A kind of housing cylindrical pouring formwork and construction method

A construction method and formwork technology, which is applied in the direction of formwork/formwork/work frame, construction, building structure, etc., can solve the problem that the steel belt can not be quickly found in the pre-tightening force, the pre-tightening force is not easy to grasp, and it is unfavorable for concrete pouring and other issues, to achieve the effect of improving construction efficiency, improving construction efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

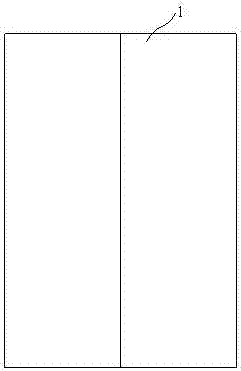

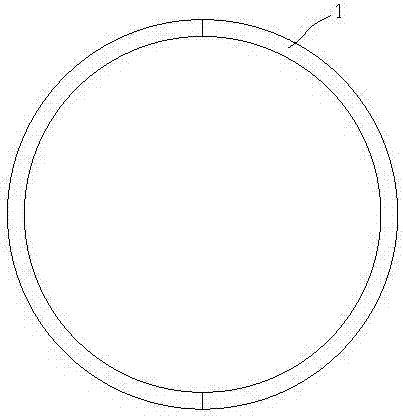

[0031] Example 1, see Figure 1-Figure 5

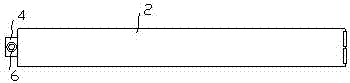

[0032] A cylindrical pouring formwork for a house, comprising a formwork body 1 and a steel belt 2, the steel belt 2 includes two hinged semicircular steel rings 3, a connecting block 4 is provided on the outside of the free end of one of the steel rings 3, and the connecting block 4 is provided with a threaded hole 5, and the threaded hole 5 is screwed with a fixed bolt 6; the outer side of the free end of the other steel ring 3 is provided with a bump 7, and the bump 7 is provided with a mounting hole 8, and the mounting hole 8 is provided with a Nut 9, nut 9 and mounting hole 8 interference fit, the two ends of projection 7 are provided with the cover plate 10 that is detachably connected with it, two cover plates 10 are all provided with through hole 11, and the diameter of through hole 11 is smaller than installation The diameter of the hole 8 is greater than the diameter of the threaded hole on the nut 9 .

[0033] The templat...

Embodiment 2

[0040] Example 2, see Figure 1-Figure 6

[0041] On the basis of Embodiment 1, the house cylindrical pouring formwork provided by this embodiment also includes an adjustment ring 12, and the adjustment ring 12 includes a coaxial inner ring 13 and an outer ring 14, and the inner ring 13 and the outer ring 14 are arranged at intervals. Two elastic steel sheets 15 are connected, and the inner ring 13 is provided with an opening 16; the outer diameter of the outer ring 14 is consistent with the outer diameter of the template body 1, the inner diameter of the inner ring 13 is consistent with the inner diameter of the template body 1, and the height of the adjustment ring 12 is less than The height of steel belt 2.

[0042] During the house construction process, many places need to use formwork and then pour concrete, which may lead to mold explosion in some cases, such as high outside temperature, uneven concrete mixing, and errors in the construction sequence. A mold explosion ...

Embodiment 3

[0048] Example 3, see Figure 1-Figure 8

[0049] This embodiment provides a construction method for pouring house cylinders, using the formwork for pouring house cylinders in Embodiment 2. The construction method includes the steps of:

[0050] A plurality of formwork bodies 1 are stacked vertically. The number of formwork bodies 1 is selected according to the height of the cylinder.

[0051] Steel strips 2 are fixed on the outer sides of every two adjacent formwork bodies 1 . The fixing of the steel strip 2 is carried out synchronously with the stacking of the formwork body 1 . The steel belt 2 can not only be fixed on the outer sides of every two adjacent formwork bodies 1, but also can be fixed at other positions, so that the reinforcement effect on the formwork body 1 is better. When the above-mentioned steel belt 2 is used for reinforcement, the reinforcement work can be carried out quickly, the safety of each part can be protected, and the construction efficiency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com