Lightweight steel structure rectangular-tube beam column connecting joint

A technology for connecting nodes and light steel structures, applied in building structures, buildings, etc., can solve problems such as general anti-loosening effect, and achieve the effect of good overall stability and excellent anti-loosening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

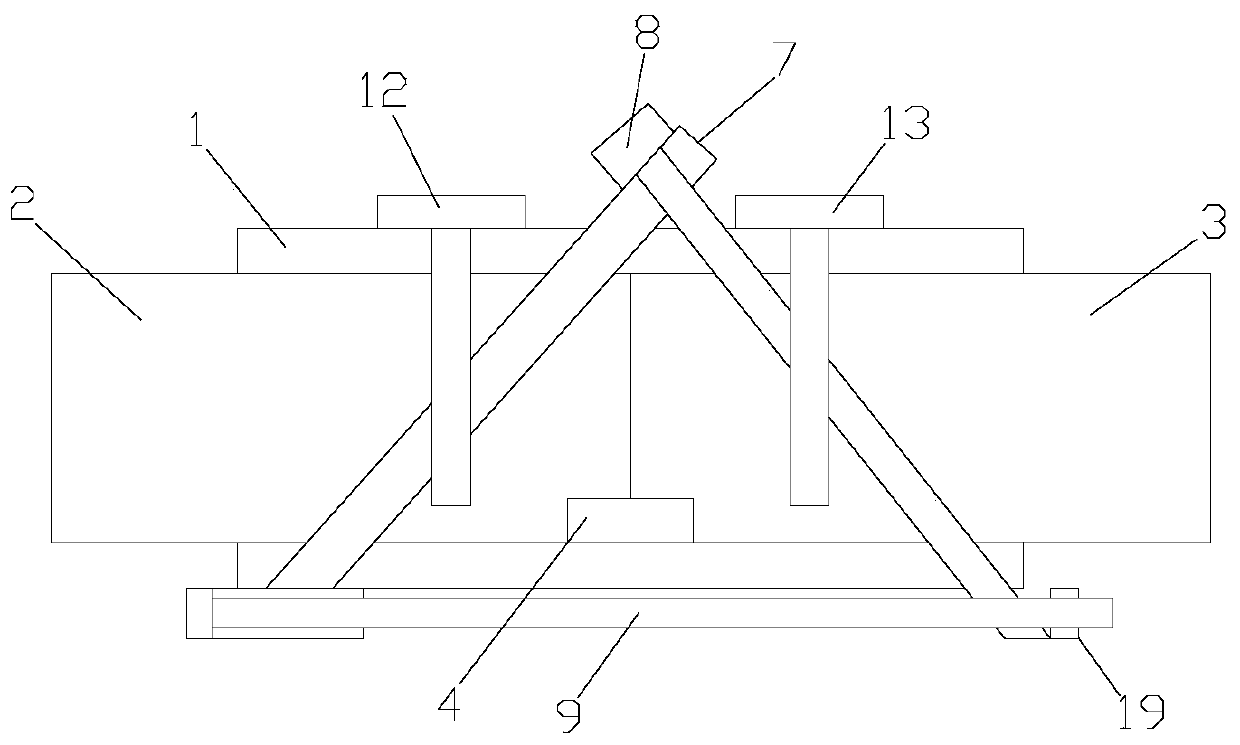

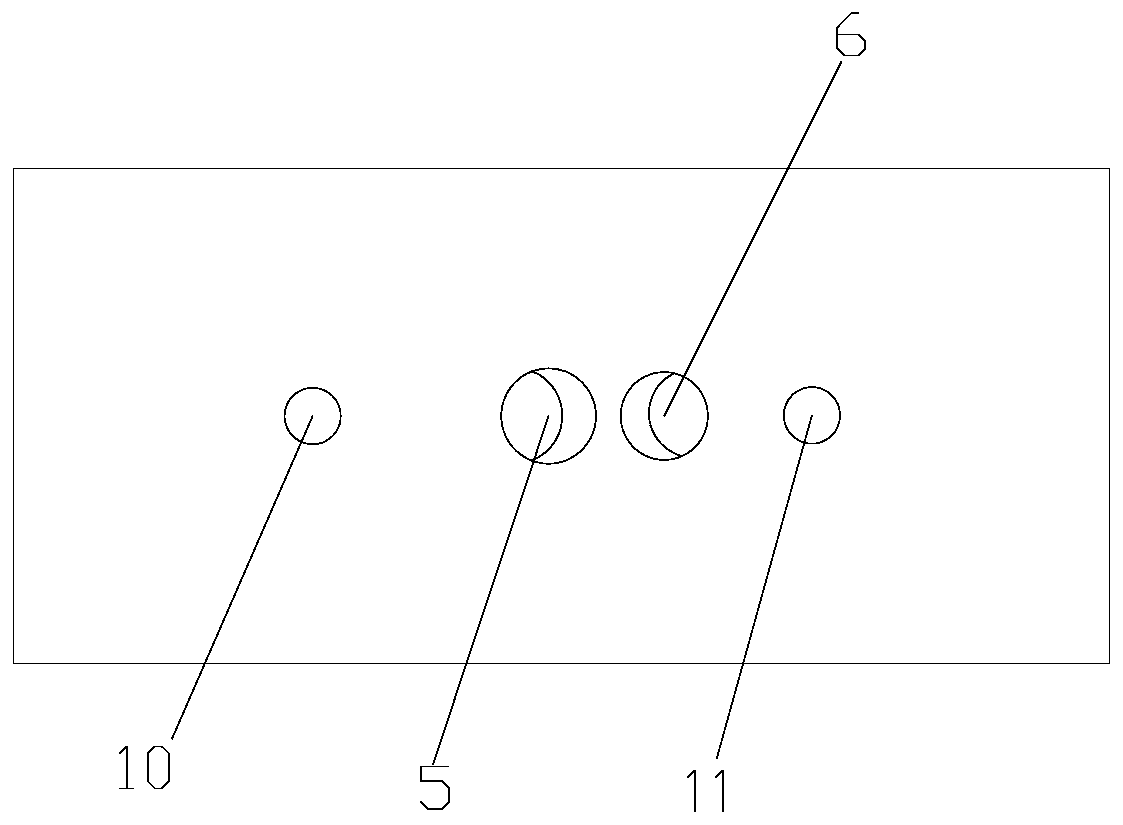

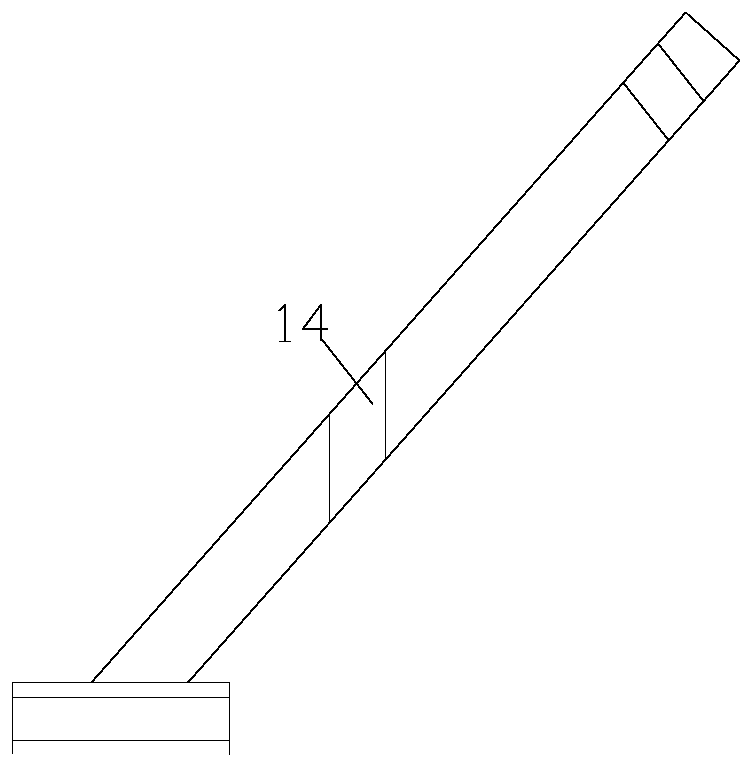

[0028] Such as Figure 1-5 As shown, a light steel structure rectangular tube beam-column connection node includes a connecting sleeve 1, a first rectangular tube beam-column 2 and a second rectangular tube beam-column 3, and a limiting protrusion 4 is arranged inside the connecting sleeve 1 , the first rectangular tube beam column 2 and the second rectangular tube beam column 3 are inserted into the connecting sleeve 1, and the first rectangular tube beam column 2 and the second rectangular tube beam column 3 are provided with limiting protrusions 4 paired limit grooves (not shown), the limit protrusion 4 is inserted into the limit groove, the connecting sleeve 1 and the first rectangular tube beam column 2 are provided with a first screw hole 5, so Both the second rectangular pipe beam column 3 and the connecting sleeve 1 are provided with a second screw hole 6, the first screw hole 5 and the second screw hole 6 are all inclined, and the first screw hole 5 is internally scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com