High-performance modified asphalt and preparation method thereof

A modified asphalt, high-performance technology, applied in building components, building insulation materials, buildings, etc., can solve the problems affecting the efficiency of road transportation and driving safety, the performance degradation of SBS modified asphalt, and the degradation of SBS polymer chain scission. , to achieve excellent thermal stability, reduce chain scission, and promote adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example provides a high-performance modified asphalt, which is made of the following raw materials: 84% of base asphalt, 14% of carbon aerogel, and 2% of compatibilizer.

[0029] The preparation process of the carbon airgel is as follows: 5 parts of hydroquinone are dissolved in 20 parts of water, then 0.5 parts of potassium chloride and 0.2 parts of sodium carbide are added, and after stirring evenly, 7 parts of furfuraldehyde are added to obtain a white viscous The thick solution was then placed in a water bath at 65° C. for 10 h, and the reaction solution gradually turned black to generate a hydrogel microsphere solution. The solution was repeatedly washed with deionized water until the pH value no longer changed, and then filtered to obtain a solid powder, which was placed in a carbonization furnace and carbonized for 4 hours at 1000°C to obtain a carbon aerogel.

[0030] Described compatibilizer is maleic anhydride grafted ethylene-octene random copolymer and ...

Embodiment 2

[0034] This example provides a high-performance modified asphalt, which is made of the following raw materials: 93% of base asphalt, 6% of carbon aerogel, and 1% of compatibilizer.

[0035] The carbon airgel preparation process is the same as in Example 1.

[0036] The compatibilizer is composed of maleic anhydride grafted ethylene-octene random copolymer and maleic anhydride grafted polyethylene according to a weight ratio of 1:1.

[0037] The preparation method of the high-performance modified asphalt of this example is the same as that of Example 1.

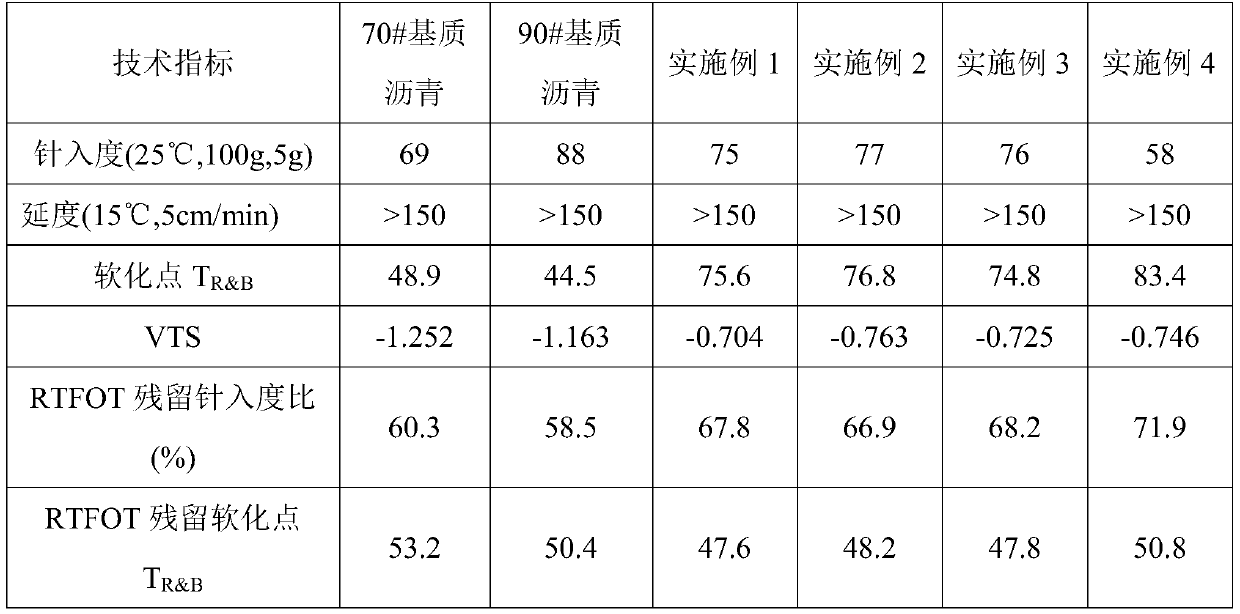

[0038] See Table 1 for the performance test results of the high-performance modified asphalt in this example.

Embodiment 3

[0040] This example provides a high-performance modified asphalt, which is made of the following raw materials: 90% of base asphalt, 7% of carbon aerogel, and 3% of compatibilizer.

[0041] The carbon airgel preparation process is the same as in Example 1.

[0042] Described compatibilizer is composed of polybutylene terephthalate and maleic anhydride grafted polyethylene according to a weight ratio of 1:1.

[0043] The preparation method of the high-performance modified asphalt of this example is the same as that of Example 1.

[0044] See Table 1 for the performance test results of the high-performance modified asphalt in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com