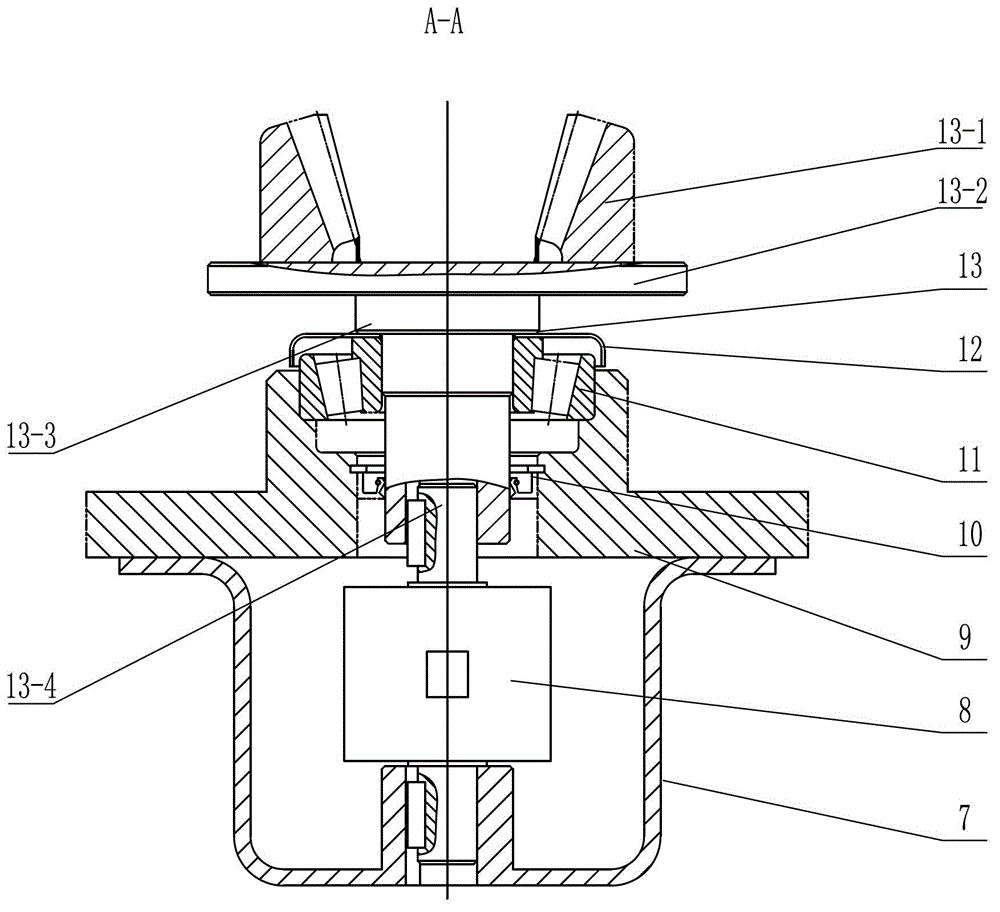

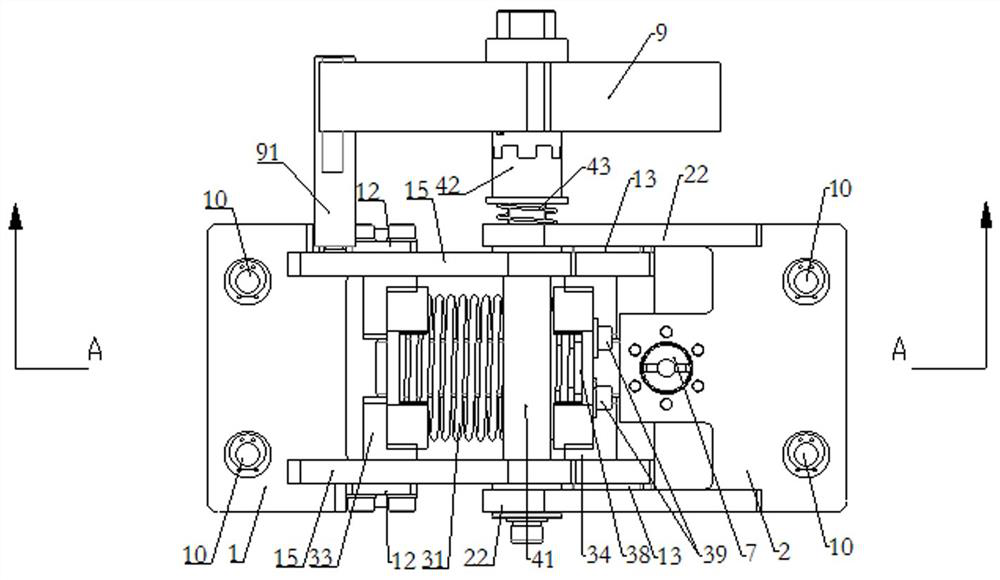

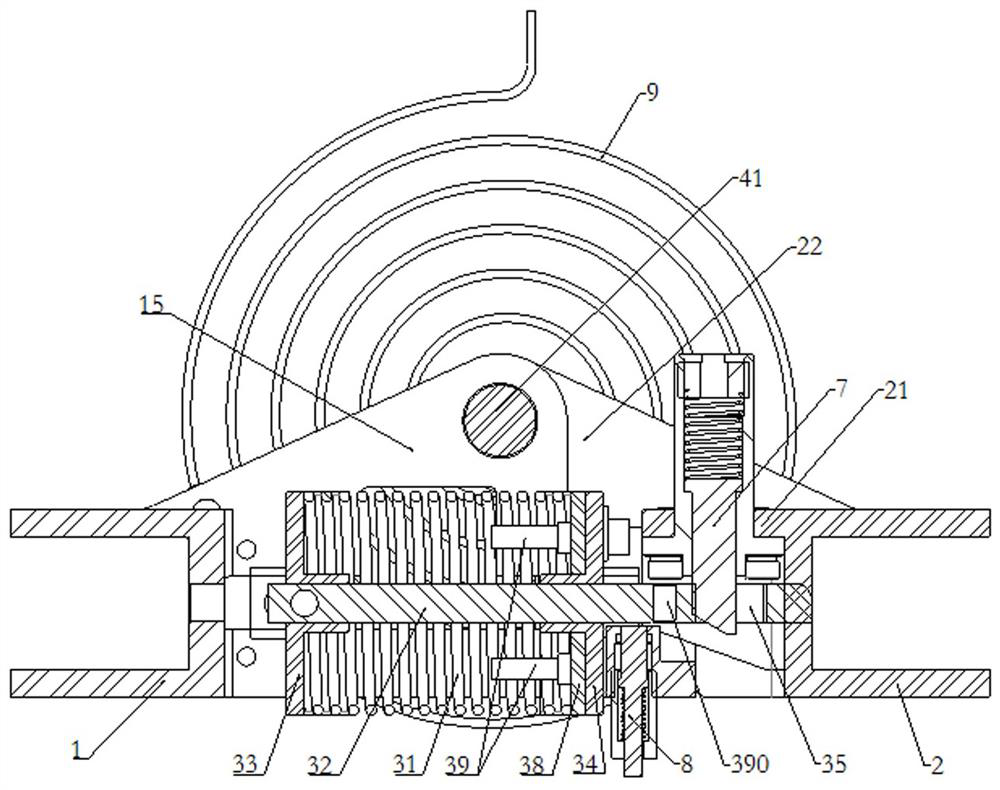

Fluid micro-spraying device and executing system thereof

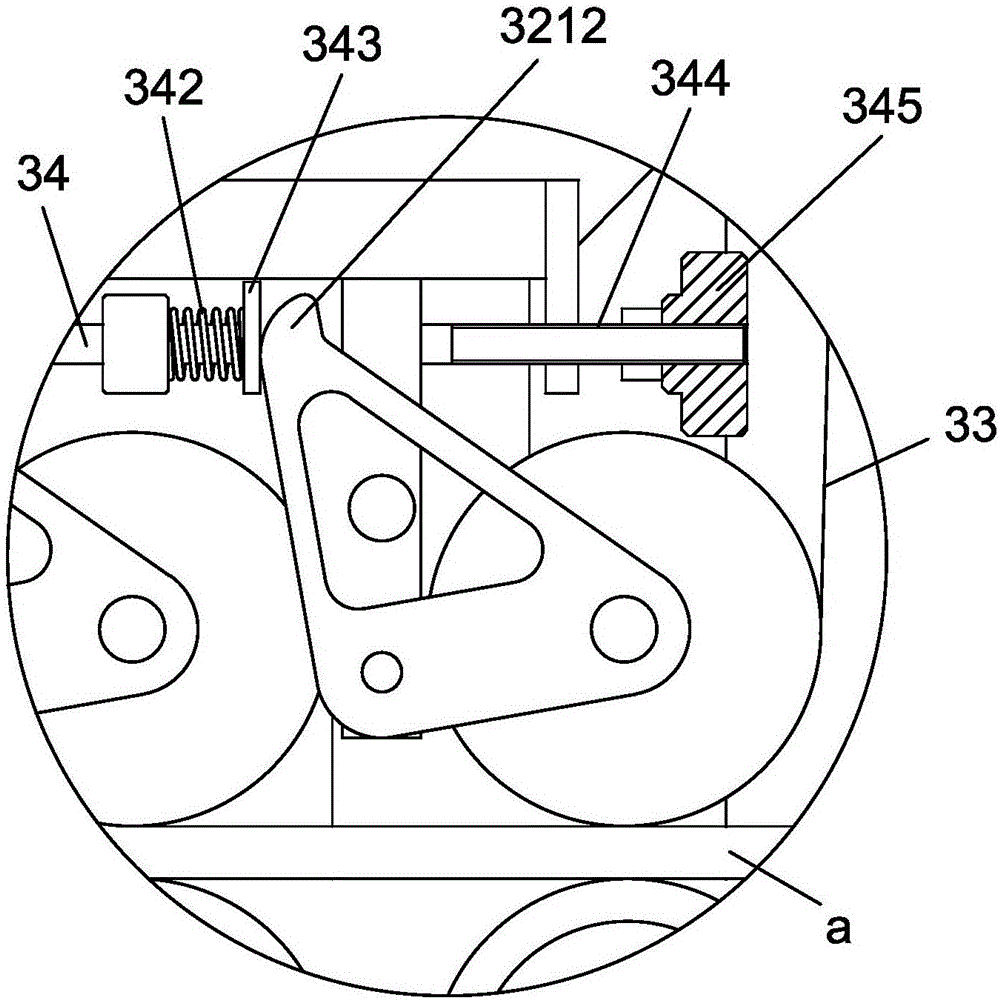

ActiveCN107127065AAdjusting the Fluid Ejection EffectAdjust the preloadSpray nozzlesComputer science

The invention discloses an executing system of a fluid micro-spraying device, and the fluid micro-spraying device with the executing system. The executing system comprises a base body, a movable element, an executing mechanism an adjusting element and a plurality of spacer shims, wherein an executing mechanism installation cavity is limited in the base body; a positioning hole communicating with the executing mechanism installation cavity is formed in the base body; the movable element can be movably arranged in the positioning hole; the executing mechanism can be movably arranged in the executing mechanism installation cavity, and is connected with the movable element so as to control the movable element to move; the adjusting element is arranged in the executing mechanism installation cavity and is connected with the executing mechanism so as to adjust a working position of the executing mechanism; the spacer shims are arranged between an inner wall surface of the executing mechanism installation cavity and the adjusting element so as to adjust a pre-tightening force of the executing mechanism. According to the executing system of the fluid micro-spraying device provided by the embodiment of the invention, the pre-tightening force of the executing mechanism can be adjusted, so that the movable displacement of the movable element is adjusted so as to adjust a fluid spraying effect of the fluid micro-spraying device.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Plastic processing device

InactiveCN107877286AClose contactAdjust the preloadPlane surface grinding machinesSpring forceArchitectural engineering

The invention discloses a plastic processing device. The plastic processing device comprises a box. A clamp is arranged on the top of the box. First electric telescopic rods are fixedly connected to the two sides of the back face of the box. The tops of the first electric telescopic rods are fixedly connected with a transverse plate. A transverse groove is formed in the transverse plate. Long holes communicating with the transverse groove are formed in the top and the bottom of the transverse plate. An inner cavity of the transverse groove is in sliding connection with a sliding plate. The bottom of the transverse plate is fixedly connected with a first connecting plate. The top of the first connecting plate penetrates the long holes and extends out of the long holes. A second electric telescopic rod is fixedly connected to the right side of the top of the transverse plate. A spring is used for generating force to a vertical rod, the vertical rod generates a force to a grinding disc, the grinding disc is promoted to make close contact with a plastic plate, the pre-tightening force between the grinding disc and the plastic plate can be adjusted, the phenomenon of excessive grindingis avoided, and the grinding quality of finished products is improved.

