Temperature sensor, injection molding packaging mold and injection molding packaging method

A packaging method and injection molding technology, which is applied in the field of temperature sensors and injection packaging molds, can solve problems such as inconsistent glue filling and shell thermal conductivity, affecting product waterproof and temperature-sensing performance, and poor positioning of temperature-sensing elements, etc., to achieve consistency in appearance Good, reduce the hidden danger of water leakage, improve the effect of temperature sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

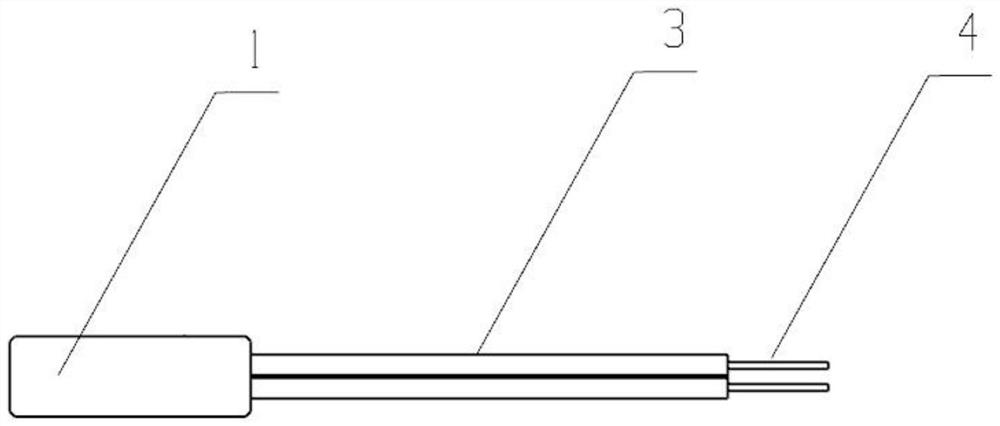

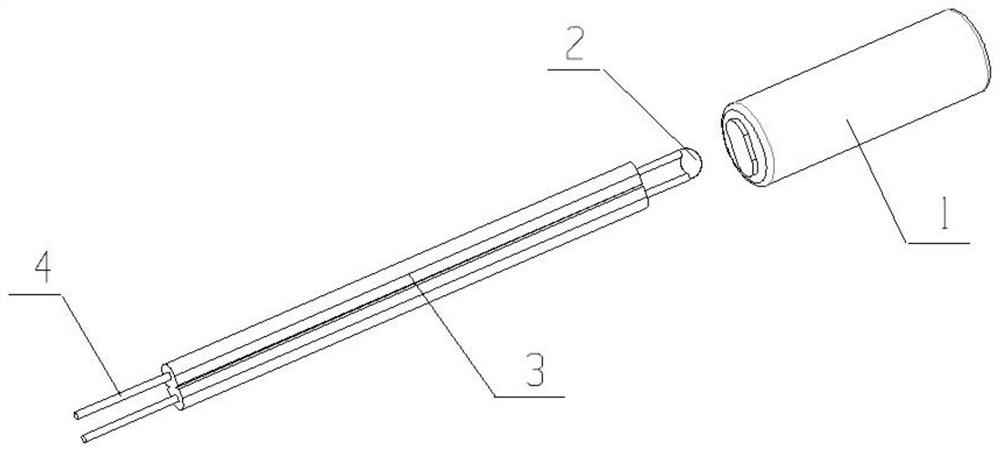

[0061] Such as figure 1 , figure 2 As shown, the temperature sensor of the present invention includes a temperature sensing element 2, a cable 3 and a terminal 4; one end of the cable 3 is equipped with a terminal 4, and the cable 3 and the terminal 4 are connected by crimping tooling, and the other One end is installed with a temperature sensing element 2, and the temperature sensing element 2 and the cable 3 are connected by soldering; the cable 3 is at the end close to the temperature sensing element 2, and there is a cable 3a with a length L and the cable 3a. The temperature-sensing element 2 described above is encapsulated in the plastic casing 1 through injection molding; the plastic casing 1 is directly wrapped around the temperature-sensing element 2 and the periphery of the cable 3a, and the connection between the plastic casing 1 and the cable 3a seal between. The plastic shell 1 is molded by injection molding with thermoplastic material. The laser-engraved LOGO ...

