Patents

Literature

31results about How to "Control preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling pre-tightening force of bolt based on axial force and elongation

ActiveCN109781332AControl preloadAccurate measurement of preloadMeasurement of torque/twisting force while tighteningMechanical pressure/force controlPropagation timeLongitudinal wave

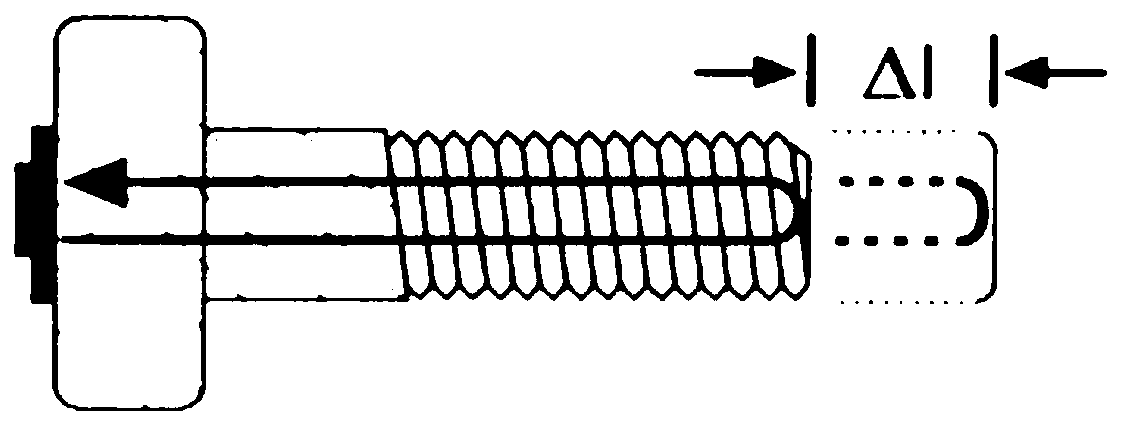

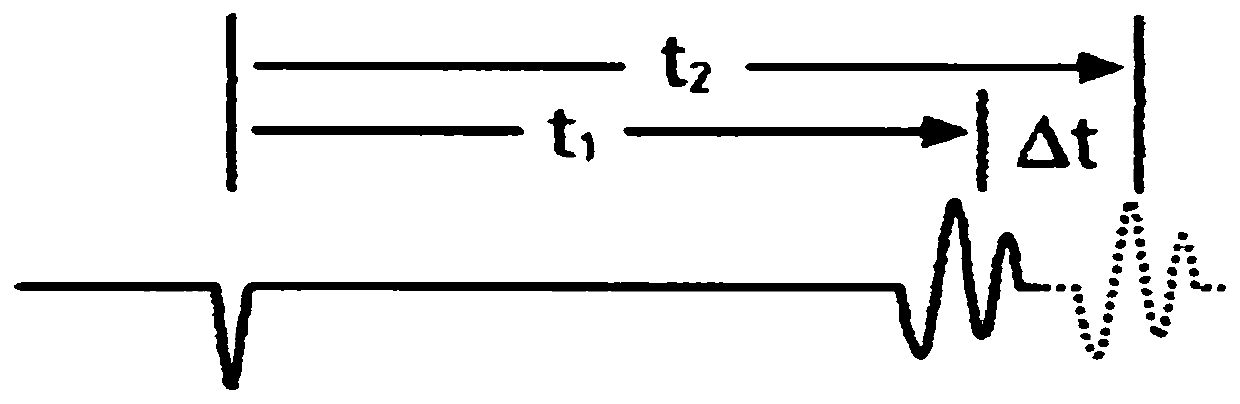

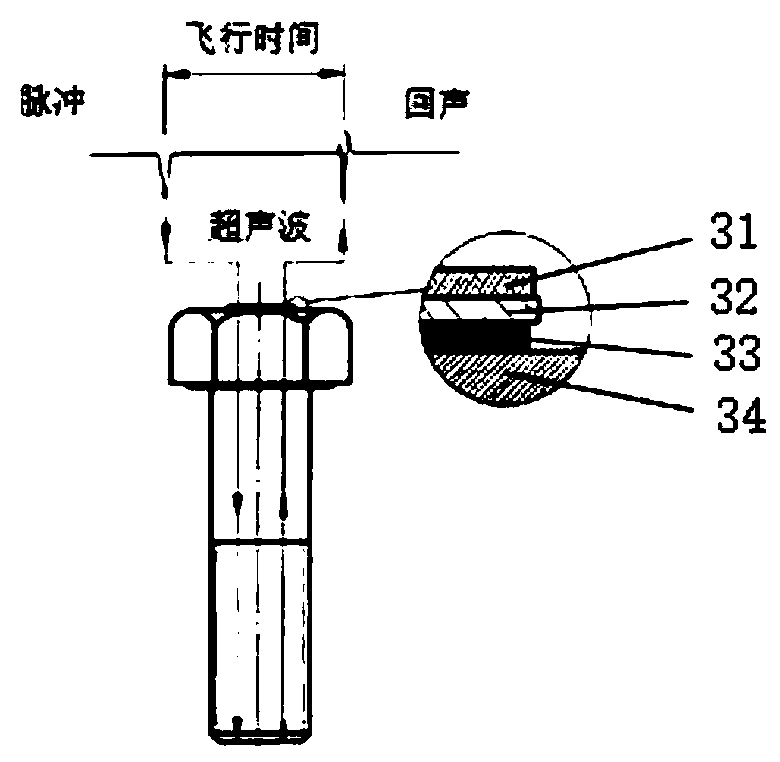

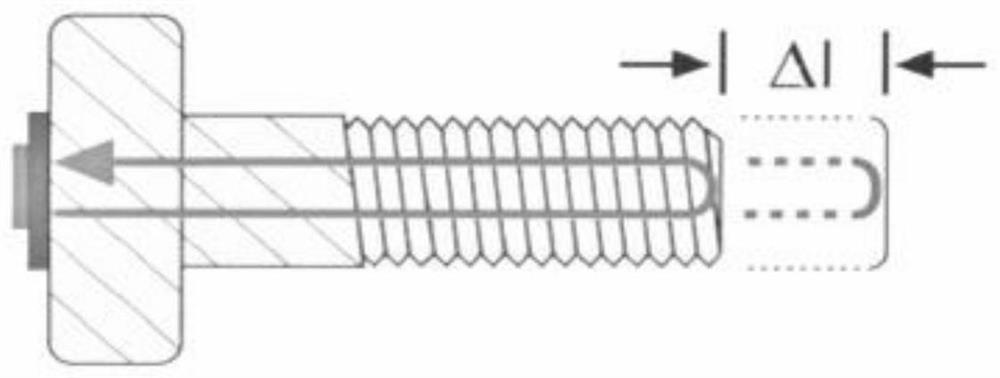

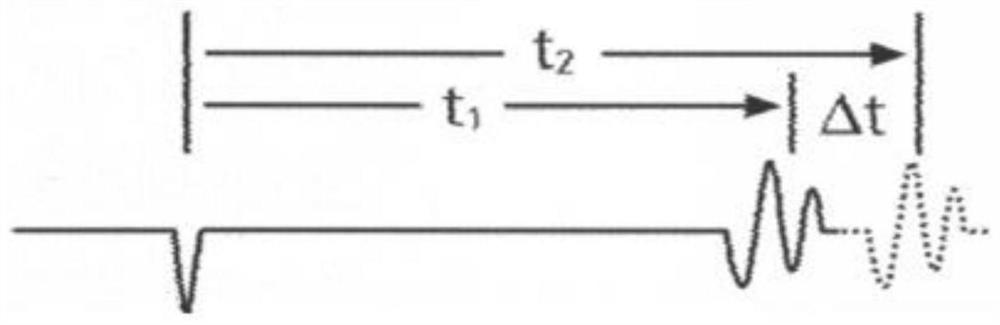

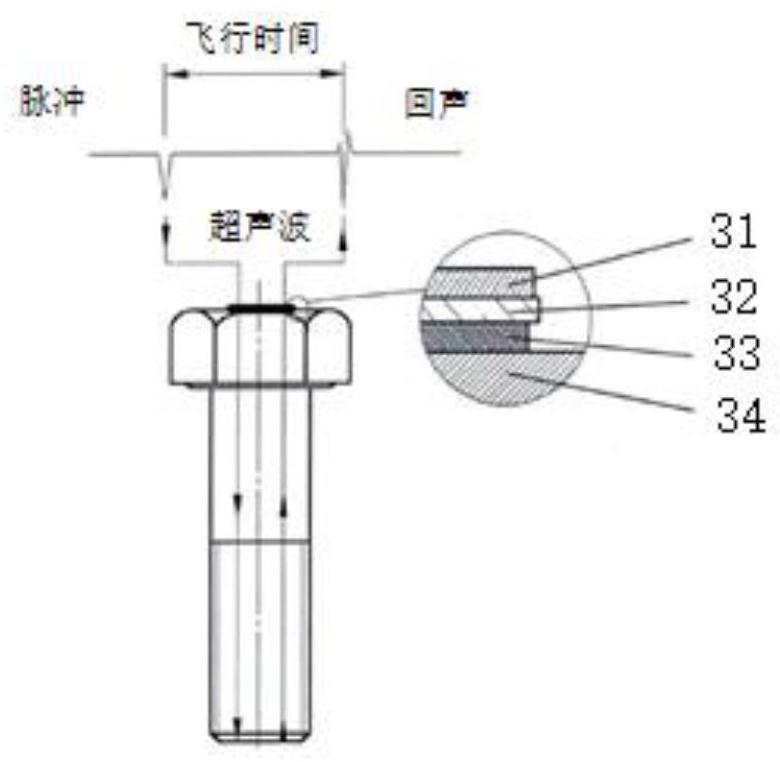

The invention relates to a method for controlling the pre-tightening force of a bolt based on axial force and elongation. The method comprises the steps that when the bolt is tightened for the first time, the acoustic time difference of the bolt in the free state and the tightened state is measured through ultrasonic waves, the elongation of the bolt is calculated based on the acoustic time difference, and the pre-tightening force of the bolt is obtained according to the elongation so that the pre-tightening force of the bolt can be accurately controlled; for an in-service bolt, based on the linear relation between the propagation time of ultrasonic transverse waves and longitudinal waves in the bolt and the axial stress of the bolt, the residual pre-tightening force of the bolt is obtained so as to determine whether the in-service bolt needs to be re-screwed or not. The pre-tightening force of the bolt and the residual pre-tightening force of the in-service bolt during first-time fastening can be accurately measured, and the purpose of accurately controlling the pre-tightening force of the bolt is achieved.

