Fire-retardant and modified asphalt mixture

A technology of modified asphalt and mixture, applied in the direction of building thermal insulation materials, building components, buildings, etc., can solve the problem of no application, and achieve the effect of reducing dosage, improving anti-aging performance and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

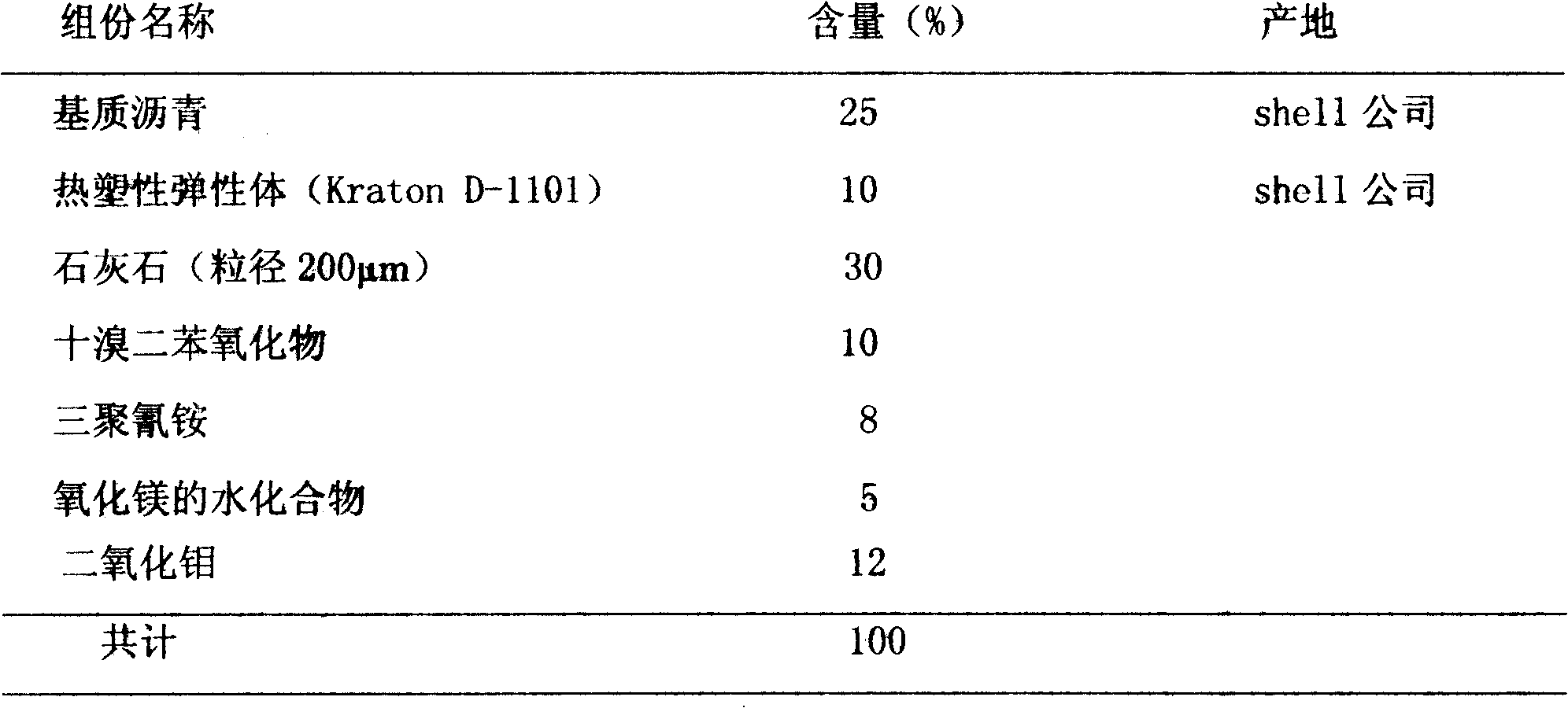

Embodiment 1

[0025] Embodiment 1: A kind of flame-retardant modified asphalt mixture, its component content is as follows:

[0026]

[0027] Prepared by a high-speed shear mixing emulsifier, first dehydrate the base asphalt at 120°C for 30 minutes, heat up to 176°C, add thermoplastic elastomer Kraton D-1101, shear for 20 minutes, and then add flame retardant: decabromodiphenyl oxide , melamine and magnesium oxide hydrate, smoke suppressant molybdenum dioxide, fillers and other components, mixed and sheared for 15 minutes.

