Engineering vehicle shifting device with buffering mechanism

A technology for shifting devices and engineering vehicles, which is applied to components with teeth, transmission control, mechanical equipment, etc., can solve the problem of large impact noise, violent vehicle shaking, and affecting the service life of engineering vehicle power transmission mechanisms. Engineering vehicle drivers Driving comfort and handling issues, to achieve the effect of reducing impact stress, smooth and gentle acceleration, and improving driving comfort and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

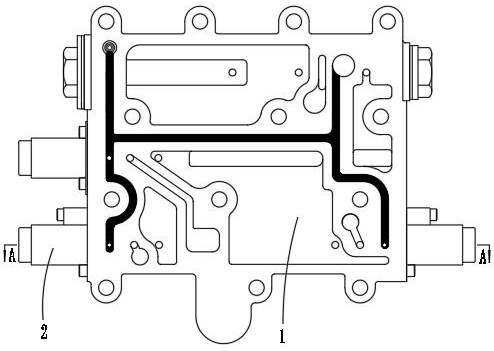

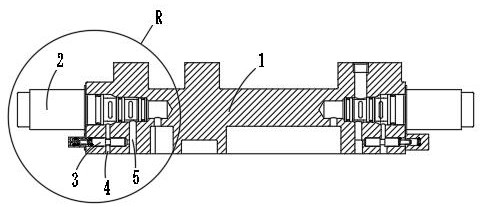

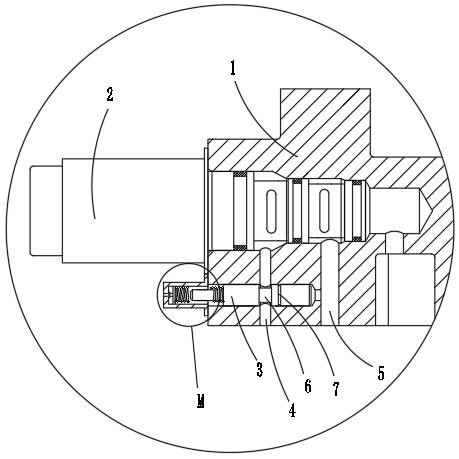

[0020]Embodiment: a shifting device of an engineering vehicle with a buffer mechanism, as shown in the figure, comprising a valve body 1 of the shifting device, the valve body 1 is provided with an oil inlet 4, an oil outlet 5 and a solenoid valve 2, The oil inlet 4 and the oil outlet 5 are arranged in parallel, and both are connected with the solenoid valve 2. In order to improve the feedback sensitivity of the buffer mechanism to the oil pressure rise, the oil inlet 4 is set close to the valve. On one side of the outer surface of the body 1, the electromagnetic valve 2 controls the on-off between the oil inlet 4 and the oil outlet 5 by pushing and pulling the spool to move the channel position set on the spool. 4. There is also a connecting channel 18 between the oil outlets 5, and the end of the connecting channel 18 that is closer to the outer surface of the valve body 1 extends outward and runs through the outer surface of the valve body 1. The connecting channel 18 The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com