A hydraulic shock absorber and method of use thereof

A shock-absorbing and hydraulic technology, applied in the field of bridge engineering, can solve problems such as difficulty in changing or changing the direction of movement, inability to adjust the hysteretic characteristics of shock-absorbing supports, and inability to improve the seismic performance of the structure according to needs, so as to improve the seismic performance of the structure. performance, the effect of prolonging the natural vibration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

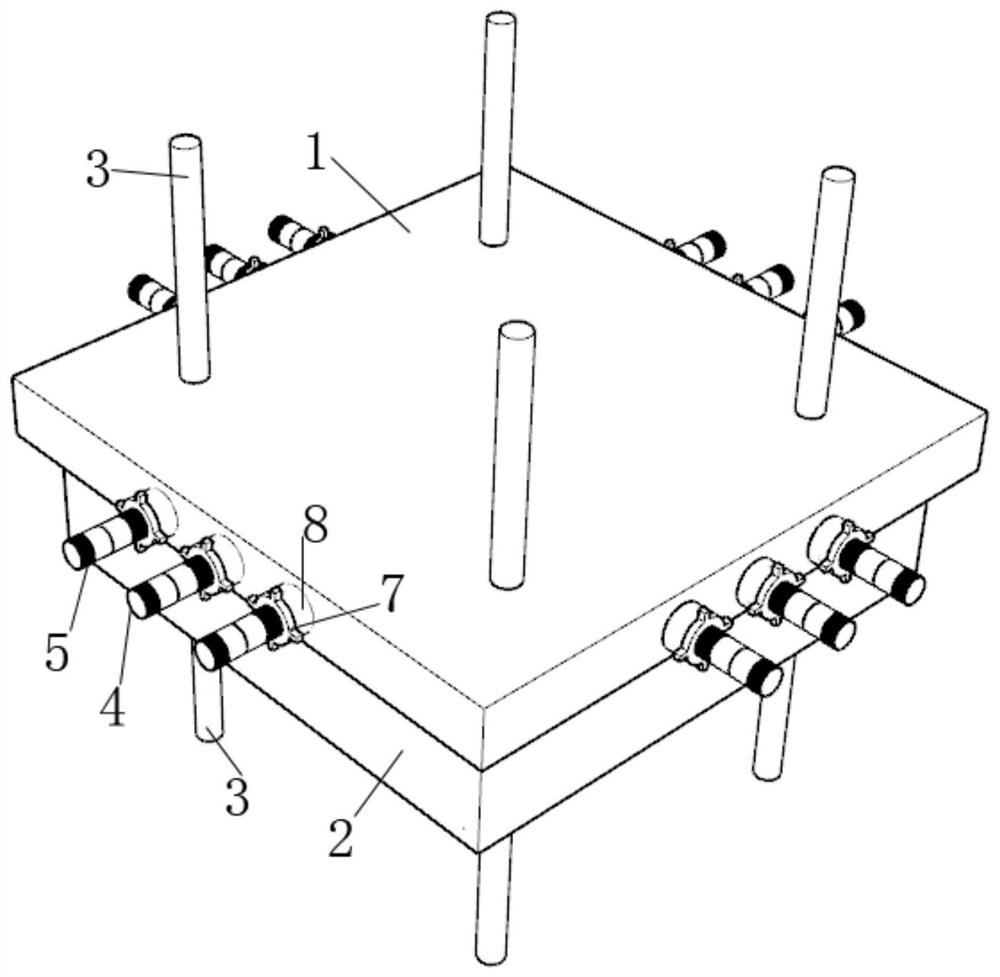

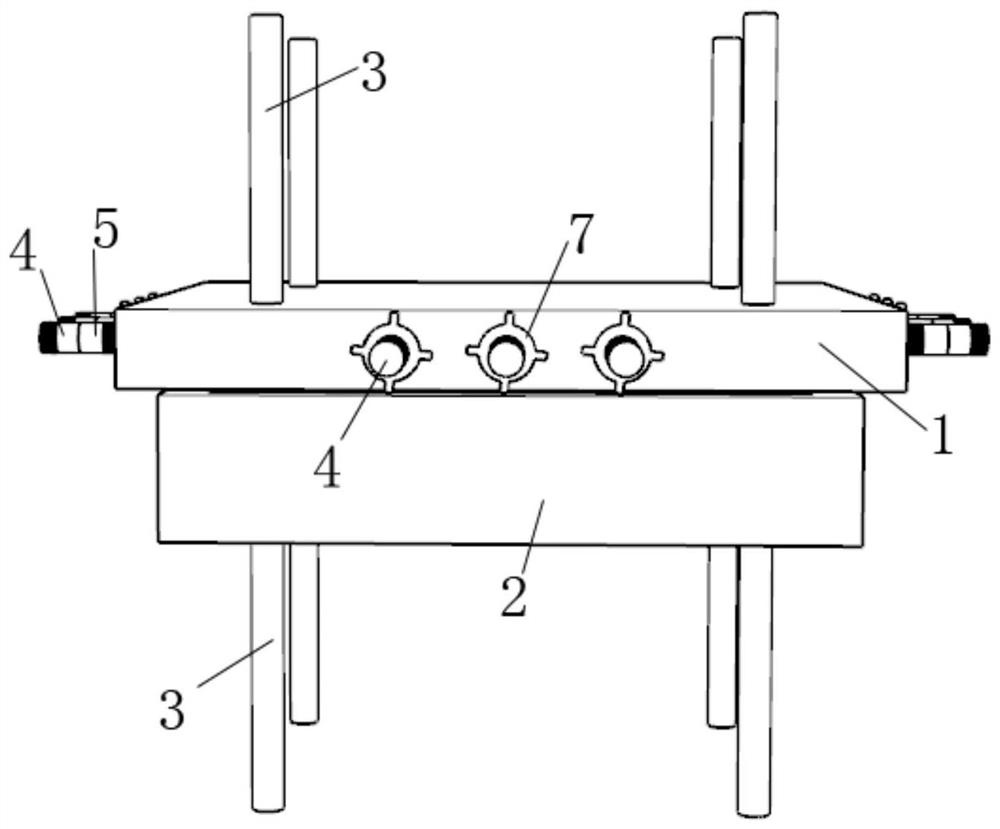

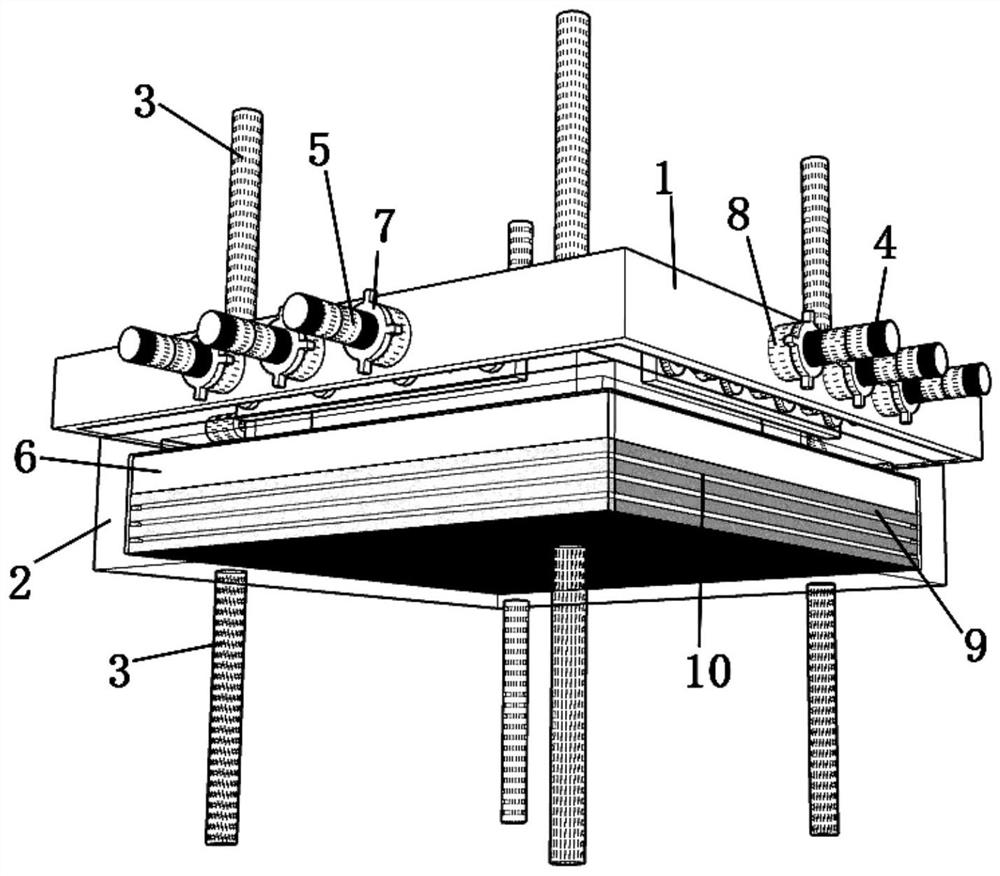

[0065] The hydraulic shock absorber of this embodiment comprises an upper plate groove 1, a lower plate groove 2, a position extension pin 4, a threaded shaft 5, a steel pad body 6, a rubber layer 9 and a steel plate 10. See details Figure 1(a) to Figure 6 .

[0066] The upper plate groove 1 is a concave groove body welded by steel plates, with pre-embedded steel bars welded on it, and the pre-embedded steel bars are made of precision rolled rebar, see Figure 8(a) ~ Figure 8(c) There are 4 oil pressure chambers 11, 3 spiral seat plates 7 and 3 seat plate grooves 8 distributed around each side of the upper plate groove 1, one end of the oil pressure chamber 11 is consolidated with the upper plate groove 1, and the other end can be connected with the retaining plate groove 1. plate 12 in contact. The top of the upper plate groove 1 is connected with 4 finish-rolled rebars. The oil pressure chamber 11 is arranged alternately with the seat plate groove 8 .

[0067] The oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com