Flame-retared modified asphalt mixed stock

A technology for modifying asphalt and mixing materials, which is applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as no application, and achieve the effects of improved strength and stability, improved temperature sensing performance, and improved processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

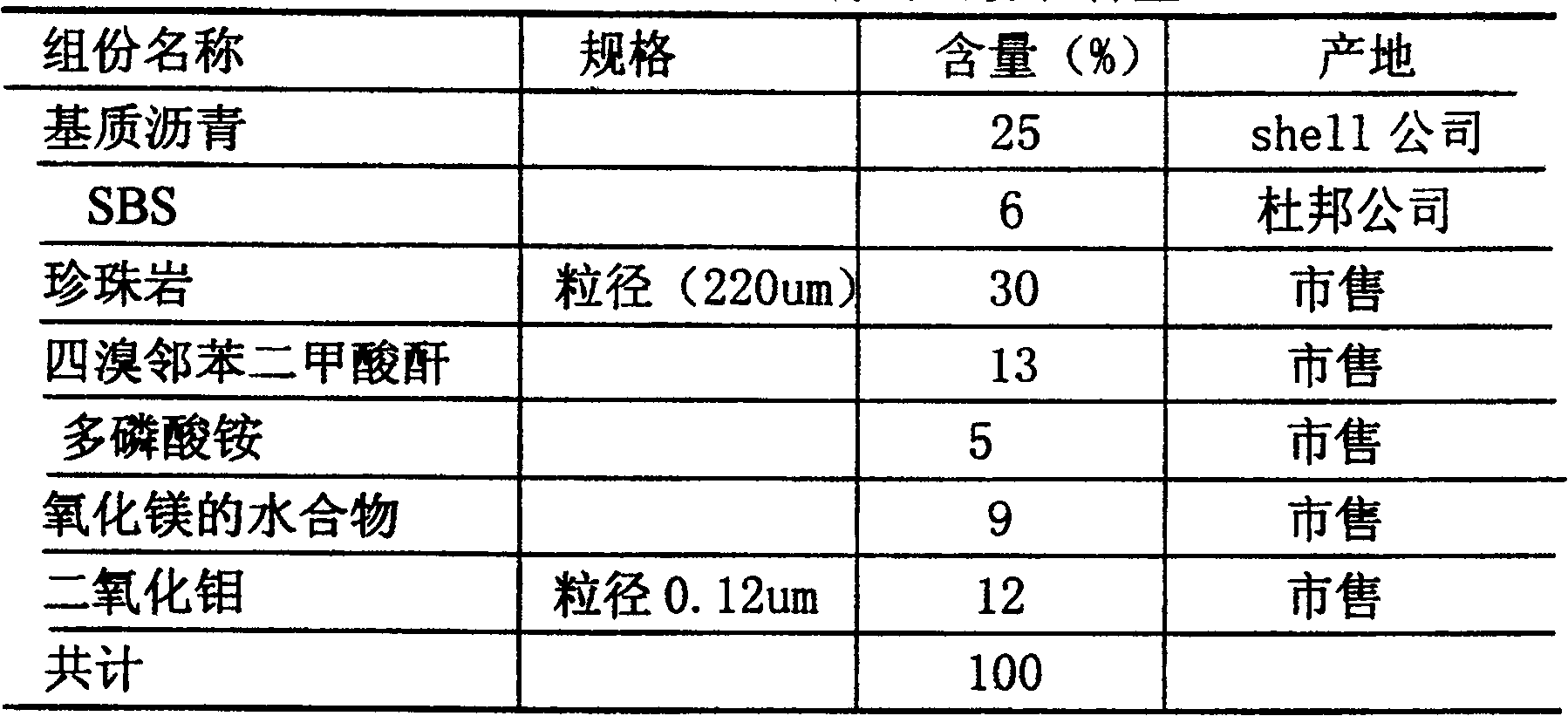

[0026] Example 1: A flame-retardant modified asphalt mixture, which contains 10 parts of flame-retardant asphalt and 90 parts of crushed stone ore powder mixture in 100 parts by weight, wherein the flame-retardant modified asphalt is modified with epoxy resin, The flame-retardant modified asphalt mixture can be formed by mixing the prepared flame-retardant modified asphalt and crushed stone powder mixture in proportion. in,

