Aluminum alloy building formwork splicing assembly

A technology for building formwork and aluminum alloy, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame connectors, construction, etc., which can solve the problems of a large number of scaffolds, complicated supporting process, and easy loosening of formwork. , to achieve the effect of simple and convenient support, high overall strength, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

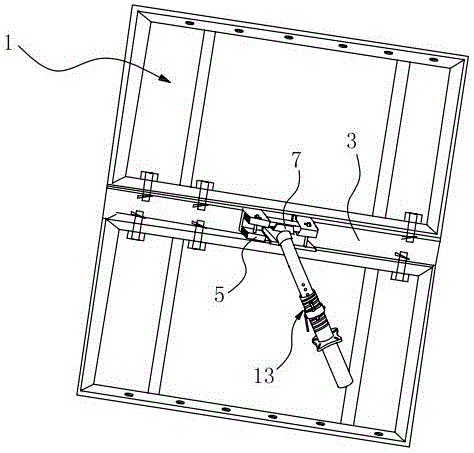

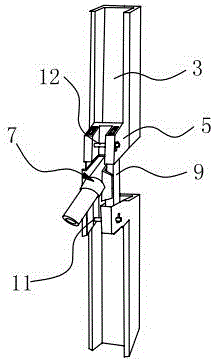

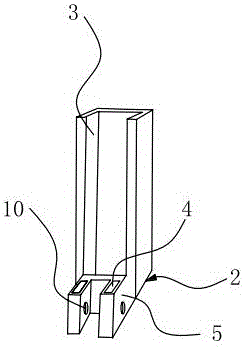

[0022] like figure 1 , 2 , 3, the aluminum alloy building formwork splicing assembly includes a plurality of sets of formwork 1 laid horizontally along the floor to be poured. The formwork 1 is made of aluminum formwork so as to reduce the weight. Multiple groups of support beams 3 with gaps 2 are provided at the intersections of two adjacent support beams 3 with a fixed block 5 fixed with the support beam 3 and with a guide groove 4, and a fixed block 5 is provided between the two fixed blocks 5. The notch 2 is adapted, and the top surface acts on the tightening member 7 with the connecting groove 6 on the floor. The top surface 8 of the tightening member 7, the formwork 1 and the support beam 3 together form a floor formwork for pouring the floor. The guide groove 4 and the connection groove 6 are provided with a connecting piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com