Owner:叶青

Shock absorber assembly for motor vehicle and method of assembling the same

ActiveCN109681574AAdjust Axial Force ThresholdControl preloadNon-rotating vibration suppressionResilient suspensionsAxial forceEngineering

The invention discloses a shock absorber assembly for a motor vehicle and a method of assembling the same. The shock absorber assembly for a motor vehicle comprises an oil cylinder, a piston rod and asupporting base, the oil cylinder is provided with an adjusting column protruding outwards, the adjusting column is sleeved with a movable block, and the movable block is composed of a rotating partand a tray part; a first spring assembly is arranged between the movable block and the supporting base, a second spring assembly is arranged between the adjusting column and the supporting base, and the second spring assembly is located in the first spring assembly. The two spring assemblies are composed of springs, upper limiting sleeves, lower limiting sleeves and wrinkling pieces, and the wrinkling pieces are arranged to transmit axial force and plastically deform when the axial force exceeds a threshold value. The spring assemblies are additionally arranged to replace an existing stop buffer, and the structural layout can be simplified; the two spring assemblies are each provided with a wrinkling piece, and therefore secondary threshold value control can be achieved. The displacement of the movable block on the adjusting column can control the pre-loading force of the outer-layer spring, and then the axial force threshold value which can be borne by the springs can be adjusted.

Owner:WUXI ZHONGYA SHOCK ABSORBER CO LTD

High-accuracy wall temperature measuring device

ActiveCN104614088AImprove the temperature sensing effectLarge output signalThermometers using electric/magnetic elementsUsing electrical meansEngineeringSignal strength

The invention provides a high-accuracy wall temperature measuring device. The high-accuracy wall temperature measuring device comprises a base part, a probe part and a metal guide tube, wherein the tail end of the metal guide tube is elastically connected with the base part, while the front end of the metal guide tube is movably connected with the probe part; the probe part comprises a metal wire tube, a probe body, a temperature-sensing element and a metal contact piece, all of which are orderly and fixedly connected with each other, and wherein one end of the metal wire tube is nested into the metal guide tube and the other end of the metal wire tube is fixedly connected with the probe body. The high-accuracy wall temperature measuring device is fixed above the wall; the probe is kept into close contact with the wall by virtue of the elastic force of a spring in the probe base to measure the temperature of the wall; besides, the device is high in temperature sensing capability, high in output signal strength and high in measurement accuracy.

Owner:SHANGHAI JIAO TONG UNIV

High-precision compact integrated joint structure

The invention discloses a high-precision compact integrated joint structure. The high-precision compact integrated joint structure comprises a rotating shaft, a speed reducer, a motor, an integrated band-type brake, a relative encoder, an absolute encoder and a joint outer shell, wherein the rotating shaft is a hollow feed shaft, a bearing is arranged between the motor and the hollow feed shaft, and a precision bearing is arranged between the joint outer shell and the hollow feed shaft; the absolute encoder is mounted at one end, extending out of the joint outer shell, of the hollow feed shaft; and the relative encoder and the integrated band-type brake are both mounted in the motor, and the integrated band-type brake is coaxial with the motor. According to the high-precision compact integrated joint structure, the band-type brake, the internal and external encoder reading heads and a motor stator are directly mounted on the joint outer shell at the same time, the band-type brake is placed inside the motor, extra space does not need to be occupied, and the axial length of a joint is reduced; and the feed shaft is connected with the crossed roller bearing, a relative encoder coded disc and a motor input shaft are integrated, the number of parts is reduced, the weight of the joint is reduced, the compactness is improved, and the anti-overturning moment of the joint and the jointoutput precision are improved.

Owner:南京安舍曼机器人研究院有限公司

Material self-unloading device

ActiveCN104590906AUninstall accelerationQuick recycling jobLoading/unloadingConveyor partsEngineeringMechanical engineering