Owner:中国大唐集团新能源科学技术研究院有限公司

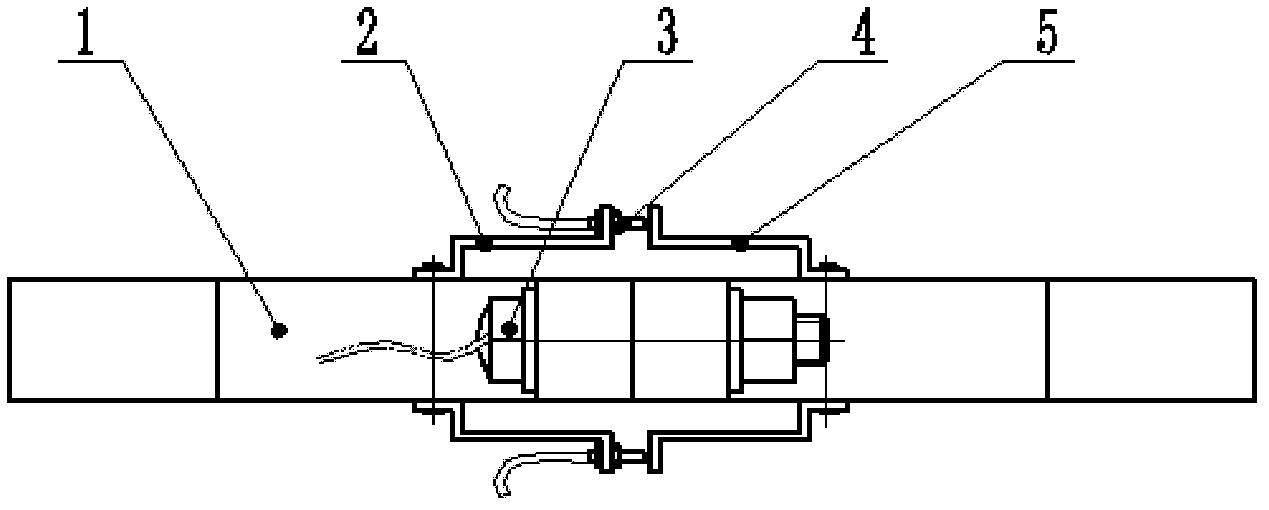

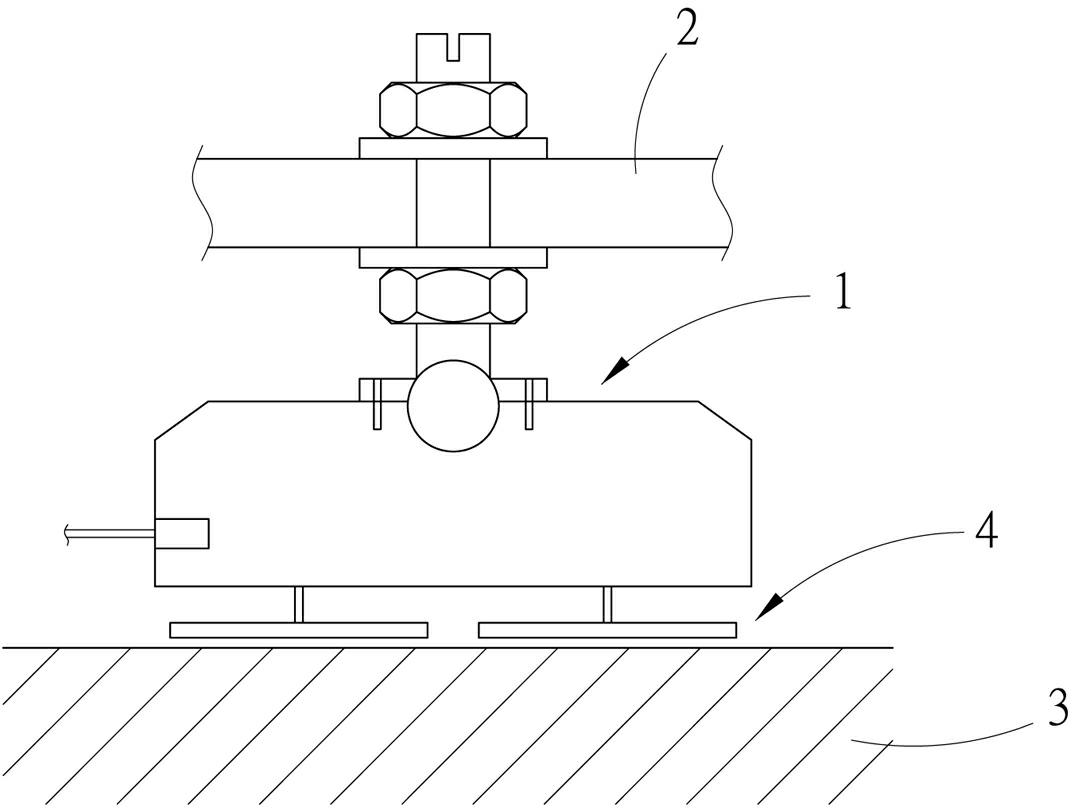

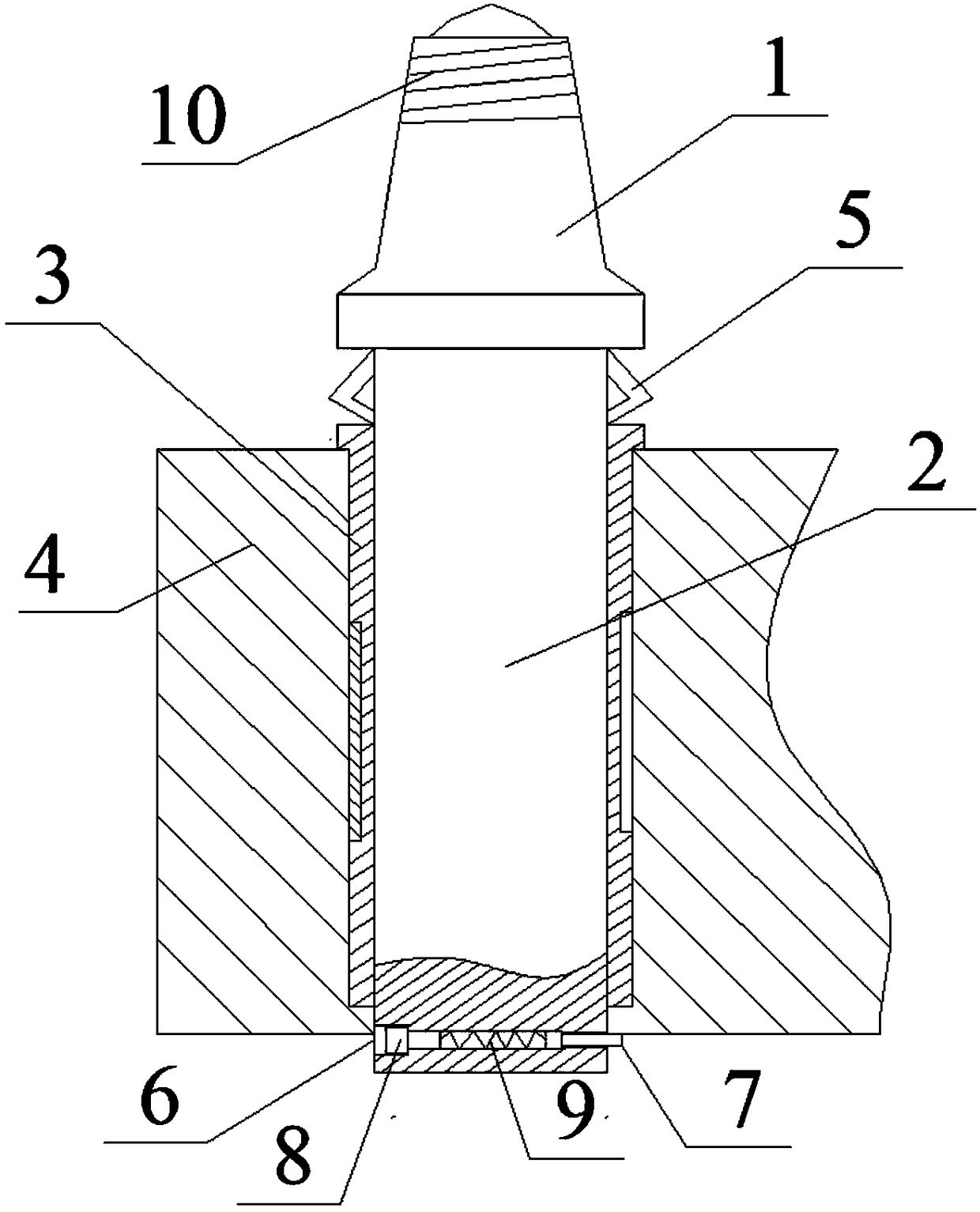

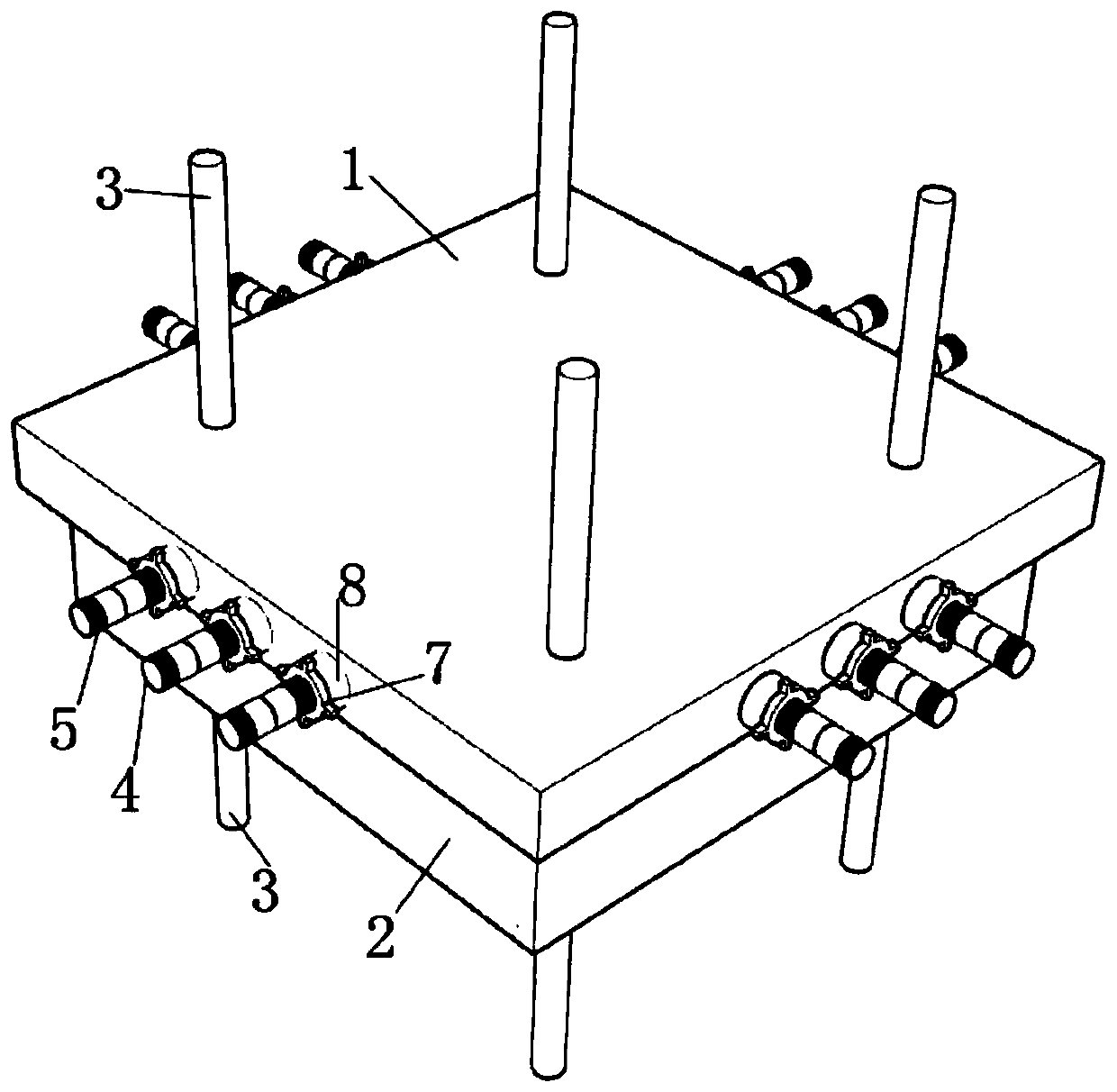

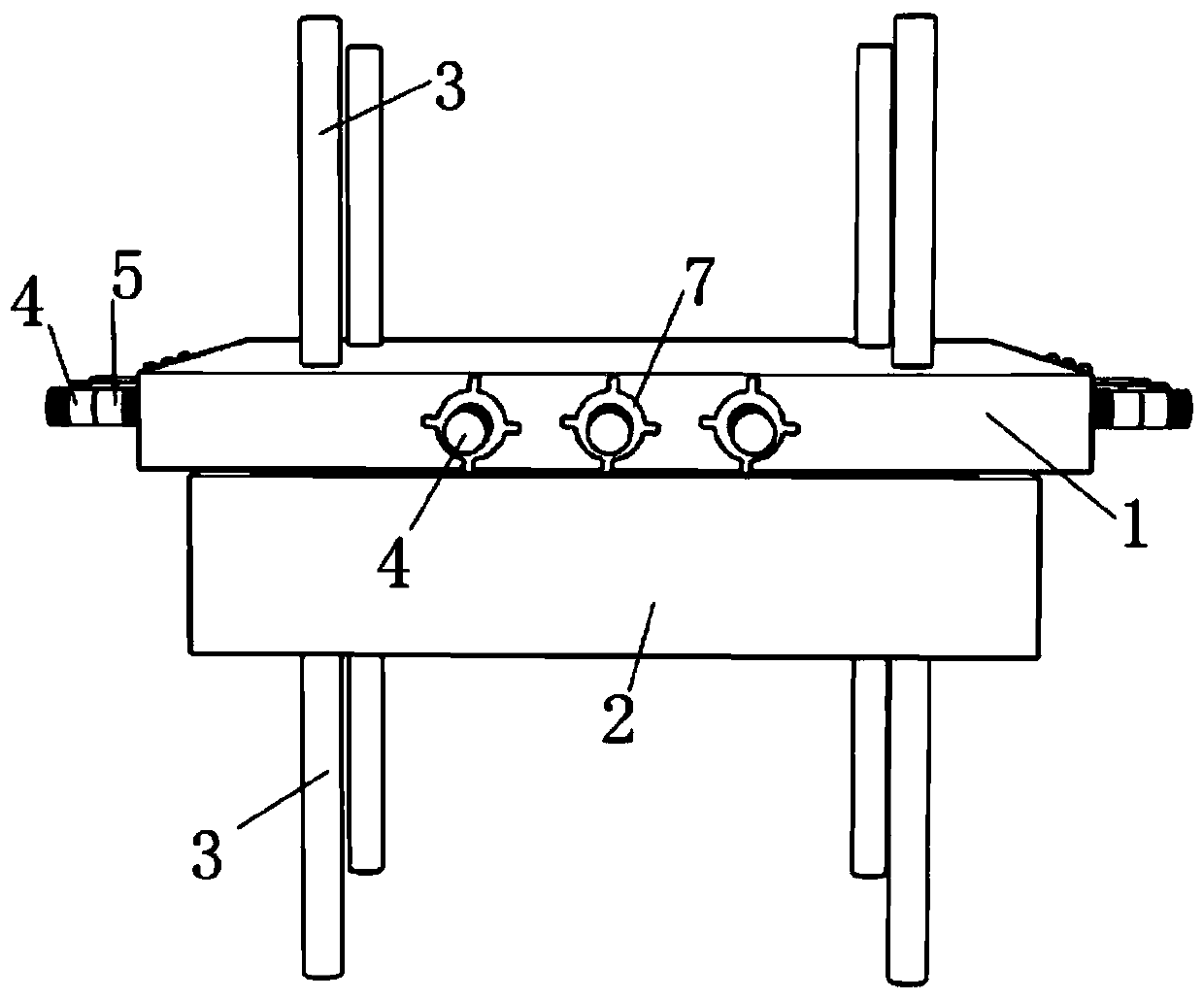

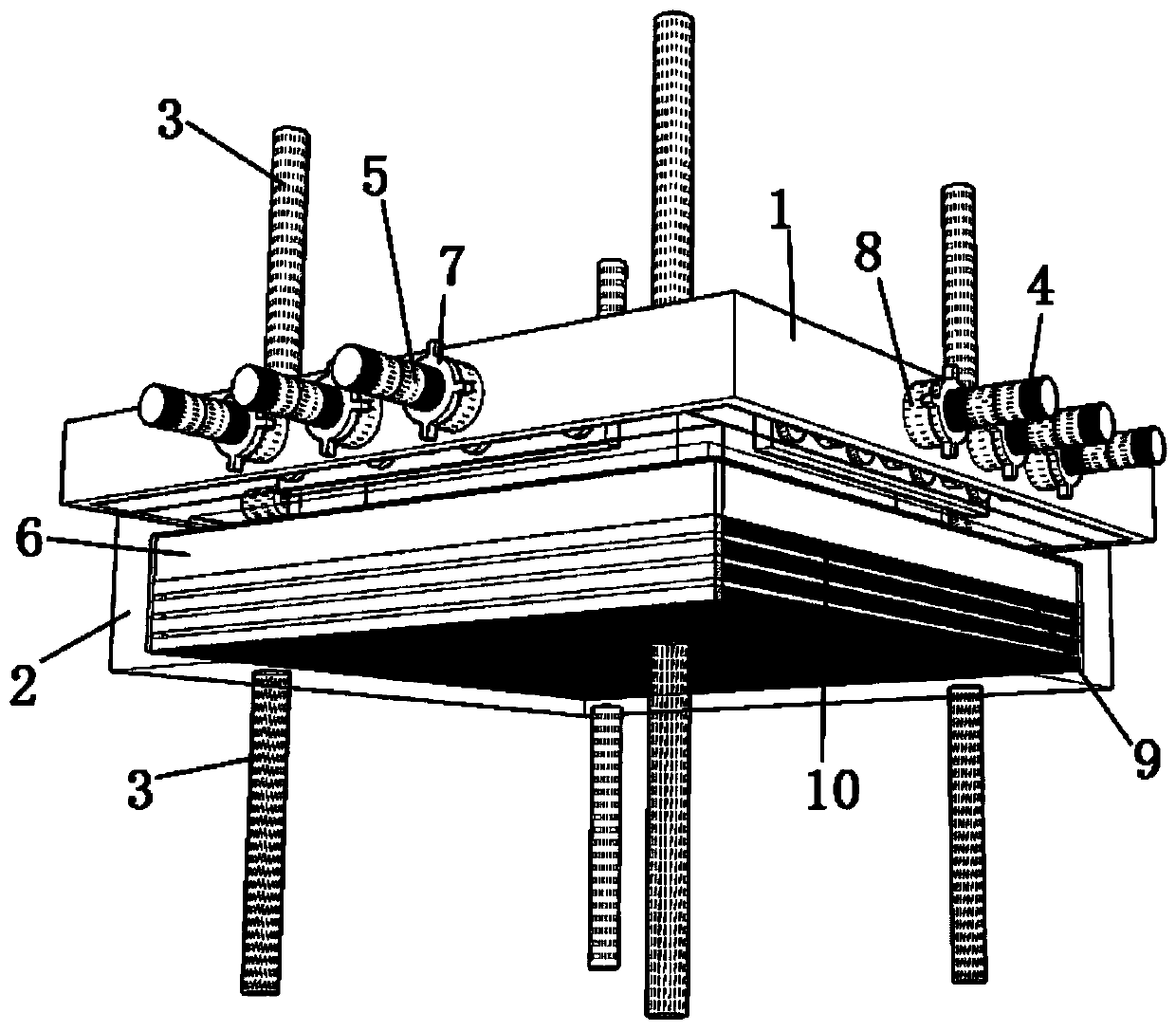

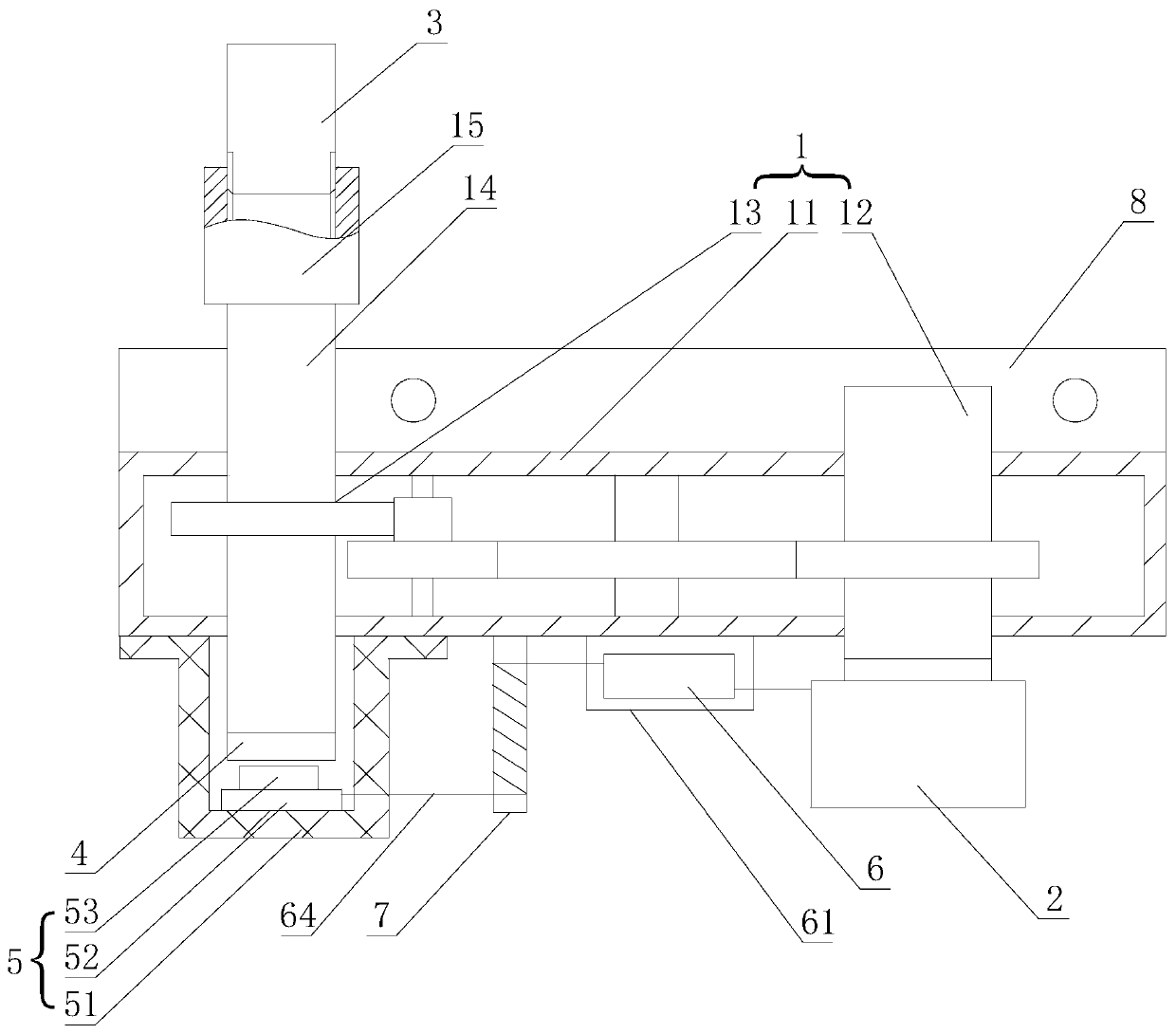

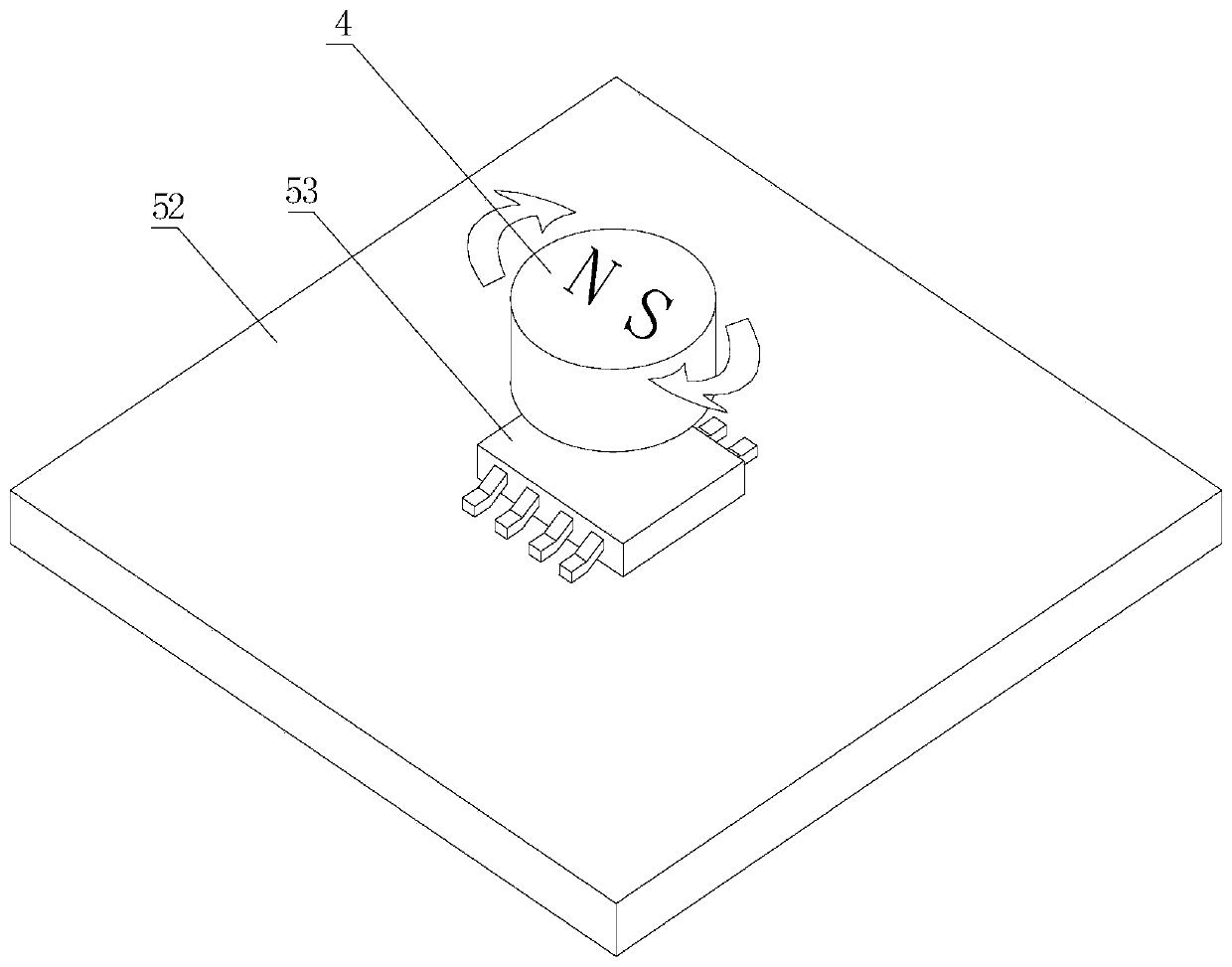

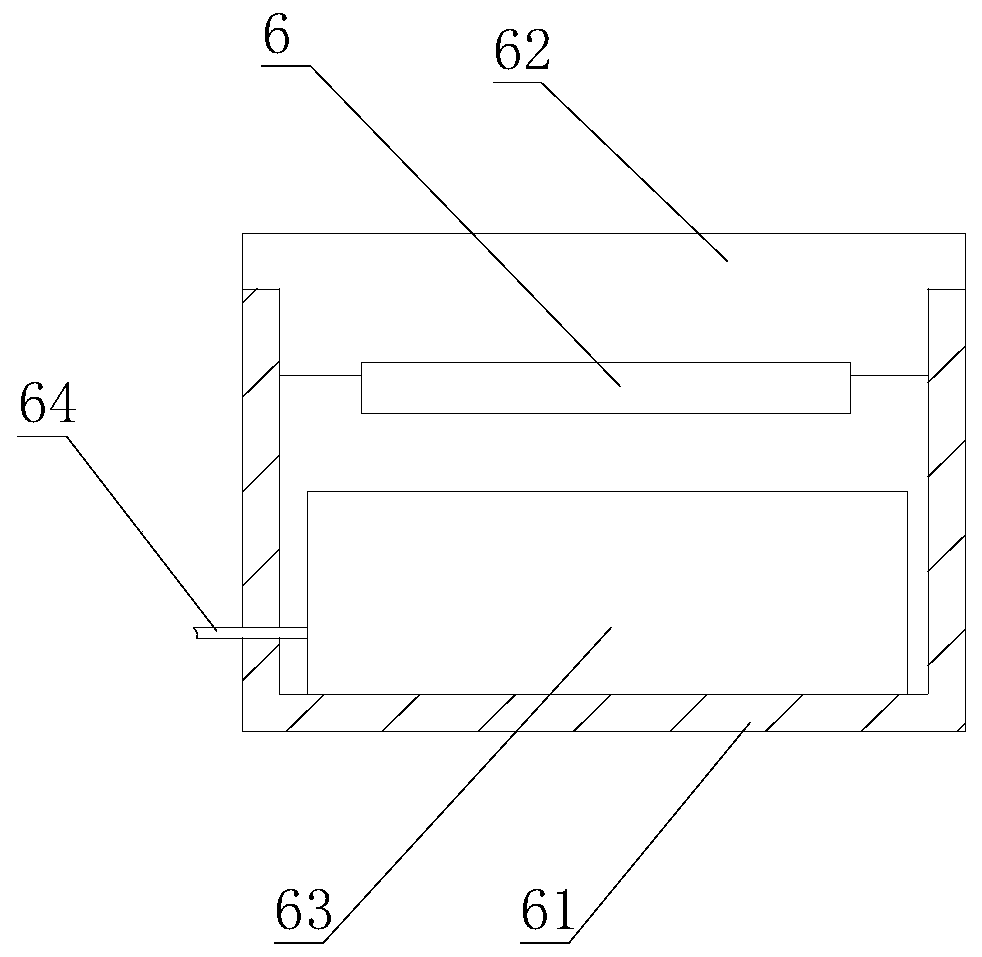

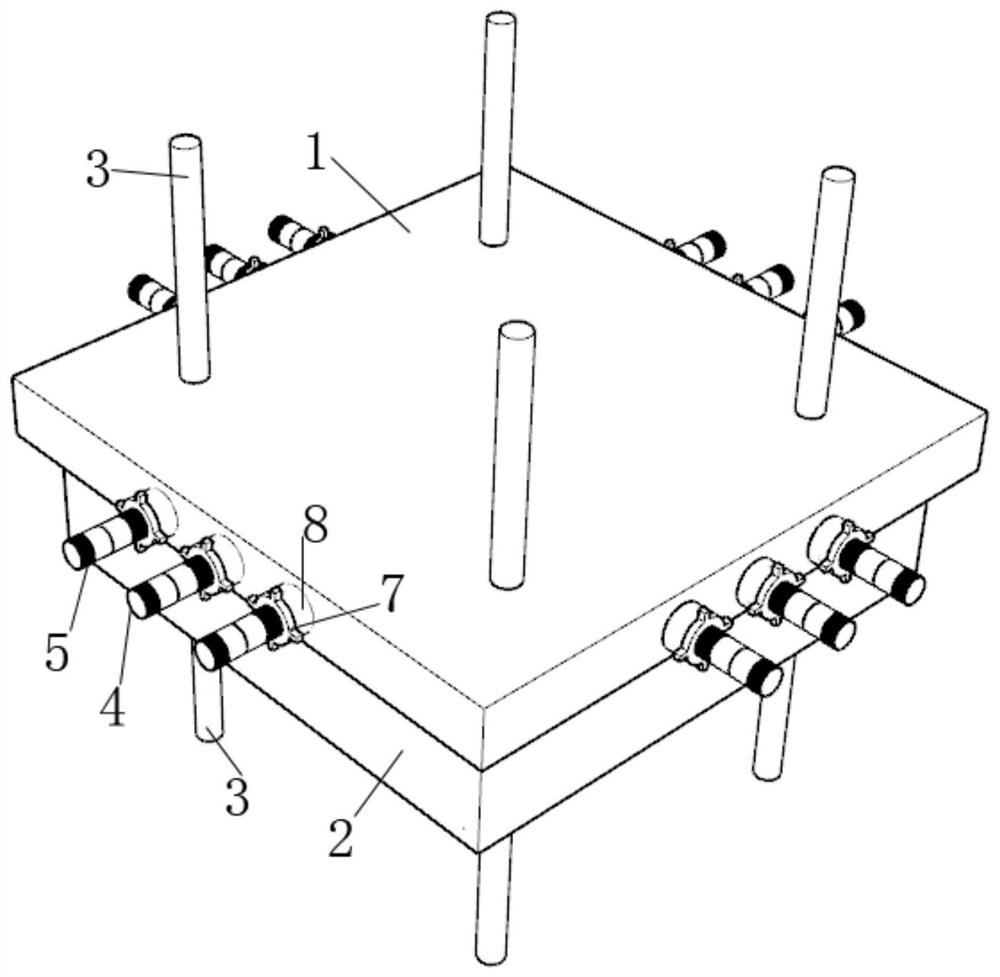

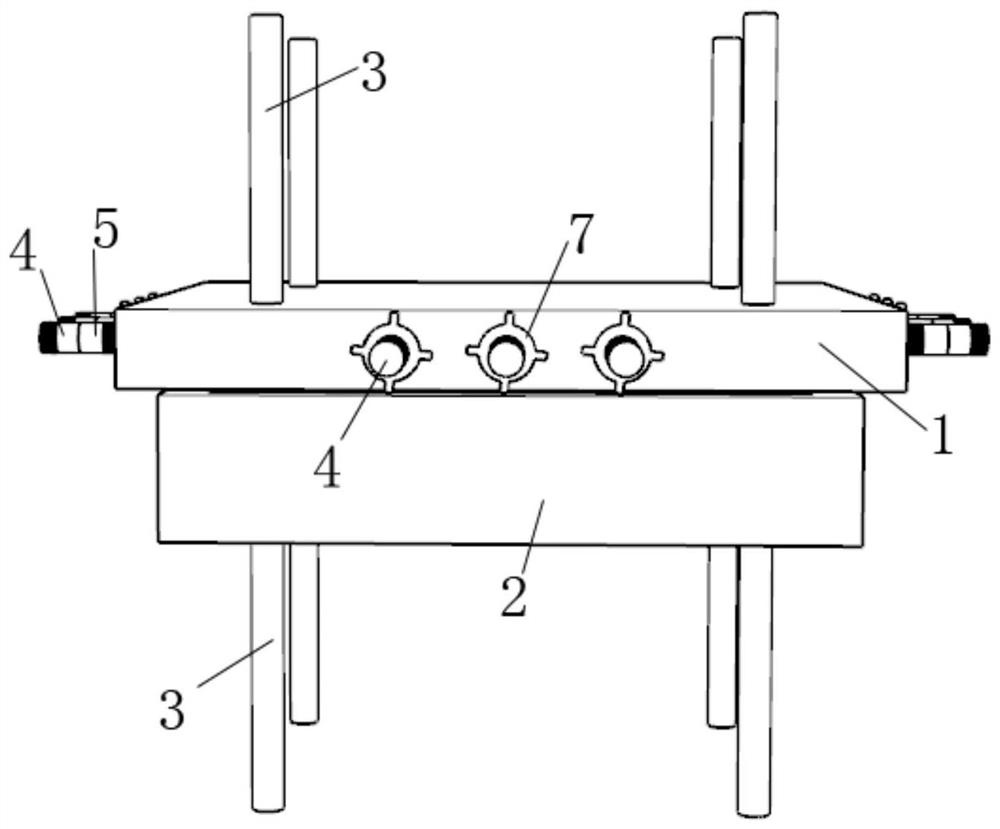

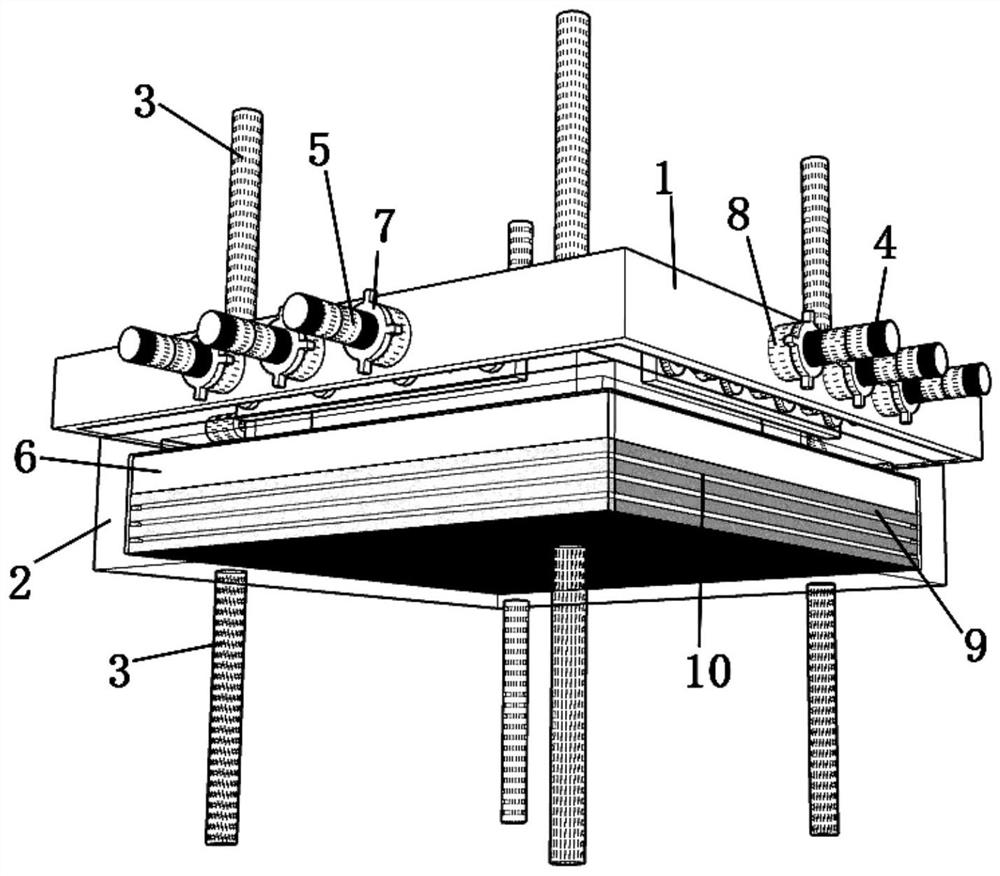

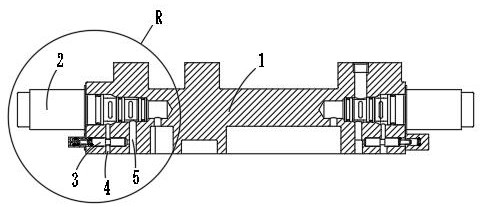

Normal stiffness and hysteresis characteristic test experimental device for double-bolt joint surface

