Cold-forging technique of gear shaft

A gear shaft, cold forging technology, applied in metal material coating process, manufacturing tools, metal processing equipment and other directions, can solve the problems of low back extrusion deformation of tooth blind holes, insufficient tooth strength, low production efficiency, etc. Achieve the effect of improving the quality and production efficiency of gear hole forming, saving raw materials and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

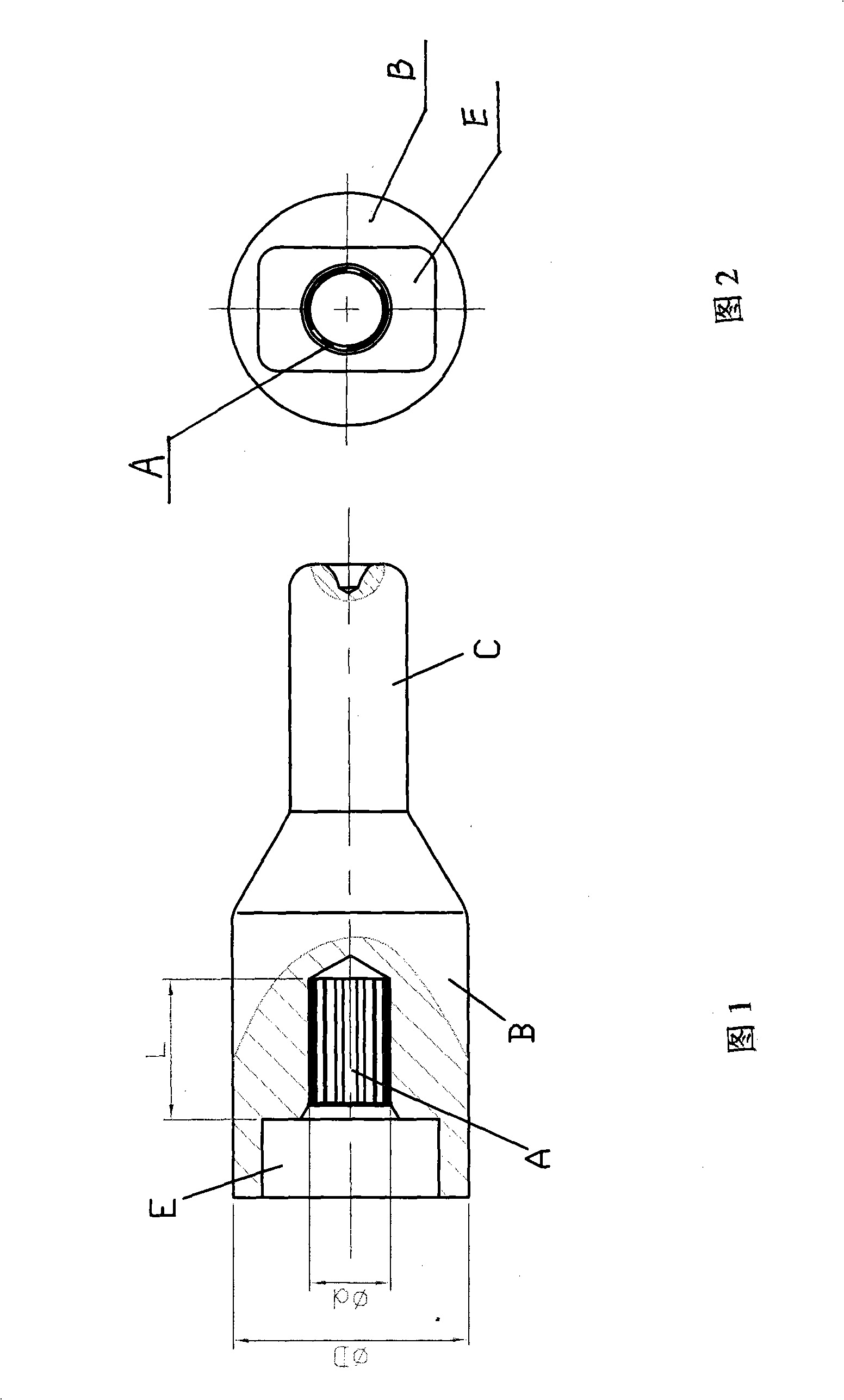