Owner:SOUTH CHINA AGRI UNIV

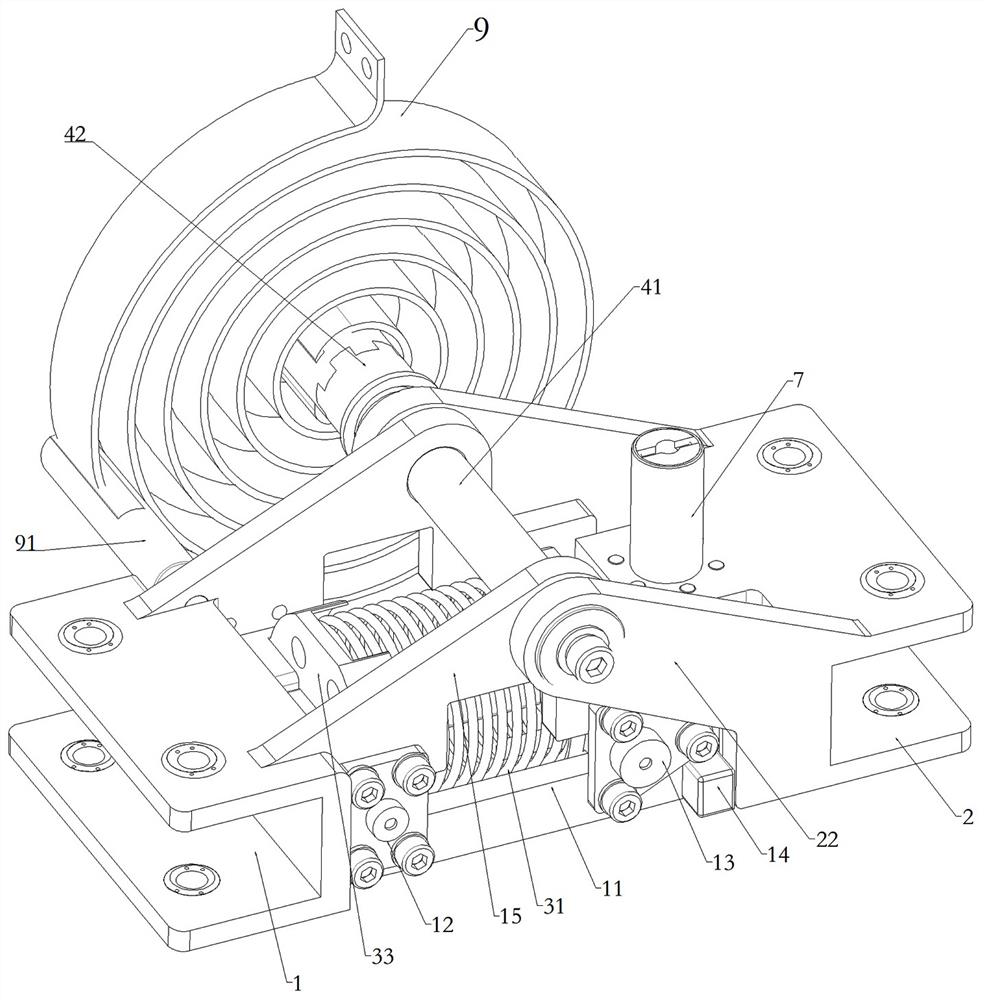

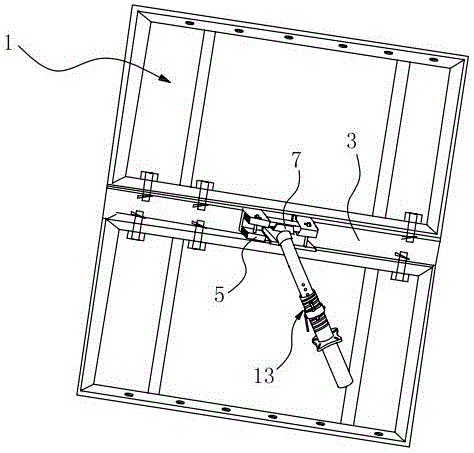

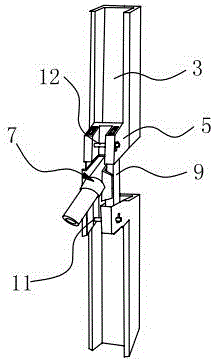

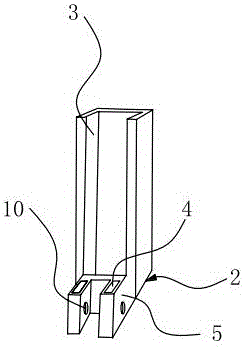

Rear press roller mechanism for cylinder forming of paper bag machine

ActiveCN106739168AEasy inspection and maintenanceAdjust the preloadBag making operationsPaper-makingFriction forcePulp and paper industry

The invention provides a rear press roller mechanism for cylinder forming of a paper bag machine. The rear press roller mechanism comprises a rack; multiple sets of lower rolling shafts are arranged on the rack; and an upper roller conveying mechanism is arranged above the lower rolling shaft. The upper roller conveying mechanism comprises a crossbeam fixed on the rack; an upper roller module which can be adjusted in height is arranged on the crossbeam and comprises a mounting plate; a plurality of upper rollers which are in one-to-one tangency with the lower rolling shafts and can independently and automatically adjust the size of the gap between the lower rolling shafts according to the thicknesses of conveyed paper bags are arranged at the bottom of the mounting plate in the conveying direction; and the upper roller module further comprises a flat belt which is tensioned among the upper rollers and used for conveying the paper bags. Each upper roller can swing independently so that when paper bags pass, the upper rollers can back up and swing upward in time and can tightly press the paper bags and supply friction force for the paper bags, and combined with the flat belt to convey, the paper bags can be conveyed more stably and fitly. By arranging an adjustable cylinder, the height of the upper roller module can be quickly adjusted, maintenance and check are convenient, and the prepressing intensity of each upper roller can be adjusted.

