Patents

Literature

40results about How to "Improve the temperature sensing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

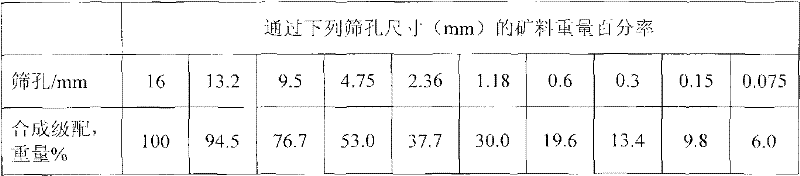

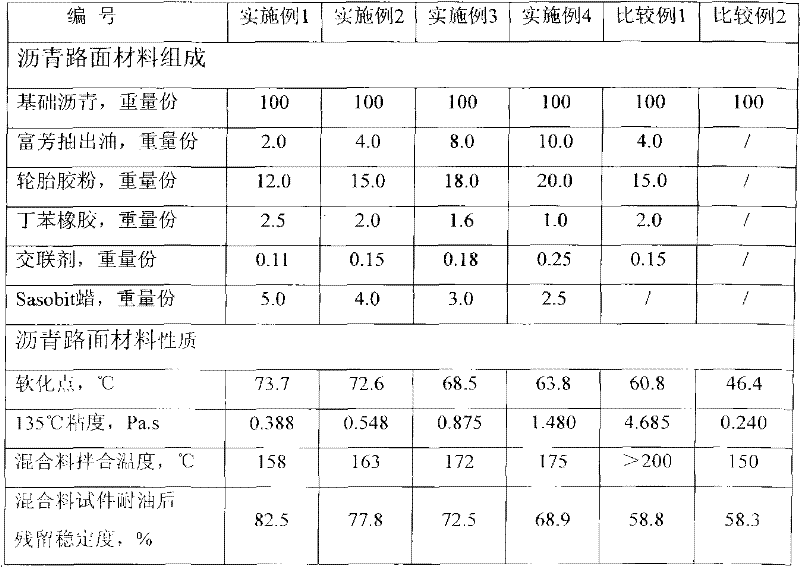

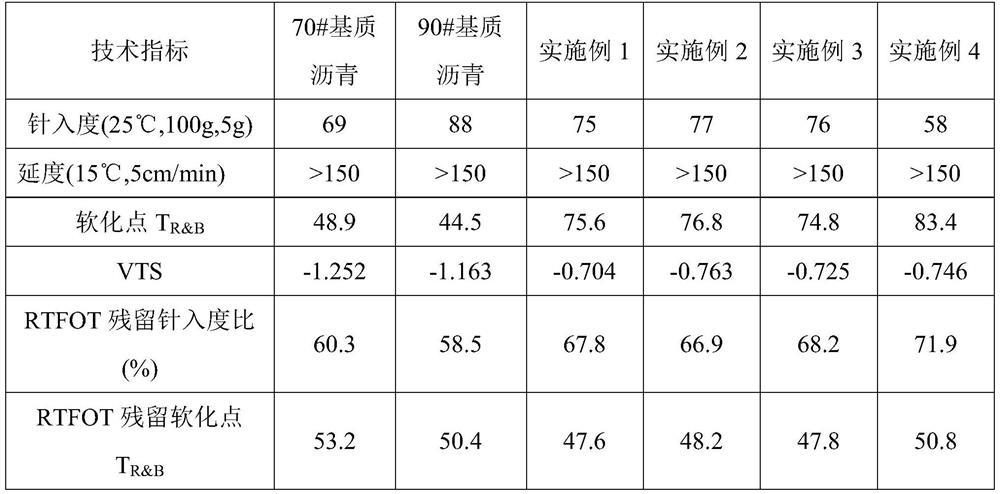

Environment-friendly oil-resistant asphalt pavement material and preparation method thereof

InactiveCN102453335AGood oil resistanceImprove temperature sensitivityIn situ pavingsBuilding insulationsWaxPolymer science

The invention discloses an environment-friendly oil-resistant asphalt pavement material and a preparation method thereof. The oil-resistant pavement material comprises the following components in part by weight: 100 parts of base asphalt, 5 to 25 parts of waste tyre rubber powder, 0.5 to 5.0 parts of styrene butadiene rubber (SBR), 1 to 10 parts of macromolecular wax, and 0.1 to 0.3 part of crosslinking agent. The preparation method comprises the following steps of: adding the macromolecular wax into molten base asphalt in the weight proportion, stirring for reaction, adding the waste tyre rubber powder and the SBR, keeping temperature for swelling, and finally adding the crosslinking agent and grinding fully to obtain the environment-friendly oil-resistant asphalt pavement material. The waste tyre rubber powder is used as an asphalt modifier and matched with the SBR and the macromolecular wax, and the environment-friendly oil-resistant asphalt pavement material has high oil resistance and low cost and is favorable for reducing environmental pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

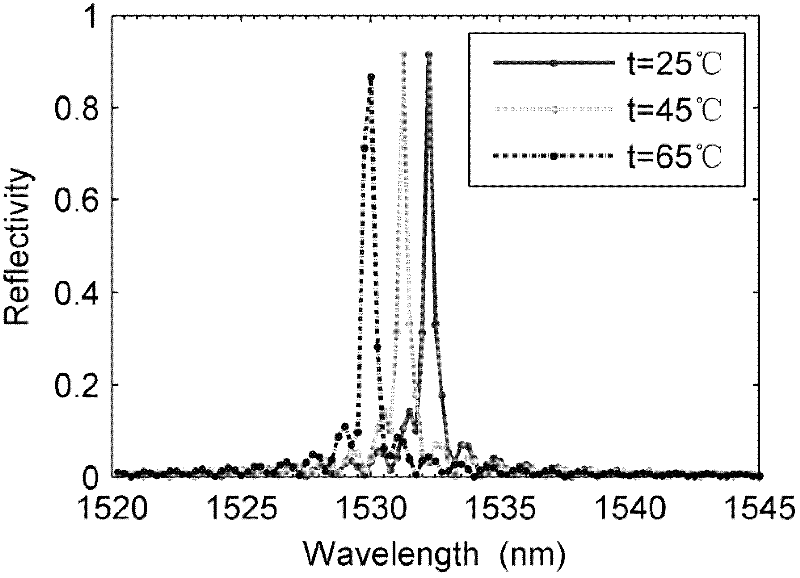

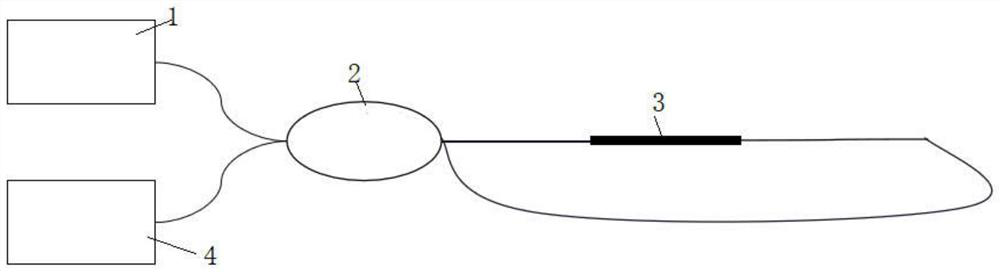

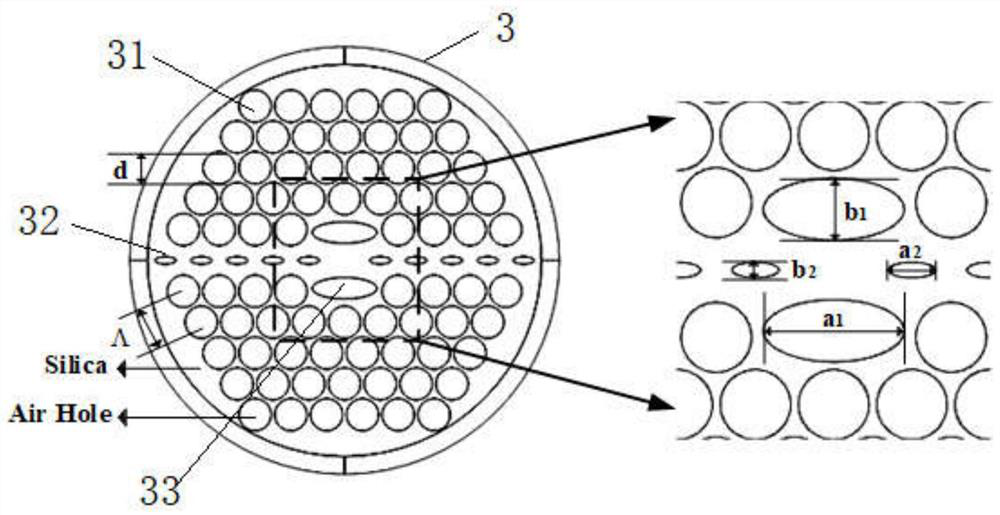

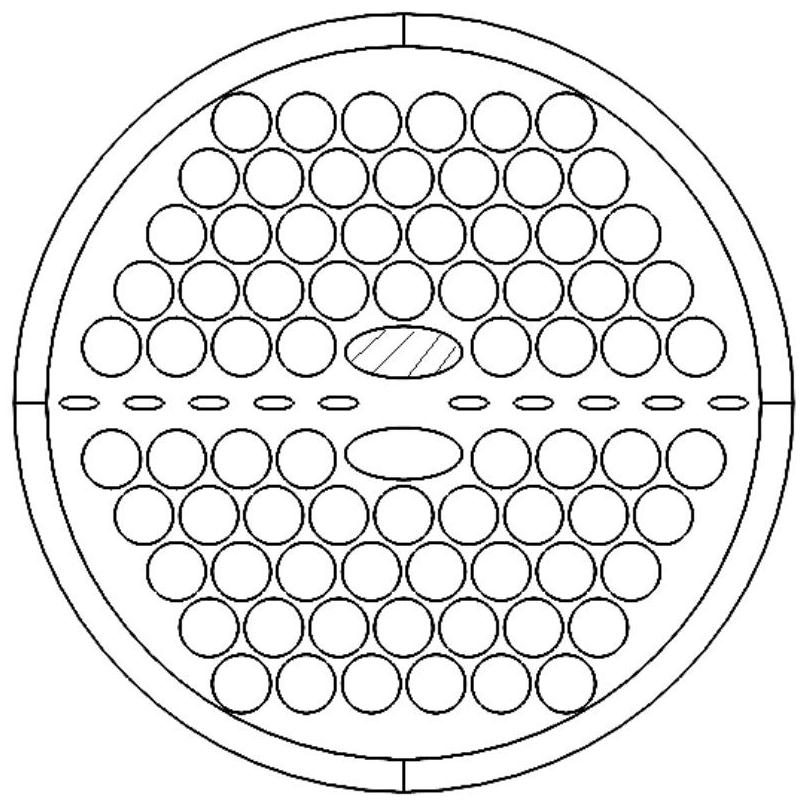

Photonic crystal fiber grating temperature sensor based on liquid filling and manufacturing method thereof

InactiveCN102564639AExcellent thermo-optic coefficientIncrease thermo-photosensitivity coefficientCladded optical fibreThermometers using physical/chemical changesGratingPhotonic crystal

The invention discloses a photonic crystal fiber grating temperature sensor based on liquid filling and a manufacturing method thereof. The photonic crystal fiber grating temperature sensor comprises a photonic crystal fiber cladding, wherein a germanium-doped fiber core is located at a center axis position in the fiber cladding; a Bragg grating structure is engraved on the surface of the fiber core; air vents are arranged along the axial direction of the fiber cladding and are distributed around the fiber core to form a multilayer matrix structure; and an index matching liquid with a thermal and light sensitive effect is filled in the air vents. The temperature sensitive property of the fiber Bragg grating temperature sensor is improved by filling the index matching liquid with the thermal and light sensitive effect into the air vents of the fiber cladding. By utilizing the photonic crystal fiber grating structure for filling liquid, the liquid thermal and light sensitive effect of a cladding area exists besides the liquid thermal and light sensitive effect and the heat expansion effect of a core area grating. The liquid thermal and light sensitive degree of the liquid is far better than that of a solid so that the photonic crystal fiber grating temperature sensor disclosed by the invention can obtain the thermal and light sensitive coefficient which are improved by 1-2 magnitude orders compared with that of the existing product.

