High-accuracy wall temperature measuring device

A temperature measurement, high-precision technology, used in measuring devices, thermometers, measuring heat, etc., can solve the problems of low measurement accuracy, inability to solve the measurement contact surface, and measurement signals are susceptible to external interference, etc., to achieve high measurement accuracy and anti-interference. Strong ability, the effect of reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

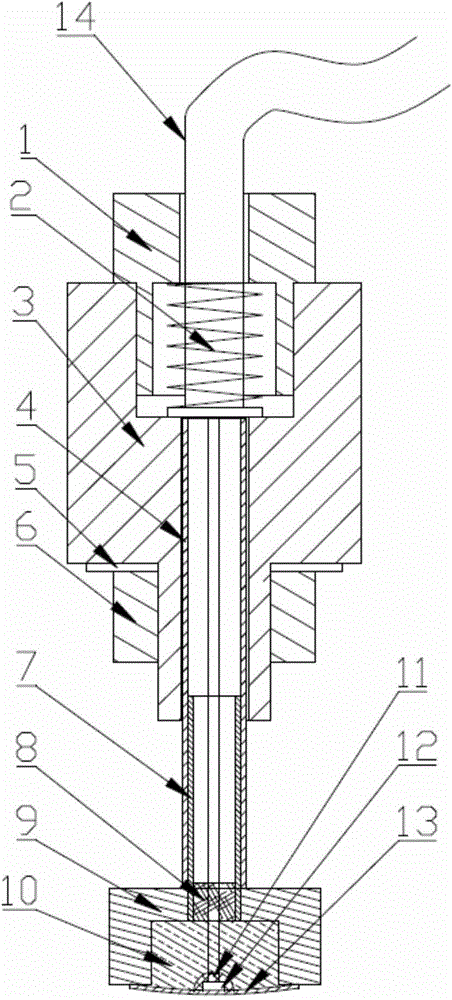

[0024] Such as figure 1 As shown, this embodiment includes: a seat part, a probe part and a metal conduit 4, wherein: the end of the metal conduit 4 is elastically connected to the seat part, and the head end is movably connected to the probe part.

[0025] The seat part includes: a compression nut 1 and a probe seat body 3 , wherein a metal conduit 4 is movably arranged inside the probe seat body 3 and its end contacts the compression nut 1 through an elastic member 2 .

[0026] The elastic member 2 is preferably a pre-compressed spring.

[0027] The top of the probe seat body 3 is provided with a fixing nut 6, and the fixing nut 6 is used to fix the detection device on the frame above the measured wall.

[0028] Preferably, at least one gasket 5 is provided between the fixing nut 6 and the probe base body 3 .

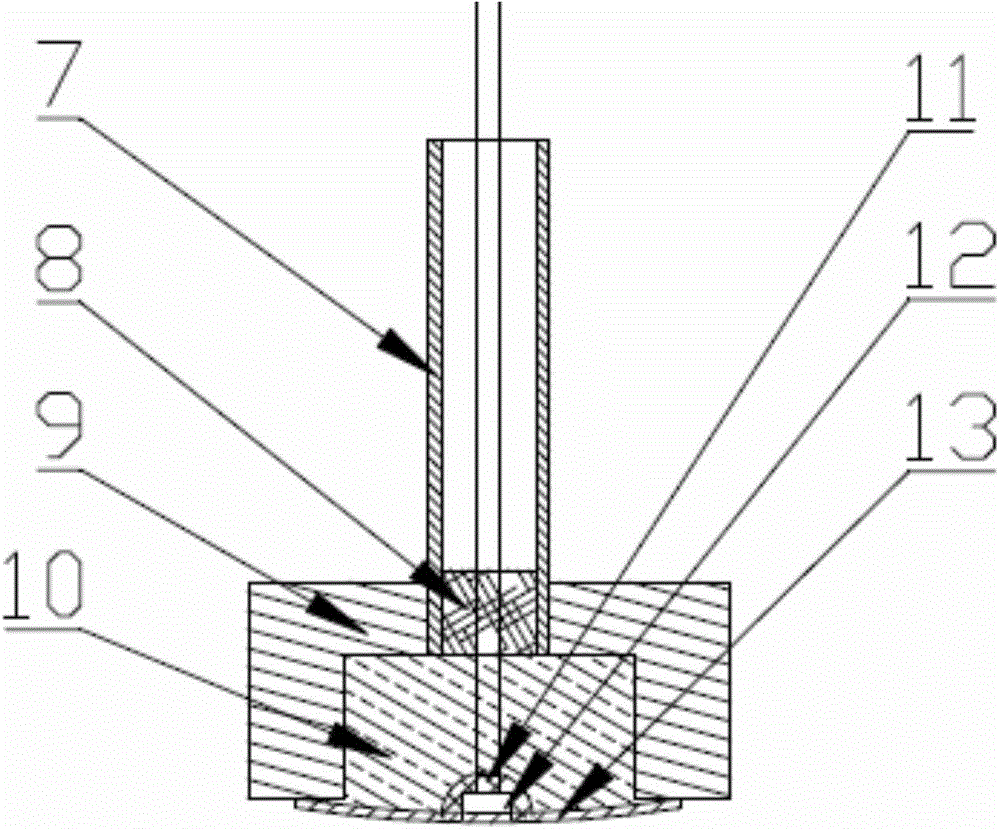

[0029] Such as figure 2 As shown, the probe part includes: a metal wire tube 7, a probe body 9, a temperature sensing element 12 and a metal contact piece 13 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com