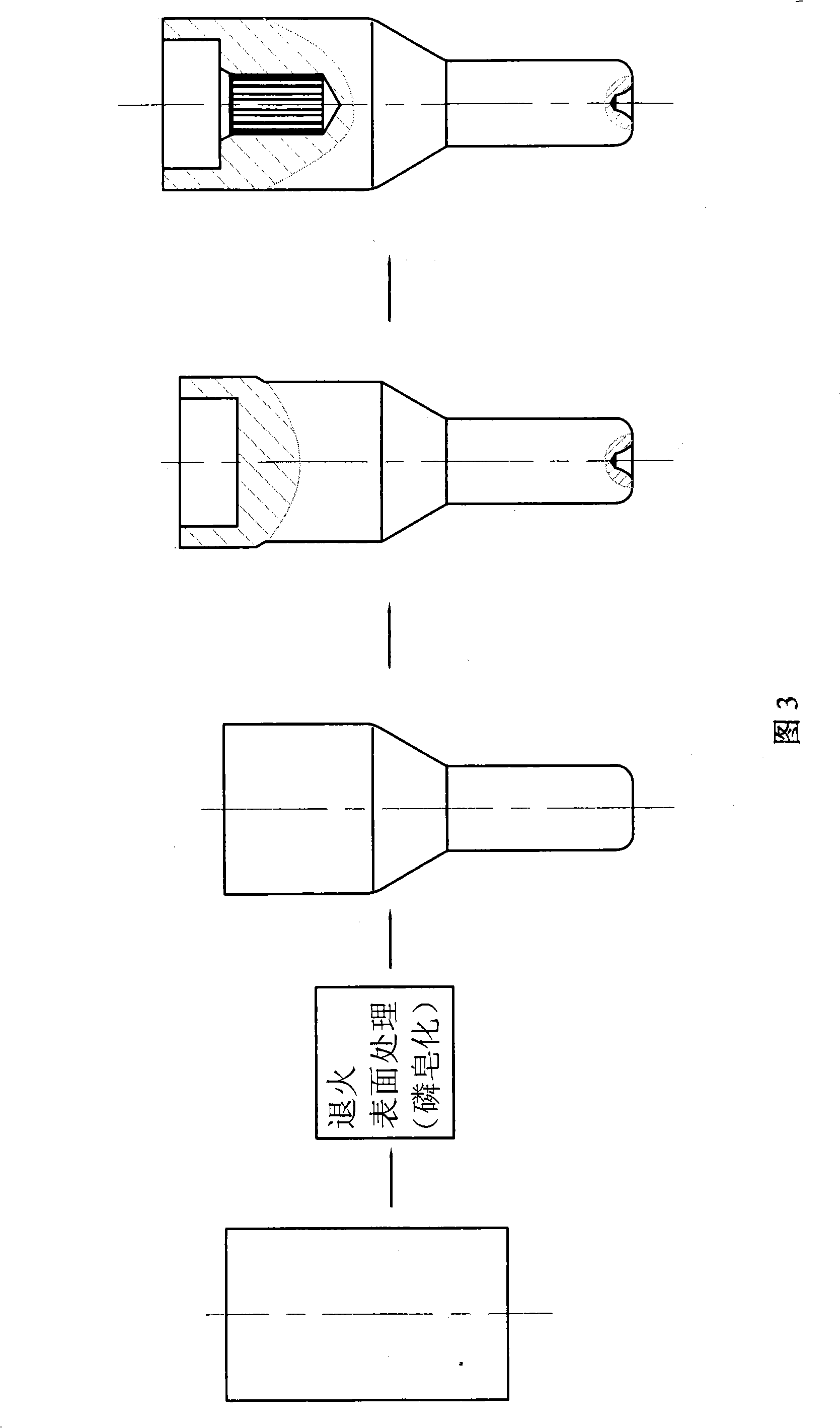

[0023] As shown in Figure 3, it is a cold forging process flow chart, and a cold forging process for a gear shaft is:

[0024] In the first step, according to the length of the gear shaft, the alloy steel bar is blanked with a circular saw machine, and the weight error of the blank is ±1 gram;

[0025] The second step is to anneal the rough bar in a well-type furnace at an annealing temperature of 860°C, hold it for 6 hours, and cool it to 300°C with the furnace;