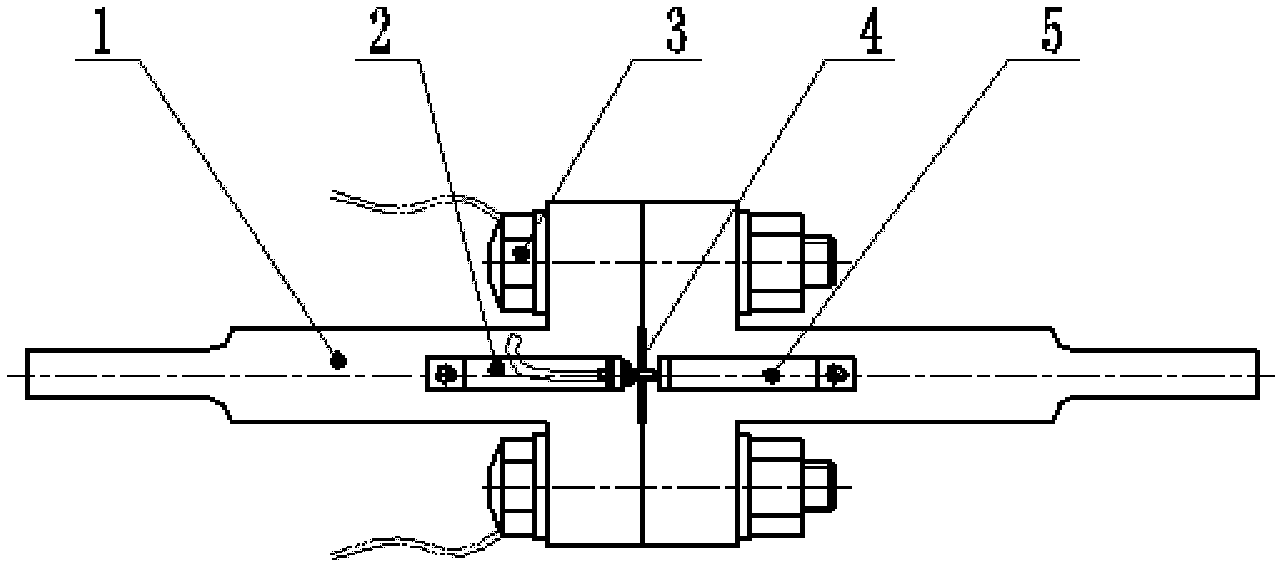

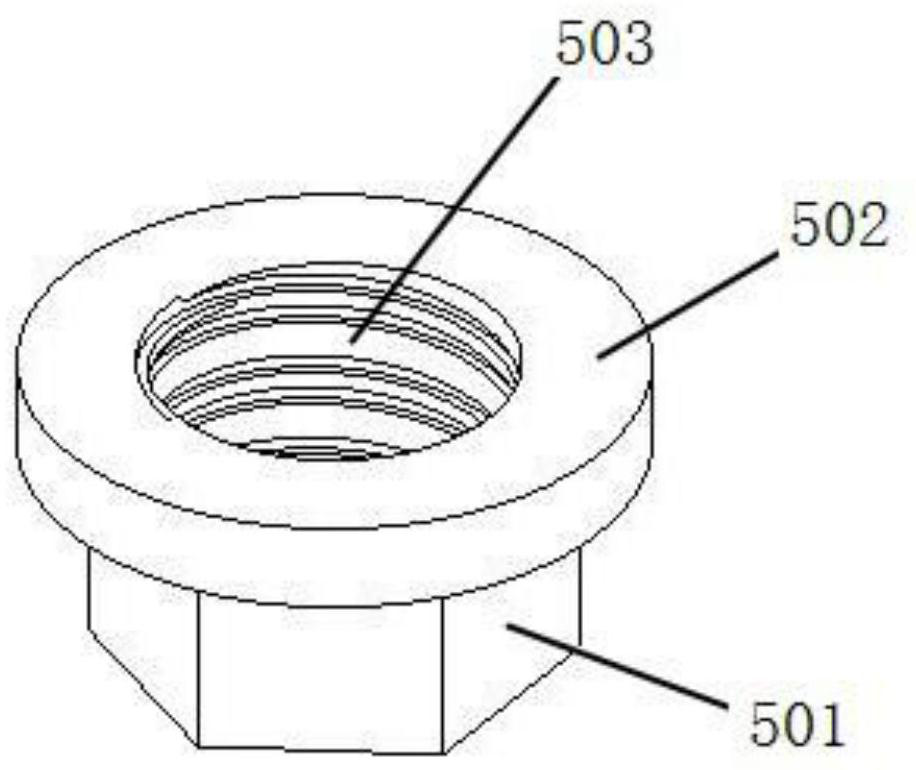

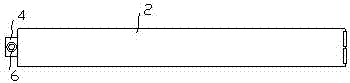

The invention relates to a joint surface normal mechanical property experimental device, in particular to a normal stiffness and hysteresis characteristic test experimental device for a double-bolt joint surface. The normal stiffness and hysteresis characteristic test experimental device for a double-bolt joint surface comprises two T-shaped rods 1, a locating bracket 2, bolts 3 for testing, an eddy current displacement sensor 4 and an eddy current sensing bracket 5, wherein the two T-shaped rods 1 are respectively connected with the locating bracket 2 and the eddy current sensing bracket 5 by locating bolts; the eddy current displacement sensor 4 is fixed on the locating bracket 2 and is used for measuring the deformation of the joint surface; the two T-shaped rods 1 are connected by two sets of high-strength hexagon headed bolt assemblies for steel structures, which pass through the through holes of the T-shaped rods, the top of each bolt is provided with a hole, a strain gauge is installed on the inner side of each hole, and the pretightening force is measured by the strain gauges. The experimental device has the characteristics of simple structure, convenience in assemble and disassemble and easiness in repeated test, and capability of accurately collecting the relevant data of mechanical properties of the bolt joint surfaces.

