Low-temperature aromatic hydrocarbon oil road modified asphalt, and preparation method thereof

A technology for modifying asphalt and aromatic oil, which is used in building thermal insulation materials, building components, buildings, etc., can solve problems such as poor asphalt strain capacity, and achieve the effects of stable performance, improved temperature sensitivity, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

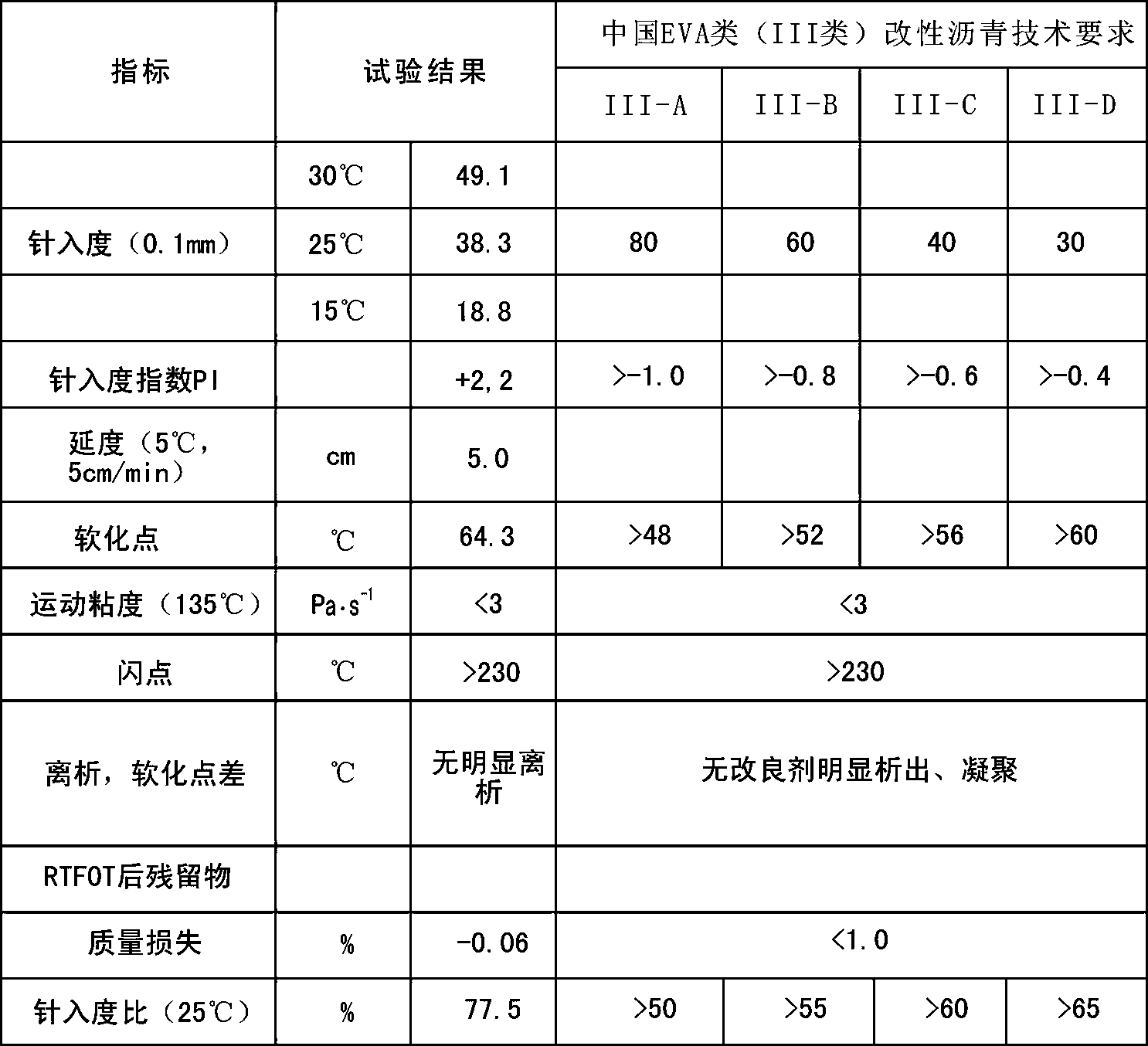

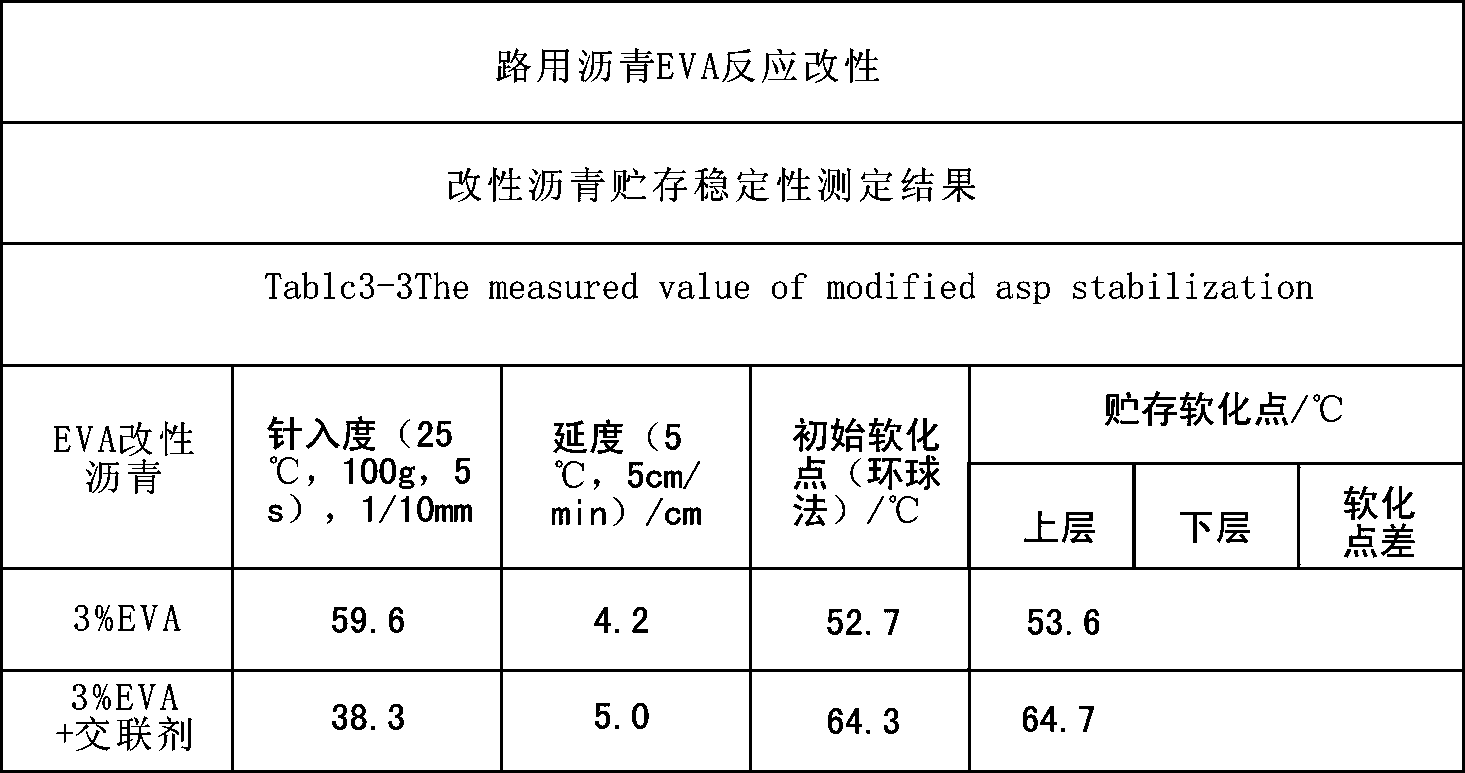

[0027] A low-temperature aromatic oil modified asphalt, wherein, asphalt modifier component A and modifier component B, the weight ratio of A and B is 20:80; EVA is the abbreviation of ethylene-vinyl acetate copolymer, VA The content is 41%, take asphalt and add it to the constant temperature modification device, heat it to 165 degrees Celsius, then add 3% EVA, 2‰ aromatic oil, asphalt thinner, asphalt modifier A and B, crosslinking agent and catalyst , the temperature was kept constant within 165°C, and the modification was carried out by shearing and stirring for 2.5 hours in a stirring tank.

[0028] The component A is methacrylamide-coal tar pitch resin and pitch, wherein methacrylamide / pitch=0.12, and the above ratio is a mass ratio.

[0029] The modifier component B is a mixture of coal and coke.

[0030] The cross-linking agent is elemental sulfur.

[0031] The preparation method of the above-mentioned methyl polyacrylamide-coal pitch resin is: methyl polyacrylamide / p...

specific Embodiment 2

[0037] A low-temperature aromatic oil modified asphalt, wherein, asphalt modifier component A and modifier component B, the weight ratio of A and B is 25:75; EVA is the abbreviation of ethylene-vinyl acetate copolymer, VA The content is 41%, take asphalt and add it to the constant temperature modification device, heat it to 170 degrees Celsius, then add 3% EVA, 2‰ aromatic oil, asphalt thinner, asphalt modifier A, B, crosslinking agent and catalyst , the temperature was kept constant within 170°C, and the modification was carried out by shearing and stirring for 2.5 hours in a stirring tank.

[0038] The above-mentioned A is polypropylene-coal pitch resin and pitch, wherein polypropylene / pitch=0.2, and the above-mentioned ratio is a mass ratio.

[0039] The modifier component B is a mixture of coal and coke.

[0040] The crosslinking agent is peroxide.

[0041] The preparation method of the above-mentioned polypropylene-coal pitch resin is as follows: wherein polypropylene / p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com