[0028] The following is the performance test of the above-mentioned flame-retardant and smoke-suppressing asphalt mixture. The asphalt mixture without adding flame retardant and smoke suppressant is used for comparison. The performance indicators are shown in Table 1 below:

[0029] Table 1

[0030]

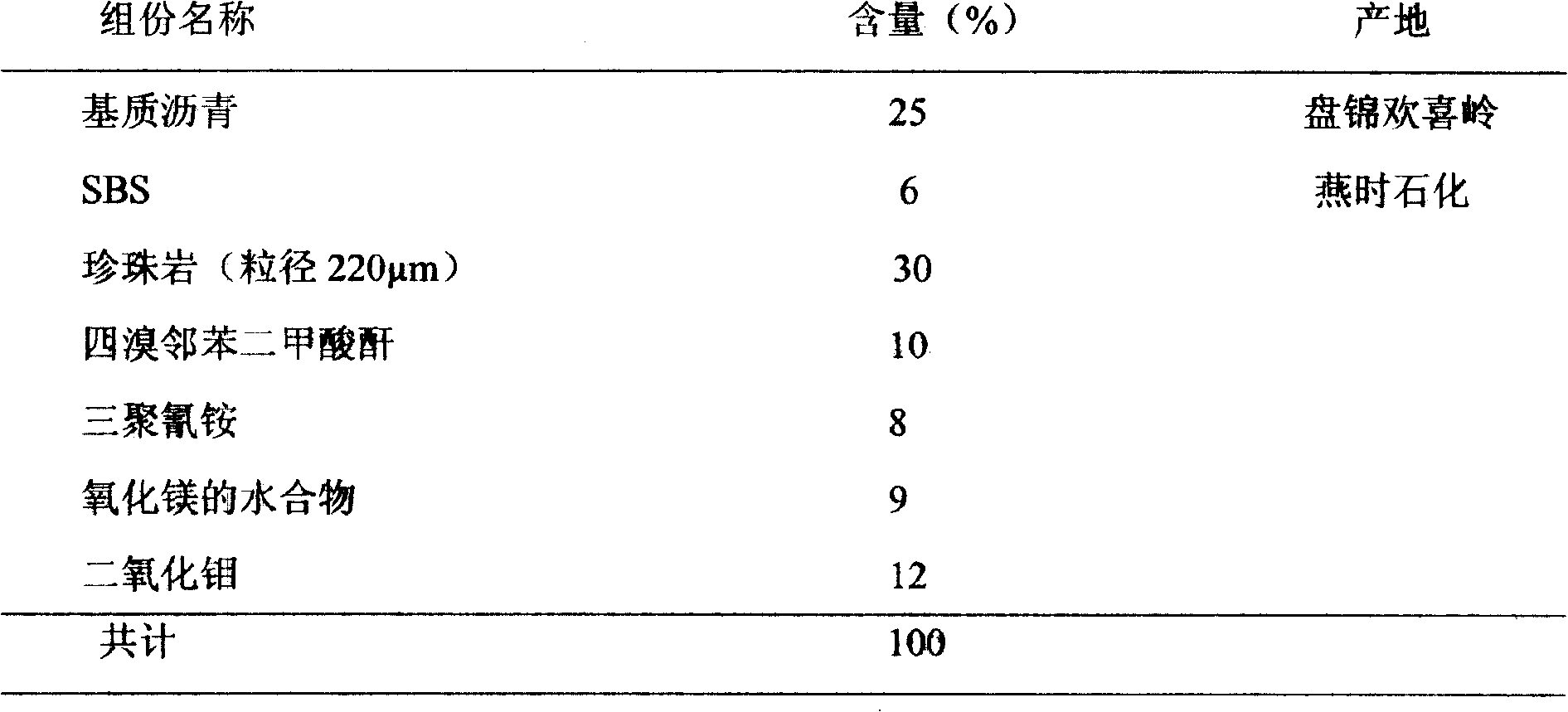

Embodiment 2

[0031] Example 2: The flame-retardant asphalt mixture described in the present invention is prepared by using SBS modified asphalt.