Owner:BEIJING UNIV OF TECH

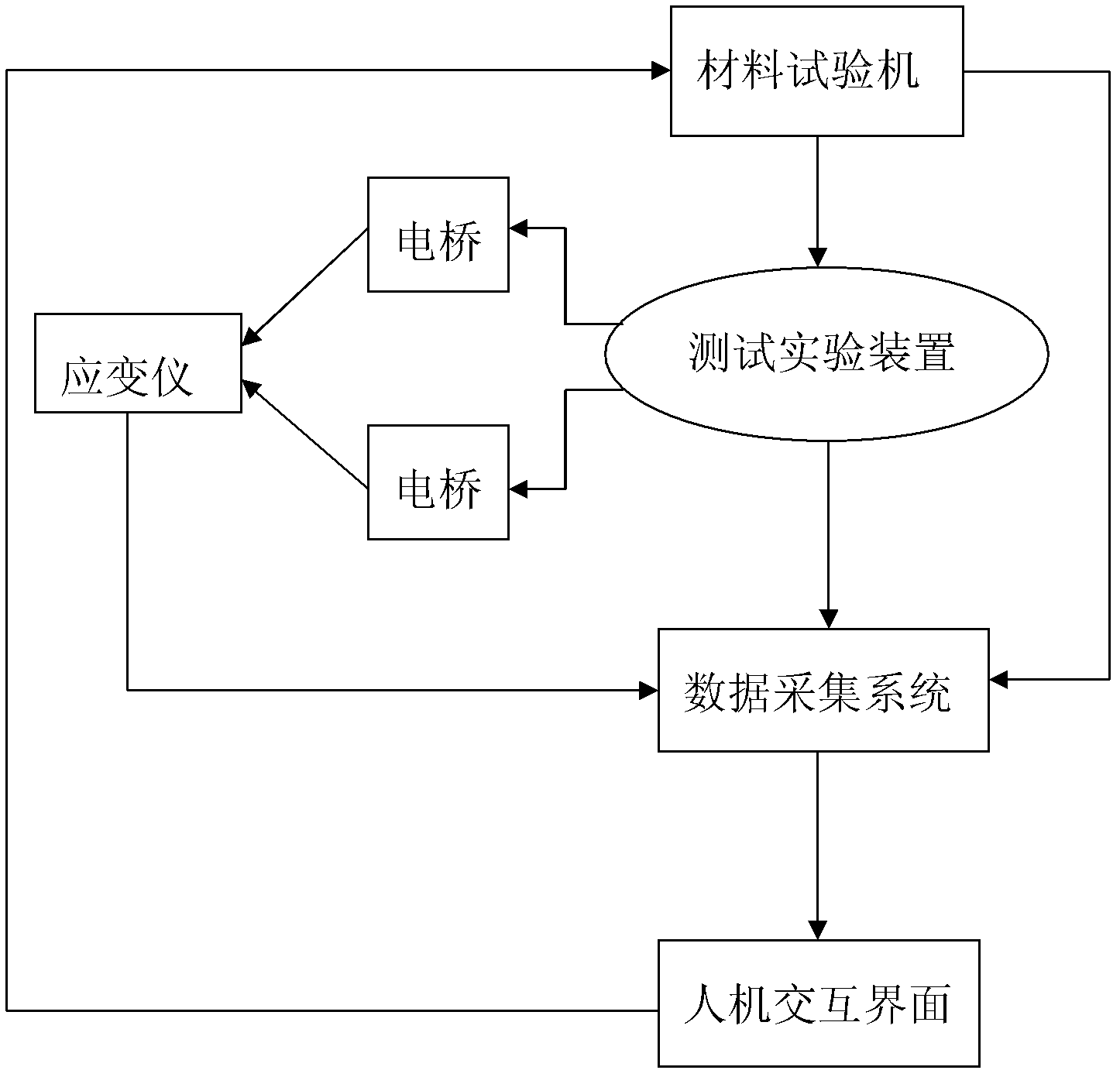

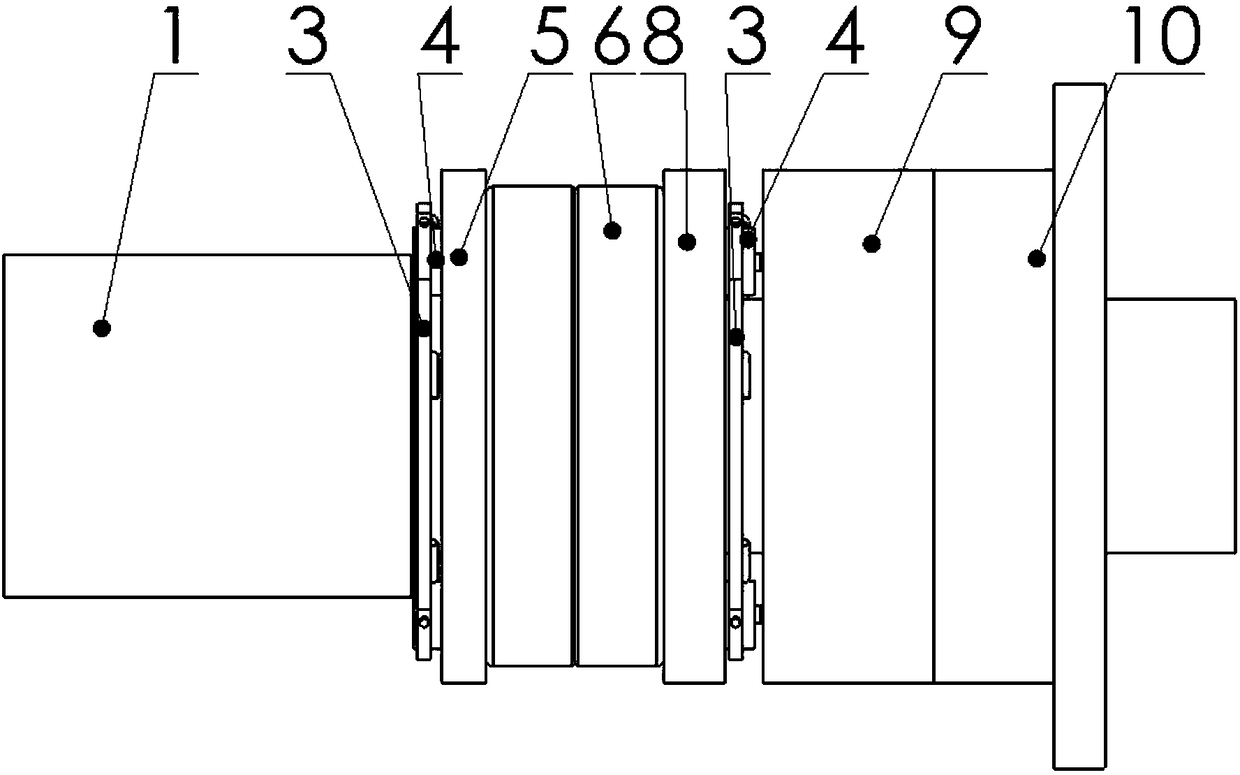

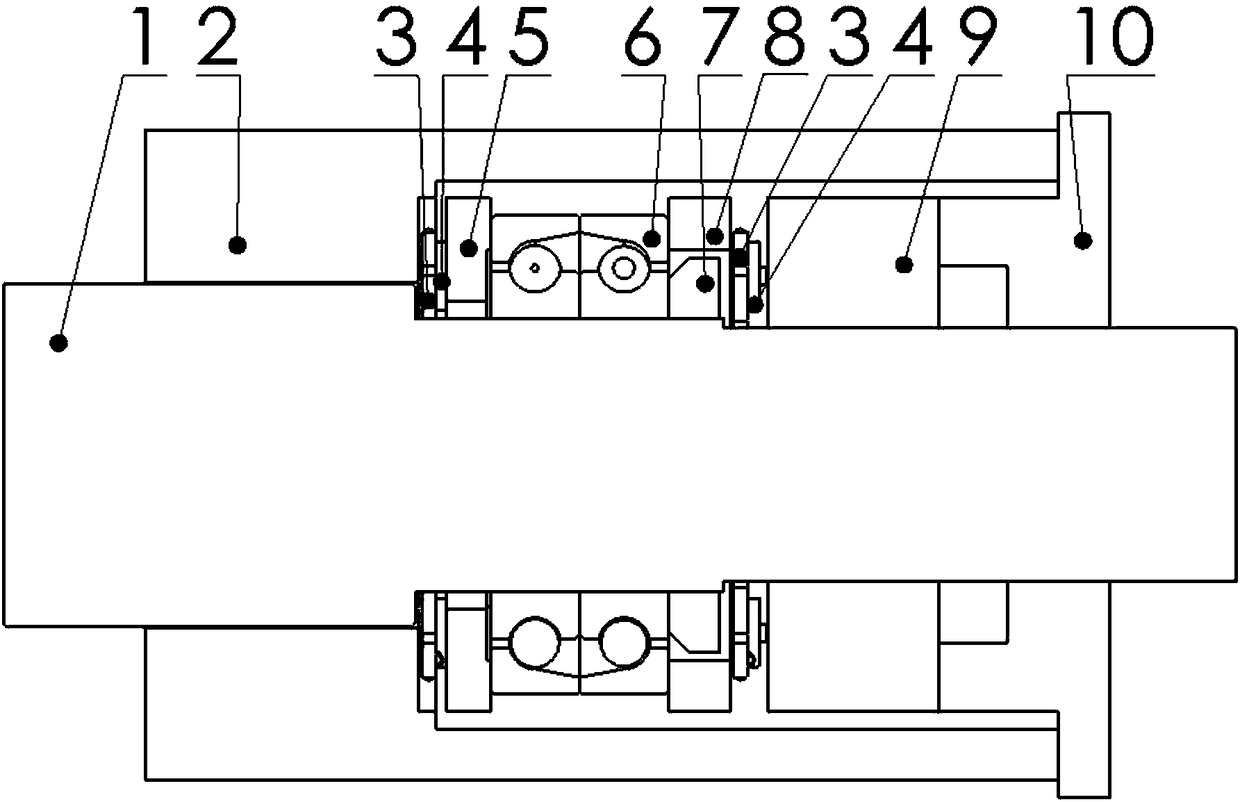

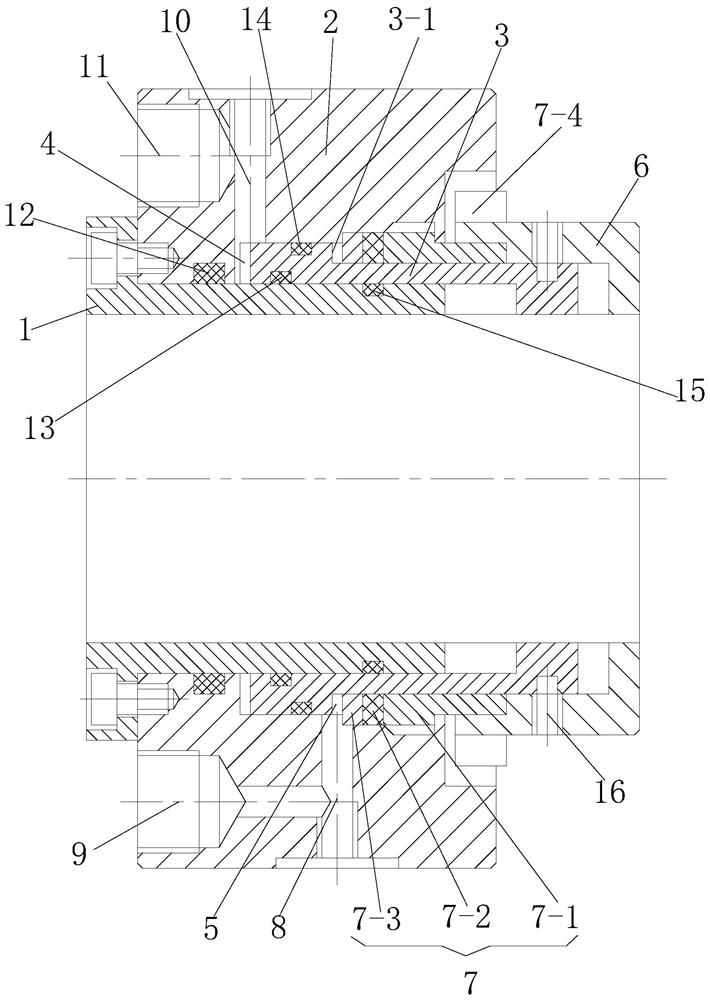

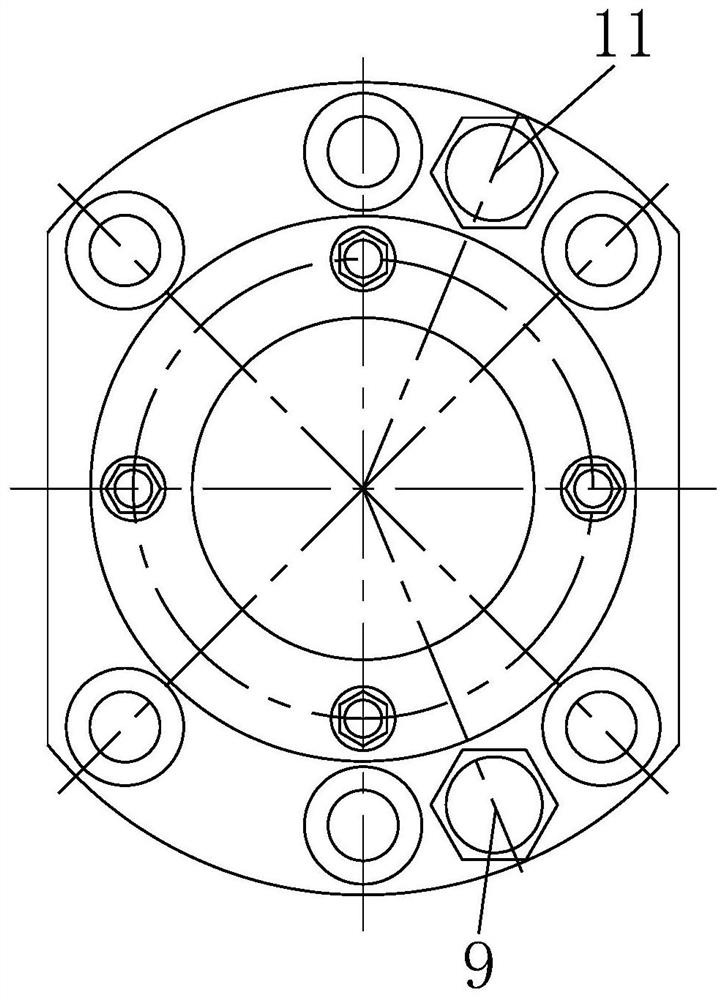

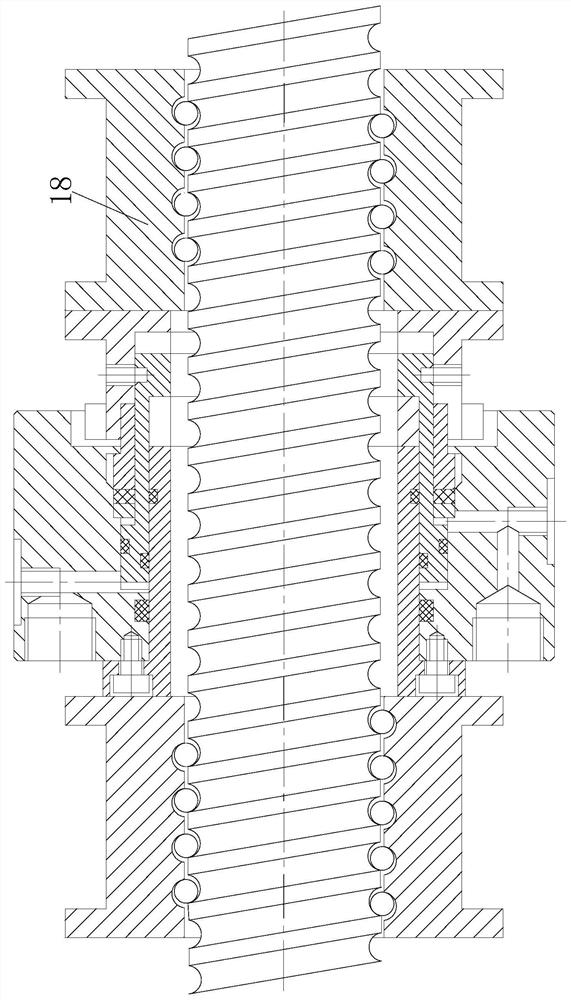

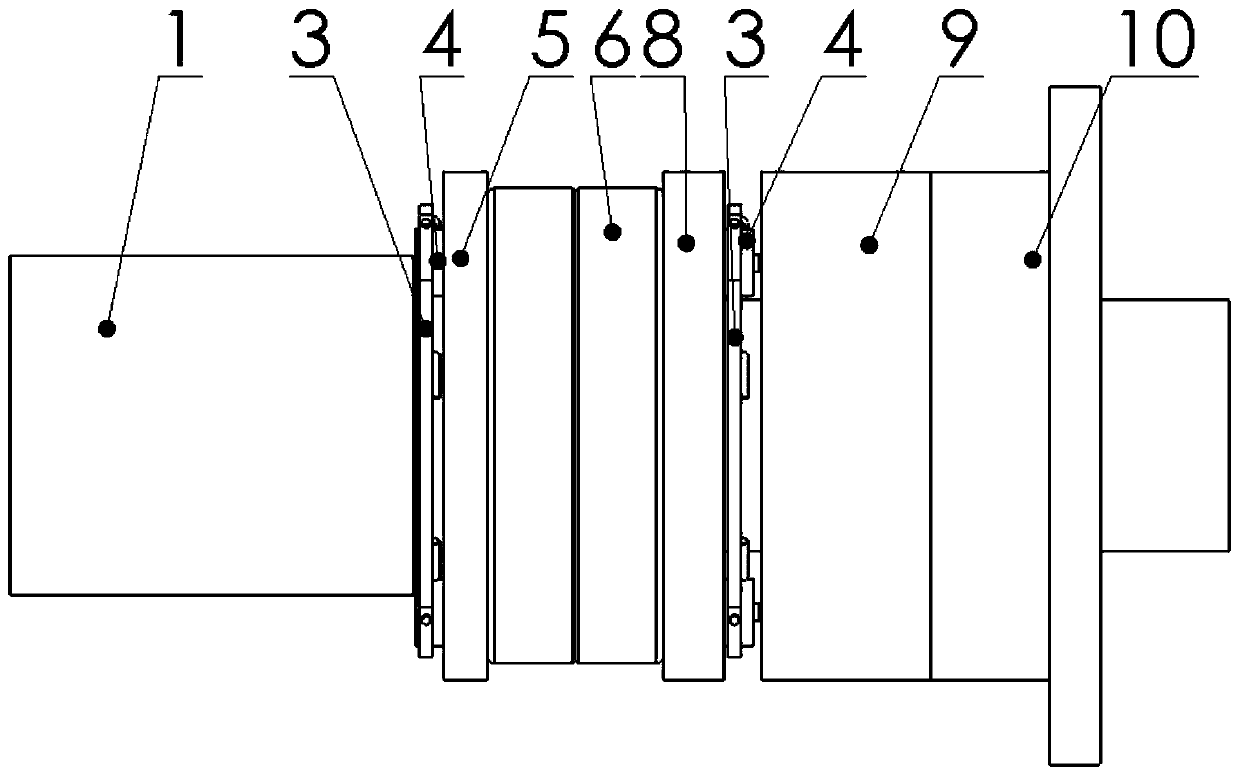

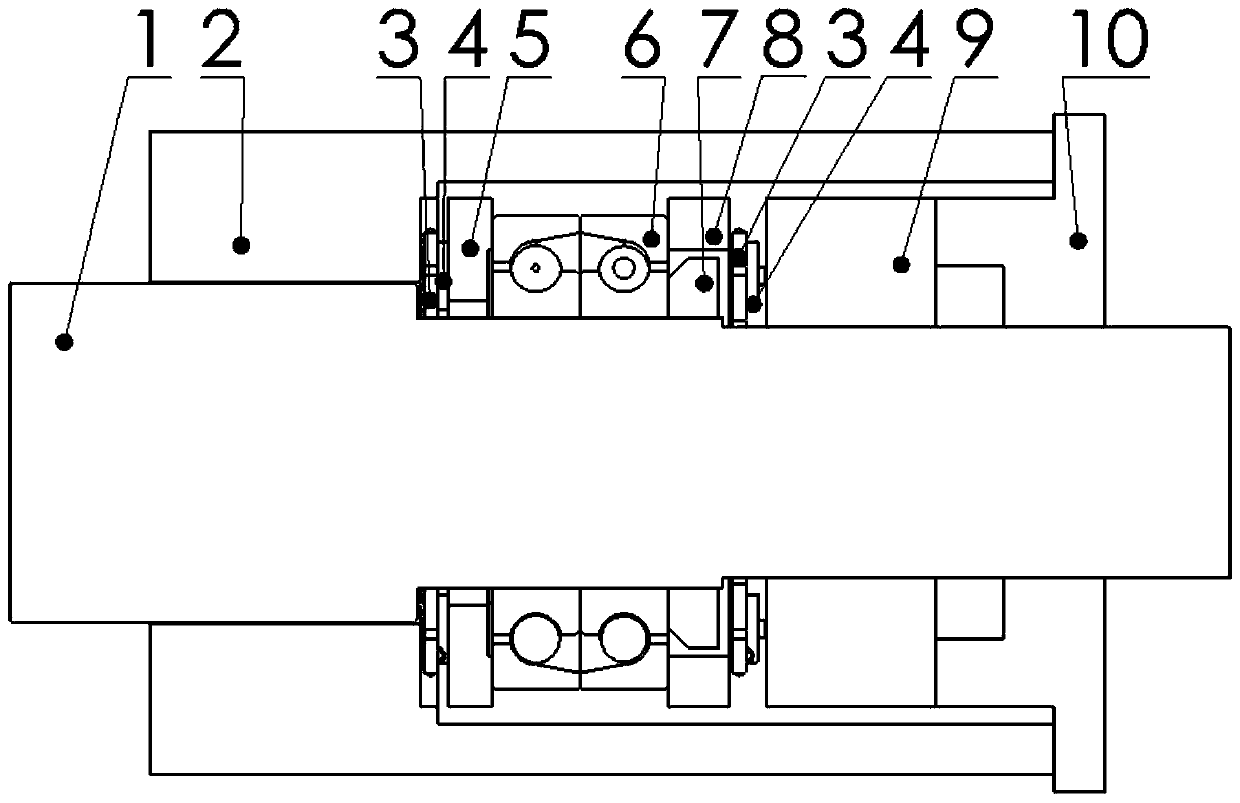

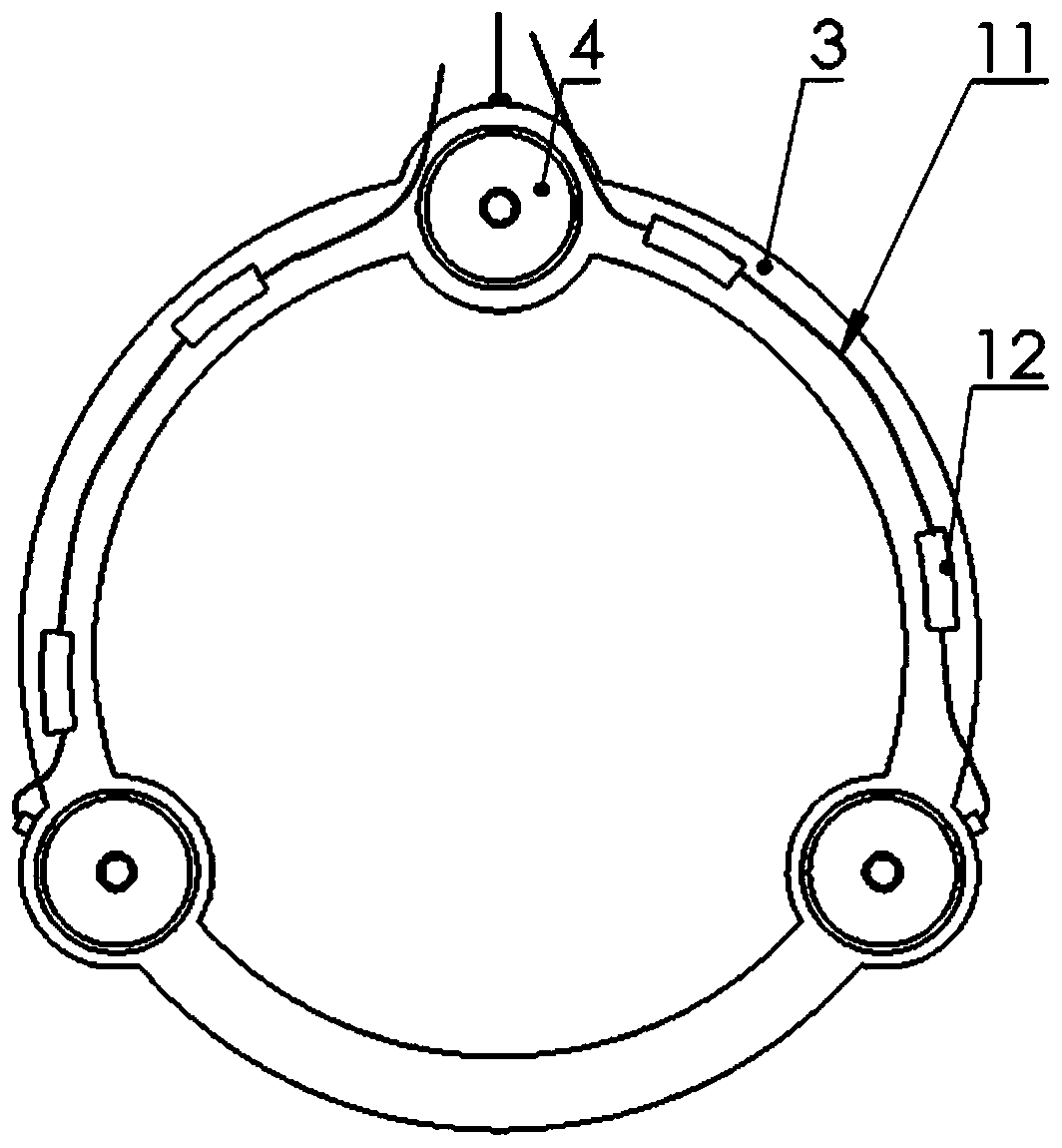

Measuring device and method for rotor axial force of double-screw compressor

ActiveCN108534940AStable and real-time measurementStable and real-time monitoringApparatus for force/torque/work measurementGas compressorThrust bearing

The invention discloses a measuring device and method for rotor axial force of a double-screw compressor. The measuring device mainly comprises two groups of stress sensors arranged on two sides of athrust bearing at an exhaust end of the double-screw compressor, each group of stress sensor assembly comprises three standard stress sensors, stress is uniform, stable measurement and real-time monitoring can be realized, and the three standard stress sensors are fixed on a corresponding bracket and are mounted and positioned by through holes. The measuring device adopts two-way force measurementdesign, can accurately measure the direction and magnitude of axial force without interference to operation of a rotor.

Owner:XI AN JIAOTONG UNIV

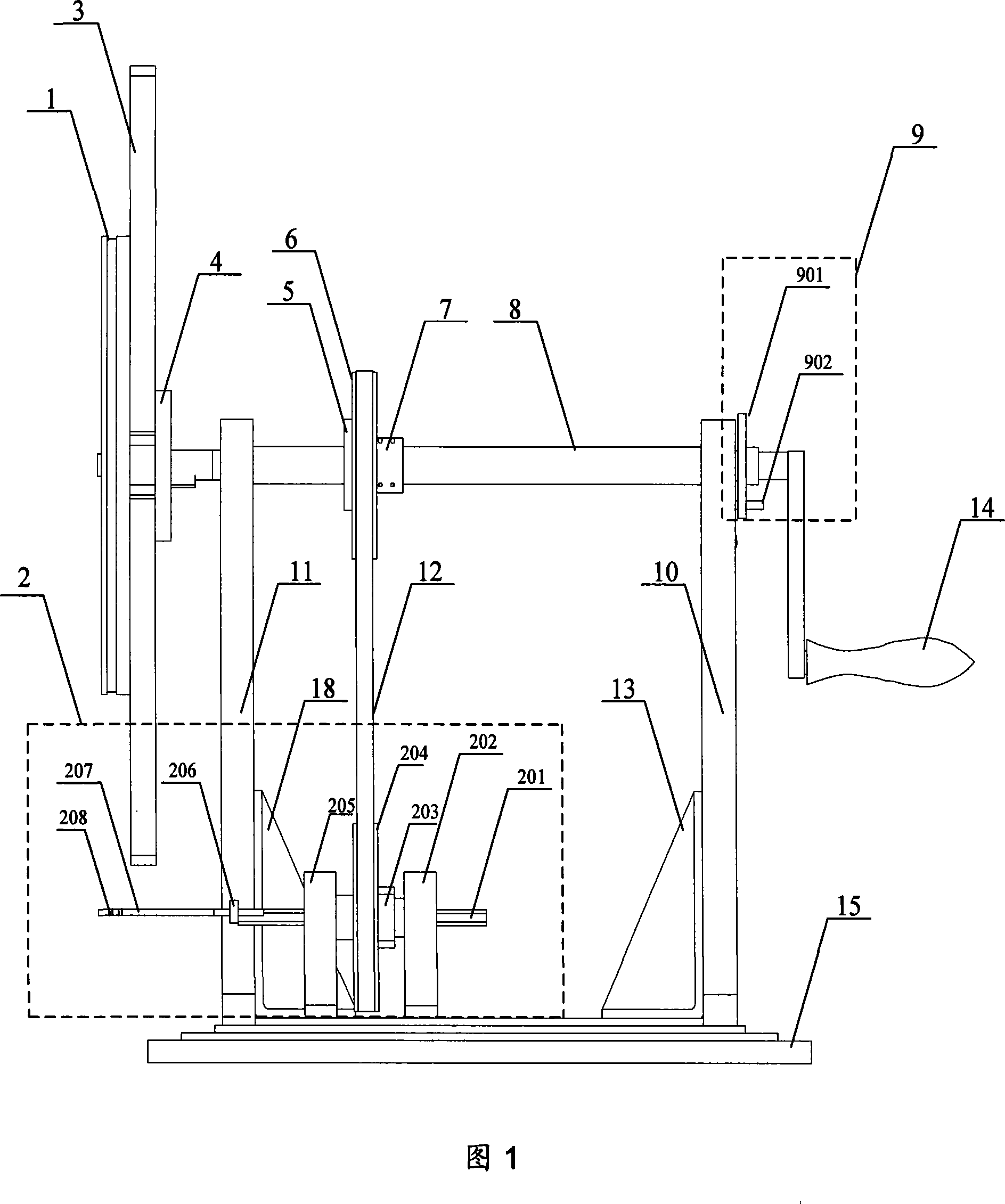

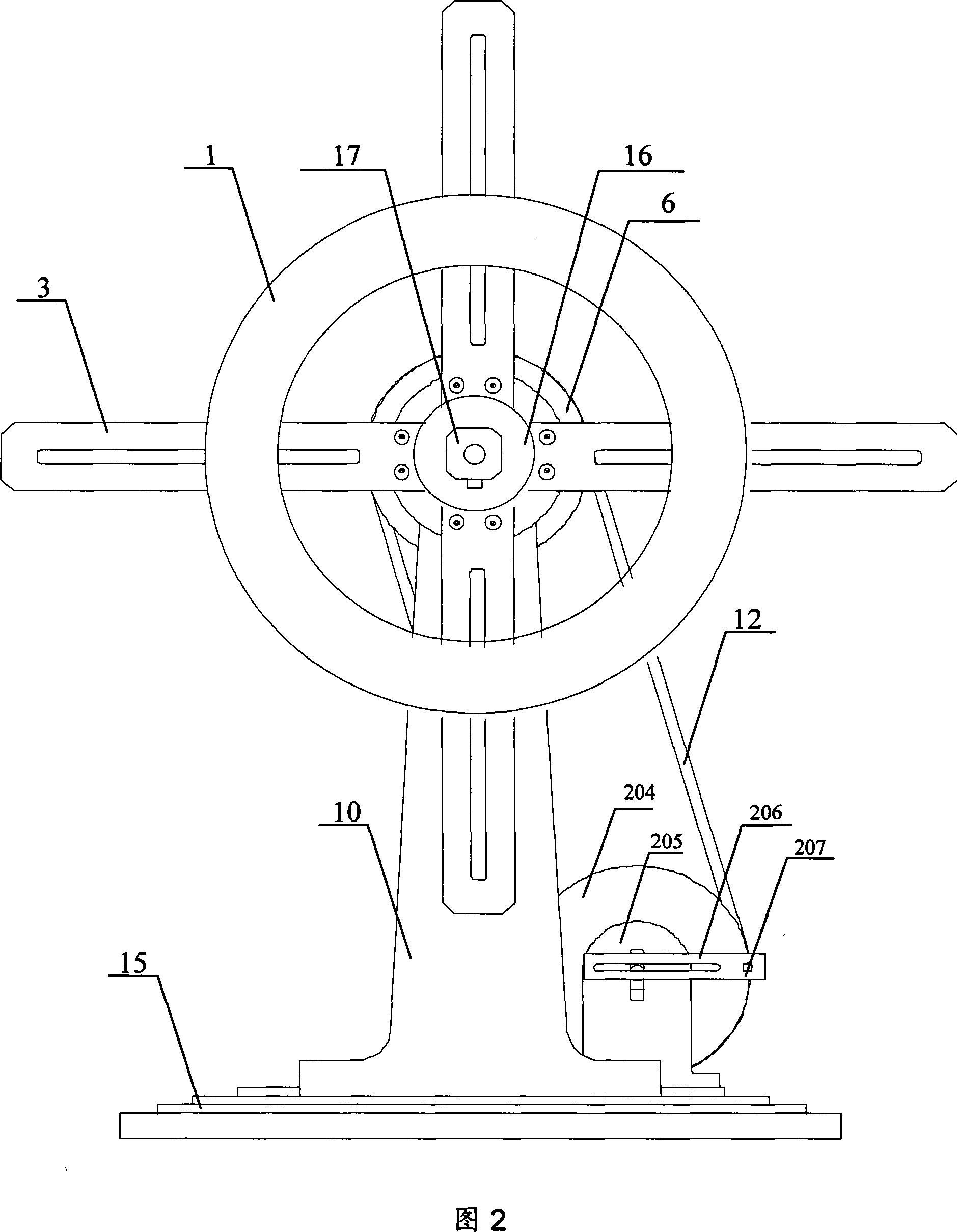

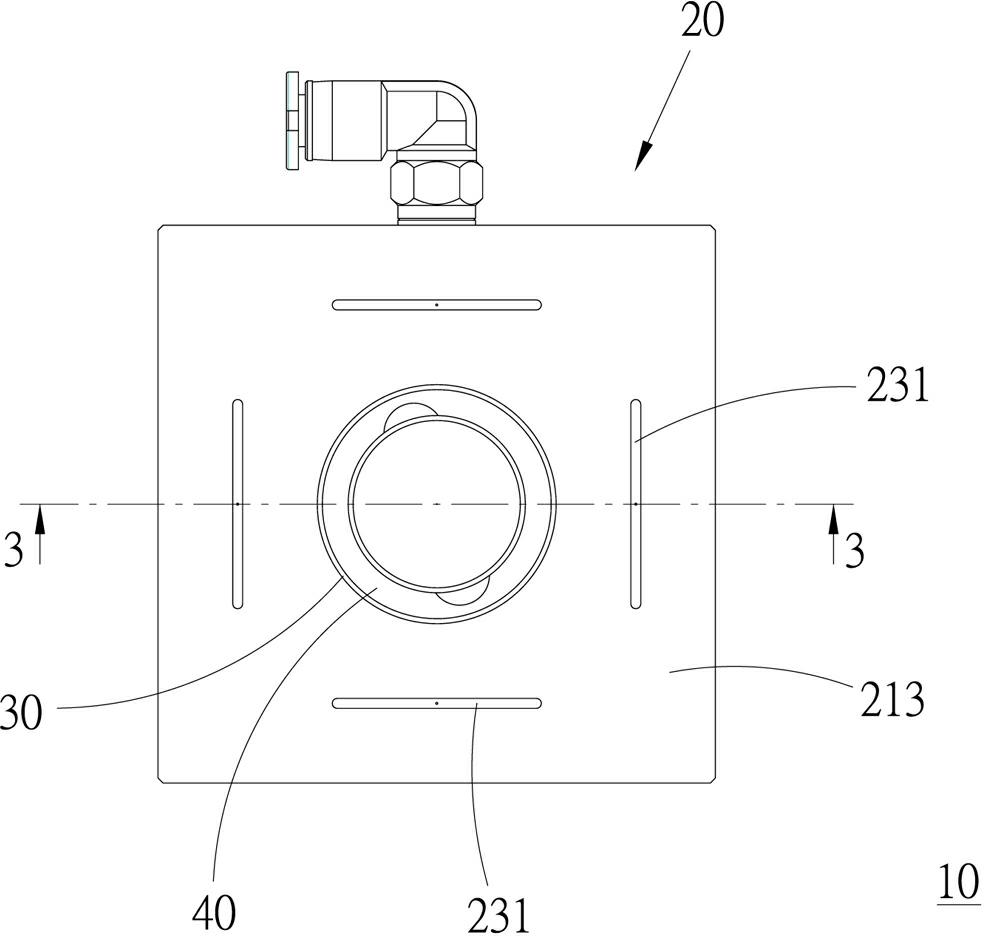

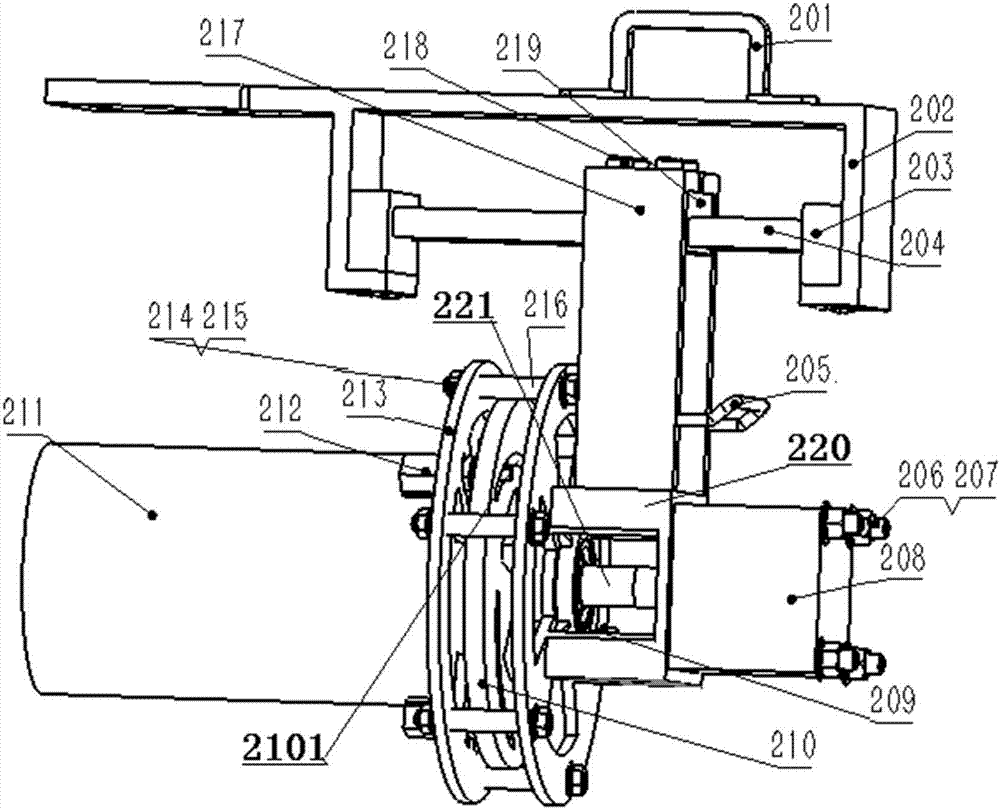

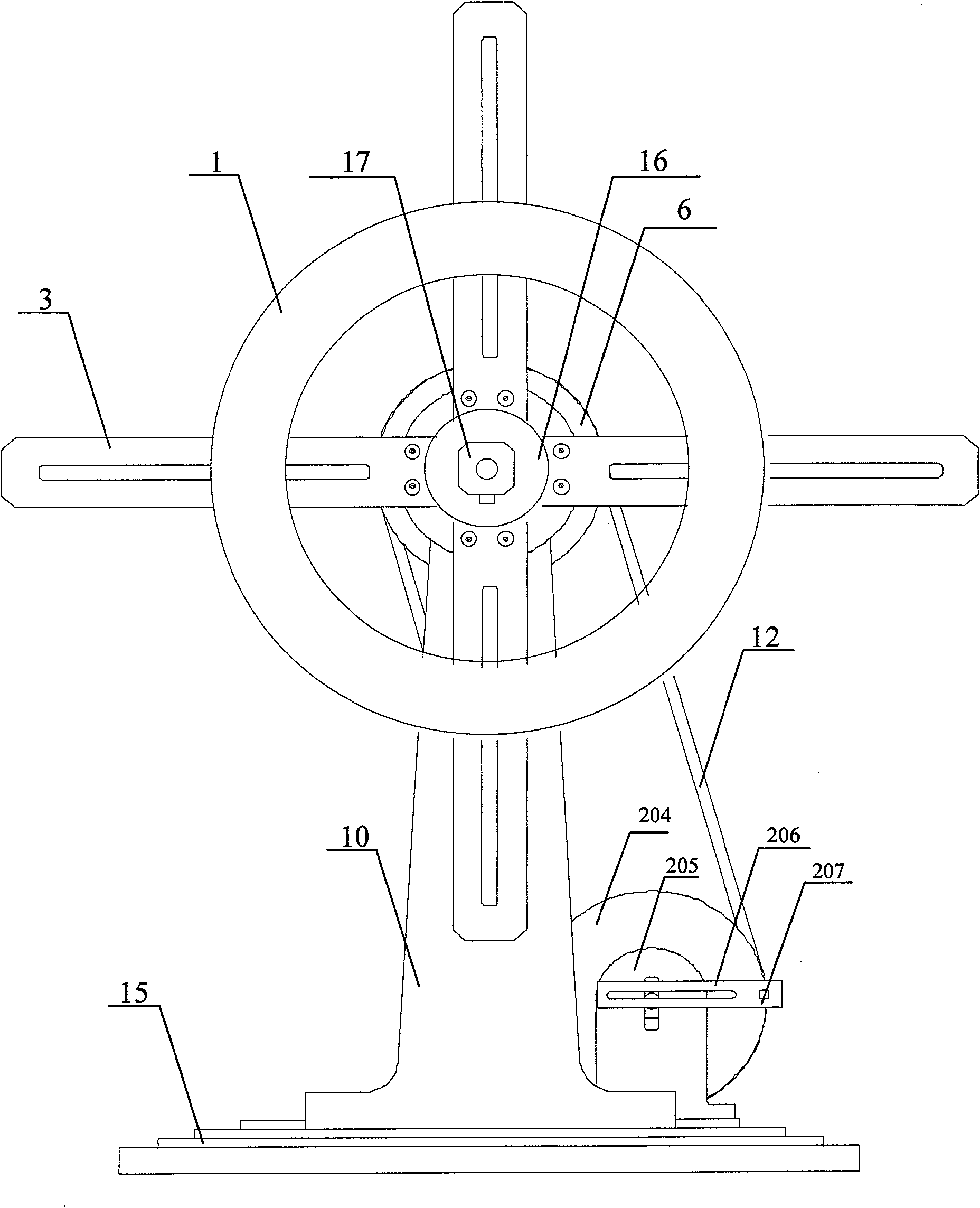

Optical fibre electric current sensor sensitive coil winding equipment

ActiveCN101216507AControl preloadPrecise control of winding pitchCurrent/voltage measurementVoltage/current isolationFiberDrive wheel

Sensitive coil winding equipment of an optical fiber current sensor comprises a nut, a pressure plate, a frame arrangement base, a drive wheel, a lock mechanism and a handle, which are sequentially arranged on a spindle from left to right, wherein a sensitive coil frame is fixed on the frame arrangement base by the nut and the pressure plate; the frame arrangement base and the drive wheel are arranged on the spindle through a coupling; a spindle bearing base is fixed on a pedestal through a support frame and are respectively positioned on both sides of the drive wheel to fix the spindle; the spindle and the coil frame can be driven to rotate by shaking the handle and further to drive the drive wheel to rotate and drive a fiber guide mechanism to operate through a transmission belt; and the lock mechanism is arranged between the handle and the spindle bearing base close to the handle for locking the rotation of the spindle, so that the coil frame is kept as the original position. The winding equipment has the advantages of no external torsion stress to optical fiber, controllable fiber tension, adjusting fiber pitch, simple operation, etc., and can be used for winding sensitive coil of interferometric optical fiber current sensor to ensure the performance uniformity of the sensitive coil.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