Owner:温州巨凯机械有限公司

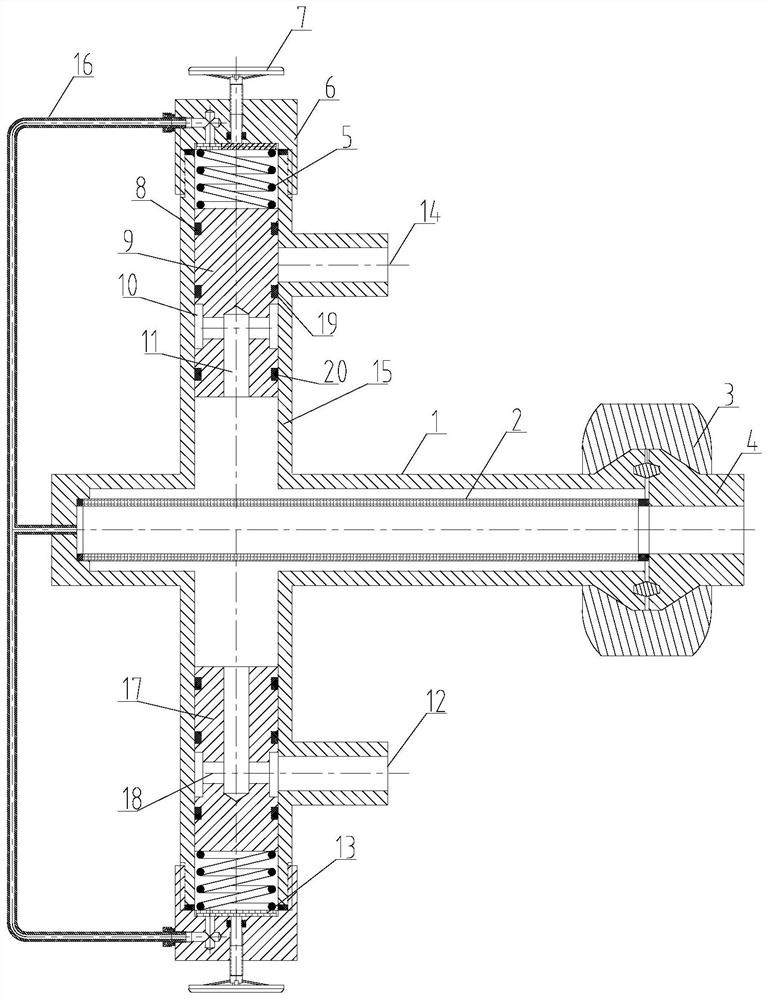

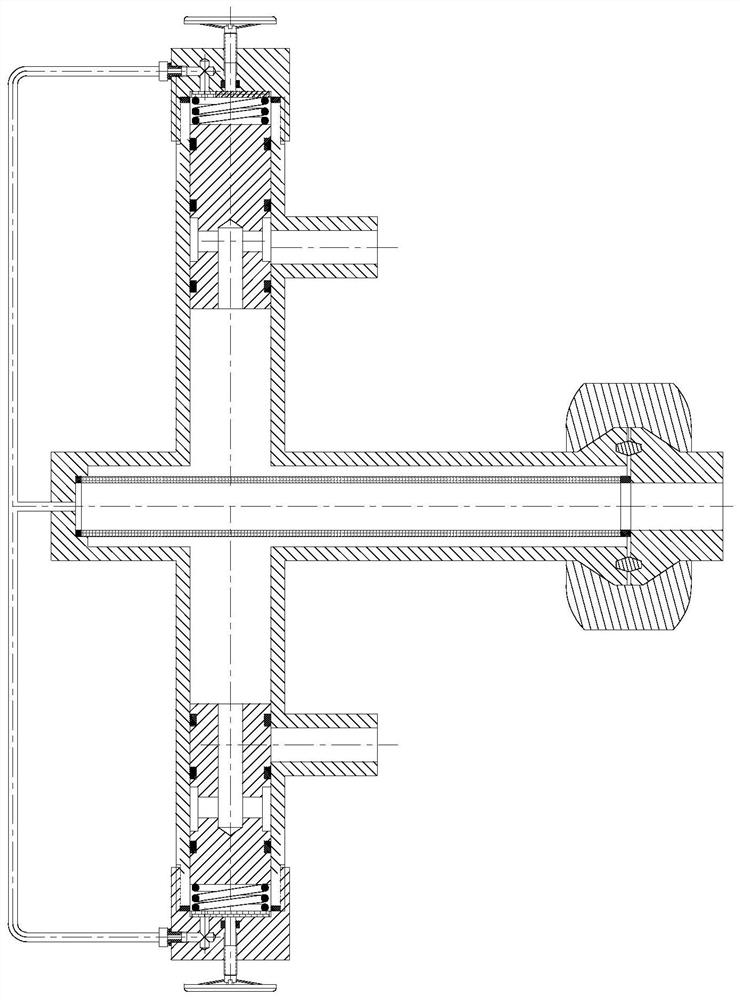

Dynamic and static combined part sealing device of rotary dry distillation furnace and rotary dry distillation furnace

InactiveCN105370888AAdjust the preloadGuaranteed tightnessEngine sealsEqualizing valvesWater vaporEngineering

The invention discloses a dynamic and static combined part sealing device of a rotary dry distillation furnace and the rotary dry distillation furnace. The sealing device comprises a fixed end, a rotating end, a support spring and a soft connecting piece, wherein the fixed end comprises a fixed support piece and a fixed connecting ring connected through the support spring and the soft connecting piece; and the support spring is provided with an adjusting ring for adjusting the pre-tightening force between the fixed connecting ring and the support spring. The sealing device further comprises a rotary sealing ring and a fixed sealing ring; the fixed sealing ring and the rotary sealing ring are arranged in a manner of fitting each other; and one side, fitting with the rotary sealing ring, of the fixed sealing ring is provided with an annular groove to form an annular water vapor cavity to be fully filled with water vapor for sealing and preventing smoke inside and outside the rotary dry distillation furnace from channeling. The sealing device uses the adjusting nut for adjusting the plane contact ratio of a fixed end friction surface and a rotary end friction surface, and thus guarantees a sealing effect of the rotary dry distillation furnace. The sealing device is provided with the water vapor cavity for further reinforcing the sealing effect in an operation state and a heat state.

Owner:HUADIAN HEAVY IND CO LTD

Water injection automatic filtering and backwashing device

ActiveCN111729383APrevent Mobile StuckChange the pressure difference valueStationary filtering element filtersEngineeringPressure difference

The invention discloses a water injection automatic filtering and backwashing device, and relates to the technical field of oil extraction. One side of a shell is connected with a water outlet pipe through a hoop, the inner end face of the shell is hermetically connected with a filter cartridge, and the other side of the filter cartridge is hermetically connected with the hoop. The upper and lowerparts of the shell are communicated with bypass pipes; an inner hole of the bypass pipe at the upper part is in clearance fit connection with a backwashing piston, a spring is arranged at the upper part of the backwashing piston, the bypass pipe at the lower part is in clearance fit connection with a filtering piston, and a spring is arranged at the lower part of the filtering piston. The devicehas the following beneficial effects that through arrangement of the backwashing piston and the filtering piston and by utilizing a pressure difference change inside and outside the filter cartridge,the purpose of automatic backwashing is achieved; the water quality index of injected liquid is ensured, manual operation is not needed, and an injection process is uninterrupted; liquid flowing intoa communicating pipe is filtered through a grid gasket so that impurities are prevented from entering a piston cavity and causing movement clamping stagnation of the piston; and the requirements for different water injection pressures can be met by arranging an adjusting screw to adjust the pre-tightening degree of the springs and changing the pressure difference value between the upper portion and the lower portion of the pistons.

Owner:西安东方宏业科技股份有限公司

Backlight source optical film dust removal device

InactiveCN109304333AAvoid secondary dust pollutionAdjust the preloadCleaning using gasesEngineeringLight source

The invention discloses a backlight source optical film dust removal device. The backlight source optical film dust removal device comprises a box body and a workbench, wherein the box body is adjacent to the workbench, the height of the workbench is one half of the box body, a controller is arranged at the top of the box body, and an optical film releasing device is arranged at the bottom of a groove; the optical film releasing device comprises a pair of supporting seats, a roller and a pair of round plates, a rotating shaft is arranged in an open hole, a dust removal rubber roller is arranged on the rotary shaft, bearings are arranged at the two ends of the dust removal rubber roller, the side face of the workbench is provided with a second air suction fan, the air suction end of the second air suction fan is connected with a second pipeline, a connecting rod is welded at the tail end of an L-shaped supporting rod, the lower end of the connecting rod is fixedly provided with an air suction device, and the air suction device is located right above the workbench. According to the backlight source optical film dust removal device, the design of the first air suction fan, dust suction treatment can be carried out on the periphery of the optical film releasing device in the box body, and dust on the periphery of the optical film releasing device is prevented from polluting the secondary dust of an optical film.