[0032]

[0033] Similar to the preparation method of the above-mentioned Example 1, the prepared flame-retardant and smoke-suppressing modified asphalt mixture was compared with the asphalt mixture without adding flame retardant and smoke-suppressing agent. The various performance indicators are shown in Table 2 below:

[0034] Table 2

[0035]

[0036] Softening point / ℃

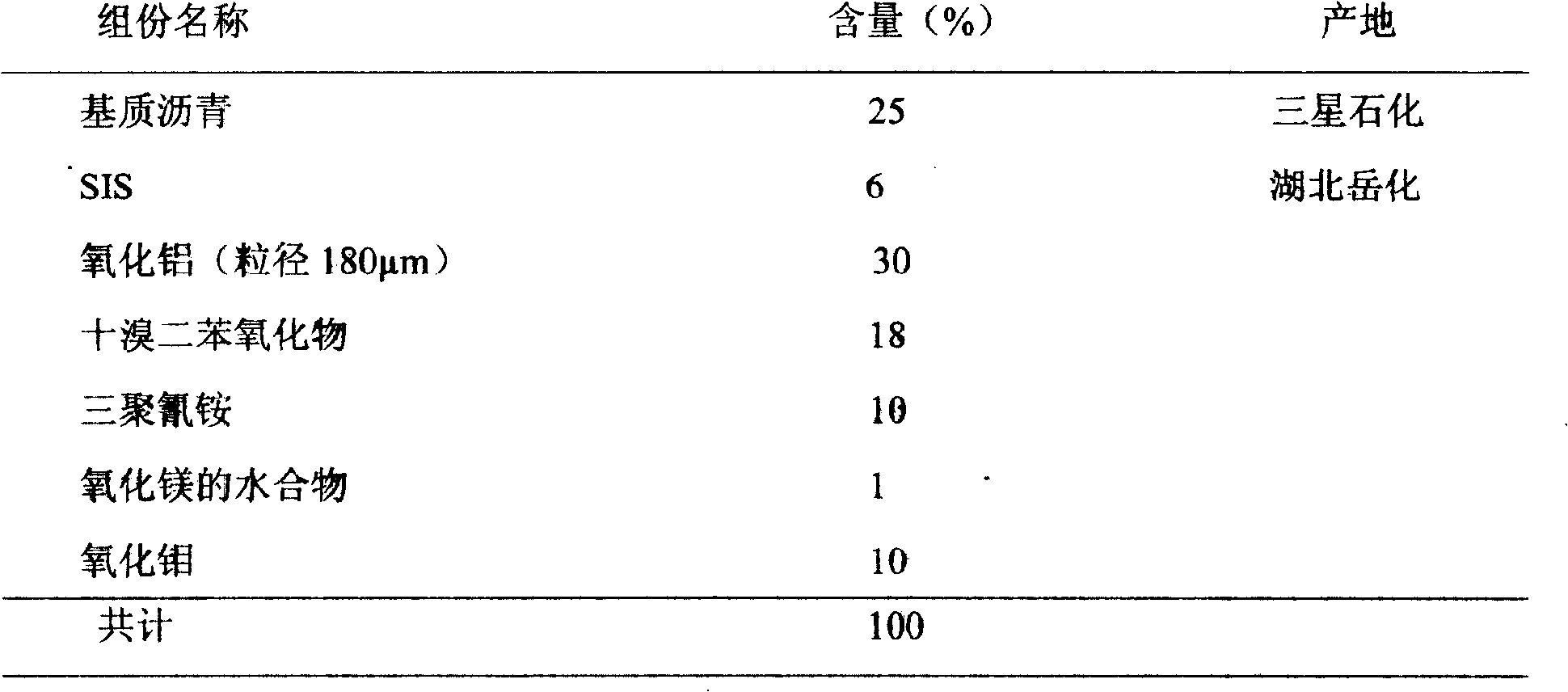

Embodiment 3

[0037] Embodiment 3: The flame-retardant asphalt mixture described in the present invention is prepared by using SIS modified asphalt.

[0038]

[0039] Similar to the preparation method of the above-mentioned Example 1, the prepared flame-retardant and smoke-suppressing modified asphalt mixture was compared with the modified asphalt mixture without adding flame retardant and smoke-suppressing agent. The performance indicators are shown in Table 3 below :

[0040] table 3

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com