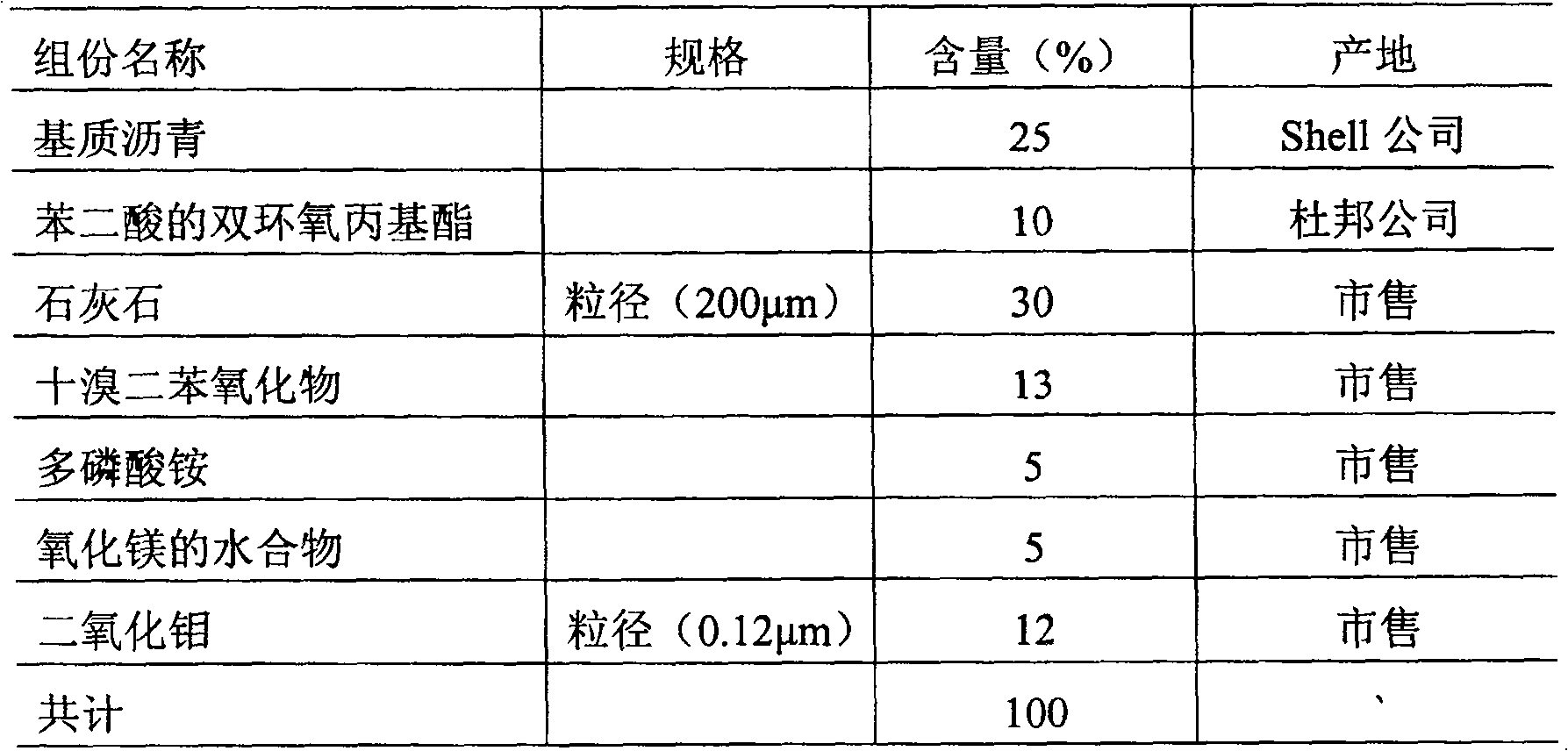

[0027] (1) The composition and content of flame retardant asphalt are: (Table 1)

[0028] Table 1: Composition and content of flame retardant asphalt

[0029]

[0030] When preparing the above-mentioned flame retardant asphalt, first prepare it by a high-speed shear mixing and emulsifying machine, dehydrate the base asphalt at 120°C for 30 minutes, raise the temperature to 176°C, add epoxy resin-diglycidyl phthalic acid, and shear 20min, then add flame retardant decabromodiphenyl oxide, ammonium polyphosphate and magnesium oxide hydrate

[0031] As ...