Owner:满文庆 +1

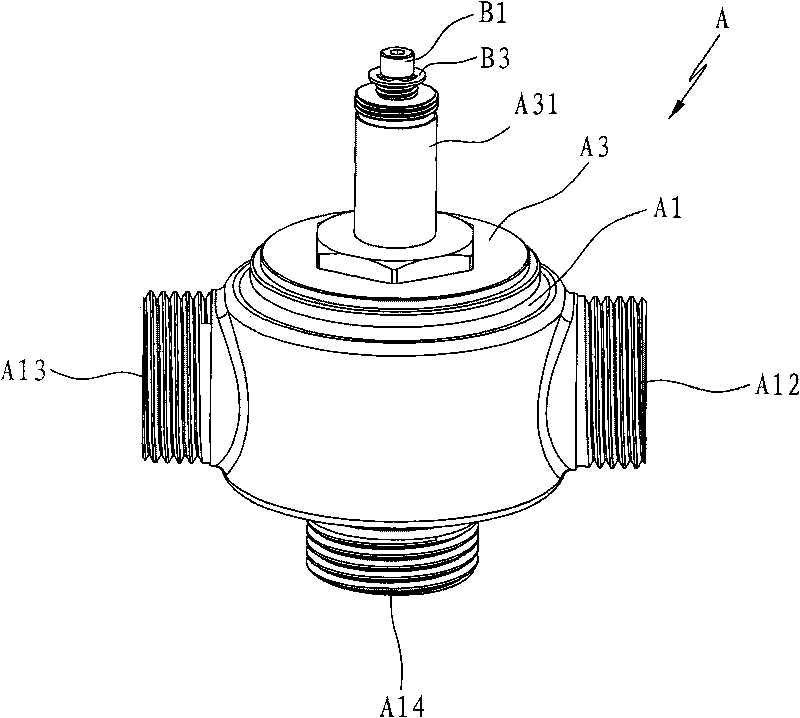

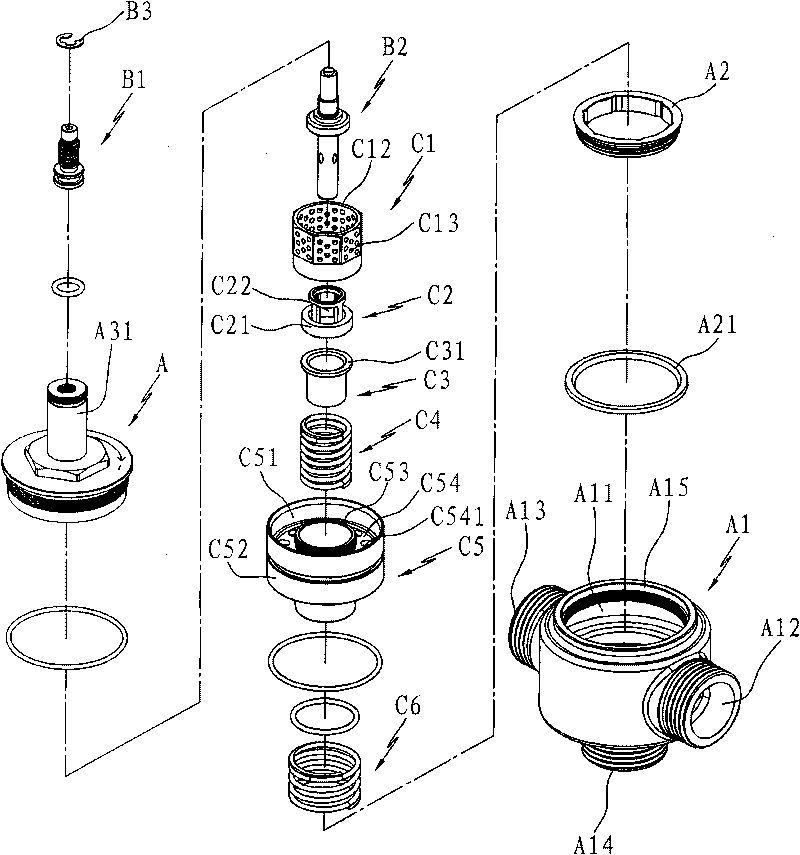

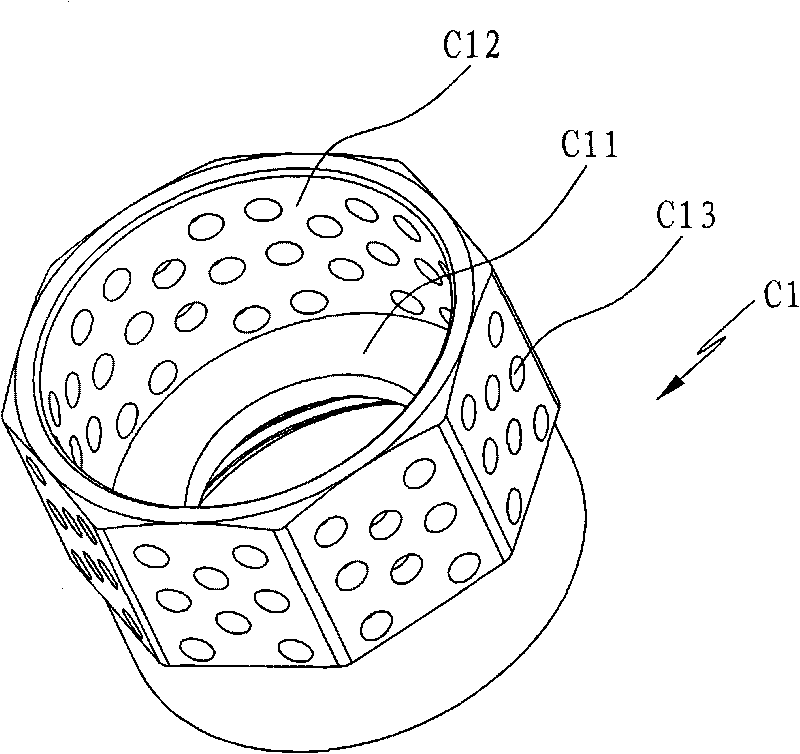

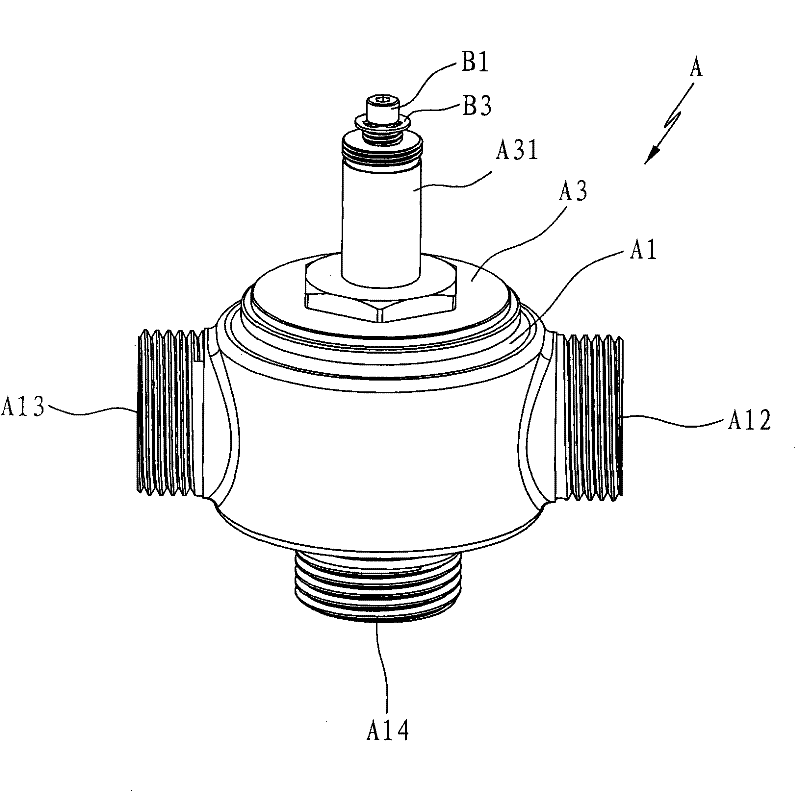

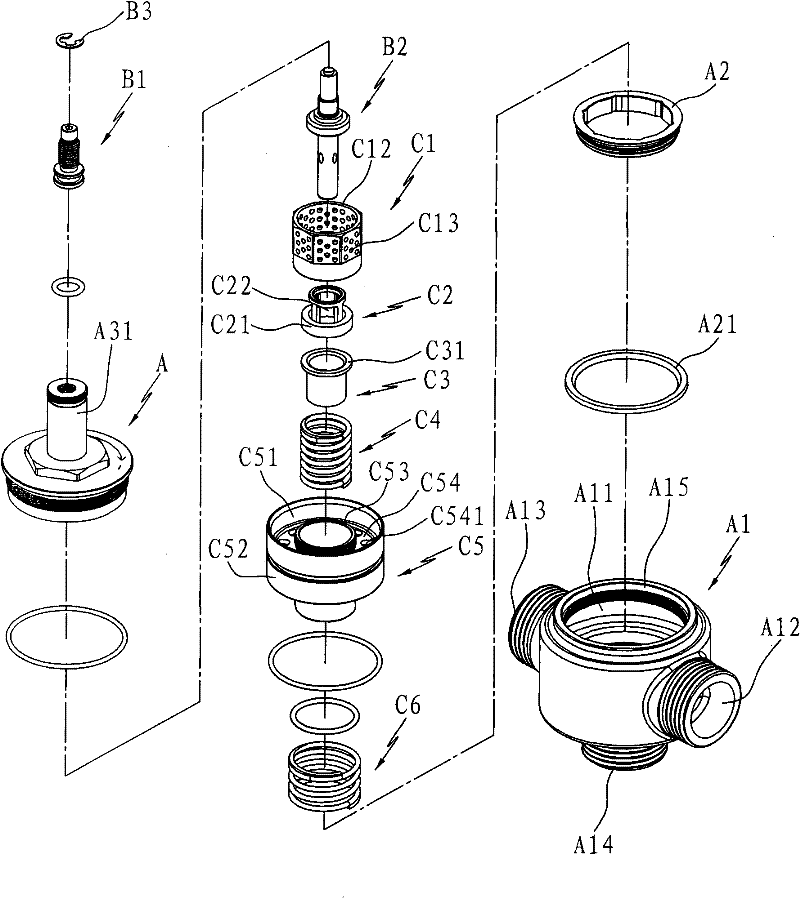

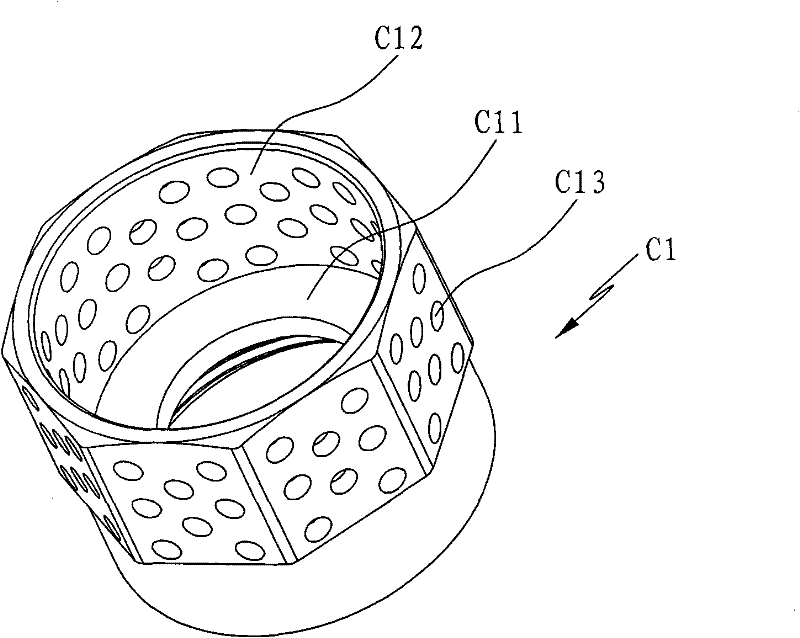

Temperature-controlled mixing valve structure

InactiveCN101706010ASimple structureLow costOperating means/releasing devices for valvesTemperatue controlEngineeringTemperature control

The invention discloses a temperature-controlled mixing valve structure which comprises a valve body assembly, a temperature controller and a constant temperature controller, wherein a reset spring of the constant temperature controller supports a sliding bar assembly which is in dynamic fit with a thermo-sensitive element; the sliding bar assembly comprises a sliding bar, a water mixer, a spring pad and a protection spring, wherein the sliding bar is supported between a valve-body upper cover and a mixed water outlet by the reset spring; the sliding bar is provided with an inner sleeve and an outer sleeve, and a water channel is formed between the inner sleeve and the outer sleeve; the upper part of the water mixer is distributed with a plurality of water inlet holes, and the lower part thereof is fixed at the upper end of the inner sleeve of the sliding bar; the spring pad is supported by the protection spring and positioned in the inner sleeve of the sliding bar; the thermo-sensitive element is arranged in the water mixer, the spring pad and the inner sleeve of the sliding bar in sequence in a penetrating way; the upper end of the spring pad is matched with the thermo-sensitive in a contacting way; the upper part of the sliding bar, the upper cover and the external wall of the water mixer form a first water mixing cavity; and the internal wall of the upper part of the water mixer and the external wall of the thermo-sensitive element form a second water mixing cavity. Cold water and hot water are mixed for twice, thus improving the water mixing effect and achieving the purpose of controlling the stability of the water temperature. In addition, a sealing pad is arranged at the hot water end of the valve body, thus improving the performance of losing efficacy of cold water, and realizing excellent safety in use.