Embodiment 2

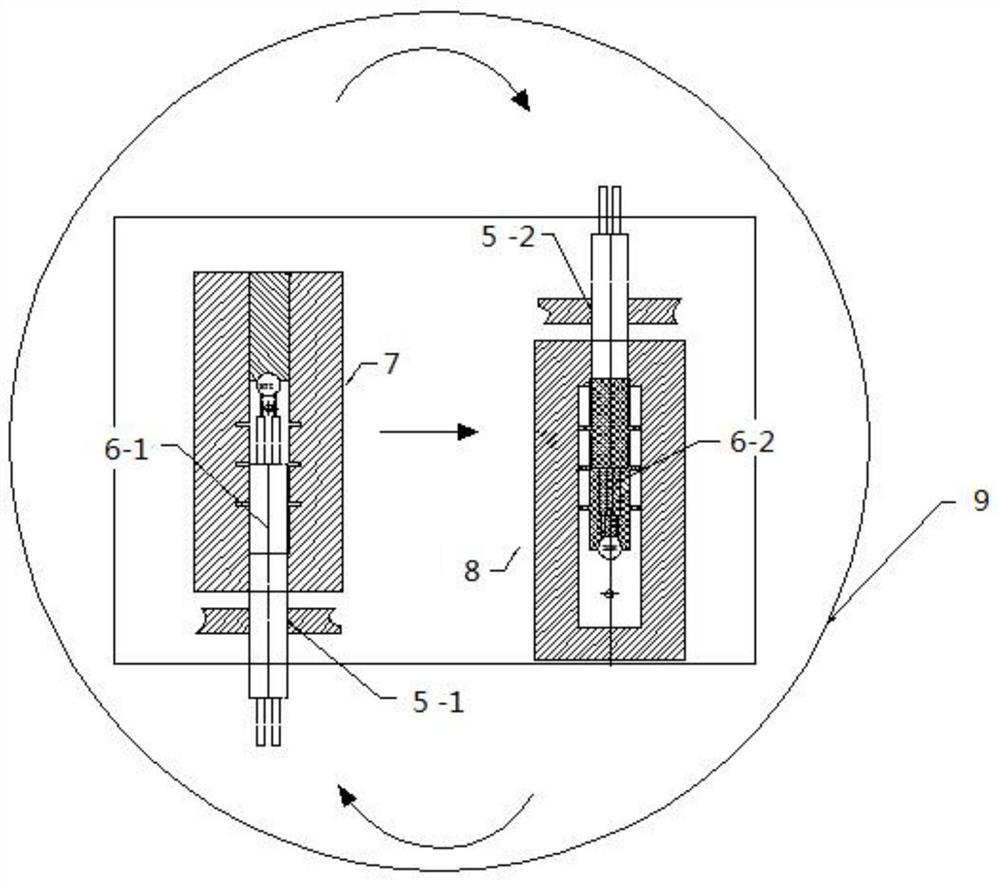

[0072] Such as Figure 3-9 As shown, the injection molding packaging equipment of the present invention includes a turntable 9, a wire harness fixing seat 5-1, a primary injection mold 7, and a secondary injection mold 8; image 3 Among them, the primary injection mold 7 and the secondary injection mold 8 are all in the mold closing state.

[0073] The turntable 9, such as image 3 As shown, driven by a rotating drive mechanism (such as a motor, etc.), it can rotate around its own center. The turntable 9 is respectively provided with a primary injection molding station and a secondary injection molding station, so that the workpiece 6-1 to be injected and packaged (specifically, in the temperature sensor, is assembled from the terminal 4, the cable 3, and the temperature sensing element 2 components, at this time, the part of the temperature sensor that needs to be packaged is still in an unpackaged state) can first complete the injection molding package at the first injecti...

Embodiment 3

[0087] The difference between this embodiment and embodiment 2 is that the primary injection mold 7 and the secondary injection mold 8 with different structural forms are used. specifically:

[0088] Such as Figure 10-Figure 12 As shown, the primary injection mold 7 described in this embodiment includes a mold body, a plastic injection port 8-1b, and an external rubber delivery pipeline 7-5. The mold body is provided with a mold cavity a7-1, a mold cavity b, and a mold cavity a7-1 is a central cylindrical cavity structure, the inner diameter matches the outer diameter of the cable 3 of the temperature sensor, the mold cavity b is a semi-closed cylindrical cavity structure, and the closed end of the mold cavity b is provided with an outer convex part 7 at the middle position -4, the shape of the protruding part 7-4 matches the top arc surface of the temperature sensing element 2 of the temperature sensor. There are more than two external conveying pipes, and each external co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com