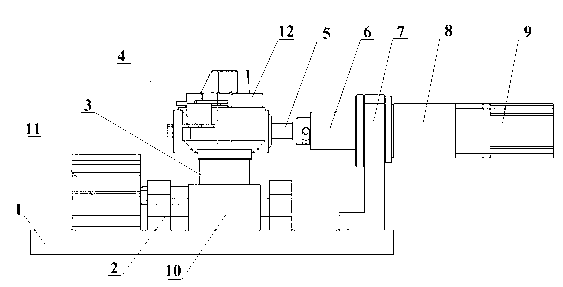

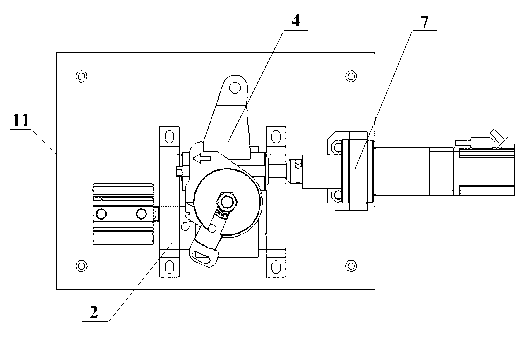

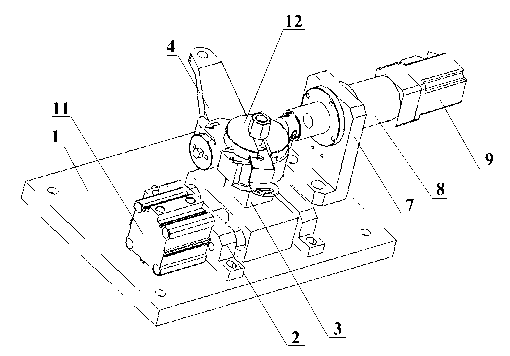

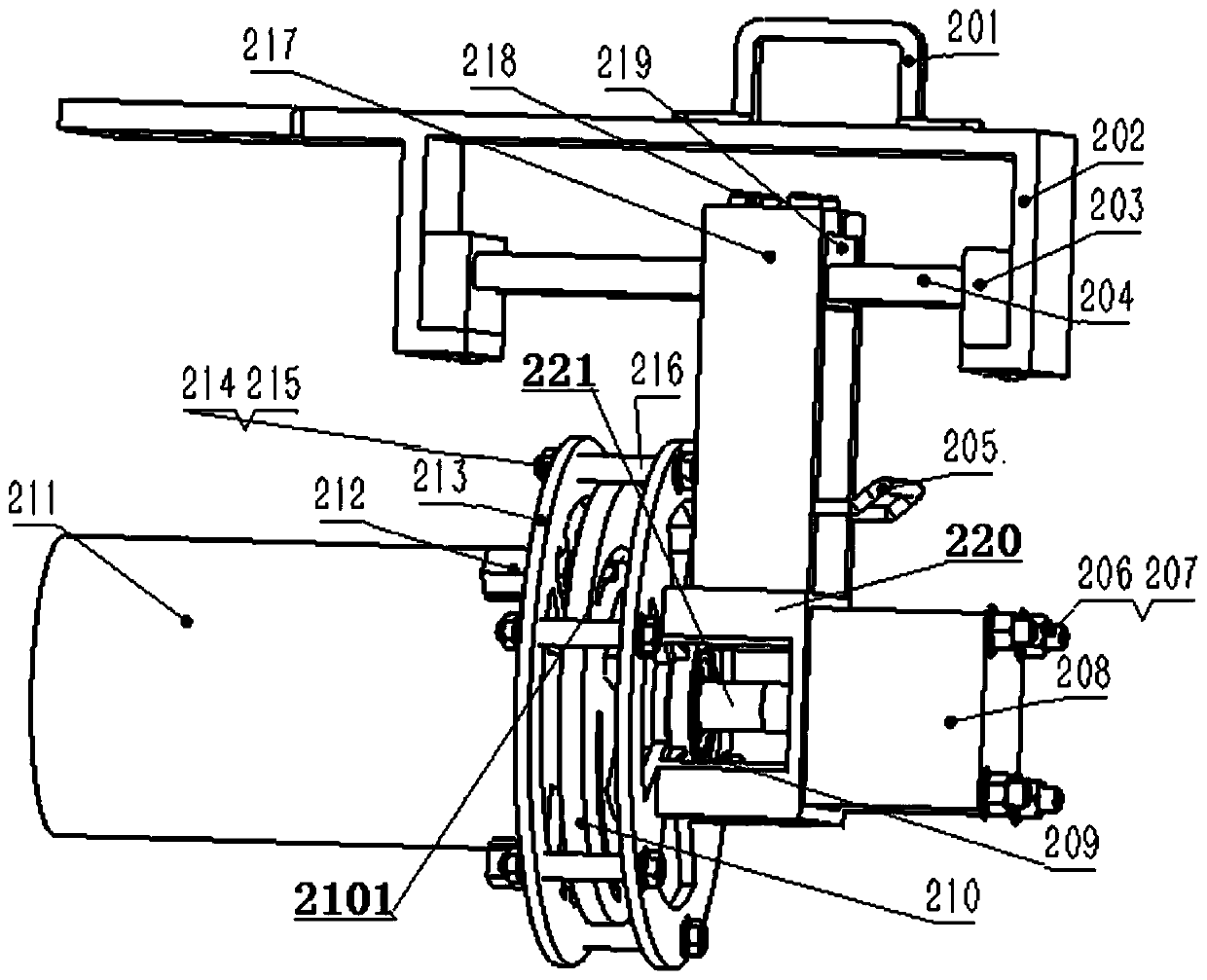

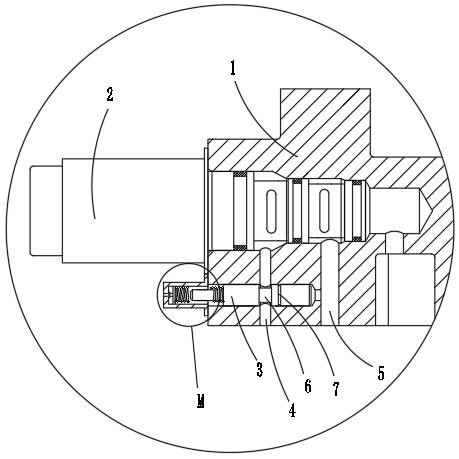

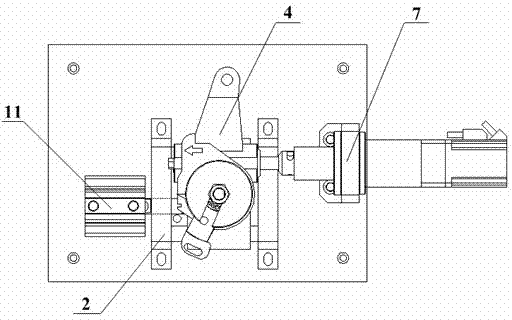

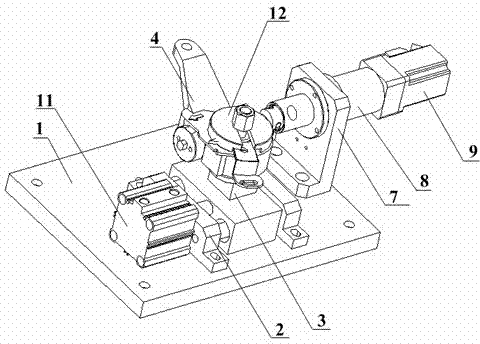

Regulating device for rear end cover of automotive automatic slack adjuster

The invention discloses a regulating device for a rear end cover of an automotive automatic slack adjuster. The regulating device is characterized in that an automatic slack adjuster bushing is sleeved on an output shaft of a clamping cylinder disposed on an automatic slack adjuster mounting base, the automatic slack adjuster is pressed by a pressure plate after the clamping cylinder is started, the automatic slack adjuster mounting base is horizontally adjusted by starting a horizontal movement cylinder, a hexagon hole of the rear end cover of the automatic slack adjuster is right aligned with and firmly abutted to a hexagon bushing, a servo motor is started to drive the hexagon bushing to rotate after rotation angle of the servo motor is set, the hexagon bushing drives the rear end cover of the automatic slack adjuster to rotate, tension of a spiral compression spring mounted inside the automatic slack adjuster is changed and adjusted, the horizontal movement cylinder is started to retreat to the original horizontal position after adjusting, and the clamping cylinder is then started to release the automatic slack adjuster to end the adjusting process. Through the regulating device for adjusting the rear end cover of the automatic slack adjuster, pretension of the spiral compression spring of the automatic compression spring can be controlled accurately, labor action is saved, labor intensity is reduced greatly and assembly efficiency is improved.

Owner:CHINA JILIANG UNIV

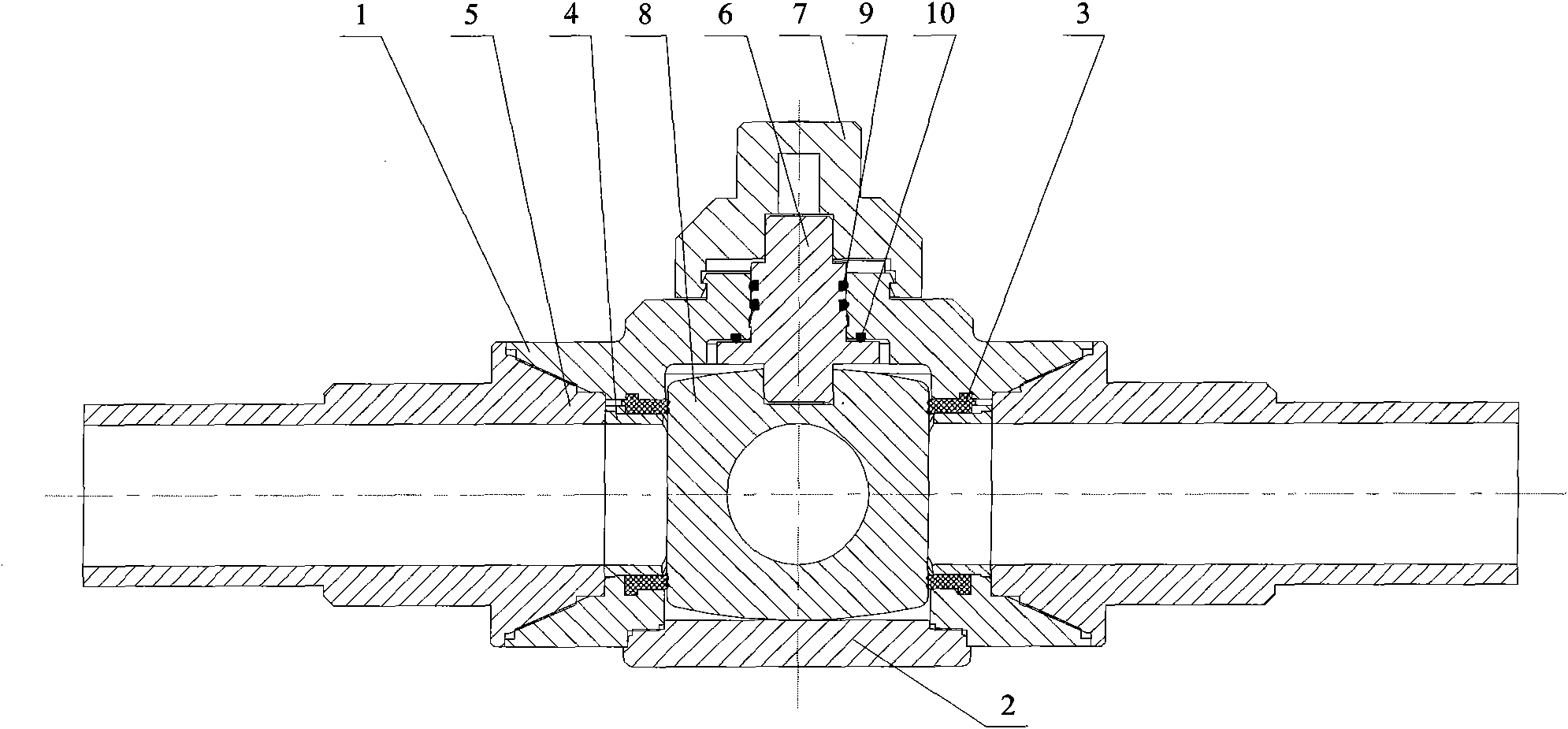

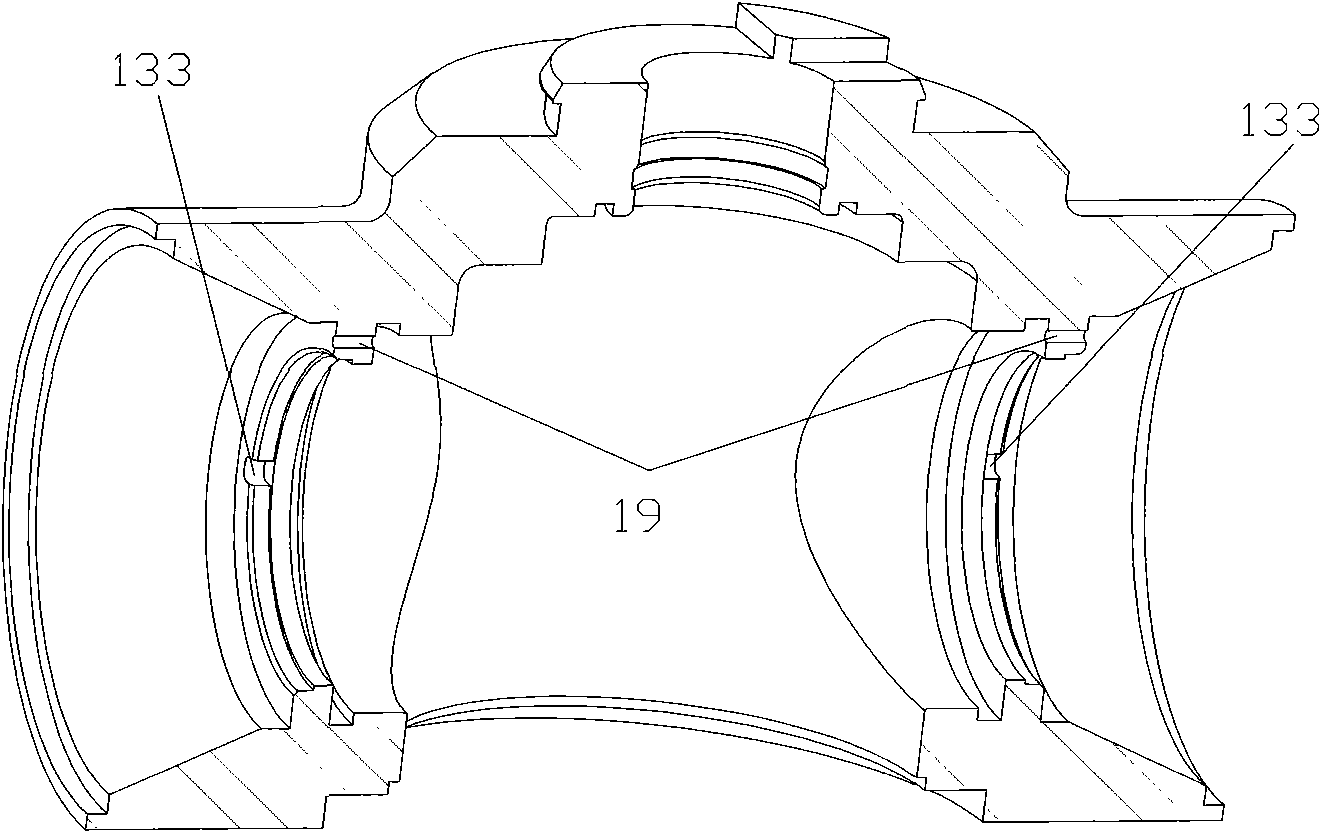

Downloading type plunger valve

InactiveCN101672378APrecise control of axial distanceControl torquePlug valvesNon-disconnectible pipe-jointsMechanical engineeringPlunger

The invention relates to a downloading type plunger valve comprising a valve body, a plunger sealing ring, a support ring of the plunger sealing ring, a left connection tube, a right connection tube,a valve rod, a valve rod cap and a plunger, wherein a plunger chamber is arranged in the valve body and is a cylindrical hollow cavity which is longitudinally arranged, the plunger is arranged in theplunger chamber and is provided with a flow passage hole in a direction vertical to the axis of the plunger, the valve body is provided with an installation hole below the plunger chamber, and the installation hole is used for installing the plunger sealing ring and the plunger in the plunger chamber; the plunger valve also comprises a valve bottom cover, wherein the valve bottom cover correspondsto the installation hole, covers the installation hole and is in mutual butt fusion with the valve body.

Owner:GUANGDONG LIANSU TECH INDAL

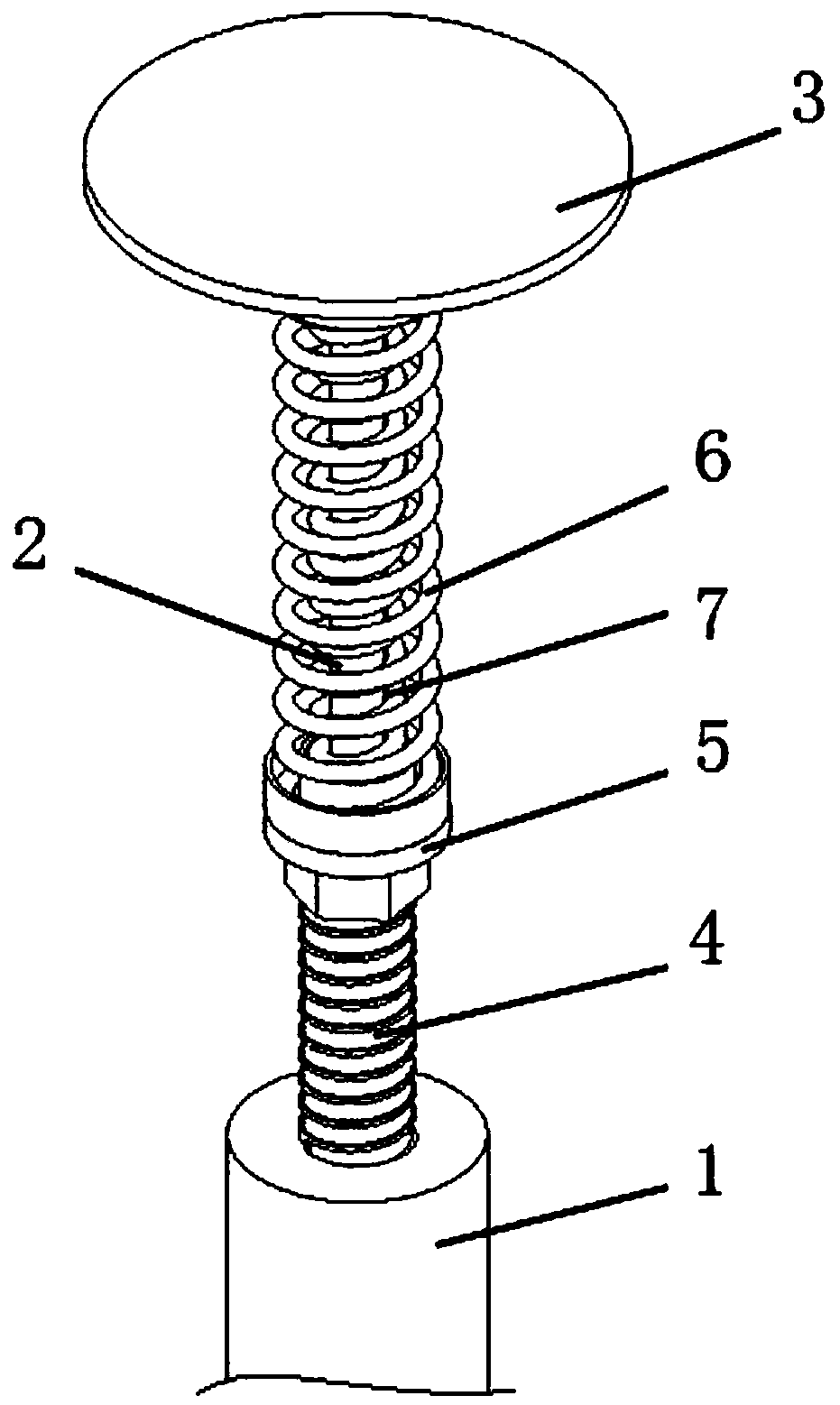

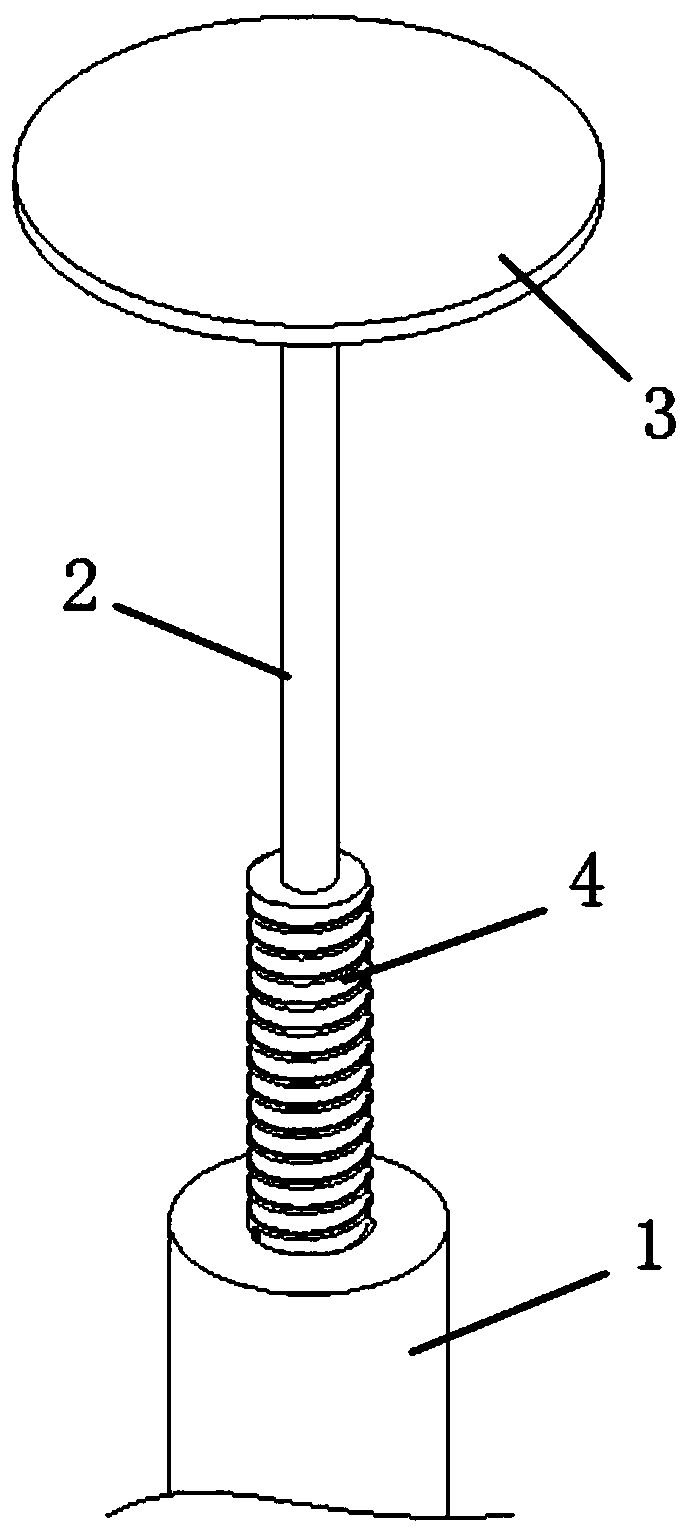

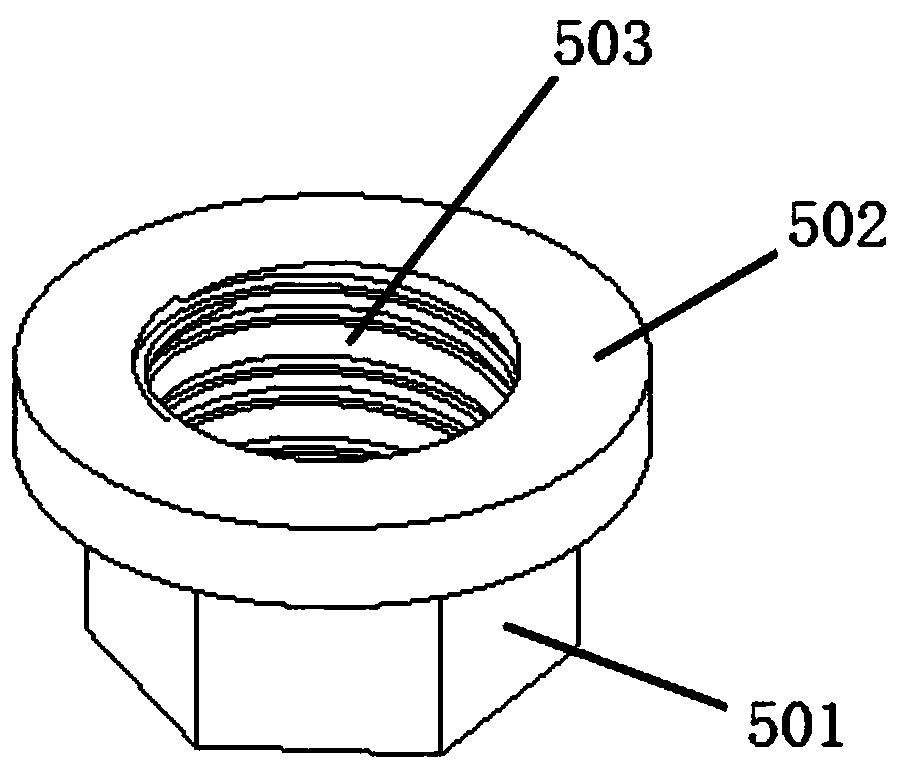

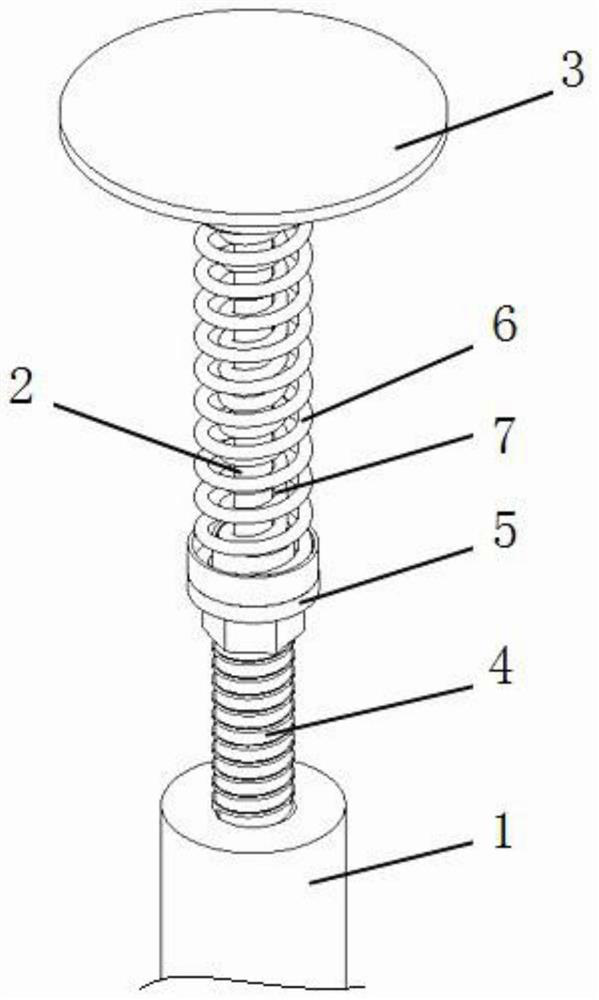

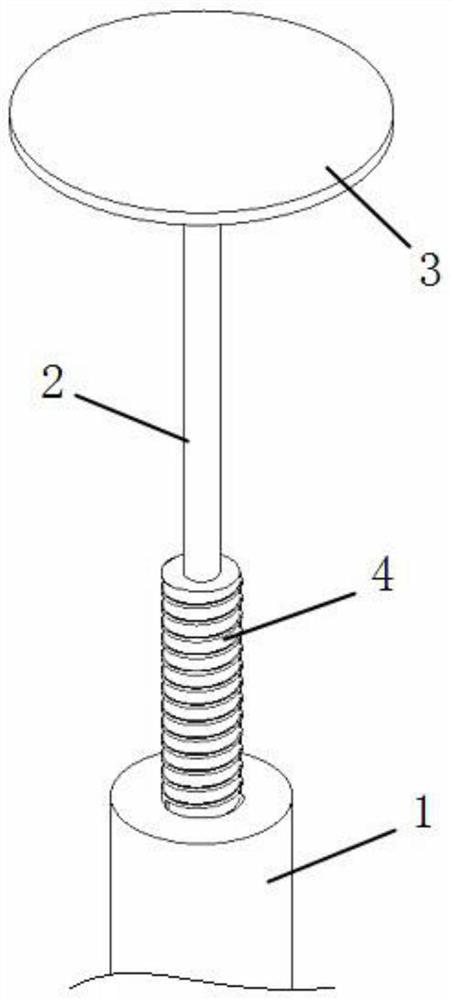

Shock absorber assembly for motor vehicle and method of assembling the same

ActiveCN109681574AAdjust Axial Force ThresholdControl preloadNon-rotating vibration suppressionResilient suspensionsAxial forceEngineering

The invention discloses a shock absorber assembly for a motor vehicle and a method of assembling the same. The shock absorber assembly for a motor vehicle comprises an oil cylinder, a piston rod and asupporting base, the oil cylinder is provided with an adjusting column protruding outwards, the adjusting column is sleeved with a movable block, and the movable block is composed of a rotating partand a tray part; a first spring assembly is arranged between the movable block and the supporting base, a second spring assembly is arranged between the adjusting column and the supporting base, and the second spring assembly is located in the first spring assembly. The two spring assemblies are composed of springs, upper limiting sleeves, lower limiting sleeves and wrinkling pieces, and the wrinkling pieces are arranged to transmit axial force and plastically deform when the axial force exceeds a threshold value. The spring assemblies are additionally arranged to replace an existing stop buffer, and the structural layout can be simplified; the two spring assemblies are each provided with a wrinkling piece, and therefore secondary threshold value control can be achieved. The displacement of the movable block on the adjusting column can control the pre-loading force of the outer-layer spring, and then the axial force threshold value which can be borne by the springs can be adjusted.