Owner:XIAMEN LOTA INT CO LTD

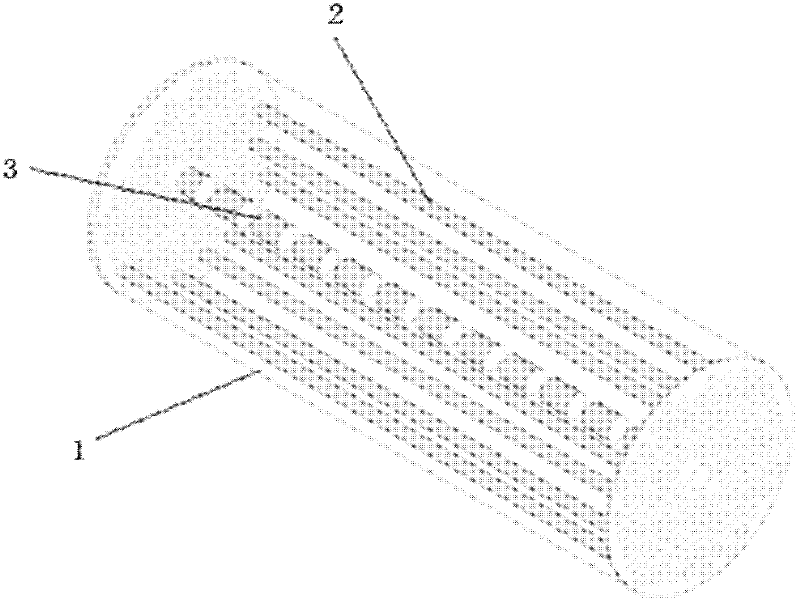

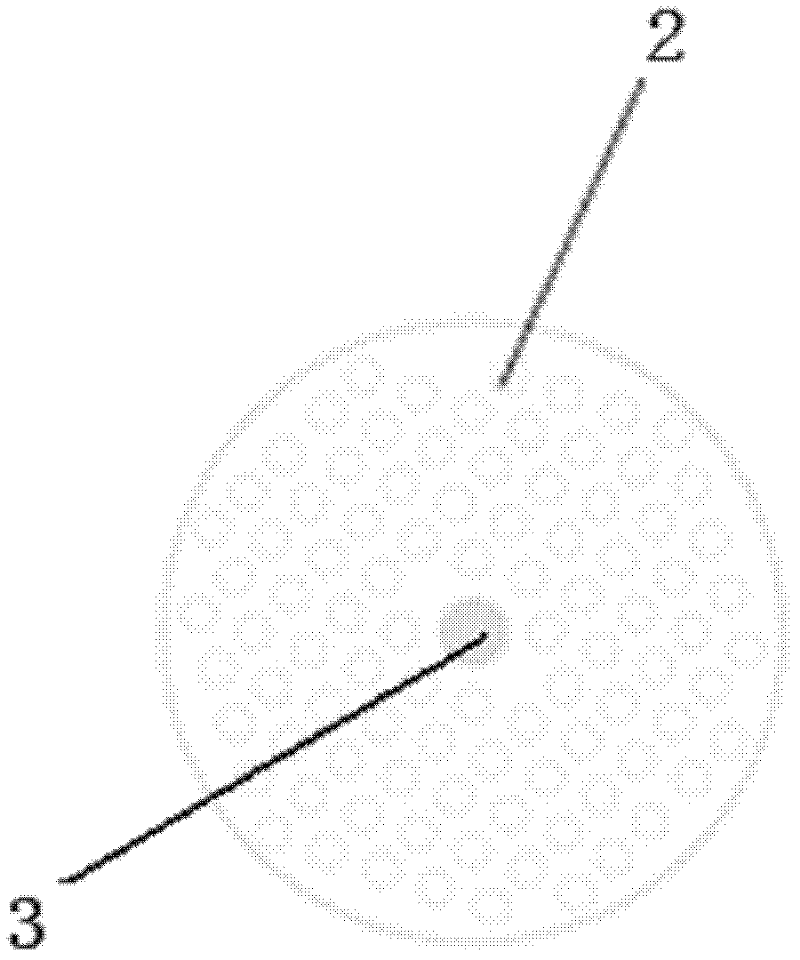

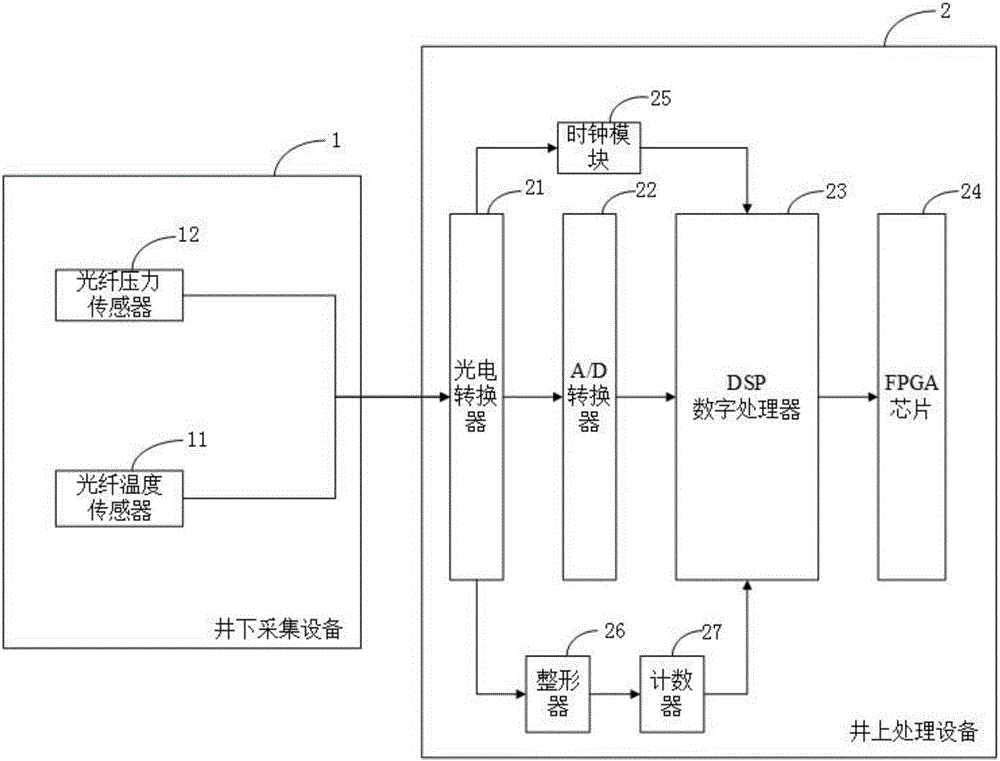

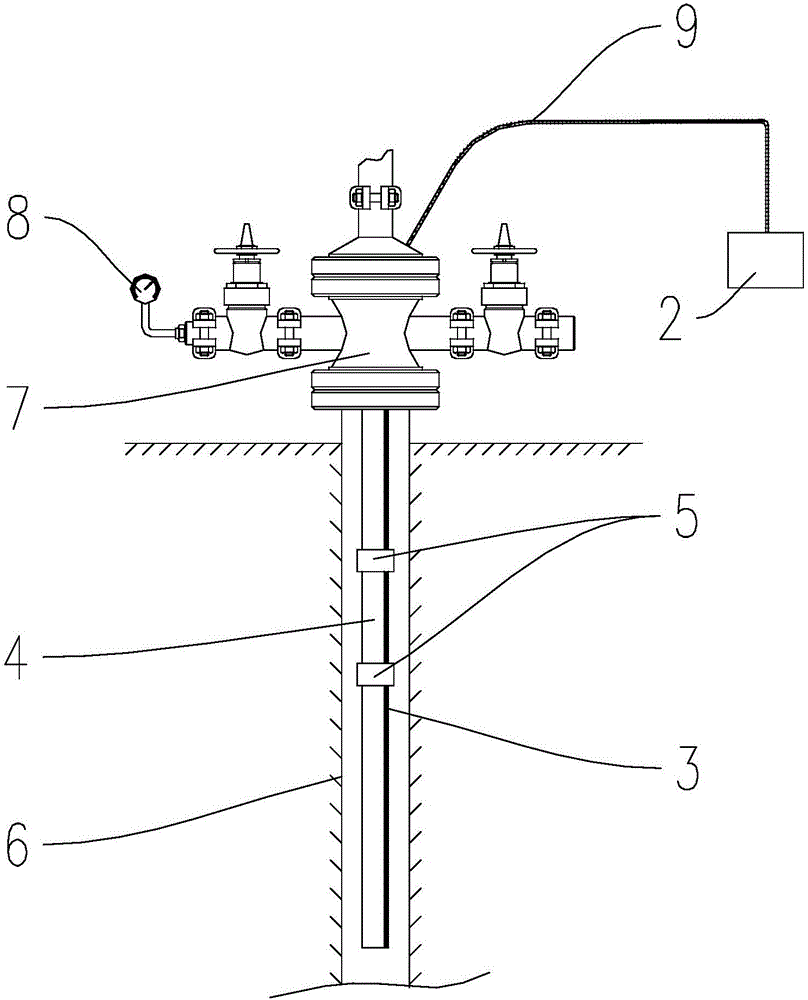

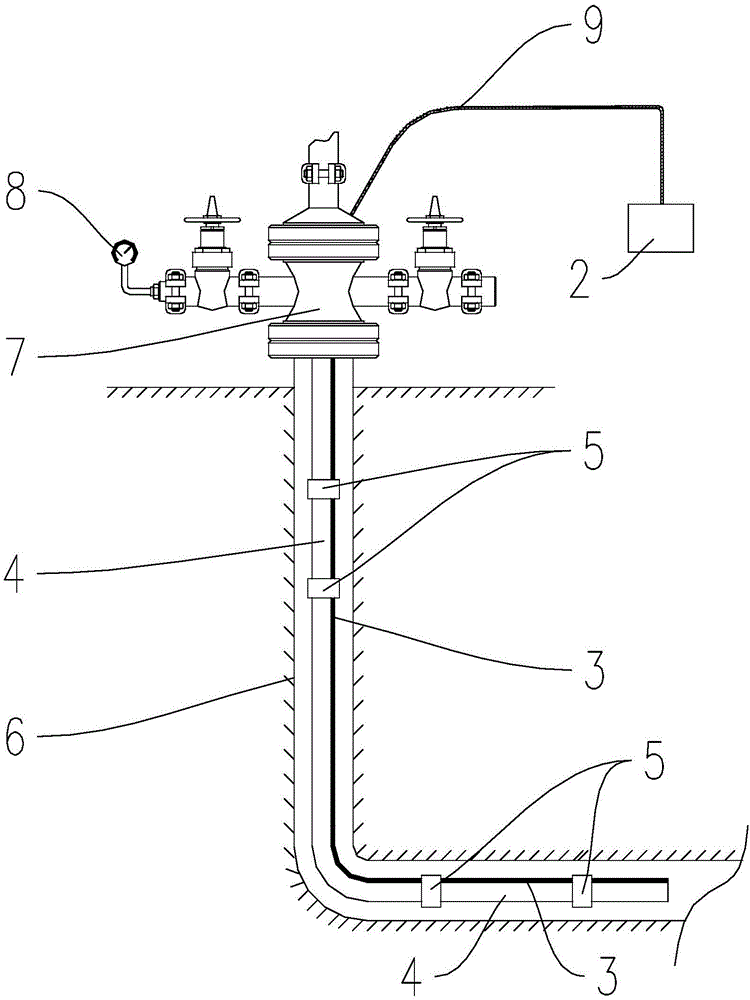

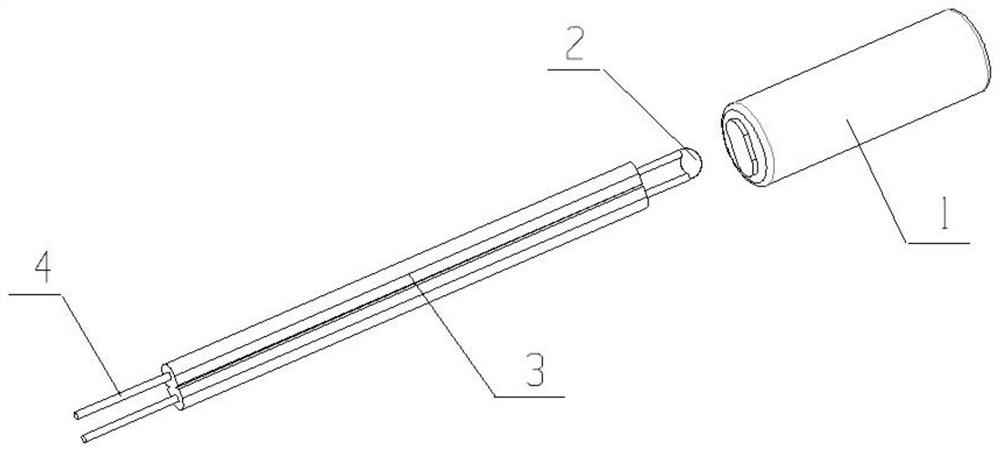

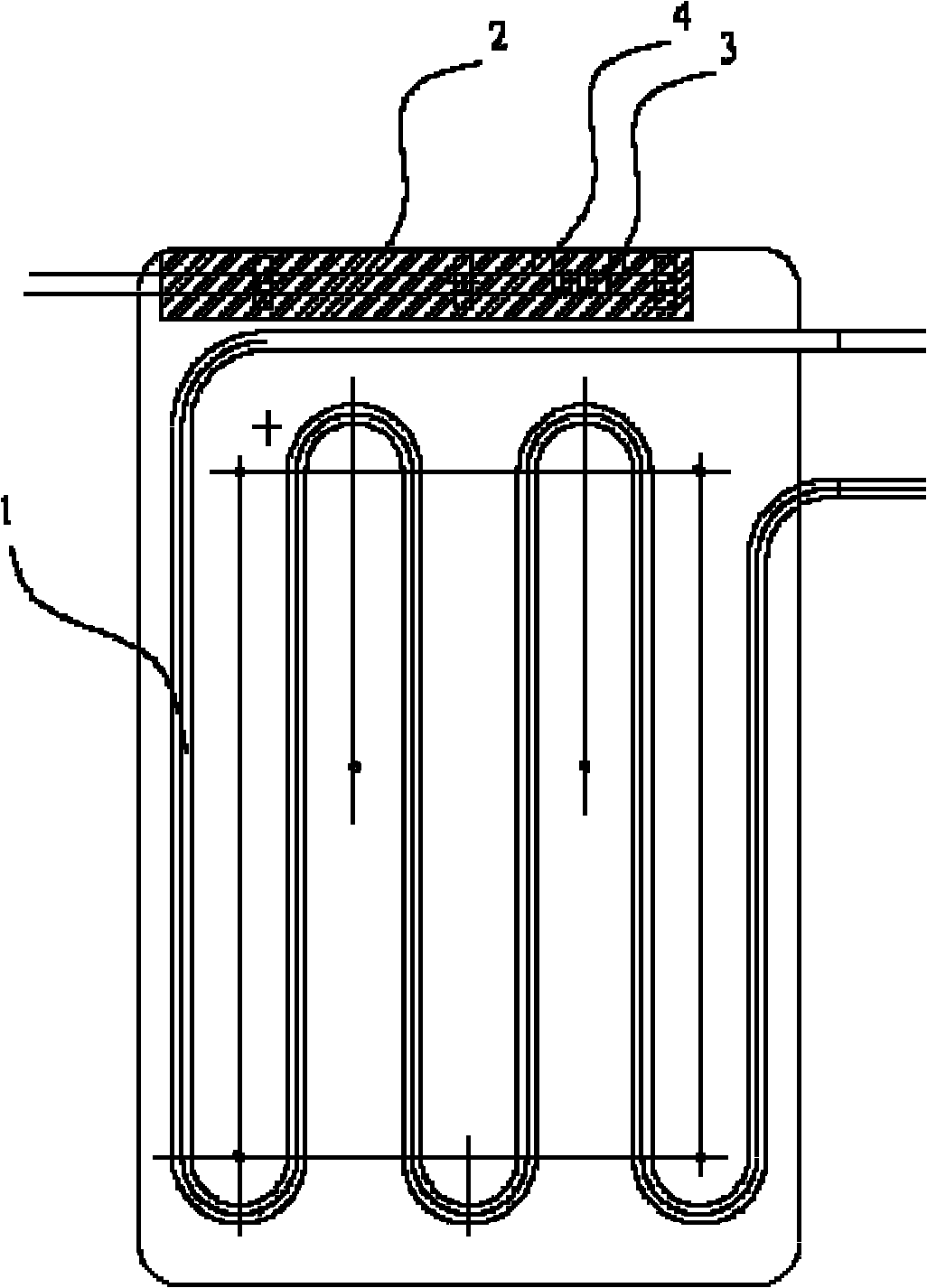

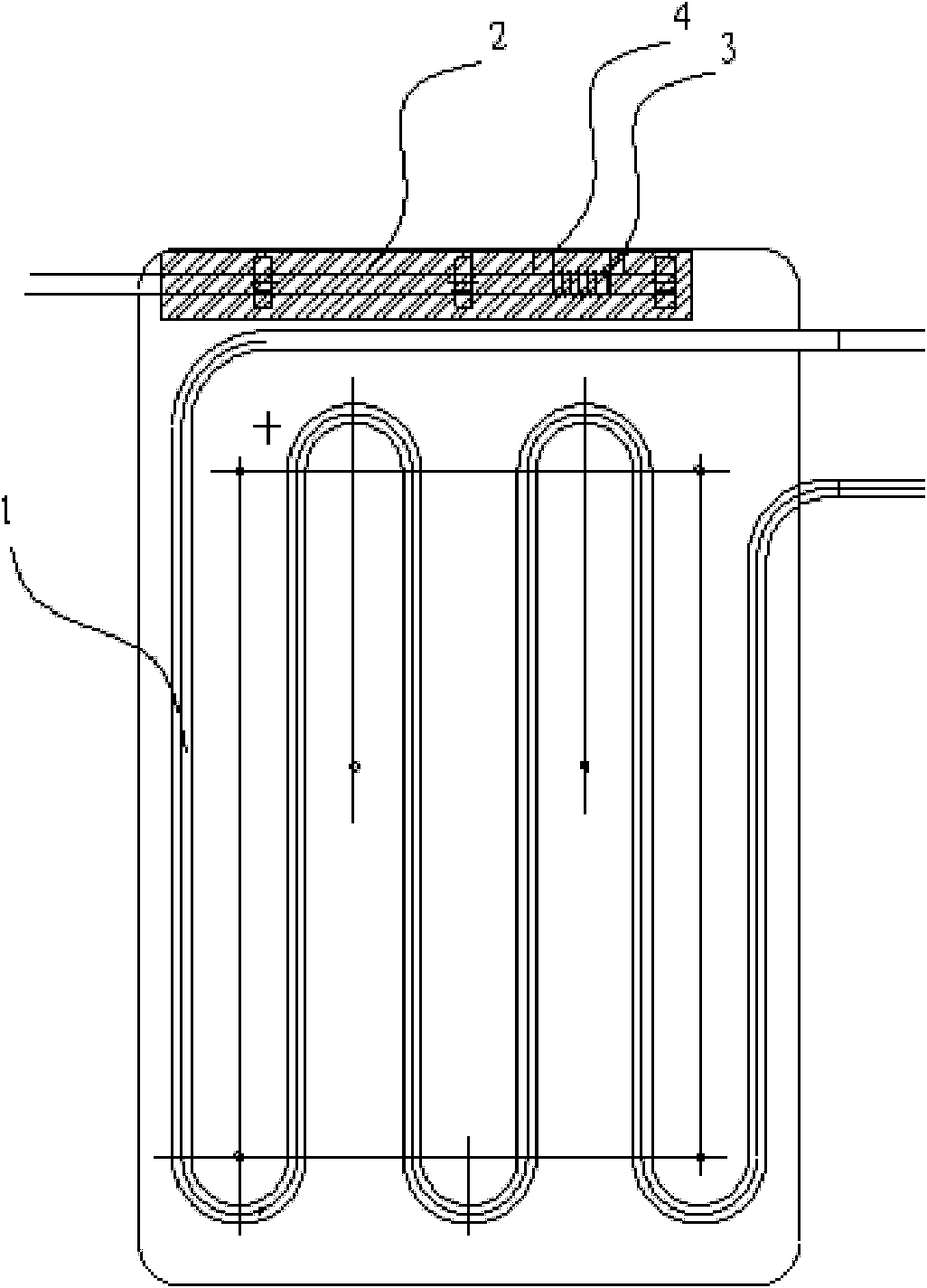

Distributed optical fiber downhole collecting device, downhole flowmeter and downhole monitoring method

The invention relates to a distributed optical fiber downhole collecting device. The distributed optical fiber downhole collecting device comprises a downhole string, downhole optical cables and optical fiber temperature sensors; all the downhole optical cables are wound around the downhole string into a spiral shape, or a part of the downhole optical cables are wound around the downhole string into a spiral shape, and the other part of the downhole optical cables are linearly arranged on the wall at one side of the downhole string; the optical fiber temperature sensors are integrated to the downhole optical cables and arranged in the extending direction of the downhole optical cables in a distributed mode. The invention further relates to a distributed optical fiber downhole flowmeter and a downhole monitoring method. According to the distributed optical fiber downhole collecting device, as the downhole optical cables are wound around the downhole string into the spiral shape, the number of collecting points in unit space is increased, resolution is improved, and a better measurement effect is achieved; as the optical fiber temperature sensors are arranged in the extending direction of the downhole optical cables in the distributed mode, distributed measurement can be achieved without separating downhole fluid, and full-hole measurement can be achieved without moving the downhole optical cables or the sensors.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Manufacturing method for temperature-changed water transfer printing

The invention provides a manufacturing method for temperature-changed water transfer printing. In the method, temperature-changed printing ink is prepared by mixing uniformly temperature-changed powder and a transparent polyester resin or a colored polyester resin according to a certain weight ratio, and a temperature-changed induction effect can be reflected on the printed material by water transfer printing without adding any hardener. By using the method, a pattern or some part of the pattern can realize temperature-changed induction, and can be combined with the printed material so as to achieve permanent wear resistance and especially favorable resistance to water boiling, water washing and acid and alkali solvent wiping. After the pattern is transferred on the surface of the printed material, the hand feeling is smooth, and the color is brilliant and bright. The method is especially applicable to transfer printing decoration on non-planar metal and glass utensils.

Owner:南京科晖精密科技有限公司

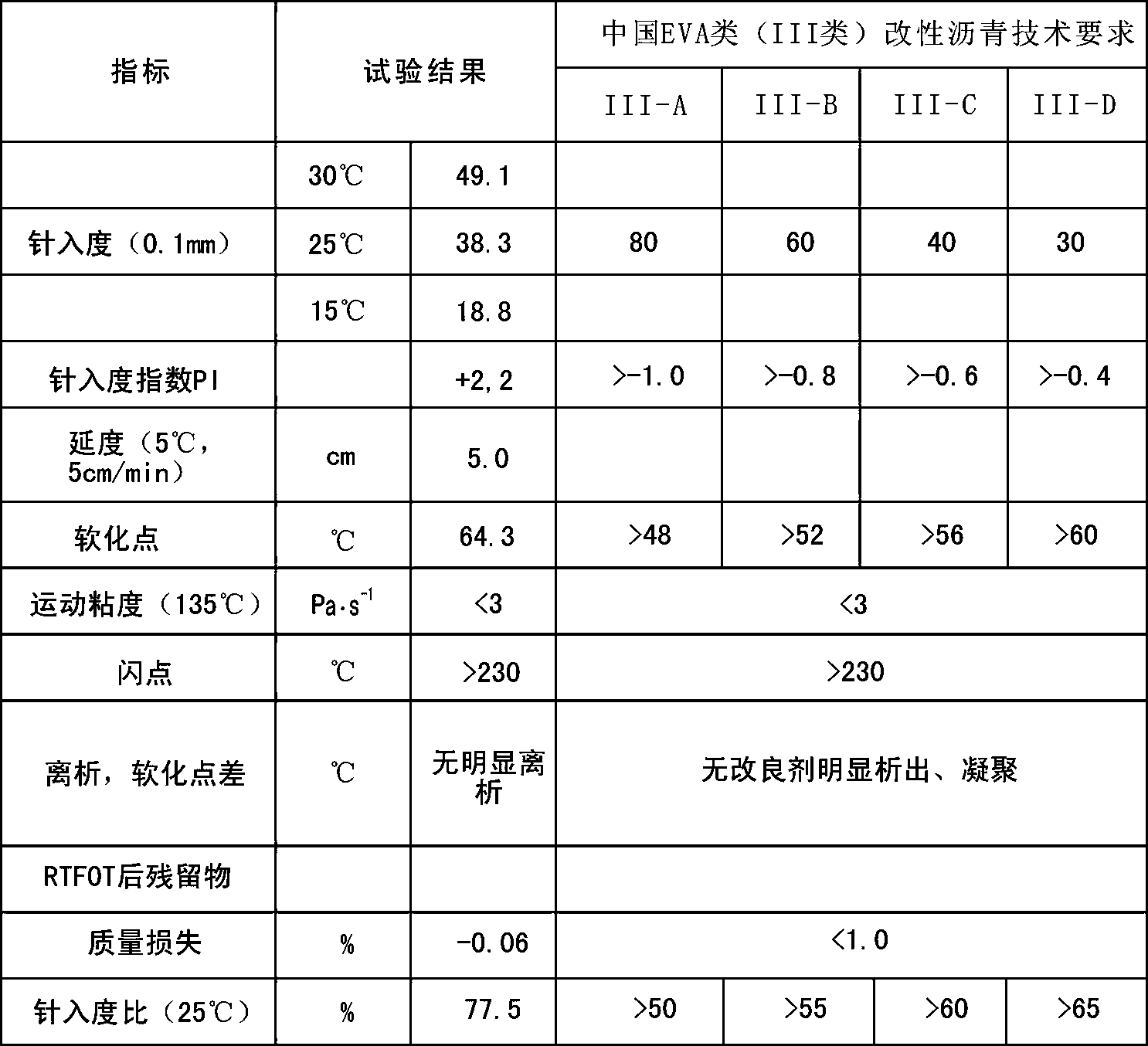

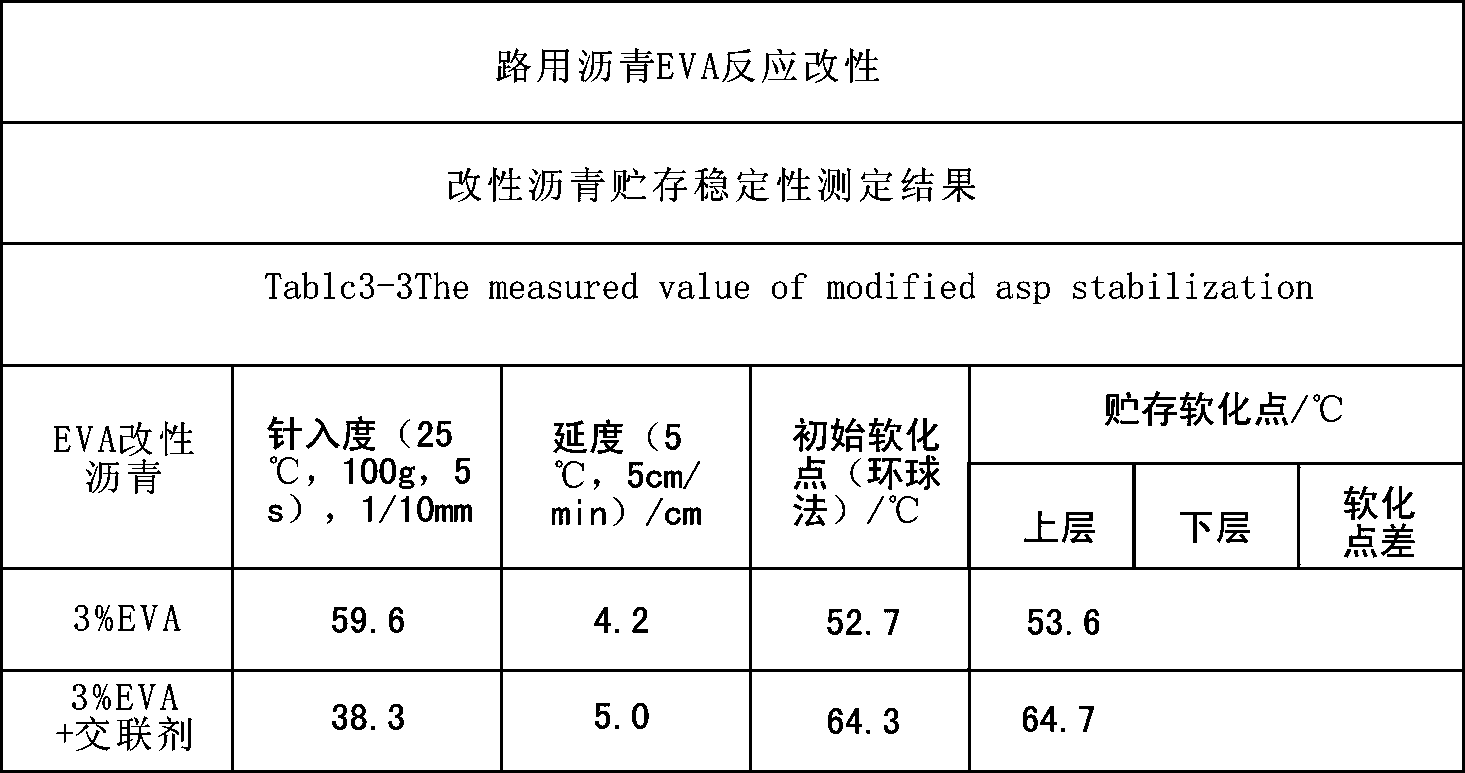

Low-temperature aromatic hydrocarbon oil road modified asphalt, and preparation method thereof

The invention relates to a low-temperature aromatic hydrocarbon oil road modified asphalt, and a preparation method thereof. The low-temperature aromatic hydrocarbon oil road modified asphalt is prepared from an asphalt modification component A, a modification component B, and the like, and weight ratio of the asphalt modification component A to the modification component B is 20-25:80-75; EVA is shorted for ethylene / vinyl acetate copolymer; the content of VA is 41%. According to the preparation method, asphalt is delivered into a constant temperature modification device, and is heated to 165 DEG C; 3% of EVA, 0.2% of an aromatic hydrocarbon oil, an asphalt diluent, the asphalt modification component A, the modification component B, a cross-linking agent, and a catalyst are added; and an obtained mixture is subjected to 2.5h of Shear mixing using an agitator tank for modification at a temperature is controlled to be 165 to 170. Advantages of the preparation method are that: cheap coal and coke are taken as the asphalt modifiers, and traditional physical method is used for modifying common asphalt, so that high and low temperature performance of asphalt is improved greatly, combination with existing technology can be realized without adding any novel equipment, and cost of asphalt modification with coal and coke is reduced greatly.

Owner:中油路之星新材料有限公司

Rubber asphalt modifier and preparation method thereof

InactiveCN105199408ALow viscosityLow production temperaturePlastic recyclingBuilding insulationsFiberPolymer science

The invention discloses a preparation method for a rubber asphalt modifier. The preparation method comprises the following steps: 1) removing metal, fiber and foreign materials in waste and old rubber and then crushing the waste and old rubber into small-grain flocculent rubber powder; 2) carrying out activation, desulphurization and regeneration on the flocculent rubber powder obtained in the step 1) by using microwave radiation; 3) placing the regenerated rubber powder obtained in the step 2) in an enclosed agitator tank, spraying heated abietic acid type resin acid and carrying out a reaction; and 4) after completion of the reaction in the step 3), carrying out cooling so as to prepare the rubber asphalt modifier. The rubber asphalt modifier can effectively reduce viscosity of modified asphalt in production, decreases production temperature of the modified asphalt, energy consumption and pollution, improves mechanical properties like anti-stripping performance of rubber asphalt and enhances compatibility and temperature-sensitive performance of the modified asphalt.