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

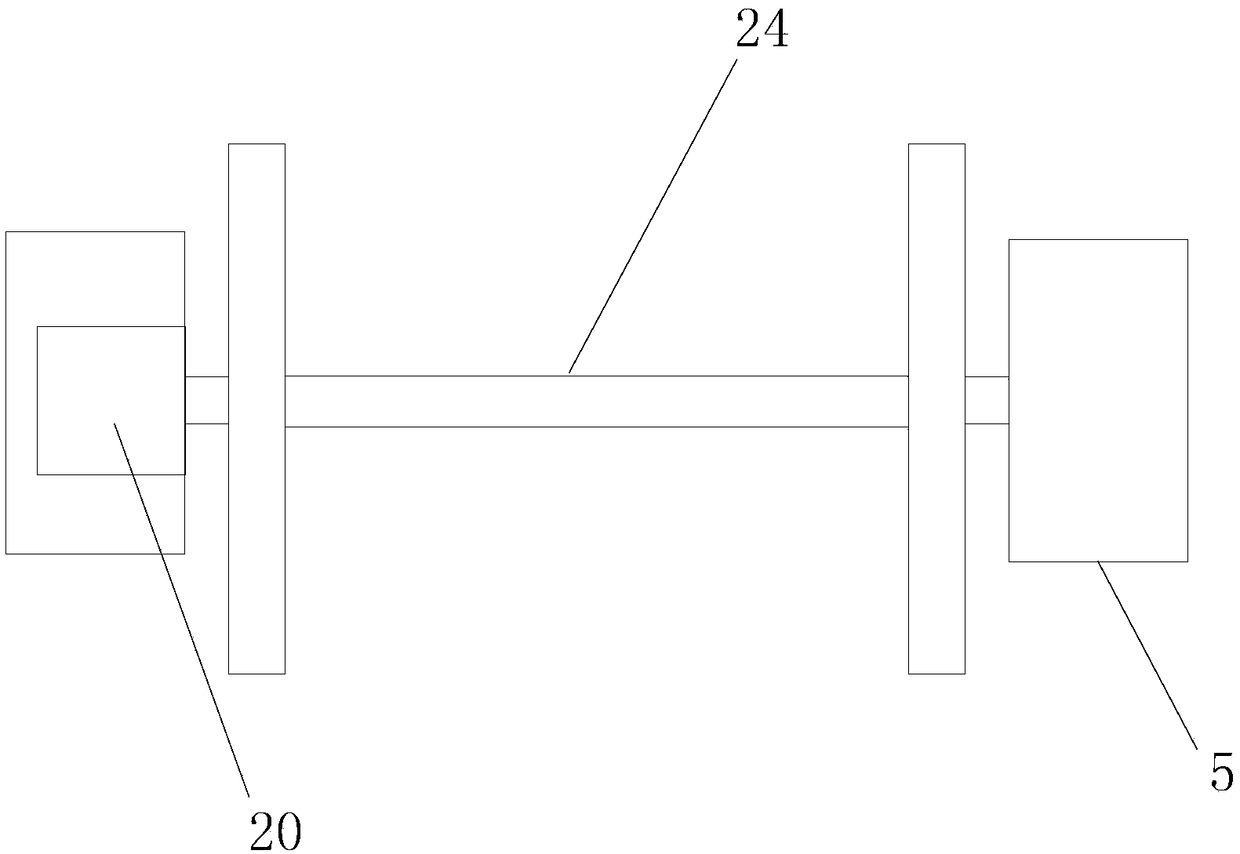

Pre-tightening force measuring device of driving gear assembly of gearbox of tractor

ActiveCN102943863AReduced operating requirementsEasy to measureMeasurement of torque/twisting force while tighteningGearing detailsEngineeringTransmitter

The invention relates to a pre-tightening force measuring device of a driving gear assembly of a gearbox of a tractor. The pre-tightening force measuring device comprises a measuring mechanism and a protecting and adjusting mechanism, wherein the measuring mechanism comprises a supporting base, a bevel gear engaging shaft, a torque transmitter and an end base, the bevel gear engaging shaft is supported on the supporting base through a bearing, a shaft shoulder end face of the bevel gear engaging shaft is connected with the bearing, a bevel gear engaging disk and a brake disk are arranged on the outer side of the bevel gear engaging shaft, the end base is installed on the supporting base, the torque transmitter is connected with the bevel gear engaging shaft and the end base, the torque transmitter is connected with a displayer, a driving part of the protecting and adjusting mechanism is installed on the supporting base, a telescopic part of the driving part is connected with a connection sleeve, a locking pin is connected with the connection sleeve, a locking pin hole and a notch are arranged on the supporting base or a locking base which is installed on the supporting base, the locking pin hole is matched with the locking pin, the notch is used for placing the brake disk, and a locking hole or a locking groove is arranged on the brake disk. The pre-tightening force measuring device has the advantages that the structure is reasonable, the pre-tightening force of the driving gear assembly can be measured and adjusted conveniently, and the assembly efficiency can be improved.

