PET (Polyethylene Terephthalate) film for solar cell backboard and preparation method of PET film

A solar cell and backplane technology, applied in chemical instruments and methods, applications, circuits, etc., can solve the problems of poor consistency and easy cracking of solar cell backplane films, and achieve good hydrophobicity, aging resistance, and tear resistance Strong, meet the life requirements of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

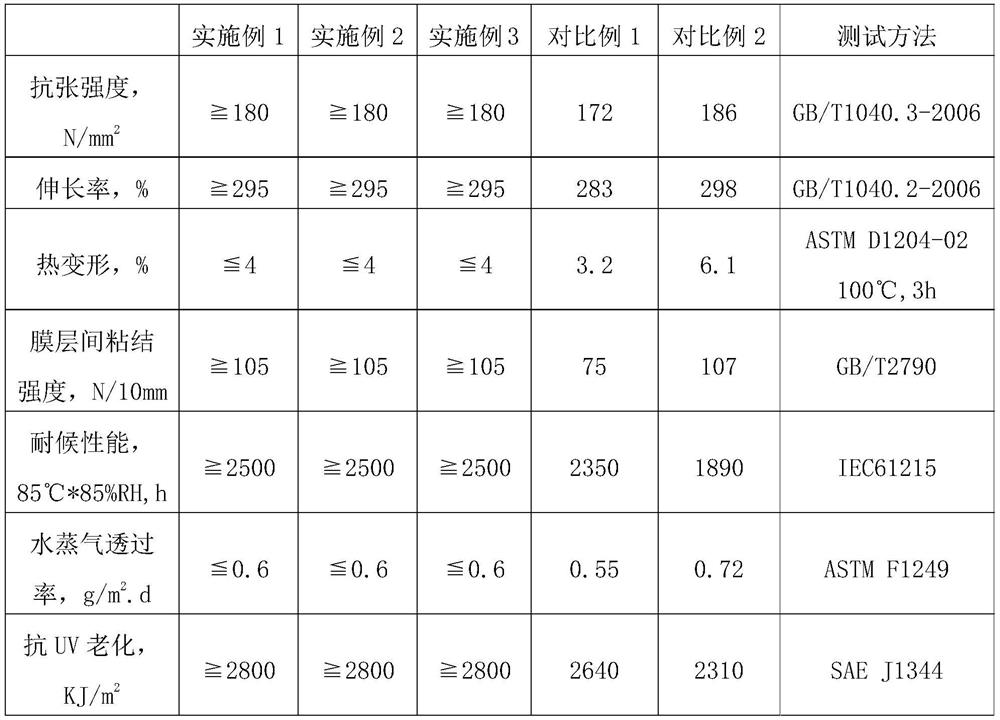

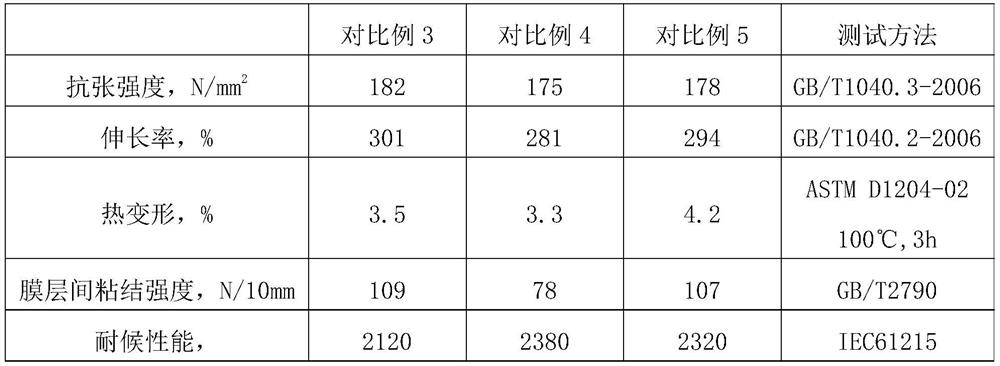

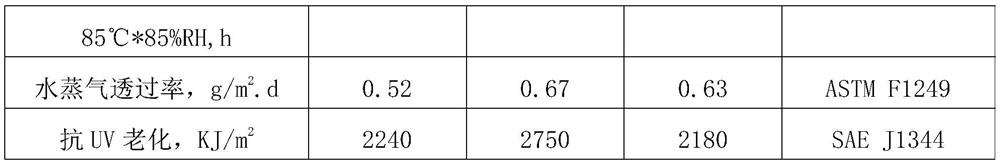

Examples

Embodiment 1

[0023] The PET film used for the solar cell backboard in this embodiment includes an intermediate PET base film and a first functional film layer and a second functional film layer respectively arranged on the upper surface and the lower surface of the PET base film. The first functional film layer and the second functional film layer are modified PET film layers, and the modified PET film layer is composed of the following raw materials in parts by weight: 90 parts of perfluoro-based cage polysilsesquioxane modified PET resin, 0.1 1 part accelerator, 3 parts modified inorganic filler, 1 part additive and 0.5 part nucleating agent sodium perfluorobutyrate. The film thicknesses of the first functional film layer and the second functional film layer are 0.045mm and 0.035mm respectively. The film thickness of the intermediate PET base film is 0.18mm.

[0024] The accelerator is obtained by compounding polyethylene glycol with a molecular weight of 1000 and zinc acetate, and the ...

Embodiment 2

[0034] The PET film used for the solar cell backboard in this embodiment includes an intermediate PET base film and a first functional film layer and a second functional film layer respectively arranged on the upper surface and the lower surface of the PET base film. The first functional film layer and the second functional film layer are modified PET film layers, and the modified PET film layer is composed of the following raw materials in parts by weight: 100 parts of perfluoro-based cage polysilsesquioxane modified PET resin, 0.5 parts Accelerator, 5.7 parts of modified inorganic filler, 3 parts of additive and 1.5 parts of nucleating agent potassium perfluorobutyrate. The film thicknesses of the first functional film layer and the second functional film layer are both 0.04 mm. The film thickness of the intermediate PET base film is 0.22 mm.

[0035] The accelerator is obtained by compounding polyethylene glycol with a molecular weight of 2000 and zinc acetate, and the mas...

Embodiment 3

[0044] The PET film used for the solar cell backboard in this embodiment includes an intermediate PET base film and a first functional film layer and a second functional film layer respectively arranged on the upper surface and the lower surface of the PET base film. The first functional film layer and / or the second functional film layer is a modified PET film layer, and the modified PET film layer is composed of the following raw materials in parts by weight: 110 parts of perfluoro-based cage polysilsesquioxane modified PET resin, 1.2 parts of accelerator, 8 parts of modified inorganic filler, 5 parts of additive and 2.5 parts of nucleating agent sodium perfluorobutyrate. The film thicknesses of the first functional film layer and the second functional film layer are 0.035mm and 0.045mm respectively. The film thickness of the intermediate PET base film is 0.30 mm.

[0045] The accelerator is obtained by compounding polyethylene glycol with a molecular weight of 3000 and zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com