Owner:GUANGXI YUANJING RUBBER TECH

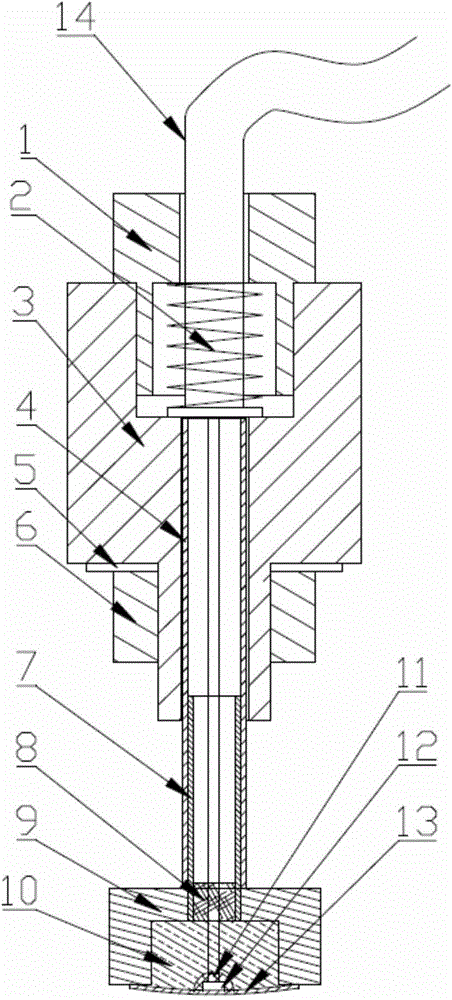

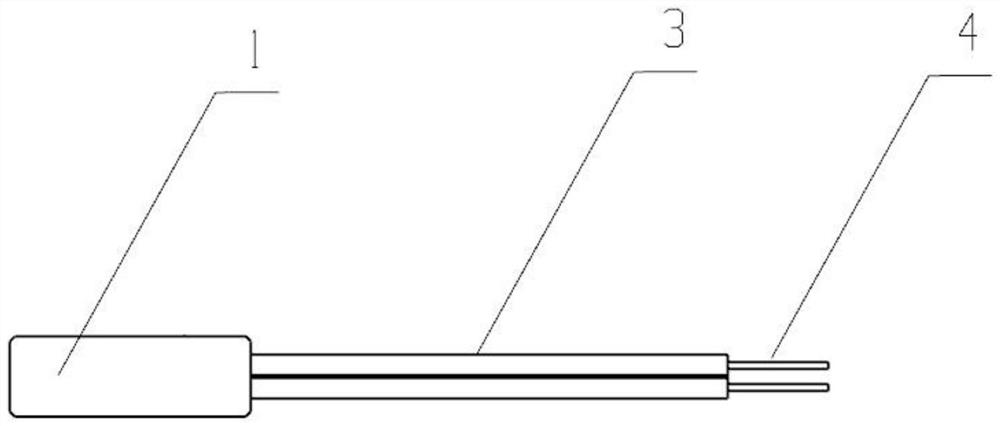

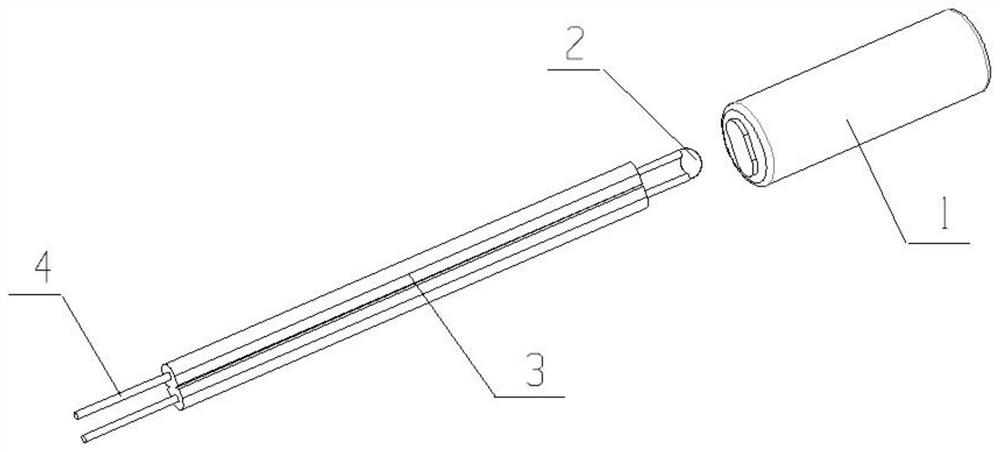

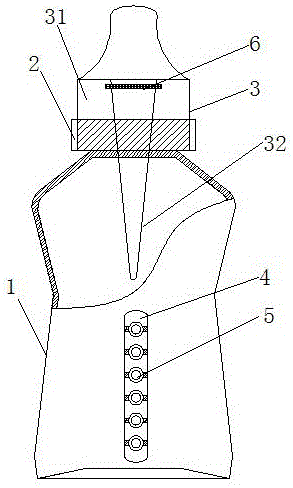

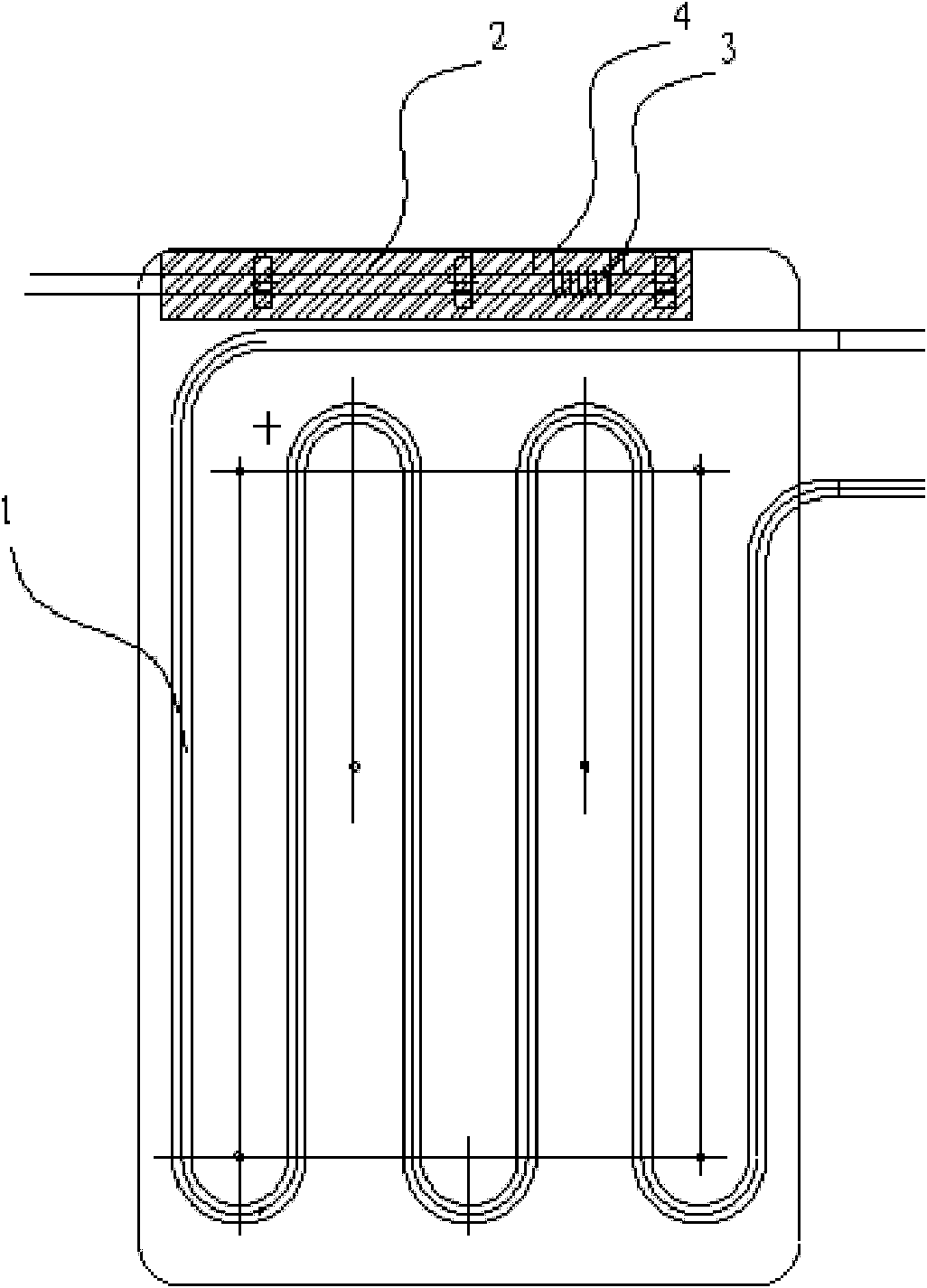

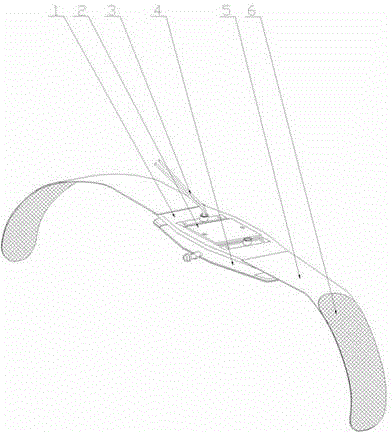

High-accuracy wall temperature measuring device

ActiveCN104614088AImprove the temperature sensing effectLarge output signalThermometers using electric/magnetic elementsUsing electrical meansEngineeringSignal strength

The invention provides a high-accuracy wall temperature measuring device. The high-accuracy wall temperature measuring device comprises a base part, a probe part and a metal guide tube, wherein the tail end of the metal guide tube is elastically connected with the base part, while the front end of the metal guide tube is movably connected with the probe part; the probe part comprises a metal wire tube, a probe body, a temperature-sensing element and a metal contact piece, all of which are orderly and fixedly connected with each other, and wherein one end of the metal wire tube is nested into the metal guide tube and the other end of the metal wire tube is fixedly connected with the probe body. The high-accuracy wall temperature measuring device is fixed above the wall; the probe is kept into close contact with the wall by virtue of the elastic force of a spring in the probe base to measure the temperature of the wall; besides, the device is high in temperature sensing capability, high in output signal strength and high in measurement accuracy.

Owner:SHANGHAI JIAO TONG UNIV

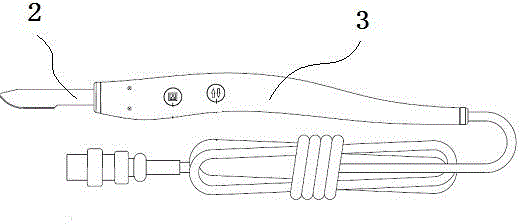

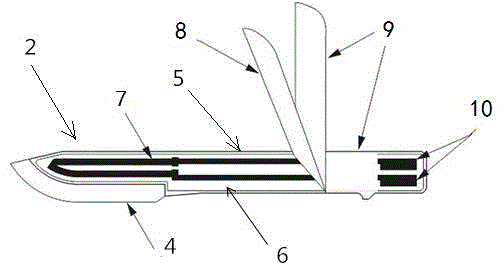

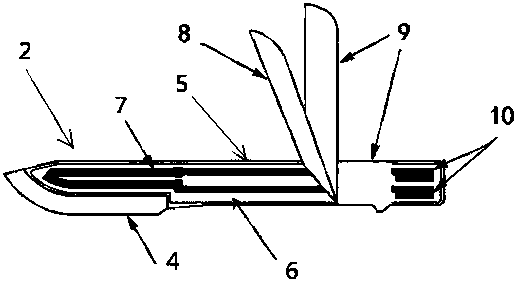

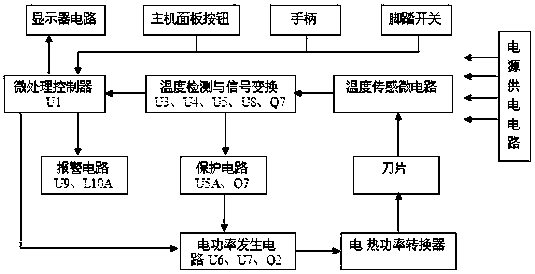

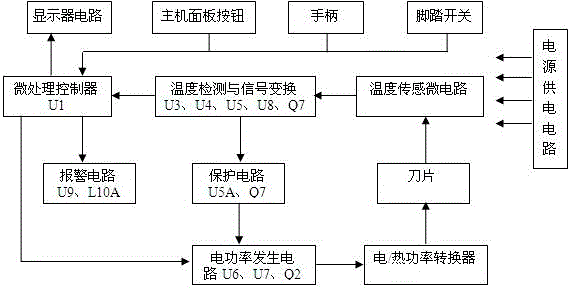

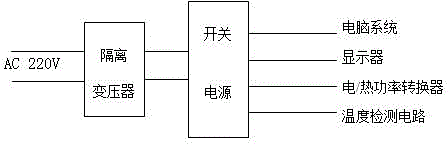

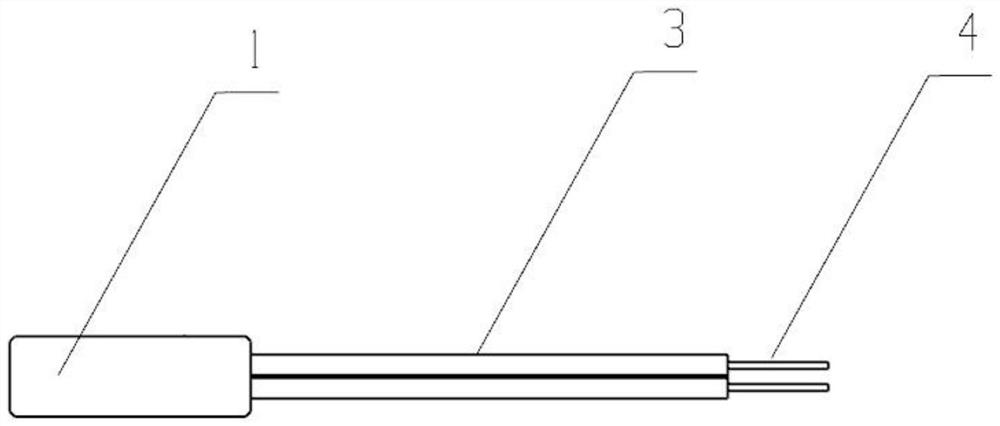

Thermosetting surgical knife device

ActiveCN104027166AAvoid cross infectionAvoid burnsSurgical instruments for heatingSurgical bladeControl system

The invention relates to a thermosetting surgical knife device, mainly consisting of a main machine and a surgical knife assembly, wherein the surgical knife assembly is composed of a surgical knife blade and a surgical knife handle; the surgical knife blade is platelike; one side of the front end of the surgical knife blade is provided with a knife edge; the peripheral connected part of the knife edge is provided with a knife body which takes the shape of a multilayer plate; the substrate of the knife body is insulated; the knife body is composed of a heating piece, an insulated packaging layer and Teflon coating from inside to outside; an electrode is arranged at the rear part of the knife body, inserted into the front end of the surgical knife handle, and integrally fixedly connected with the same; an external heater and an external temperature sensor are attached to the exterior of the a surgical knife blade, and the external heater is a heating circuit; the heating piece is a looped heating strip; the knife blade surface adopts an external heating style that an external heating circuit is arranged at the outer part of the surgical knife blade surface, and controlled by an accurate control system composed of computer systems, so that the knife blade is warm but not electrified, and thereby the use safety of the surgical knife is ensured.

Owner:江苏凝克医疗器械科技有限公司

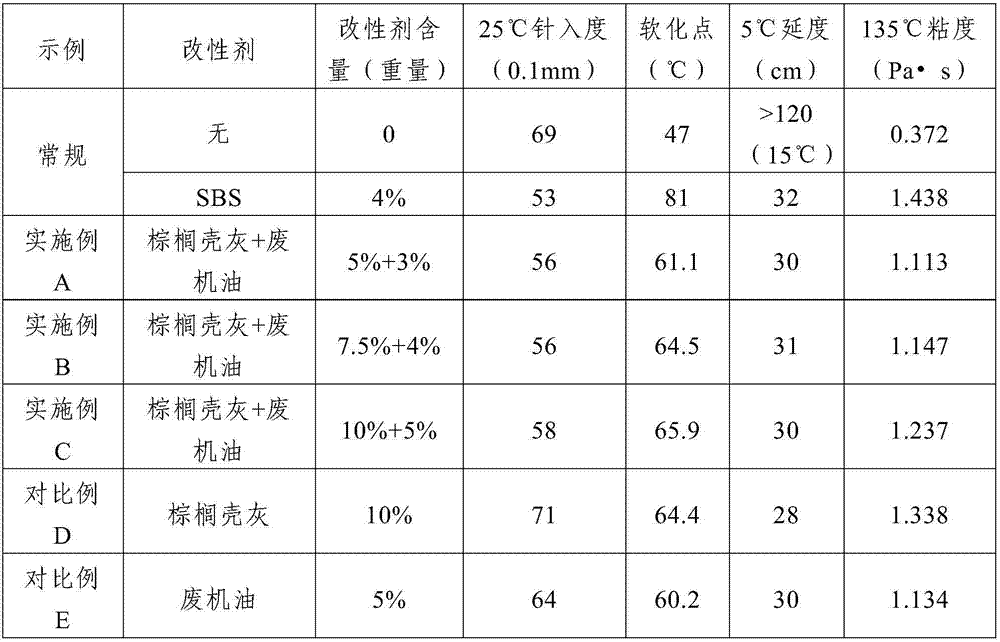

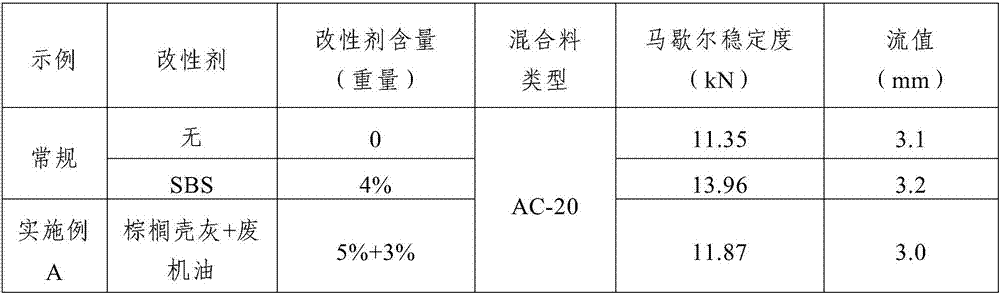

Modified asphalt

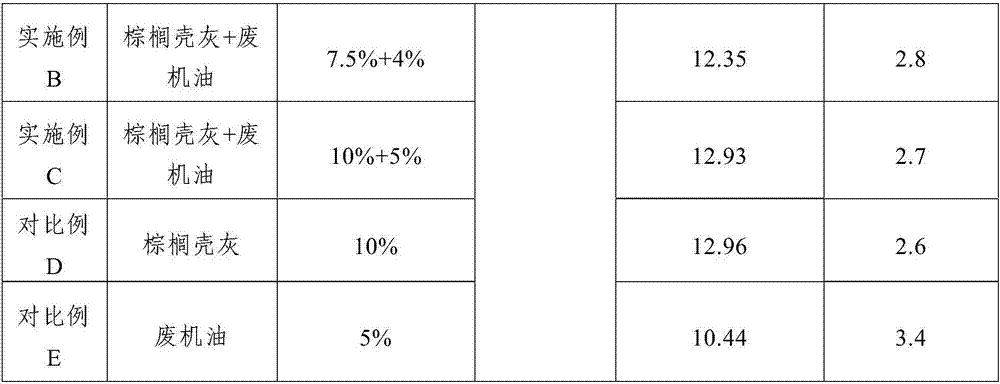

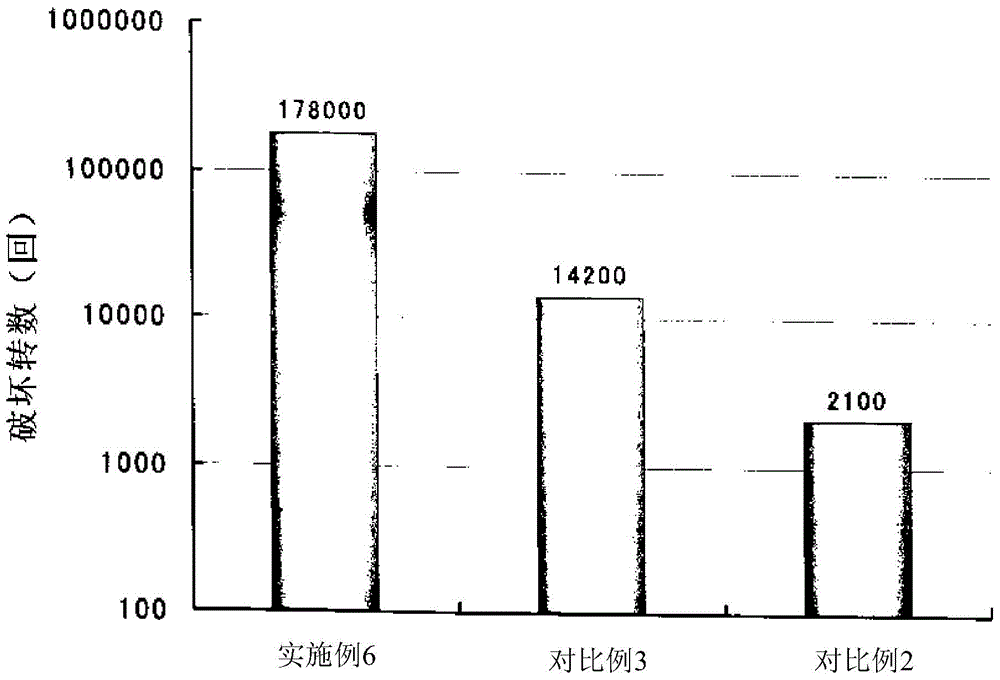

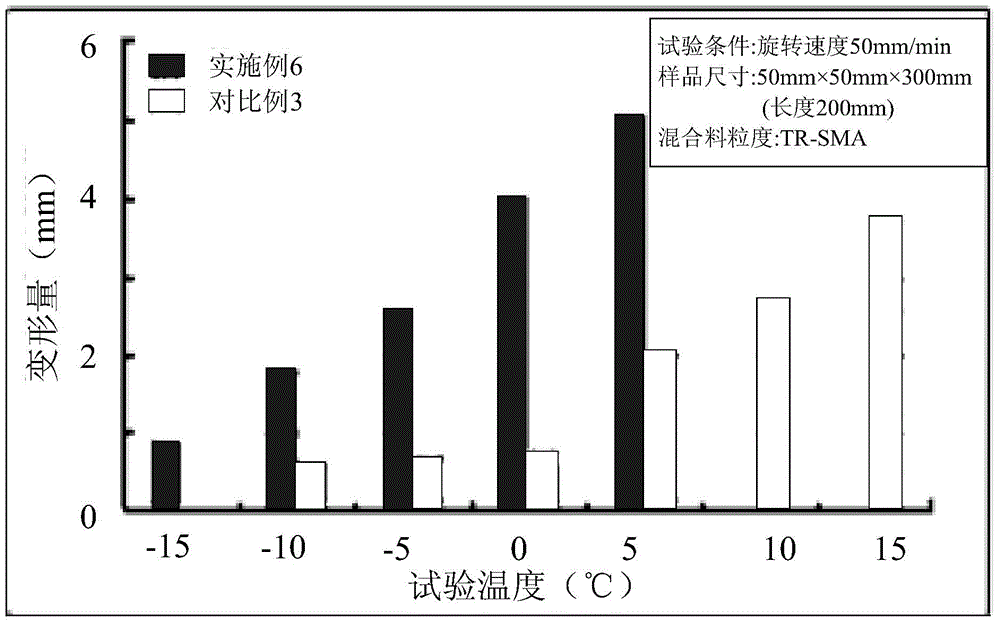

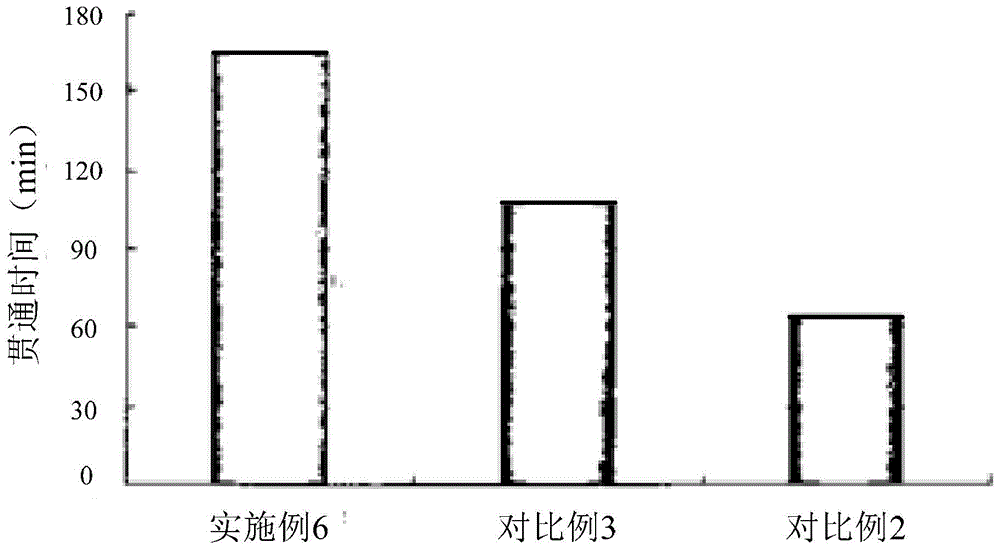

InactiveCN106916462AReduce in quantityImprove continuityBuilding insulationsSocial benefitsPalm fruit

Modified asphalt is provided. The modified asphalt includes matrix asphalt and a modifier. The modifier includes palm fruit shell ash and waste engine oil. The palm fruit shell ash is ash generated after palm fruit shell is combusted. The waste engine oil is engine oil wasted after vehicle maintenance. A large amount of palm fruit shell is adopted, thus providing a beneficial supplement for the flourishing palm oil industry at present, reducing pollution caused by secondary treatment of the palm fruit shell ash and the waste engine oil, reducing the fuel using amount during modified asphalt production, and meeting the social requirements of energy conservation and emission reduction at present. A construction process is convenient, the cost is low, and the effective utilization rate is increased. The modified asphalt can be widely used in highway and building projects, and has significant economic benefit and social benefit.

