Temperature-controlled mixing valve structure

A technology of mixing valve and constant temperature control, applied in valve shell structure, temperature control, valve details, etc., can solve problems such as pressure difference between cold and hot water, and achieve the effect of reliable performance, wide application range and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

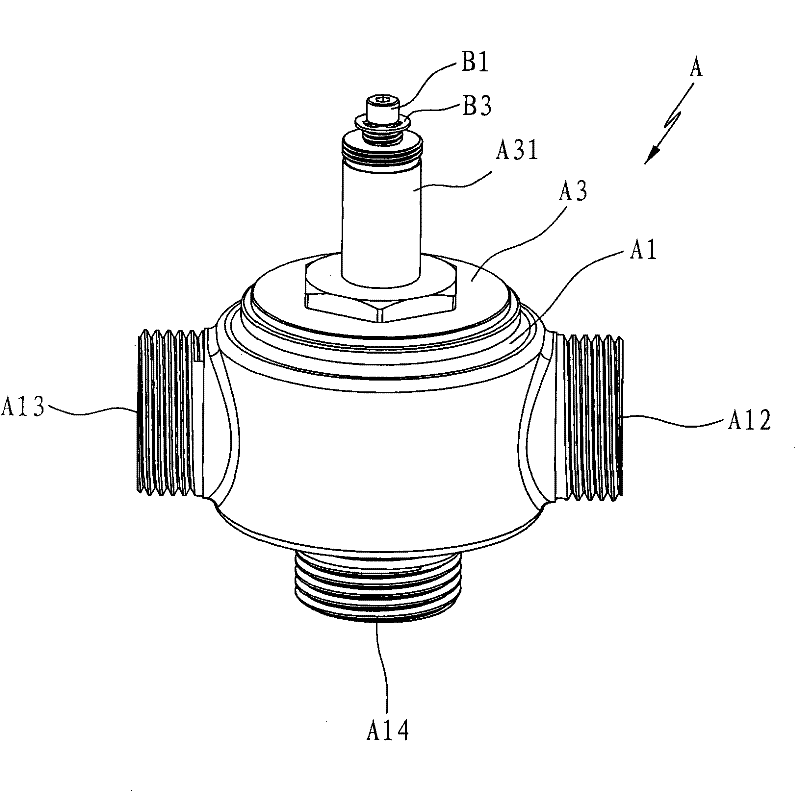

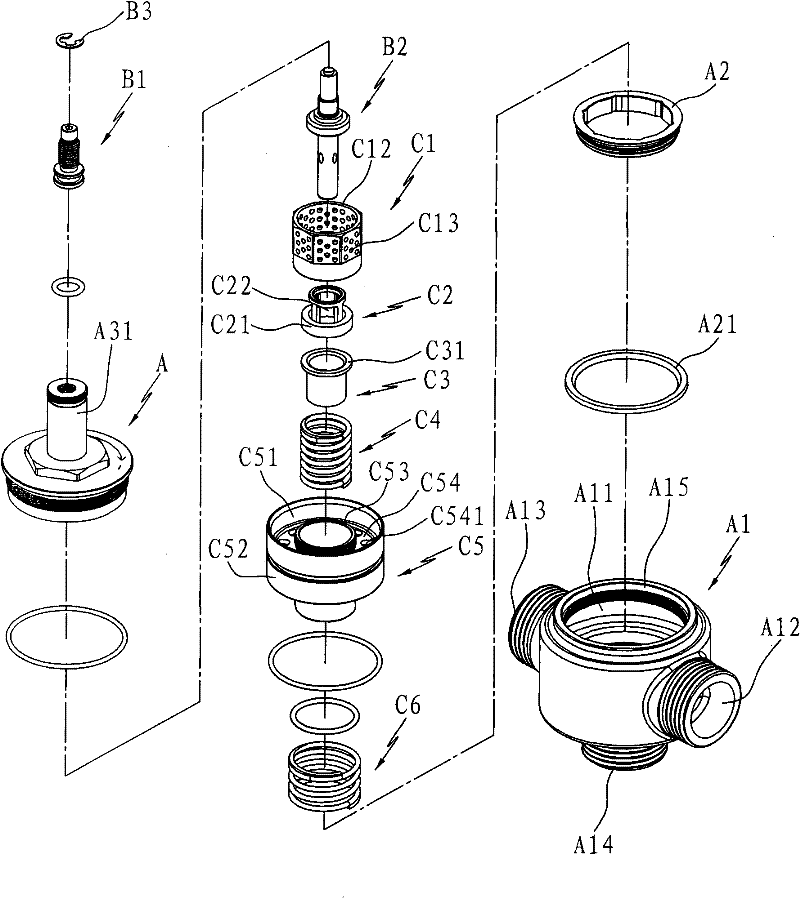

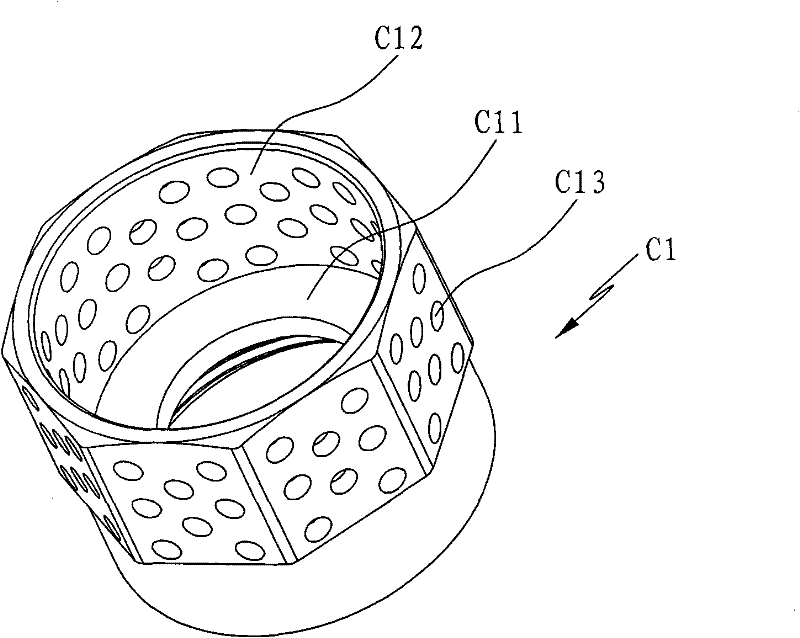

[0026] Such as Figure 1 to Figure 7 As shown, a temperature-controlled mixing valve structure disclosed by the present invention includes a valve body group A, a temperature regulating device B and a constant temperature control device C.

[0027] Cooperate figure 2 , 6 As shown, the valve body group A includes the valve body A1, the gland A2 and the upper cover A3; the valve body A1 forms an inner cavity A11 to accommodate the temperature adjustment device B and the constant temperature control device C, and the valve body is provided with an inner chamber A11. The cold water inlet A12, the hot water inlet A13 and a mixed water outlet A14 connected by the cavity; the gland A2 is a ring cover corresponding to the upper port A141 at the water outlet A14 in the inner cavity A11 of the valve body A1, and the sealing gasket is set therein A21 cooperates with port A141; the section of the sealing gasket is trapezoidal, "丄" shape, "L" shape, "Z" shape or "I" shape. The middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com