Owner:CHANGZHOU DONGFENG AGRI MACHINERY GROUP

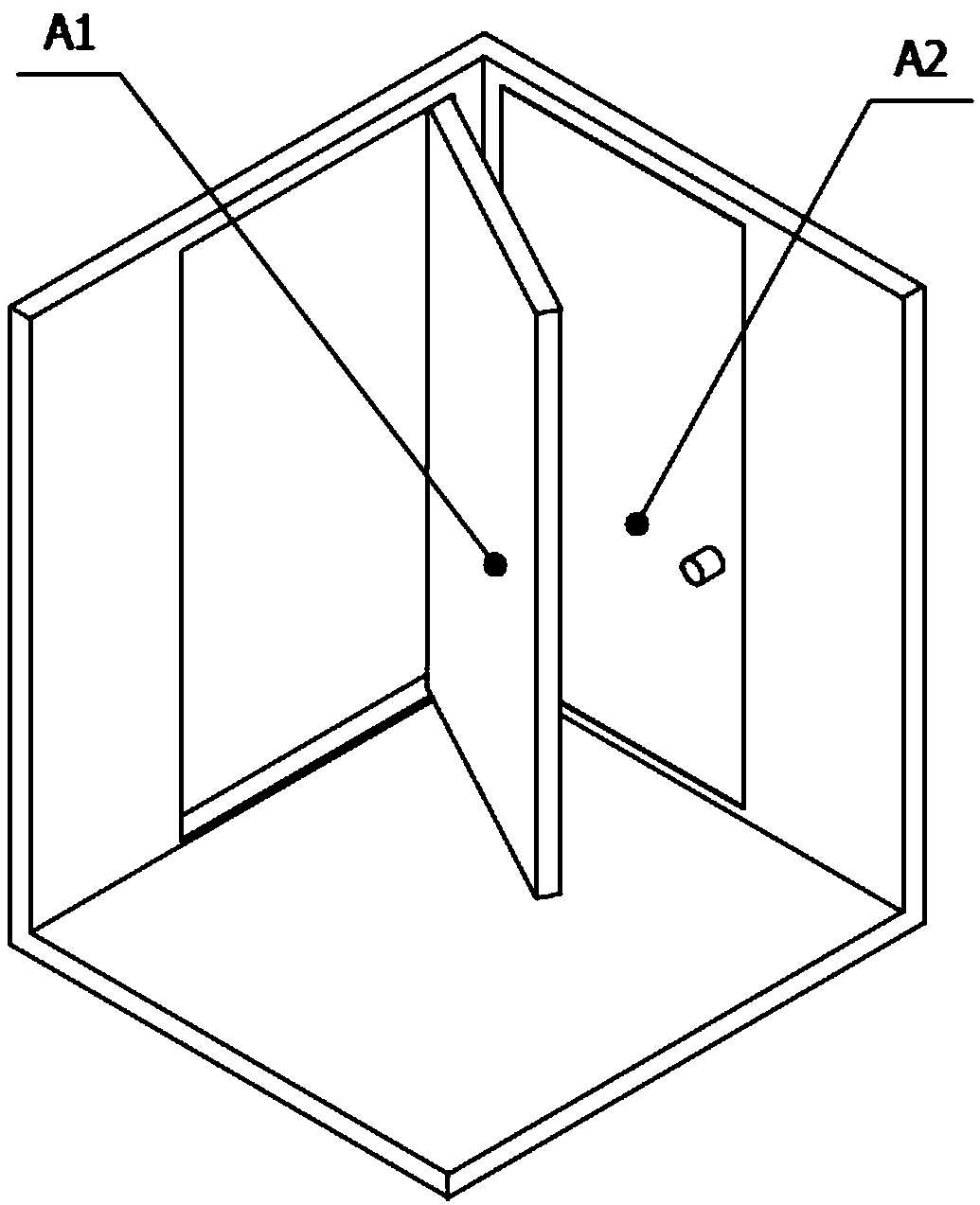

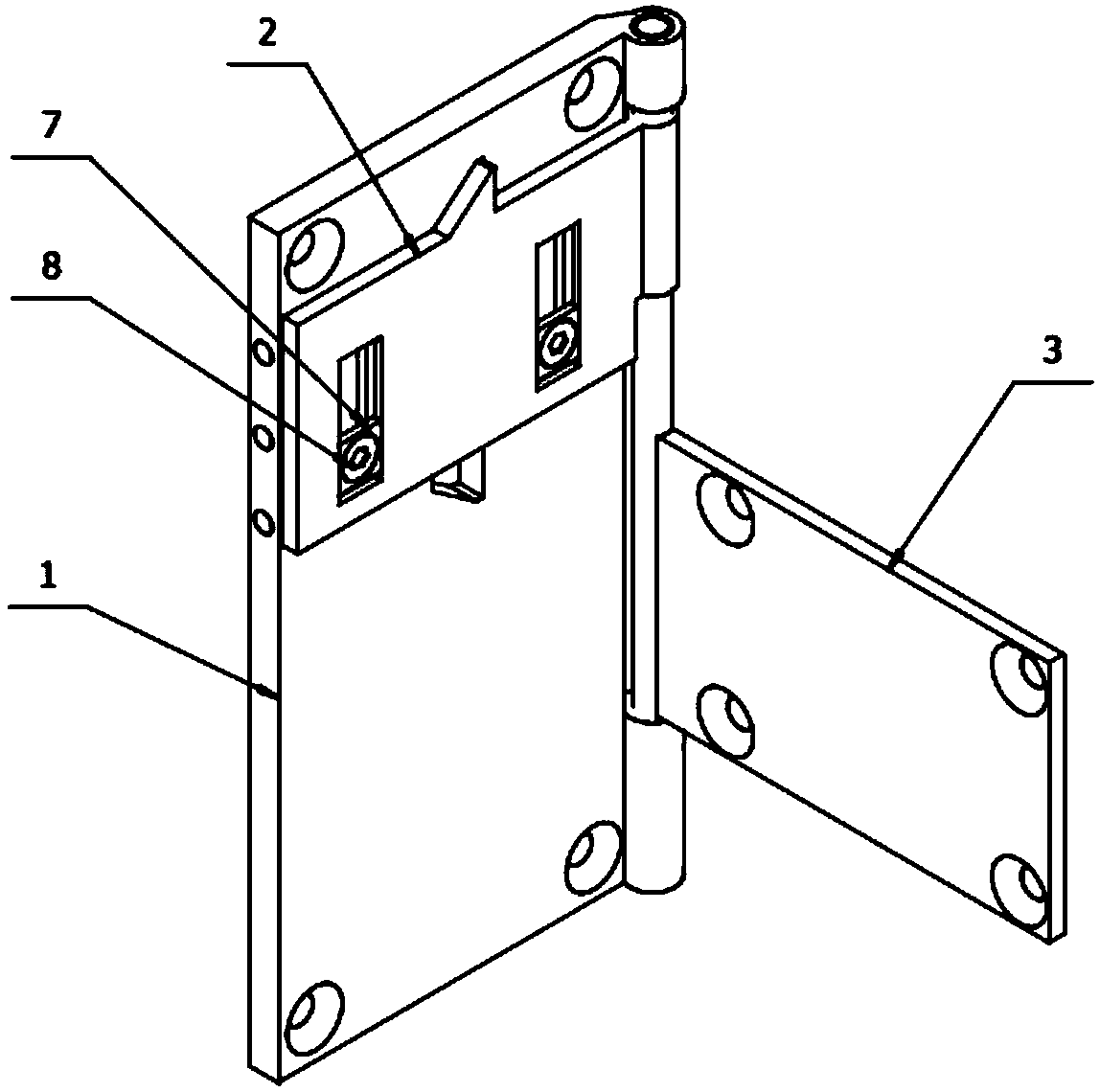

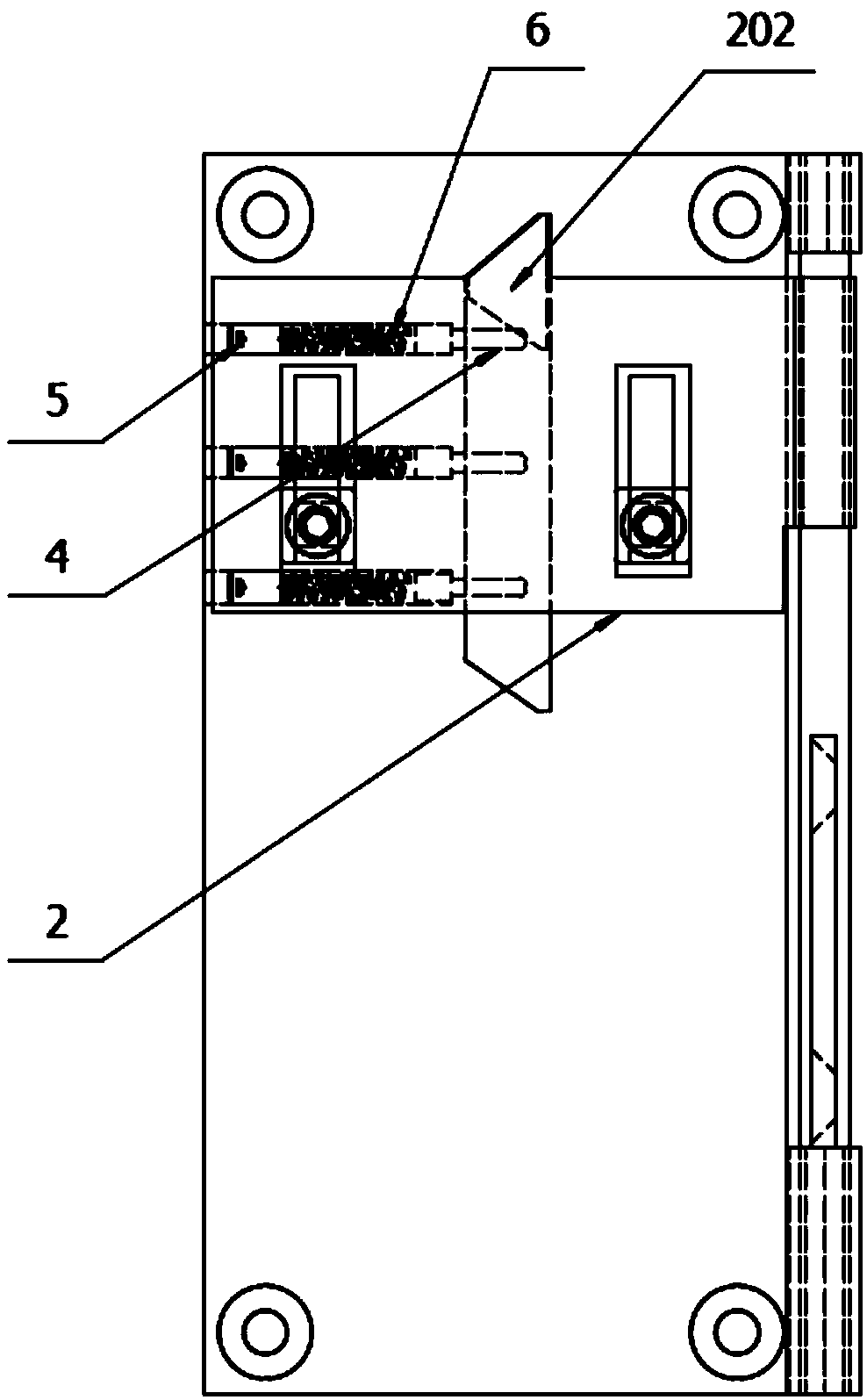

Low-impact energy storage pre-tightening hinge

ActiveCN114001086AReduce shockFit clearance is smallPivotal connectionsEngineeringMechanical engineering

The invention relates to a low-impact energy storage pre-tightening hinge comprising a male hinge, a female hinge and an energy storage pre-tightening device, the male hinge and the female hinge are hinged through a rotating shaft assembly, the energy storage pre-tightening device is installed between the male hinge and the female hinge, the energy storage pre-tightening device comprises an energy storage part, a locking rod, a first check block and a second check block, and the energy storage part is connected between the first check block and the second check block; when the male hinge and the female hinge are in a folded state, the first check block is locked with the male hinge through a first elastic lock pin, and the second check block is locked with the locking rod through a second elastic lock pin. In the unfolding process of the male hinge and the female hinge, the female hinge abuts against one end of the locking rod and pushes the locking rod to move axially, and the locking rod drives the second check block to move towards the first check block and enables the energy storage part to store energy. When the male hinge and the female hinge are in an unfolded state, the female hinge and the locking rod are locked, the first check block and the male hinge are unlocked, the first check block and the locking rod are locked through the first elastic lock pin, the second check block and the locking rod are unlocked, and the second check block and the male hinge are locked through the second elastic lock pin.

Owner:北京微纳星空科技有限公司 +4

Aluminum alloy building formwork splicing assembly

InactiveCN106193587AGood overall stabilitySimple and convenient supportForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabStructural engineering