Owner:XIAN UNIV OF SCI & TECH

Flexible asphalt, preparation method therefor, road pavement material and road

InactiveCN105524475AGood weather resistanceImprove antioxidant capacityIn situ pavingsBuilding insulationsButadiene DioxidePavement engineering

The invention discloses flexible asphalt, a preparation method therefor, a road pavement material and a road and relates to the technical field of road pavement materials. The flexible asphalt can have relatively high flexibility and stress relaxation in low-temperature and normal-temperature states, can have relatively good plastic deformation resistance in a high-temperature state and can be used for inhibiting the generation of reflection cracks in asphalt-plus-concrete pavement constructions. The flexible asphalt disclosed by the invention contains 4-9 parts (by mass) of matrix asphalt, 1-6 parts (by mass) of aromatic hydrocarbon oil, sulfur, of which the mass is 0.01-1% the total mass of the matrix asphalt and aromatic hydrocarbon oil, copper oxide, of which the mass is 0.01-1% the total mass of the matrix asphalt and aromatic hydrocarbon oil, an anti-stripping agent, of which the mass is 0.01-1.5% the total mass of the matrix asphalt and aromatic hydrocarbon oil, and a butadiene-styrene block copolymer, of which the mass is 4-12% the total mass of the matrix asphalt and aromatic hydrocarbon oil. The flexible asphalt disclosed by the invention is applicable to a reforming process for cement concrete pavements.

Owner:北京路新大成景观建筑工程有限公司

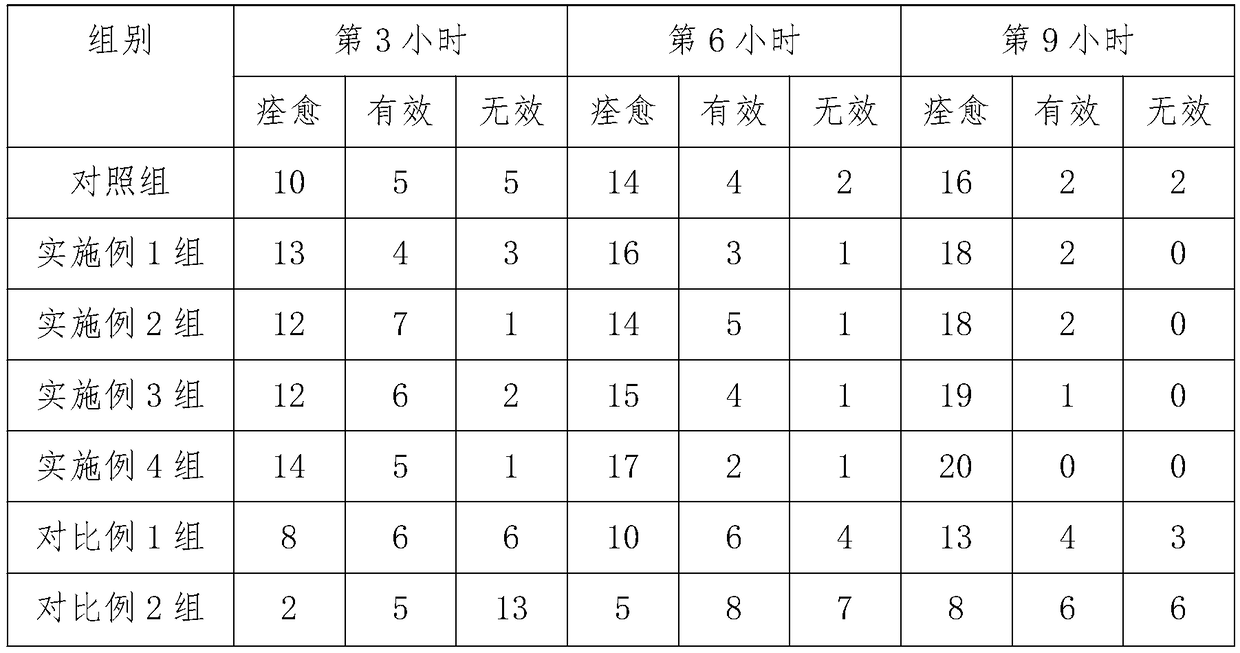

Brain protecting temperature sensing condensed bead medical gel patch and preparation method

InactiveCN109481133AHigh sensitivityEffective observationTherapeutic coolingTherapeutic heatingColor changesNatural medicine

The invention relates to the technical field of medicines, in particular to a brain protecting temperature sensing condensed bead medical gel patch and a preparation method. The patch comprises a non-woven fabric lining, a gel layer and a CPP embossed film; the gel layer is located between the non-woven fabric lining layer and the CPP embossed film, and the gel layer internally contains functionalcondensed beads. The patch has the advantages that a temperature-sensing color-changing material is added to the patch, the temperature-sensing color-changing material is added to the gel layer or printed on the surface of the non-woven fabric lining layer, or the temperature-sensing color-changing material is added to the gel layer and the non-woven fabric lining layer; indications can be flexibly and rapidly sent according to the body temperature variation, the patch further comprises functional condensed beads which are sensitive to the temperature, rapid in temperature reduction and easyto preserve, the double functions of physical temperature reduction and natural medicine treatment are achieved, the temperature at a pasted position can be effectively reduced, the optimal fever abatement effect can be achieved, and the syndromes of cold are relieved.

Owner:ZHUHAI GUOJIA NEW MATERIAL +1

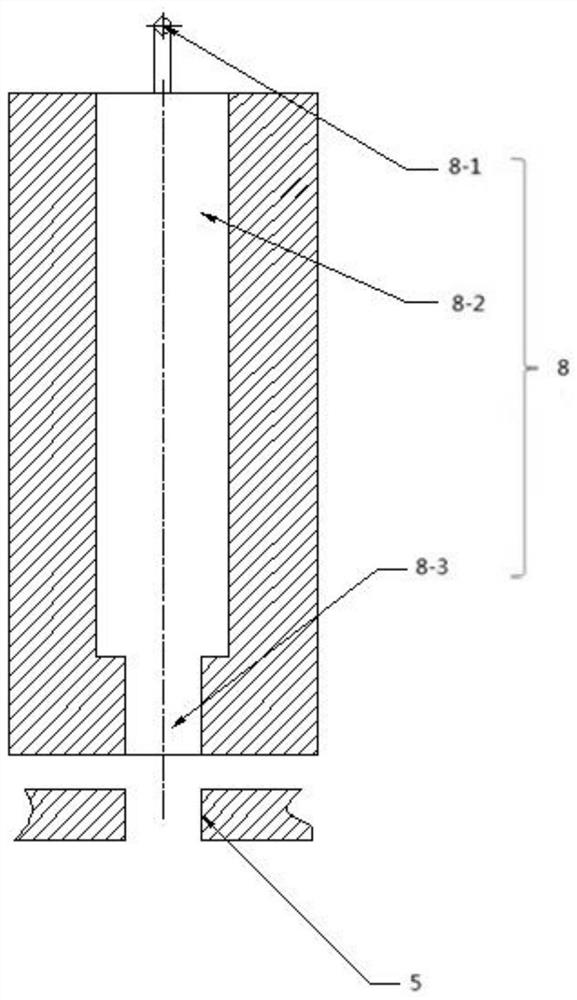

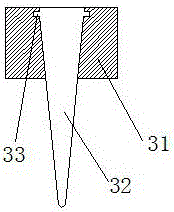

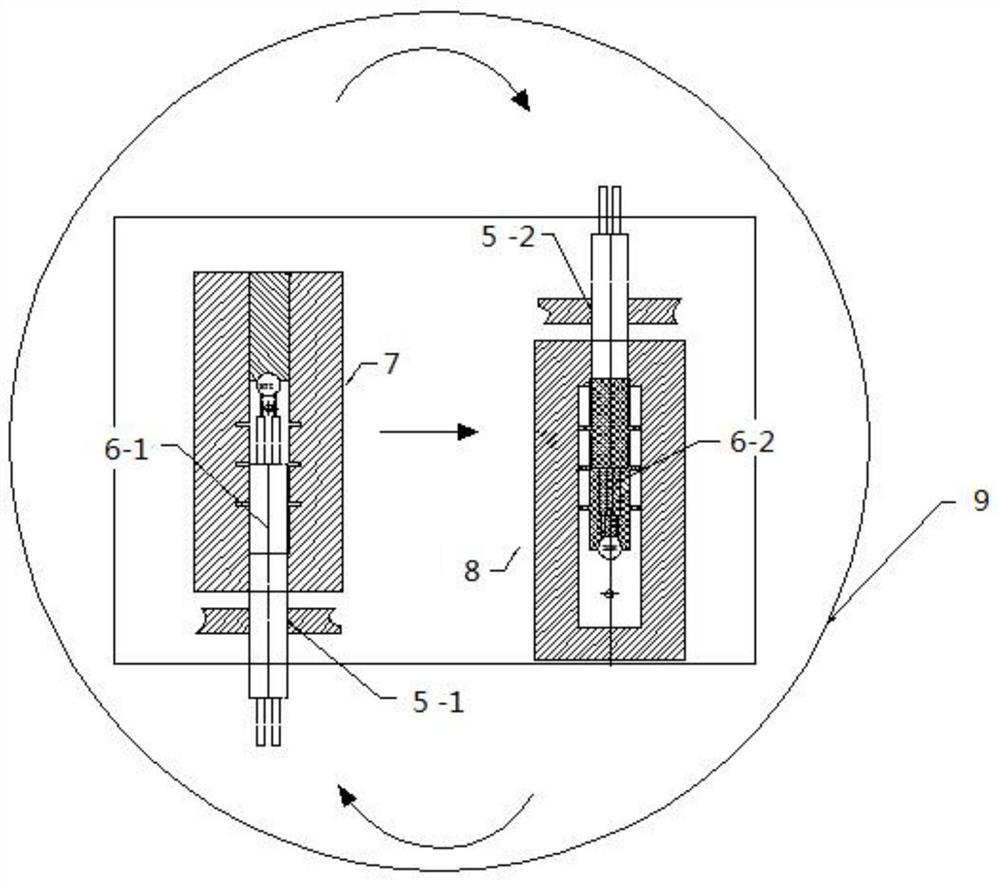

Temperature sensor, injection molding packaging mold and injection molding packaging method

ActiveCN111923322AAvoid damageGood appearance consistencyDomestic articlesThermometer applicationsEngineeringWater leak

The invention discloses a temperature sensor, an injection molding packaging mold and an injection molding packaging method. The part to be packaged of a sensor assembly is subjected to injection molding and packaging through the injection molding packaging method, and glue is injected into the part to be packaged of the sensor assembly in a step-by-step glue filling mode to finally form a plasticshell capable of directly wrapping the part to be packaged, so that the packaging of the sensor assembly is completed. The injection molding packaging mold is used for achieving the injection moldingpackaging method. According to the temperature sensor, the plastic shell is formed through the injection molding packaging method so as to directly warp a temperature sensing element, the connectingpoint between the temperature sensing element and a cable A and the periphery of the cable A. Therefore, the appearance consistency is good, the cost is reduced, the hidden danger of water leakage isreduced, the temperature sensing performance is improved, and the damage to the temperature sensing element caused by misoperation in assembly and glue filling process is reduced.

Owner:帕艾斯电子技术(南京)有限公司

Photonic crystal fiber temperature sensor and measuring method thereof

PendingCN114001843AEasy to integrateMiniaturizationThermometers using physical/chemical changesSpectrum analyzerBirefraction

The invention relates to a photonic crystal fiber temperature sensor and a measuring method thereof. Light emitted by a wide-spectrum light source is divided into two beams of coherent light through a 3dB coupler, the two beams of coherent light are transmitted along opposite light paths in a photonic crystal fiber and then enter a spectrum analyzer through coherent superposition, an output spectrum is obtained, and the sensitivity of the temperature sensor is obtained according to the change relation of the formant peak value position of the transmission spectrum along with the movement of the temperature. According to the invention, the photonic crystal fiber is adopted, and the photonic crystal fiber has the excellent characteristics of infinite cutoff single-mode transmission characteristic, dispersion characteristic, large mode field area, high nonlinearity, birefringence characteristic and the like. Ethanol liquid is doped into the fiber core, so that the temperature sensing sensitivity is improved, a better temperature sensing effect can be achieved under a smaller sensing length, and integration and miniaturization are easy.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of high-performance modified asphalt and its preparation method

ActiveCN110951266BGood anti-aging performanceImprove temperature sensitivityBuilding insulationsRoad engineeringProcess engineering

The invention provides a high-performance modified asphalt and a preparation method thereof. It is made of the following raw materials in parts by weight: 84% to 93% of matrix asphalt, 6% to 14% of carbon airgel, and The additive is 1% to 3%, and the sum of the parts by weight of the raw materials is 100%. The high-performance modified asphalt of the present invention has both excellent anti-aging performance and temperature-sensitive performance, which plays an important role in promoting the sustainable development of road engineering, and is especially suitable for the construction of asphalt pavement in western my country and high-altitude areas . The preparation process of the invention greatly reduces the heating temperature and swelling development time in the traditional modified asphalt preparation process, reduces resource consumption and has a simple preparation method.