Owner:WUXI ZHONGYA SHOCK ABSORBER CO LTD

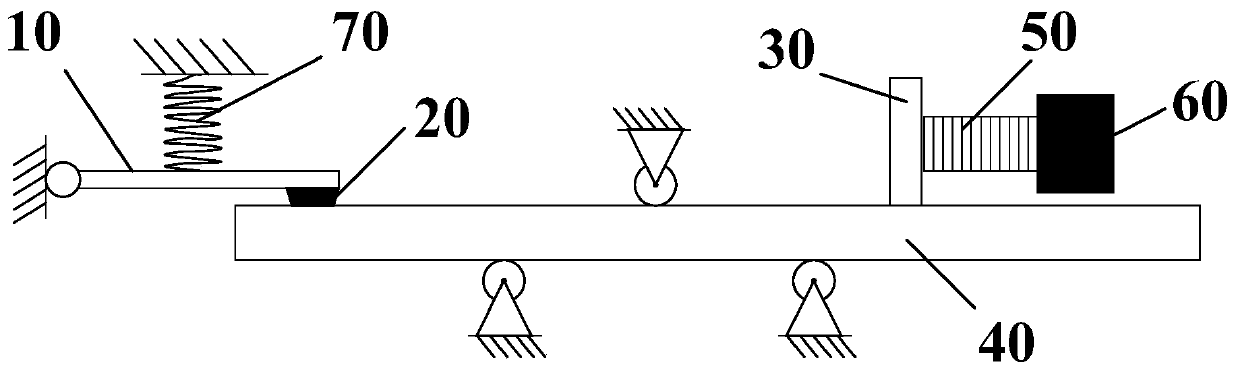

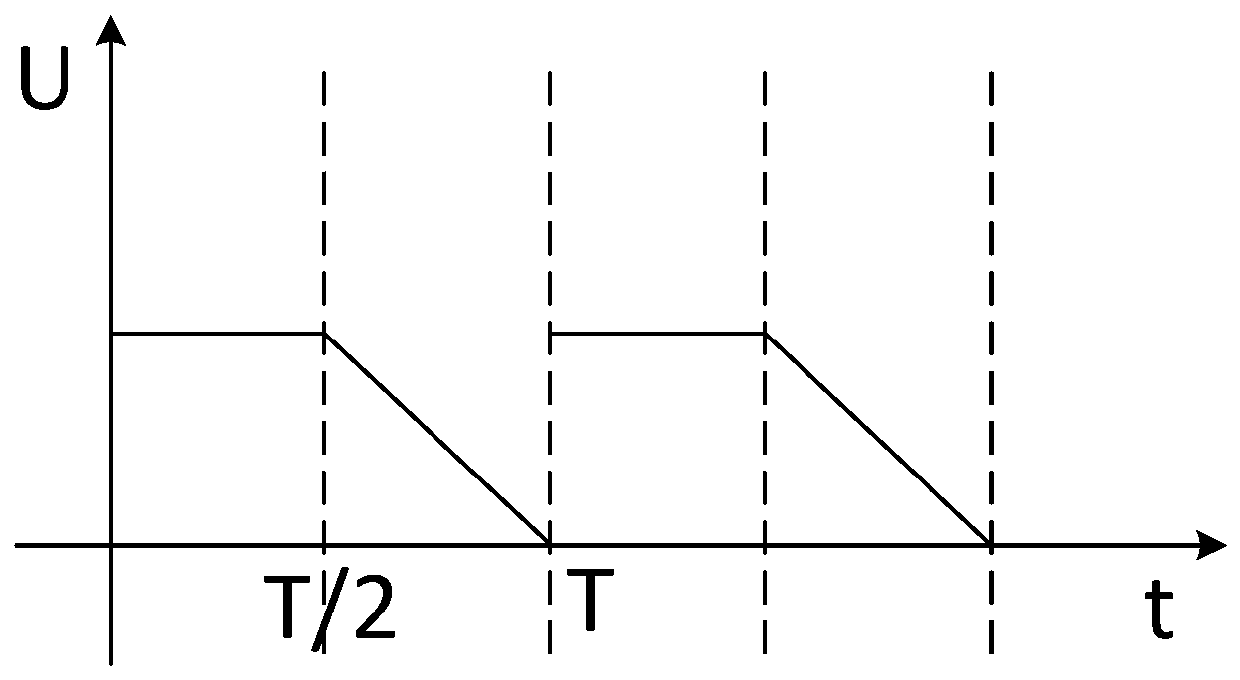

Friction force controllable type linear piezoelectric actuator and control method thereof

PendingCN110224632ALarge thrustWith power-off self-locking functionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

The invention discloses a friction force controllable type linear piezoelectric actuator and a control method thereof. The friction force controllable type linear piezoelectric actuator comprises a rotating block, a contact head, a fixed block, a rotor, a laminated piezoelectric ceramic, a mass block and an elastic element; the rotor can move in a first direction; the fixed block is fixedly arranged on the rotor; one end of the laminated piezoelectric ceramic is fixedly arranged on a side wall of the fixed block, and the other end of the laminated piezoelectric ceramic is fixedly connected with the mass block; the fixed block, the laminated piezoelectric ceramic and the mass block are arranged in sequence in the first direction; the second end of the rotating block can swing around the first end; the second end of the rotating block is fixedly provided with the contact head; and the elastic element is connected with the rotating block to enable the contact head to press against the rotor.

Owner:HUAQIAO UNIVERSITY

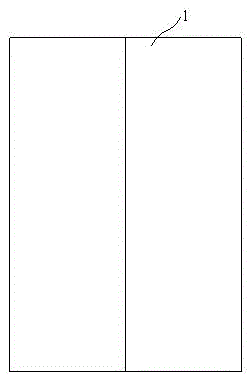

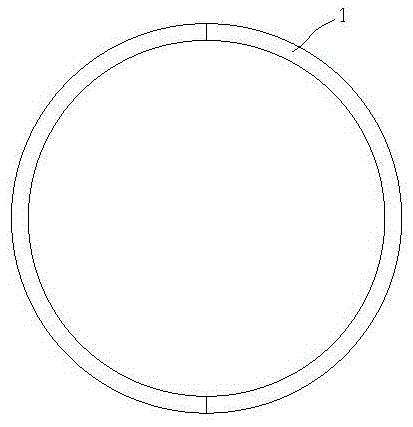

House support column pouring template and construction method

ActiveCN105544972AImprove construction efficiencyControl preloadForms/shuttering/falseworksBuilding material handlingInterference fitArchitectural engineering

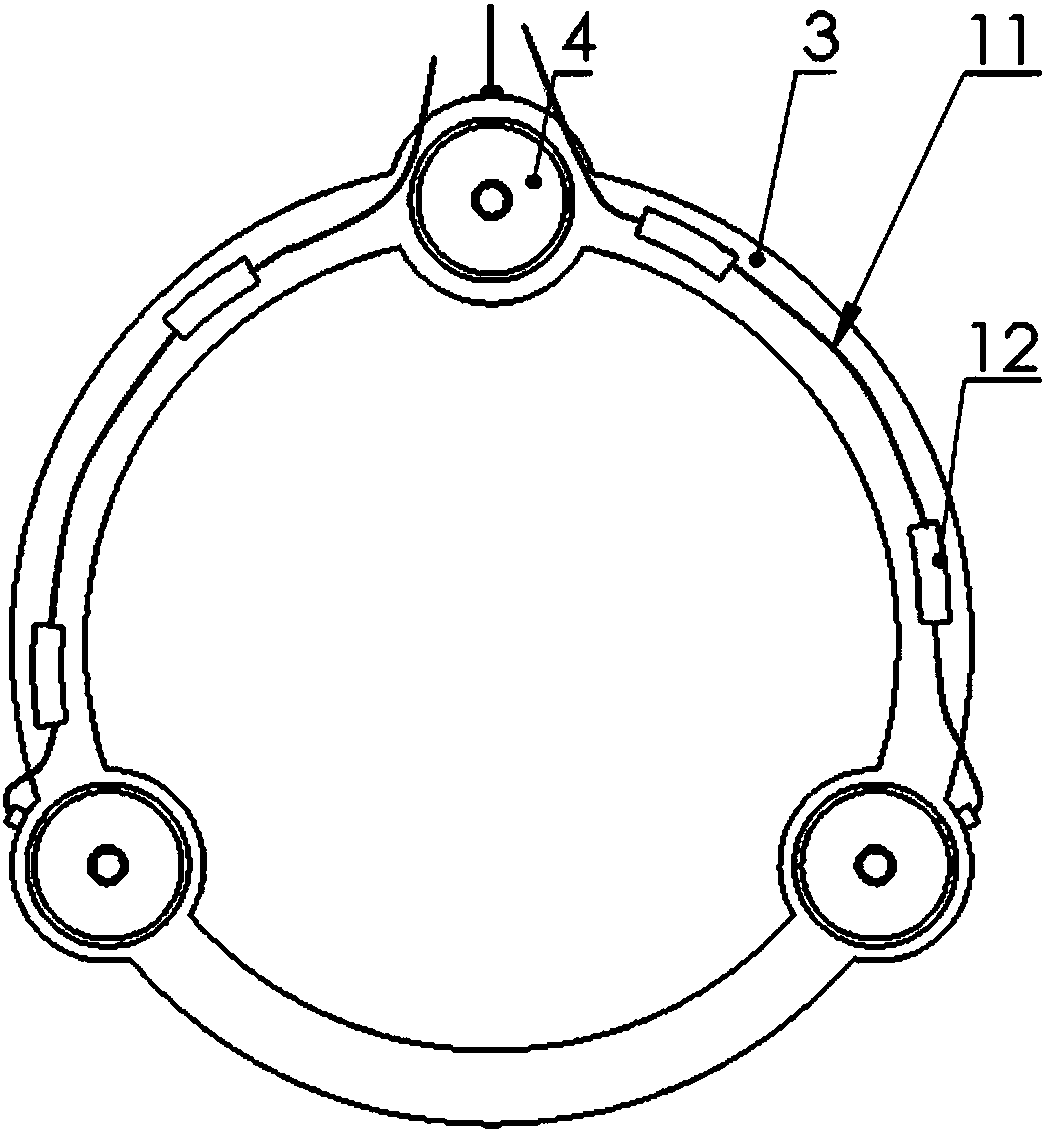

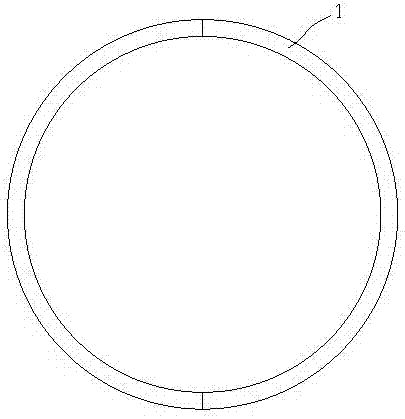

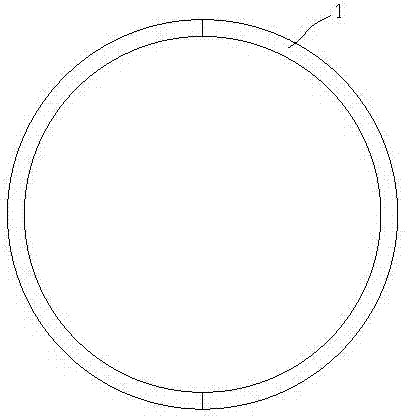

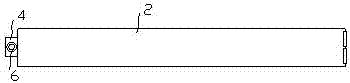

The invention provides a house support column pouring template and a construction method, and belongs to the technical field of house construction. The template includes a template body and a steel belt; the template body is formed by a wood; the steel belt includes two semi-circular steel rings which are mutually hinged; an outer side of a free end of one steel ring is welded to a connection block, a threaded hole is arranged in the connection block, and the threaded hole is in thread connection with a fixing bolt; and an outer side of a free end of the other steel ring is provided with a convex block, an installation hole is arranged in the convex block, a nut is arranged in the installation hole, the nut is in an interference fit with the installation hole, and two ends of the convex block are each provided with a cover plate which is detachably connected to the convex block. Through the template and the method, the steel belt can be quickly pre-tightened, the construction efficiency can be improved, template burst can be effectively avoided, and potential risks can be decreased.