Embodiment 2

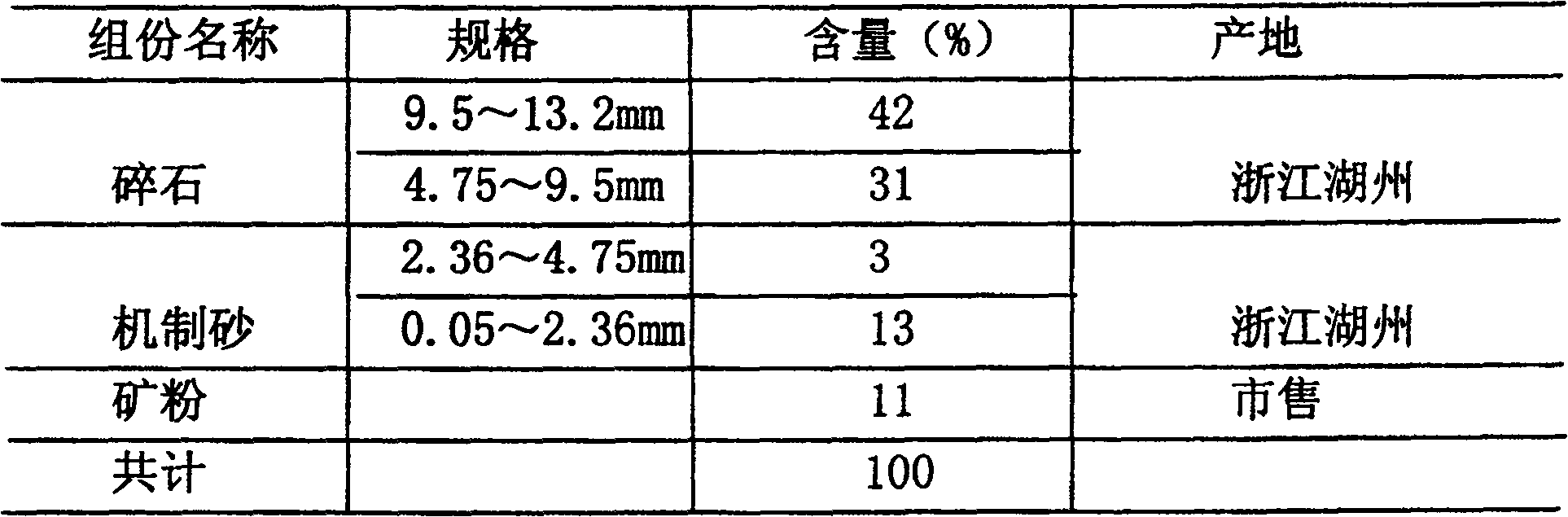

[0042] Example 2: Based on 100 parts by weight, it contains 8 parts of flame-retardant asphalt and 92 parts of crushed stone ore powder mixture, wherein the flame-retardant modified asphalt is modified with SBS, and the prepared flame-retardant modified asphalt and crushed stone The mineral powder mixture is mixed in proportion to form a flame-retardant modified asphalt mixture. in,

[0043] (1) The composition and content of flame retardant asphalt are: (Table 5)

[0044] Table 5: Composition and content of flame retardant asphalt

[0045]

[0046] Similar to the preparation method of the above-mentioned Example 1, the prepared flame-retardant asphalt was compared with the asphalt without adding flame retardants and smoke suppressants. The performance indicators are shown in Table 6 below:

[0047] Table 6: Performance test results of flame retardant modified asphalt

[0048]

Indicator name

No flame retardant or smoke suppressant added

Mod...

Embodiment 3

[0054] Example 3: Based on 100 parts by weight, it consists of 8 parts of flame-retardant asphalt and 92 parts of crushed stone powder mixture, wherein the flame-retardant modified asphalt is modified with SIS, and the prepared flame-retardant modified asphalt and crushed The stone ore powder mixture is mixed in proportion to form a flame-retardant modified asphalt mixture. in,

[0055] (1) The composition and content of flame retardant asphalt are: (Table 8)

[0056] Table 8: Composition and content of flame retardant asphalt

[0057]

[0058] Similar to the preparation method of the above-mentioned Example 1, the prepared flame-retardant asphalt was compared with the asphalt without adding flame retardants and smoke suppressants, and its performance indicators are shown in Table 9:

[0059] Table 9: Performance test results of flame retardant modified asphalt

[0060]

Indicator name

No flame retardant or smoke suppressant added

Modified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com