Optical fibre electric current sensor sensitive coil winding equipment

A technology of sensitive coil and fiber optic current, applied in voltage/current isolation, measurement of current/voltage, instruments, etc., can solve problems such as uncomfortable and accurate control, complex structure, easy to introduce torsional stress, etc., to avoid torsional stress and ensure consistency , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

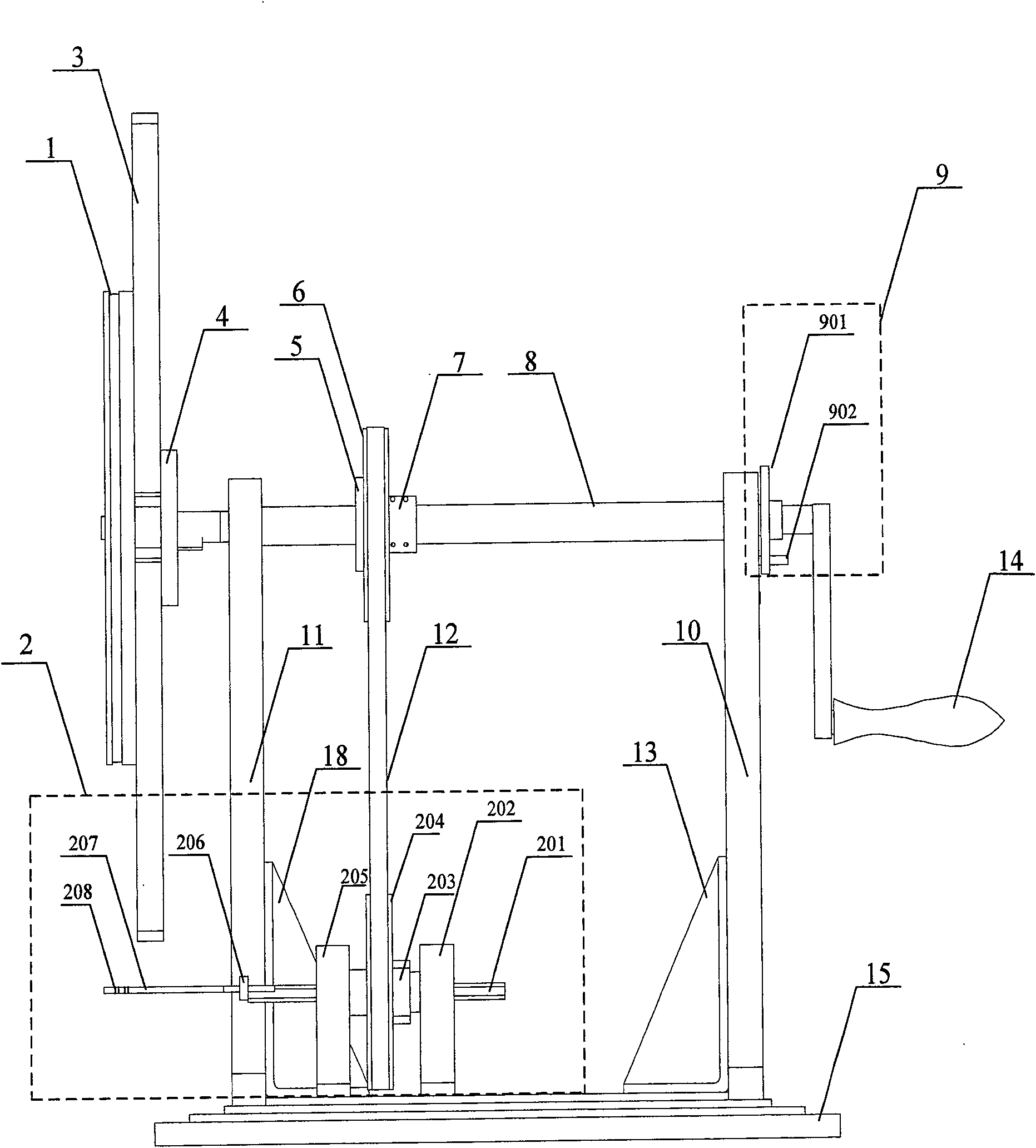

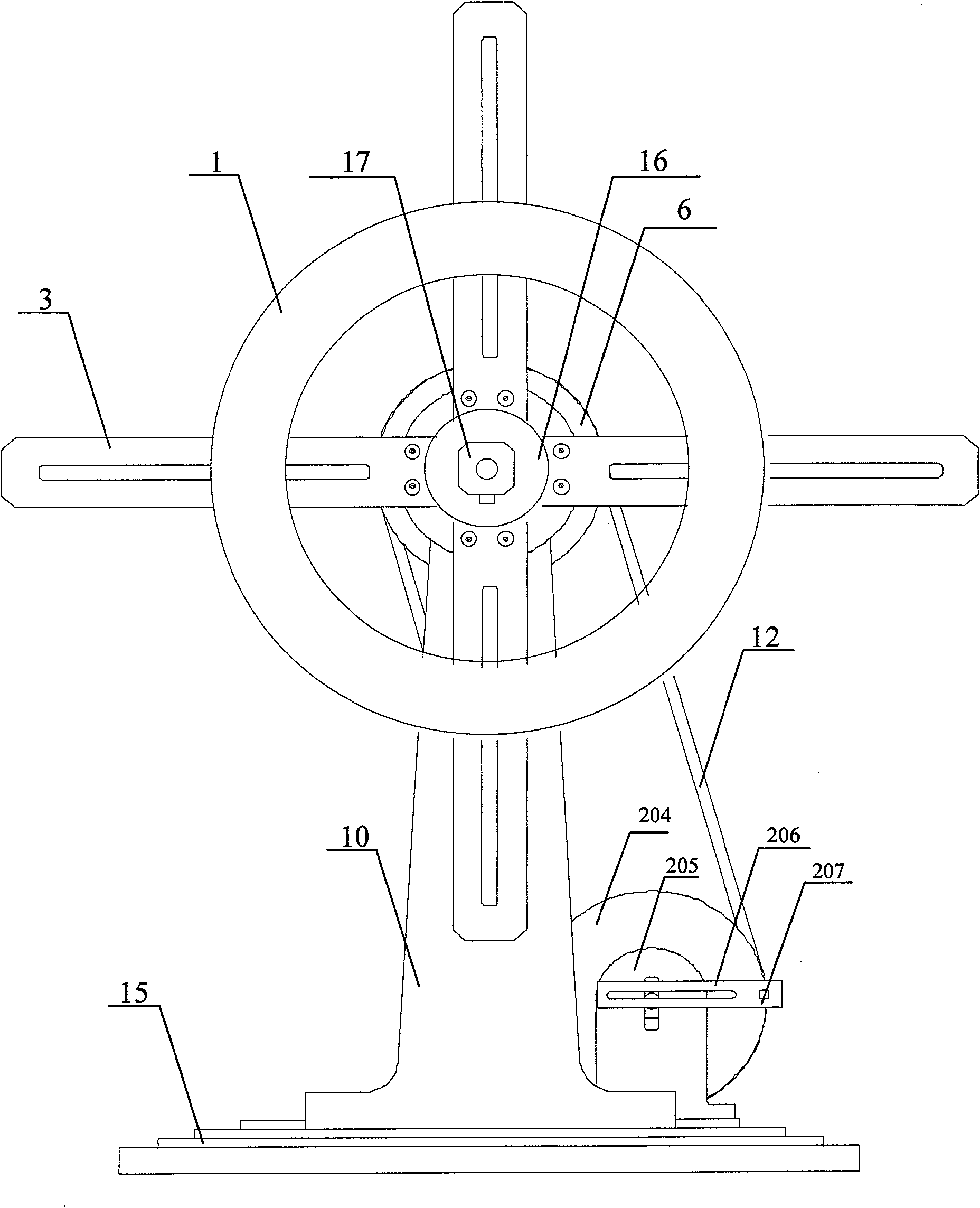

[0016] Such as figure 1 and 2 As shown, the optical fiber current sensor sensitive coil winding equipment of the present invention includes a fiber guide mechanism 2, a skeleton mounting seat 3, a shaft coupling 4, 5, 7, a driving wheel 6, a main shaft 8, a locking mechanism 9, a main shaft bearing seat 10, 11. Transmission belt 12, supporting bone 13, 18, handle 14, base 15, pressure plate 16, nut 17; on the main shaft 8, there are nut 17, pressure plate 16, skeleton mounting seat 3, driving wheel 6, lock in turn from left to right The tightening mechanism 9 and the handle 14, the nut 17 and the pressure plate 16 fix the sensitive coil skeleton 1 on the skeleton mounting seat 3, the skeleton mounting seat 3 and the driving wheel 6 are installed on the main shaft 8 through the couplings 4, 5, 7, and the main shaft The bearing housings 10, 11 are fixed on the base 15 through the supporting bones 13, 18 and are respectively located on both sides of the driving wheel 6 to fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com