An automobile self-adjusting arm rear end cover adjusting device

A back end cover and self-adjusting technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of weak coil compression spring, reduced separation force, reduced braking clearance perception ability, etc., to improve assembly efficiency, The effect of saving manpower and reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

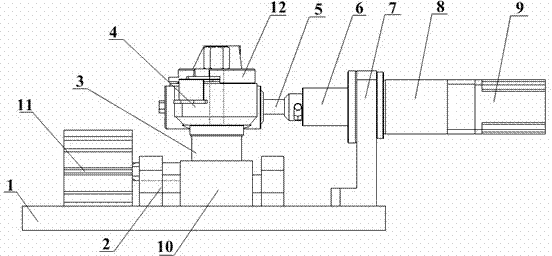

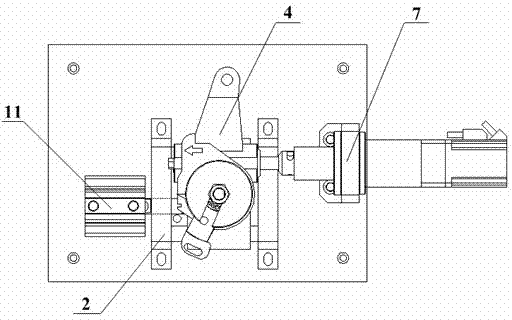

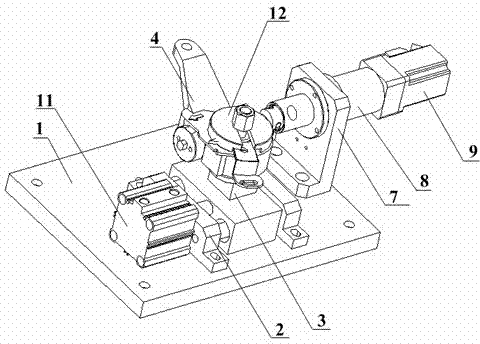

[0012] Further illustrate the present invention below in conjunction with accompanying drawing.

[0013] Such as figure 1 , figure 2 , image 3 As shown, an automobile self-adjusting arm rear end cover adjustment device includes a base 1, a sliding guide rail 2, a clamping cylinder 3, an self-adjusting arm 4, a hexagonal sleeve 5, a bearing sleeve 6, a corner piece 7, a reducer 8, Servo motor 9, self-adjusting arm mounting base 10, horizontal moving cylinder 11, pressing plate 12.

[0014] A sliding guide rail 2 and a corner piece 7 are arranged on the base 1 . The sliding guide rail 2 includes a guide rail support frame and a guide rail. A horizontal moving cylinder 11 is installed on the outside of the guide rail support frame. Two horizontal guide rails perpendicular to the guide rail support frame are arranged on the guide rail support frame. On the guide rail, the output push rod of the horizontal moving cylinder 11 penetrates the guide rail support frame and is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com