Owner:世昌建设集团有限公司

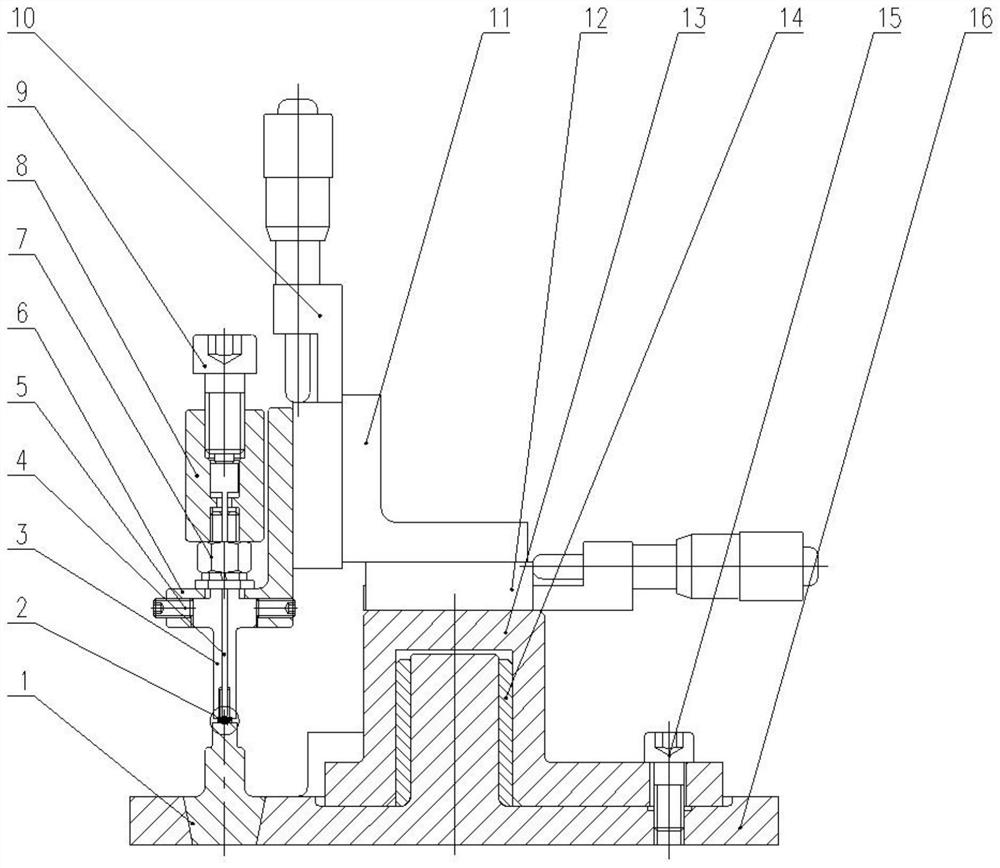

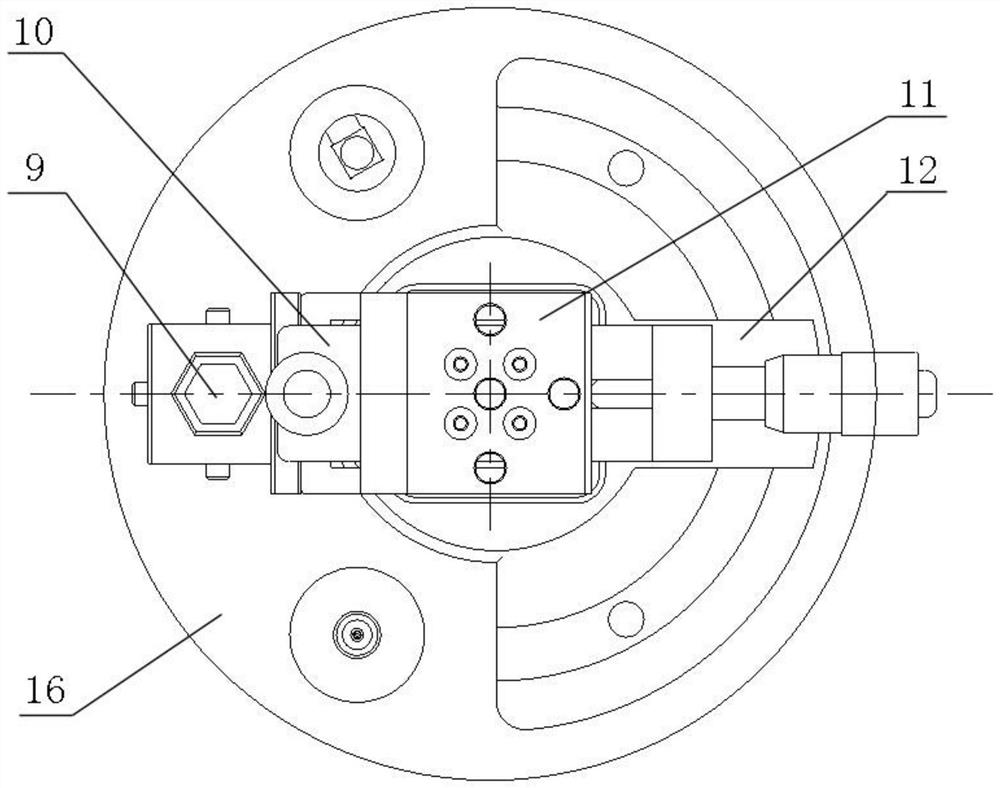

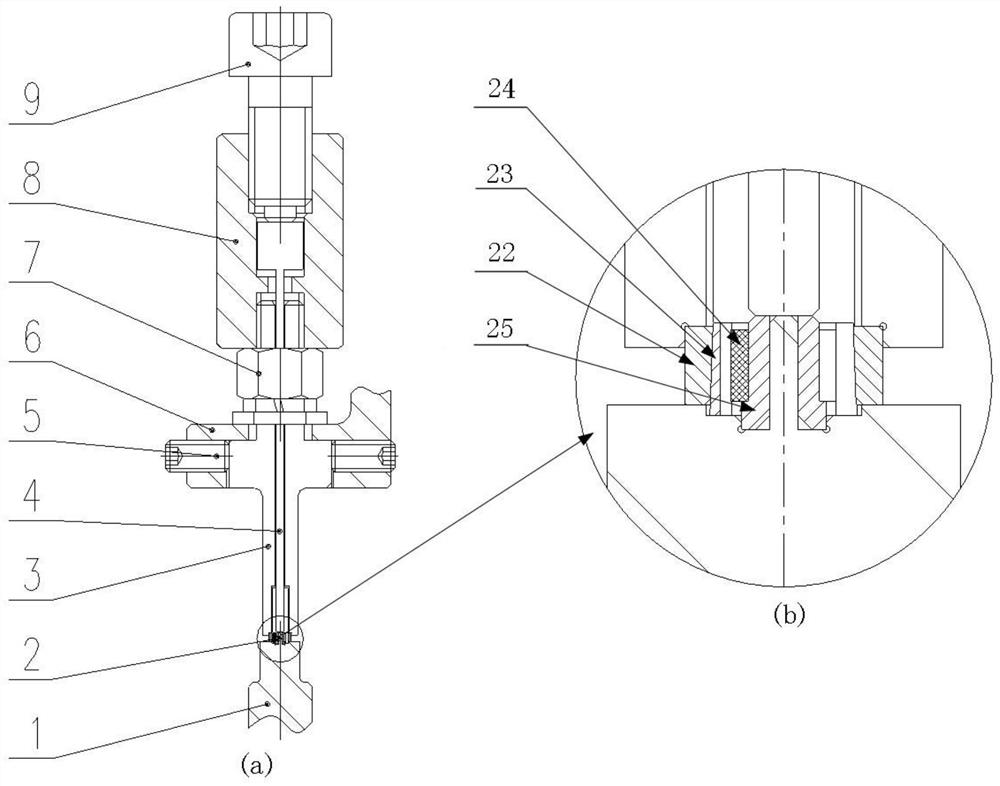

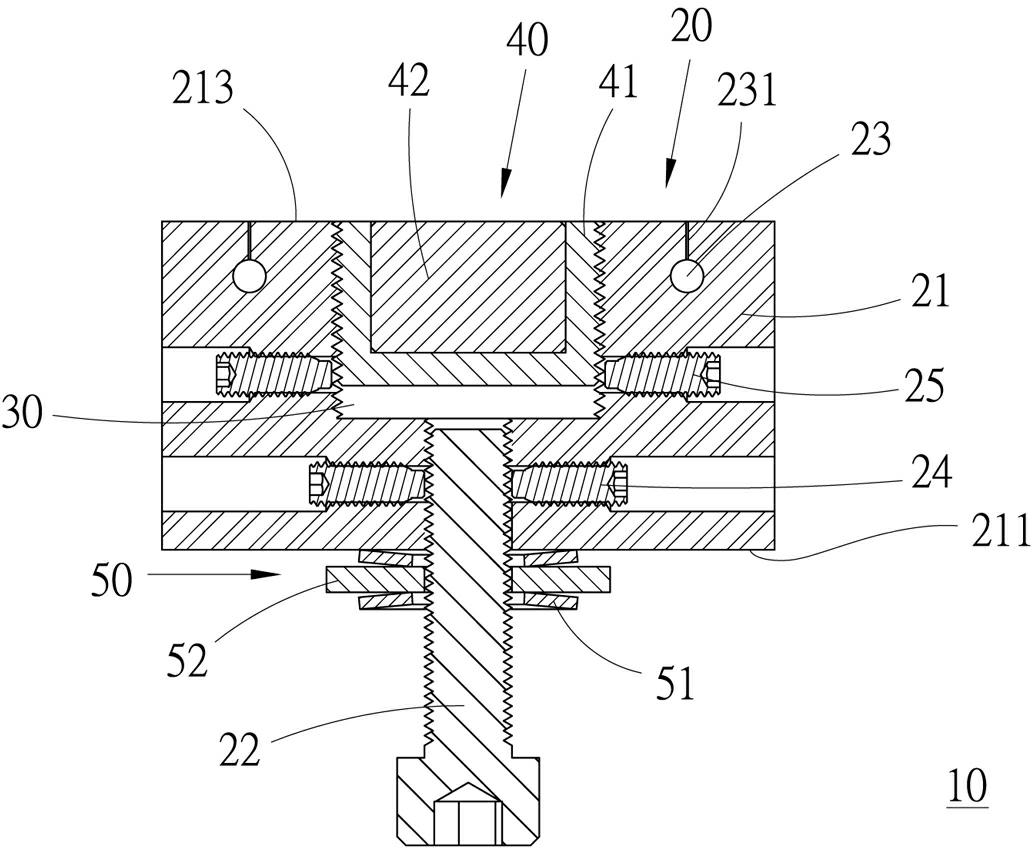

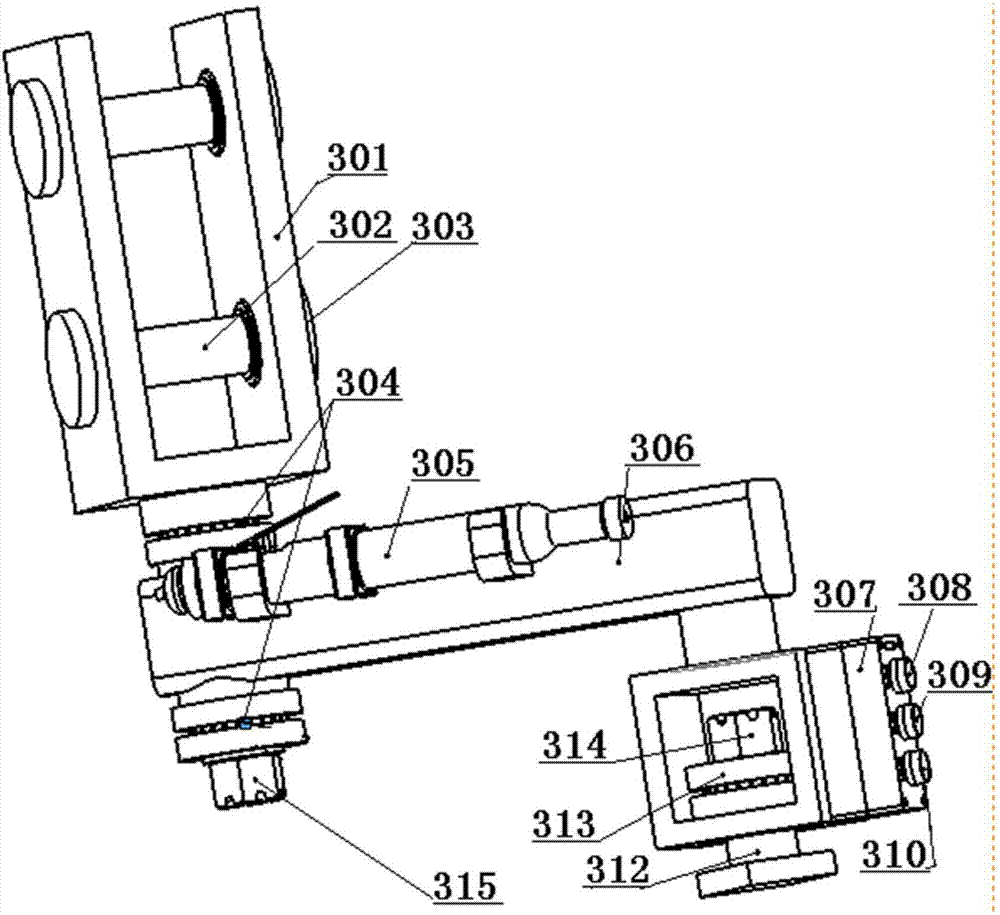

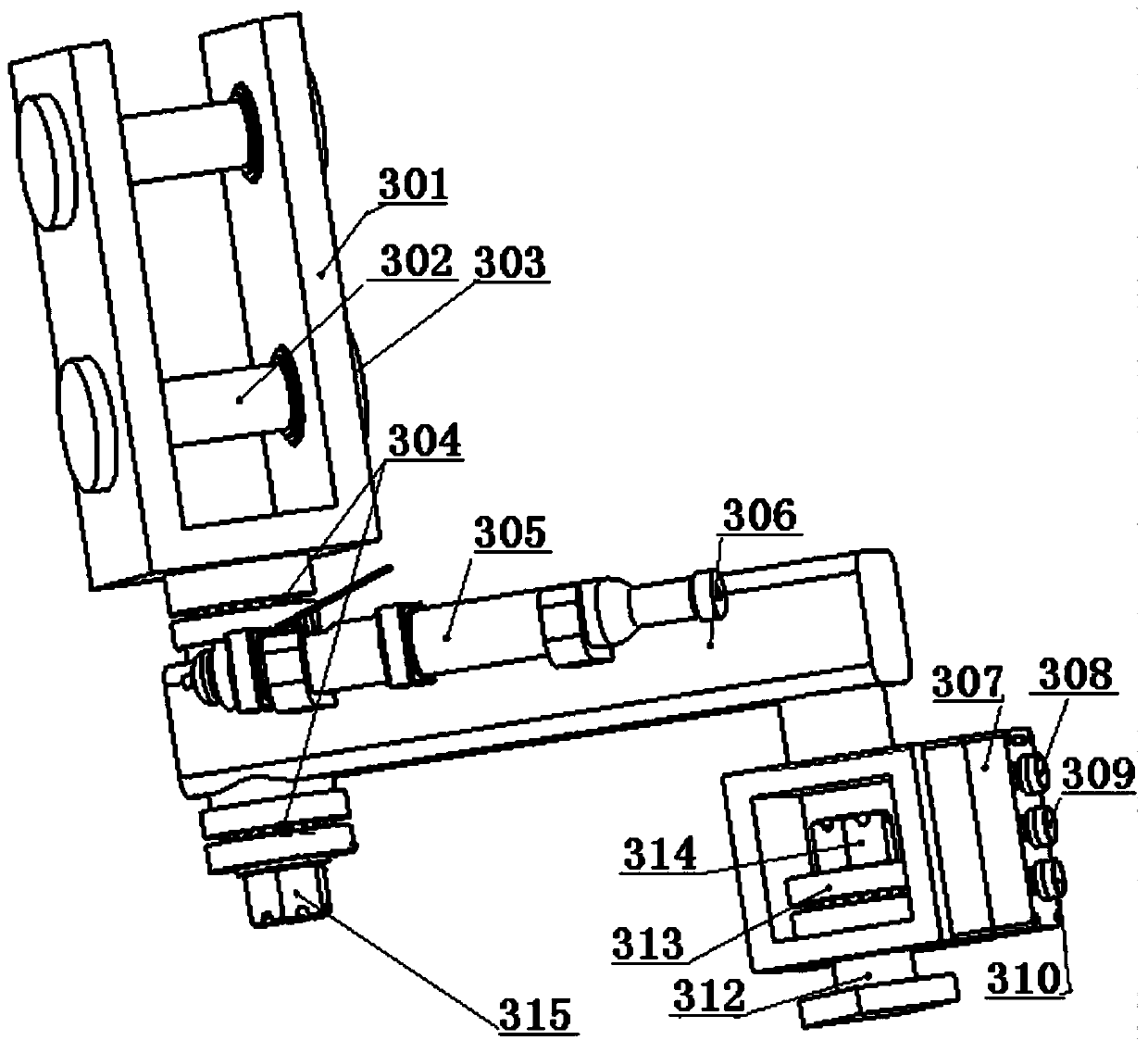

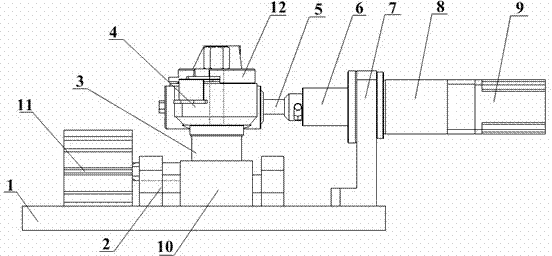

Assembly tool for miniature acceleration sensor

ActiveCN112643591AImprove assembly work efficiencyExpand the scope of useAssembly machinesWork holdersEngineeringMechanical engineering

The invention discloses an assembly tool for a miniature acceleration sensor. The assembly tool comprises a multidirectional adjusting mechanism, a pressure head, a clamp and an ejector pin. The pressure head is connected with the adjusting end of the multidirectional adjusting mechanism; the first end of the pressure head is used for cooperating with the first end of the clamp to install the acceleration sensor; the mounting direction of the clamp is parallel to the second direction; a part of the acceleration sensor is positioned and placed at the first end of the clamp; a channel for the ejector pin to move is formed in the pressure head; and the ejector pin is movably arranged in the channel, and the first end of the ejector pin is matched with the first end of the clamp to install the acceleration sensor. According to the assembly tool, the clamp can be replaced, and is suitable for the assembly of various types of sensors. Under the condition that the clamp is not replaced, inner and outer conical rings, a piezoelectric patch and a positioning ring can be assembled, and the assembling efficiency and the product consistency are ensured; and the axial assembly size between the inner conical ring and the outer conical ring can be accurately controlled through a vertical fine adjustment platform, and therefore the pre-tightening force of the piezoelectric patch is effectively controlled.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

A formwork and construction method for building support columns

ActiveCN105544972BImprove construction efficiencyControl preloadForms/shuttering/falseworksBuilding material handlingInterference fitArchitectural engineering

The invention provides a house support column pouring template and a construction method, and belongs to the technical field of house construction. The template includes a template body and a steel belt; the template body is formed by a wood; the steel belt includes two semi-circular steel rings which are mutually hinged; an outer side of a free end of one steel ring is welded to a connection block, a threaded hole is arranged in the connection block, and the threaded hole is in thread connection with a fixing bolt; and an outer side of a free end of the other steel ring is provided with a convex block, an installation hole is arranged in the convex block, a nut is arranged in the installation hole, the nut is in an interference fit with the installation hole, and two ends of the convex block are each provided with a cover plate which is detachably connected to the convex block. Through the template and the method, the steel belt can be quickly pre-tightened, the construction efficiency can be improved, template burst can be effectively avoided, and potential risks can be decreased.

Owner:世昌建设集团有限公司

Pre-pressed type air bearing

The invention provides a pre-pressed type air bearing, which is arranged on a platform and comprises a base piece, at least one air path, at least one containing part, at least one magnetic piece and an elastic part, wherein the base piece comprises a base body and an adjusting part; the adjusting part extends outwards from the connection end surface at one side of the base body along a geometric center shaft direction of the base body, and enables the extending tail end to be slidably connected on the platform; the air path is arranged inside the base body and forms at least one air outlet on the working end surface of the base body, back to the connection end surface of the base body; the containing part is concavely arranged on the working end surface; the magnetic piece is contained in the containing part; and the elastic part is slidably arranged on the adjusting part, is arranged between the base body and the platform and is used for supplying elastic force so as to enable a buffer distance to be kept between the base body and the platform. The pre-pressed type air bearing disclosed by the invention has the advantages of saving space, simplifying manufacturing process, and being free from moment formed in a process of generating pre-pressing force, and easy for controlling the pre-pressing force and the like.

Owner:HIWIN MIKROSYST

Telescopic anti-stripping cutting tooth

InactiveCN108868763AAutomatic control of cutting forceAvoid breakageSlitting machinesCutting machinesEngineering

The invention discloses a telescopic anti-stripping cutting tooth, which comprises a cutting tooth head part and a cutting tooth shaft part, wherein the cutting tooth is assembled into a cutting toothbase through a cutting tooth sleeve; the cutting tooth shaft part is inserted into the cutting tooth sleeve; a first spring is arranged between a cutting tooth head part and the cutting tooth sleeve;the lower end part of the cutting tooth shaft part extends out of the lower end of the cutting tooth base and is provided with an anti-stripping structure; the anti-stripping structure comprises a step through hole, a clamp pin, a round head screw and a second spring; the step through hole is transversely formed in the lower end part of the cutting tooth shaft part. The telescopic anti-strippingcutting tooth has the advantage that the impact damage problem caused by unexpected hard rock on the cutting tooth can be solved.

Owner:天津皓钻科技有限公司

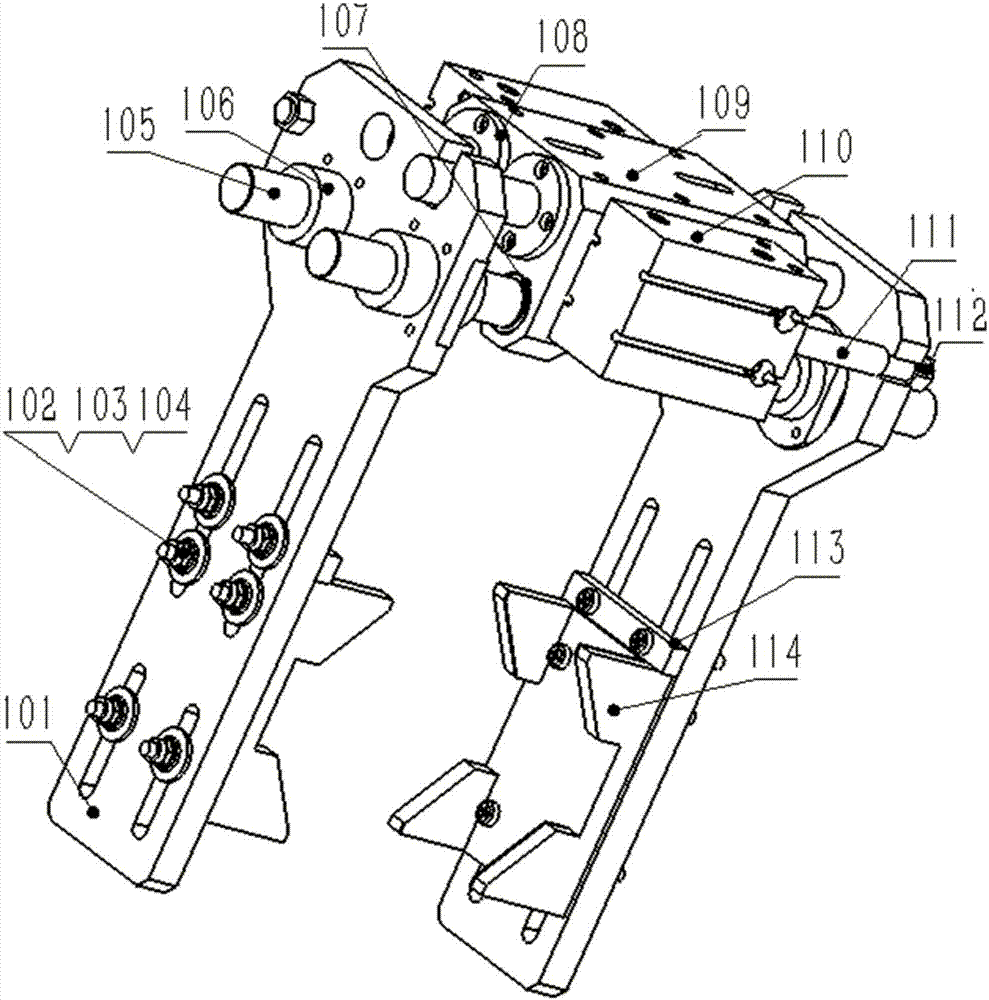

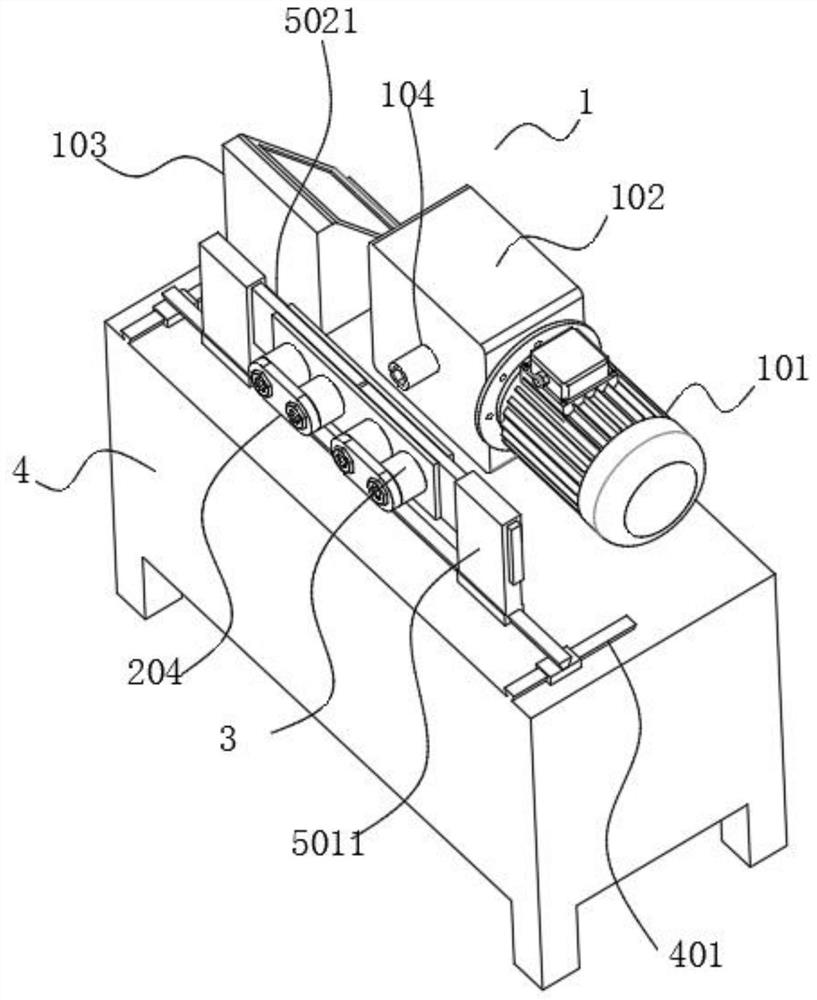

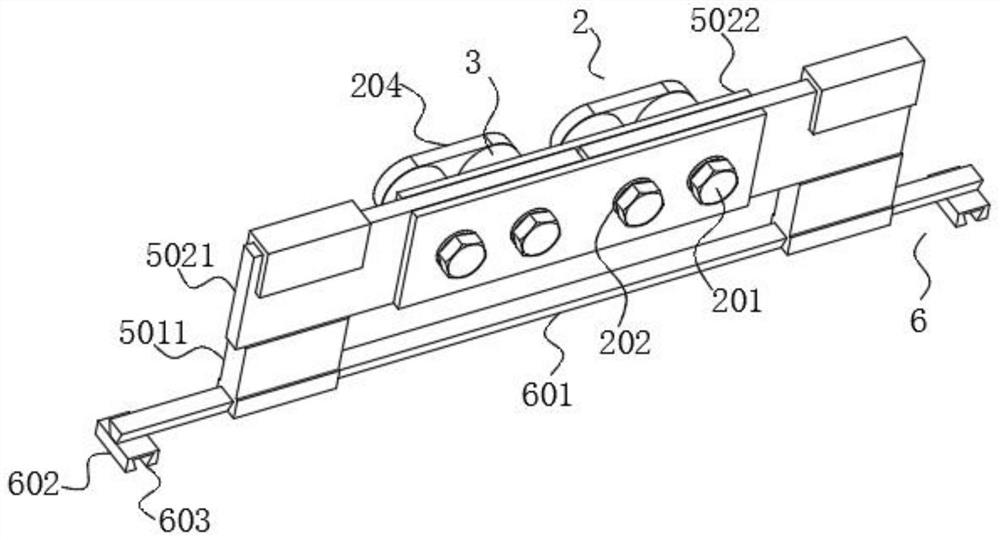

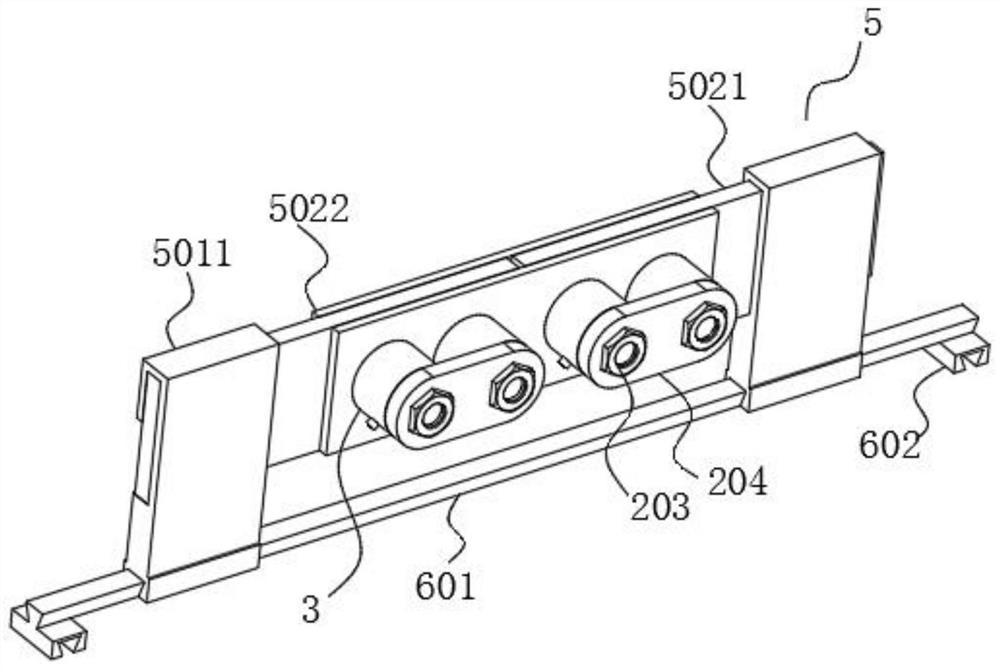

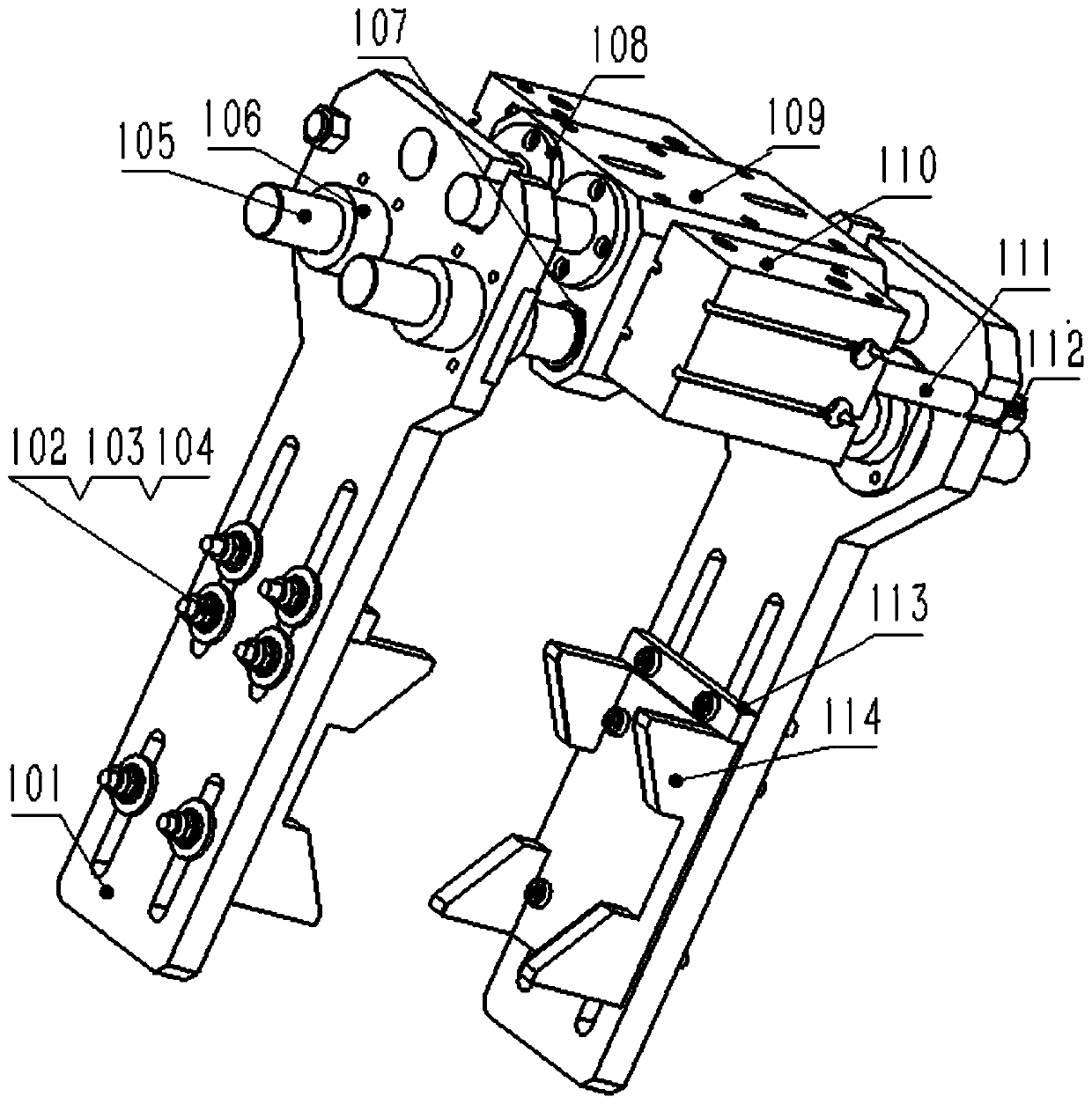

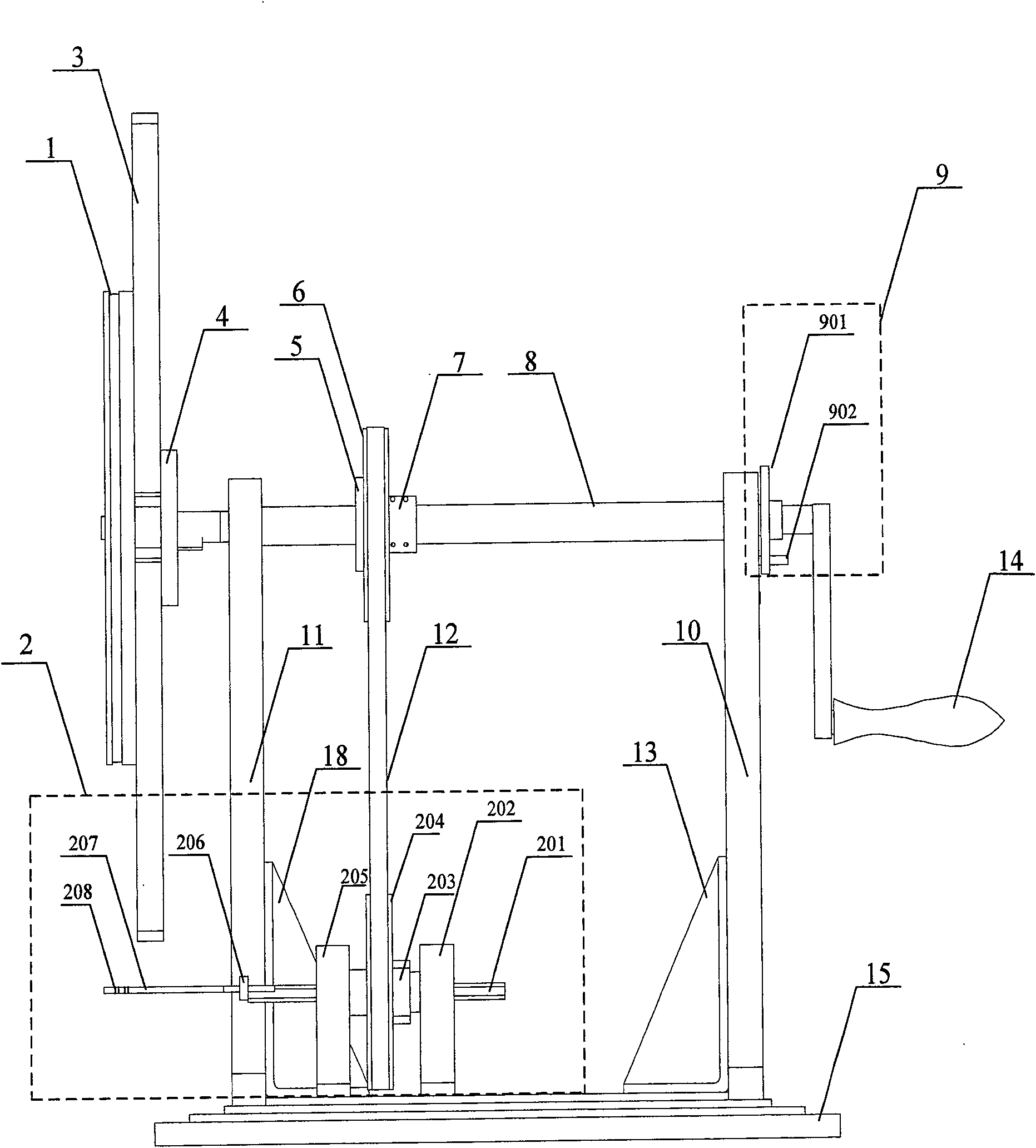

Auxiliary manipulator system for changing mould of six-mould cold heading machine