Owner:CHANGAN UNIV

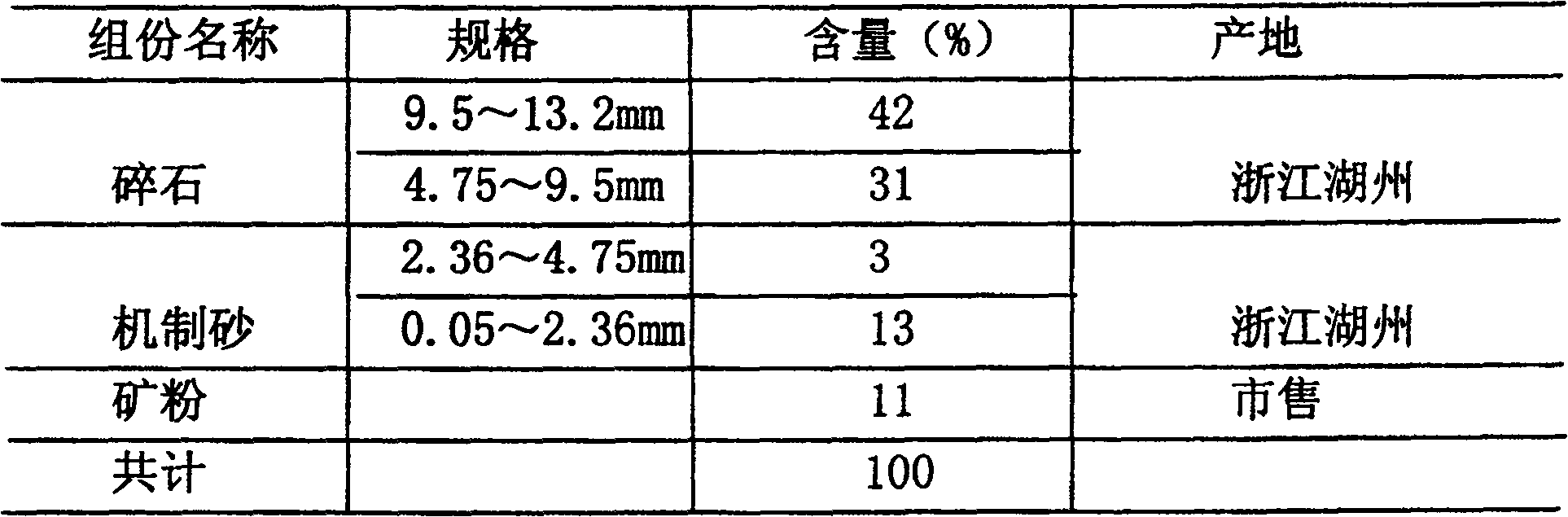

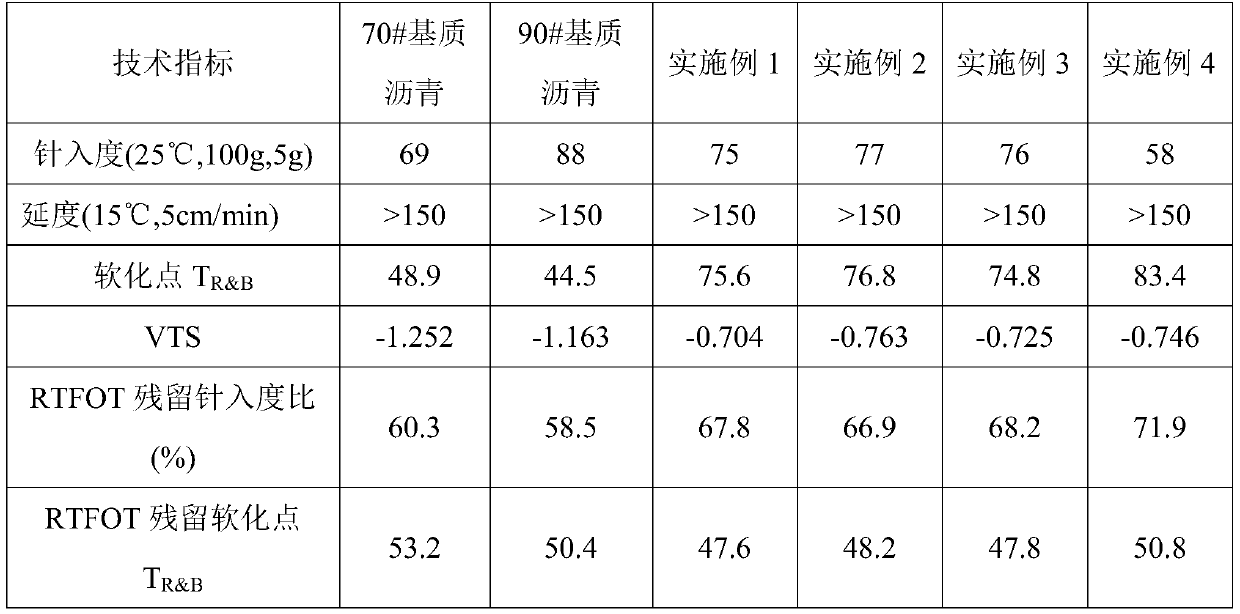

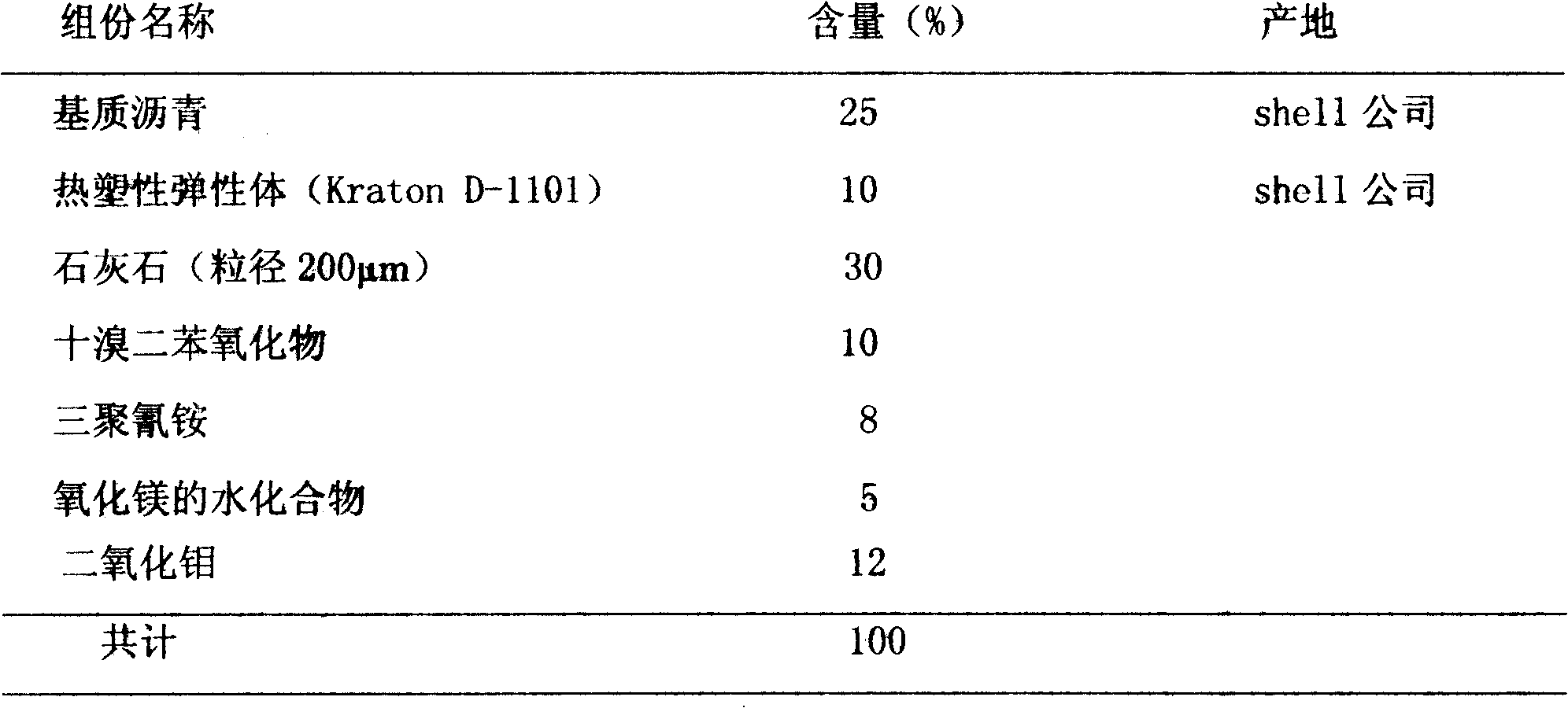

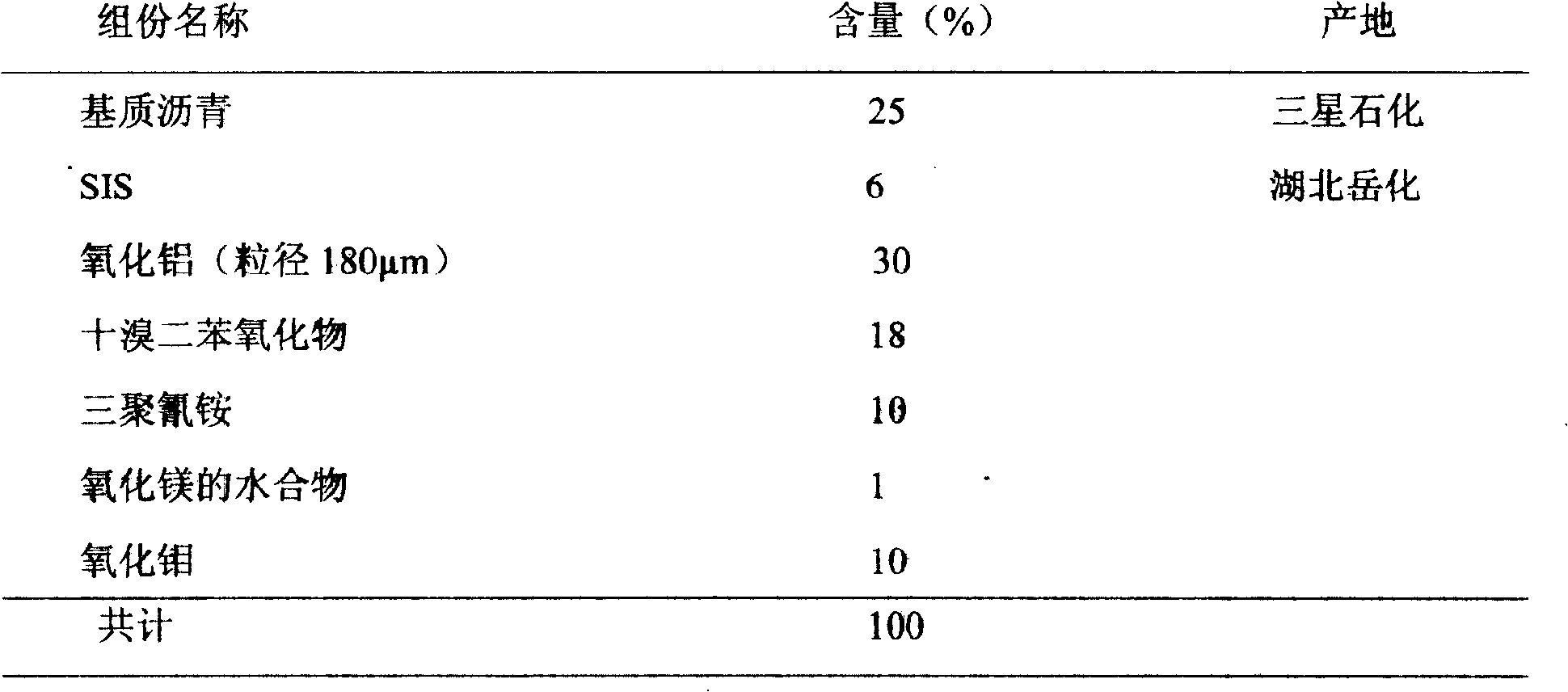

Flame-retared modified asphalt mixed stock

InactiveCN100424134CImprove high temperature performanceImprove anti-aging propertiesBuilding insulationsHalogenCombustion

The invention refers to a kind of bituminous mixture, is especially applied to modified bituminous mixture with the effect of combustion-supporting used in the paving of inner road surface of calzada's tunnel and is composed of between 1 and 10 of combustion-supporting asphaltum and between 80 and 95 of mixture of detritus and mineral powder. The combustion-supporting asphaltum includes between 20% and 40% of modified asphalt, between 2% and 30% of halogen combustion adjuvant, between 2% and 4% of phosphorus-containing mineral and between 10% and 20% of smoke-repressing agent and the mixture of detritus and mineral powder is composed of between 60% and 80% of detritus, with the grain size of 4.75mm and 13.2mm, the between 9% and 25% of machine-made sand, with the grain size of between 0.05mm and 4.75mm, and between 7% and 18% of mineral powder. The asphaltum road surface of tunnel paved with it has better high temperature performance, age resistance and temperature sensibility than ordinary asphaltum, improves its intensity and stability and has obvious effect of inflaming retarding and smoke-repressing.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Novel high-strength and wear-resistant thermochromic glass milk bottle and preparation process thereof

PendingCN105997524AImprove cutting efficiency and effectShorten the production and processing cycleFeeding-bottlesGlass reforming apparatusChemistryBiotechnology

The invention discloses a novel high-strength and wear-resistant thermochromic glass milk bottle and a preparation process thereof. The milk bottle comprises a milk bottle body and a bottle cap, wherein the milk bottle body is in threaded and sealed connection with the bottle cap; a nipple connector in threaded and sealed connection with the bottom cap is arranged at the upper end of the bottle cap and is connected with a nipple in a sealed manner; a thermochromic groove is vertically formed in the milk bottle body, and a plurality of thermochromic parts are arranged in the thermochromic groove in parallel in the longitudinal direction. The milk bottle is simple in structure and can conveniently, quickly and accurately sense the temperature in the bottle milk, the safety is improved when a baby drinks milk in the milk bottle, and besides, the milk bottle prepared with the preparation process has high strength, high thermal resistance, good wear resistance and high production efficiency.

