Auxiliary manipulator system for changing mould of six-mould cold heading machine

A technology of manipulators and cold pier machines, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of easily damaged contact surface accuracy, high processing accuracy, and high processing cost, and achieve Reduce assembly size, meet installation stroke requirements, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

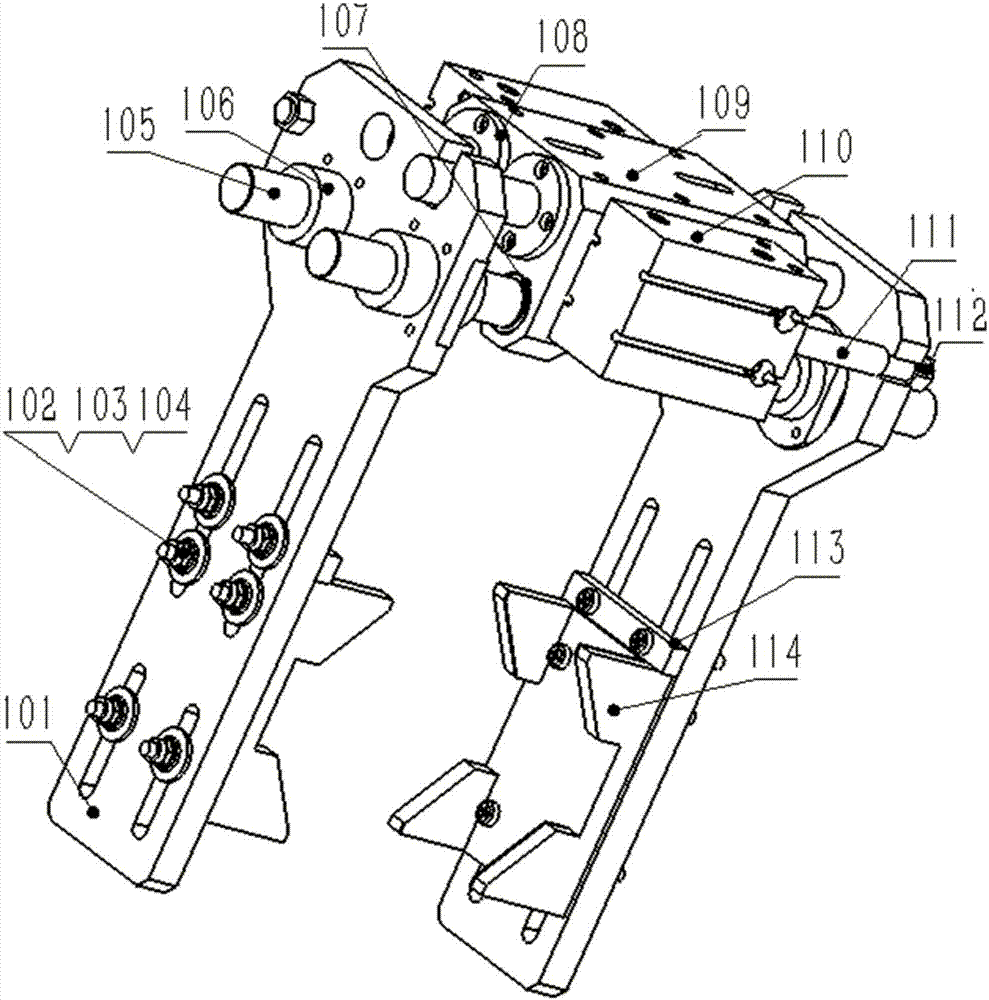

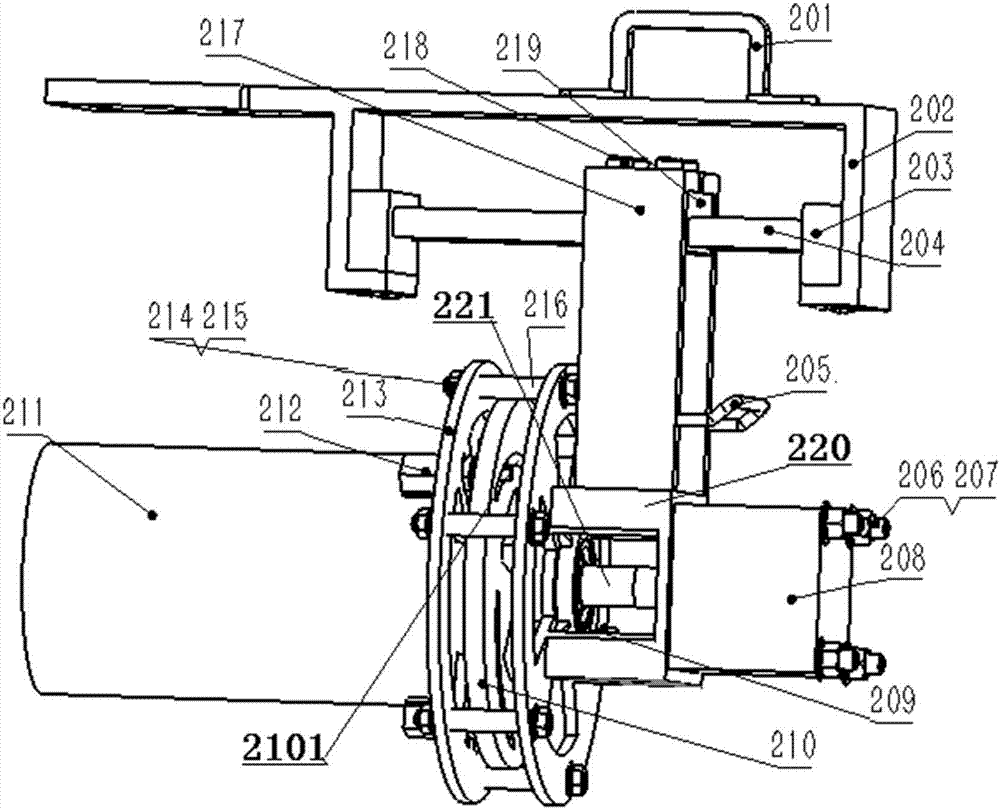

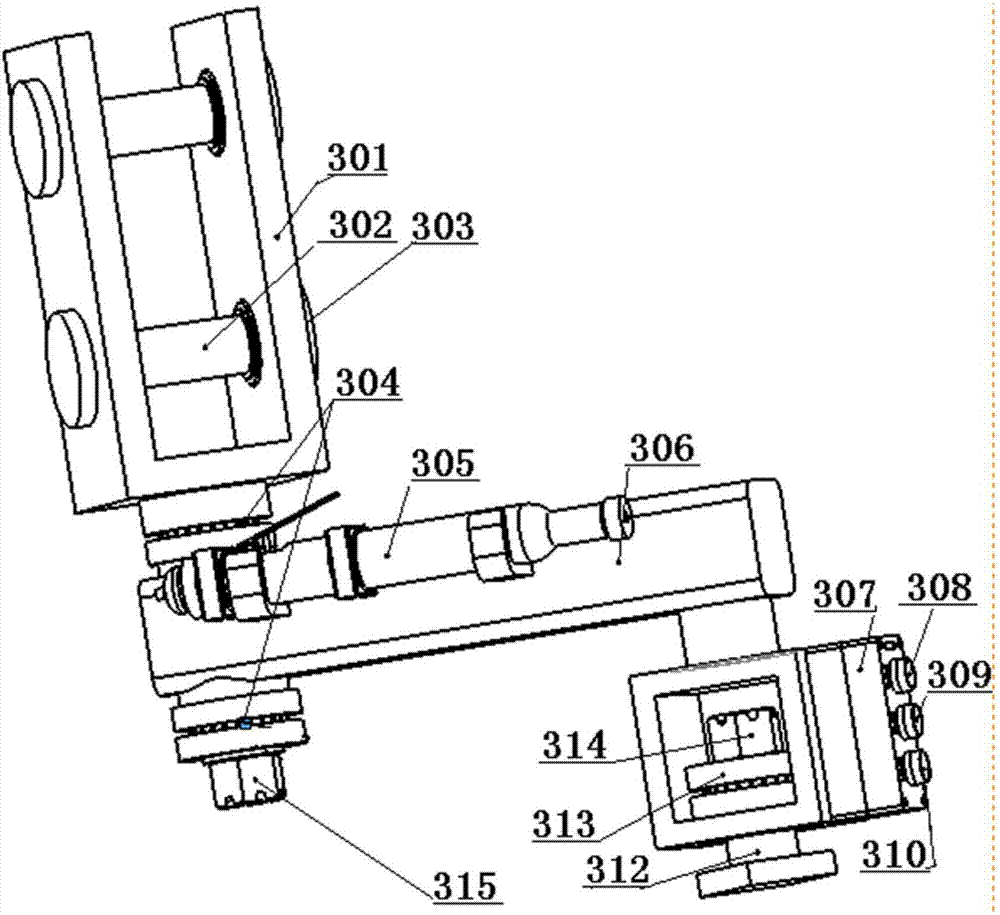

[0014] Such as Figure 1-8 as shown in figure 1As shown, the six-mode cold pier machine mold change auxiliary manipulator system of the present embodiment includes a boom 400 arranged on one side of the cold pier machine, a small arm 300 arranged at the upper end of the boom 400 and its cantilever end swings up and down, and a horizontal plane. The main gripper 100 that rotates and is arranged under the cantilever end of the small arm 300, and the secondary gripper 200 that is horizontally telescopic on the main gripper 100 and used to clamp the mold 211; the secondary gripper 200 is located in the cavity 001 of the cold pier machine above. The boom 400 includes a main column 408 installed on the cold pier machine, an intermediate connecting column 407 arranged on the main column 408, a rotating connecting rod 403 whose lower part is rotated or fixedly arranged on the upper part of the intermediate connecting column 407, and two parallel connecting rods arranged on the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com