The invention discloses an aluminum alloy building formwork splicing assembly which comprises multiple groups of formworks transversely laid along floor slabs to be cast. Multiple groups of supporting beams connected with the formworks and provided with gaps are arranged among the formworks, a fixing block fixed to the supporting beams and provided with a guiding groove is arranged at the intersection position of every two adjacent supporting beams, jacking parts matched with the gaps, provided with the top faces acting on the floor slabs and provided with connecting grooves are arranged between two fixing blocks, the top faces of the jacking parts, the formworks and the supporting beams jointly form a floor slab formwork for floor slab casting, connecting pieces fixedly connected with the fixing blocks are arranged in the guide grooves and the connecting grooves. The aluminum alloy building formwork splicing assembly further comprises adjustable supporting rods arranged on the ground, with the top ends in plugged connection with the jacking parts and used for jacking the formworks and the supporting beams. The aluminum alloy building formwork splicing assembly is simple in structure, convenient to splice, high in efficiency, good in overall stability, small in scaffold number, economic and efficient.

Owner:QINGDAO NO 1 CONSTR GRP

Decorative film winding device

The invention discloses a decorative film winding device, which comprises a base and bolts. The left side of the top of the base is fixedly connected with a first vertical board and a second vertical board in sequence from front to back, and the back of the second vertical board is fixed A first motor is connected, the rotating shaft of the first motor passes through the second riser and extends to the outside of the second riser, the back of the first riser and the rotating shaft of the first motor are fixedly connected with a mounting flange, The opposite side of the mounting flange is fixedly connected with a reel through bolts, the right side of the top of the base is fixedly connected with a support platform, and the front and rear sides of the top of the support platform are fixedly connected with U-shaped plates. The spring of the present invention generates a tension force on the support plate and the extrusion shaft, so that the extrusion shaft and the reel are in close contact, the pre-tightening force between the extrusion shaft and the reel can be adjusted, the decorative film can be well clamped, and the reel is avoided. The occurrence of looseness when winding the decorative film facilitates the winding of the decorative film.

Owner:浙江欧科新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com