Dynamic and static combined part sealing device of rotary dry distillation furnace and rotary dry distillation furnace

A technology of sealing device and carbonization furnace, which is applied in the direction of engine sealing, valve device, measuring device, etc. It can solve the problems of easy wear and tear, the system cannot detect and make up for air leakage in real time, and cannot effectively reduce air leakage, etc., and achieves low consumption , low cost, enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

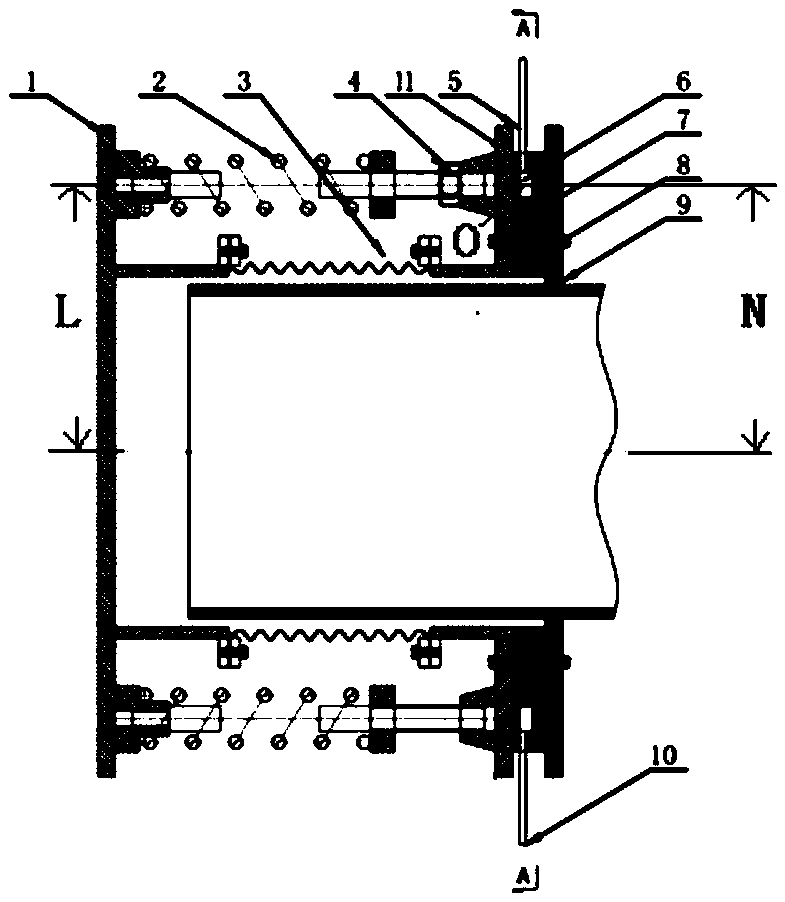

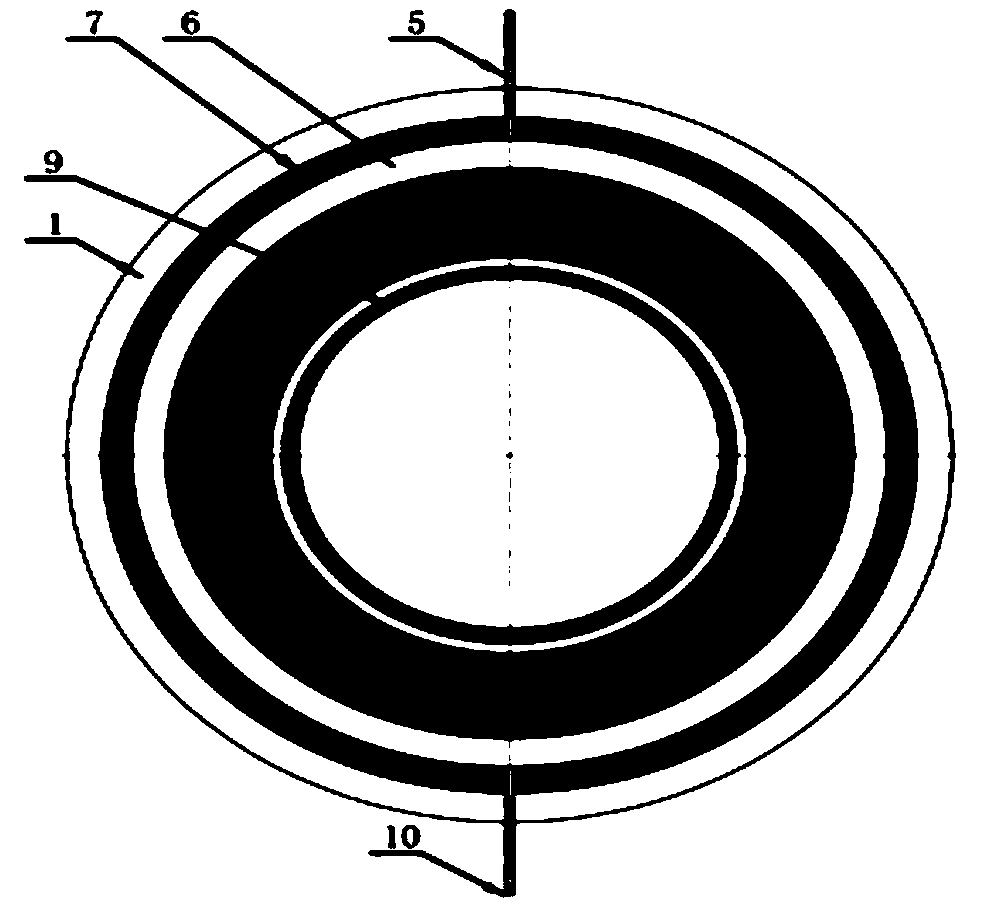

[0030] Such as Figure 1-2 As shown, a sealing device for the dynamic and static joint of a rotary retort furnace according to the present invention includes a fixed end connected to the feed end or discharge end of the rotary retort furnace, a rotating end 9 fixedly connected to the drum, a support spring 2 and a soft connection piece 3.

[0031] The fixed end includes a fixed support 1 connected to the feed end or discharge end of the rotary retort furnace and a fixed connection ring 11 sleeved on the drum, and the fixed support 1 and the fixed connection ring 11 pass through the The support spring 2 is connected with the soft connector 3, and the support spring 2 is also equipped with an adjustment nut 4 to adjust its telescoping performance, so as to adjust the pre-tightening force between the fixed connection ring 11 and the support spring 2; the soft The connecting piece 3 is a metal soft connecting piece, in this embodiment, it is a bellows, and in other embodiments, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com