[0026] The third step is to use the phosphorus saponification line to carry out phosphating and saponification treatment on the annealed blank bar according to the conventional process to form a surface lubricating layer. The phosphating temperature is 70 ° C and the time is 20 minutes; the saponification temperature is 60 ° C and the time for 10 minutes;

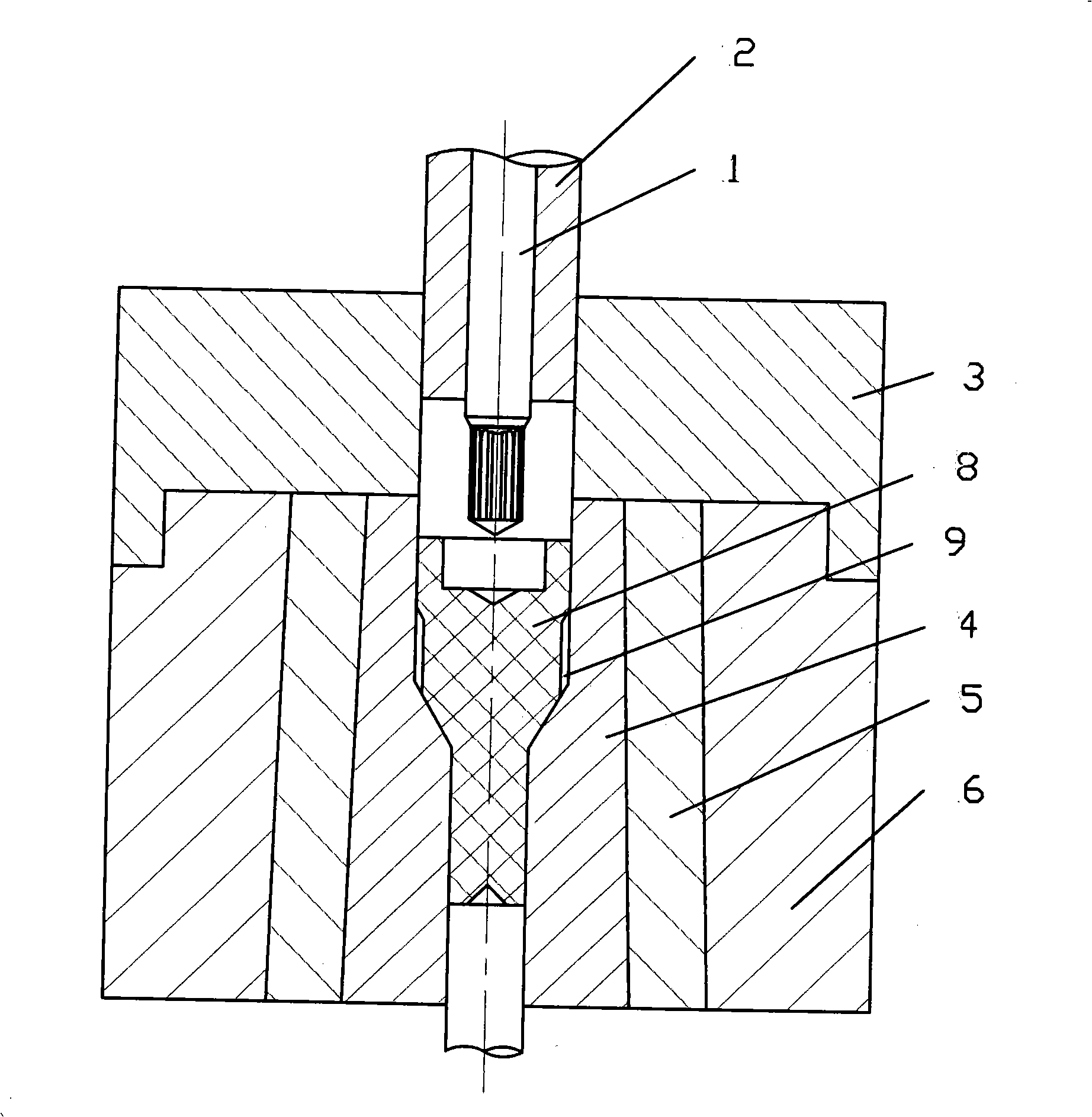

[0027] The fourth step is to use high-strength die steel to manufacture forward extrusion dies, reverse extrusion dies and gear hole forming dies;

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com