ActiveCN107234207AImprove securityImprove efficiencyForging/hammering/pressing machinesVertical planeThrust bearing

The invention relates to an auxiliary manipulator system for changing a mould of a six-mould cold heading machine. The auxiliary manipulator system for changing the mould of the six-mould cold heading machine is characterized by comprising a large arm, a small arm, a primary gripper, a secondary gripper, a pneumatic wrench, a pneumatic controller and other link components. The large arm is fixed to a cold heading machine through nuts; the circular tube end of a rotating connecting rod is directly arranged on an intermediate connecting post in a sleeving manner to realize rotating movement on a horizontal plane; long and short connecting rods of a large arm swing in a vertical plane; the small arm is hinged with the large arm connecting rod through thrust bearings which are arranged symmetrically, so that the small arm performs horizontal rotating movement relative to the axis of the large arm connecting rod; the auxiliary manipulator system for changing the mould of the six-mould cold heading machine is reasonable in design, compact in structure and convenient to use.

Owner:WENZHOU UNIVERSITY

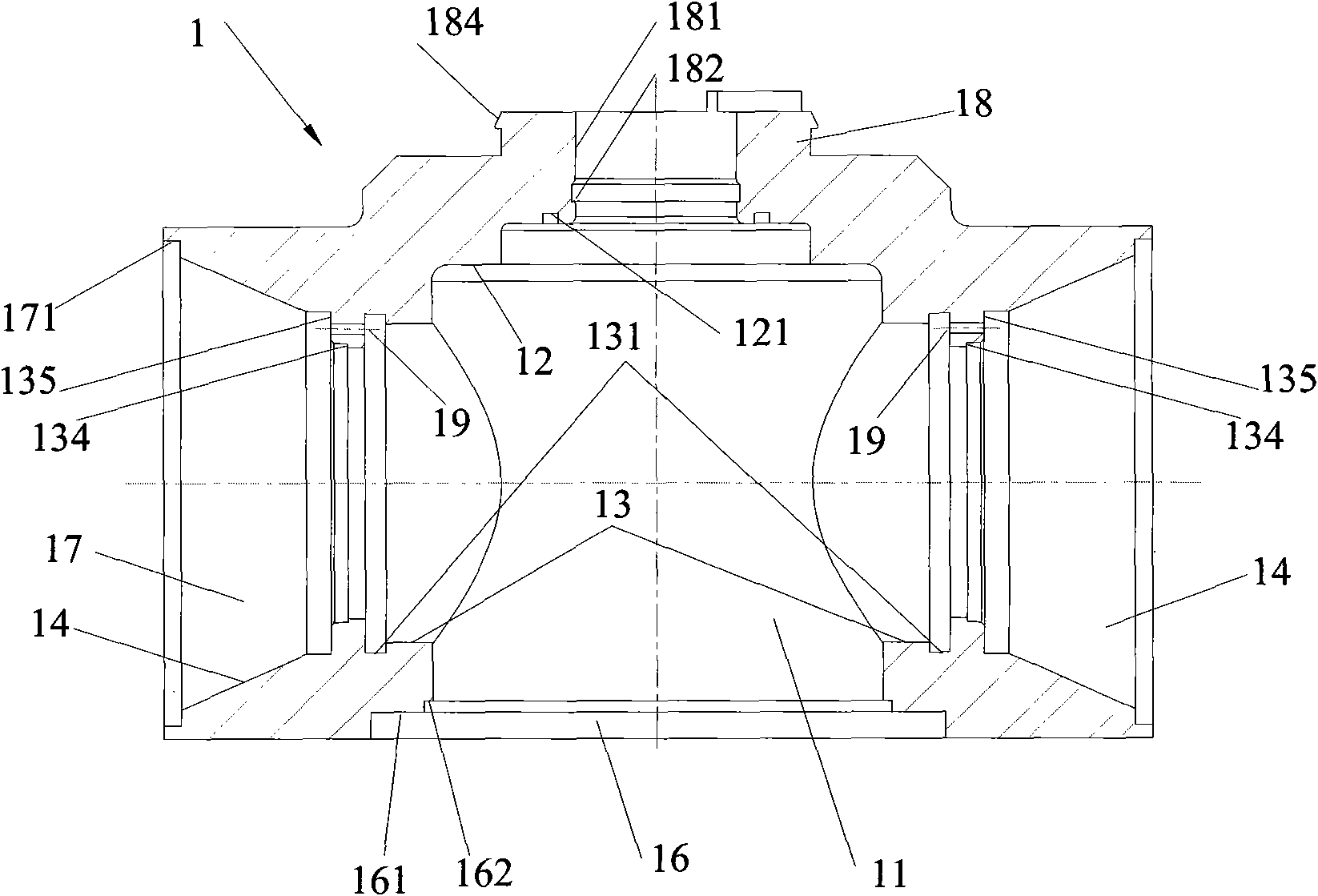

Oil pressure type shock absorption and isolation support and using method thereof

The invention discloses an oil pressure type shock absorption and isolation support and a using method thereof. An upper plate trough is formed above a lower plate trough, grooves are formed in the lower portion of the upper plate trough and the upper portion of the lower plate trough, and embedded steel bars are arranged at the upper portion of the upper plate trough and the lower portion of thelower plate trough; a steel pad body is cuboid and is arranged on the upper surface of a damping layer, the damping layer is arranged in the groove in the upper portion of the lower plate trough, andthe upper portion of the steel pad body extends into the groove in the upper plate trough and makes contact with the bottom face of the groove; And baffles are arranged on the side faces of the steelpad body in the groove of the upper plate trough, an oil hydraulic cylinder used for shock absorption is arranged between each baffle and the inner wall of the groove of the upper plate trough, each baffle is connected with the upper plate trough through a position adjusting mechanism, and the position adjusting mechanisms can enable the baffles to make contact with the side faces of the steel padbody or enable preset distances to be reserved between the baffles and the side faces of the steel pad body. The hysteretic characteristic of the support can be controlled, the natural vibration period of the structure is prolonged, and the anti-seismic property of the structure is improved; and the support can be used as a fixed, one-way or two-way support.

Owner:CHANGAN UNIV

Automatic detection device for anti-slip coefficient

PendingCN112730222ASimple structureSave human effortUsing mechanical meansMaterial analysisControl engineeringElectric machinery

The invention discloses an automatic detection device for an anti-slip coefficient, and relates to the technical field of anti-slip coefficient detection devices. The device comprises a work control table top; a hardware assembly is fixed to the upper surface of the work control table top, the output end of the work control table top is in signal connection with a pressure sensor, and a connecting pair is in sliding fit with the work control table top. The pressure sensor is in threaded running fit with the connecting pair, and the connecting pair comprises a connecting pair sliding table and a sliding coefficient plate; and the sliding coefficient plate is in sliding fit with the connecting pair sliding table. After the anti-slip coefficient connecting pair is installed on the device, software controls the motor to operate, the output torque is increased through the RV speed reducer, and the torque output requirement is met. And when the pressure sensor on the high-strength bolt reaches a preset value, the motor is controlled to stop, and the high-strength bolts of different specifications provide different output torques.

Owner:ZHOUSHAN INST OF CALIBRATION & TESTING FOR QUALITY & TECHNICAL SUPERVISION

A Method of Controlling Bolt Pretightening Force Based on Axial Force and Elongation

ActiveCN109781332BControl preloadAccurate measurement of preloadMeasurement of torque/twisting force while tighteningMechanical pressure/force controlPropagation timeLongitudinal wave

The invention relates to a method for controlling the pretightening force of bolts based on axial force and elongation, comprising: when the bolts are fastened for the first time, measuring the acoustic time difference between the free state and the fastened state of the bolt through ultrasonic waves, and calculating the bolt based on the acoustic time difference The elongation of the bolt is obtained according to the elongation, so as to accurately control the bolt pre-tightening force; for the bolts in service, based on the relationship between the time of ultrasonic transverse wave and longitudinal wave propagating in the bolt and the axial stress of the bolt The linear relationship can be used to obtain the residual pre-tightening force of the bolts to determine whether it is necessary to re-tighten the bolts in service. The invention can accurately measure the pre-tightening force of the bolt when it is fastened for the first time and the residual pre-tightening force of the bolt in service, so as to achieve the purpose of accurately controlling the pre-tightening force of the bolt.

Owner:中国大唐集团新能源科学技术研究院有限公司

A formwork and construction method for pouring supporting columns in the basement of a house

ActiveCN105421765BImprove construction efficiencyControl preloadForms/shuttering/falseworksInterference fitBasement

The invention provides a house basement support pillar pouring template and a construction method and belongs to the technical field of house building. The template comprises a template body and a steel belt, wherein the steel belt comprises two semi-circular steel rings hinged with each other, a connecting block is welded at the outer side of the free end of one of the steel rings, a threaded hole is formed in the connecting block, a fixed bolt is screwed into the threaded hole; and a lug is welded at the outer side of the free end of the other steel ring, a mounting hole is formed in the lug, a nut is arranged in the mounting hole, the nut is in interference fit with the mounting hole, cover plates are arranged at two ends of the lug, and each cover plate is connected with the lug by four bolts. By adopting the template and the method, the steel belt can be pre-tightened quickly, so that the construction efficiency is improved, occurrence of template blast is effectively prevented, and potential safety hazard can be reduced.

Owner:金居建设发展股份有限公司

A shock absorber assembly for a motor vehicle and its assembly method

ActiveCN109681574BAdjust Axial Force ThresholdControl preloadNon-rotating vibration suppressionResilient suspensionsClassical mechanicsAxial force

The invention discloses a shock absorber assembly for a motor vehicle and a method of assembling the same. The shock absorber assembly for a motor vehicle comprises an oil cylinder, a piston rod and asupporting base, the oil cylinder is provided with an adjusting column protruding outwards, the adjusting column is sleeved with a movable block, and the movable block is composed of a rotating partand a tray part; a first spring assembly is arranged between the movable block and the supporting base, a second spring assembly is arranged between the adjusting column and the supporting base, and the second spring assembly is located in the first spring assembly. The two spring assemblies are composed of springs, upper limiting sleeves, lower limiting sleeves and wrinkling pieces, and the wrinkling pieces are arranged to transmit axial force and plastically deform when the axial force exceeds a threshold value. The spring assemblies are additionally arranged to replace an existing stop buffer, and the structural layout can be simplified; the two spring assemblies are each provided with a wrinkling piece, and therefore secondary threshold value control can be achieved. The displacement of the movable block on the adjusting column can control the pre-loading force of the outer-layer spring, and then the axial force threshold value which can be borne by the springs can be adjusted.

Owner:WUXI ZHONGYA SHOCK ABSORBER CO LTD

A kind of housing cylindrical pouring formwork and construction method

ActiveCN105442837BImprove construction efficiencyControl preloadForms/shuttering/falseworksInterference fitArchitectural engineering

The invention provides a house cylindrical pouring formwork and a construction method and belongs to the technical field of house building. The formwork comprises a formwork body and a steel band, the steel band comprises two semicircular steel rings which are hinged to each other, a connecting block is arranged at the outer side of the free end of one of the two semicircular steel rings, the connecting block is provided with a threaded hole, and a fixed bolt is in threaded connection with the threaded hole; a protruding block is arranged at the outer side of the free end of the other steel ring, the protruding block is provided with a mounting hole, a nut is arranged in the mounting hole, the nut is in interference fit with the mounting hole, cover plates are arranged at the two ends of the protruding block, and the cover plates are detachably connected with the protruding block. By means of the house cylindrical pouring formwork and the construction method, the steel band can be pre-tightened rapidly, and construction efficiency is improved; formwork burst is effectively prevented, and potential safety hazards are decreased.

Owner:四川省建筑机械化工程有限公司

Fastener pre-tightening force control device

The invention relates to a fastener pre-tightening force control device. The fastener pre-tightening force control device comprises a gear reducer, wherein the gear reducer comprises an output end, the output end comprises a connecting head and a magnetic column, the magnetic column comprises an N pole and an S pole, the N pole is arranged at one end of the magnetic column, the S pole is arrangedat the other end of the magnetic column, and a sensor for detecting the rotation angle of the magnetic column is further arranged on a box body. The fastener pre-tightening force control device has the advantages that the rotation angle of the output end is identified through the magnetic column arranged on the output end, due to the fact that the rotation angle of a fastener during tightening isin a proportional relation with the sum of the bolt elongation and the loosening amount of a tightened part, and the fact that the deformation elongation of the fastener in the elastic area is in direct proportion to the rotation angle of the fastener, the pre-tightening force of the fastener can be accurately controlled by controlling the rotation angle of the fastener, the pre-tightening force dispersion degree of the fastener can be reduced, the pre-tightening force of the fastener reaches 70%-80% of the yield limit, the utilization rate of a material is improved, the fixing quality of thefastener is also improved, and the effects of being safe and reliable are achieved.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +2

Six-mode cold pier machine mold change auxiliary manipulator system

ActiveCN107234207BImprove securityImprove efficiencyForging/hammering/pressing machinesRobot handControl engineering

The present invention involves a six -mode cold pier machine model auxiliary robot system.It is characterized by: the auxiliary robot handle system includes big arms, arm, main grabbed, secondary grip, pneumatic wrench, pneumatic controllers and other link parts.The large arm is fixed on the cold pier through the nut, and the round pipe end of the rotating connecting rod is directly connected to the middle connection column to achieve the rotation movement of the horizontal plane.The arm is linked with the large arm connection rod through the littering of the lintel of the arm, which realizes the horizontal rotation movement of the small arm compared to the large arm connector rod. The invention is reasonable, the structure is compact and easy to use.

Owner:WENZHOU UNIV

A formwork and construction method for building basement column pouring

ActiveCN105507582BImprove construction efficiencyControl preloadForms/shuttering/falseworksBasementInterference fit

The invention provides a house basement cylinder pouring formwork and a construction method and belongs to the technical field of house building. The formwork comprises a formwork body and a steel belt, the steel belt comprises two semicircular steel rings which are hinged, a connecting block is welded on the outer side of a free end of one of the steel rings, a threaded hole is formed in the connecting block, a fixing bolt is connected on the threaded hole in a threaded manner, a convex block is arranged on the outer side of a free end of the other steel ring, a mounting hole is formed in the convex block, a nut is arranged in the mounting hole and is in interference fit with the same, and cover plates are arranged at two ends of the convex block and connected with the convex block through bolts. By the formwork and the construction method, the steel belt can be pretightened quickly, so that construction efficiency is improved; formwork explosion is prevented effectively, and potential safety hazards are lowered.

Owner:天宏控股集团有限公司

House cylindrical pouring formwork and construction method

ActiveCN105442837AImprove construction efficiencyControl preloadForms/shuttering/falseworksInterference fitArchitectural engineering

The invention provides a house cylindrical pouring formwork and a construction method and belongs to the technical field of house building. The formwork comprises a formwork body and a steel band, the steel band comprises two semicircular steel rings which are hinged to each other, a connecting block is arranged at the outer side of the free end of one of the two semicircular steel rings, the connecting block is provided with a threaded hole, and a fixed bolt is in threaded connection with the threaded hole; a protruding block is arranged at the outer side of the free end of the other steel ring, the protruding block is provided with a mounting hole, a nut is arranged in the mounting hole, the nut is in interference fit with the mounting hole, cover plates are arranged at the two ends of the protruding block, and the cover plates are detachably connected with the protruding block. By means of the house cylindrical pouring formwork and the construction method, the steel band can be pre-tightened rapidly, and construction efficiency is improved; formwork burst is effectively prevented, and potential safety hazards are decreased.

Owner:四川省建筑机械化工程有限公司

A hydraulic shock absorber and method of use thereof

ActiveCN111305054BExtend the natural vibration periodImprove seismic performanceBridge structural detailsHydraulic cylinderRebar

The invention discloses an oil pressure shock-absorbing and isolating support and a method for using the same. The upper plate groove is arranged above the lower plate groove, the lower part of the upper plate groove and the upper part of the lower plate groove are provided with grooves, and the upper plate groove The upper part and the lower part of the lower plate groove are equipped with pre-embedded steel bars; the shape of the steel pad is cuboid and set on the upper surface of the shock-absorbing layer, and the shock-absorbing layer is set in the groove on the upper part of the lower plate groove. It extends into the groove of the upper plate groove and contacts the bottom surface of the groove; the groove of the upper plate groove is provided with baffles on the side of the steel pad body, and each baffle and the inner wall of the groove of the upper plate groove are provided with a For shock-absorbing hydraulic cylinders, each baffle is connected to the groove of the upper plate through a position adjustment mechanism. The position adjustment mechanism can make the baffle contact with the side of the steel pad body or make the gap between the baffle plate and the side of the steel pad body Leave a preset distance. The invention can control the hysteresis characteristic of the support, prolong the natural vibration period of the structure, and improve the anti-seismic performance of the structure; and can be used as a fixed, one-way or two-way support.

Owner:CHANGAN UNIV

Optical fibre electric current sensor sensitive coil winding equipment

ActiveCN100549701CControl preloadPrecise control of winding pitchCurrent/voltage measurementVoltage/current isolationFiberDrive wheel

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Pressure medium spring and transmission nut using same

PendingCN113639023AControl movementControl preloadGearingGearing detailsEngineeringMechanical engineering

The invention discloses a pressure medium spring. The pressure medium spring comprises a pressure medium spring inner ring, a pressure medium spring outer ring, a pressure medium spring annular piston, a first pressure cavity, a second pressure cavity and an anti-rotation connecting piece. The first pressure cavity is formed in the other end of the pressure medium spring annular piston, and a pressure medium in the first pressure cavity can push the pressure medium spring annular piston to slide between the pressure medium spring inner ring and the pressure medium spring outer ring. The second pressure cavity is formed in the outer side of the pressure medium spring annular piston, and a pressure medium in the second pressure cavity can push the pressure medium spring annular piston to slide between the pressure medium spring inner ring and the pressure medium spring outer ring. The invention further discloses a transmission nut using the pressure medium spring. According to the pressure medium spring, the pre-tightening force of a nut in a nut lead screw pair can be controlled through the pressure in the first pressure cavity and the pressure in the second pressure cavity, the lead screw precision is improved, and the service life is prolonged.

Owner:田间 +1

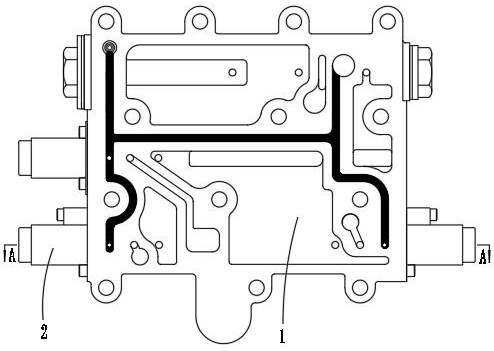

Engineering vehicle shifting device with buffering mechanism

PendingCN113154023AAcceleration smooth and gentleImproved driving comfort and handlingGearing controlBlind holeControl theory

The invention discloses an engineering vehicle shifting device with a buffering mechanism. The engineering vehicle shifting device comprises a valve body, wherein an oil inlet and an oil outlet are formed in the valve body, a communicating channel is arranged between the oil inlet and the oil outlet, and one end of the communicating channel penetrates through the outer surface of the valve body; a piston rod is arranged in the communicating channel, the piston rod is provided with an oil passing channel capable of enabling the oil inlet or the oil outlet to communicate, a control rod is arranged on the piston rod, and the diameter of the control rod is smaller than that of the piston rod; a control cover is arranged on the outer surface of the valve body, and a blind hole is formed in the control cover; and the control rod is sleeved with a control spring, one end of the control spring abuts against the end face of the piston rod, the other end of the control spring abuts against the bottom face of the blind hole, and a micro-channel communicating with the two ends of the oil inlet is formed in the piston rod. Due to the fact that the shifting mechanism is provided with the buffering mechanism, the service life of a power transmission mechanism part of an engineering vehicle can be prolonged, and the driving comfort and controllability of the engineering vehicle are improved.

Owner:仙居县巨力机械厂(普通合伙)

An automobile self-adjusting arm rear end cover adjusting device

The invention discloses a regulating device for a rear end cover of an automotive automatic slack adjuster. The regulating device is characterized in that an automatic slack adjuster bushing is sleeved on an output shaft of a clamping cylinder disposed on an automatic slack adjuster mounting base, the automatic slack adjuster is pressed by a pressure plate after the clamping cylinder is started, the automatic slack adjuster mounting base is horizontally adjusted by starting a horizontal movement cylinder, a hexagon hole of the rear end cover of the automatic slack adjuster is right aligned with and firmly abutted to a hexagon bushing, a servo motor is started to drive the hexagon bushing to rotate after rotation angle of the servo motor is set, the hexagon bushing drives the rear end cover of the automatic slack adjuster to rotate, tension of a spiral compression spring mounted inside the automatic slack adjuster is changed and adjusted, the horizontal movement cylinder is started to retreat to the original horizontal position after adjusting, and the clamping cylinder is then started to release the automatic slack adjuster to end the adjusting process. Through the regulating device for adjusting the rear end cover of the automatic slack adjuster, pretension of the spiral compression spring of the automatic compression spring can be controlled accurately, labor action is saved, labor intensity is reduced greatly and assembly efficiency is improved.

Owner:CHINA JILIANG UNIV

Measuring device and method for axial force of rotor of twin-screw compressor

ActiveCN108534940BControl preloadWon't interfereApparatus for force/torque/work measurementClassical mechanicsThrust bearing

The invention discloses a measuring device and method for rotor axial force of a double-screw compressor. The measuring device mainly comprises two groups of stress sensors arranged on two sides of athrust bearing at an exhaust end of the double-screw compressor, each group of stress sensor assembly comprises three standard stress sensors, stress is uniform, stable measurement and real-time monitoring can be realized, and the three standard stress sensors are fixed on a corresponding bracket and are mounted and positioned by through holes. The measuring device adopts two-way force measurementdesign, can accurately measure the direction and magnitude of axial force without interference to operation of a rotor.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com