Hard shell pumice concrete, light building block and its preparation method

A technology for concrete and pumice, which is applied in the field of building materials and its preparation, can solve the problems of poor thermal insulation performance of hollow blocks, affecting the quality of pumice concrete, etc., and achieves the effects of reasonable stress, convenient construction and reduction of cement consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

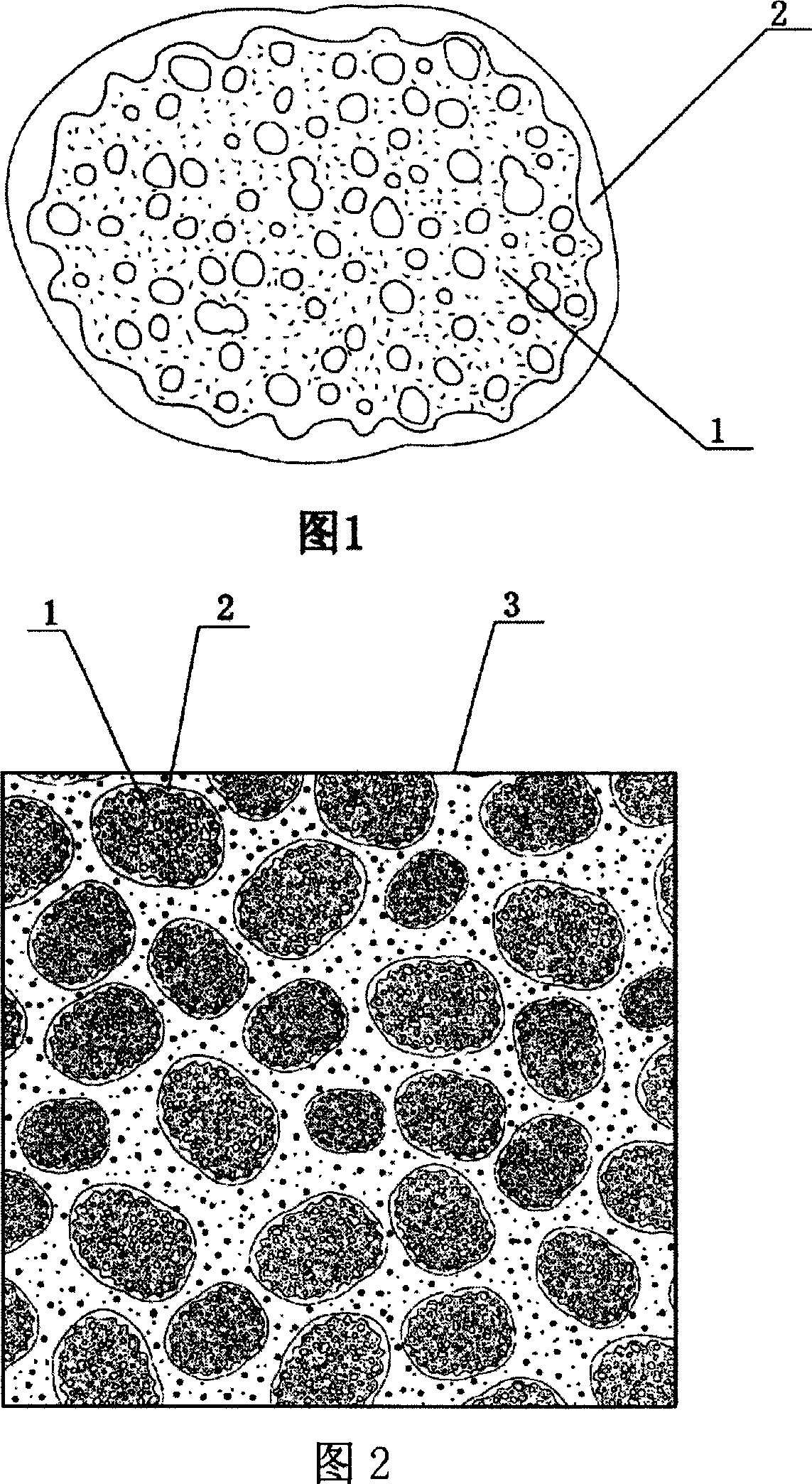

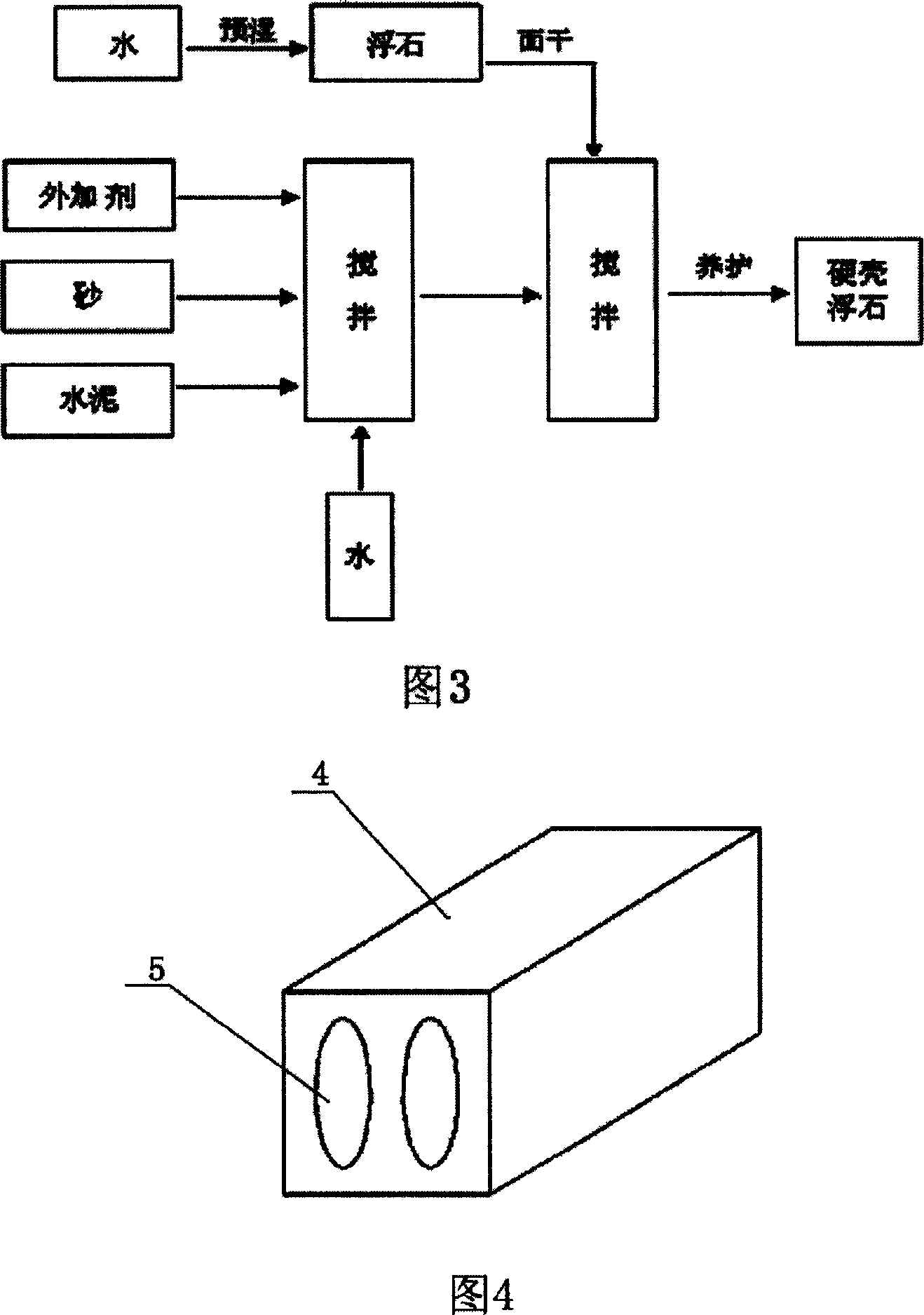

[0028] Referring to the embodiment shown in Figure 1, this hard-shell pumice concrete of the present invention is a concrete material made by mixing cement, fine aggregate and coarse aggregate with water, wherein the coarse aggregate is formed on the surface of the pumice 1 A hard shell pumice wrapped with a hard shell 2, and the open micropores on the surface of the pumice stone are closed.

[0029] The structural diagram of hard-shell pumice concrete 3 is shown in Figure 2. The preparation method of hard-shell pumice concrete is to wrap the pumice aggregate before mixing the concrete, and then mix the hard-shell pumice concrete. The process flow is shown in Figure 3 :

[0030] Step 1, first soak the pumice stone in water for more than 5-10 minutes to make it saturated with water.

[0031] Step 2, control the moisture in the wet pumice stone to make it dry.

[0032] Step 3, mixing sand, cement, water, and air-entraining agent in a forced mixer to form mortar. The ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com