Owner:DANYANG SHUANGFENG GLASS

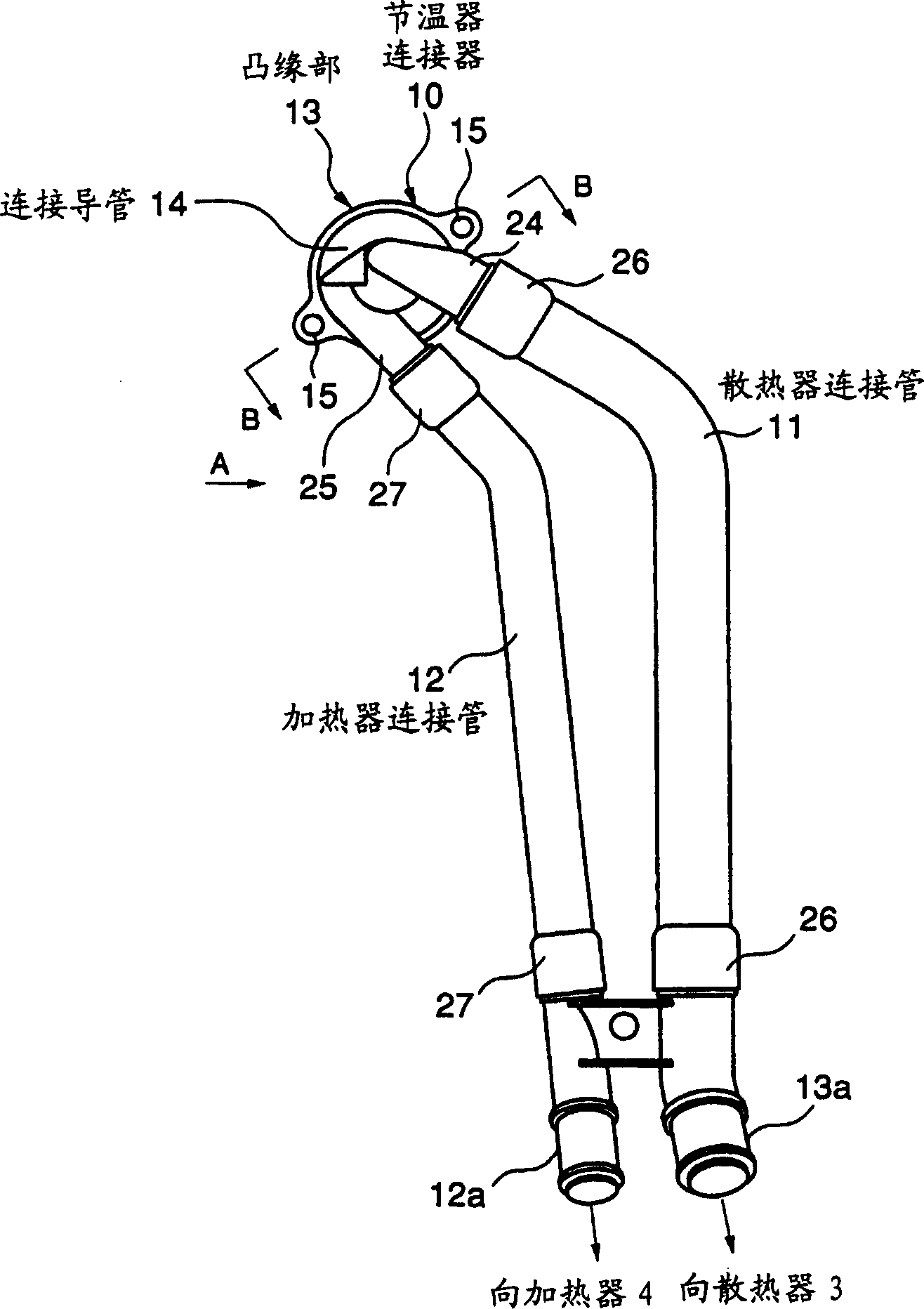

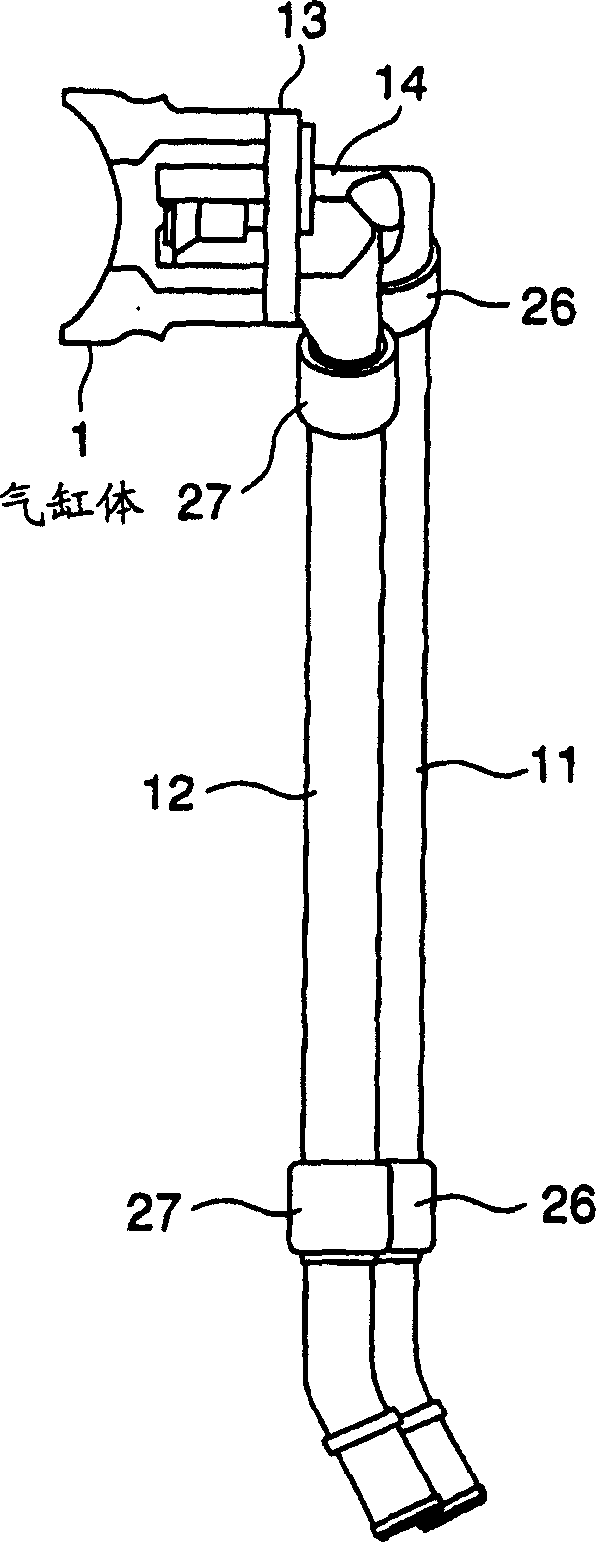

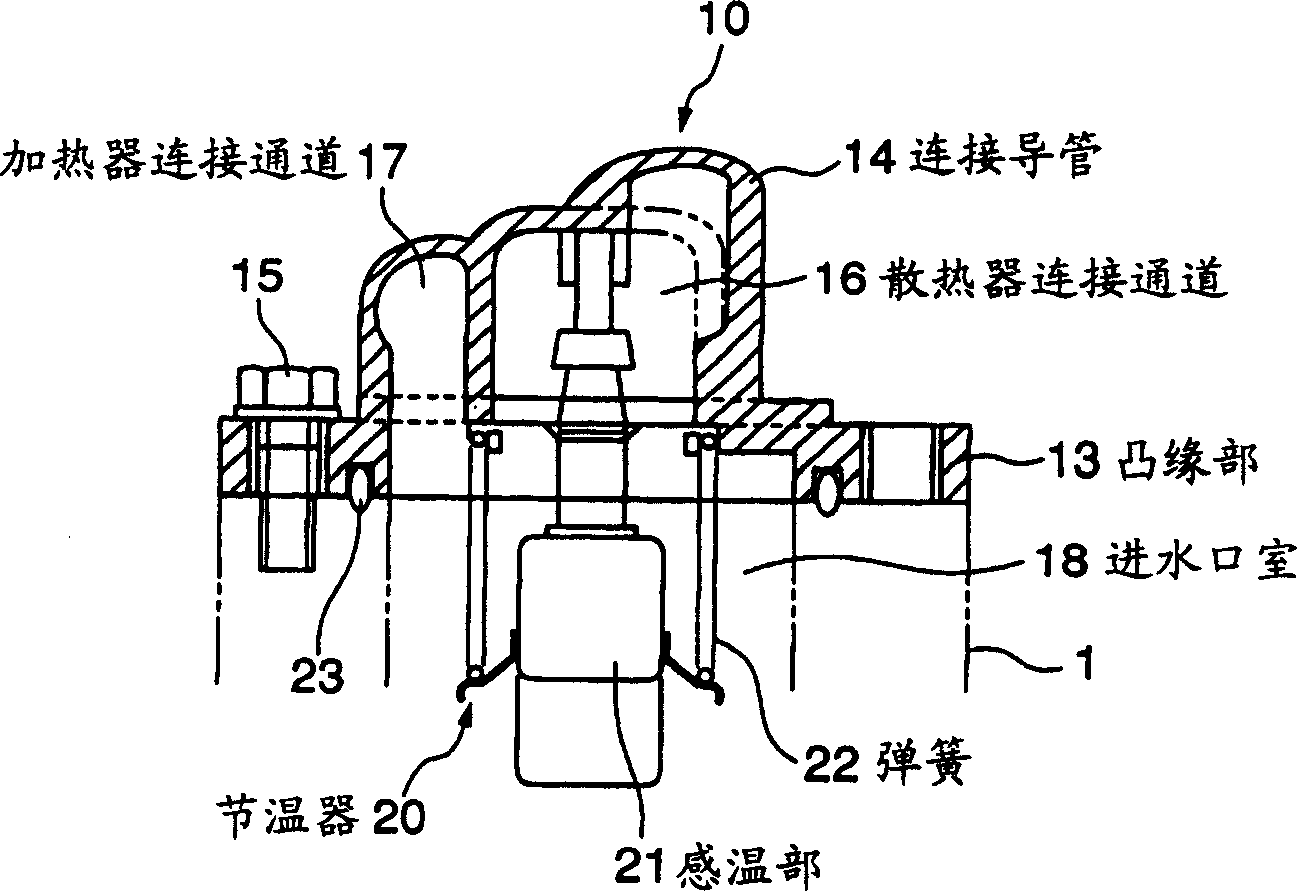

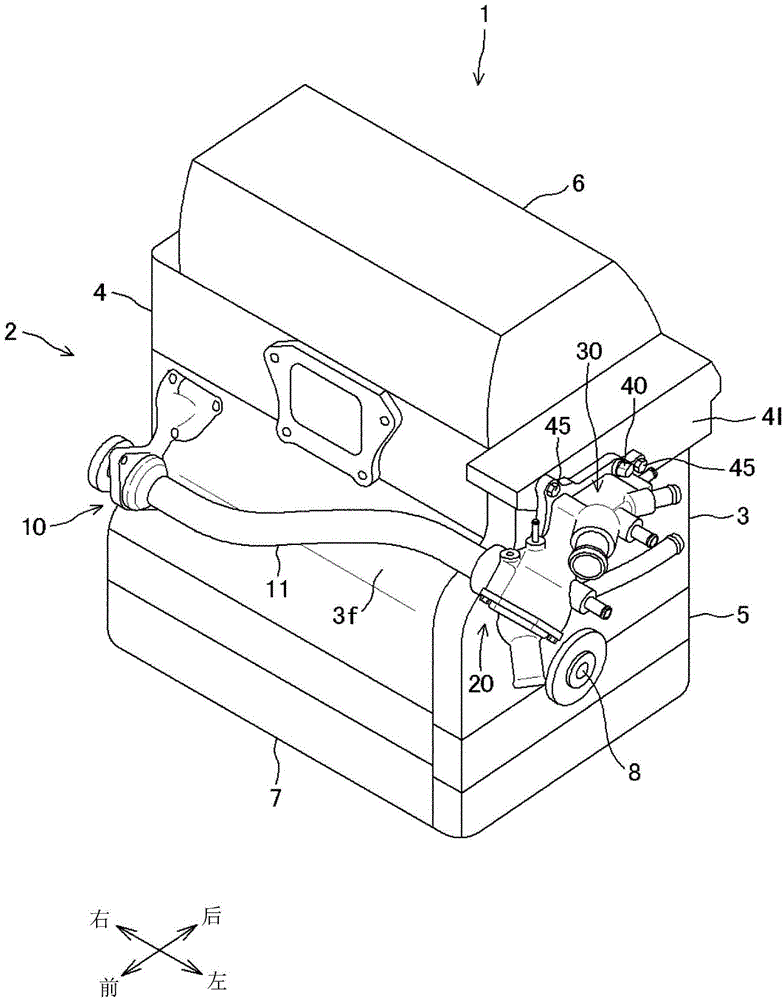

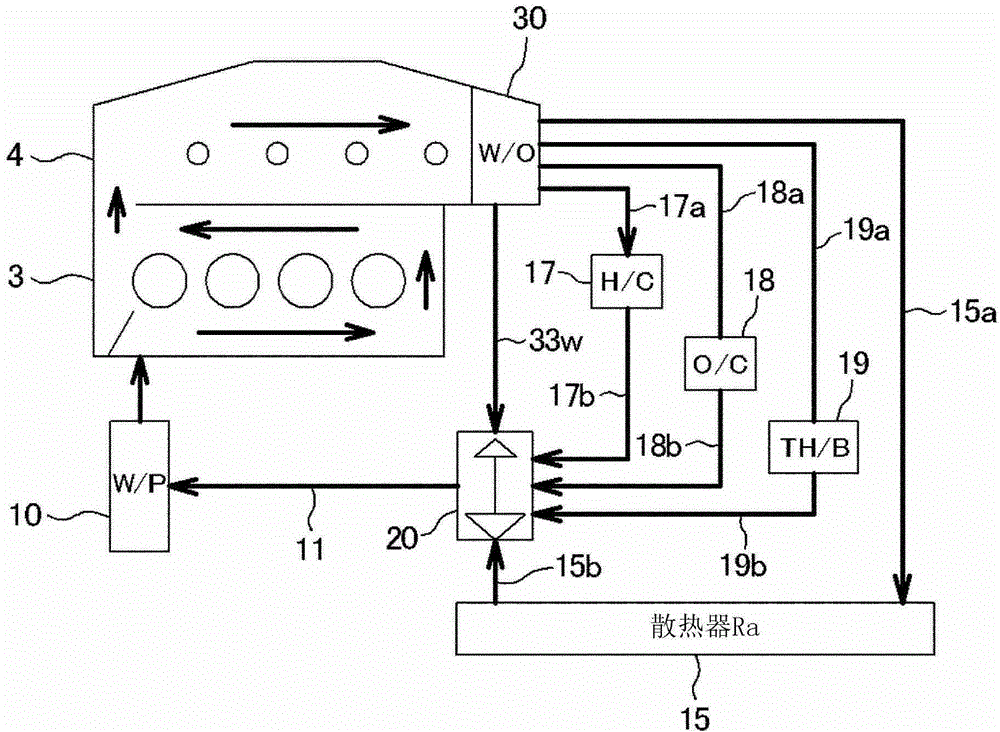

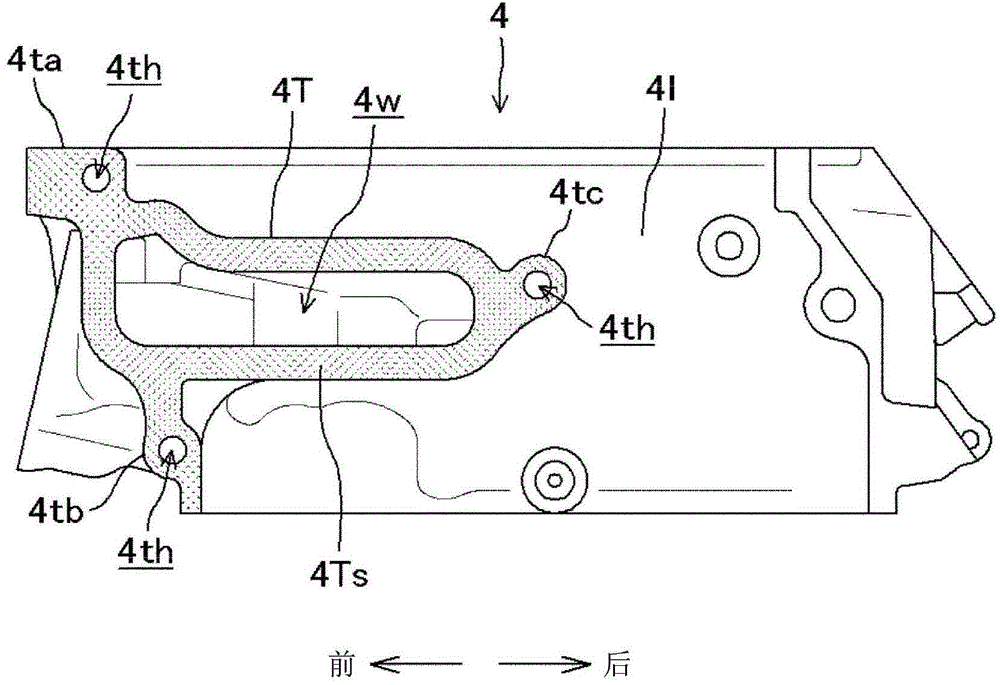

Cooling device of engine

ActiveCN1621668ACompact and simplified structureReduce assemblyLiquid coolingCoolant flow controlWater flowThermostat

The invention provides a cooling device for an engine, which is provided with a thermostat at the cooling water outlet of the engine, and at the same time, the water inlet pipe of the heater is connected with the cooling water outlet to maintain the temperature sensitivity of the thermostat at a high degree, and make the thermostat The thermostat of the cooling water outlet and the connection structure of the radiator water inlet pipe and the heater water inlet pipe become simple and compact. According to the engine cooling device of the present invention, the cooling water flowing out from the engine is provided to the radiator through the thermostat and the radiator water inlet pipe, and at the same time provided to the heater through the heater water inlet pipe, it is characterized in that the cooling device includes a throttle Thermostat connector, the thermostat connector includes a connecting conduit, the connecting conduit is detachably assembled on the engine body, in the connecting conduit, the radiator connecting channel and the heater connecting channel are integrally formed, and the radiator connecting channel is set There is a thermostat and it is connected to the radiator water inlet pipe, while the heater connection channel is connected to the heater water inlet pipe.

Owner:MITSUBISHI MOTORS CORP +1

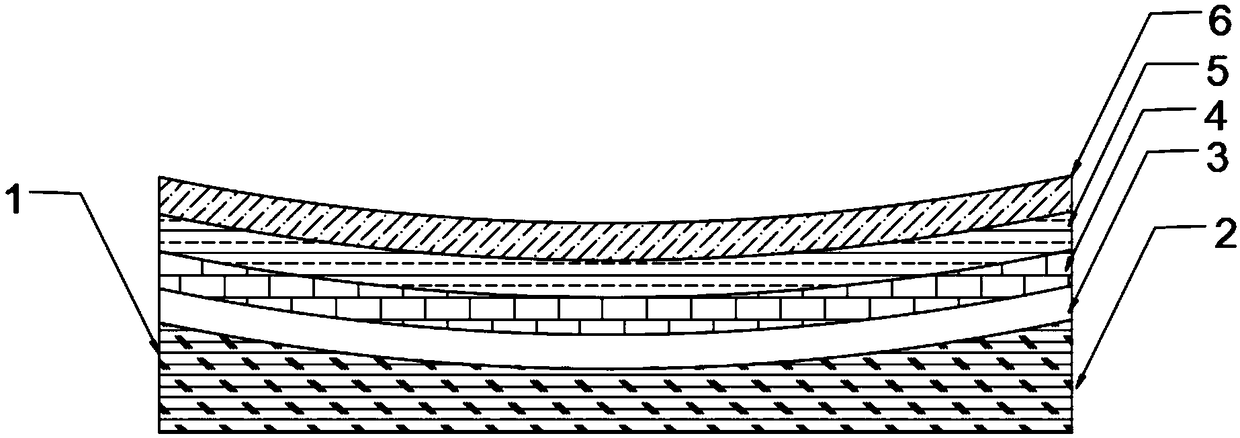

Concave curved-roof-surface waterproof structure and construction technology thereof

InactiveCN108979017AImprove performanceGood weather resistanceBuild-up roofsRoof covering insulationsEngineeringSteel frame

The invention relates to the technical field of building designing, in particular to a concave curved-roof-surface waterproof structure and a construction technology thereof. The concave curved-roof-surface waterproof structure comprises a waterproof structure body, a concrete layer is arranged at the bottom of the waterproof structure body, a waterproof layer is connected to the top face of the concrete layer, a heat preservation layer is arranged on the top face of the waterproof layer, a rigid waterproof layer is arranged on the top face of the heat preservation layer, and a house decorating layer is connected to the top face of the rigid waterproof layer. The construction technology of the waterproof structure body includes the following steps that steel is rolled, a steel frame is placed, concrete is poured, the top face of the concrete is poured into a concave curved structure after fine building, the waterproof layer is laid, the heat preservation layer is sprayed, concrete is poured, and the decorating layer is laid. According to the concave curved-roof-surface waterproof structure and the construction technology thereof, the waterproof layer is directly arranged on the concrete structure layer, construction is simple, the construction procedure is simple, and the waterproof effect of the curved roof surface is good.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

High-performance modified asphalt and preparation method thereof

ActiveCN110951266AGood anti-aging performanceImprove temperature sensitivityBuilding insulationsRoad engineeringProcess engineering

The invention provides high-performance modified asphalt and a preparation method thereof, wherein the high-performance modified asphalt is prepared from the following raw materials by weight: 84-93%of matrix asphalt, 6-14% of carbon aerogel and 1-3% of a compatibilizer. According to the invention, the high-performance modified asphalt has excellent aging resistance and excellent temperature sensing performance, has important effect in promoting of the sustainable development of road engineering, and is especially suitable for construction of asphalt pavements in western China and high altitude areas; and the preparation process substantially reduces the heating temperature and the swelling development time in the traditional modified asphalt preparation process, reduces the resource consumption, and is simple.

Owner:CHANGAN UNIV

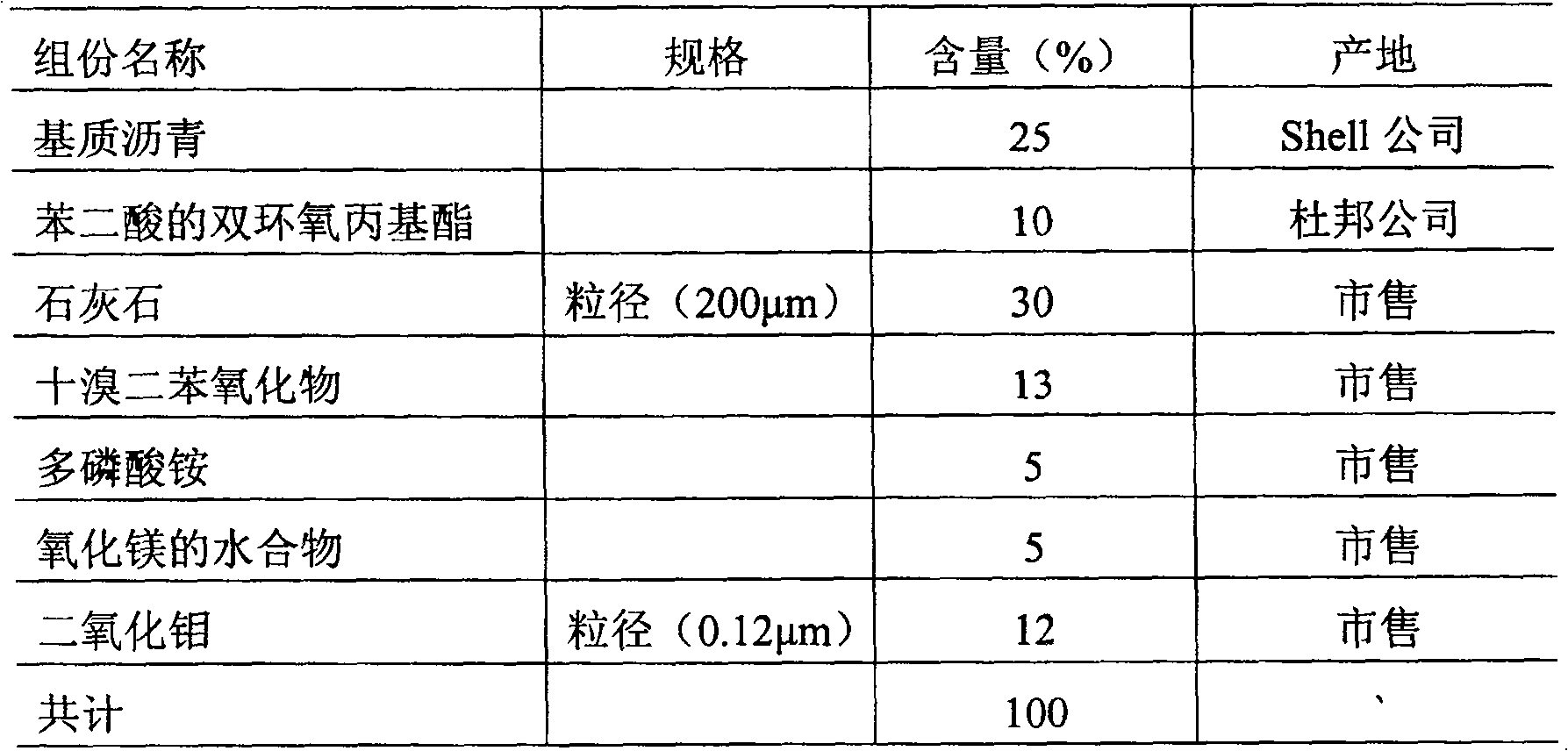

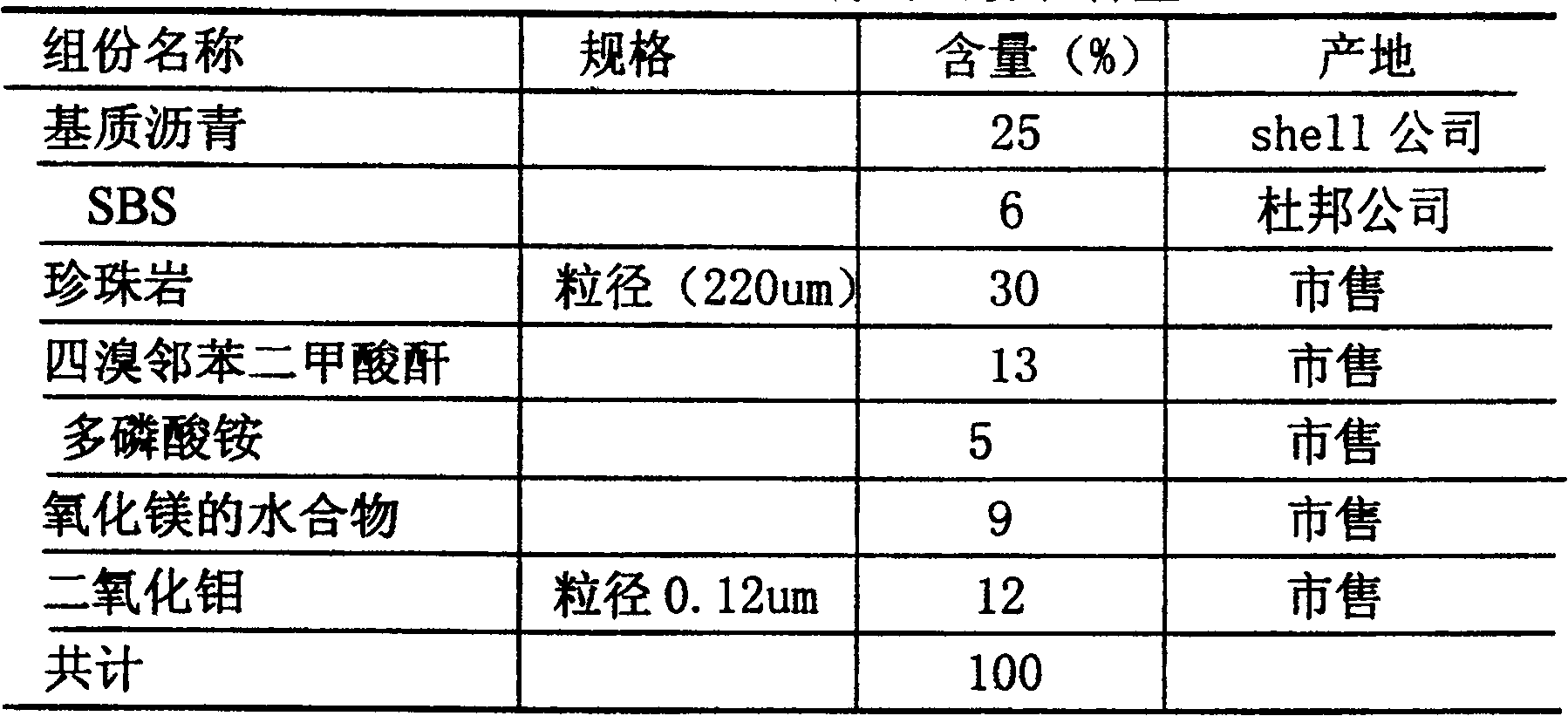

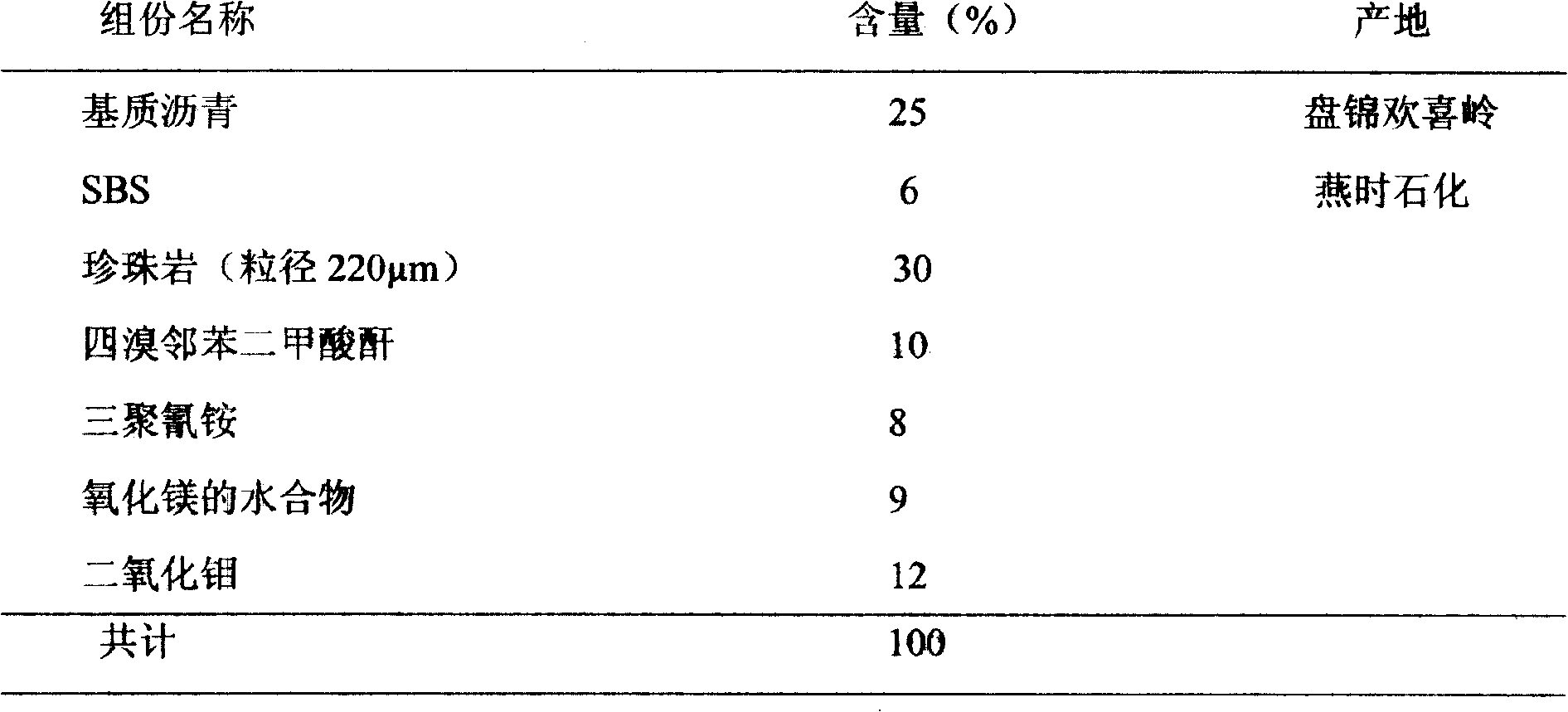

Fire-retardant and modified asphalt mixture

InactiveCN100419026CImprove high temperature performanceImprove anti-aging propertiesBuilding insulationsCombustionThermoplastic elastomer

