Measuring device and method for rotor axial force of double-screw compressor

A technology for measuring devices and compressors, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as inability to measure, increase in compressor monitoring and maintenance costs, and inaccuracy, saving maintenance time and Maintenance cost, stable measurement and real-time monitoring, the effect of accurate installation location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

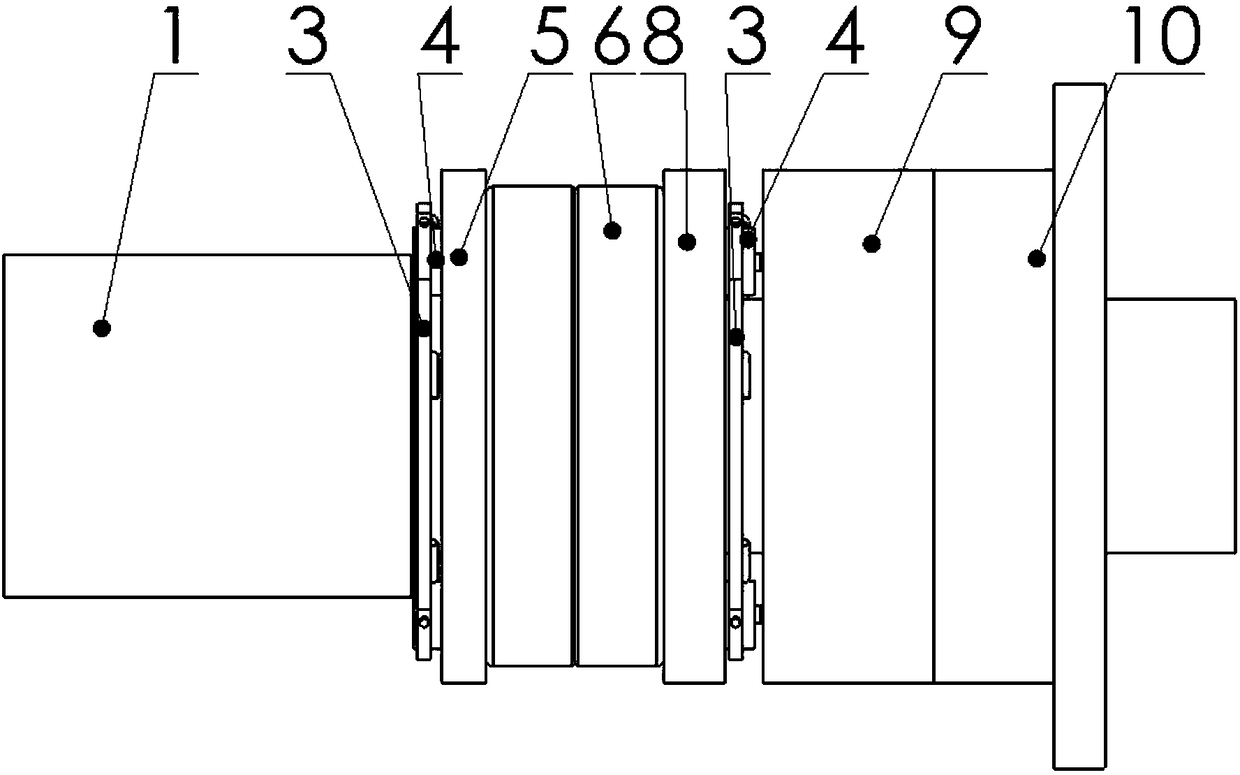

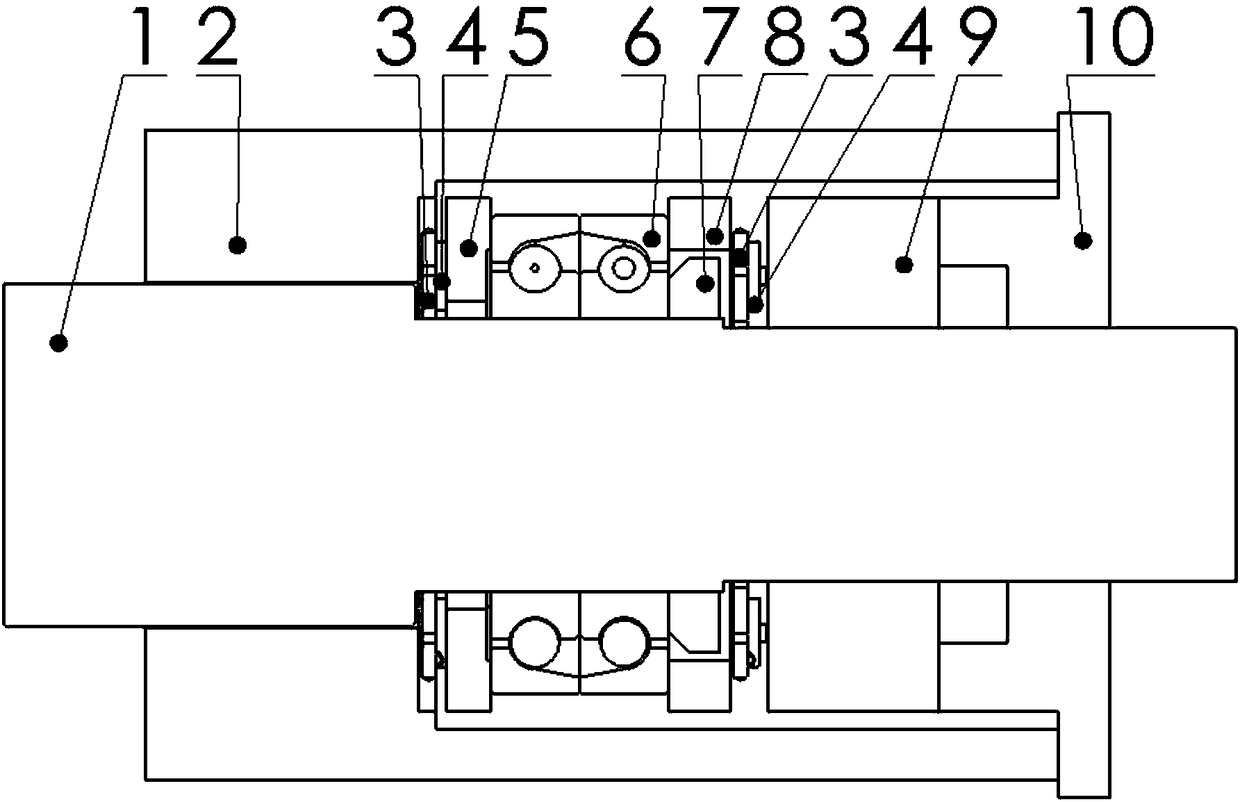

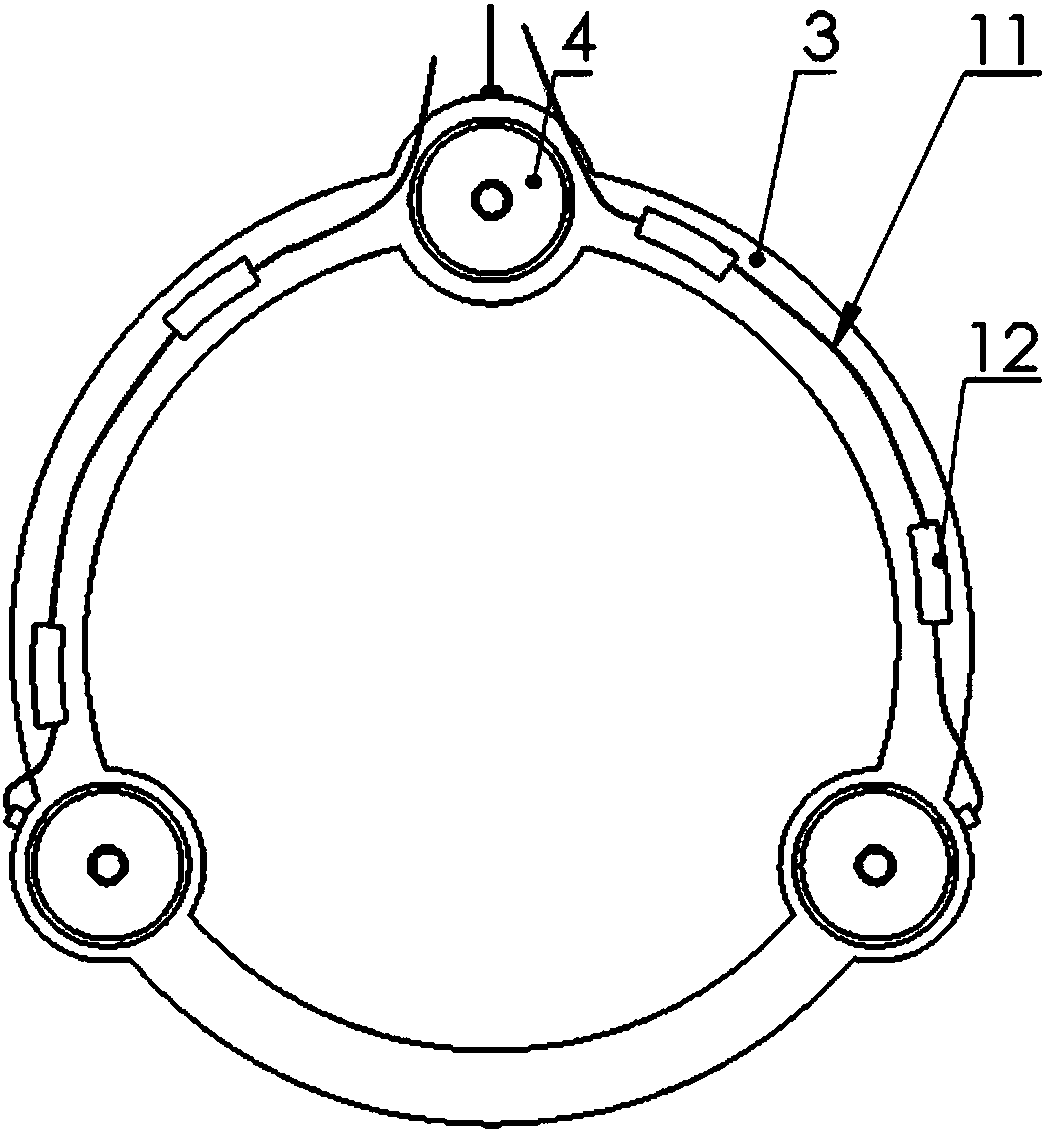

[0032] see figure 1 and figure 2 The measuring device for the axial force of the rotor of the twin-screw compressor according to the present invention includes two stress sensor assemblies arranged in the bearing cavity of the exhaust seat of the twin-screw compressor. The bearing cavity includes a housing 2 and a The shaft seal sleeve 9 at one end, the thrust bearing 6 is installed in the bearing cavity, and the rotor protruding shaft 1 is sleeved in the thrust bearing 6. The stress sensor assembly includes a bracket 3 and a standard stress sensor 4 arranged on the bracket 3, the bracket 3 is a ring structure as a whole, so as to be installed and positioned along the axial direction of the compressor rotor (i.e. figure 1The rotor shown in the figure extends out from the shaft 1 and runs through the stress sensor assembly), and the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com