Pressure-limiting valve

A pressure limiting valve and pressure relief technology, applied in the field of pressure limiting valves, can solve the problems of small outflow openings and easy clogging, and achieve the effect of preventing clogging and good distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

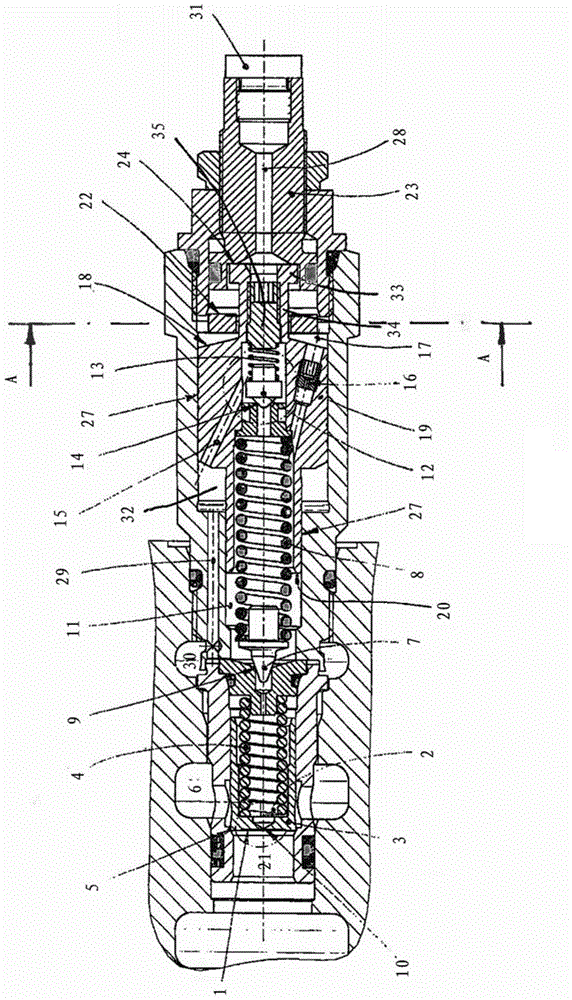

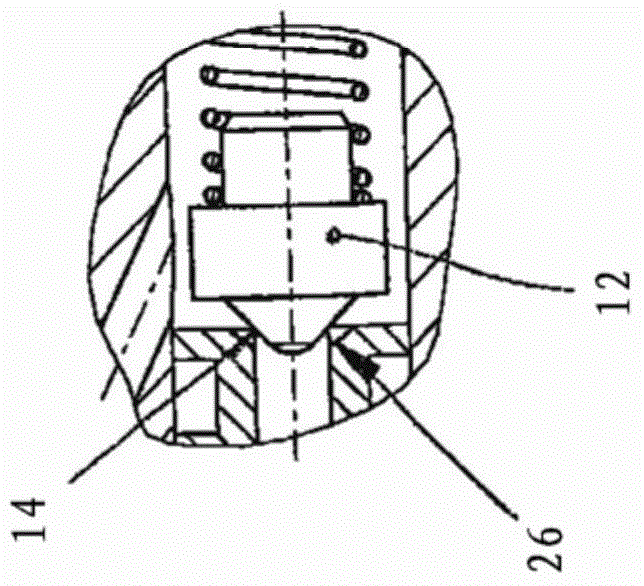

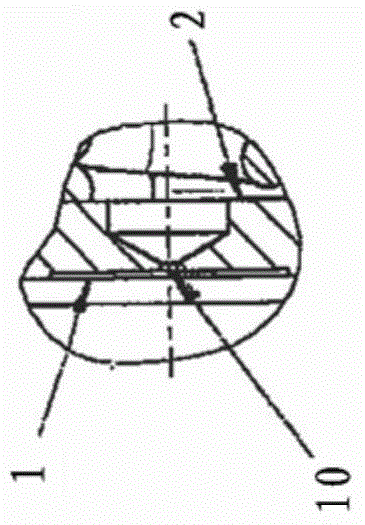

[0042] In the following it will now first be described in detail in the Figures 1 to 4 The basic function of the pressure limiting valve shown in .

[0043] The pressure limiting valve here has a main stage with a main piston 3 , which prevents or releases the connection between the pressure connection 21 and the tank connection 6 . The main piston 3 is pretensioned via a compression spring 4 against the pressure from the pressure port 21 acting on the end side 1 of the main piston. The edge 5 of the main piston 3 cooperates with the corresponding valve seat here and thus in the presence of the main piston. figure 1 In the position shown in , the passage between the pressure connection 21 and the tank connection 6 is blocked.

[0044] The main piston 3 is arranged in the main piston cavity of the housing in an axially movable manner. Here, the main piston chamber is connected to the pressure port 21 via the intermediate wall 10 on the front side of the main piston 3 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com