Disclosed is a asphalt mixture, in particular a modified asphalt mixture suitable for pavement in highway tunnel and capable of causing flame-proof effect, which comprises ground substance asphalt, plasticoelastic member, inactive filler, bittern combustion inhibitor, hydrate of metallic oxide and combustion inhibitor containing aza rings.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

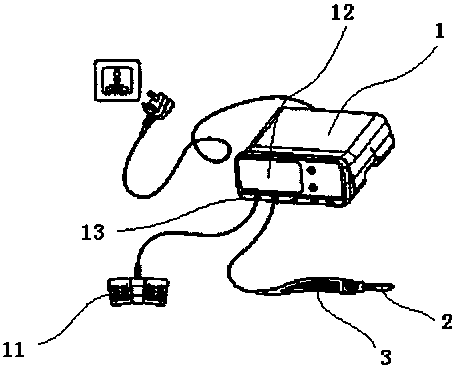

Heat coagulation scalpel device

InactiveCN107753100ASimple structureHigh power/heat conversion efficiencySurgical instruments for heatingSurgical bladeControl system

The invention relates to a heat coagulation scalpel device which is mainly composed of a main device and a scalpel assembly. The scalpel assembly comprises a scalpel blade and a scalpel handle; the scalpel blade is in a sheet shape, a cutting edge is arranged on one side of the front end of the scalpel blade, a scalpel body is arranged at the joint of the periphery of the cutting edge, the scalpelbody is in a multi-layer sheet shape, the base layer of the scalpel body is an insulation base layer, the scalpel body comprises a heating body, an insulation packaging layer and a Teflon coating from interior to exterior, an electrode is arranged at the rear portion of the scalpel body, the electrode is inserted into the front end of the scalpel handle to be fixedly connected on the whole, an external heater and an external temperature sensor are attached to the exterior of the scalpel blade, and the external heater is a heating circuit; the heating body is a loop heating belt in a loop shape, the blade face adopts the external heating mode, the external heating circuit is arranged outside the scalpel blade and controlled by a precise control system formed by a computer system, the scalpel is hot and is not electrified, and the using safety of the scalpel is ensured.

Owner:常州市斯博特医疗器械有限公司

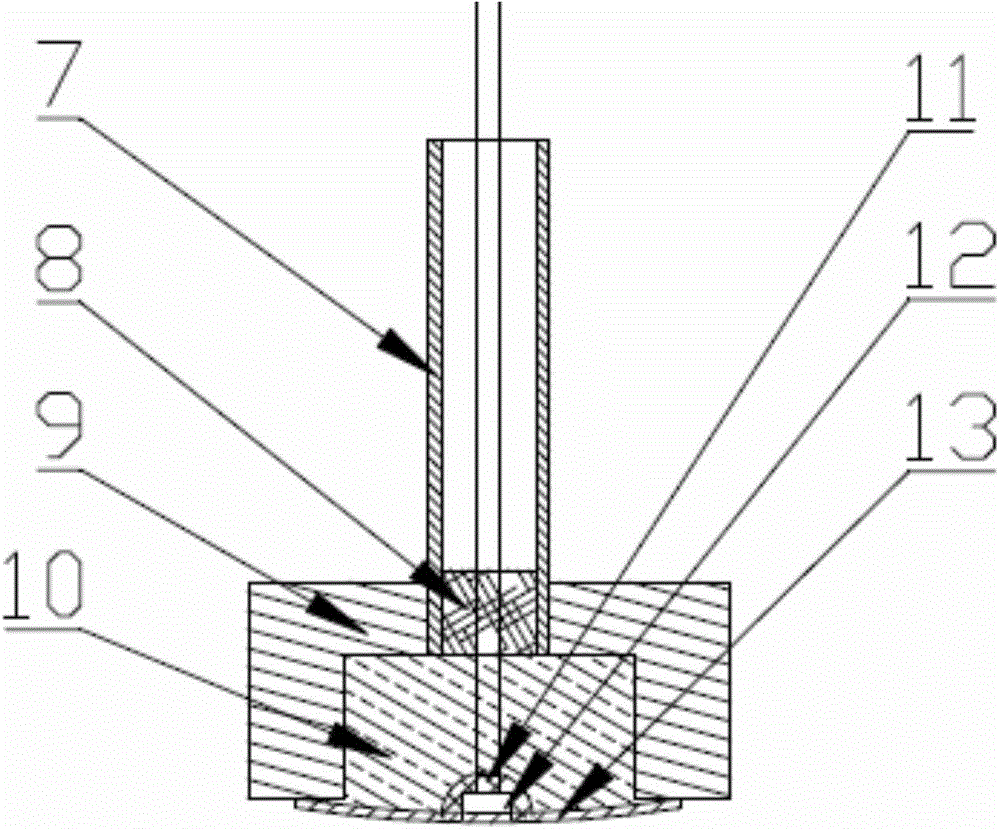

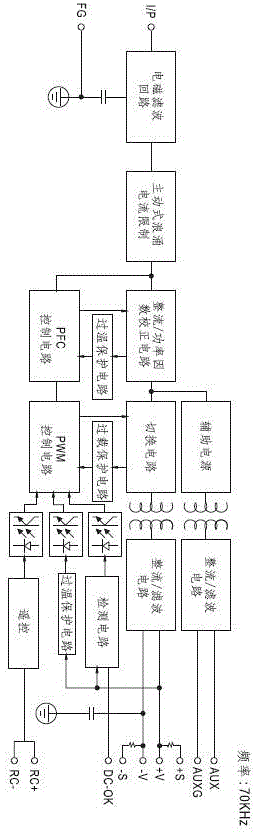

Thermocoagulation surgical system

InactiveCN104000649ASimple structureHigh power/heat conversion efficiencySurgical instruments for heatingSurgical bladeDisplay device

The invention relates to a thermocoagulation surgical system comprising a main unit, a surgical knife assembly, and a pedal control system. A computer system, an analog-digital conversion circuit, a temperature control system, an operation prompt circuit and a display circuit are arranged inside the main unit. A power isolation transformer disposed inside the main unit converts mains supply into direct current which is output to the computer system, a display and an electric / heat power converter. The surgical knife assembly comprises a surgical blade and a surgical handle; a heating element is disposed inside the surgical blade and comprises a heating member, an insulating coating layer and a Teflon coating. The pedal control system comprises a pedal switch and a main unit pedal switch socket connected with the same through a wire. The heating member is a looped heating tape in a loop shape; the surface of the surgical blade is externally heated; an external heating circuit is arranged outside the surface of the surgical blade and is precisely controlled by the computer system to be 'hot' or 'unchanged', and usage safety of the surgical blade is ensured.

Owner:江苏凝克医疗器械科技有限公司

Temperature sensor, injection molding packaging mold and injection molding packaging method

ActiveCN111923322BAvoid damageGood appearance consistencyThermometer applicationsDomestic articlesWater leakageMechanical engineering

The invention discloses a temperature sensor, an injection packaging mold and an injection packaging method. The injection molding packaging method is used for injection molding packaging of the part to be packaged of the sensor assembly, which adopts the method of step-by-step glue filling, directly injects glue to the part of the sensor component to be packaged, and finally forms a plastic shell that can directly wrap the part to be packaged, Thus, the packaging of the sensor component is completed. The injection molding packaging mold described in the present invention is used to realize the above injection molding packaging method. The temperature sensor of the present invention forms a plastic shell through the above-mentioned injection molding packaging method, so as to directly wrap the temperature sensing element, the connection point between the temperature sensing element and the cable a, and the periphery of the cable a. It can be seen that the present invention has good appearance consistency, reduces cost, reduces hidden dangers of water leakage, improves temperature-sensing performance, and reduces damage to temperature-sensing elements due to misoperation in assembly and glue filling processes.

Owner:帕艾斯电子技术(南京)有限公司

Refrigerator

ActiveCN102494462AImprove heating efficiencyAchieve sealingLighting and heating apparatusDomestic refrigeratorsFoaming agentHeat losses

The invention discloses a refrigerator. The refrigerator comprises a body, a door body, a refrigerating chamber evaporator, a temperature induced tube and a compensating heater, wherein a refrigerating chamber and a freezing chamber are defined in the body; the door body is installed on the body; the refrigerating chamber evaporator is arranged in the refrigerating chamber; the temperature induced tube is adjacent to the refrigerating chamber evaporator and is used for detecting the surface temperature of the refrigerating chamber evaporator; and the compensating heater is arranged on the temperature induced tube and is used for heating the refrigerating chamber when the temperature of the external environment in which the refrigerator is positioned is lower than the preset threshold. The refrigerator has the following advantages that: by arranging the compensating heater on the temperature induced tube, sealing between the periphery of the compensating heater and the refrigerating chamber evaporator and the temperature induced tube can be realized and then void sticking and covering and foaming agent leakage between the compensating heater and the evaporator can be avoided, thus improving the heating efficiency of the refrigerator and reducing the heat losses.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

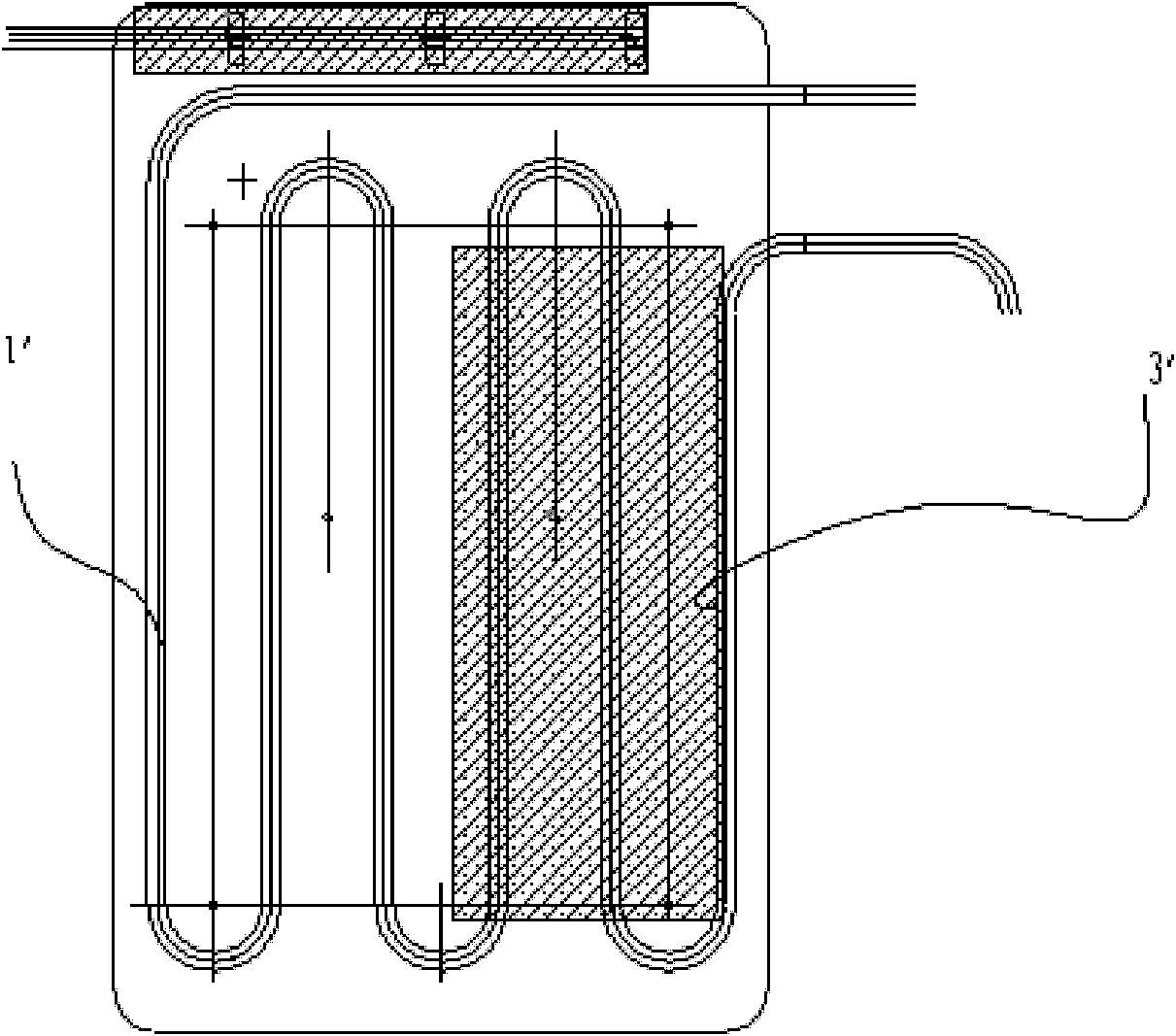

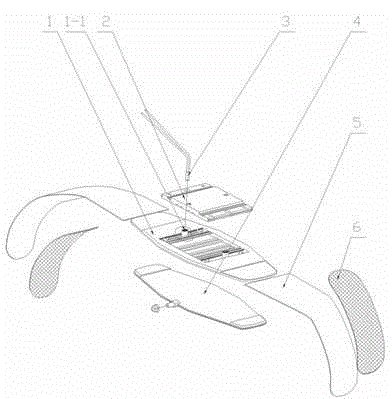

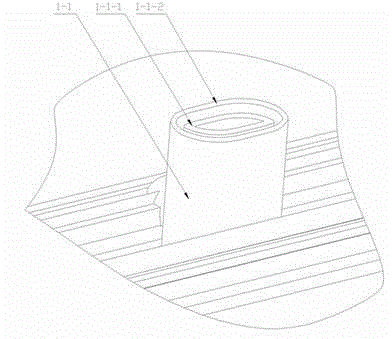

Human head wearing physical cooling device ice belt

InactiveCN104546278AImprove reliabilityImprove the temperature sensing effectTherapeutic coolingTherapeutic heatingUltrasonic weldingEngineering

A human head wearing physical cooling device ice belt comprise a cold guide plate, soft gel, a wearing belt, a water bag, temperature sensors and Velcro tapes. The ice belt is characterized in that the feature that the soft gel is made of plastic is utilized, grooves and holes are formed in the cold guide plate, and the cold guide plate is injected into the soft gel directly by the injection molding machining process; the feature that the wearing belt and the soft gel are made of plastic is utilized, and the wearing belt and the soft gel are welded by the high frequency or ultrasonic welding machining process; holes are formed in left and right sides of the cold guide plate, and the soft gel penetrates the holes to form blind holes for installing the temperature sensors; a water injecting pipe and a plug are arranged on one side of the water bag independently for water injection; the Velcro tapes are arranged on left and right belt units to wear a product. By the aid of the human head wearing physical cooling device ice belt, the product reliability, temperature sensing effect, practicality and wearing comfort are improved comprehensively.

Owner:吕建新

Novel azocyclotin

InactiveCN107549196AImprove the bactericidal effectImprove the temperature sensing effectBiocideFungicidesAdjuvantEmulsion

The present invention provides a novel triazolium tin, including flufenuron, triazolium tin and auxiliary agent, the described flufenuron and triazolium tin are mixed according to the ratio of 1:1.5; the content of each component of the triazolium tin is Chlorocyclohexane 200‑300 kg / t, 1,2,4‑triazole 100‑120 kg / t, benzidine imidazole 800 kg / t, tin 2500‑3500 kg / t and chlorine gas 150‑170 kg / t; The content of each component of the auxiliary agent is 10 kg / t of pine resin mixture, 5-8 kg / t of machine-pumped emulsion, and 1-5 kg / t of lime sulfur mixture. Good bactericidal effect, little harm to citrus.

Owner:NANJING GAOZHENG AGROCHEM

Outlet structure of internal combustion engine

ActiveCN103133116BSuppress turbulenceSmall pressure lossLiquid coolingCoolant flow controlAcute angleCylinder head

A water outlet structure of an internal combustion engine includes a water outlet and a thermostat. The water outlet includes a cooling-water inflow portion, a radiator outflow passage, and a bypass passage. The cooling-water inflow portion is provided to face a cooling-water outlet of a cylinder head. Cooling water is to flow out to a radiator through the radiator outflow passage. The radiator outflow passage linearly extends from the cooling-water inflow portion. The bypass passage linearly and obliquely extends from the cooling-water inflow portion to provide a water flow at an acute angle to a water flow in the radiator outflow passage. The thermostat is provided integrally with the water outlet and includes a thermo housing provided downstream of the bypass passage.

Owner:HONDA MOTOR CO LTD

Refrigerator

ActiveCN102494462BImprove heating efficiencyAchieve sealingLighting and heating apparatusDomestic refrigeratorsFoaming agentHeat losses

The invention discloses a refrigerator. The refrigerator comprises a body, a door body, a refrigerating chamber evaporator, a temperature induced tube and a compensating heater, wherein a refrigerating chamber and a freezing chamber are defined in the body; the door body is installed on the body; the refrigerating chamber evaporator is arranged in the refrigerating chamber; the temperature induced tube is adjacent to the refrigerating chamber evaporator and is used for detecting the surface temperature of the refrigerating chamber evaporator; and the compensating heater is arranged on the temperature induced tube and is used for heating the refrigerating chamber when the temperature of the external environment in which the refrigerator is positioned is lower than the preset threshold. The refrigerator has the following advantages that: by arranging the compensating heater on the temperature induced tube, sealing between the periphery of the compensating heater and the refrigerating chamber evaporator and the temperature induced tube can be realized and then void sticking and covering and foaming agent leakage between the compensating heater and the evaporator can be avoided, thus improving the heating efficiency of the refrigerator and reducing the heat losses.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Temperature-controlled mixing valve structure

InactiveCN101706010BImprove the temperature sensing effectStable waterOperating means/releasing devices for valvesTemperatue controlTemperature controlHeat sensitive

The invention discloses a temperature-controlled mixing valve structure which comprises a valve body assembly, a temperature controller and a constant temperature controller, wherein a reset spring of the constant temperature controller supports a sliding bar assembly which is in dynamic fit with a thermo-sensitive element; the sliding bar assembly comprises a sliding bar, a water mixer, a springpad and a protection spring, wherein the sliding bar is supported between a valve-body upper cover and a mixed water outlet by the reset spring; the sliding bar is provided with an inner sleeve and an outer sleeve, and a water channel is formed between the inner sleeve and the outer sleeve; the upper part of the water mixer is distributed with a plurality of water inlet holes, and the lower part thereof is fixed at the upper end of the inner sleeve of the sliding bar; the spring pad is supported by the protection spring and positioned in the inner sleeve of the sliding bar; the thermo-sensitive element is arranged in the water mixer, the spring pad and the inner sleeve of the sliding bar in sequence in a penetrating way; the upper end of the spring pad is matched with the thermo-sensitivein a contacting way; the upper part of the sliding bar, the upper cover and the external wall of the water mixer form a first water mixing cavity; and the internal wall of the upper part of the watermixer and the external wall of the thermo-sensitive element form a second water mixing cavity. Cold water and hot water are mixed for twice, thus improving the water mixing effect and achieving the purpose of controlling the stability of the water temperature. In addition, a sealing pad is arranged at the hot water end of the valve body, thus improving the performance of losing efficacy of cold water, and realizing excellent safety in use.

Owner:XIAMEN LOTA INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com